Gas cylinder link mechanism used for piston type internal combustion engine or gas compressor

A technology of internal combustion engine and gas compressor, which is applied in the field of cylinder connecting rod mechanism to achieve the effects of increasing movement speed, eliminating slap and improving lubrication state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

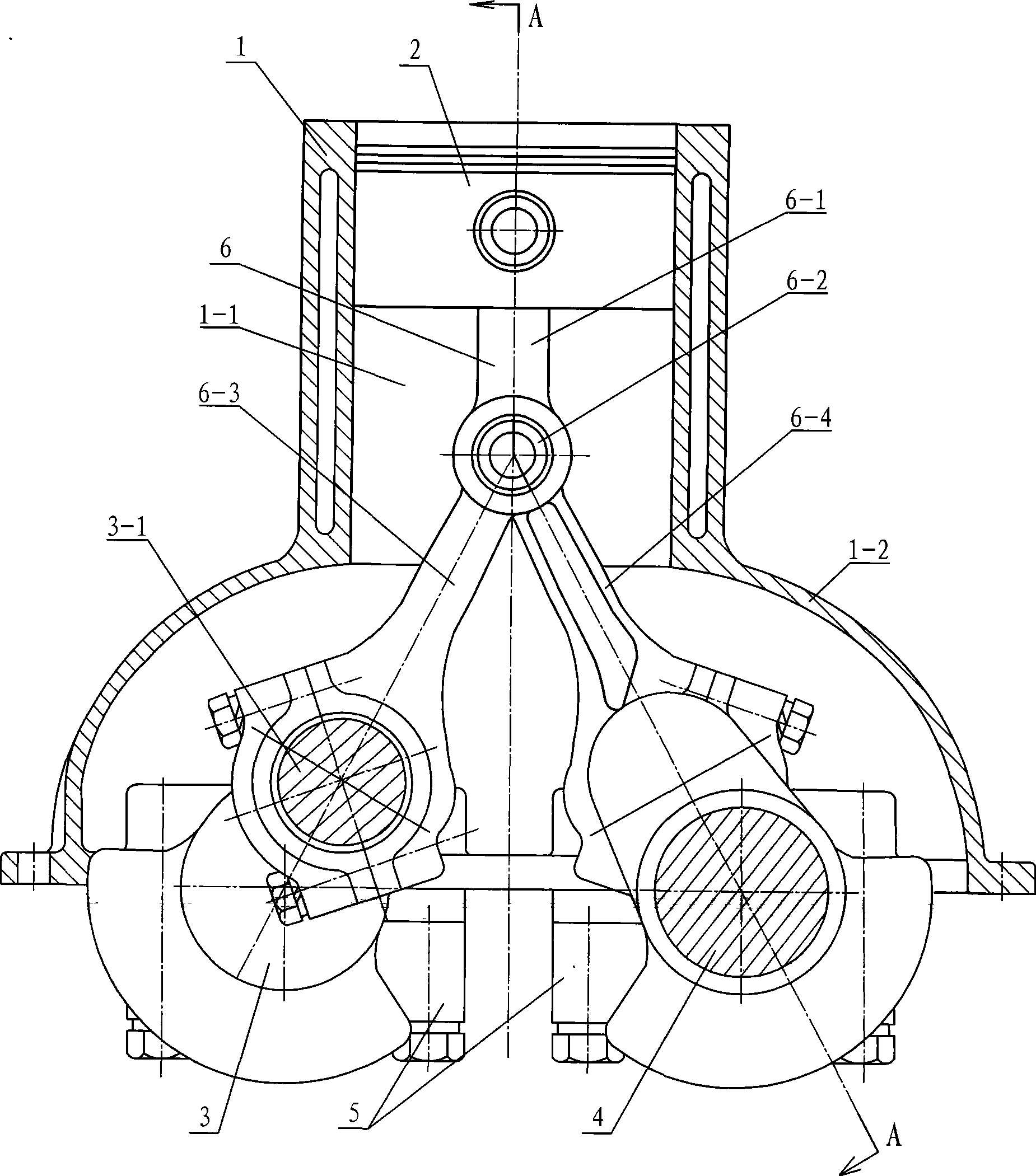

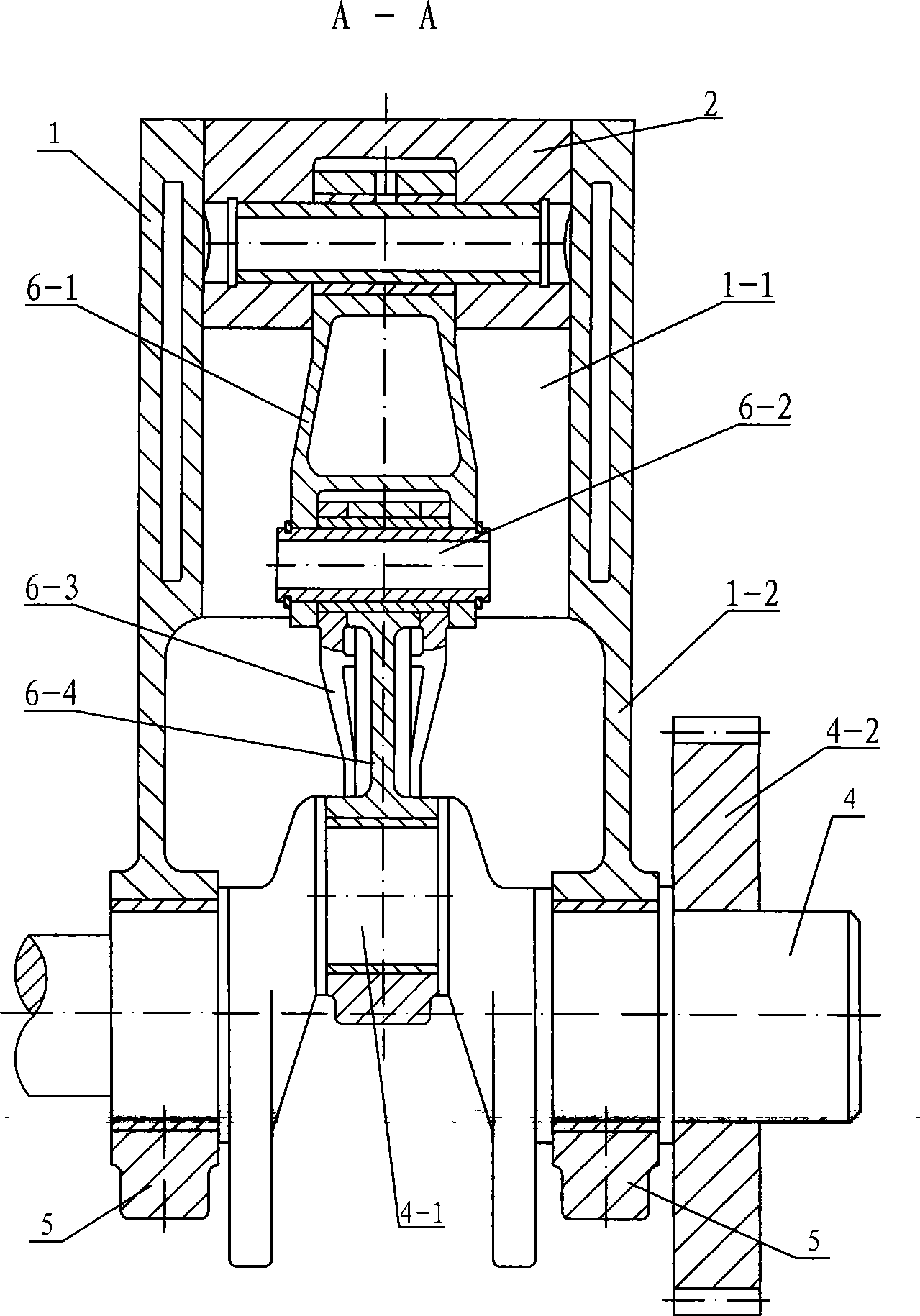

[0010] Specific implementation mode one: combine figure 1 , figure 2 and Figure 7Describe this embodiment, this embodiment includes a first cylinder block 1, at least one piston 2, a first crankshaft 3, a second crankshaft 4, a first gear 3-2, a second gear 4-2, a plurality of bearing housings 5 and At least one first primary and secondary linkage mechanism 6, the first cylinder block 1 is composed of at least one cylinder 1-1 and at least one first crankcase 1-2, the cylinder 1-1 is located in the first crankcase 1-2 The top and the two are integrated, the cylinder 1-1 communicates with the inner cavity of the first crankcase 1-2, the piston 2 is installed in the cylinder 1-1, the first crankshaft 3 and the second crankshaft 4 are along the first crankcase The width direction of the body 1-2 is set in the inner chamber of the first crankcase 1-2 and installed on the bottom of the first crankcase 1-2 through the bearing seat 5, and the second gear 4-2 is fixed on the se...

specific Embodiment approach 2

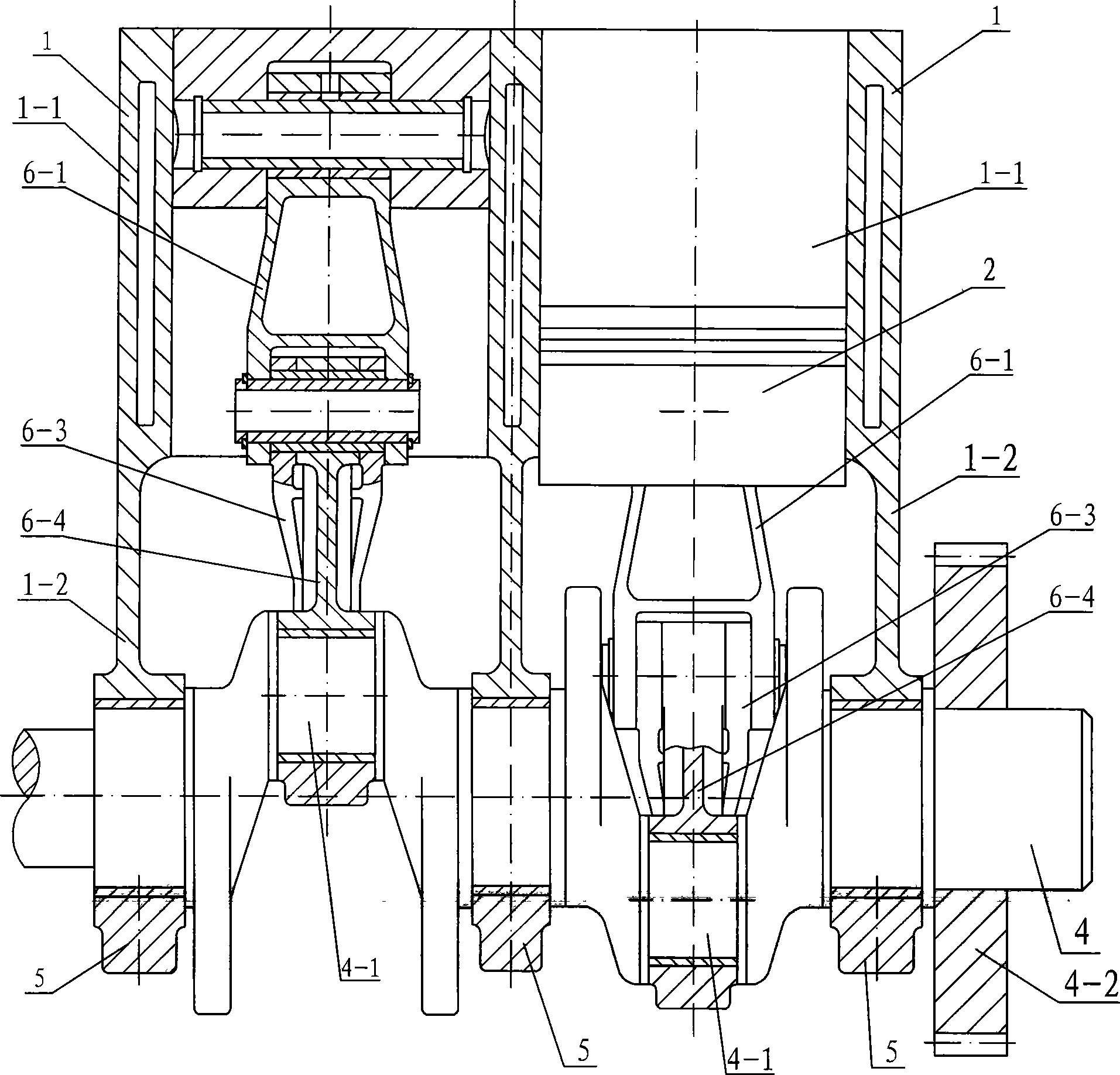

[0011] Specific implementation mode two: combination image 3 and Figure 8 Describe this embodiment, there are two cylinders 1-1 and first crankshaft housings 1-2 in this embodiment, two cylinders 1-1 and two first crankshaft housings 1-2 along the first crankshaft 3 and The axial direction of the second crankshaft 4 is arranged side by side, the first crankshaft 3 is provided with two first crankpins 3-1, the second crankshaft 4 is provided with two second crankpins 4-1, each cylinder 1-1 A piston 2 is housed inside, and each piston 2 is hinged with a set of first primary and secondary linkage mechanisms 6, and so on, the first cylinder block 1 can be provided with three crankshafts along the axial direction of the first crankshaft 3 and the second crankshaft 4 Above the first cylinder 1-1.

[0012] The working process of the specific embodiment one and the specific embodiment two:

[0013] see figure 1 , for an internal combustion engine, during the explosive stroke, t...

specific Embodiment approach 3

[0014] Specific implementation mode three: combination Figure 4 , Figure 5 and Figure 7 Describe this embodiment, this embodiment includes a first cylinder block 1, at least one piston 2, a first crankshaft 3, a second crankshaft 4, a first gear 3-2, a second gear 4-2, a plurality of bearing housings 5 and At least one second main and auxiliary connecting rod mechanism 16, the first cylinder block 1 is composed of at least one cylinder 1-1 and at least one first crankcase 1-2, and the cylinder 1-1 is located in the first crankcase 1-2 The top and the two are integrated, the cylinder 1-1 communicates with the inner cavity of the first crankcase 1-2, the piston 2 is installed in the cylinder 1-1, the first crankshaft 3 and the second crankshaft 4 are along the first crankcase The width direction of the body 1-2 is set in the inner chamber of the first crankcase 1-2 and installed on the bottom of the first crankcase 1-2 through the bearing seat 5, and the second gear 4-2 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com