Patents

Literature

236results about How to "Improve lubrication status" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Engine oil of long-service life gasoline engine

InactiveCN101851549AImprove lubrication statusExtended service lifeLubricant compositionGasolineReducer

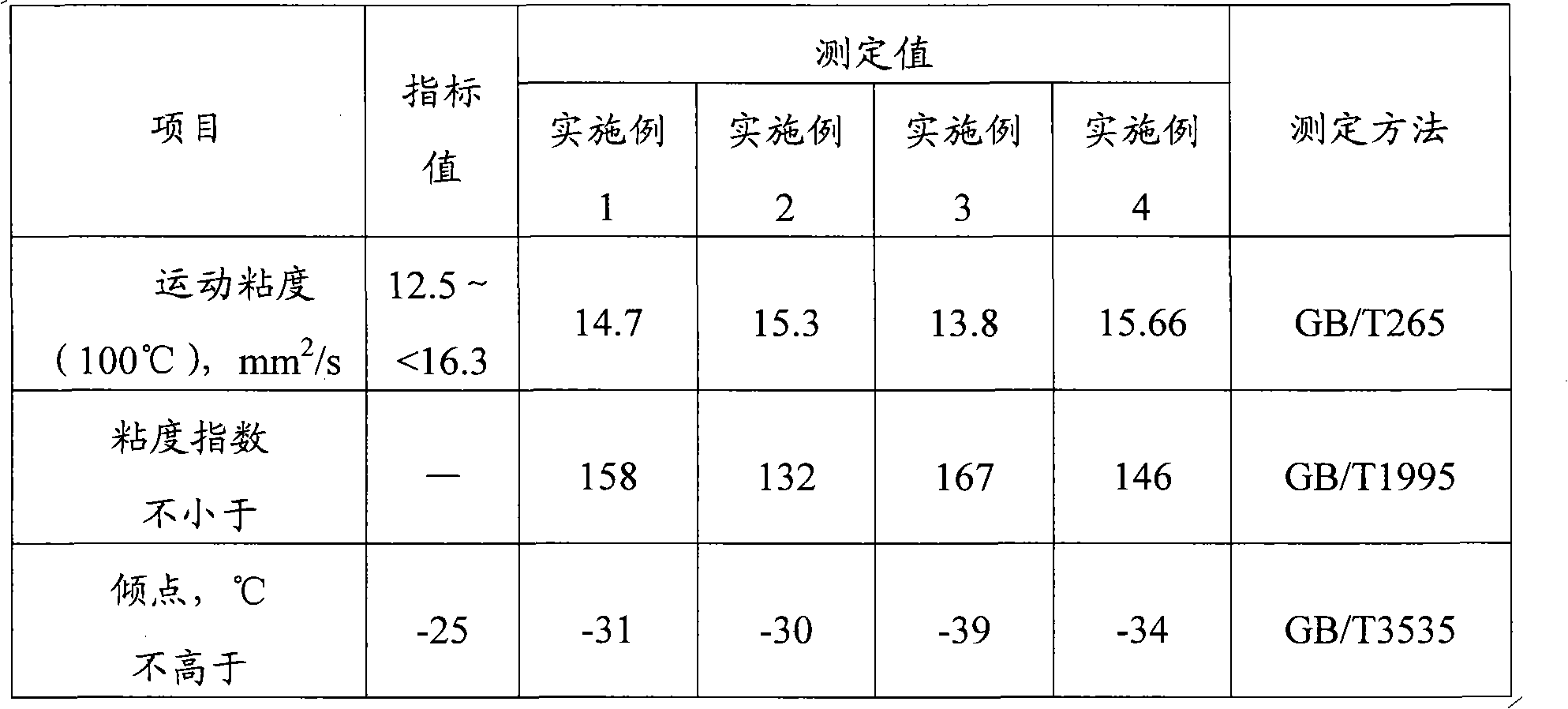

The invention provides engine oil of a long-service life gasoline engine, which comprises basic oil and additives, wherein the additives comprise the following ingredients in percentage by weight: 4.0 percent to 6.0 percent of dispersing agents, 2.5 percent to 4.5 percent of detergent additives, 0.2 percent to 0.8 percent of corrosion inhibitors, 0.1 percent to 0.2 percent of antioxidizers, 0.01 percent to 0.15 percent of nanometer copper wear resistance agents, 5.0 percent to 9.0 percent of viscosity index improving agents, 0.3 percent to 0.5 percent of pour point reducers and the balance ofbasic oil, wherein the basic oil is semisynthesis composite basic oil consisting of API type III basic oil accounting for 40 percent to 65 percent of the mass percentage of the basic oil and 35 percent to 60 percent of poly-alpha olefin synthesis oil. The engine oil can meet the requirements of high-temperature high-speed automobile and motorcycle engines, and can ensure that the engines are always in a good lubricating state, in addition, the service life is long, and the cost is low.

Owner:LOGISTICAL ENGINEERING UNIVERSITY OF PLA

Preparation process and device of nano-particle reinforced bimetal composite

InactiveCN101914767ALow melting pointImprove toughnessMetallic material coating processesCorrosionBonding strength

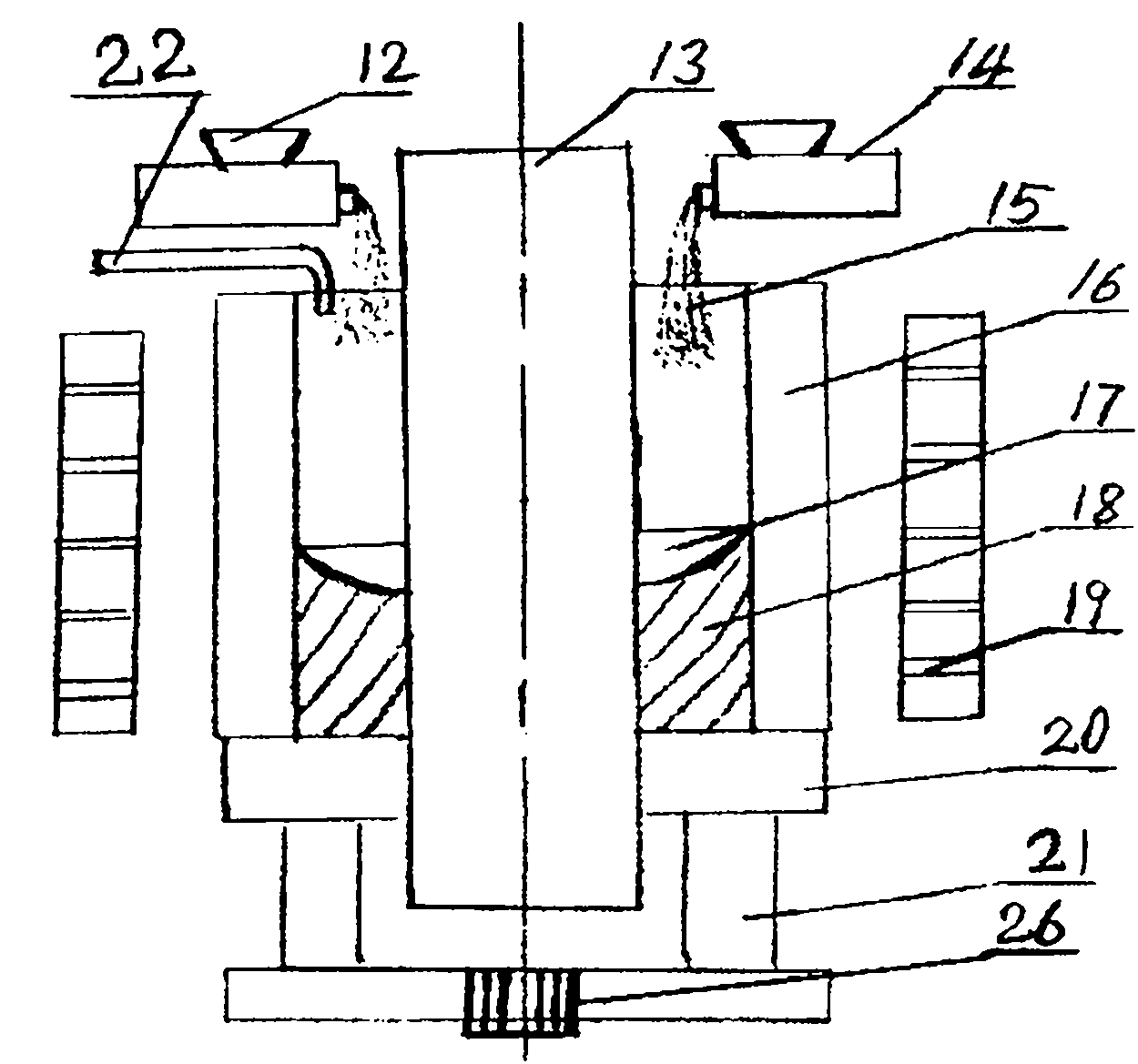

The invention relates to a preparation process and a device of a nano-particle reinforced bimetal composite, the nano-particle reinforced bimetal composite comprises the following chemical components by weight percent: 6-25% of Cr, 4-18% of Ni, 1.0-4% of Mo, 1.0-1.8% of Si, 1.2-3% of Mn, 0.4-2.2% of B, 0.1-1.2% of MgO, 0.2-2% of CaF2, 0.2-0.7% of C, 0.2-0.8% of Nb, not more than 0.9% of one or the combination of CeO2, Y3O2 and La2O3, 0.0-0.8% of Co, and the balance of Fe, and mixed particles of nano-sized carbides, nitrides, borides or carbonitrides are added in alloy powder. The vacuum induction melting and the cladding processes and equipment are adopted for melting and cladding the mixture on a workpiece, the thickness of a cladding layer is 0.1-25mm, the cladding layer contains 1%-50% of nano-reinforcing particles of one or the combination of the carbides, the nitrides, the borides and silicides, and the cladding layer has special performances of wear resistance, corrosion resistance, electrical conductivity, self-lubrication performance and the like. A coating layer and a base material form the metallurgical bonding, thereby having high bonding strength, overcoming the drawbacks in various coating processes at home and abroad, leading the coating layer to avoid the defects of shrinkage cavities, inclusion, cracking, shedding and the like and having the advantages of high heating temperature, fast speed, high production efficiency, small energy consumption, simple preparation process and low cost.

Owner:丁家伟

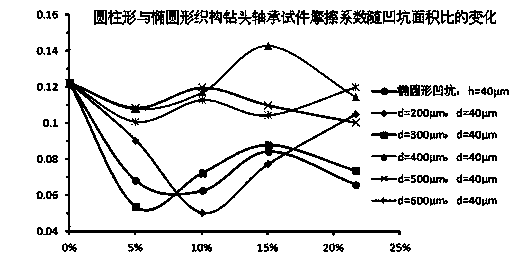

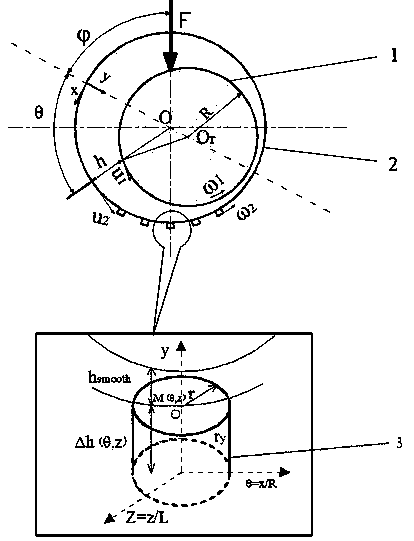

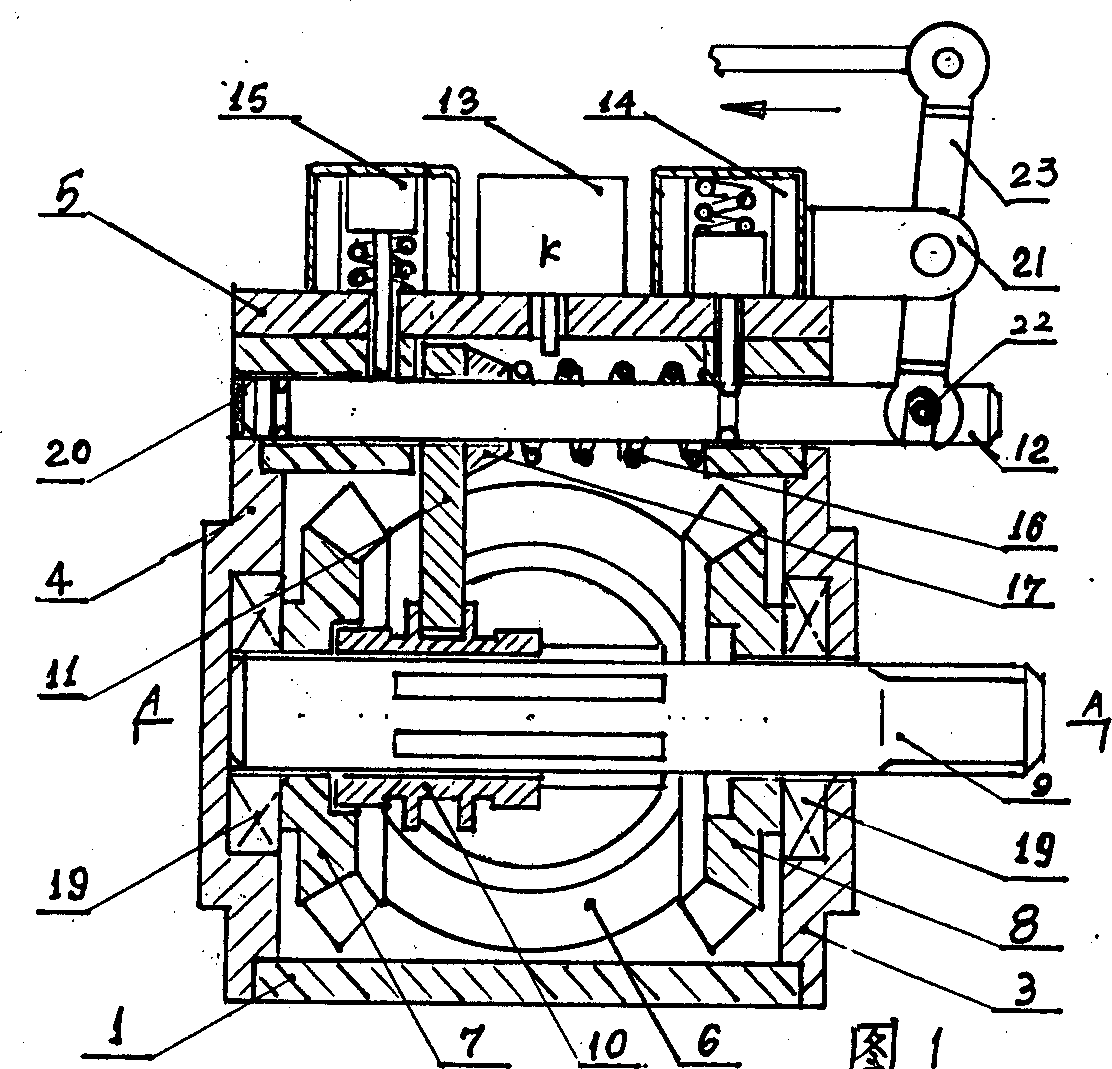

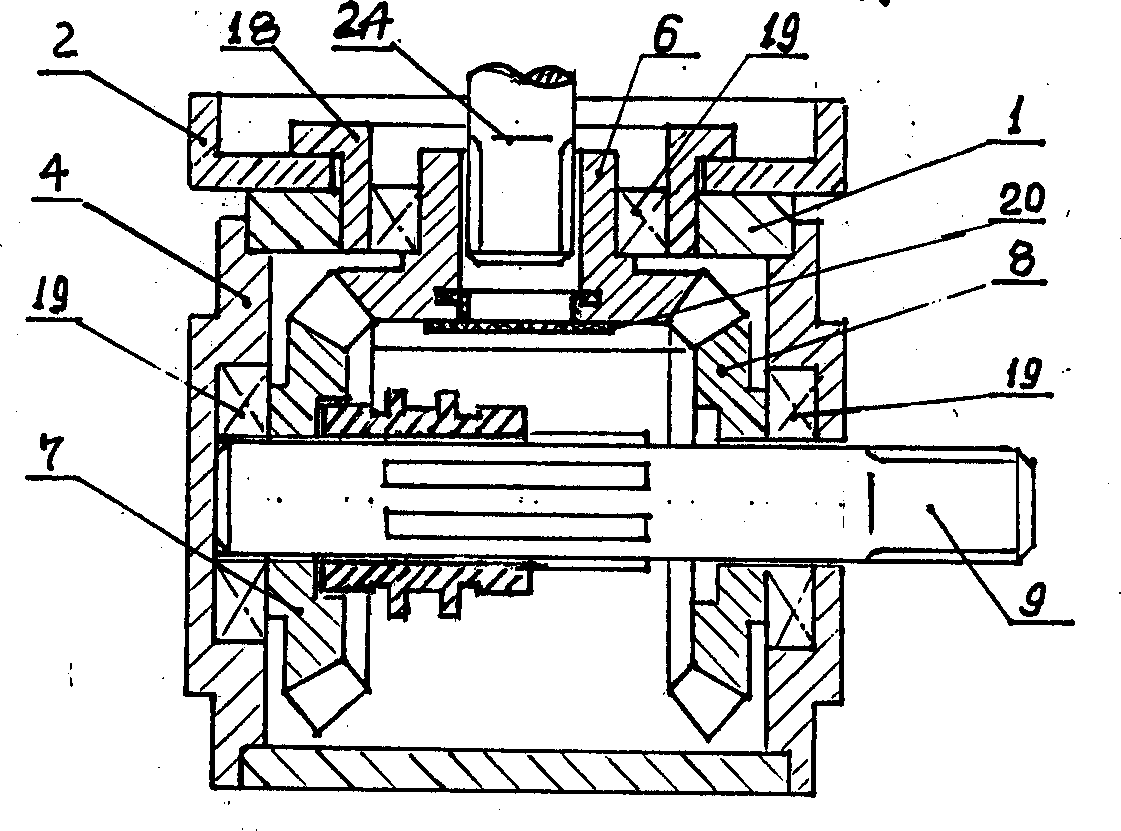

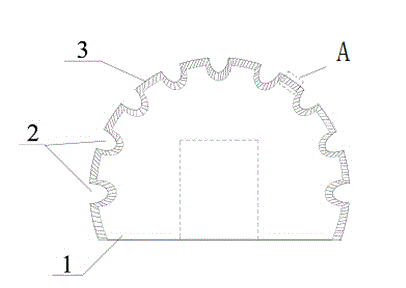

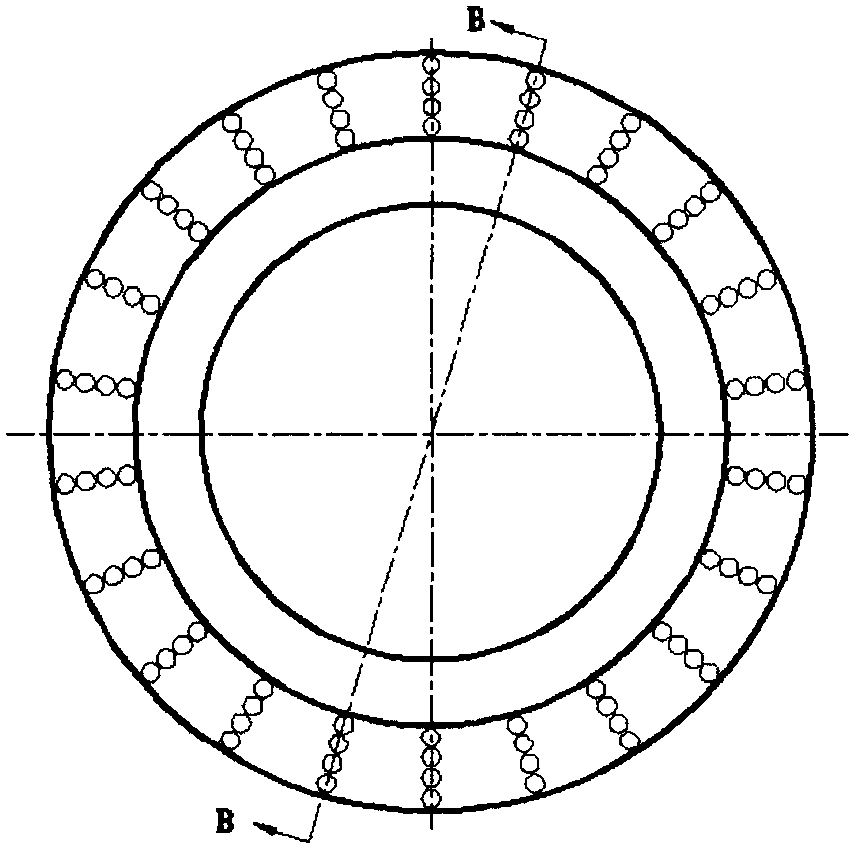

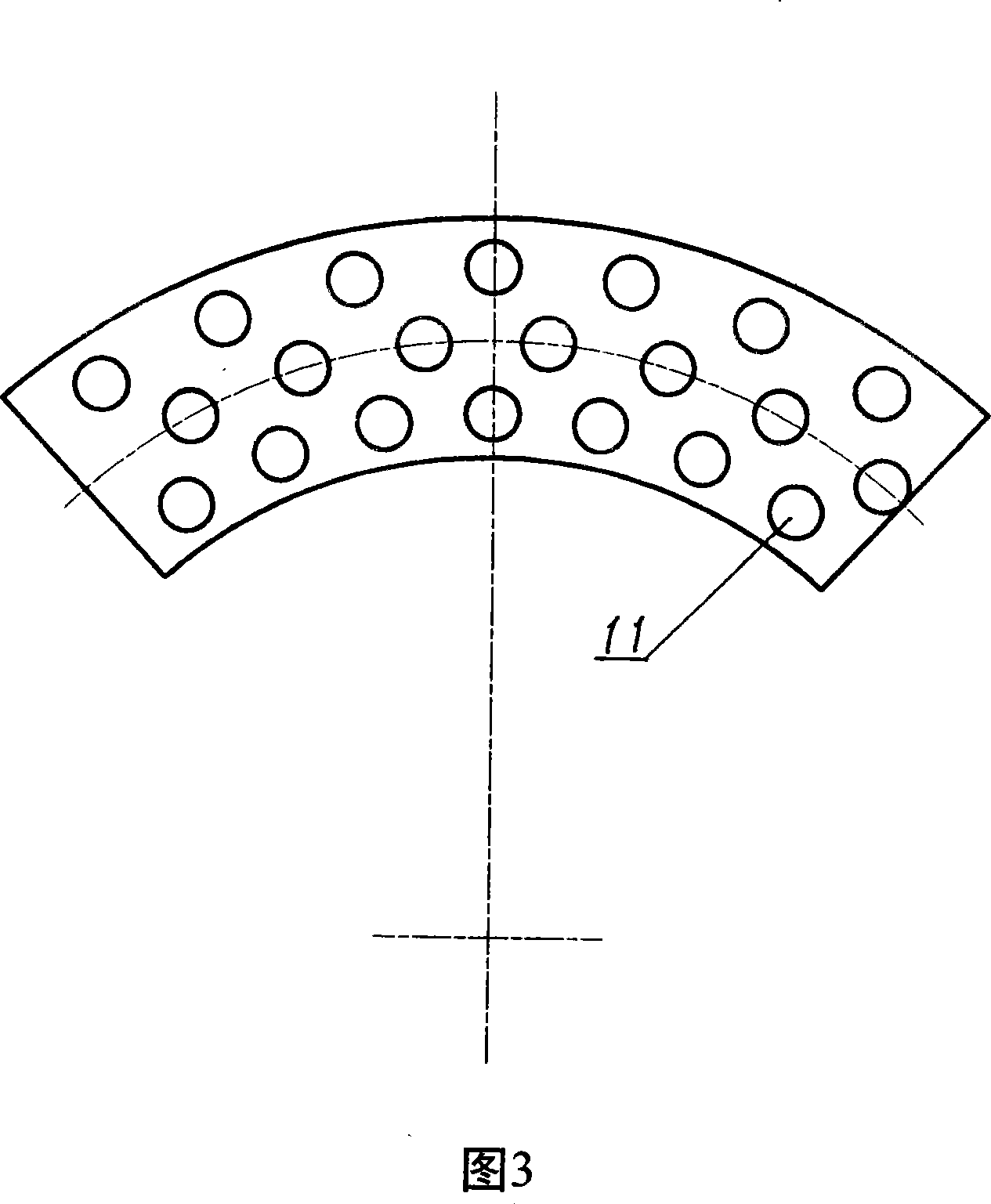

Textured roller bit sliding bearing and test method of unit tribological property of texture roller bit sliding bearing

ActiveCN103453021AImprove mechanical propertiesImprove the lubrication effectMachine bearings testingBearing componentsEllipseEngineering

The invention discloses a textured roller bit sliding bearing and a test method of the unit tribological property of the texture roller bit sliding bearing. According to the textured roller bit sliding bearing disclosed by the invention, a lubricating medium is arranged between a shaft neck and a bearing, wherein the shaft neck is made of a 20 CrNiMo material; the bearing is made of a beryllium bronze material; a surface texture is arranged on the inner surface of the bearing; the surface texture comprises a plurality of cylindrical pits or elliptically cylindrical pits in uniform distribution or cross distribution along the peripheral direction of the bearing. Aiming at the working condition and special structure of the roller bit sliding bearing disclosed by the invention, the adhesive failure problem of the traditional drill bearing is solved by providing the sliding bearing combined with cylindrical or elliptically cylindrical texture parameters through microscopic structure optimization, thus the service life of a roller bit is prolonged.

Owner:SOUTHWEST PETROLEUM UNIV

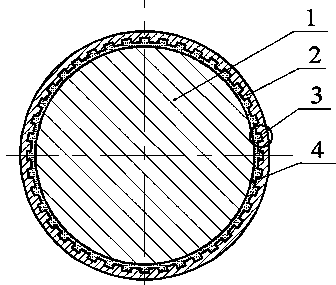

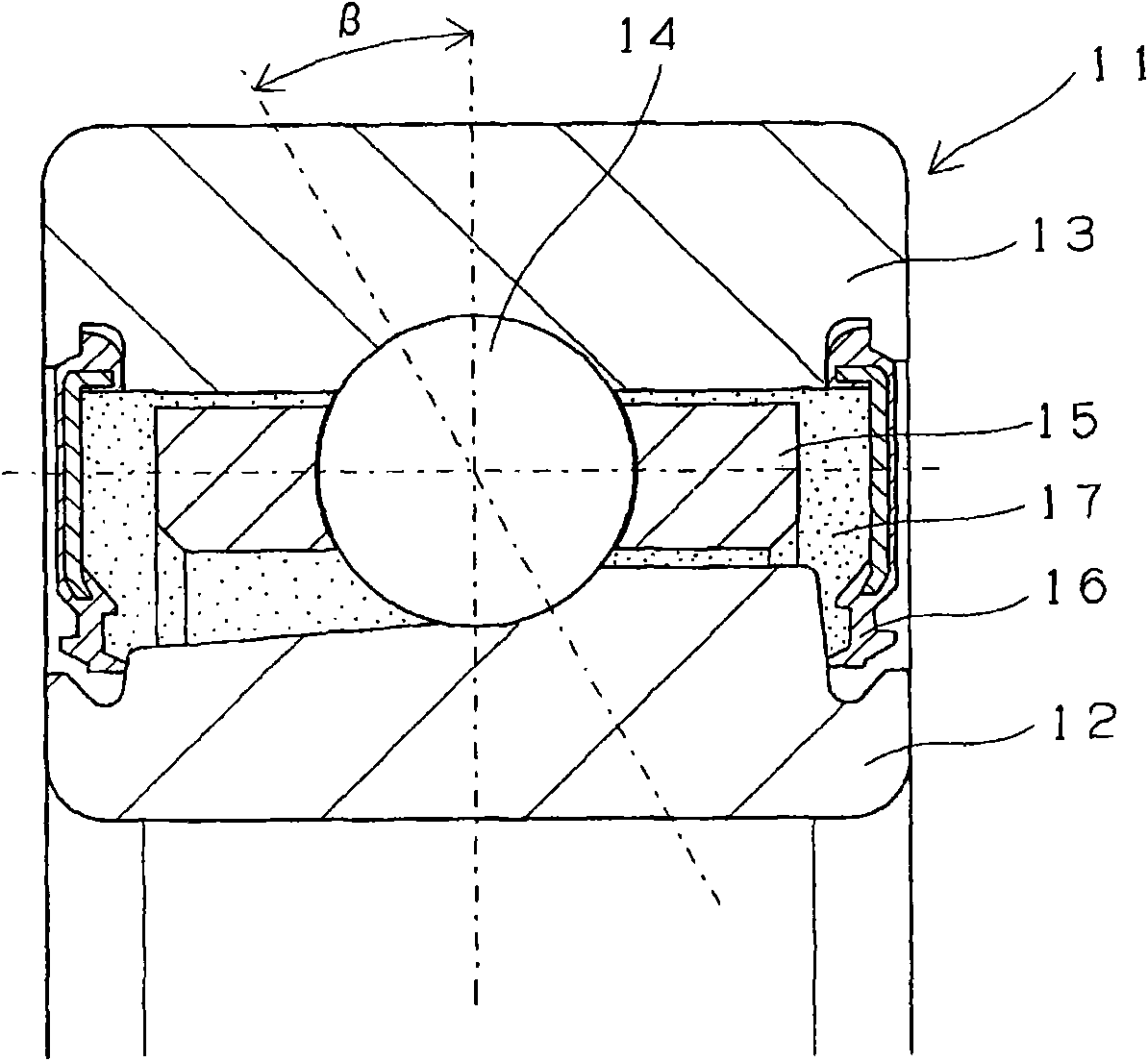

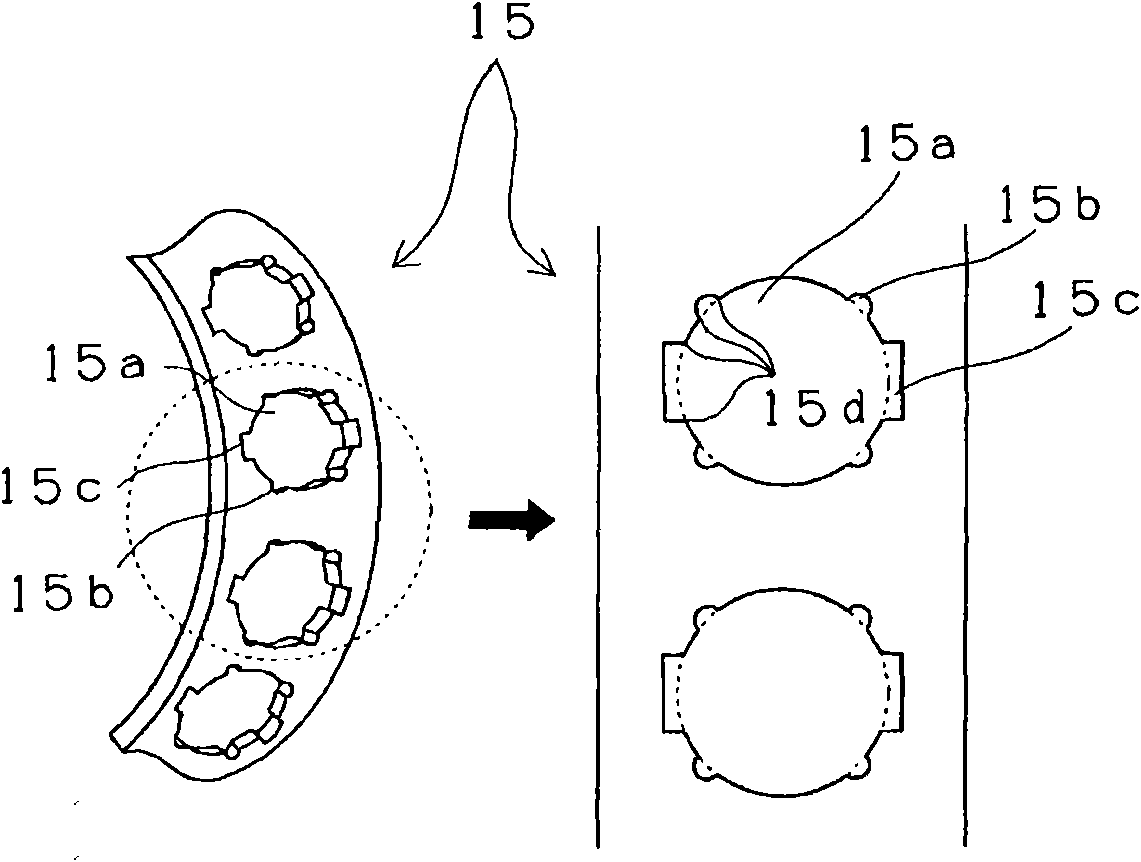

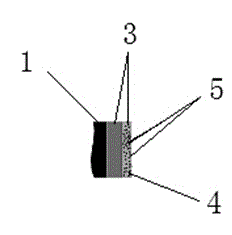

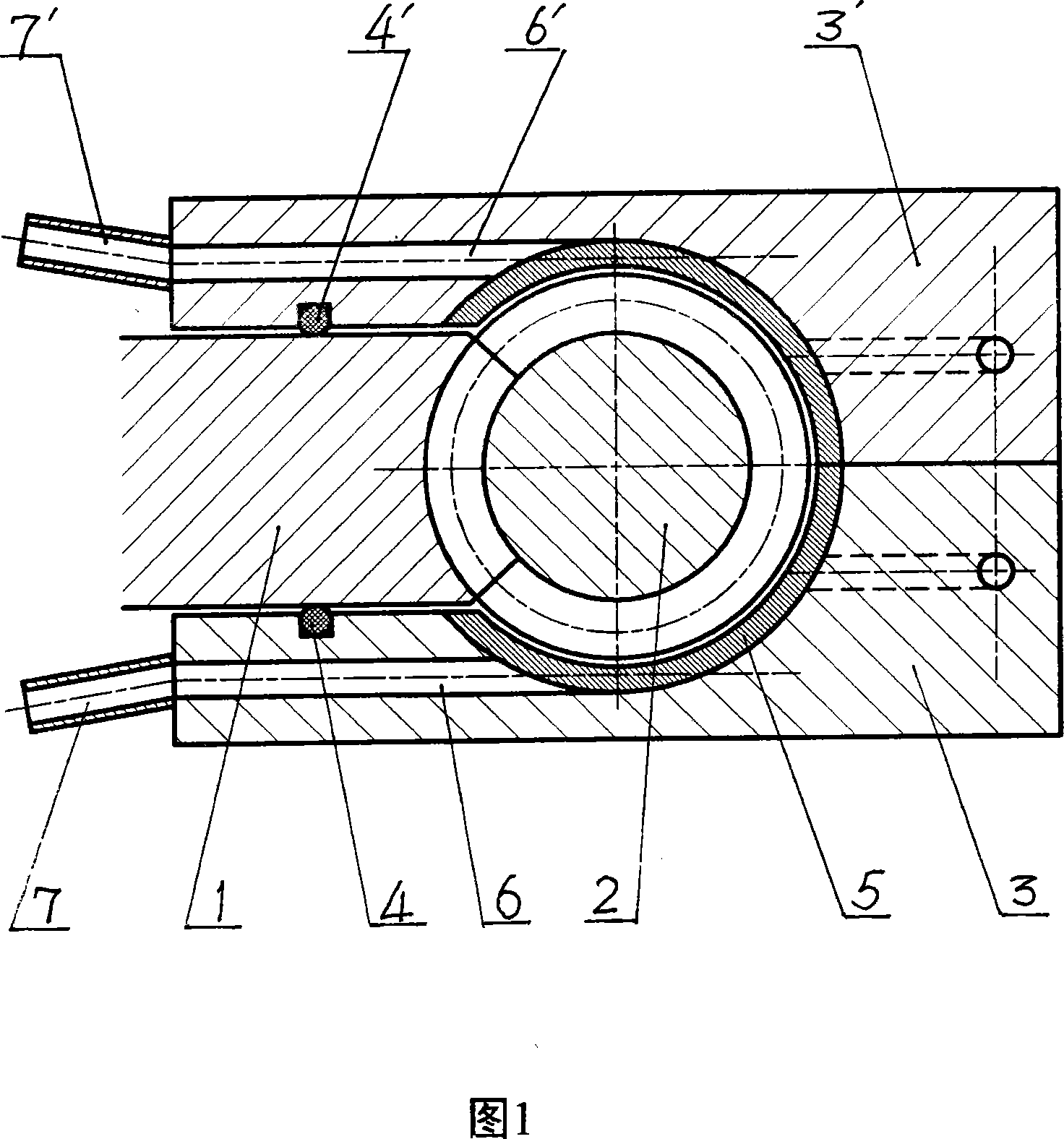

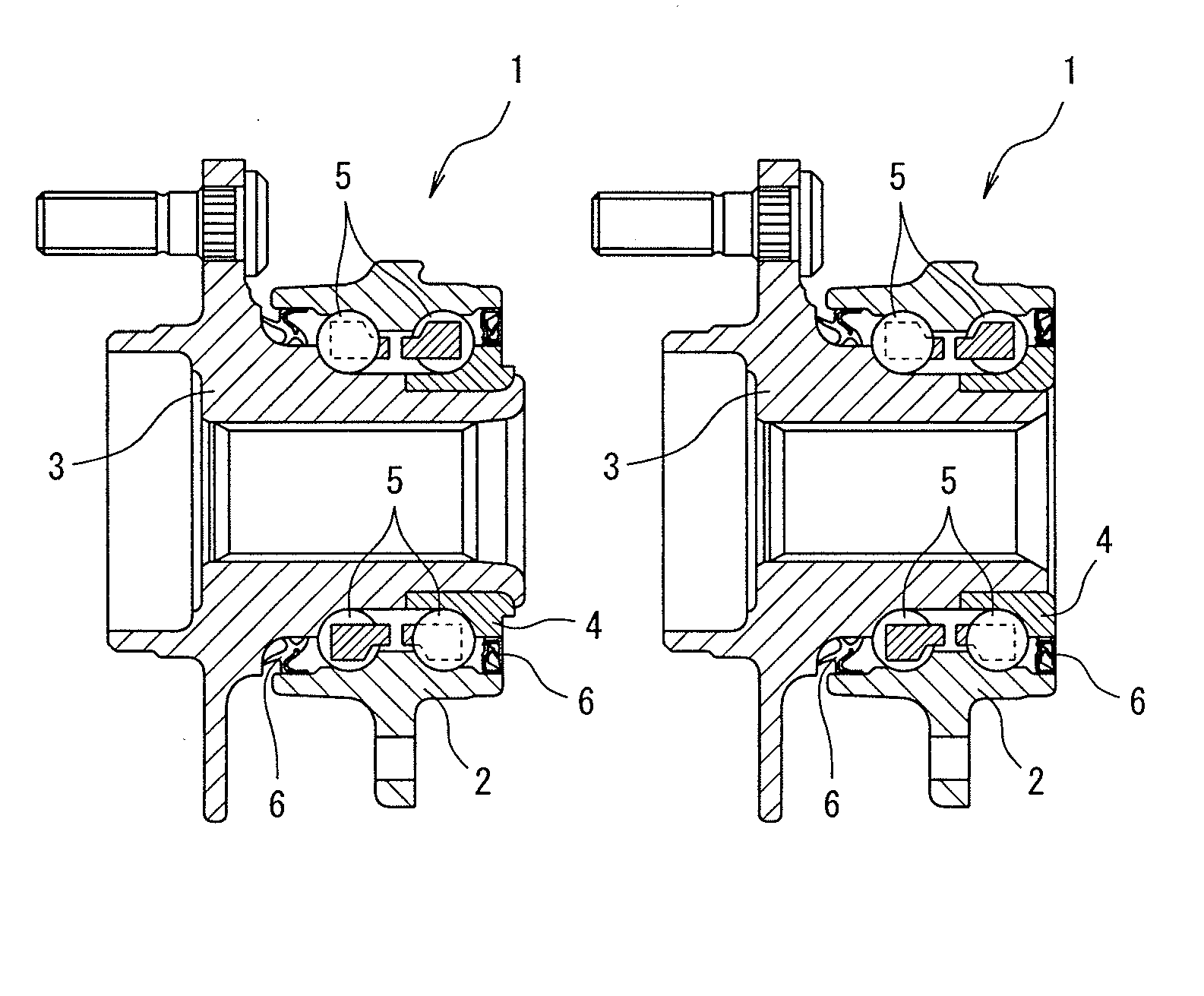

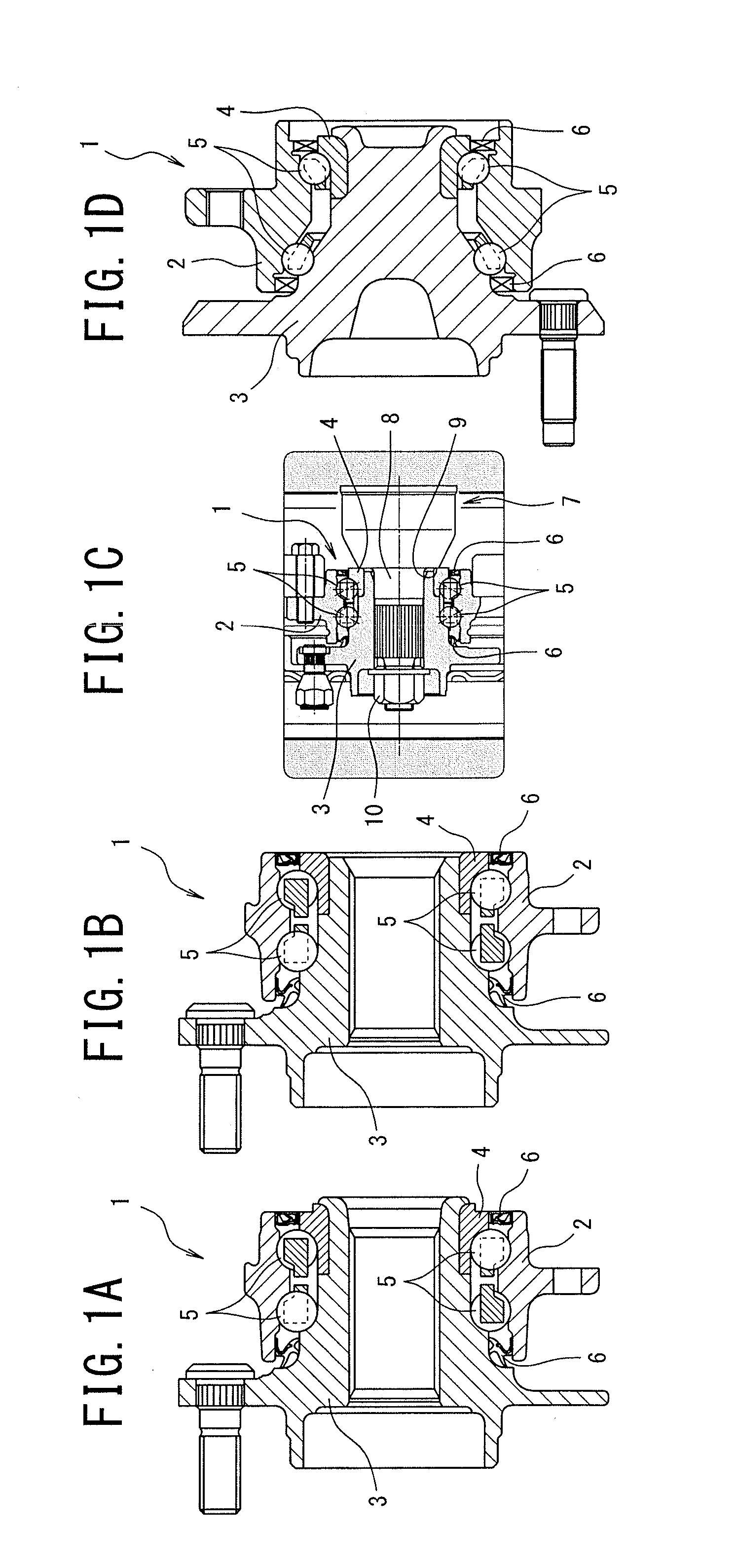

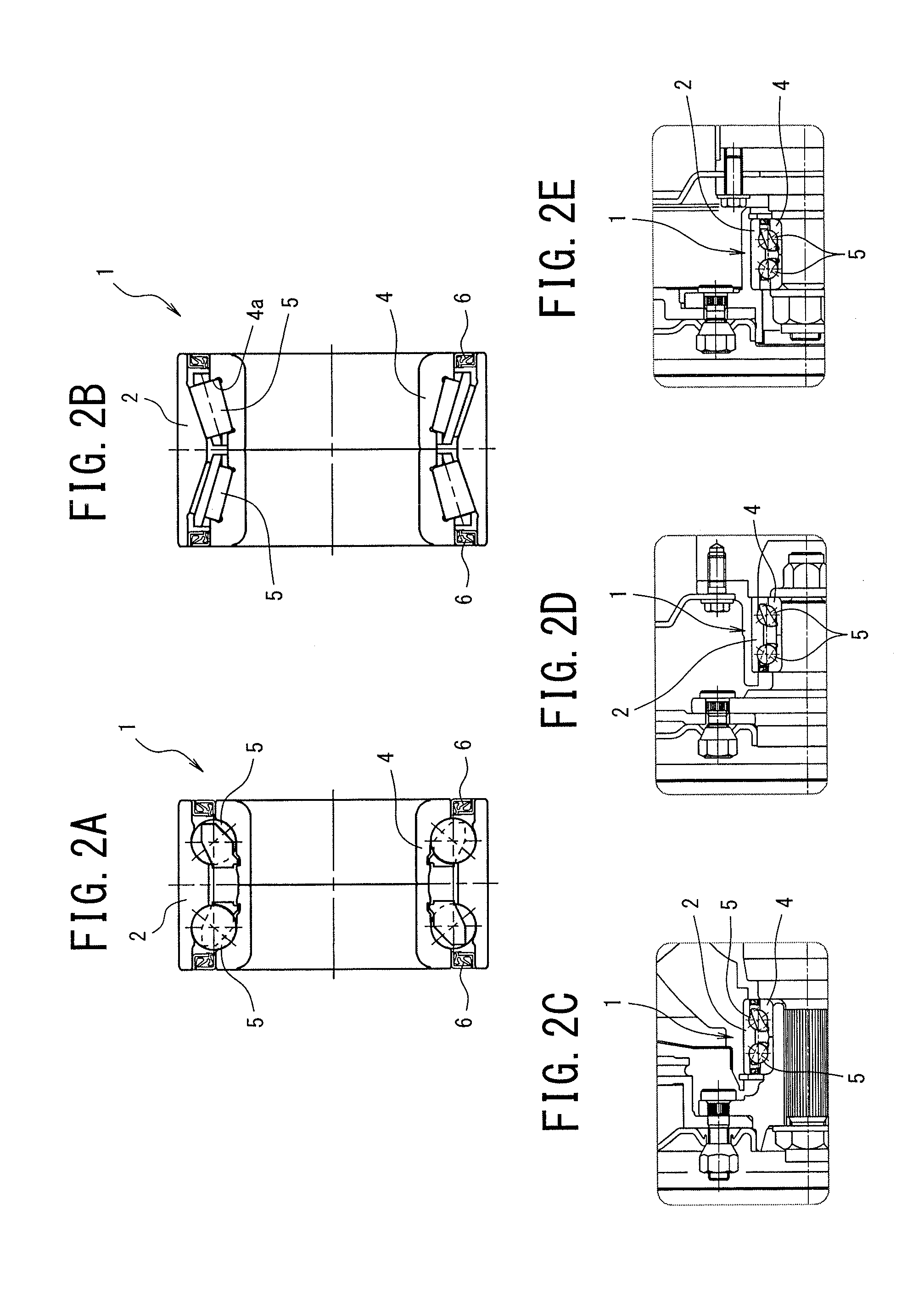

Grease for high-speed bearing and rolling bearing for high speed

InactiveCN101622333AMaintain load resistanceExcellent ability to supply oilBearing componentsThickenersEngineeringHigh velocity

A grease for high-speed bearing and rolling bearing for high speed that enable satisfactorily coping with a high-speed rotation of 170x10<4> or higher dmN value and enable realizing compaction of machine tool and cutback of operating costs. The grease is one comprising a mixture of urea grease containing a urea compound as a thickener and nonurea grease not containing the urea compound, wherein the urea compound is one obtained by reaction between a polyisocyanate component and a monoamine component, the monoamine component containing 50 mol% or more of at least one monoamine selected from among aliphatic monoamines and alicyclic monoamines based on all the monoamines. Rolling bearing for high speed (1) is one comprising inner ring (2), outer ring (3), multiple rolling elements (4) interposed between the inner ring (2) and the outer ring (3) and seal member (6), wherein the above grease (8) is hermetically introduced around the rolling elements(4).

Owner:NTN CORP

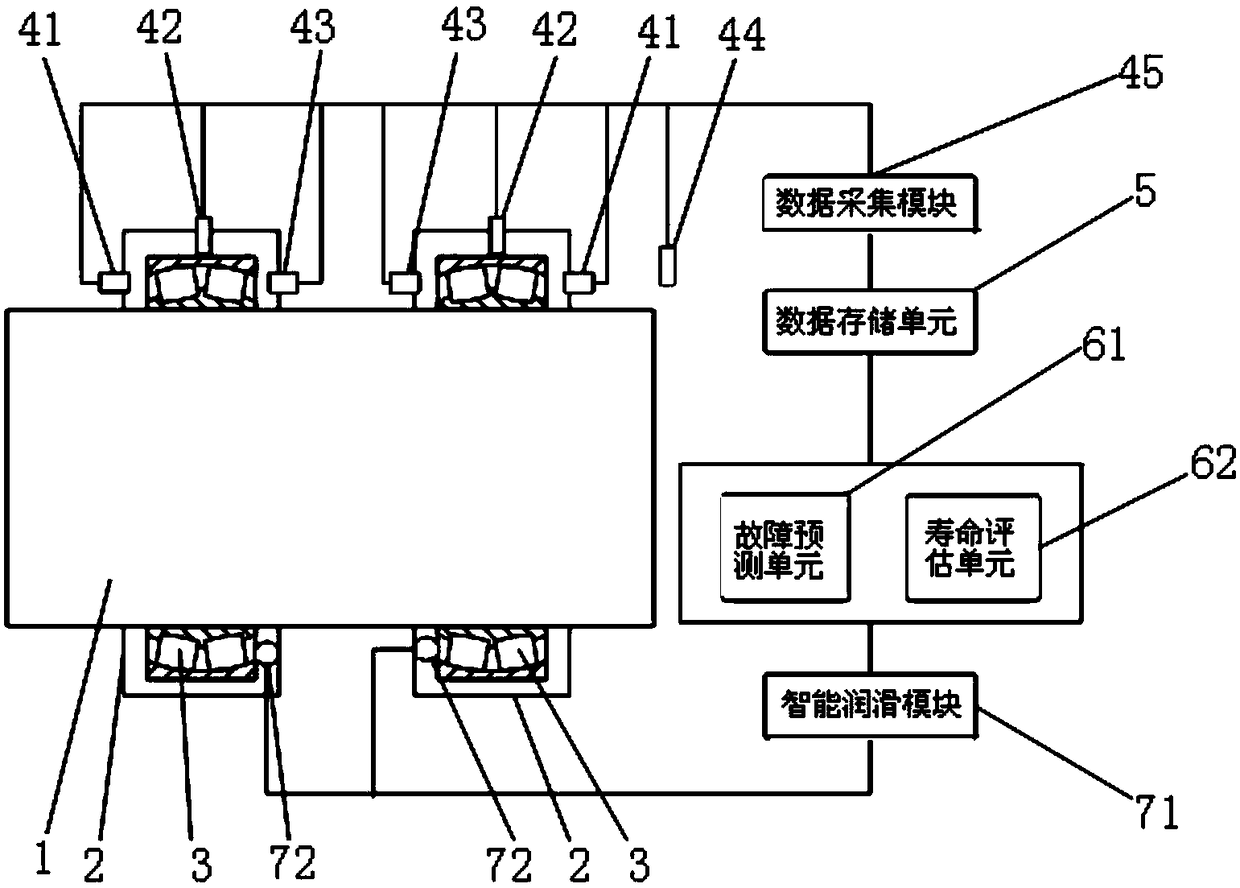

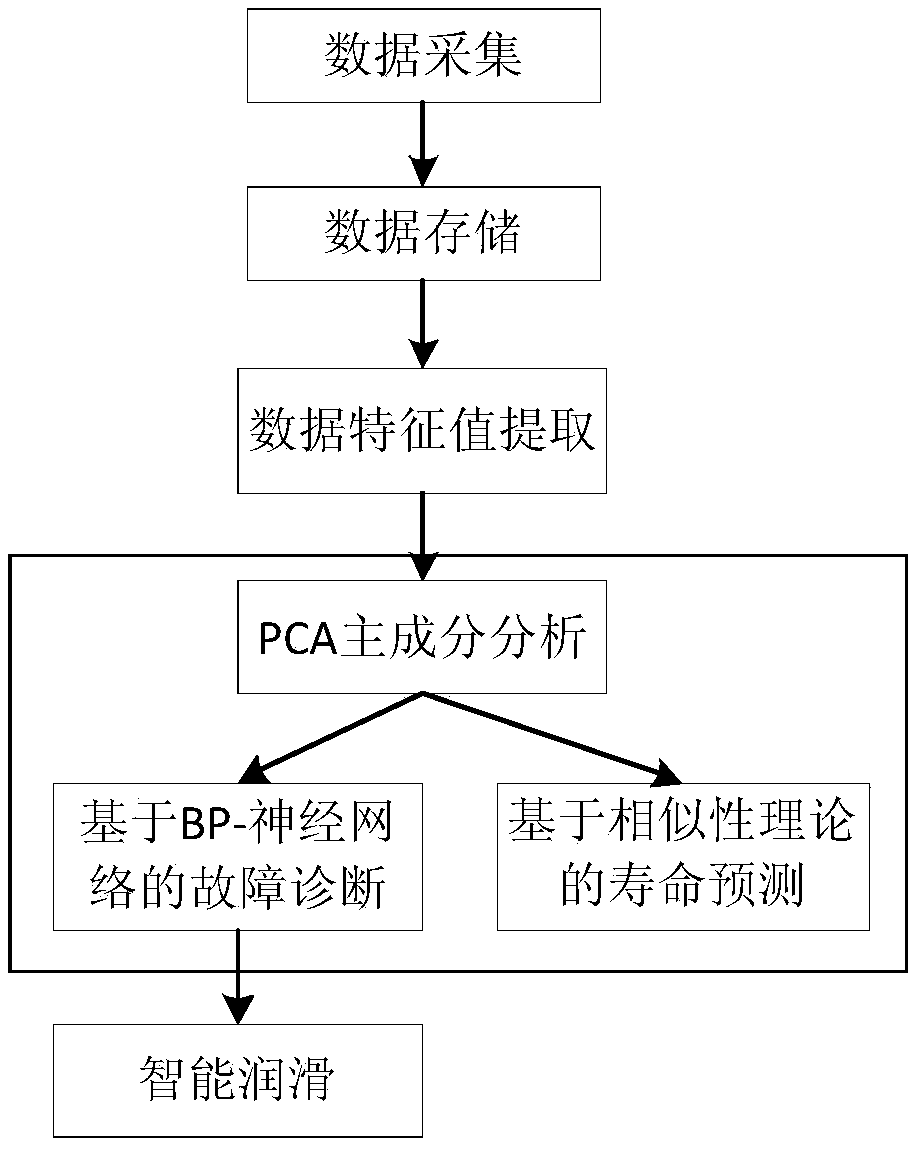

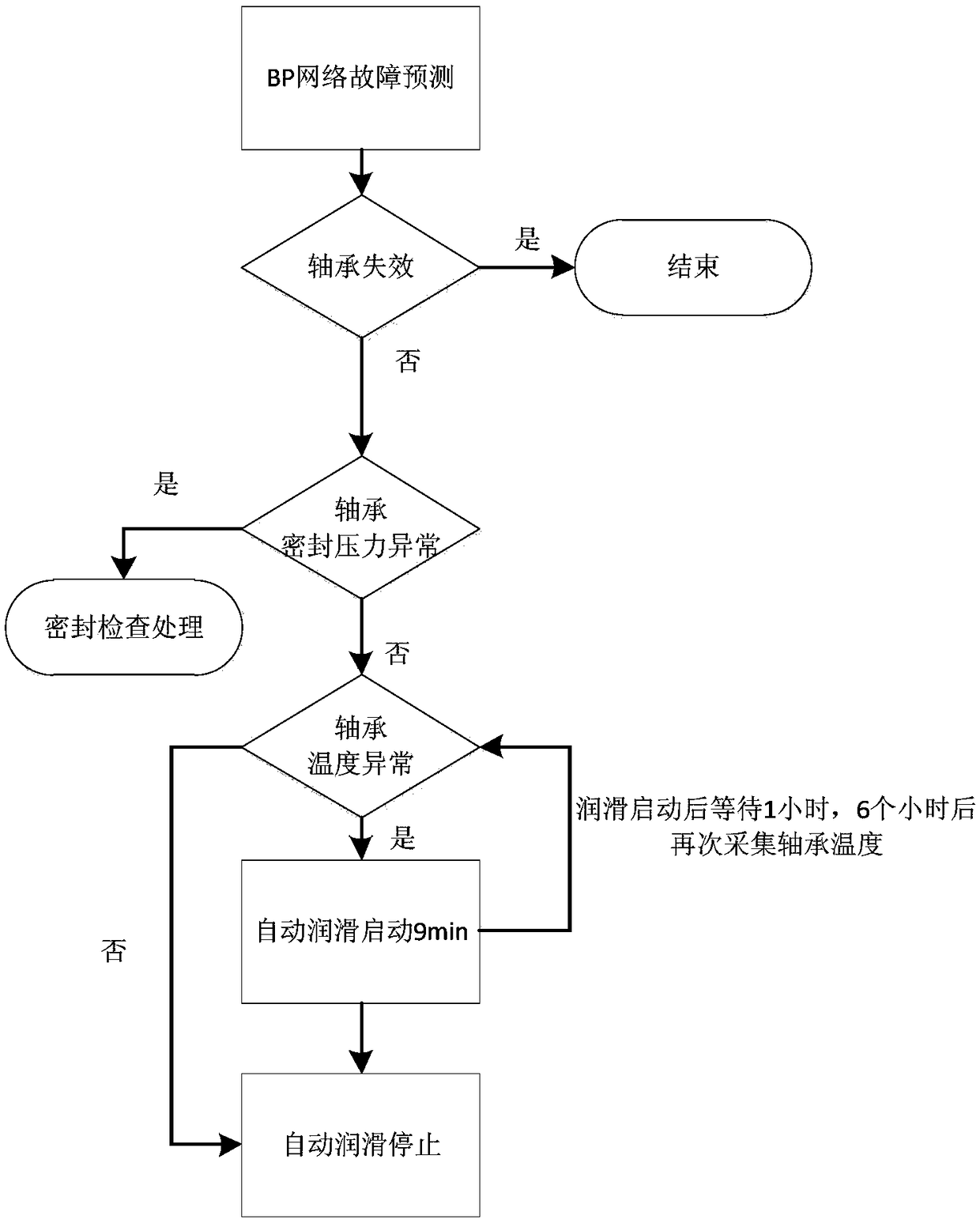

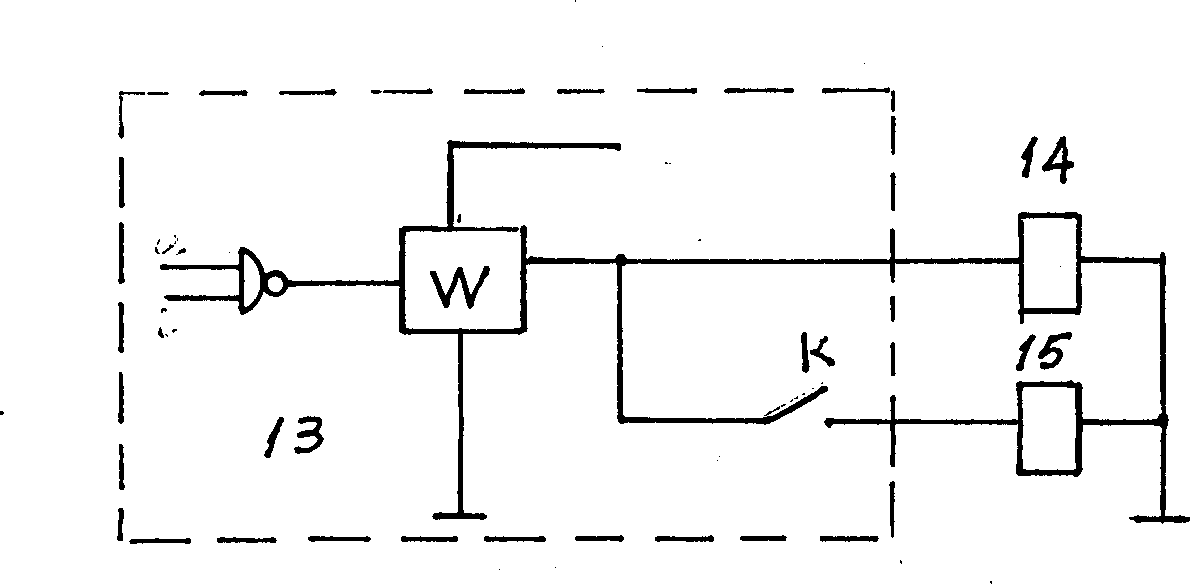

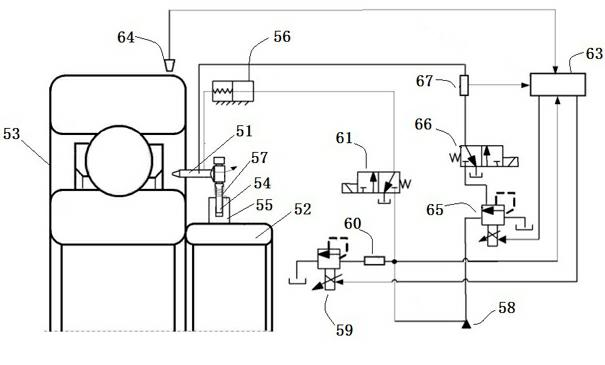

Fault predication and service life evaluation system and method of wind power main bearing

PendingCN108896312AComprehensive assessmentComprehensive forecastMachine bearings testingPrincipal component analysisData acquisition

The invention discloses a fault predication and service life evaluation system of a wind power main bearing. The fault predication and service life evaluation system comprises a data acquisition unit,a data storage unit, a fault predication unit and a service life evaluation unit, wherein the data acquisition unit comprises a plurality of sensors for detecting a vibration component and a temprature signal of the wind power main bearing and a pressure signal in a cavity of the main bearing, and a data acquisition module connected with the plurality of sensors; the data storage unit is used forreceiving data and storing; the fault predication unit is used for carrying out principle component analysis on the data transmitted by the data storage unit, so as to realize fault predication of the wind power main bearing; the service life evaluation unit is used for predicating a residual service life of the main bearing through carrying out the principle component analysis on the data transmitted by the data storage unit. The invention further discloses a fault predication and service life evaluation method of the wind power main bearing. According to the fault predication and service life evaluation system, after the data is acquired, the data is subjected to PCA (Principal Component Analysis) processing; bearing faults are predicated based on a neural network model; the service life of the bearing is predicted based on a similarity principle, and real-time lubricating adjustment of the bearing is also realized based on a predication result.

Owner:GUODIAN UNITED POWER TECH

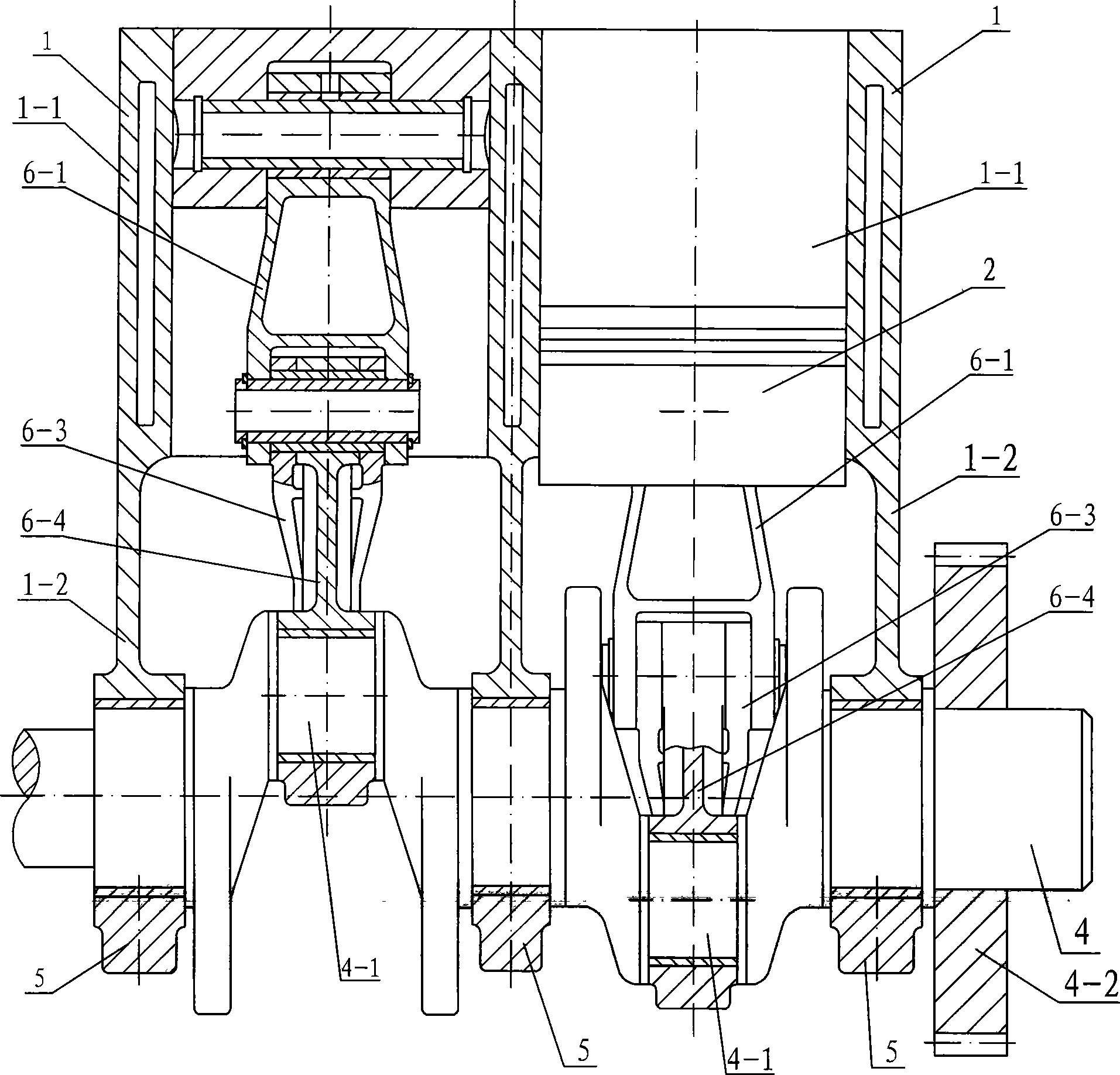

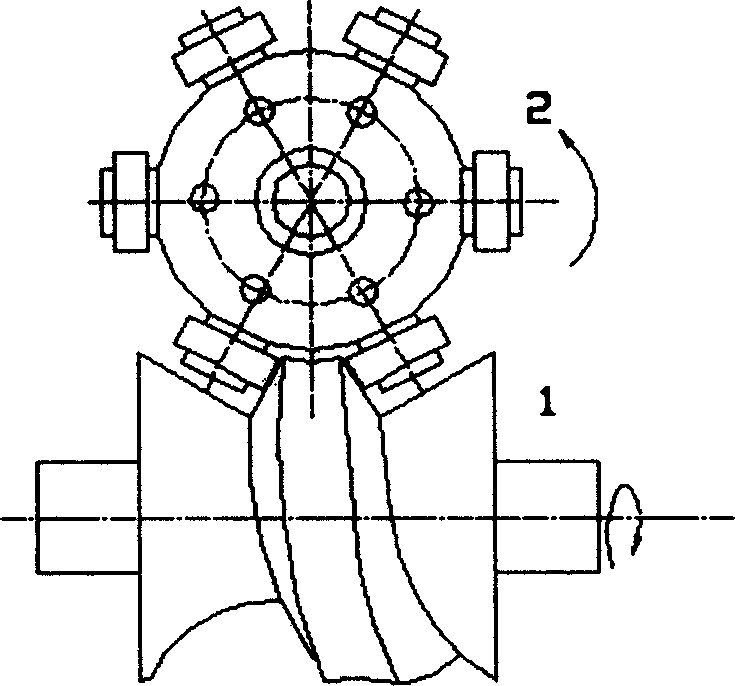

External reverse gear unit of speed variator for motorcycle engine

InactiveCN1356235APrevent leakageImprove lubrication statusCycle actuatorsEngineeringMechanical engineering

An external reverse gear unit for the speed variator of motorcycle is composed of a case assemblage for changing the rotational direction of driven axle, a manipulating mechanism installed on case body for driving the driven axle to change its rotational direction, and a reverse gear controlling drive for controlling the said manipulating mechanism. It features that the reverse gear can only be performed at low gear position, that is, reverse gear position "I", resulting in higher safety.

Owner:谢光荣 +1

Titanium alloy artificial articular head with wear resistant ceramic coating and preparation method of titanium alloy artificial articular head

ActiveCN104562146AHigh hardnessImprove wear resistanceSurface reaction electrolytic coatingProsthesisArticular headPlasma electrolytic oxidation

The invention discloses a titanium alloy artificial articular head with wear-resistant ceramic coating and a preparation method of the titanium alloy artificial articular head. The titanium alloy artificial articular head comprises a titanium alloy articular head body, wherein a micropore array texture is formed on the surface of the titanium alloy articular head body, an antifriction and wear-resistant ceramic coating is arranged on the surface of the titanium alloy artificial articular head, and the surface layer of the antifriction and wear-resistant ceramic coating is a compact ceramic coating subjected to pore filling and sealing with hard nanoparticles; the microproe array texture is a regular micropore array which is formed in the surface where the titanium alloy articular head is in contact with a joint cup; and an oxidation ceramic coating is a hard oxidation layer prepared by adopting a two-step plasma electrolytic oxidation process and is compounded on a textured surface. The artificial articular head with the wear-resistant ceramic coating capable of improving lubricating property has the advantages that wear resistance is enhanced, and the wear of paired friction parts, namely cotyle, can be obviously reduced; meanwhile, toughness of the titanium alloy body is maintained, and cost is obviously lower than that of a full ceramic articular head.

Owner:NANJING HONGSHENGJIAN BIOLOGICAL TECH

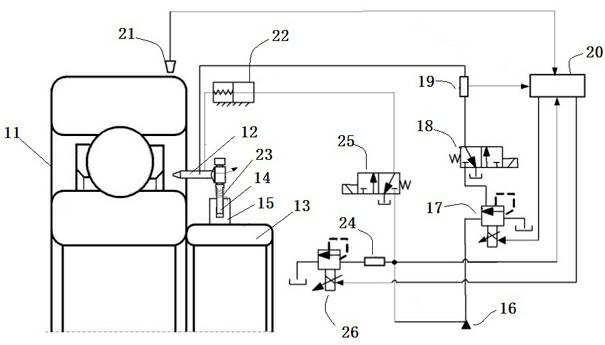

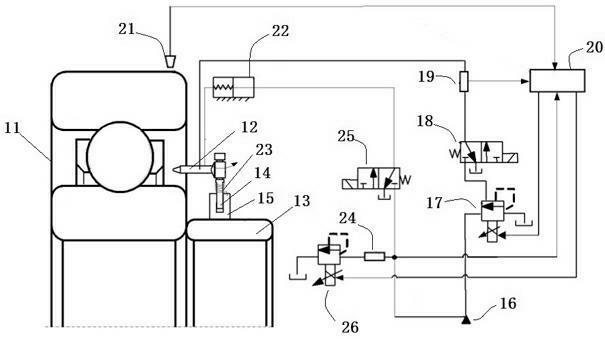

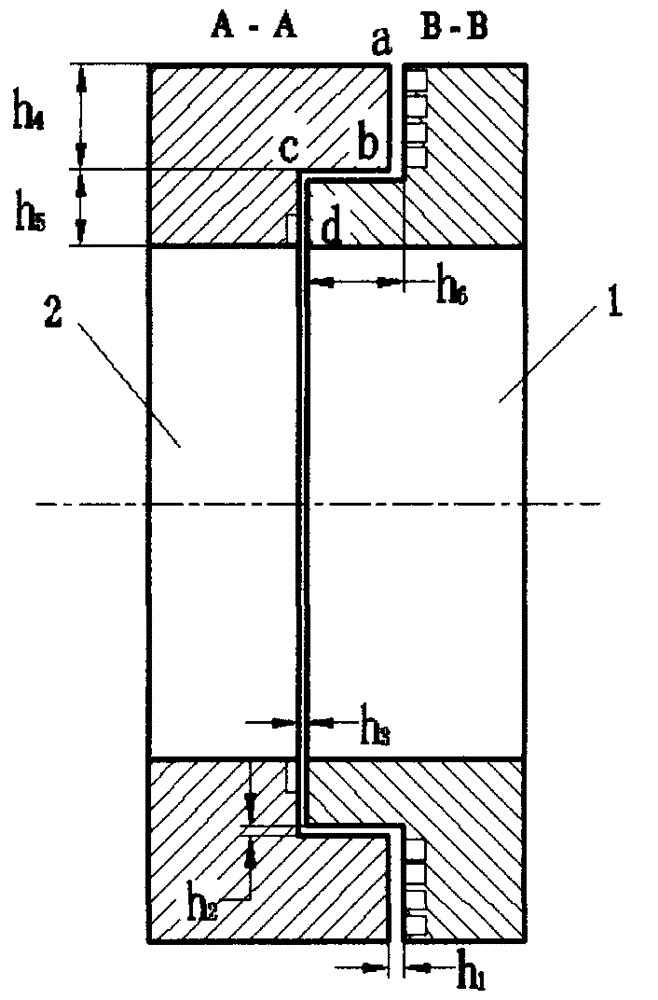

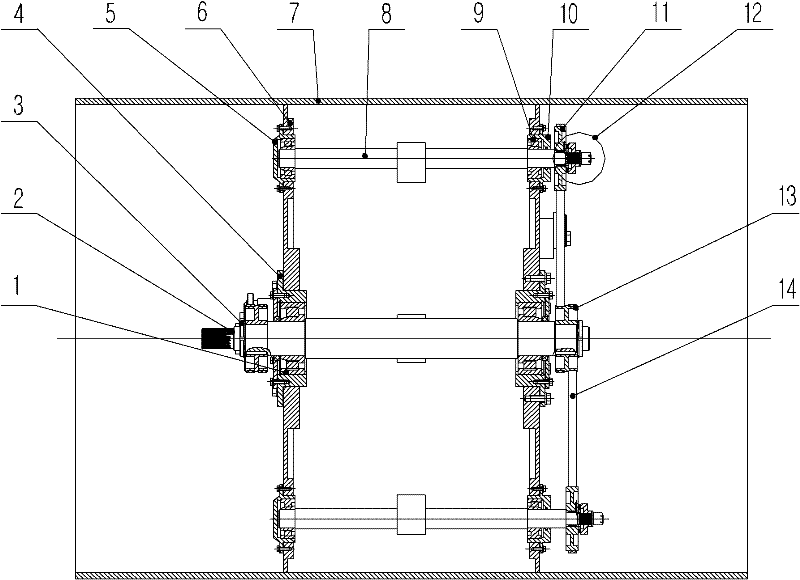

Method and device for implementing jet lubrication among rolling bearing rings

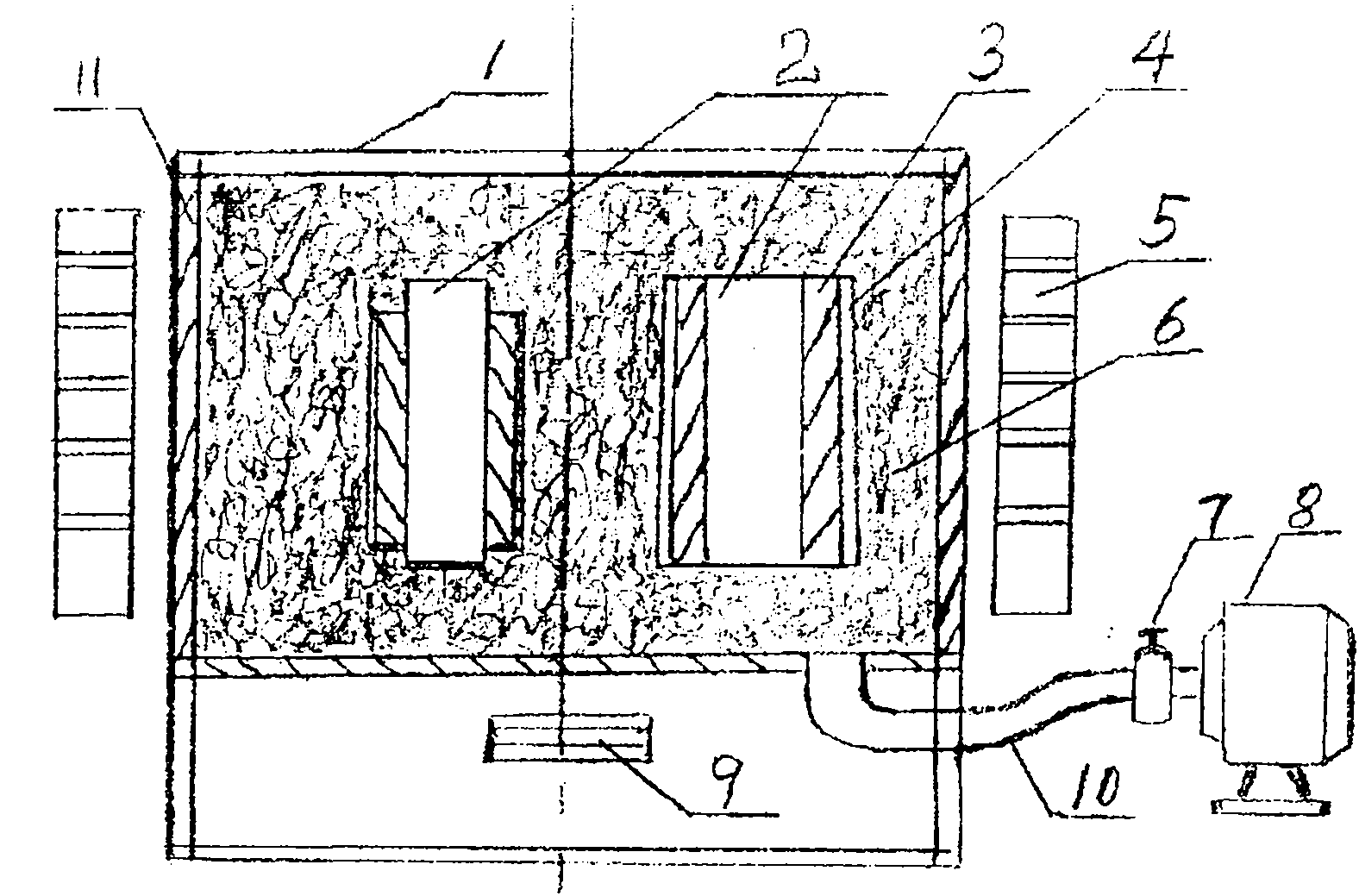

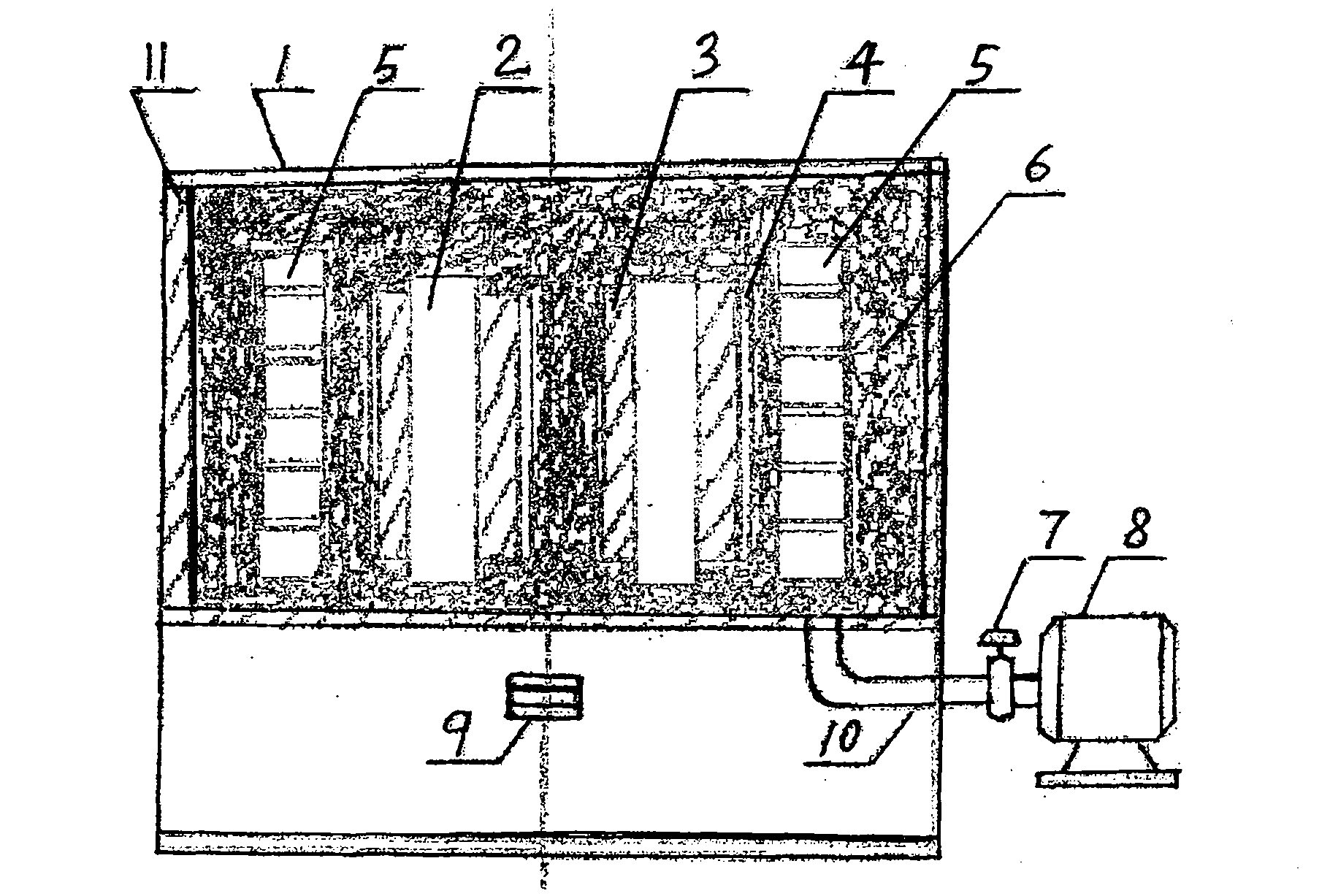

InactiveCN102679120AImprove lubrication statusImprove operating conditionsBearing assemblyLubrication check valvesRotational axisRolling-element bearing

The invention relates to a method and device for implementing jet lubrication among rolling bearing rings. The method for implementing jet lubrication among rolling bearing rings comprises the following steps of: 1) rotatablely arranging a nozzle on the axial side of a rolling bearing, wherein the rotational axis of the nozzle is perpendicular to the rotational axis of the rolling bearing, and a mouth of the nozzle faces a position between the inner ring of the rolling bearing and a cage; 2) connecting an oil pump on the nozzle, and setting the oil jet pressure and jet speed of the nozzle; and 3) rotatablely connecting a driving device for driving the nozzle to swing so as to adjust the inward-jet angle of lubricating oil on the nozzle, monitoring the rotating speed of the rolling bearing through a rotating speed sensor, transmitting a rotating speed signal of the rolling bearing to a controller, and presetting a proportion coefficient between the inward-jet angle of the lubricating oil and the DN (nominal diameter) of the rolling bearing in the controller, so that the controller controls the driving device to drive the nozzle to swing to a corresponding inward-jet angle of the lubricating oil according to the signals of the rotating speed sensor and the proportion coefficient between the inward-jet angle of the lubricating oil and the DN of the rolling bearing. According to the invention, the amount of oil jetted to the inside of the rolling bearing can be controlled.

Owner:HENAN UNIV OF SCI & TECH

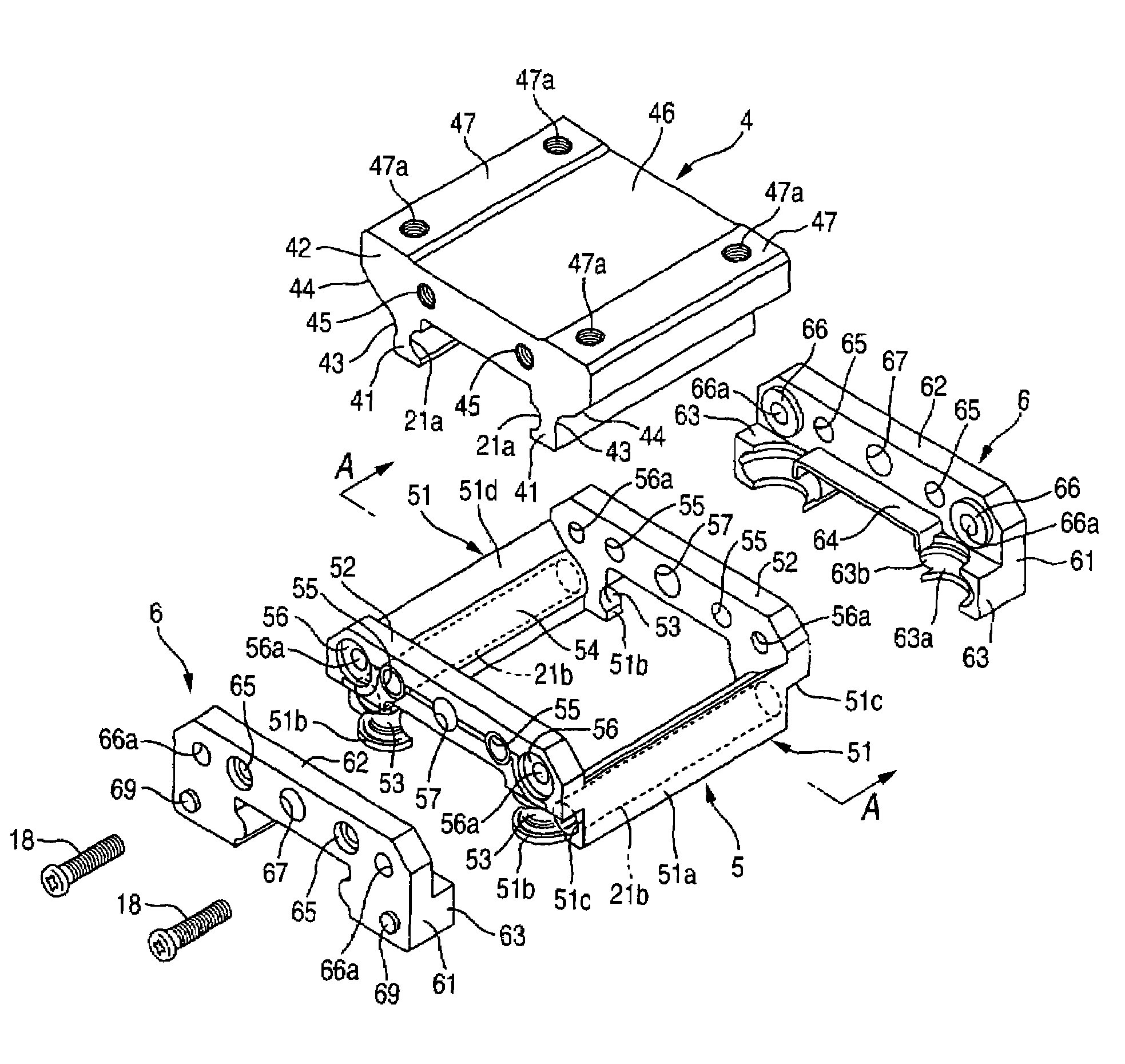

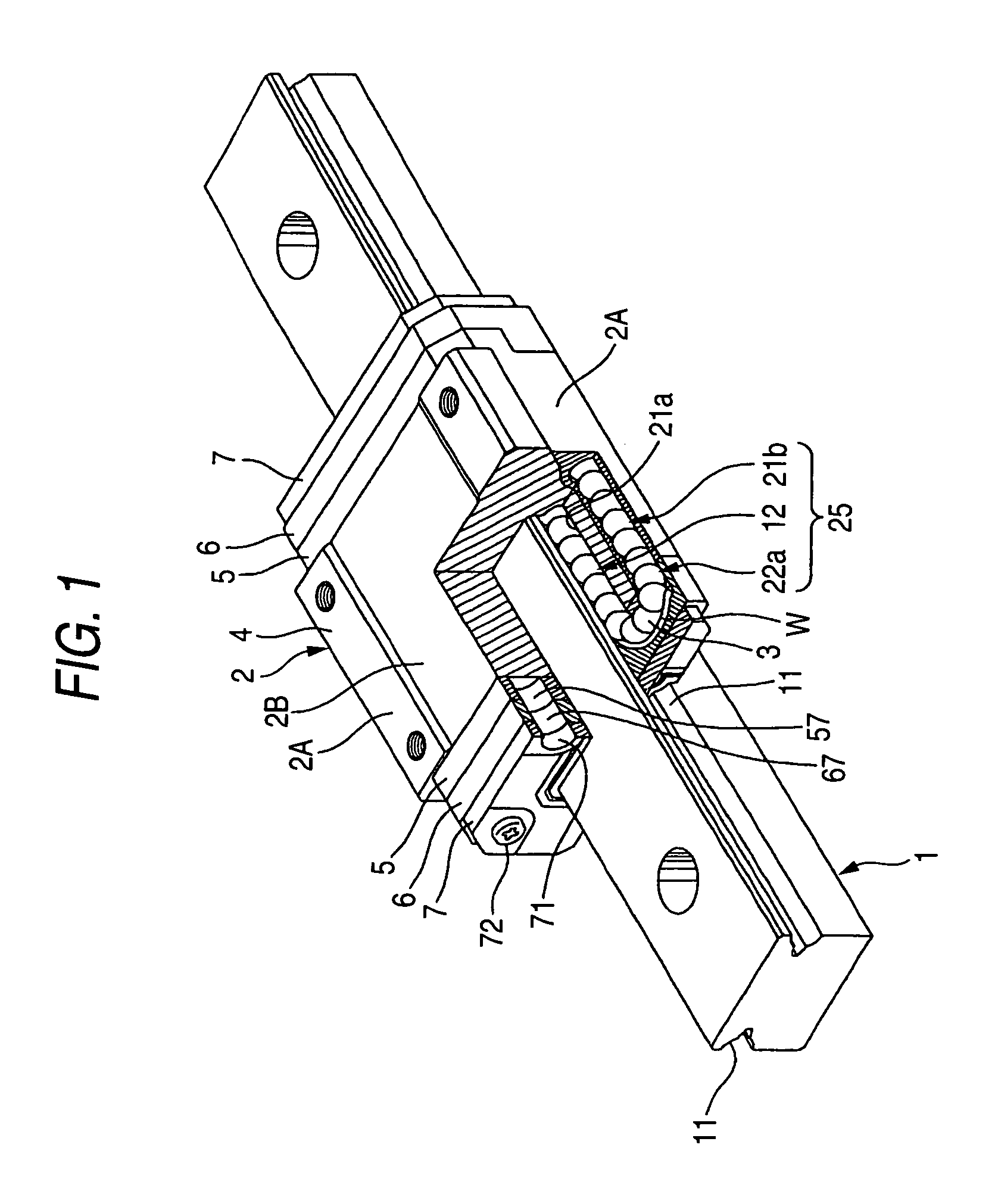

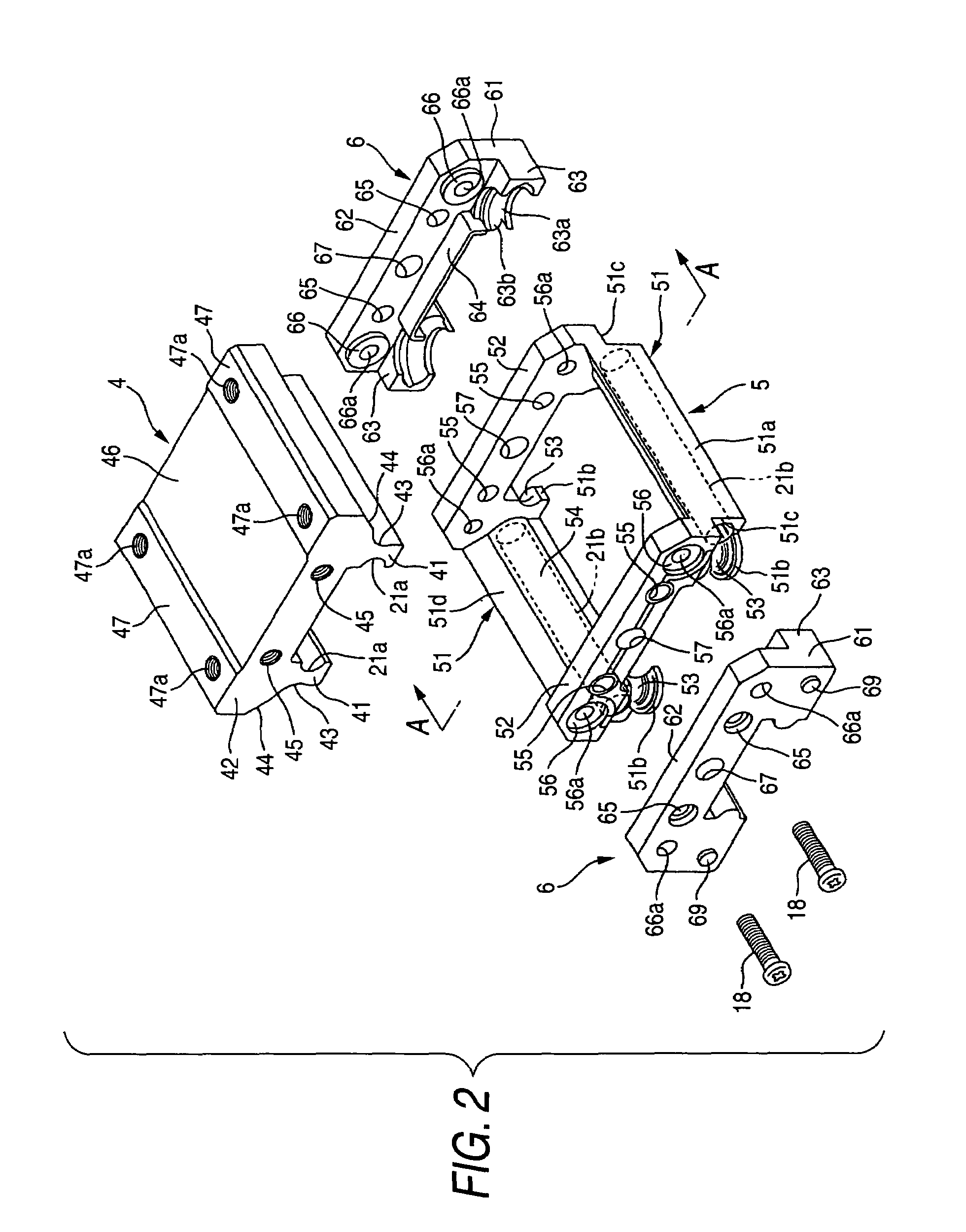

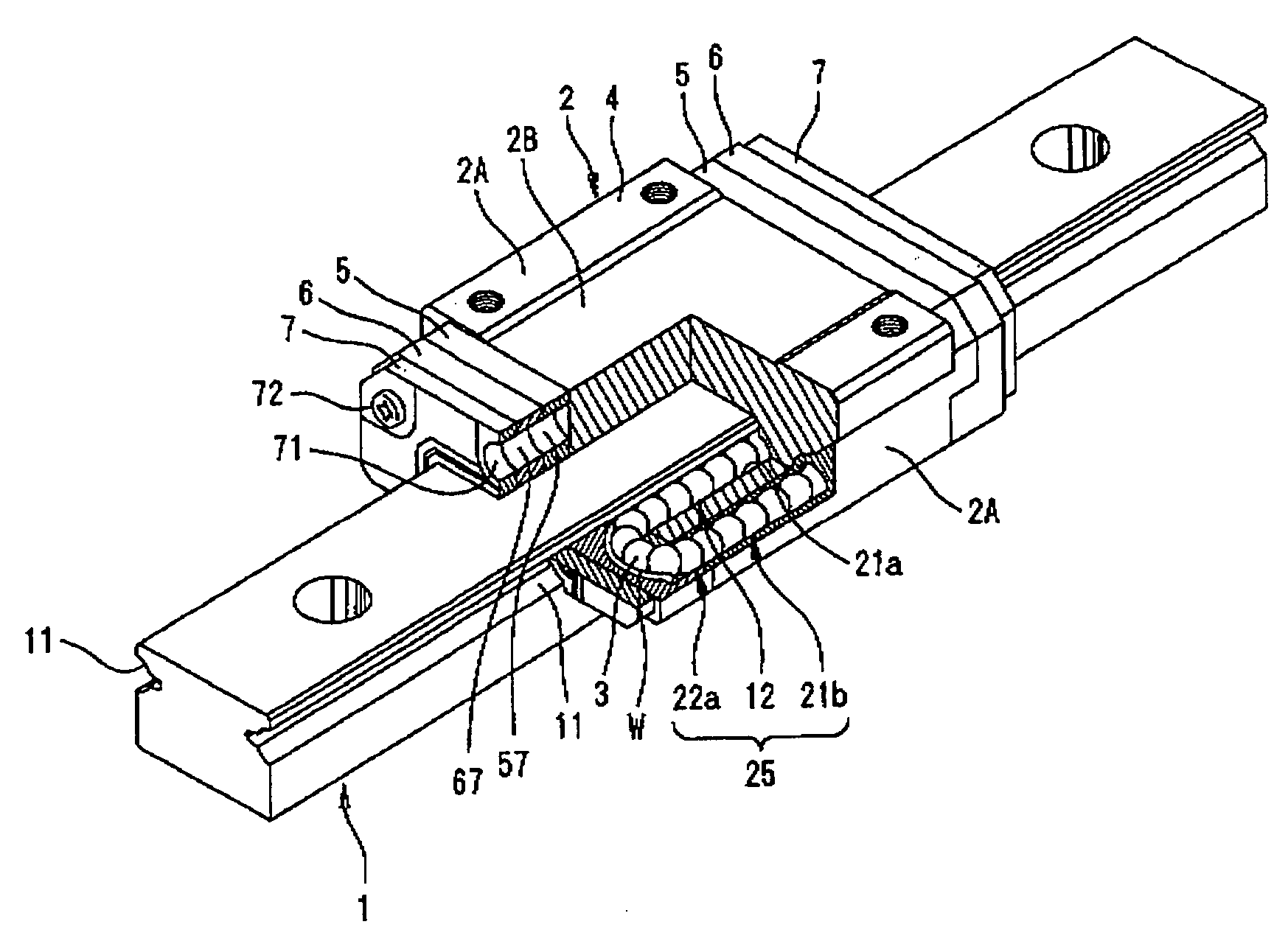

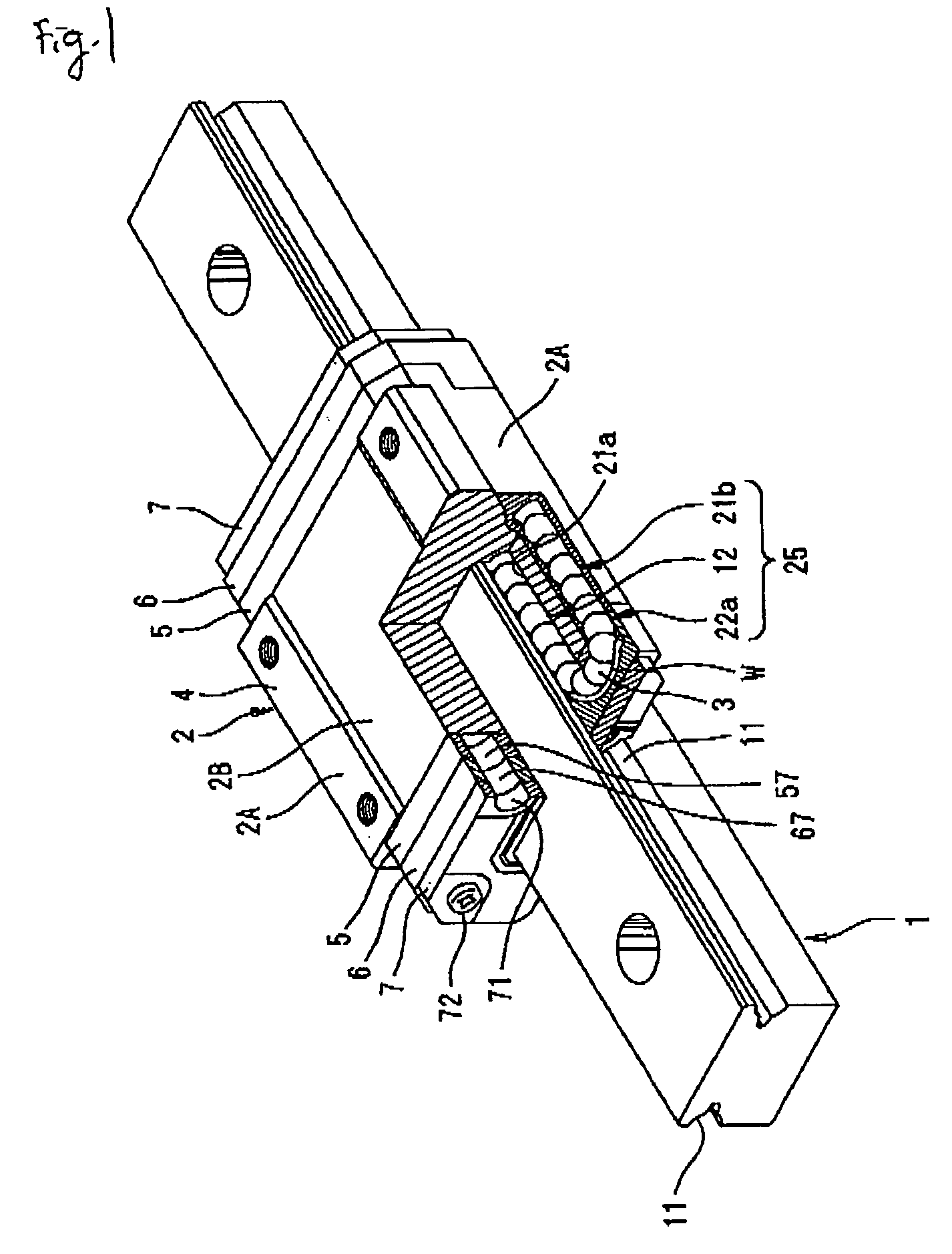

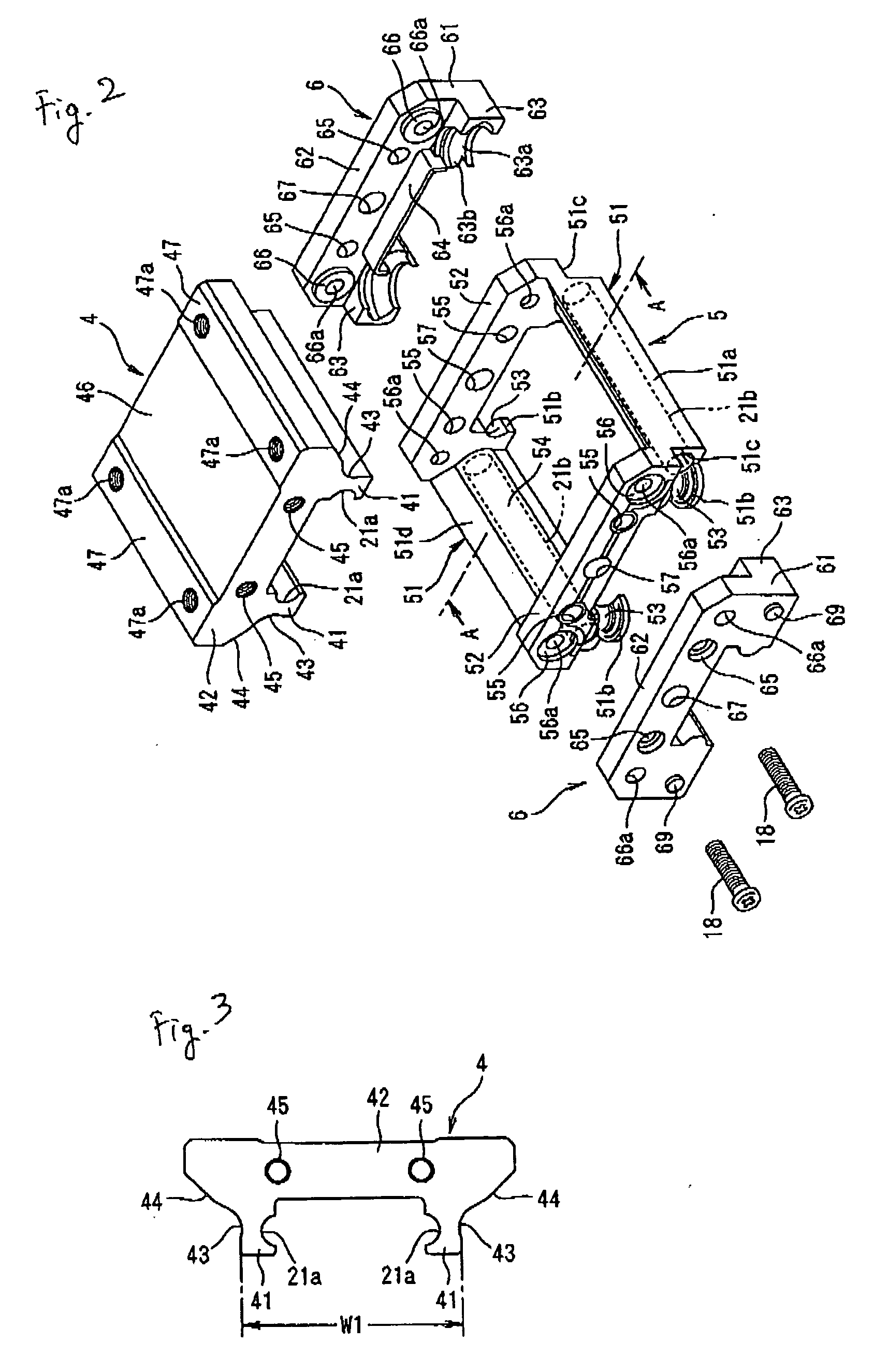

Linear guide apparatus

A slider is constituted by a main body made of a metal and a frame member and an end cap made of a synthetic resin. The main body is provided with a rolling groove. The frame member is provided with a return passage and an inner side groove of a direction changing passage. The end cap is provided with an outer side groove of the direction changing passage. A longest outer dimension in a slider width direction between lower end portions of inner legs of the main body is made to be larger than a shortest dimension in the slider width direction between projected portions of the frame member. The frame member is detachably engaged with the main body by putting a side of a leg portion of the main body to and from a side of a frame member horizontal portion by elastically deforming the frame member.

Owner:NSK LTD

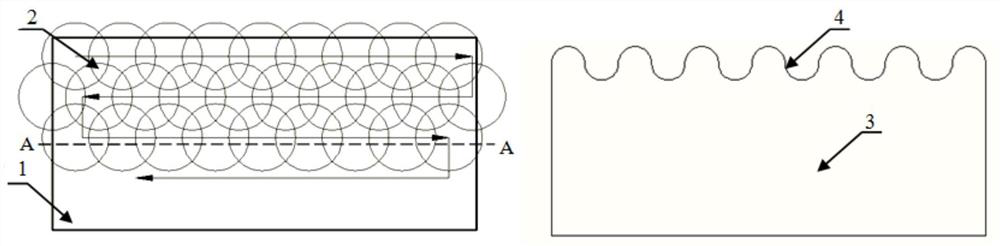

Metal member surface microscopic topographic controlled manufacturing process implement method

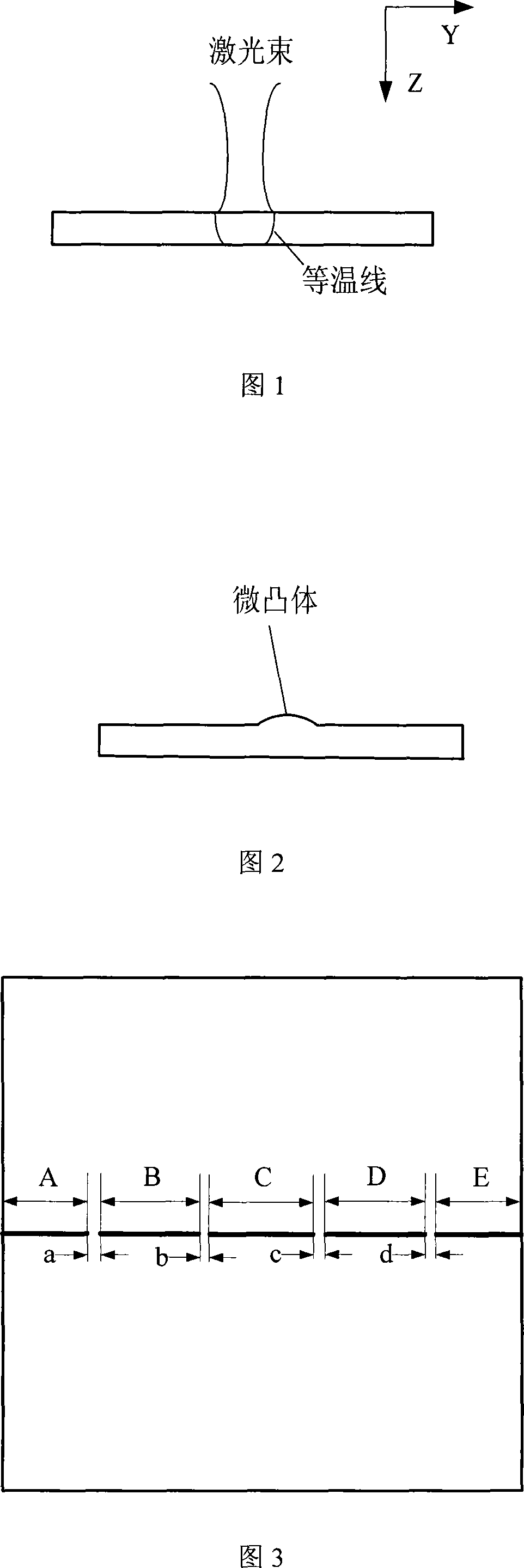

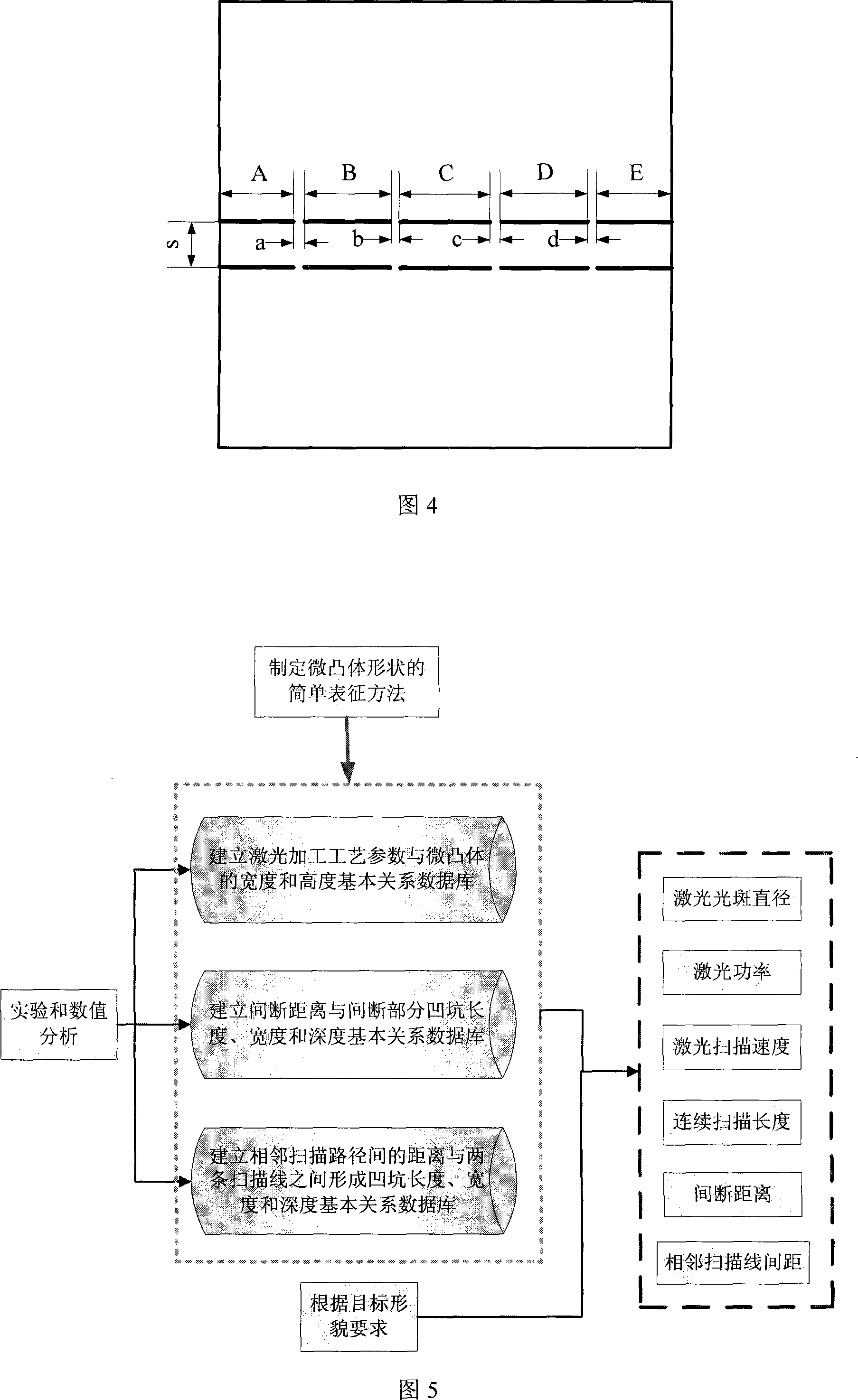

InactiveCN101204755AImprove lubrication statusSimple processLaser beam welding apparatusThermal stateNickel alloy

The invention relates to a method for realizing a microcosmic topography controllable manufacture on a metal component surface. The invention is characterized in that the invention realizes the processing on the microcosmic topography on the metal component surface through changing the processing technical parameters, scanning the line interruption distance as well as the length of each section of scanning line and the space between neighboring scanning routes based on that the thermal effect of laser results in uneven temperature fields on the metal component surface to lead part of the metal component surface to generate plastometric set to form a micro-bulge. The technique is characterized in that being as thermal state accumulative forming, the invention is not only suitable for a normal metal material, but also suitable for the controllable manufacture on the surfaces of high-hard brittle difficult-deforming materials like titanium alloy, nickel alloy, ceramics and silicon chip; the invention can be applied to a friction pair for bearing / gap block, cylinder sleeve / piston of different materials and has an important significance on improving the librating state of the friction pair.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

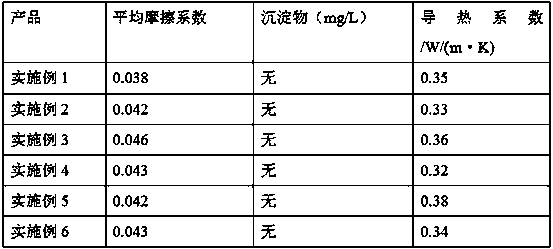

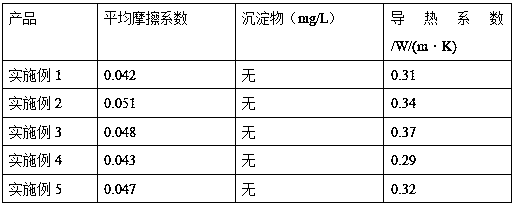

High thermal conductivity lubricating oil and preparation method thereof

ActiveCN108587755AGood compatibilityImprove stabilityCarbon compoundsLubricant compositionPolyethylene glycolBoron nitride

The invention discloses a high thermal conductivity lubricating oil and a preparation method thereof. The lubricating oil is prepared from the following raw materials, in parts by weight: 100-150 parts of basic oil, 1-3 parts of modified graphene, 0.1-0.5 part of yttrium oxide, 0.1-0.5 part of boron nitride, 1-3 parts of polyethylene glycol dehydroabietate ester, 0.5-1.5 parts of succinate sulfonated hydrogenated castor oil, 1-2 parts of diglycolamide oleate borate, 0.5-1.5 parts of defoaming agent, 0.5-1.5 parts of lubricating agent and 0.5-1.5 parts of anti-oxidant. The lubricating oil provided by the invention has the excellent compatibility and stability, is low in friction coefficient and high in heat conductivity coefficient, has the good protection effect on mechanical parts, prolongs the service life of the mechanical parts, and has the good economic benefits and social benefits.

Owner:南宁隆腾科技有限公司

Lip seal for water pump

InactiveUS20140203520A1Effective prevention of softening and swellingReduce hardnessEngine sealsPump componentsVulcanizationEngineering

Disclosed is a lip seal for water pump made of a rubber-like elastic material, fixed to a housing as a fixed side and in sliding contact with a shaft rotating relative to the housing; the lip seal being obtained by vulcanization-molding of a rubber composition comprising 100 parts by weight of the rubber-like elastic material, 1 to 150 parts by weight of a reinforcing filler, 5 to 90 parts by weight of a non-reinforcing filler having an average particle diameter of 1 μm or more, 0.1 to 5 parts by weight of a coupling agent, 1 to 15 parts by weight of a co-crosslinking agent, and 0.5 to 10 parts by weight of an organic peroxide. The lip seal for water pump provides a materially solution, rather than a structural solution, to prevent softening and volume swelling of the rubber-like elastic material and the generation of deposits in the rotating shaft, which are problematic for rotation torque and LLC resistance.

Owner:EAGLE INDS

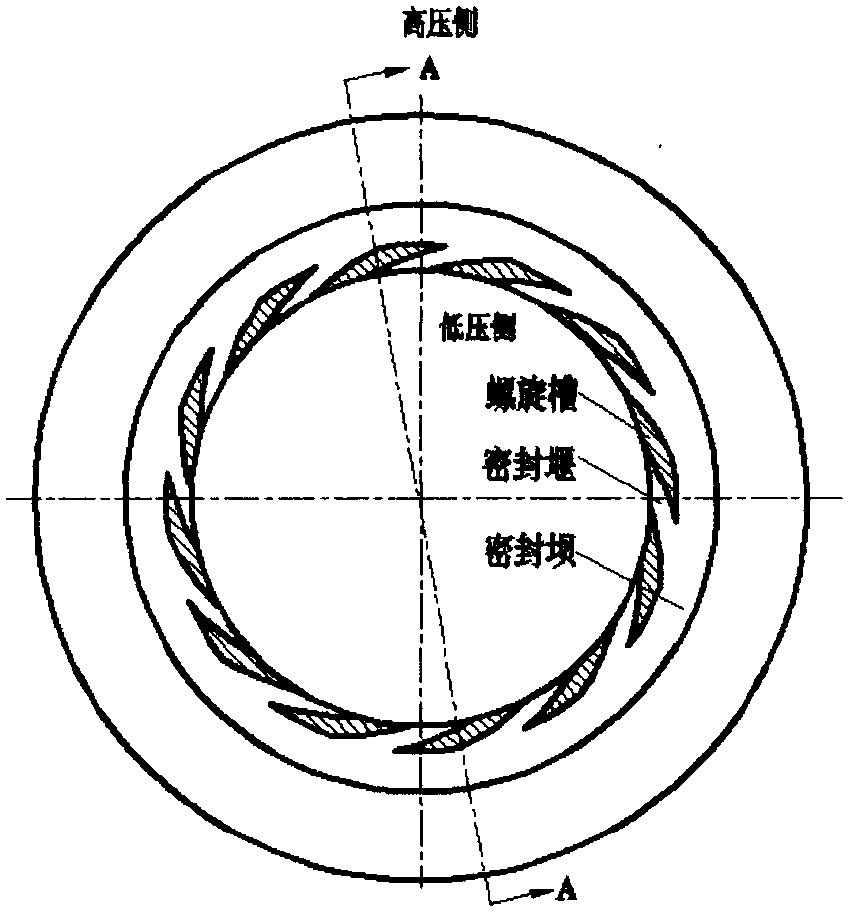

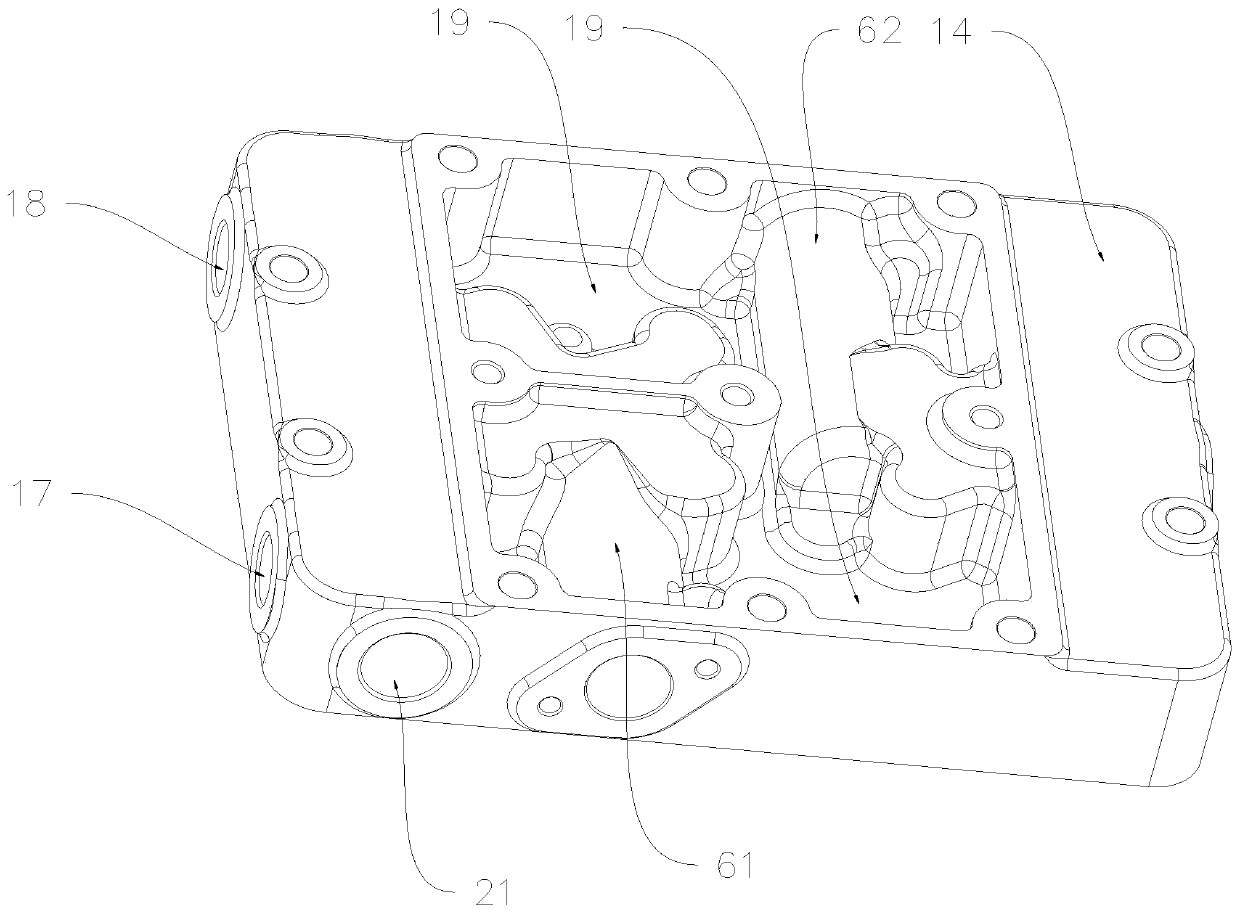

Multiple-end face combined type mechanical seal for realizing zero leakage and non-contact

InactiveCN103557334AImprove the state of friction and lubricationRelieve pressureEngine sealsLiquid mediumThermal deformation

The invention provides a mechanical seal provided with multiple end faces arranged between a moving ring and a stationary ring for realizing zero leakage and non-contact through the combined actions of micro concave cavities, gap channels and pumping slots. Micro concave cavities or pumping slots are respectively formed in different end faces of the mechanical seal friction pair; the dynamic pressure effect of the micro concave cavities and the pumping slots is utilized to realize the non-contact; the pressure of leaked medium is reduced by utilizing the gap channels (or provided with mazes) among different end faces; the leakage amount is reduced or the zero leakage is achieved by utilizing the pumping effect of the pumping slot. The mechanical seal has the advantages that the zero leakage and non-contact are realized through the combination of surface micro molding structures of different end faces and the gap channels, the lubricating performance during the operating process is improved, besides, good sealing performance in the case of start-up and parking can be realized through the different seal gaps of different end faces, a certain effect is achieved on the aspects of mechanical seal thermal deformation reduction and particle abrasion prevention, and the mechanical seal is applicable to the field of high parameter mechanical seal of all liquid mediums.

Owner:JIANGSU UNIV

Worm wheel and worm with dynamic and static pressure lubricating at engagement zone

InactiveCN101067437AImprove the lubrication effectReduce churning lossToothed gearingsPortable liftingGear driveGear wheel

The invention discloses the worm and gear with the active and static pressure lubricant used in the mechanically-driven meshing zone. The sealing mass is installed in the out of the meshing zone of the worm and the gear, which contacts with the worm and has the sealing strip. The maze tooth is on the relative surface of the sealing mass and the gear, which is directed to the bear without the oil through the oil pipe from the oil hole opened in the sealing zone formed between the sealing mass hollow and the worm or gear. The screw vanes with the same direction are set on the meshed end of the basal leptospira in gear. The ring oil groove in sealing mass hollow is connected to the sealing zone through the oil hole; on the tooth surface of the worm or gear, the unconnected oil slots are opened. The structure of the invention has improved the lubricant of the worm and gear to improve the loading ability. The driven efficiency has improved by 3%, so it can instead the multilevel gear or planet gear and used in the big speed ratio field.

Owner:刘继清

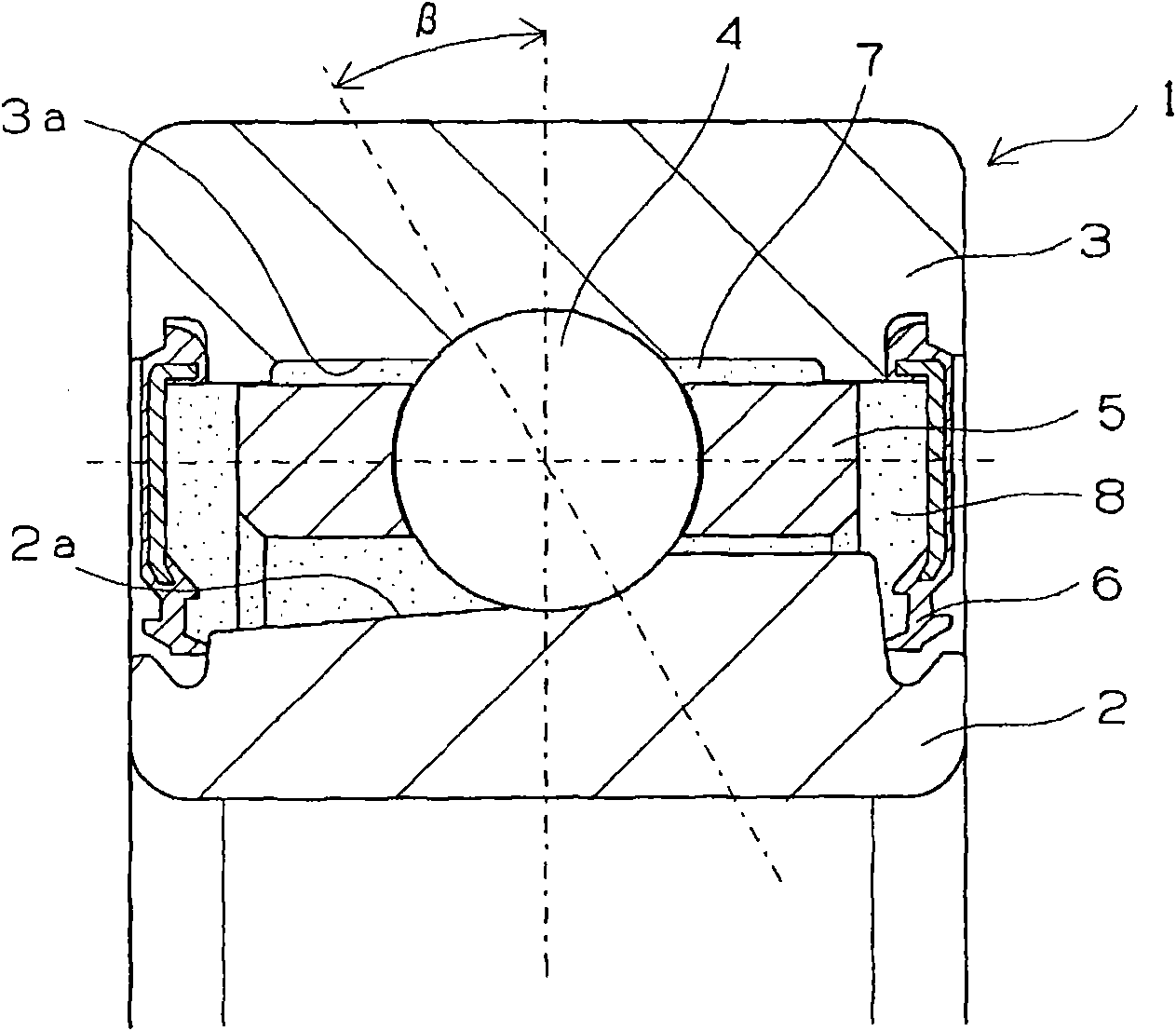

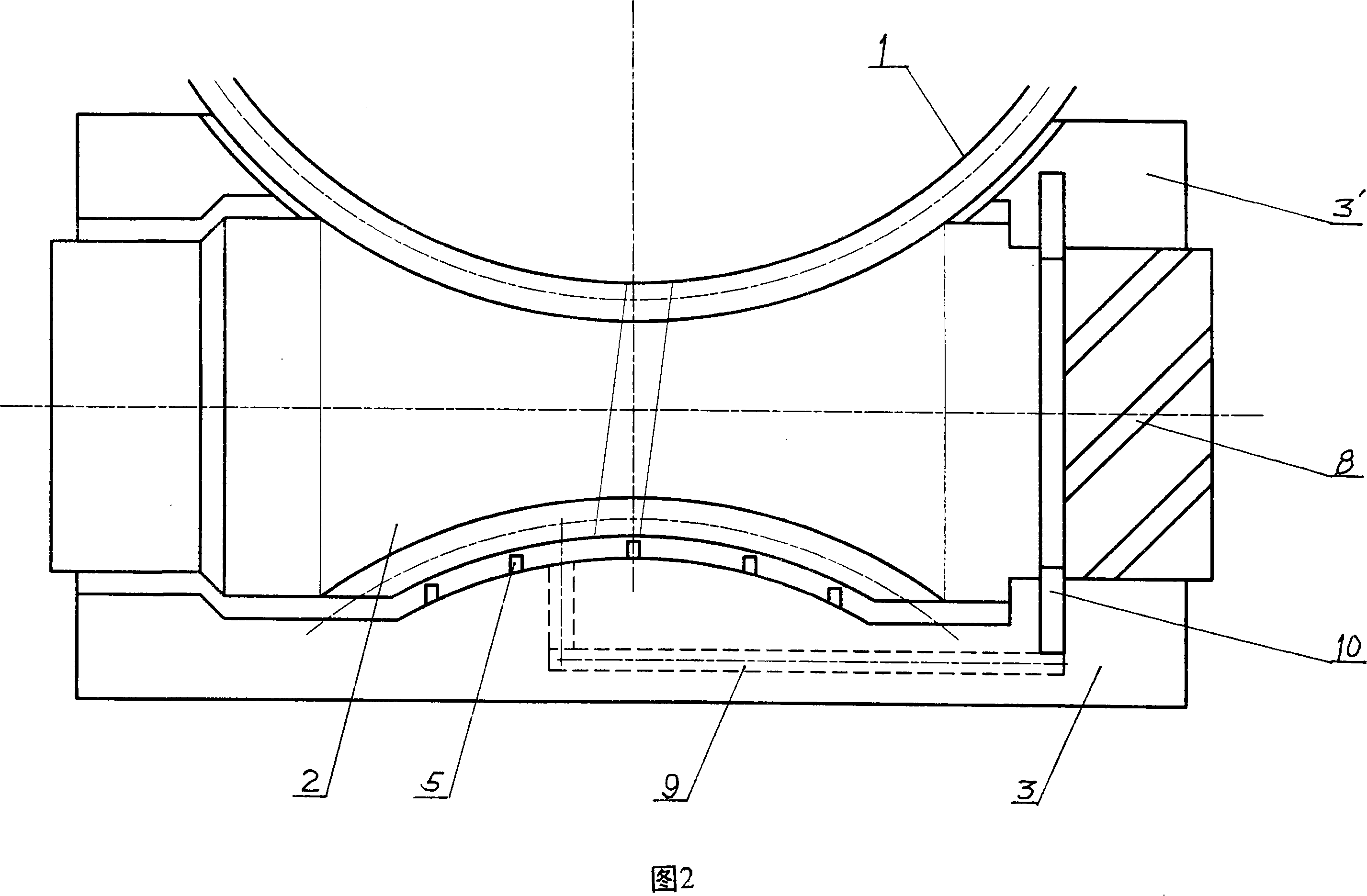

Grease Composition and Wheel Supporting Rolling Bearing Unit Having Grease Composition Packed Therein

InactiveUS20140193110A1Reduce load sensitivityNecessary performanceRolling contact bearingsCastorsRolling-element bearingMass ratio

There is provided a grease composition decreasing the load sensitivity to a running torque, maintaining necessary performances for a wheel supporting rolling bearing unit, and maintaining a good lubricated condition for a long time, and, a wheel supporting rolling bearing unit having the grease composition packed therein. The grease composition contains base oil, thickeners, rust inhibitors, and anti-wear agents, the base oil contains mineral oil, synthetic oil or blend oil of the mineral oil and the synthetic oil, a mix ratio (mass ratio) of the mineral oil and the synthetic oil is 0:100 to 20:80, a kinematic viscosity of the base oil at a temperature of 40° C. is 70 to 150 mm2 / s, and a pour point of the base oil is equal to or lower than −40° C. The wheel supporting rolling bearing unit is packed with this grease composition.

Owner:NSK LTD

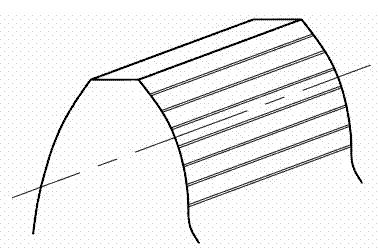

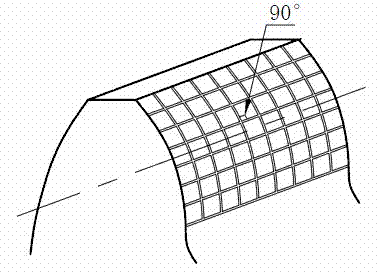

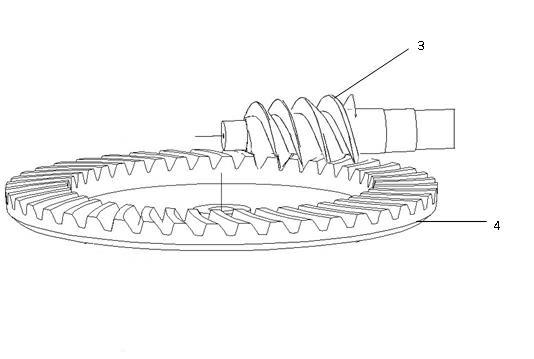

Gear with surface texture tooth surfaces

InactiveCN102889362AReduce abrasive wearAvoid Three-Body FrictionGear lubrication/coolingPortable liftingMachined surfaceLubrication theory

The invention discloses a gear with surface texture tooth surfaces. Uniformly arranged surface texture mark forms are arranged on each tooth surface of the gear. The surface texture mark forms are strip-type convex mark forms or strip-type concave mark forms which are parallel to gear engagement lines. Or, the surface texture mark forms are provided with grid-like convex mark forms or grid-like concave mark forms which are parallel and vertical to gear engagement lines. A surface texture is machined on a tooth surface, so that the gear with surface texture tooth surfaces can accommodate abrasive particles, and reduce the abrasive particle abrasion between the tooth surfaces; the gear with the surface texture tooth surfaces can store lubricating oil, take away friction heat generated between the tooth surfaces, reduce the tooth surface temperature, and prevent tooth surface agglutination from invalidation; and according to a partial film elastic fluid lubrication theory, the gear with surface texture tooth surfaces is favorable for forming an elastic fluid hydrodynamic lubricating oil film to improve the lubrication state. By the surface texture tooth surfaces, the wearing resistance of the gear can be improved, and the service life of the gear can be prolonged.

Owner:ZHEJIANG UNIV +1

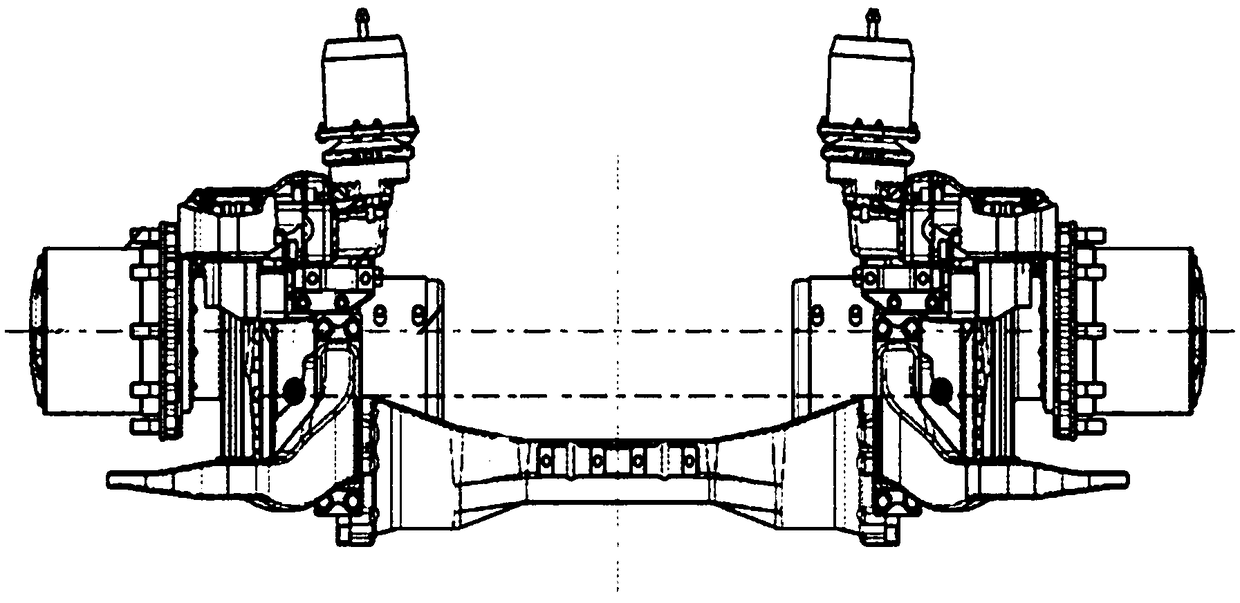

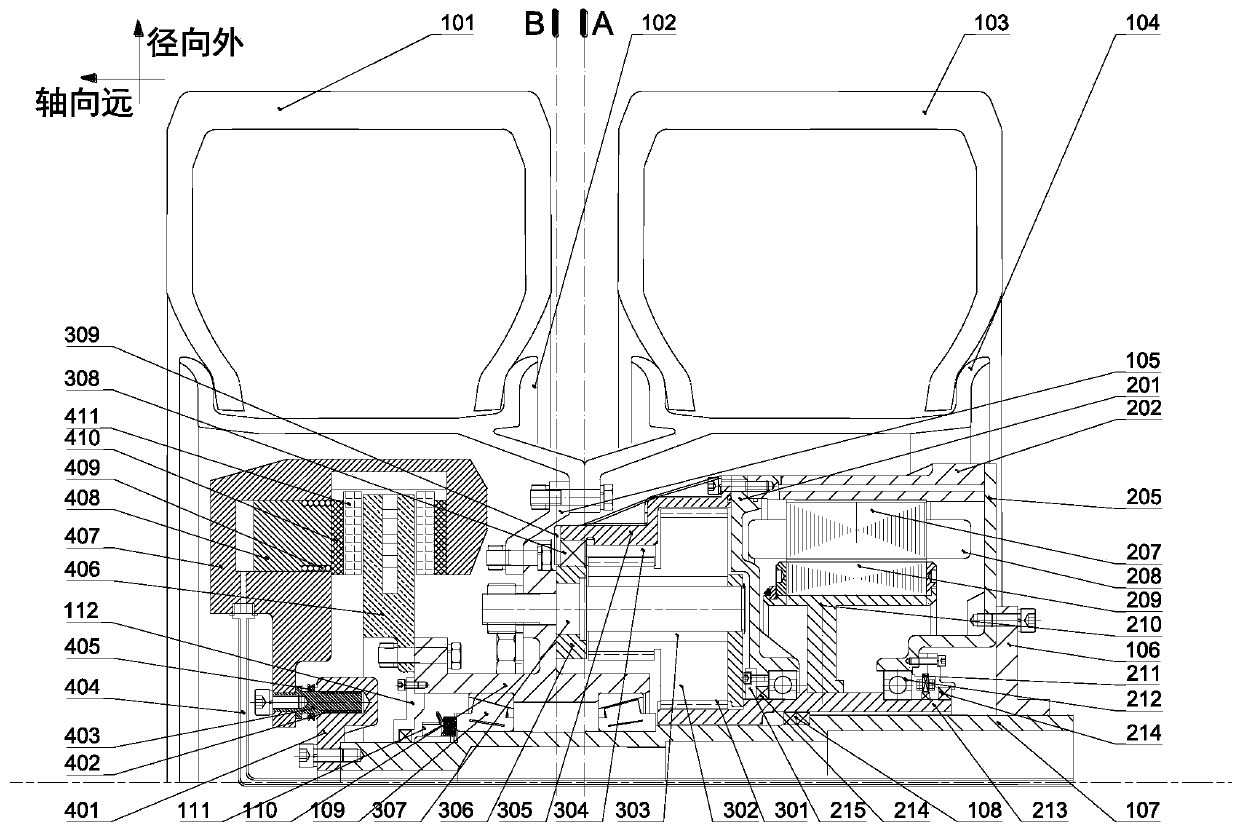

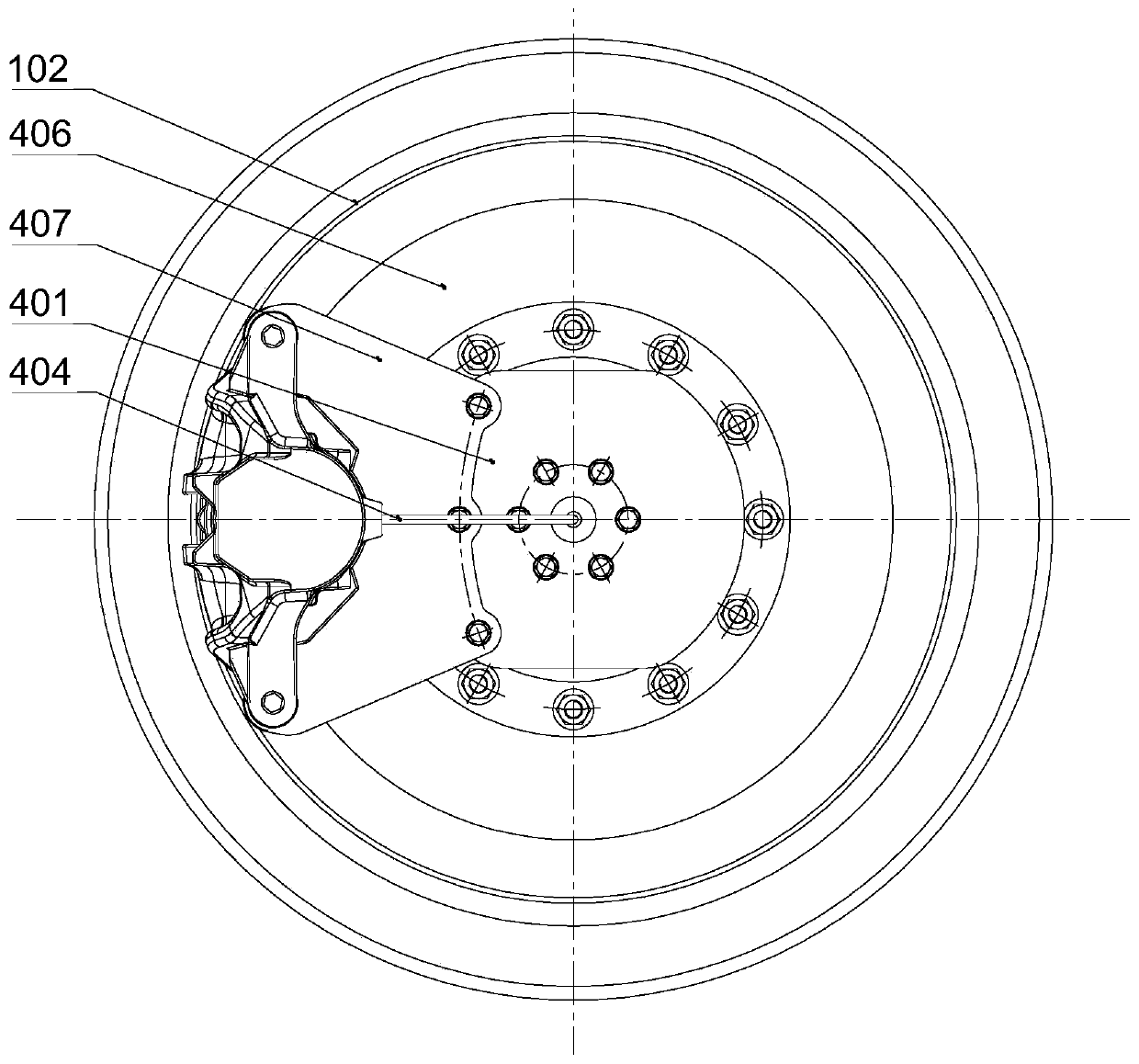

Electric wheel assembly, axle and vehicle suitable for twin tires and loading wheels

ActiveCN109130839AAxial dimension shortCost controlBraking element arrangementsBrake coolingReduction driveGear wheel

The invention discloses an electric wheel assembly, axle and vehicle suitable for twin-tire parallel loading wheels. The electric wheel assembly comprises wheels and a support shaft assembly, an innerrotor hub motor, a planetary gear reducer and a braking system. A planet carrier is connected with a wheel hub, the wheel hub connects a spoke and a wheel rim, a wheel support shaft passes through arotor sleeve, and hub bearings are arranged on the wheel support shaft to support the wheel hub and the whole wheel. The sun gear at one end of the rotor sleeve of the inner rotor hub motor is the power input of the planetary gear reducer, and the planet carrier is the power output. The planetary gear of planetary gear reducer adopts tower gear to realize larger transmission ratio under smaller axial length. The brake system adopts drum brake, the brake drum is connected with the rotor sleeve, and the braking force is amplified through the planetary gear reducer, which can reduce the braking force required by the brake system, and the electric motor can provide the electric braking force when braking. The electric wheel assembly can be used for the non-independent suspension of the commercial vehicle, and the cooling lubrication mode of the integrated cooling lubrication can be adopted to improve the performance.

Owner:南京清研易为新能源动力有限责任公司

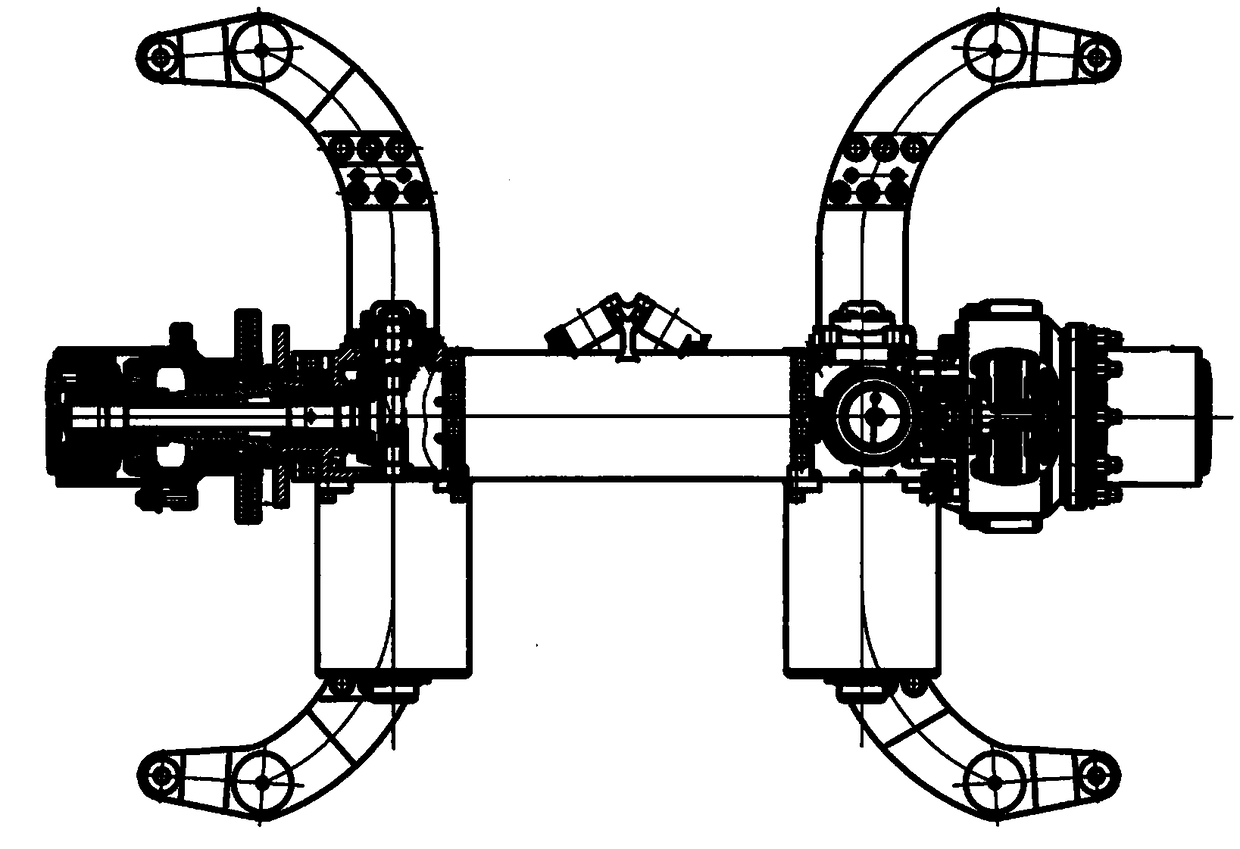

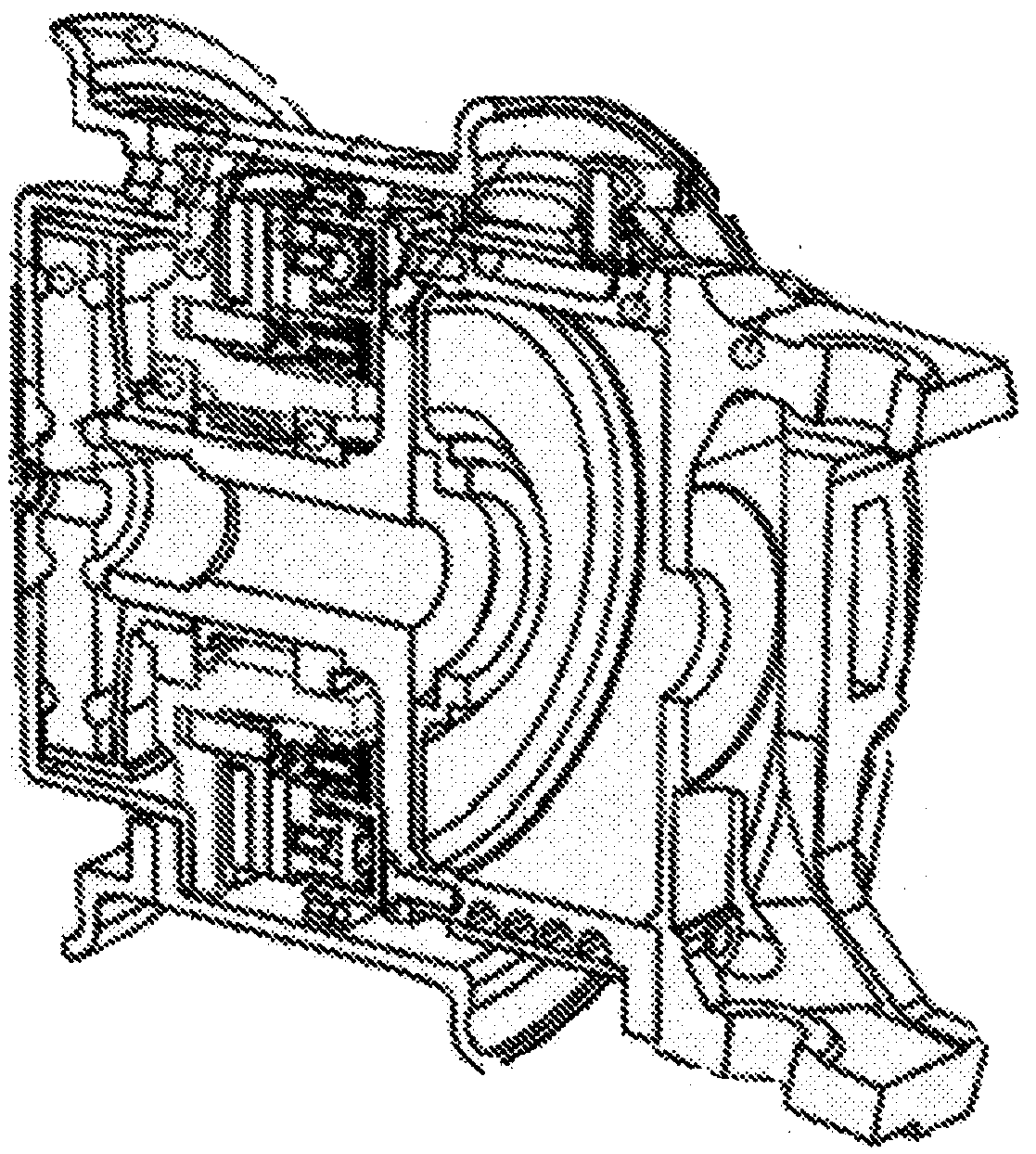

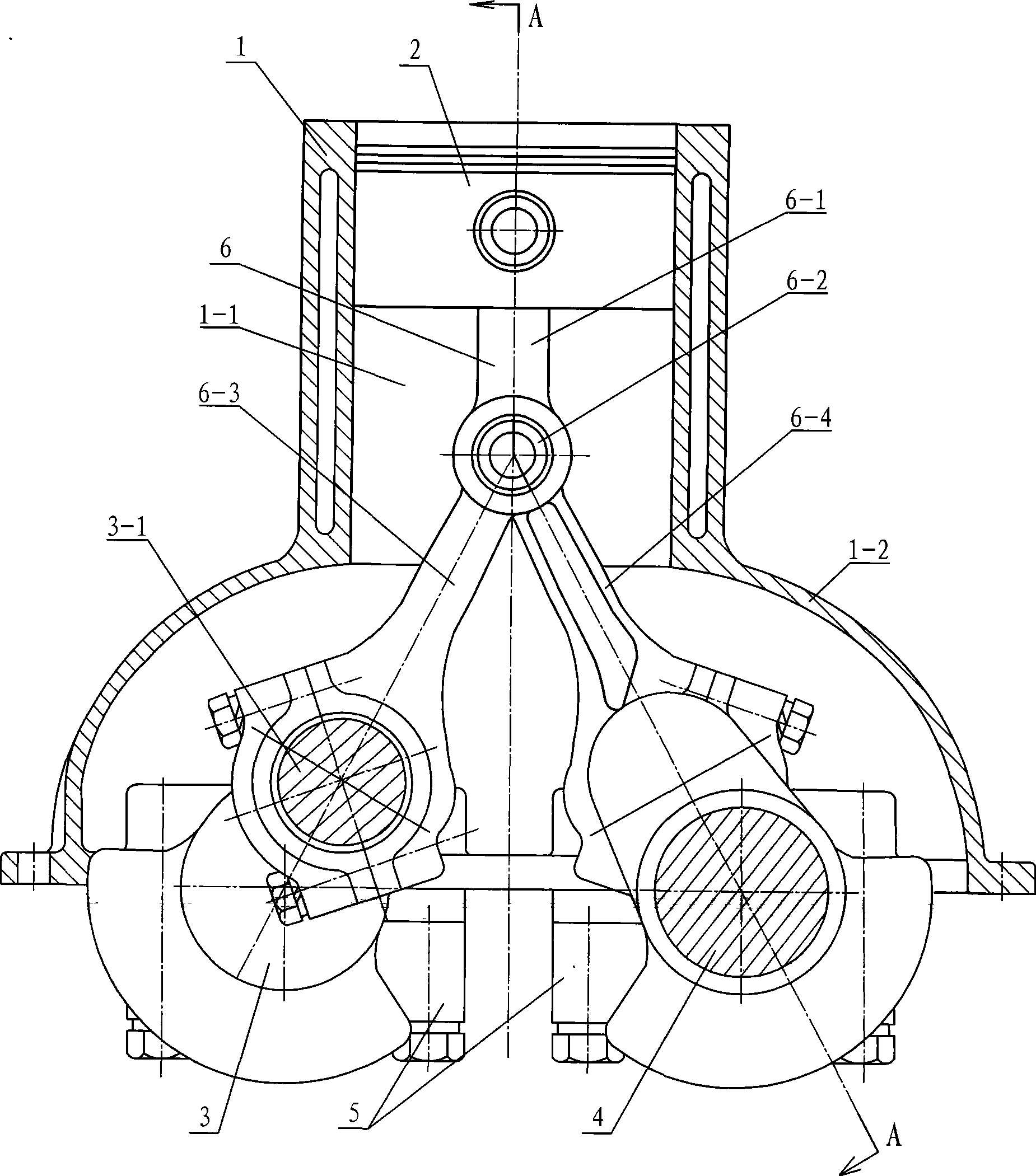

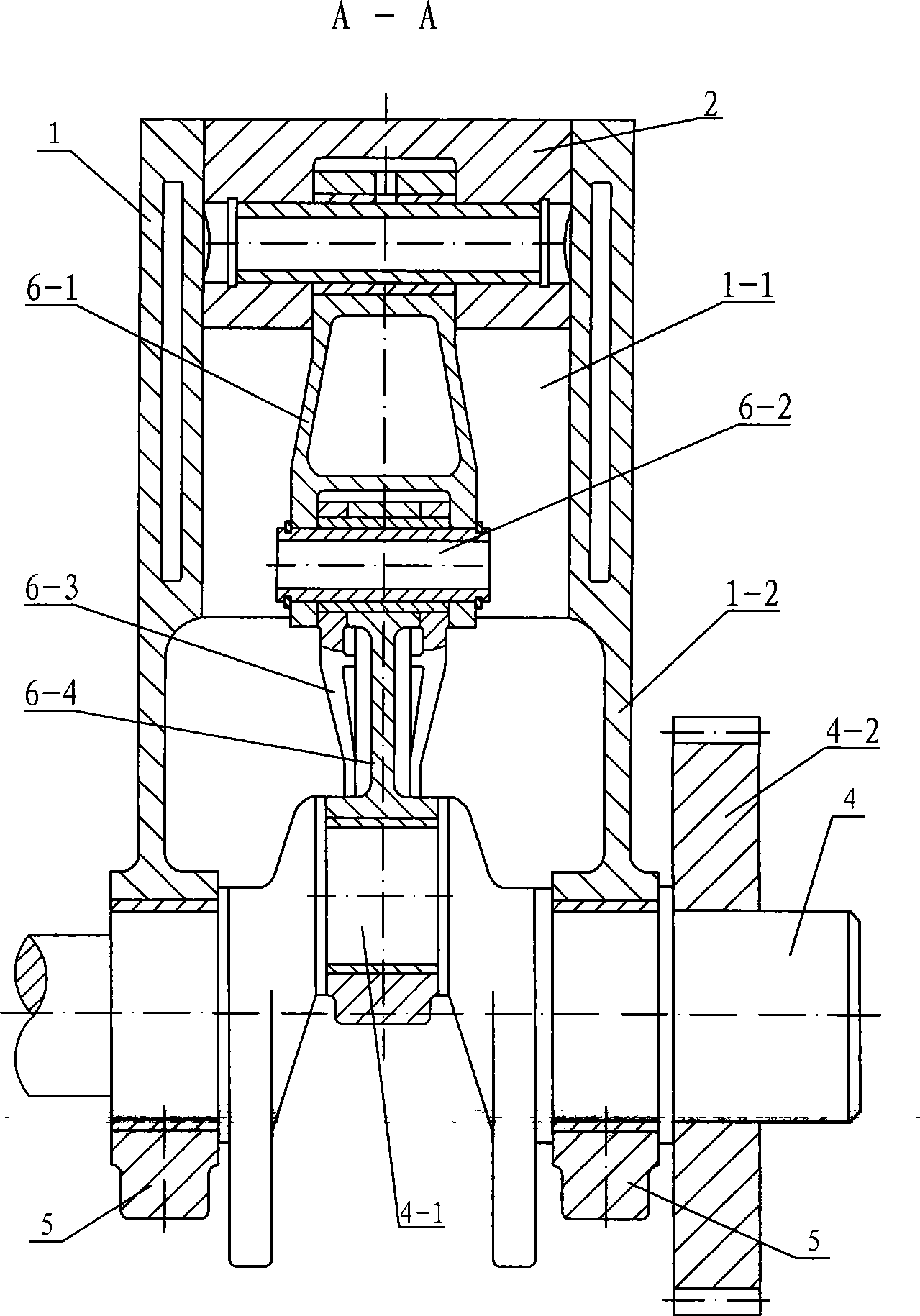

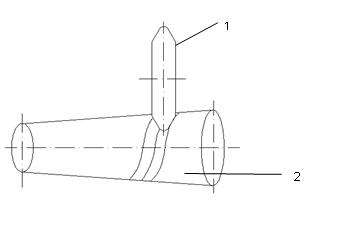

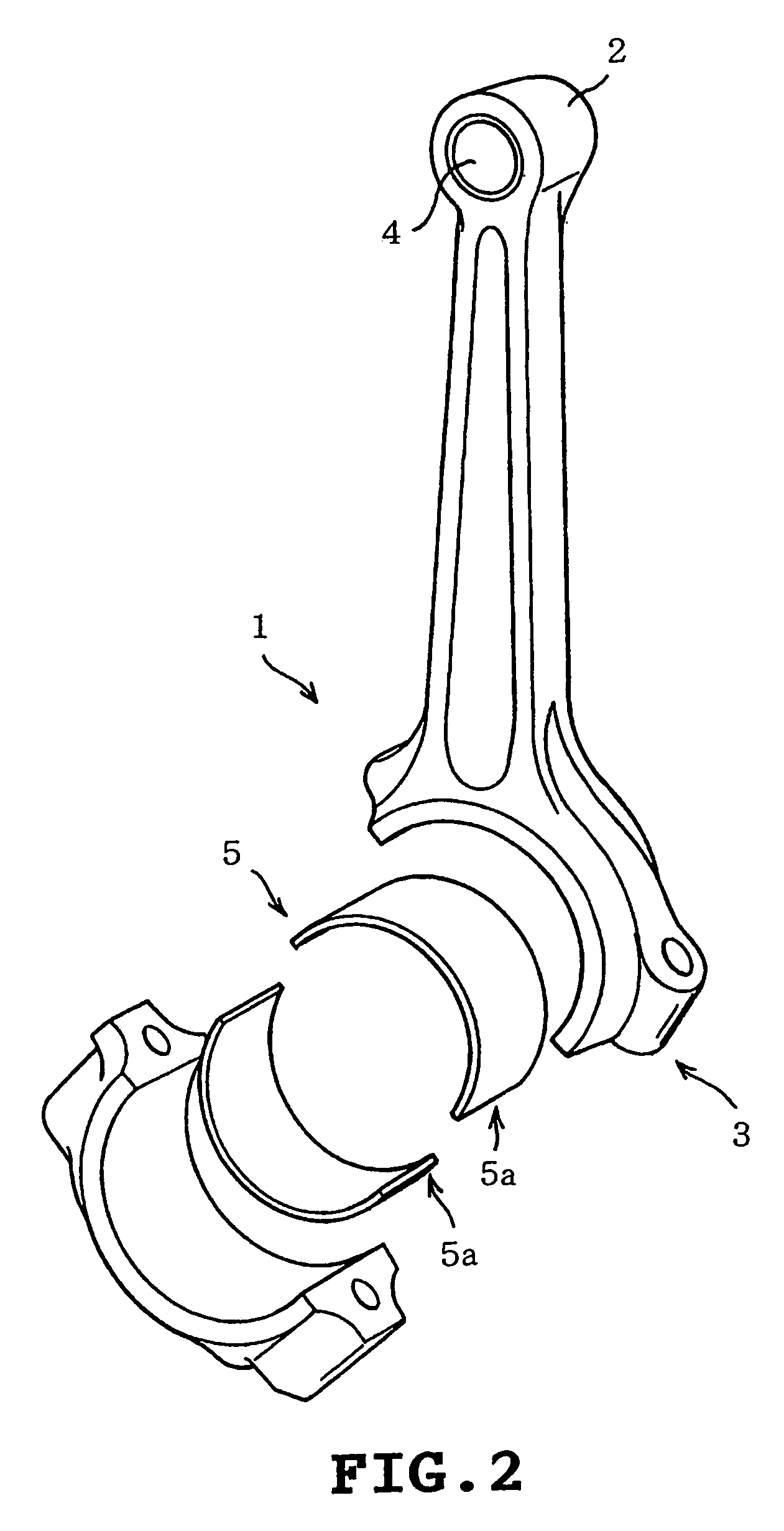

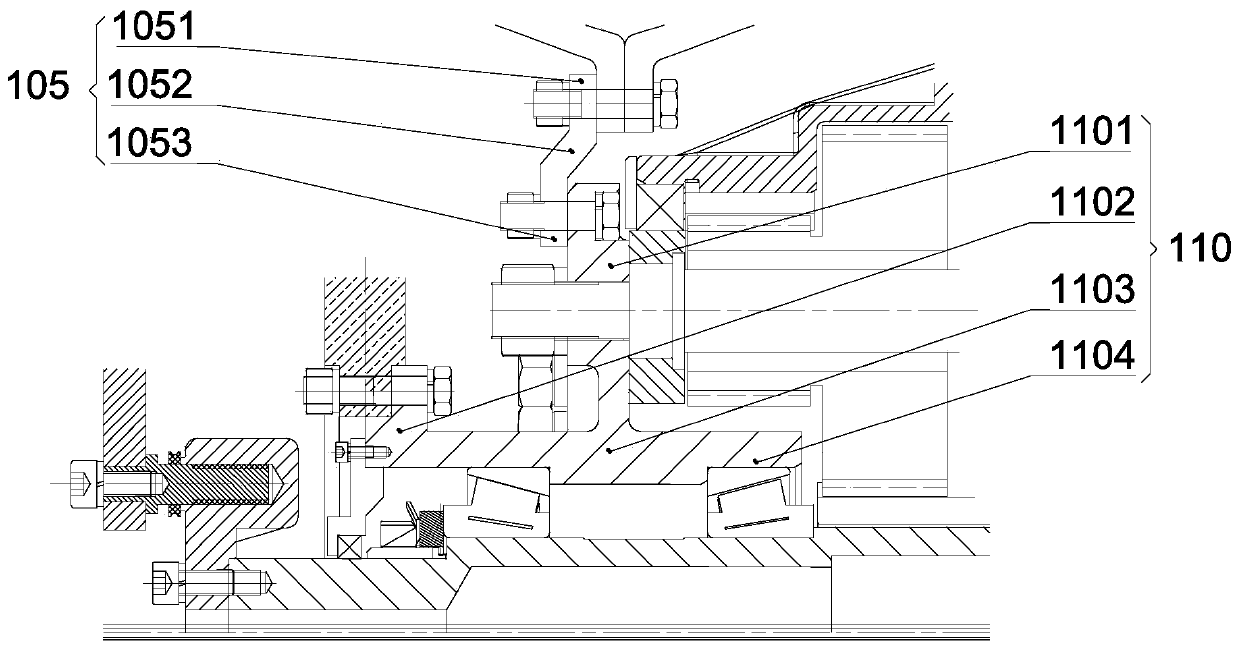

Gas cylinder link mechanism used for piston type internal combustion engine or gas compressor

InactiveCN101503966AMove fastImprove lubrication statusPiston pumpsReciprocating piston enginesGas compressorGas cylinder

The invention discloses a cylinder link mechanism for a piston type internal-combustion engine or on an air compressor, relates to a cylinder link mechanism, and solves the problem that lateral pressure and beat are generated between a piston and a cylinder in the prior piston type internal-combustion engine or the air compressor. In a first proposal, a single cylinder is adopted, and two secondary link levers have different structures and are hinged with a primary link lever through a link lever pin. A second proposal and the first proposal have the difference that the two secondary link levers have the same structure and are hinged with the primary link lever through two link lever pins. A third proposal and the first proposal have the difference that two cylinders are parallel, and two secondary link levers in each set of link mechanism have different structures and are hinged with the primary link lever through a link lever pin. A fourth proposal and the third proposal have the difference that the two secondary link levers in each set of link mechanism have the same structure and are hinged with the primary link lever through two link lever pins. A transmission mode of the primary-secondary link mechanism is adopted between the piston and a crank shaft, so that the lateral pressure is not generated between the piston and the cylinder, and the beat phenomenon between the piston and the cylinder is eliminated.

Owner:唐人忠

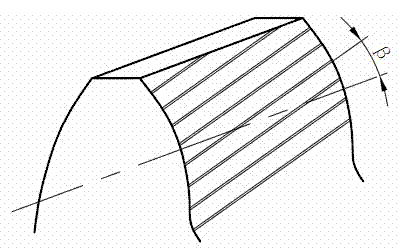

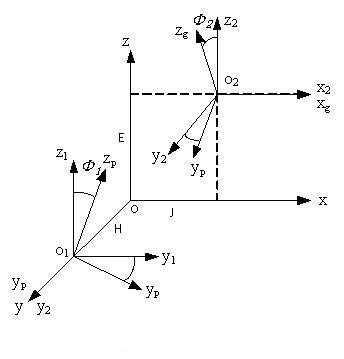

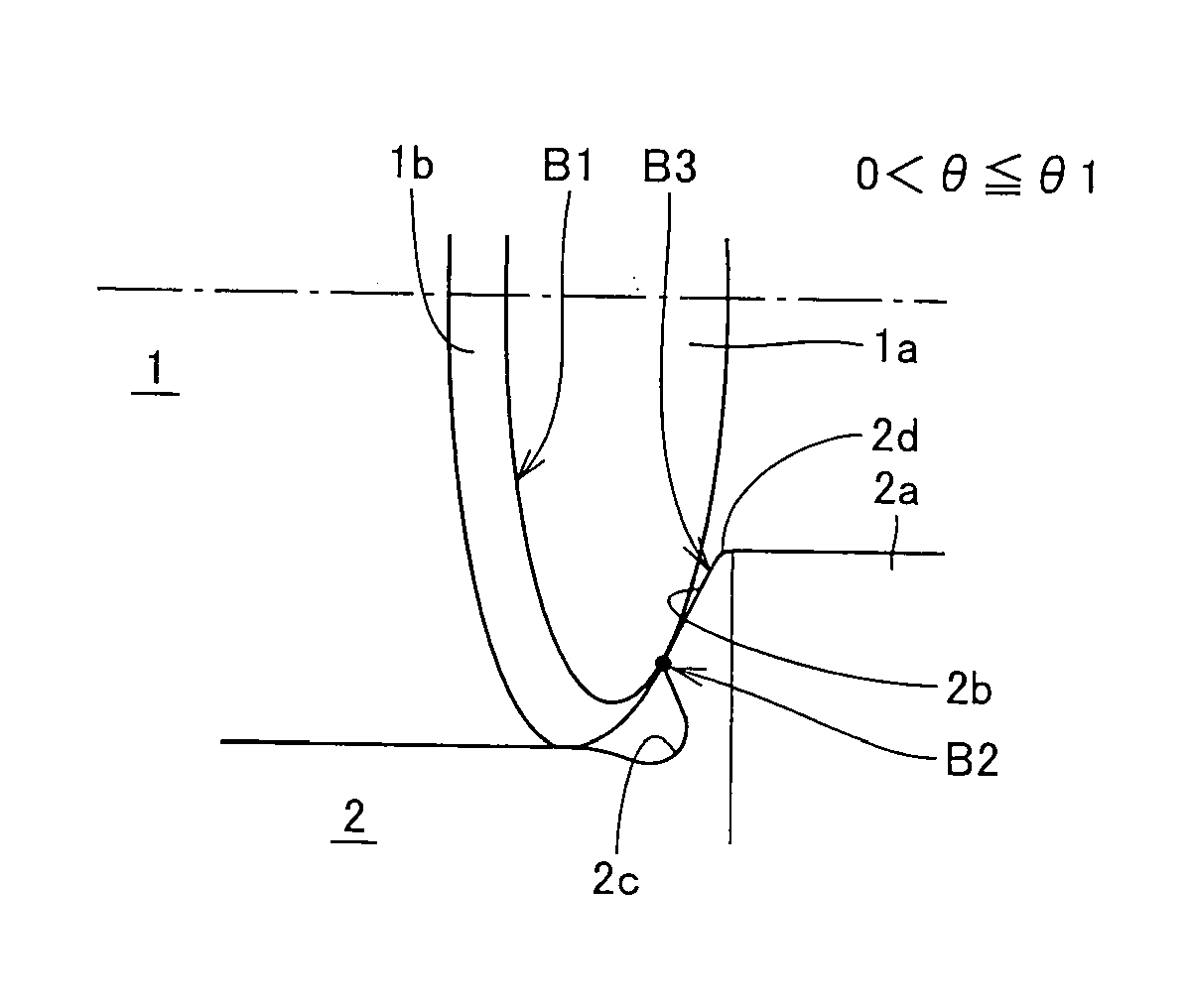

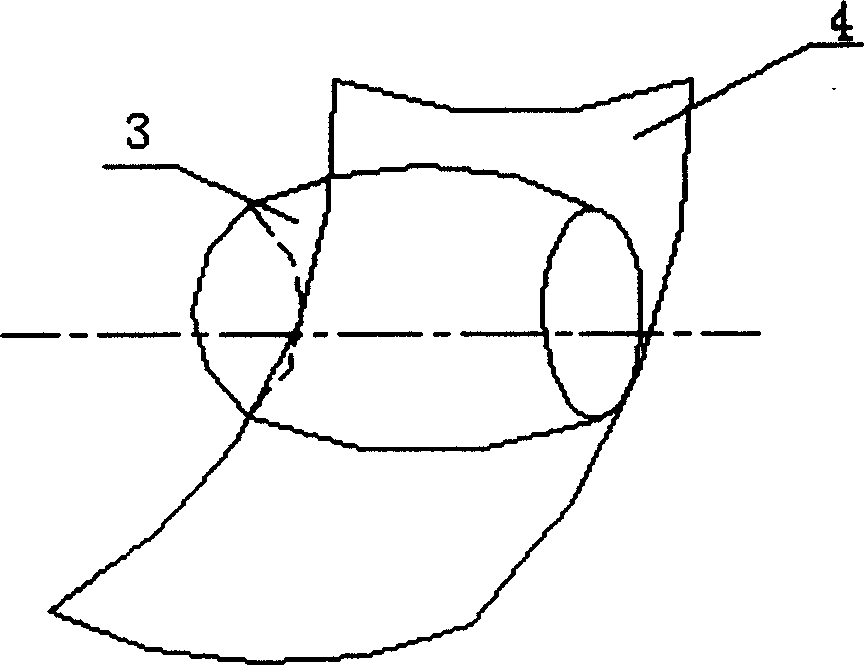

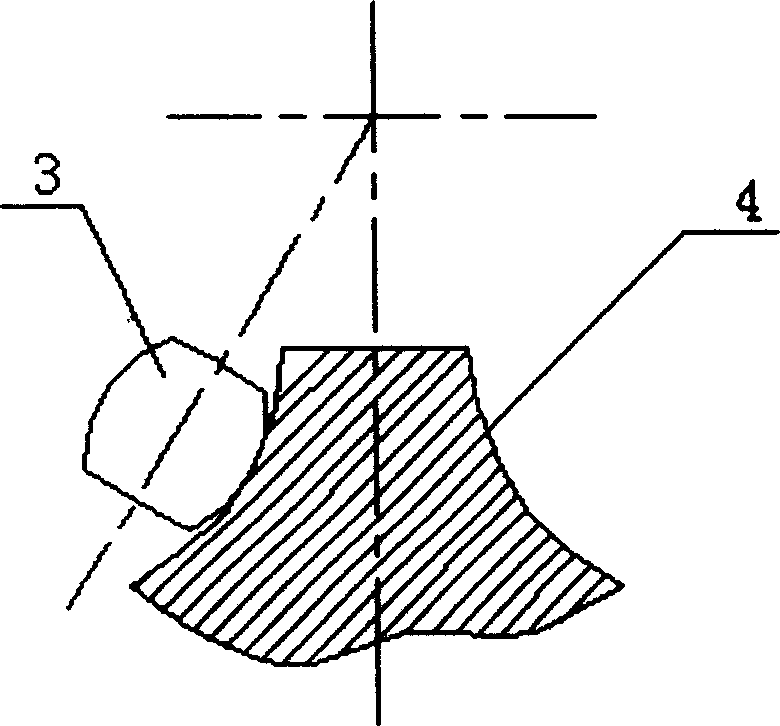

Offset worm and wormwheel transmission designing and manufacturing method

InactiveCN102672283AImprove lubrication statusEasy to adjust engagement impressionGear teeth manufacturing toolsWorm wheelsLong axisRelative motion

The invention discloses an offset worm and wormwheel transmission designing and manufacturing method. The offset worm and wormwheel transmission designing and manufacturing method comprises the following steps: a. determining a gear face equation of the worm according to an actual machining parameter and a worm design principle; b. obtaining a gear face equation of the wormwheel according to the gear face equation of the worm and a gear face meshing principle and according to the installing position of the worm and wormwheel; and c. carrying out tooth direction and tooth profile shaping to the wormwheel so as to drive the worm and the wormwheel to form point contact that the contact area is elliptically shaped, and the long axis direction of the contact area is perpendicular to the relative movement direction of the gear face of the worm and the wormwheel so as to form a beneficial contact condition of extreme pressure lubrication. According to the method, after the worm and the wormweel which are meshed mutually are designed, the worm is shaped, so that the gear face is meshed to be point contact; the meshing moulage is adjusted conveniently; the installation error is absorbed; and at the same time the contact area of the worm and the wormwheel is elliptically shaped and the long axis of the contact area is perpendicular to the direction that the gear faces of the worm and the wormwheel move relatively, so that the worm and the wormwheel which are meshed mutually are under lubrication in a good state.

Owner:HENAN UNIV OF SCI & TECH

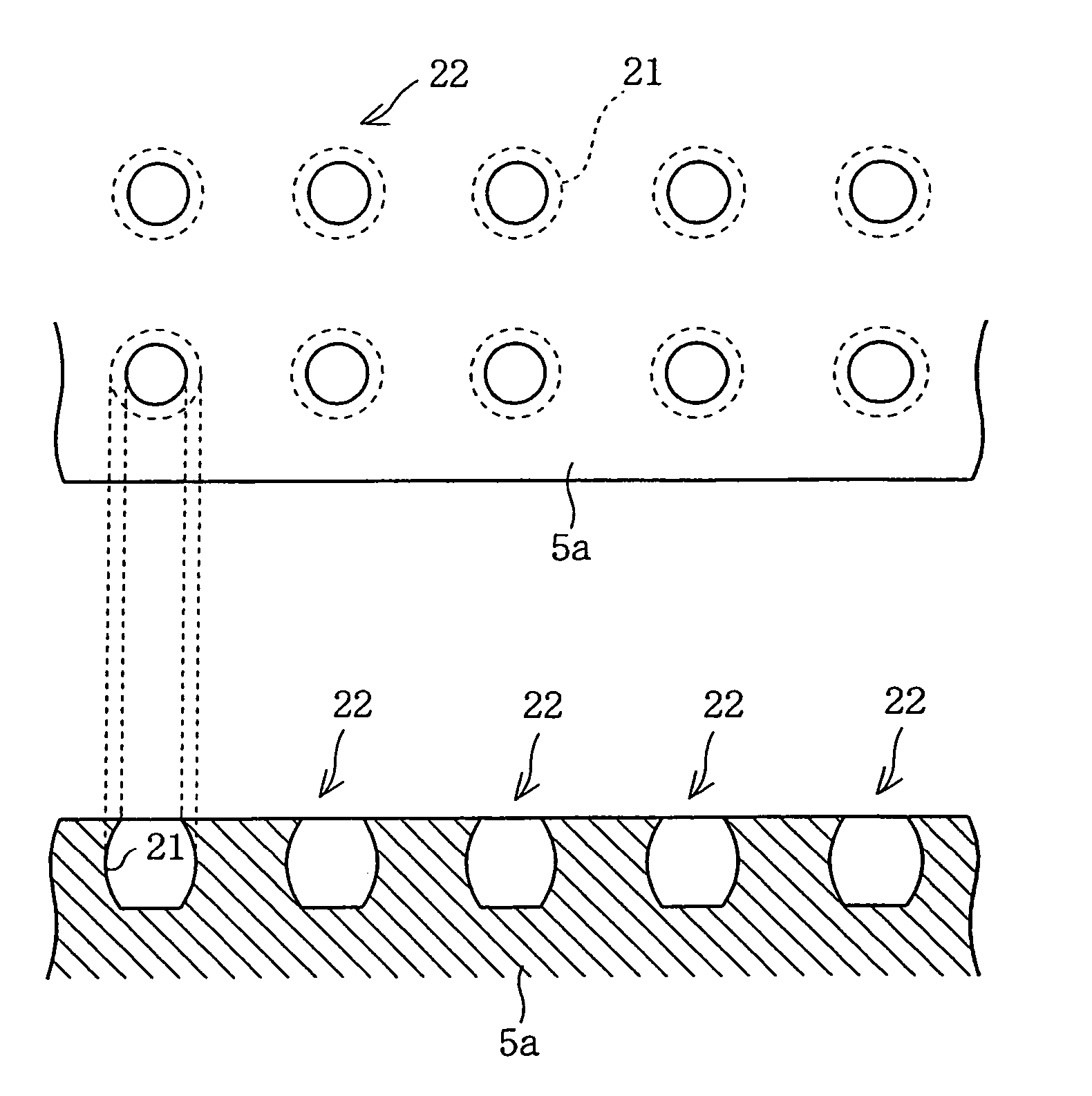

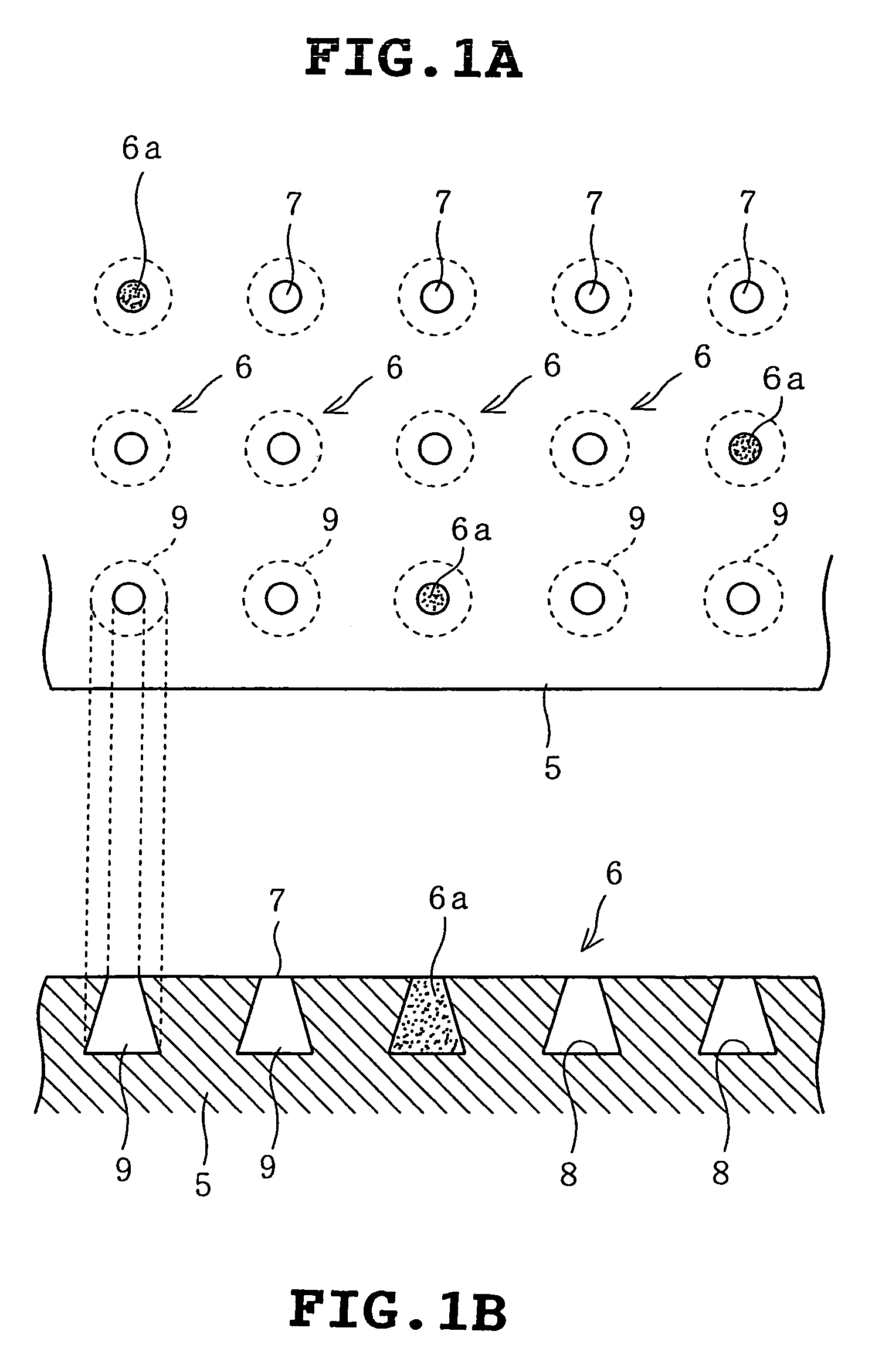

Sliding member and method of manufacturing the same

InactiveUS7118279B2Pressure of lubricating presentIncrease pressureConnecting rod bearingsShaftsEngineeringMechanical engineering

The invention provides a sliding member including a plurality of holes formed on a sliding surface thereof, which sliding surface is adapted to slide on a mating member, at least one of the holes having an enlarged portion in at least a portion between an opening end and a bottom end thereof, the enlarged portion being larger than the opening end on the sliding surface.

Owner:DAIDO METAL CO LTD

Cylindrical Roller Bearing

InactiveUS20070263952A1Contact part be preventedInhibit heat generationRoller bearingsShaftsEngineeringFlange

A relief groove (23) is provided at a corner in which a track surface (21) and a flange surface (24) cross, in an inner ring (20) of a cylindrical roller bearing. A chamfer (42) is provided at a corner part in which a rolling surface (41) and an end surface (43) cross, in a cylindrical roller (40). When it is assumed that the height of the chamfer (42) from the rolling surface (41) is “h” and the curvature radius of the chamfer is “R”, the relation such that 1.0≦R / h≦1.5 is satisfied.

Owner:NTN CORP

Linear guide apparatus

A slider is constituted by a main body made of a metal and a frame member and an end cap made of a synthetic resin. The main body is provided with a rolling groove. The frame member is provided with a return passage and an inner side groove of a direction changing passage. The end cap is provided with an outer side groove of the direction changing passage. A longest outer dimension in a slider width direction between lower end portions of inner legs of the main body is made to be larger than a shortest dimension in the slider width direction between projected portions of the frame member. The frame member is detachably engaged with the main body by putting a side of a leg portion of the main body to and from a side of a frame member horizontal portion by elastically deforming the frame member.

Owner:NSK LTD

Modified graphene and application thereof in lubricating oil

The invention discloses modified graphene and application thereof in lubricating oil. The modified graphene is modified by virtue of coco fatty acid diethanol amide, octaphenyl caged sesquisiloxane and a rare-earth coupling agent. The modified graphene is applied to the lubricating oil, and the lubricating oil is prepared from the following raw materials in parts by weight: 100 to 150 parts of basic oil, 0.5 to 2 parts of modified graphene, 0.1 to 0.5 part of silicon carbide, 1 to 3 parts of polysiloxane aminoester acrylate, 0.5 to 2 parts of succinate sulfonated hydrogenated castor oil, 1 to3 parts of oleic acid diethanolamide borate, 0.5 to 1.5 parts of defoaming agent and 1 to 2 parts of antioxidant. The lubricating oil has excellent compatibility and stability, low friction coefficient, high heat conduction coefficient and good effect for protecting mechanical parts, and can prolong the service life of the mechanical parts.

Owner:钦州市窑宝坭兴陶艺有限公司

Arc surface calibratkon cam mechanism and its processing method

InactiveCN1556340AExtended service lifeGuaranteed accuracyGearingGearing detailsLow noiseEngineering

Convex profile surface includes position section, transition section and division section. Characters are that the transition section and division section are concave surface, and radius of curvature of drum type roller is less than radius of curvature of the concave surface to be matched. The manufacturing method is method of four coordinates interlock of processing in single side face including interlock between z1 rotation axis of cam and z2 rotation axis of cutting tool as well as straight-ahead travel of cutting tool along y2 and z2 coordinates. Features are: small abrasion, low noise, long service life and raised manufacturing accuracy and efficiency.

Owner:TIANJIN POLYTECHNIC UNIV

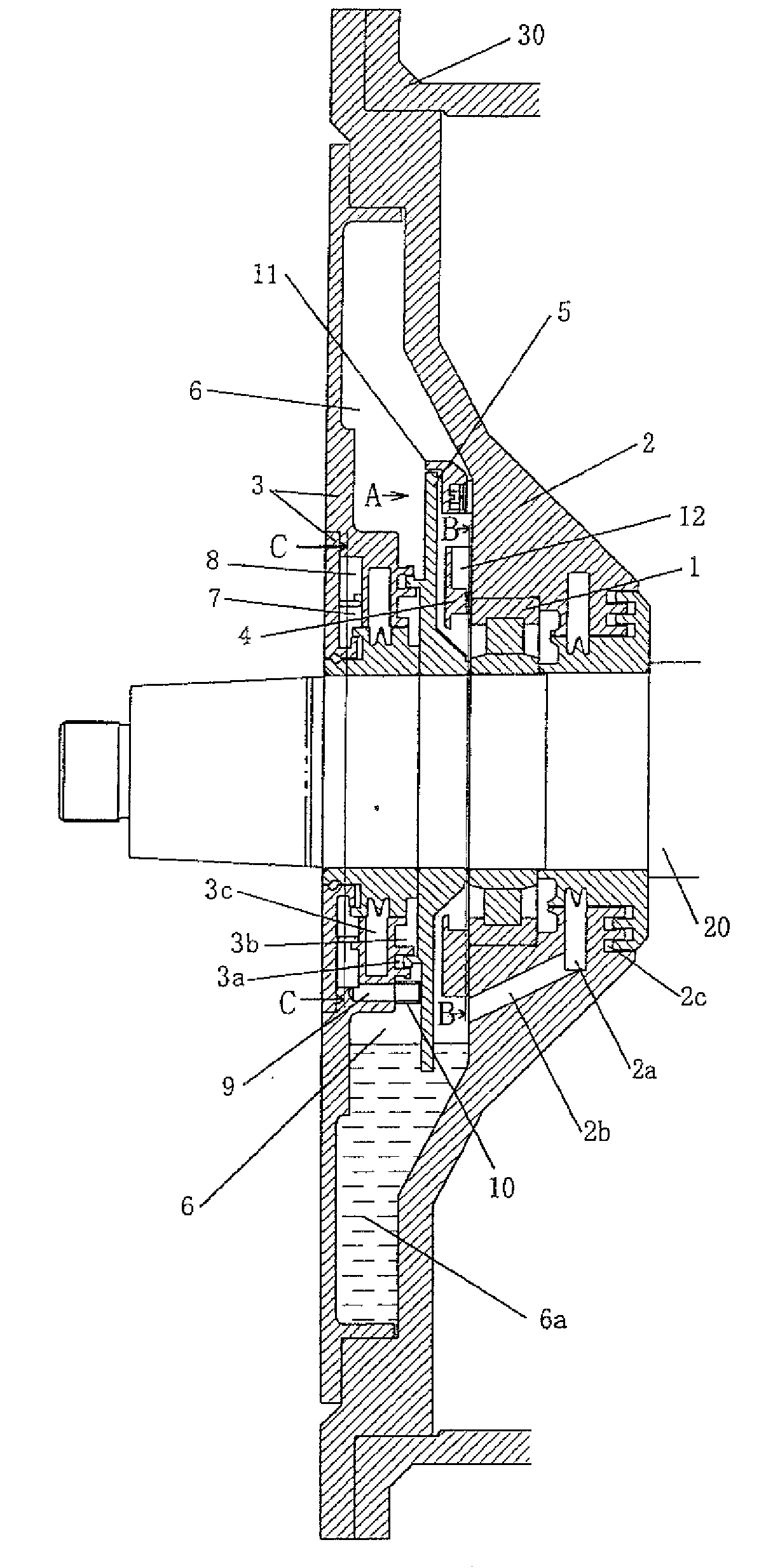

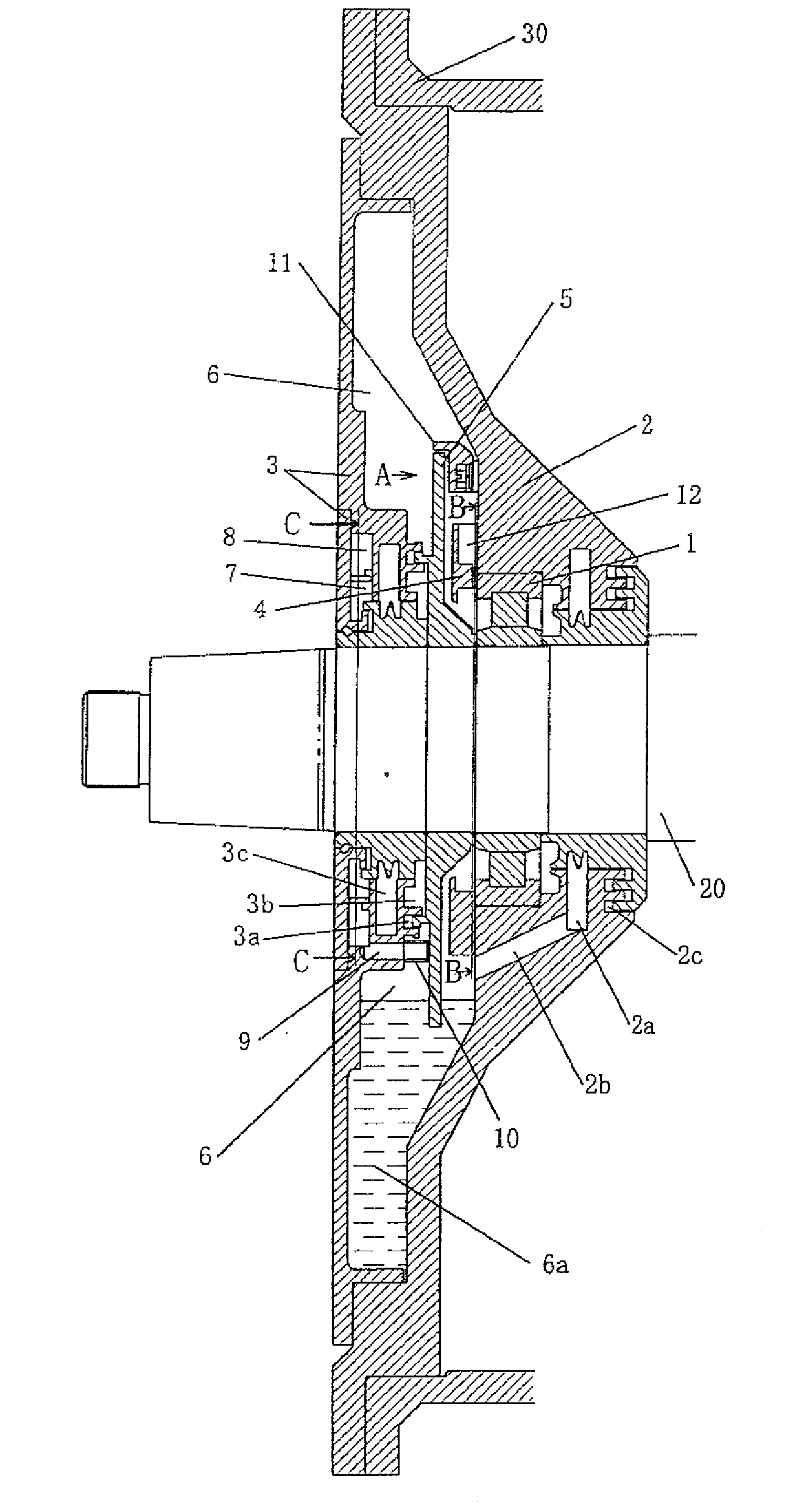

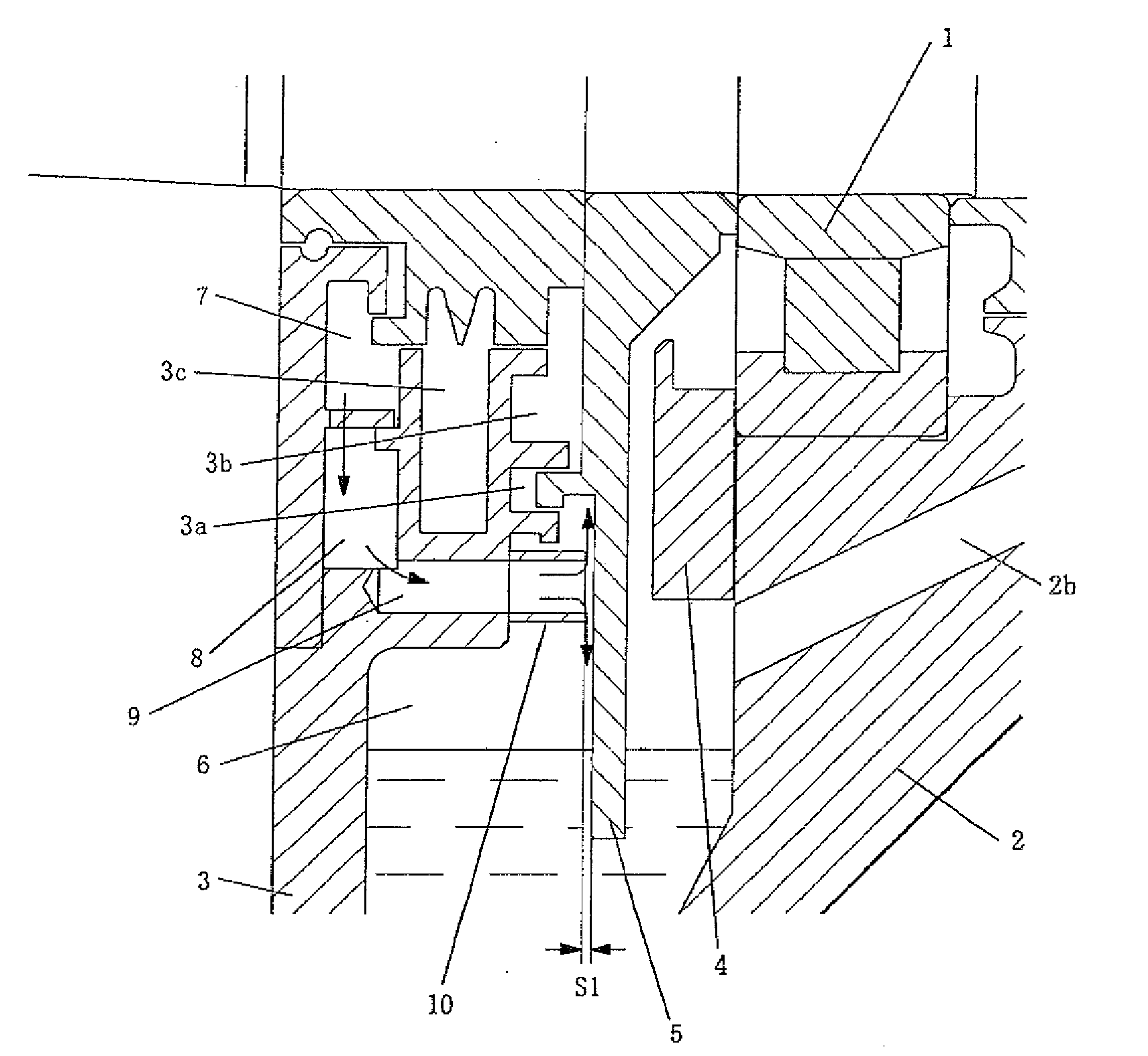

Bearing device for main electric motor for vehicle

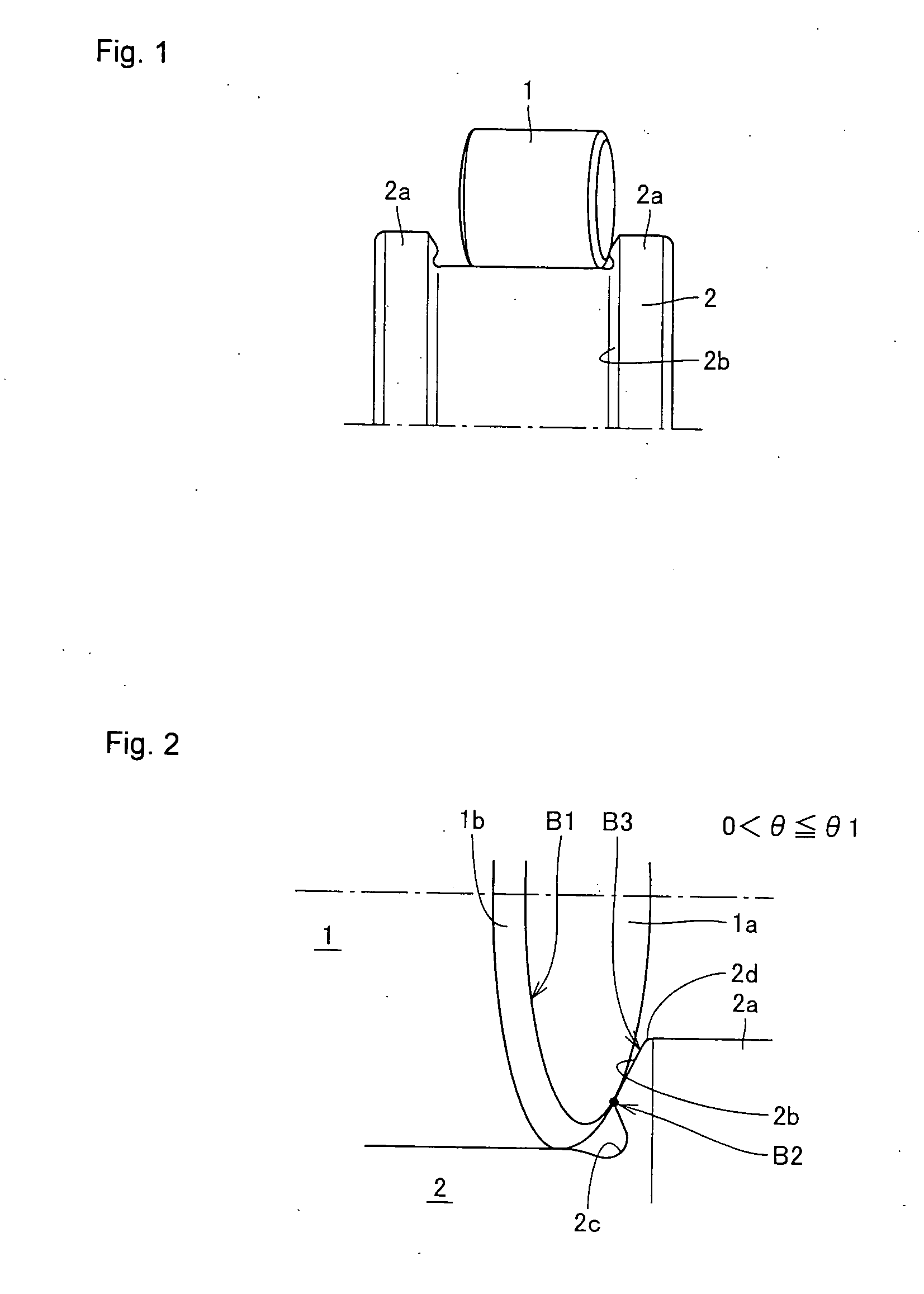

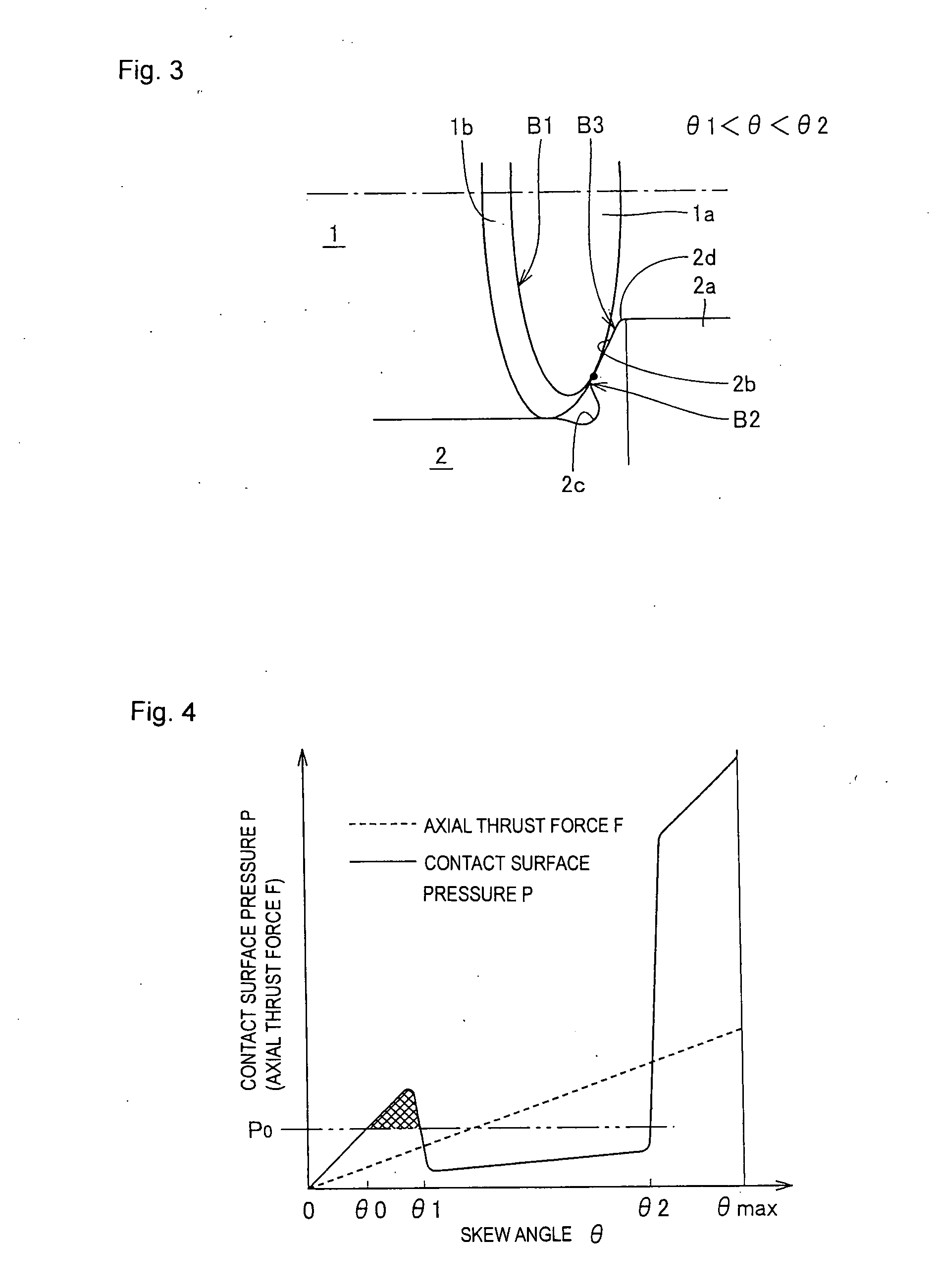

ActiveUS20090174269A1Maintenance work is reducedPrevent leakageRolling contact bearingsDrip or splash lubricationElectric motorOil storage

Oil is supplied to bearing 1 and returned to oil storage chamber 6a via chamber 2a and pipe 2b. First oil return chamber 8 and second oil return chamber 7 communicate via a hole, and second oil return chamber 7 communicates with oil supply chamber 6 via oil return hole 9. The opening of the extension pipe 10 of oil return hole 9 has a small gap, to result in negative pressure in extension pipe 10. The negative pressure sucks the oil leaking from between bearing cover 3 and rotor shaft 20. The oil leaking is suppressed, keeping the supply of the lubricating oil to the bearing excellent.

Owner:TOYO DENKI SEIZO KK

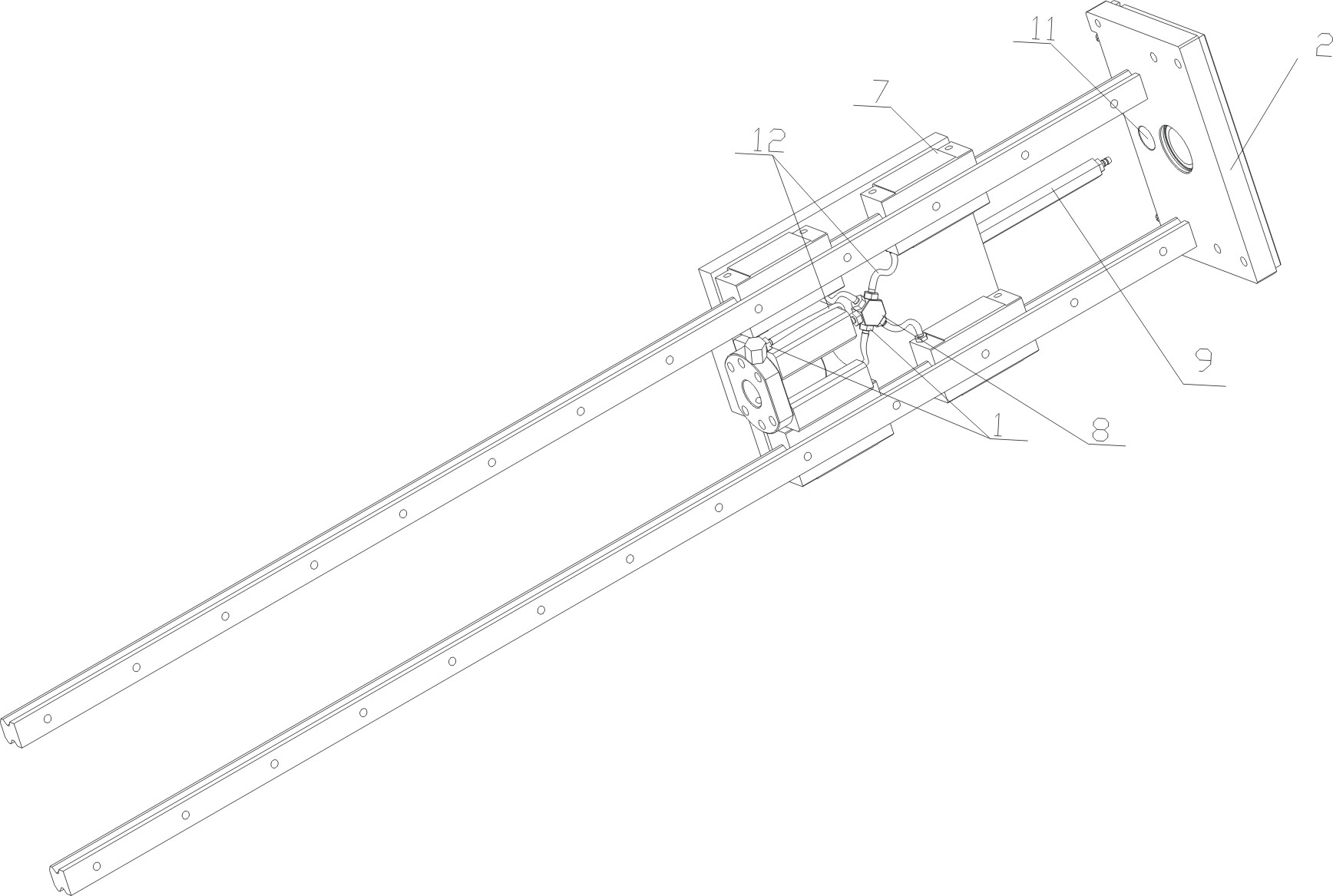

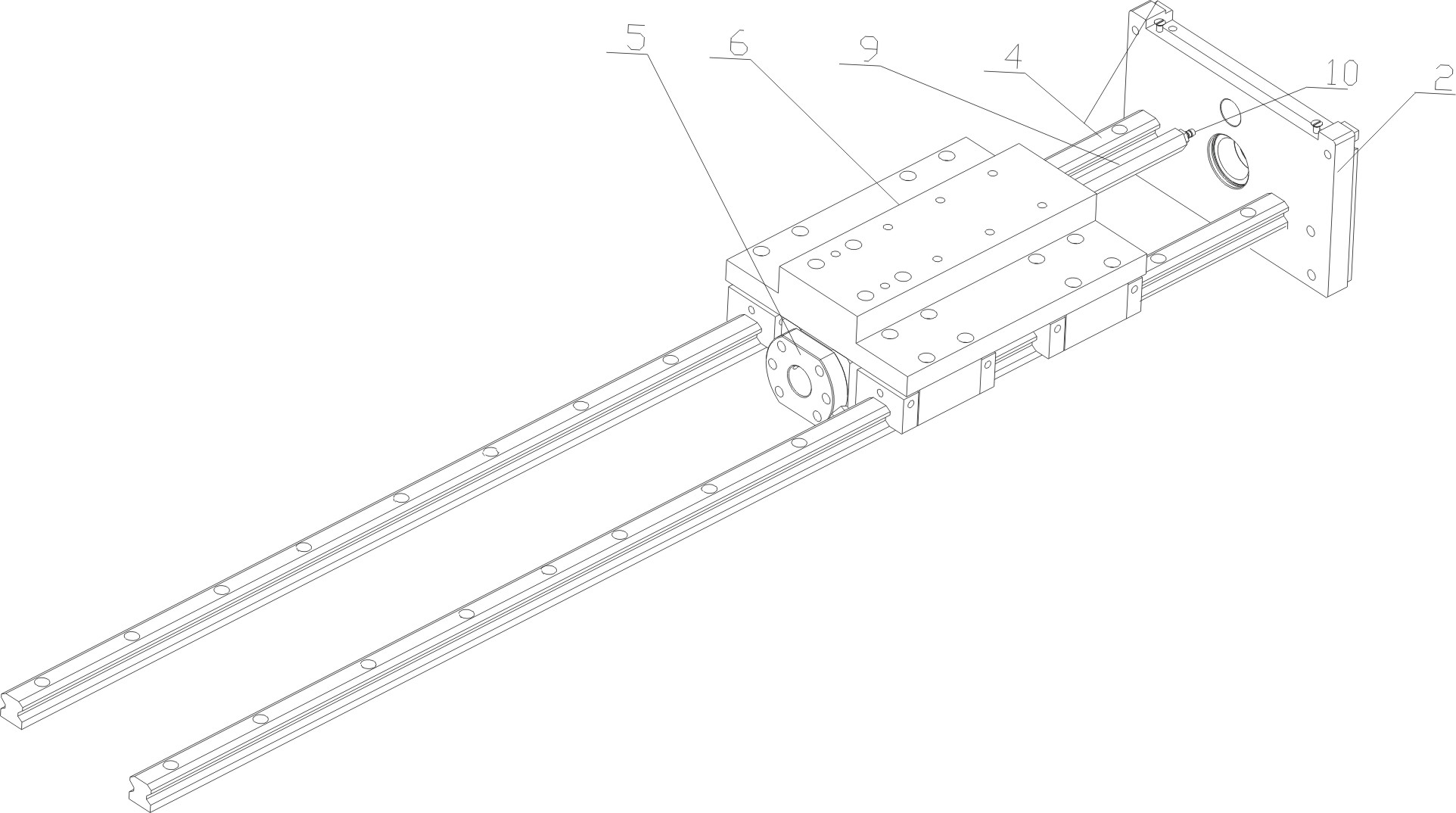

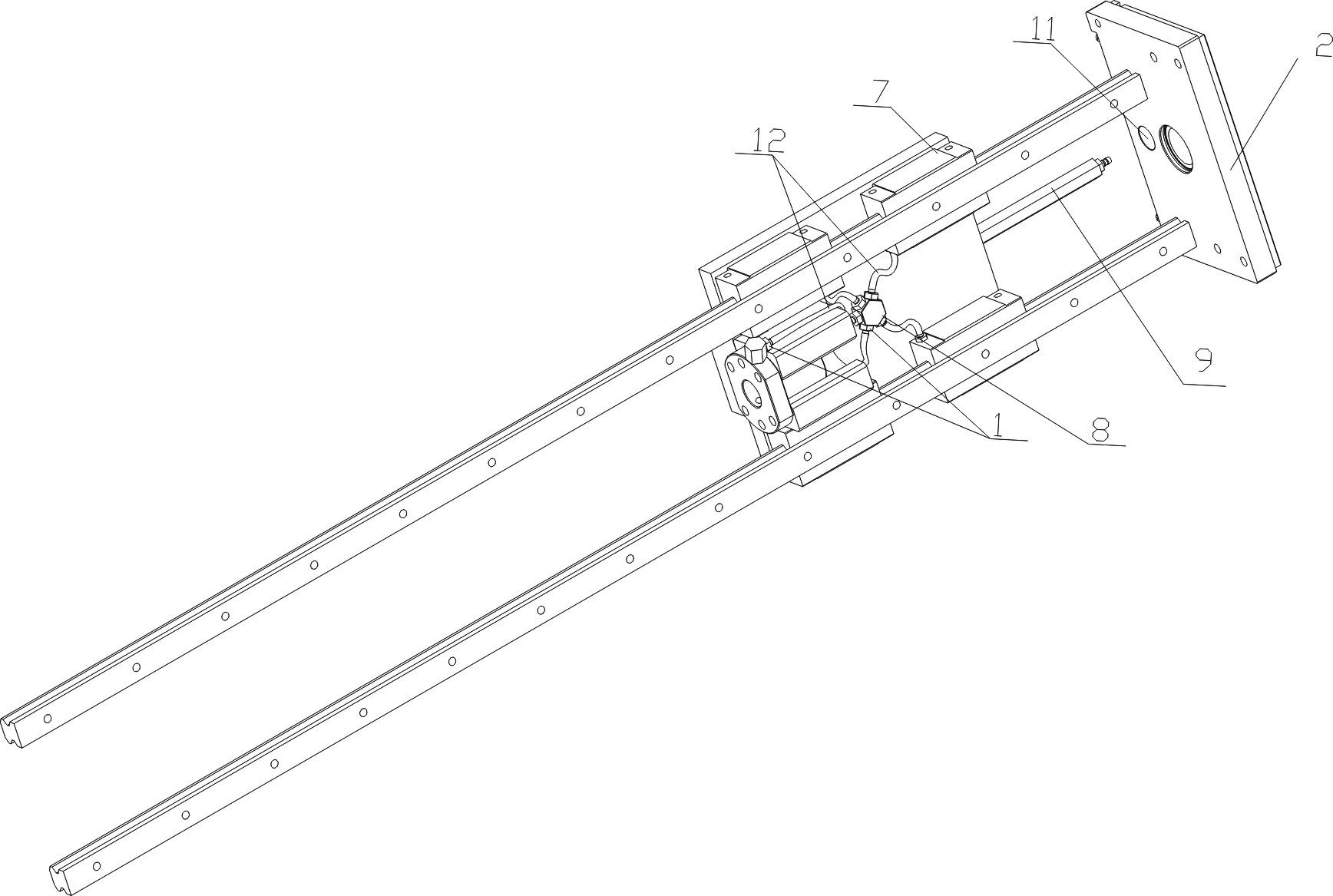

Concentrated oil feeder for manipulator linear platform

InactiveCN101804641AGuaranteed accuracyImprove lubrication statusManipulatorEngine lubricationBall screwManipulator

The invention relates to a concentrated oil feeder for a manipulator linear platform, which comprises a base, a dust-proof plate, a fixed seat, a supporting seat, a linear guide rail and a ball screw, wherein the fixed seat and the supporting seat are respectively arranged on both ends of the base; the supporting seat arranged at the front end of the base supports the front end spindle nose of the ball screw of a transmission mechanism; a nut head screwed with the ball screw is connected with a slide block fixed on a connecting plate; and the slide block and the linear guide rail form a sliding joint. The concentrated oil feeder is characterized in that the lower part of the connecting plate is fixedly provided with an oil catcher, the oil inlet end of the oil catcher is communicated with an oil inlet pipe through an oil passage on the connecting plate, the oil catcher is provided with a plurality of oil outlet ends, and the oil outlet ends are communicated with the slide block and the nut head through oil pipes and flow nipples. When injecting oil to the platform or one machine in the platform combination, the operator can inject oil only after opening the dust cap without affecting the original usage precision of the sliding way, therefore, the invention has the advantages of concentrated oil feeding and simple operation, and can properly increase the number of oil feeding so that the platform is in a favorable lubrication state all along.

Owner:天津市中马骏腾精密机械制造有限公司

Heavy-load electric wheel

PendingCN111361358AAxial dimension shortCost controlBraking element arrangementsMagnetic circuit rotating partsReduction driveGear wheel

The invention discloses a heavy-load electric wheel, and belongs to the field of electric vehicle power devices. A brake, a planetary gear reducer and a hub motor are sequentially arranged on the outer side of a supporting shaft from the distant to the near; the outer side of a hub is connected with a spoke mounting plane of a rim through a spoke, and the hub is mounted on the outer side of the supporting shaft through a pair of hub bearings; a brake caliper support in the brake is installed outside the distal facet of the wheel supporting shaft through a bolt, and a brake disc is installed ona brake disc installation flange of the hub; a hub part of the hub motor rotor support is sleeved on the rotor shaft; and a sun gear in the planetary gear reducer is disposed outside the distal end side of the rotor shaft. The axial size of the whole electric wheel assembly is short, and the hub motor, the planetary gear reducer and the brake are all arranged in the space defined by the rim on the inner side and the outer side of the electric wheel assembly, so that the electric wheel assembly can be suitable for common commercial vehicle double-tire parallel loading wheels.

Owner:南京清研易为新能源动力有限责任公司

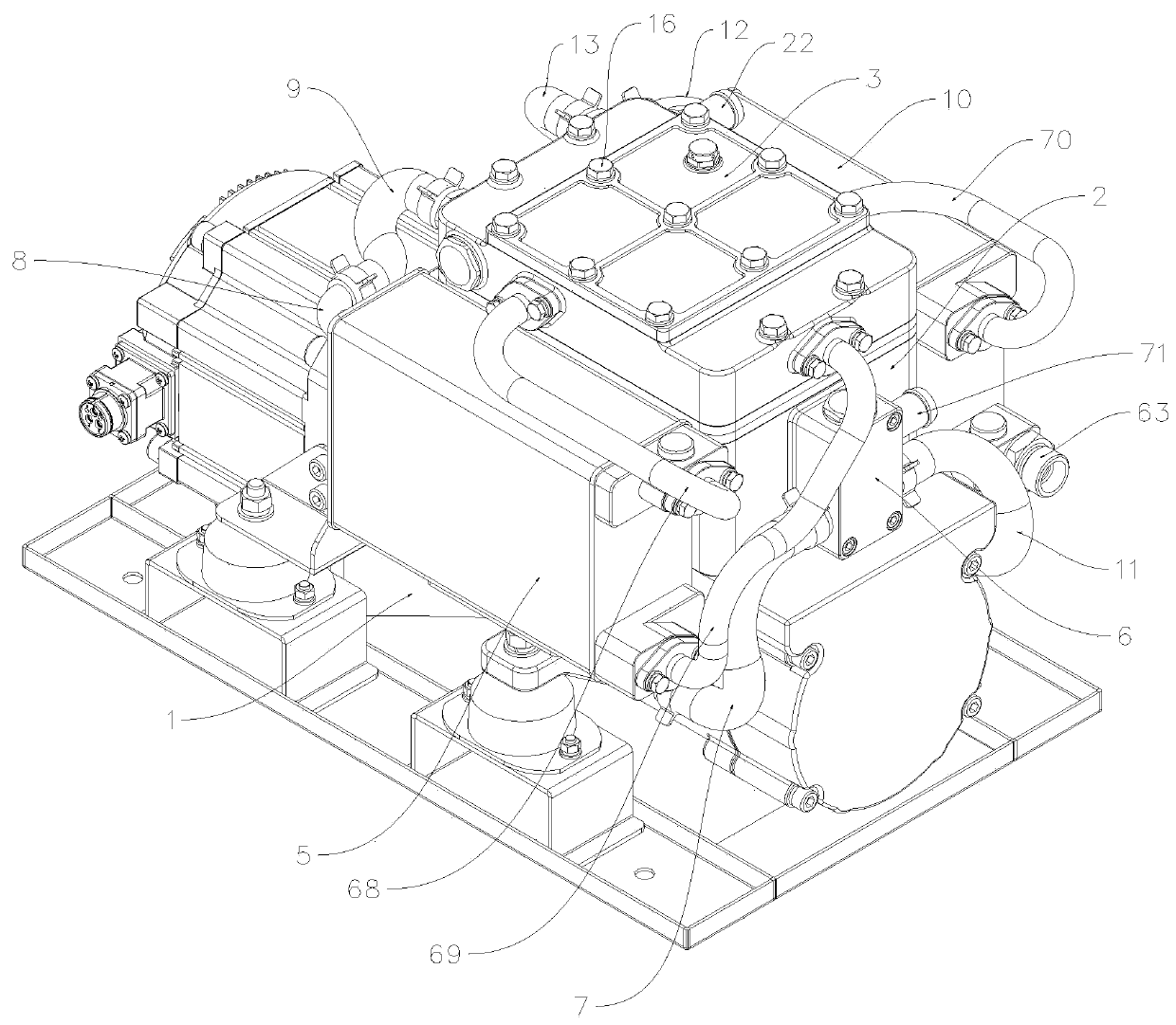

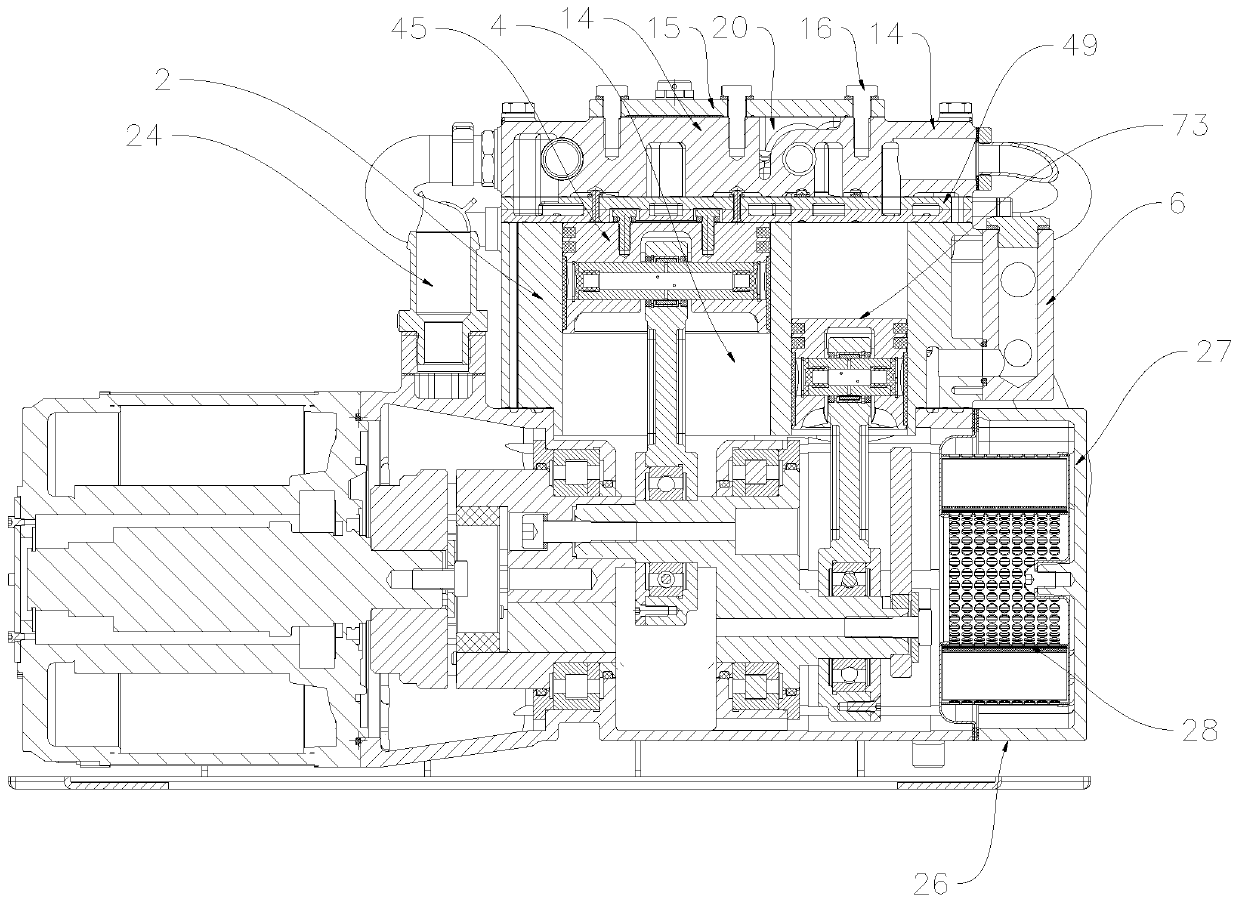

Oil-free piston type air compressor for new energy vehicle

ActiveCN110107473AExtended service lifeImprove lubrication statusPositive displacement pump componentsMulti-stage pumpsCylinder headEngineering

The invention relates to the technical field of air compressors, and discloses an oil-free piston type air compressor for a new energy vehicle. The oil-free piston type air compressor for the new energy vehicle comprises a crank case, a cylinder body and a cylinder head assembly, wherein a piston cylinder is arranged in the cylinder body; the cylinder body is arranged above the crank case and is connected with the crank case; the cylinder head assembly is arranged above the cylinder body and is connected with the cylinder body; a low-pressure heat exchanger connected with the crank case is arranged on the front side of the cylinder body; a manifold block connected with the cylinder body is arranged at the right end of the cylinder body and is connected with the low-pressure heat exchangerthrough a first water inlet pipe; a first water outlet is formed in the left end of the low-pressure heat exchanger and is connected with the cylinder head assembly through a first drainage pipe; a high-pressure heat exchanger connected with the crank case is arranged on the back side of the cylinder body; the manifold block and the high-pressure heat exchanger are connected through a second waterinlet pipe; and a second water outlet is formed in the left end of the high-pressure heat exchanger and is connected with the cylinder head assembly through a second drainage pipe. The oil-free piston type air compressor for the new energy vehicle provided by the invention adopts water-cooling and air-cooling double-acting cooling manners so as to be sufficient in cooling and better in effect.

Owner:ZHEJIANG KELI VEHICLE CONTROL SYST

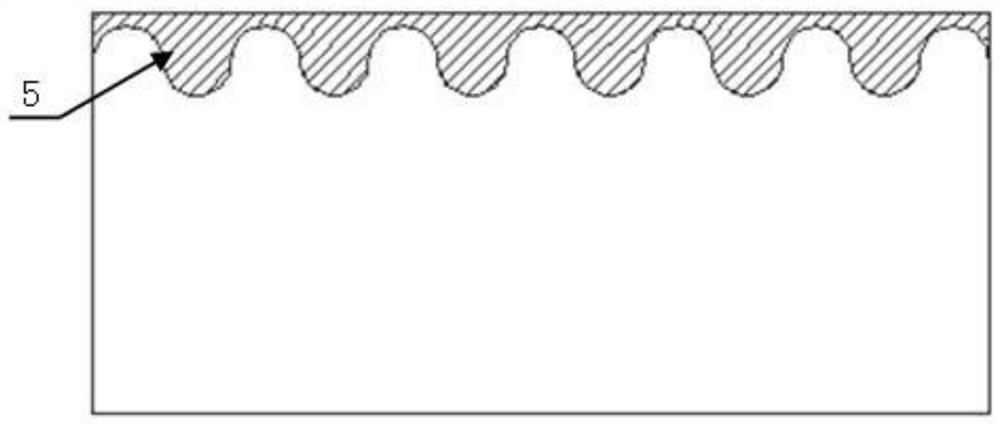

Anti-fretting fatigue protection method for laser shock and coating lubrication composite modification

InactiveCN111961837AImproved fretting fatigue performanceImprove lubrication statusMolten spray coatingLaser beam welding apparatusMetallic materialsWear resistance

The invention provides an anti-fretting fatigue protection method for laser shock and coating lubrication composite modification. The method comprises the following steps of: preparing micro-pit groups distributed in a regular array on the surface of a metal material by adopting a laser shock strengthening technology, wherein the diameter of a single pit is 1-10mm, and the depth of the pit is 1-20microns; and coating the surfaces of the pits with a lubricant by adopting a coating preparation technology. The method fully utilizes the micro-pit modeling characteristics of laser shock and the introduction characteristics of residual compressive stress of the surface layer, and introduces three strengthening factors comprising the residual compressive stress, coating lubrication and surface micro-pit texturing into the surface layer of the material through a laser shock surface texturing and coating lubrication composite modification technology, and the factors synergistically improve thefretting fatigue performance of the material. The composite modification technology can improve the fretting wear resistance of the coating, reduce the surface friction force and slow down the residual stress relaxation speed in order to achieve the strengthening effect of prolonging the fretting fatigue life.

Owner:DALIAN UNIV OF TECH +1

Road roller combining vibration, oscillation and complex excitation as whole

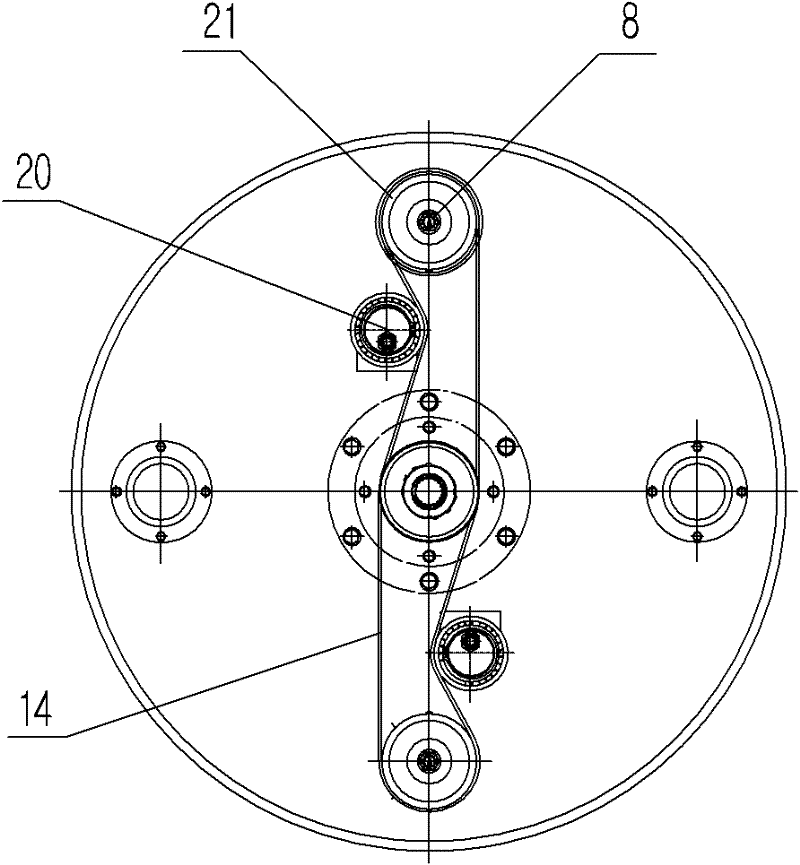

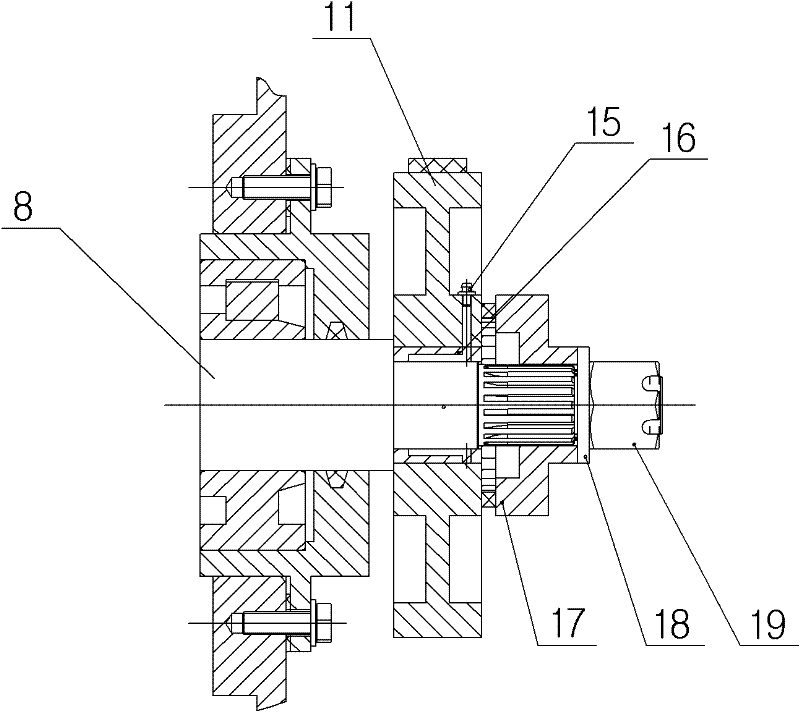

ActiveCN102454151ADense and flat surfacePrevent looseningRoads maintainenceWheel cylinderEngineering

The invention discloses a road roller combining vibration, oscillation and complex excitation as a whole, which comprises a frame; an engine, a vibrating wheel, and a transmission part connected with the engine are disposed in the frame; a cab is disposed above the frame; the vibrating wheel comprises a vibrating wheel cylinder body; a center shaft is disposed at the center of the vibrating wheel cylinder body; four eccentric shafts are disposed around the center shaft with equal angles; the eccentric shafts are mounted on a supporting plate disposed on the vibrating wheel cylinder body; the end parts of the eccentric shafts are movably connected with driven pulleys; the driven pulleys are connected by a driving belt with driving pulleys which are disposed at the end part of the center shaft and at the same side as the driven pulleys; the driven pulleys are connected with a phase adjusting mechanism by gears at the end surfaces. The invention combines vibration, oscillation and complex excitation functions as a whole, enhances the application effect, expands the application scope, has a simple structure, is convenient for using, and is convenient for popularization and application.

Owner:SHAANXI JOINTARK MASCH GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com