Road roller combining vibration, oscillation and complex excitation as whole

A composite excitation and road roller technology, applied in the field of road rollers, can solve the problems of fine construction cracks on the compacted surface, crushing of surface aggregates, shallow compaction depth, etc., to meet the requirements of different working conditions and materials, and the lubrication state. Good, dense and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

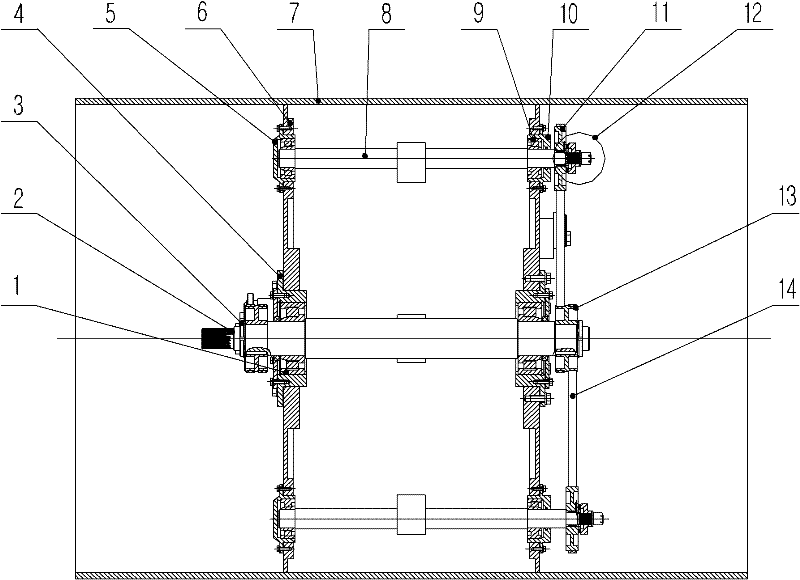

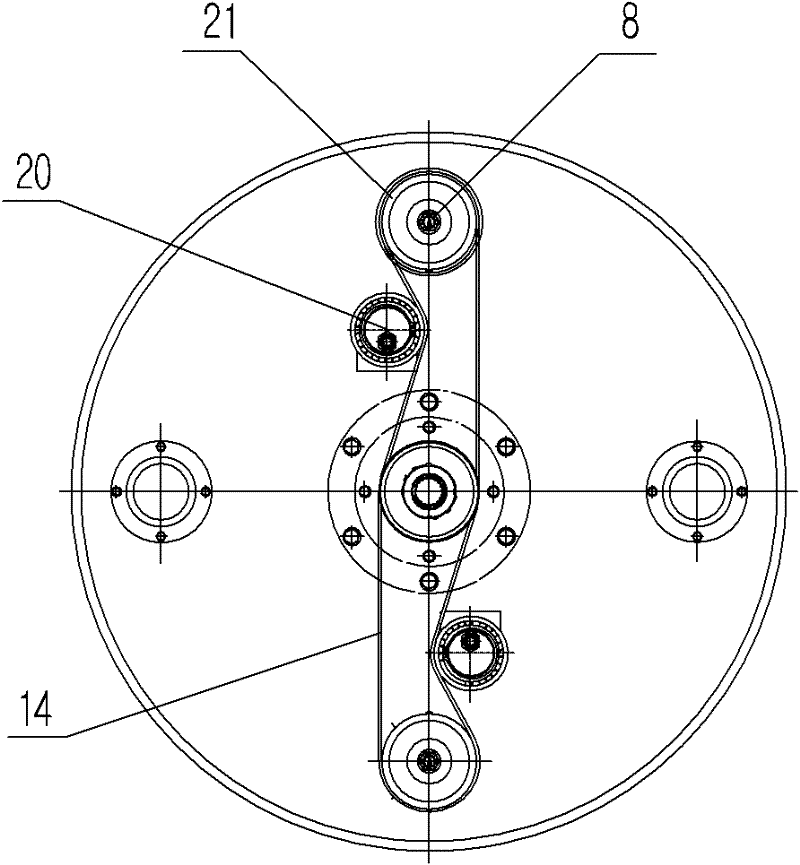

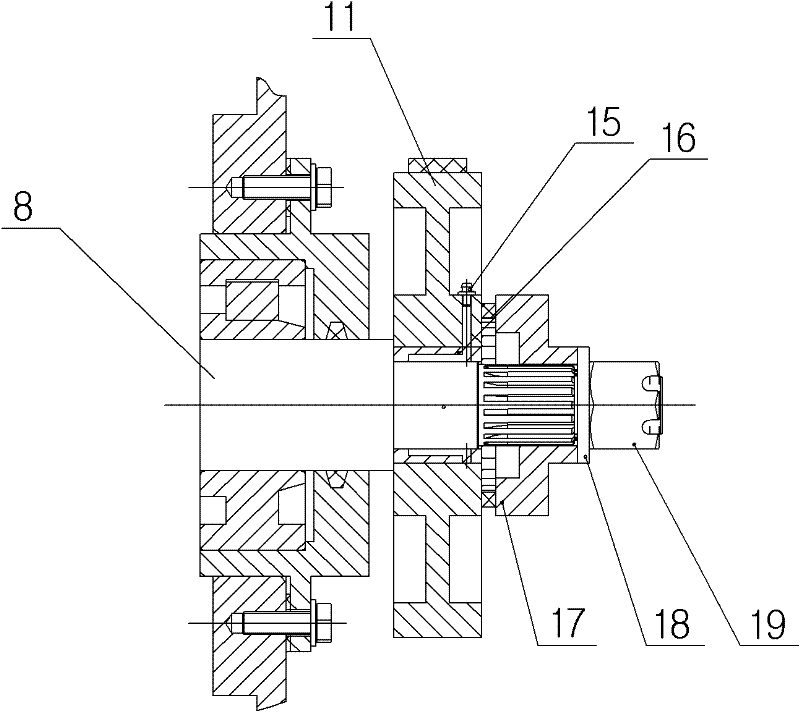

[0029] A road roller integrating vibration, oscillation and compound excitation, including a frame, the frame is equipped with an engine, a vibrating wheel and a transmission component connected with the engine, and a driver's cab is arranged above the frame. vibrating wheel (such as figure 1 Shown) includes a vibrating wheel cylinder 7, the center of the vibrating wheel cylinder 7 is provided with a central shaft 2, and the central shaft 2 is installed and positioned by the central shaft bearing 1 and the central shaft bearing seat 4, around the central shaft 2 Four eccentric shafts 8 are arranged at equal angles. The eccentric shafts 8 are installed and positioned through the eccentric shaft bearings 9 and the eccentric shaft bearing seats 10. The eccentric shafts 8 are installed on the support plate 6 arranged on the vibrating wheel cylinder 7. The end of the eccentric shaft 8 is provided with an eccentric shaft bearing end cover 5, and the end of the eccentric shaft 8 is m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com