Exhaust structure of high-pressure oil pump

A high-pressure oil pump and low-pressure technology, which is applied in the field of exhaust structure of high-pressure oil pumps, can solve problems such as air not being in the circuit, affecting engine starting performance, and difficulty in functioning of the deflation screw, etc., and achieves the effect of convenient exhaust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

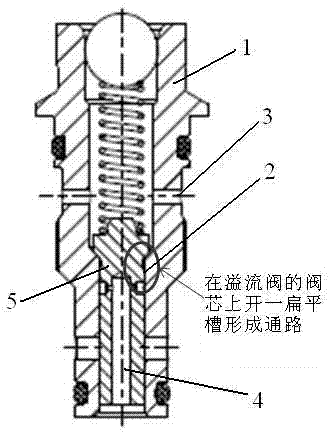

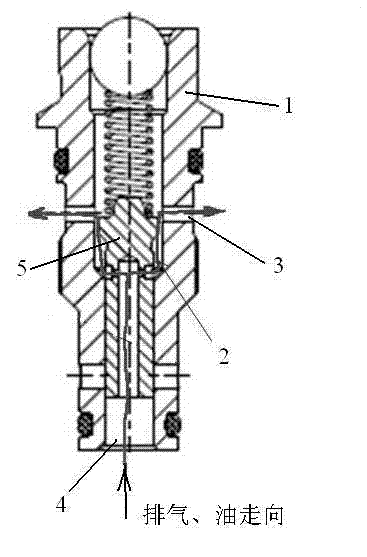

[0014] Example: see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 .

[0015] An exhaust structure of a high-pressure oil pump, including a relief valve 1, an oil drain groove 2 is opened on the spool of the relief valve 1, and the low-pressure oil circuit inlet 4 of the relief valve 1 communicates with the overflow through the oil drain groove 2 The overflow outlet hole 3 of the valve 1 is connected to the oil return circuit of the outer circulation.

[0016] The oil drain groove 2 is a flat groove with a groove depth of 0.05-0.07 mm.

[0017] The description of the improved oil pump circuit: see attached Figure 4 ,

[0018] (1) Fuel passes through the filter, vane pump, fuel quantity control unit and fuel inlet valve from the fuel tank to the high-pressure plunger cavity.

[0019] (2) Part of the excess oil returns to the oil tank through the external return oil, and the other part returns to the oil inlet end of the vane pump through the internal return oi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com