Hydraulic volume control forming device for metal corrugated pipe

A metal bellows, volume control technology, applied in the field of bellows manufacturing, can solve the problems of no clear reference index for adjusting the expansion pressure, unable to meet the actual needs of product quality, poor consistency of the wave height and wave distance of the bellows, etc. Achieve stable and reliable product quality, low cost and high waveform consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

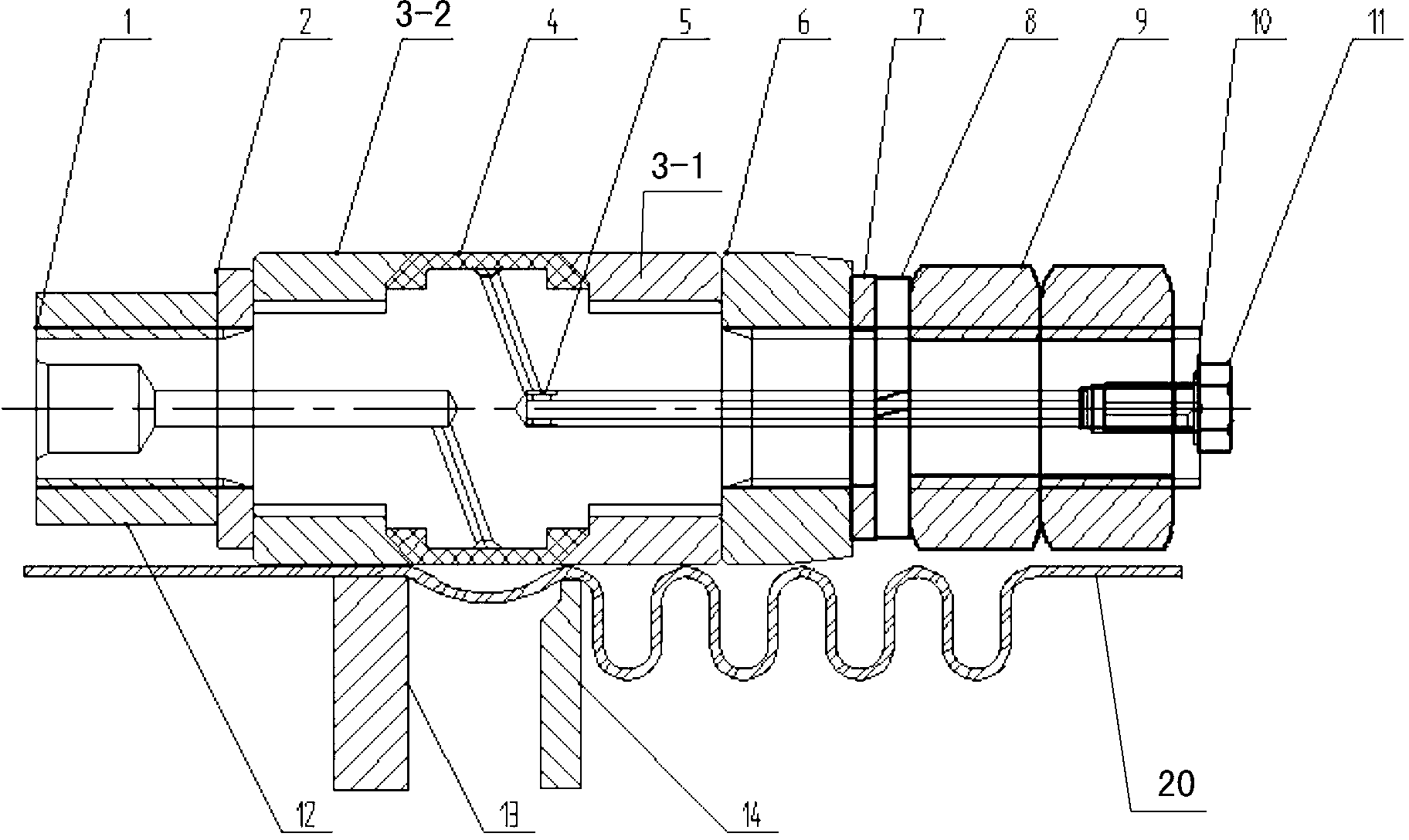

[0018] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0019] refer to Figure 1-Figure 4 , taking the axial direction of the mandrel 1 as the reference, the direction close to the air release bolt 11 is forward and forward, and the direction away from the air release bolt 11 is backward and retreat.

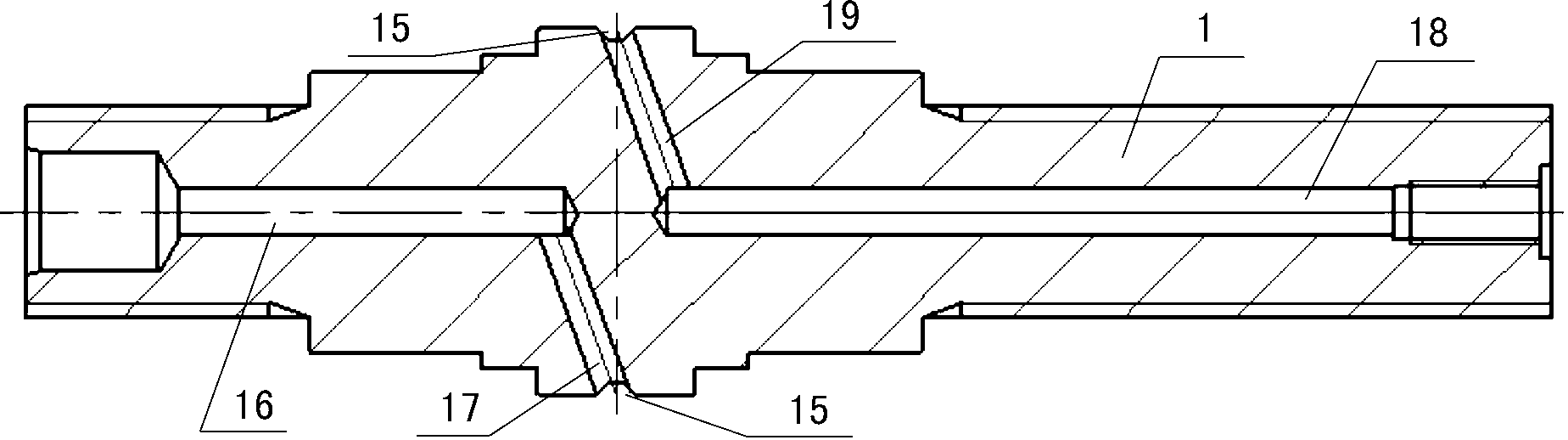

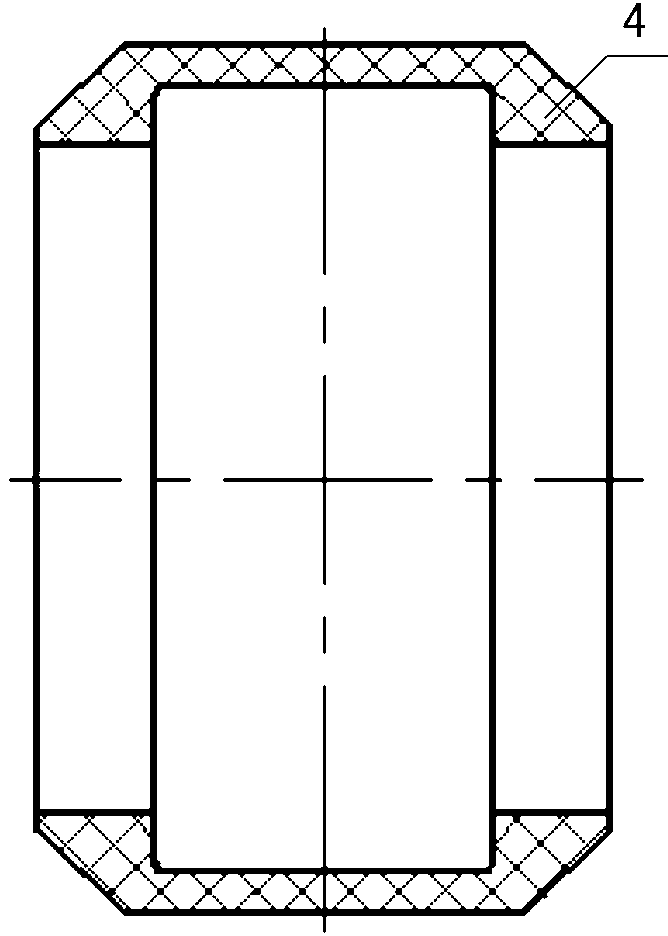

[0020] A metal bellows hydraulic volume control molding device, which includes a mandrel 1, the mandrel 1 is provided with two shoulders, and a circular groove 15 is formed on the surface of the highest shoulder section along the axial direction, so that Both ends of the mandrel 1 are threaded, the rear of the mandrel 1 is provided with an oil passage 16, and the front end of the oil passage 16 communicates with the circular groove 15 through the side oil passage 17. The front part is provided with a ventilation pipeline 18, and the rear end of the ventilation pipeline 18 communicates with the circular groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com