Patents

Literature

124results about How to "Meet the requirements of different working conditions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

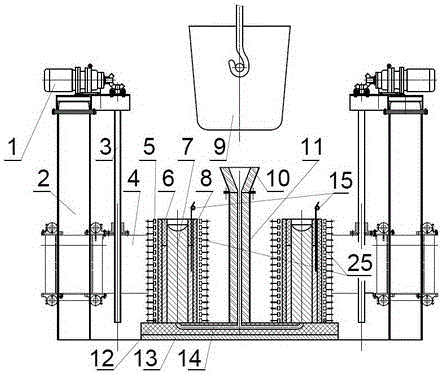

Micro-nano-alloy bimetal composite material preparation technique and device thereof

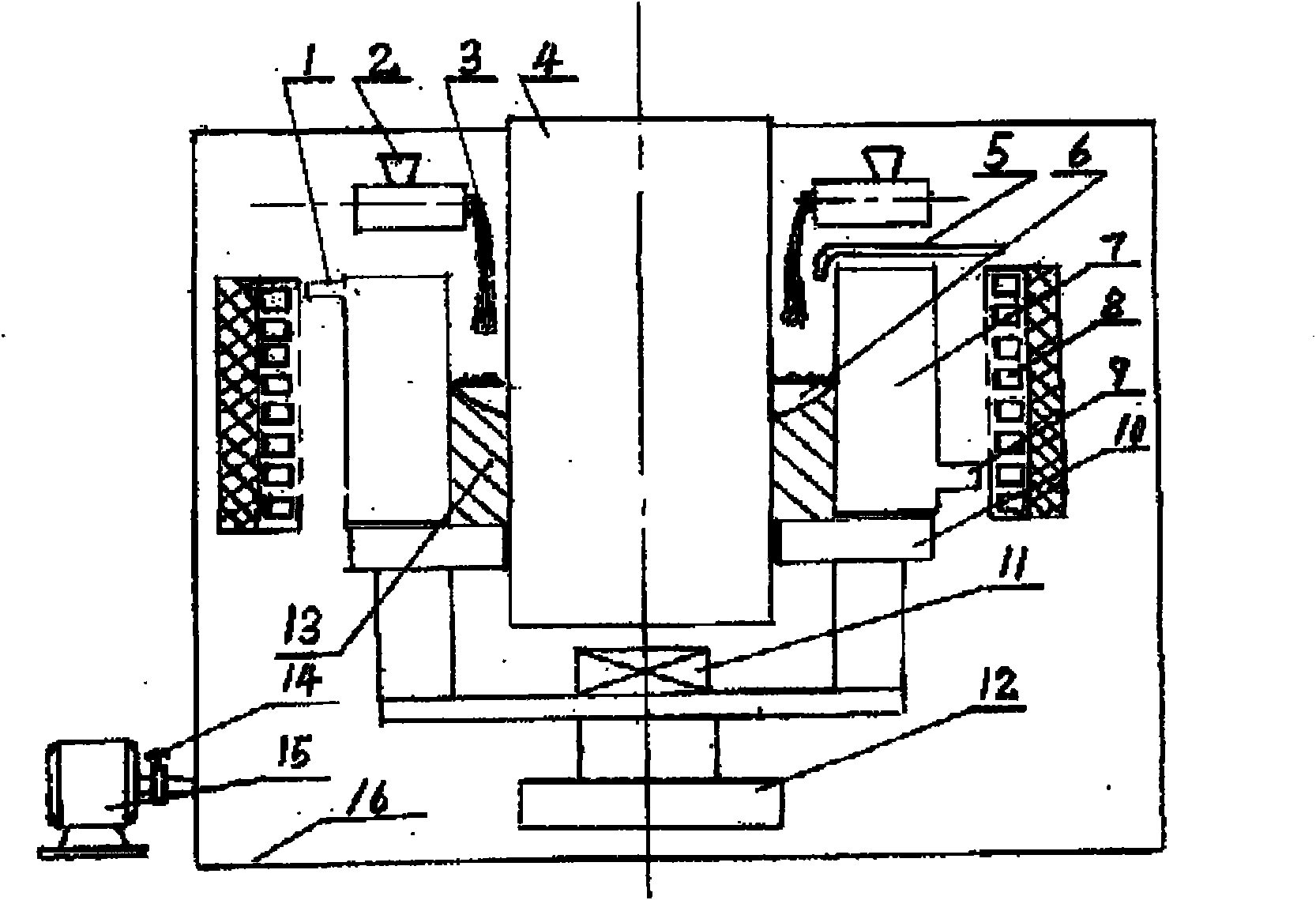

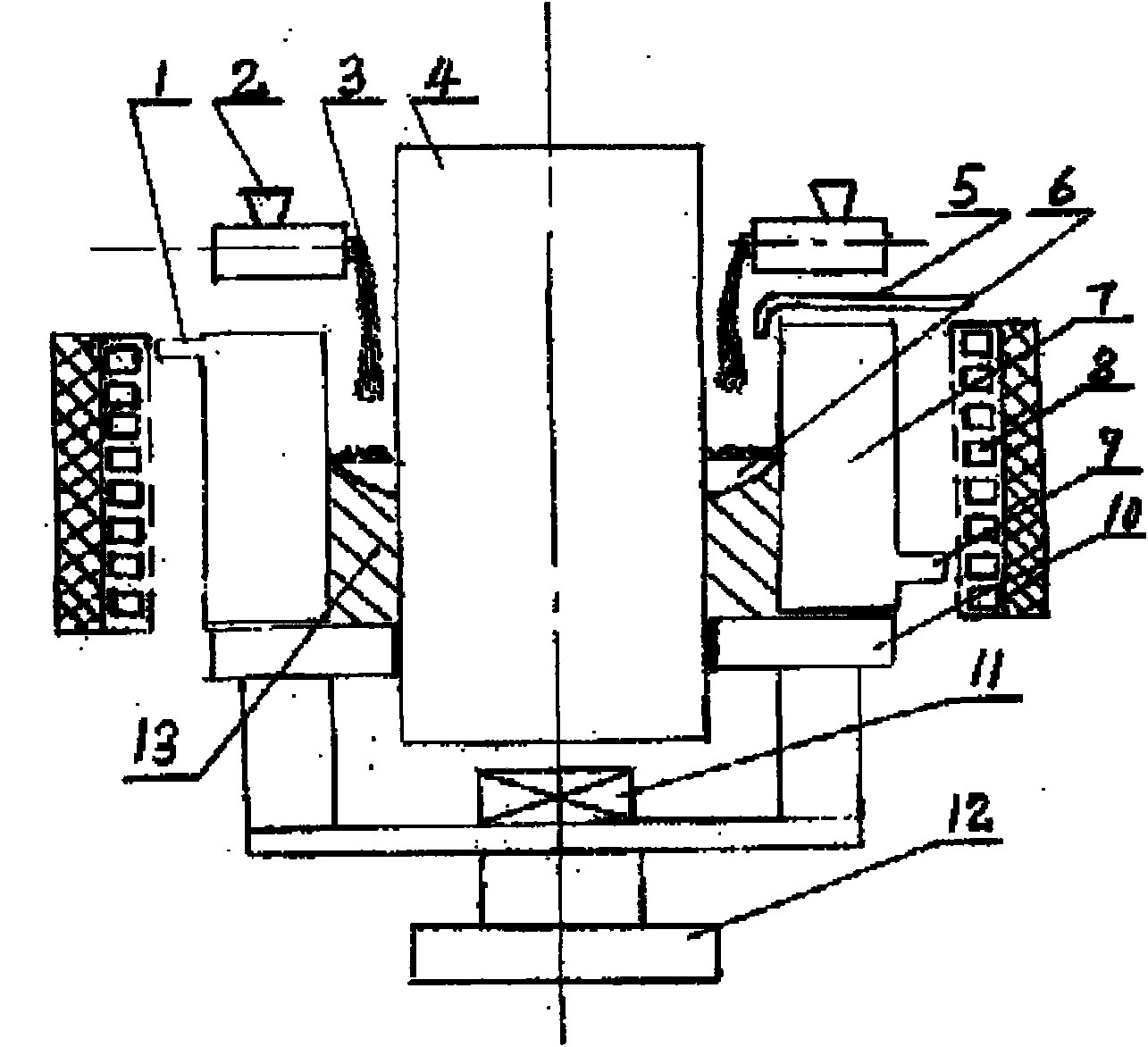

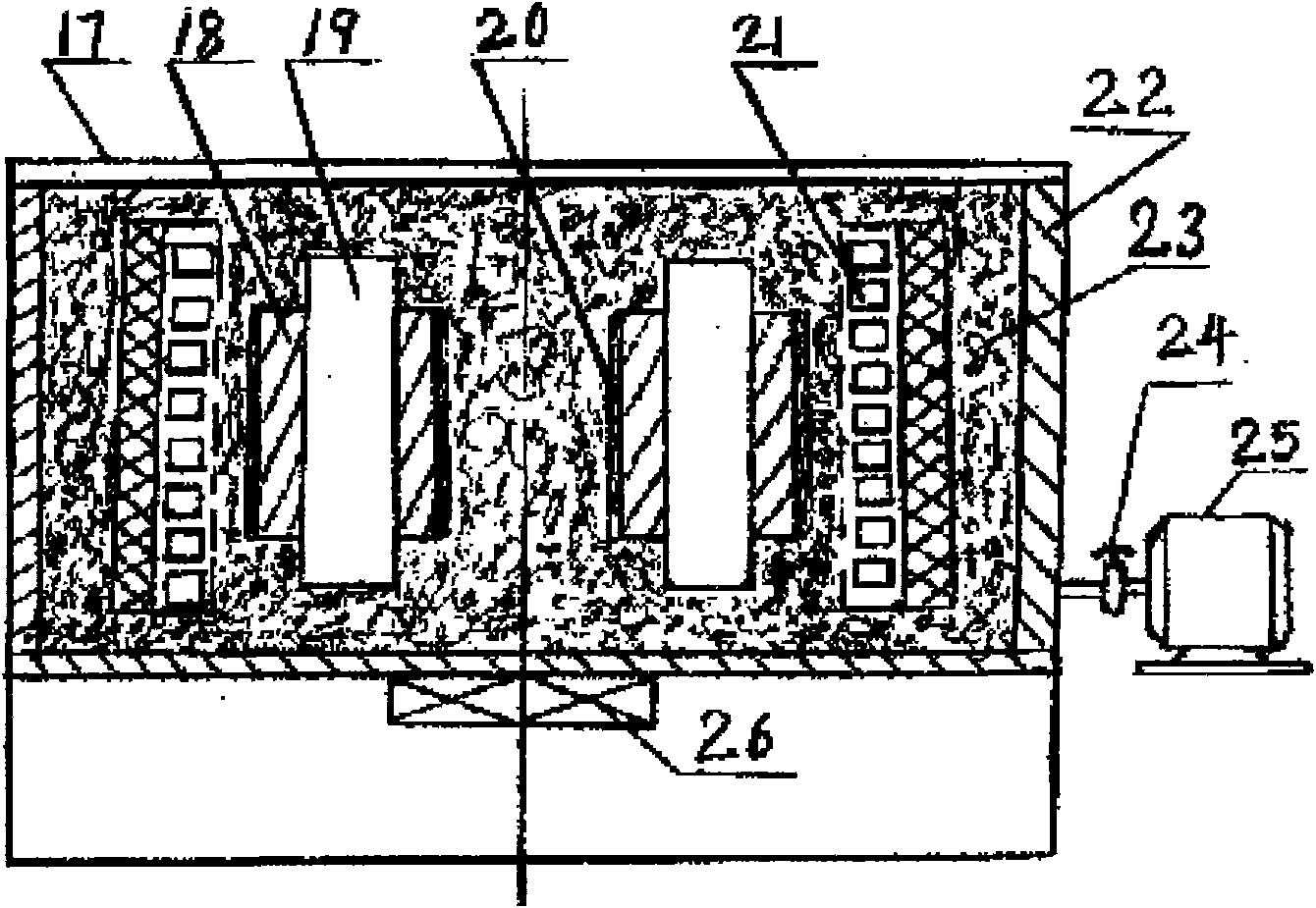

The invention relates to a micro-nano-alloy bimetal composite material preparation technique and a device thereof; one of wear-resistant and corrosion-resistant ferrous metal material, non-ferrous metal material and various self-fluxing alloy is prepared into power; then, the powder is added with less than or equal to 0.8% of one or combination in CeO2, Y2O3 and La2O3, 0.3-1.5% of MgO, 0.3-1.8% of CaF2, 0.0-1.5% of B, 0.1-0.8% of Nb, 0.1-1.0% of Ti, 0.1-2.0% of grain refining and recrystallization inhibitor according to the mass percent; or the powder is added with 1-40% of carbide, nitride, micro-nano or nano particles of boride; and the mixture is put into a high-energy stirring ball grinding mill for grinding and ball milling, so that the micro-nano or nano alloy powder can be prepared. A variable frequency induction heating device is adopted for cladding and melting vacuum or inert gas, so that a workpiece can be melted and coated with a micro-nano or nano scale alloy cladding layer which has the grain size of 0.1-35mm and is wear-resistant and corrosion-resistant, and the bimetal composite material can be prepared. The invention overcomes the defects in various coating techniques in China at present, can complete the preparation of the workpiece with the cladding layer having high thickness for once, does not need repeated coating and sintering, has high material utilization rate, low machining allowance and preparation cost, simple preparation technique and high production efficiency.

Owner:泰州海天机械配件有限公司

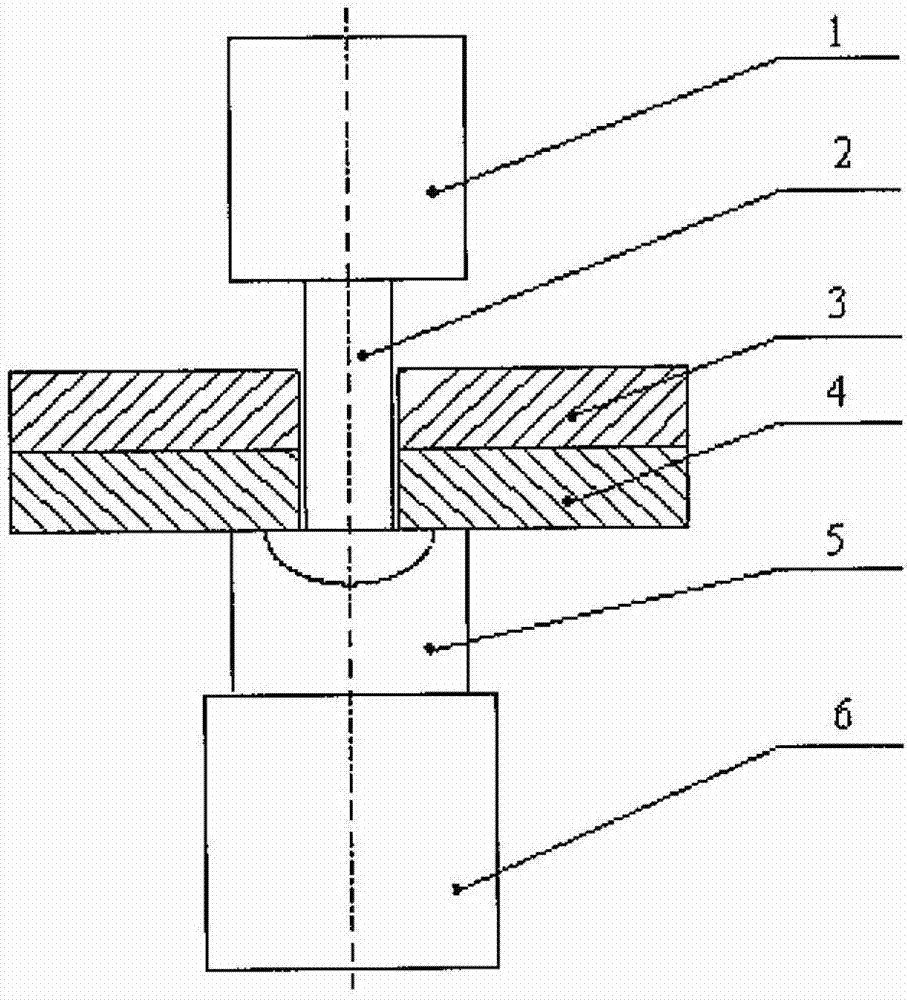

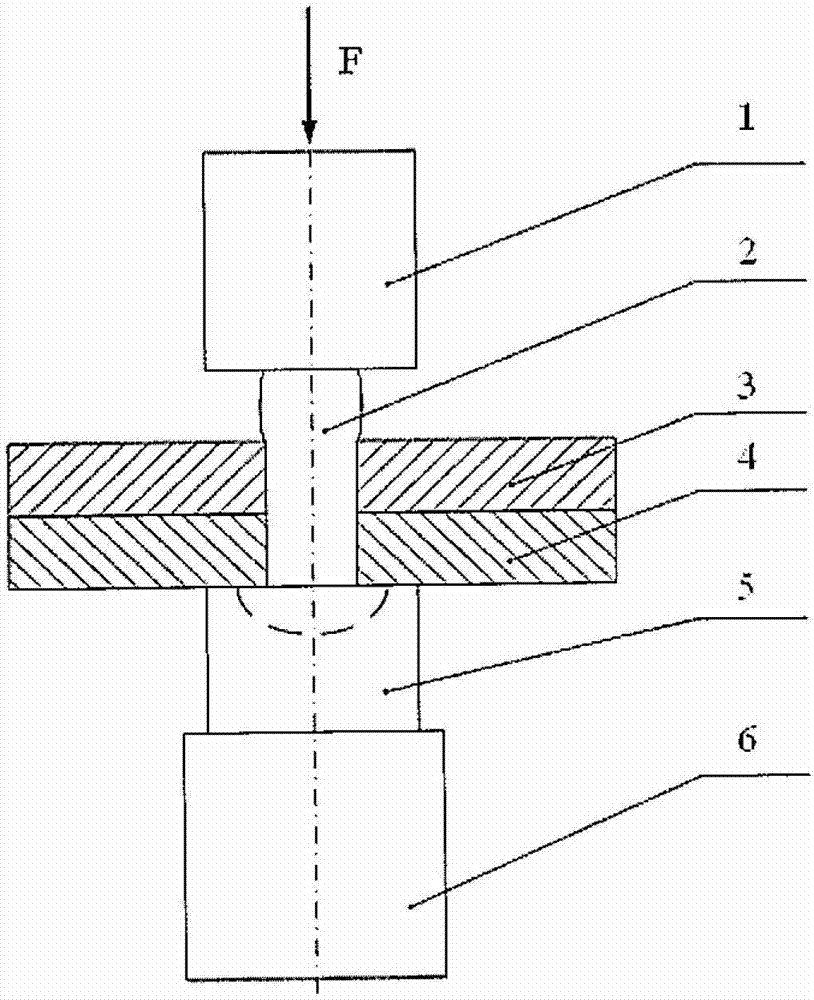

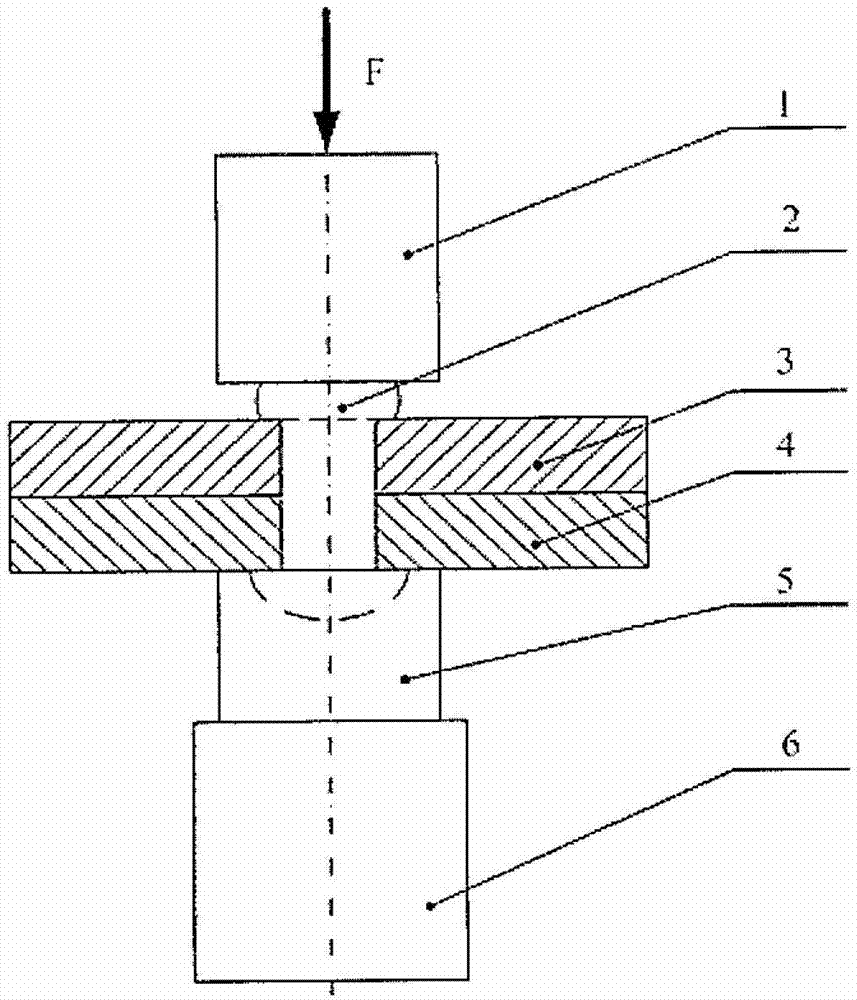

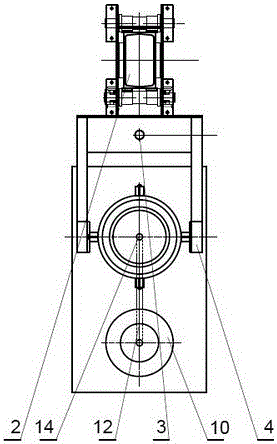

Interference riveting method and device based on ultrasonic assistance

The invention provides an interference riveting method based on ultrasonic assistance, which comprises the stages of integral upsetting, riveting and forming, maintaining the pressure and unloading, an ultrasonic generation device is installed on the lower part of a lower riveting mould or the upper part of an upper riveting mould to provide continuous ultrasonic excitation during the integral upsetting, riveting and forming and pressure maintaining processes so as to change the flowing friction resistance of a rivet material and internal flow stress in the rivet material during the process of deforming the rivet through a rivet hole wall to guarantee the rivet material to uniformly flow along the axial direction to uniformly upset the rivet. The invention further provides an interference riveting device based on ultrasonic assistance, which comprises an upper riveting mould (1), a rivet (2), an upper connecting plate (3), a lower connecting plate (4), a lower riveting mould (5) and an ultrasonic generation device (6). The riveting method and device provided by the invention is easy in realization, good in riveting quality, high in efficiency and is capable of meeting different working condition demands by changing the execution mode of ultrasonic.

Owner:SHANGHAI AIRCRAFT MFG +1

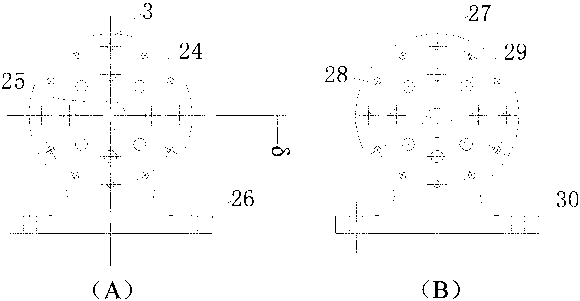

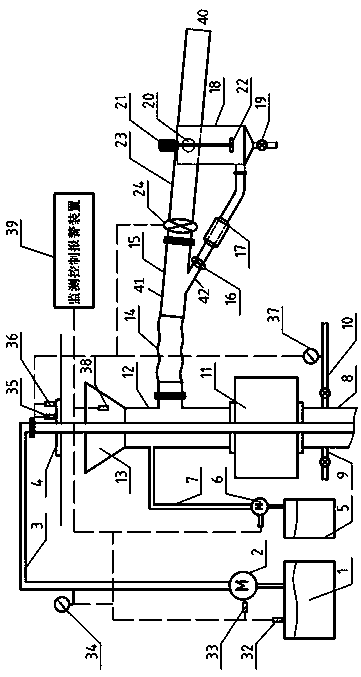

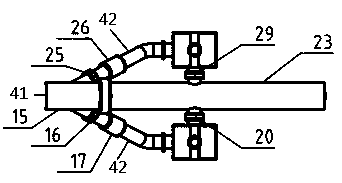

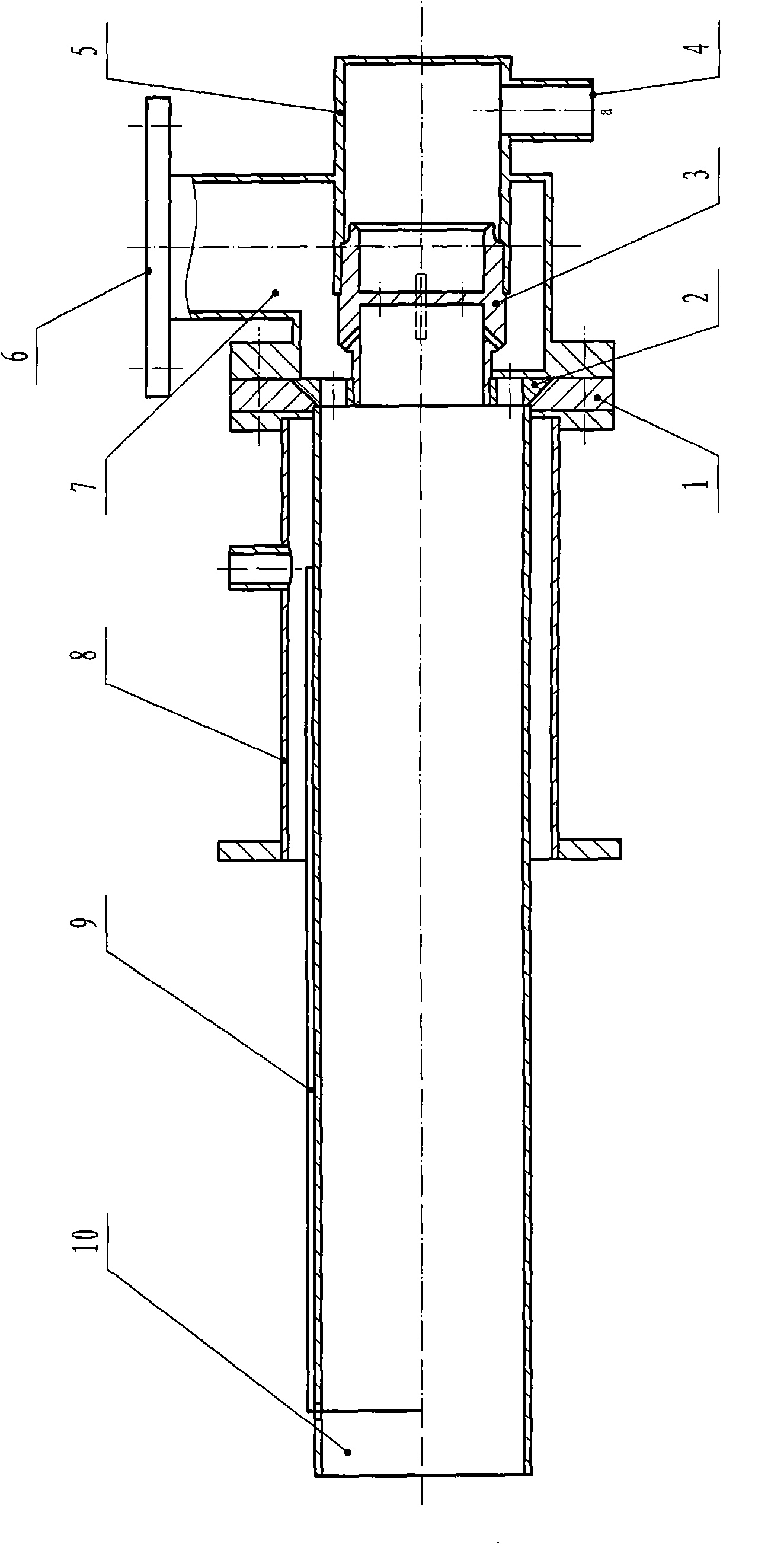

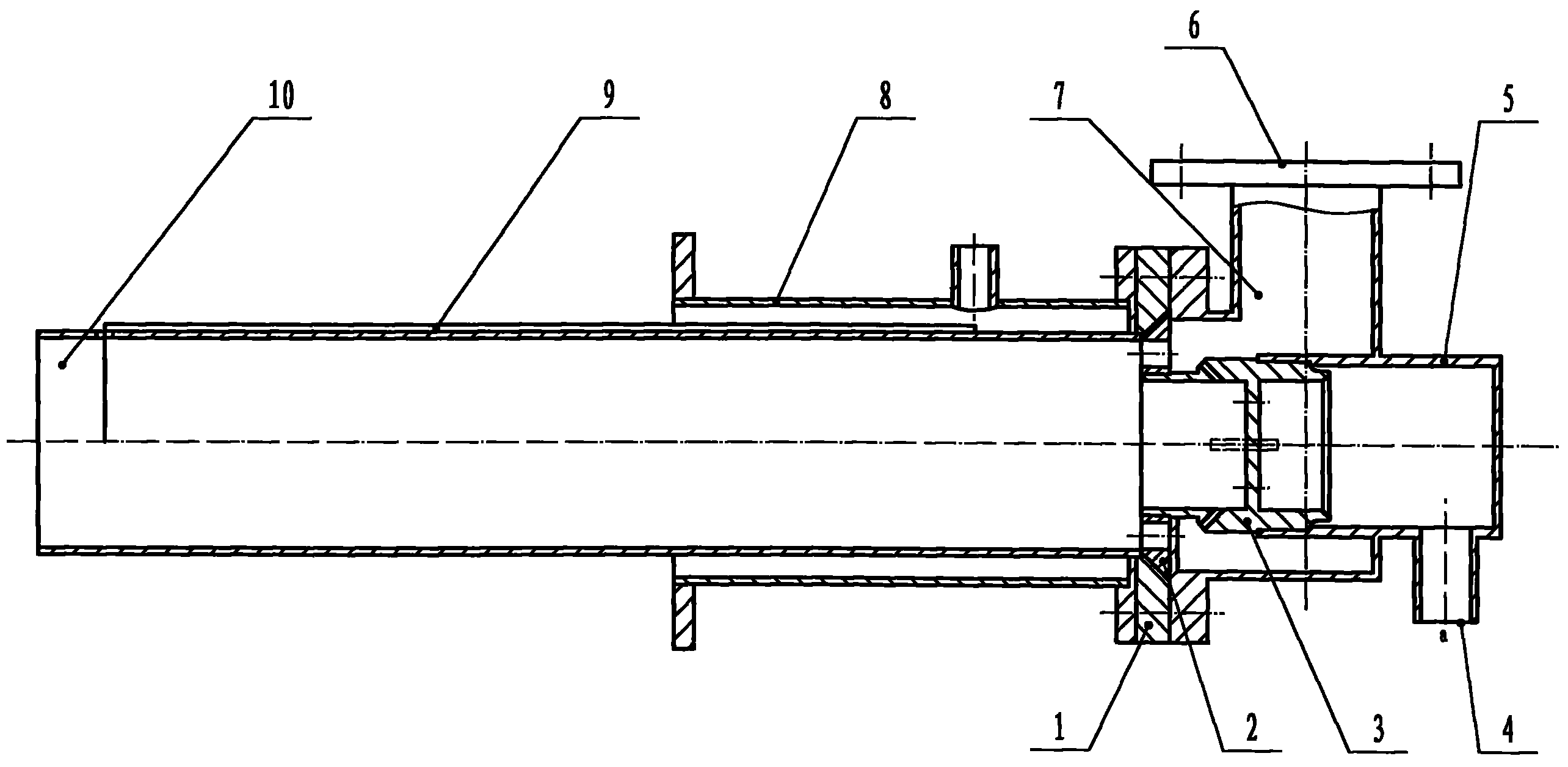

Experimental device and method for simulating wellbore annulus drilling fluid flow characteristics

InactiveCN103323212AEasy to operateMeet the requirements of different working conditionsHydrodynamic testingDrift angleEngineering

The invention relates to an experimental device and method for simulating wellbore annulus drilling fluid flow characteristics. The method includes the steps of simulating an wellbore annulus through an outer cylinder and a simulating drill rod and fixing the wellbore annulus on a supporting platen, driving the simulating drill rod to rotate through a rotating motor, controlling the rotating speed of the simulating drill rod, injecting mud into the wellbore annulus between the outer cylinder and the simulating drill rod through a mud pump, controlling the flow of the mud, controlling a lifting motor to adjust the angle between the supporting platen and the horizontal line, and controlling the drill rod eccentricity through a specially-made eccentric hole flange plate. According to the experimental device and method, the wellbore annulus drilling fluid flow characteristics can be simulated under different drill rod rotating speeds, different types of flow, different hole drift angles and different eccentric distances, requirements of different working conditions are met, the mud used for experiments can be repeatedly pumped into the wellbore annulus and recycled, and cost is saved.

Owner:SOUTHWEST PETROLEUM UNIV

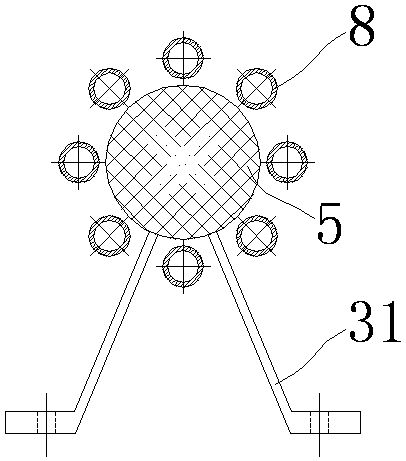

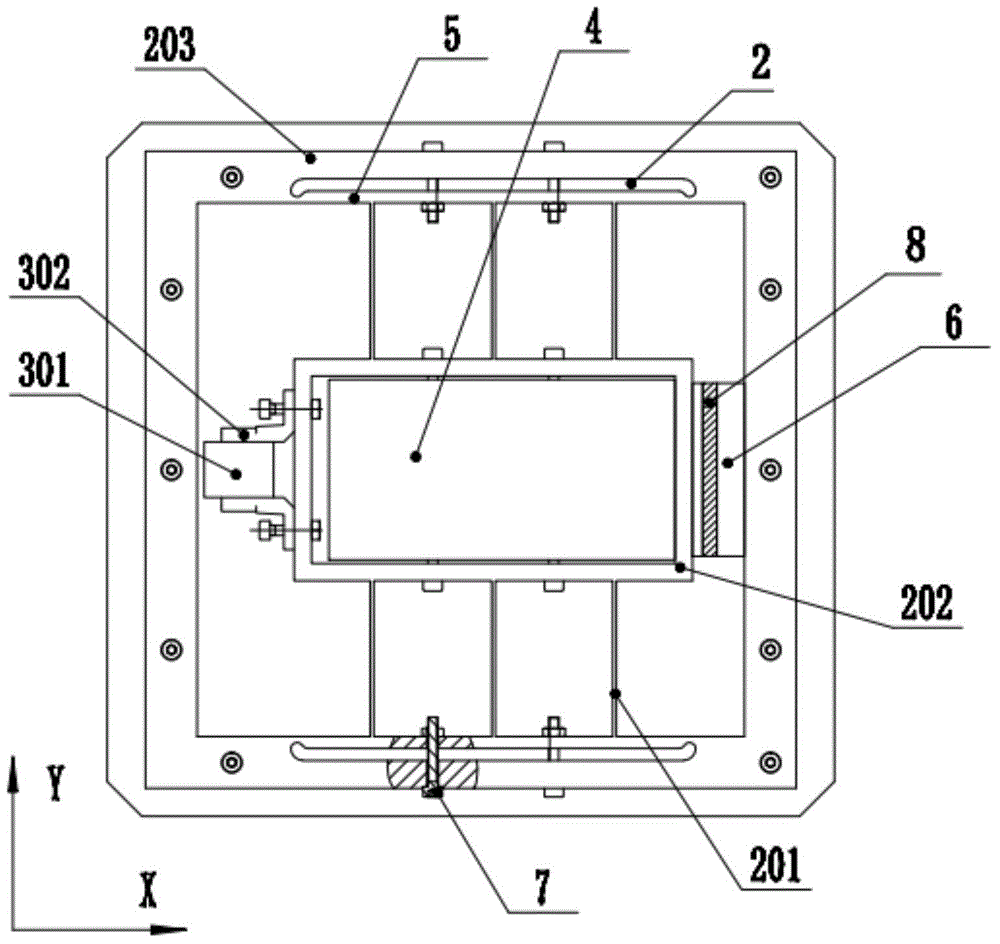

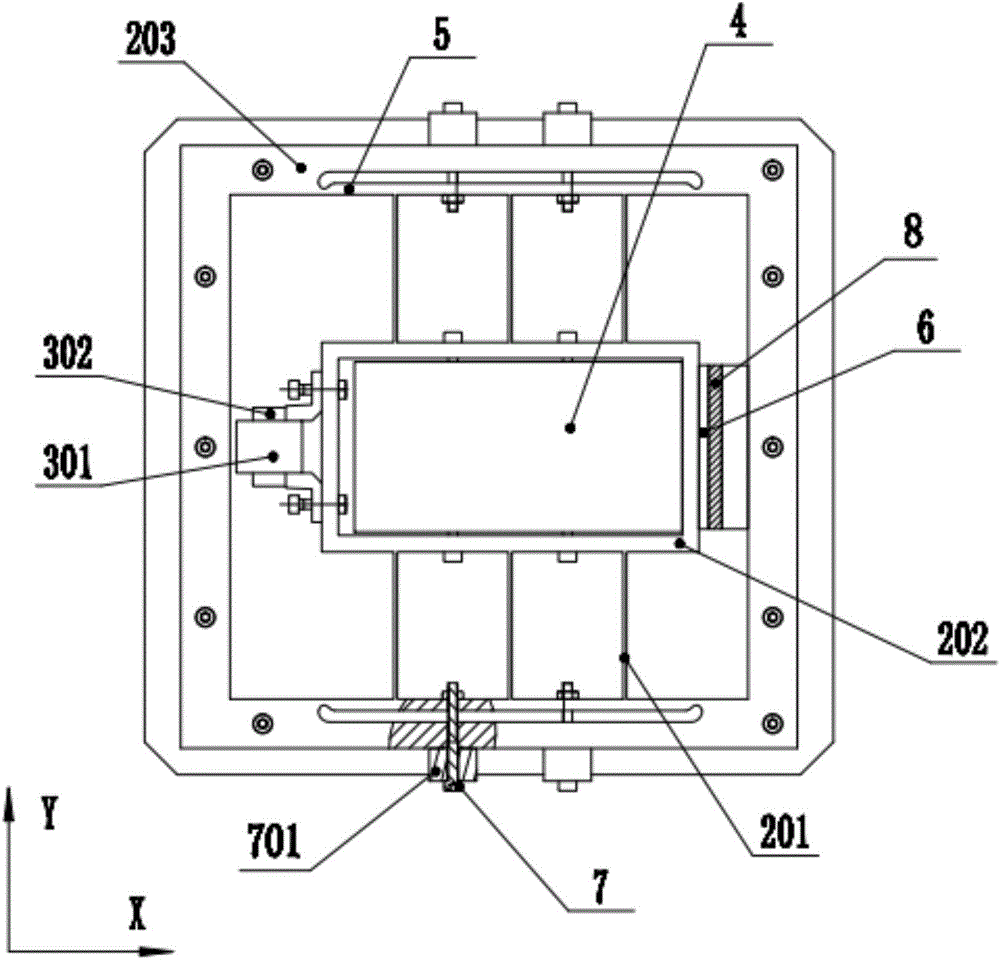

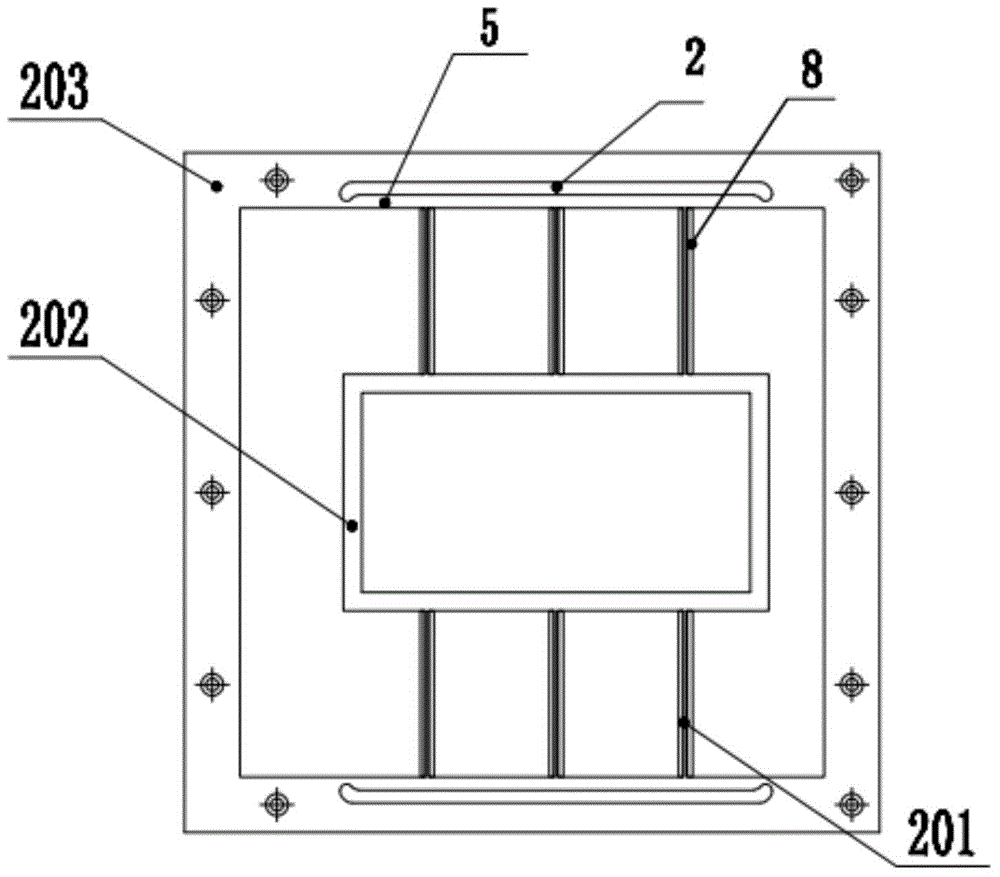

Dynamic characteristic adjustable micro-motion platform

InactiveCN104889950AMeet the requirements of different working conditionsAchieving consistent displacement output requirementsWork benchesLarge fixed membersControl theoryMicro motion

Provided is a dynamic characteristic adjustable micro-motion platform. The dynamic characteristic adjustable micro-motion platform comprises a base, a spring sheet group, a micro-motion sub-platform, an outer frame, a drive, a micro-motion workbench, a tension adjusting mechanism, a displacement sensor, and a variable damper, the base is fixed on a base plate, the spring sheet group is arranged at two sides of the micro-motion workbench, the length direction of spring sheets is vertical to the moving direction of the micro-motion workbench, the micro-motion workbench is fixed in the base, the micro-motion workbench is provided with the displacement sensor in the feeding direction, the displacement sensor is used for displacement precision detection, a connecting position of the base and the spring sheet group is provided with a tension adjusting module for realizing precise dynamic adjustment of rigidity frequency, and the variable damper is arranged between the micro-motion workbench and the base and can cooperate with the requirement of the rigidity frequency to configure the optimal damping. According to the dynamic characteristic adjustable micro-motion platform, the mechanism rigidity and inherent frequency are changed via the adjustment of the tension, the optimal damping at any frequency point can be set via the variable damper, and the consistent displacement output requirement at any frequency can be realized.

Owner:GUANGDONG UNIV OF TECH

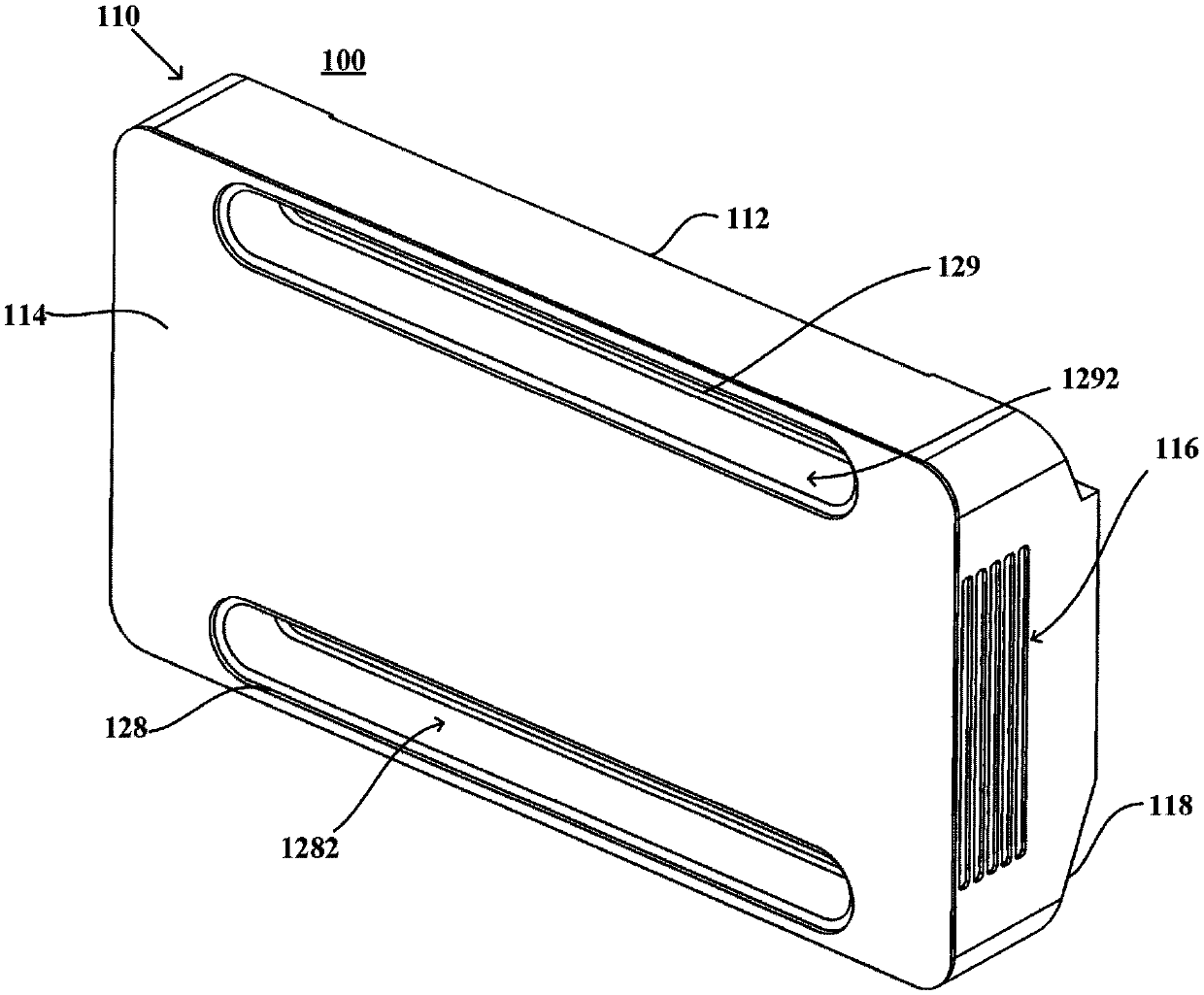

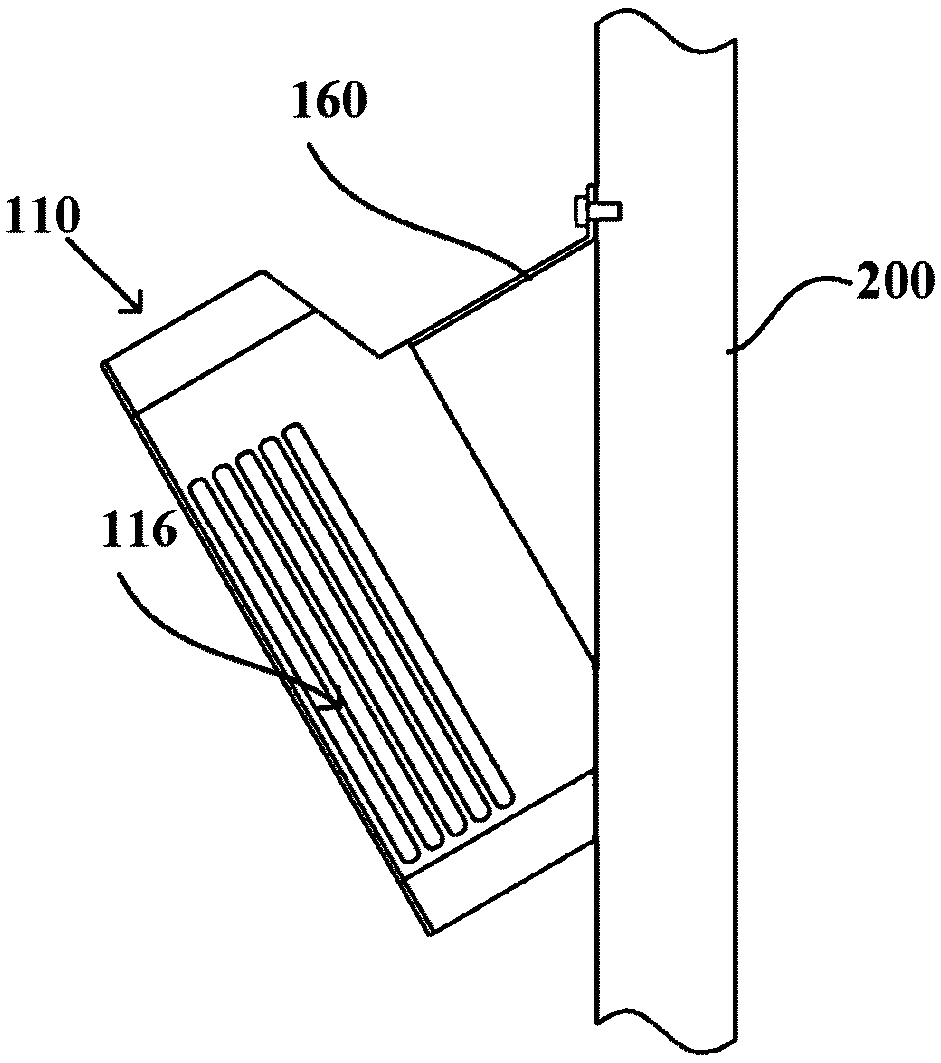

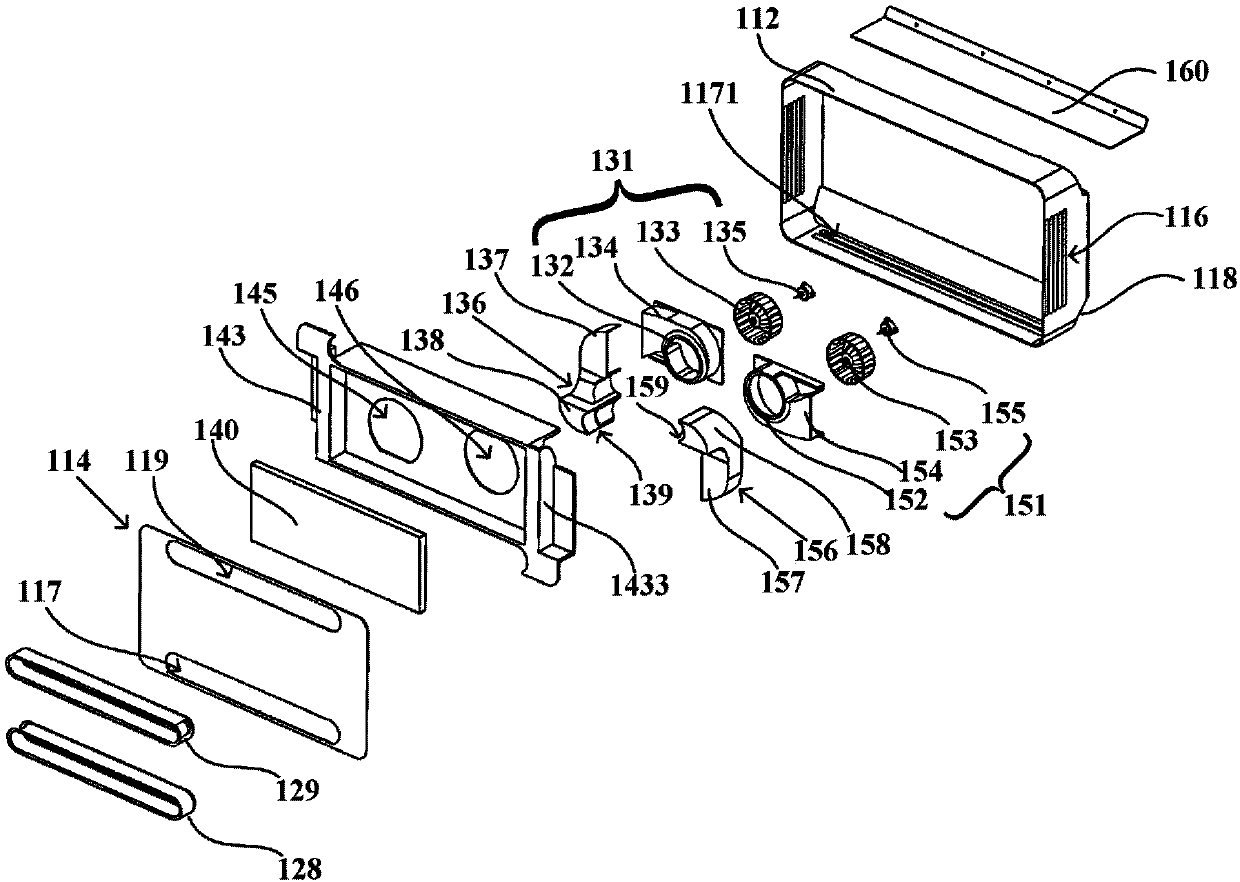

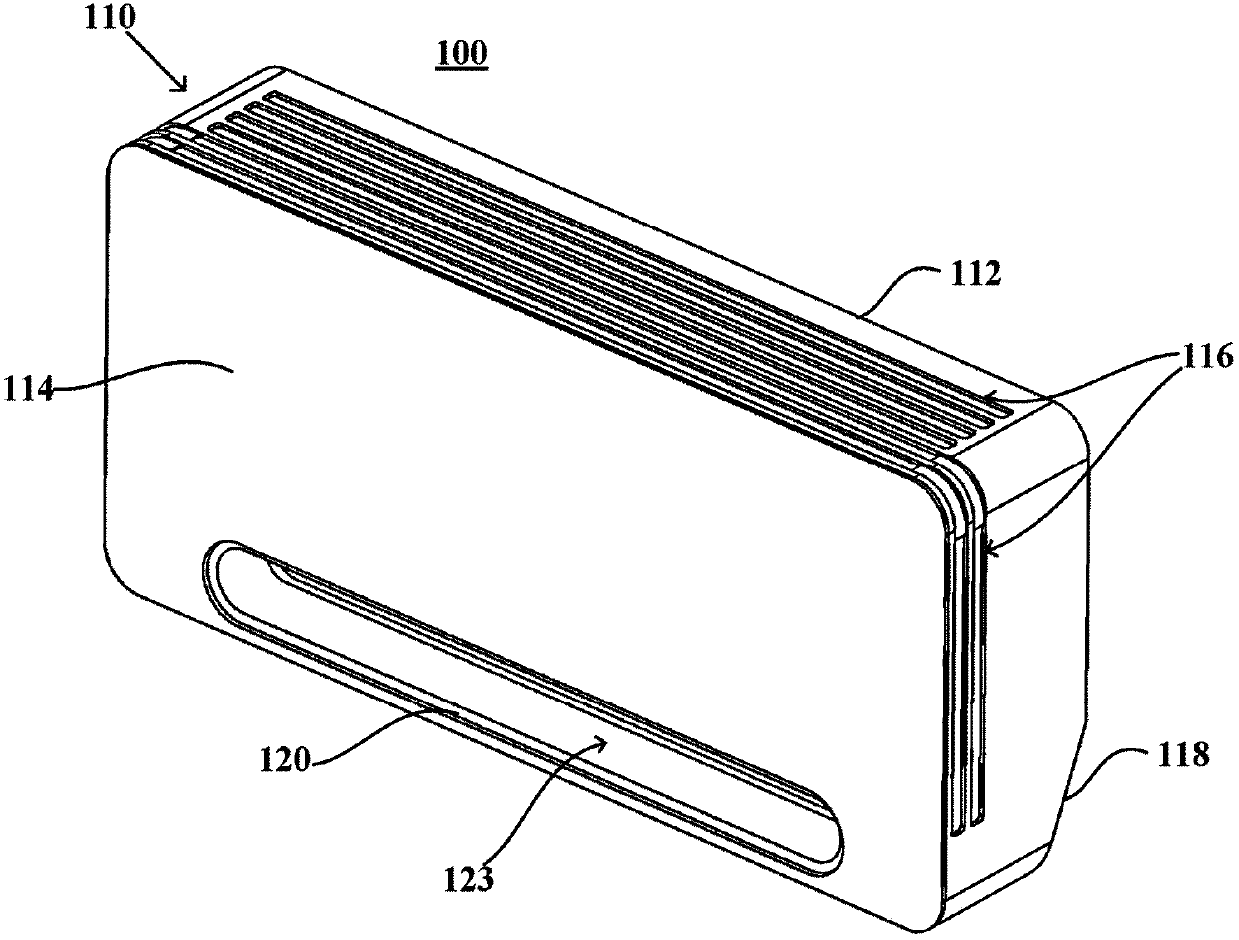

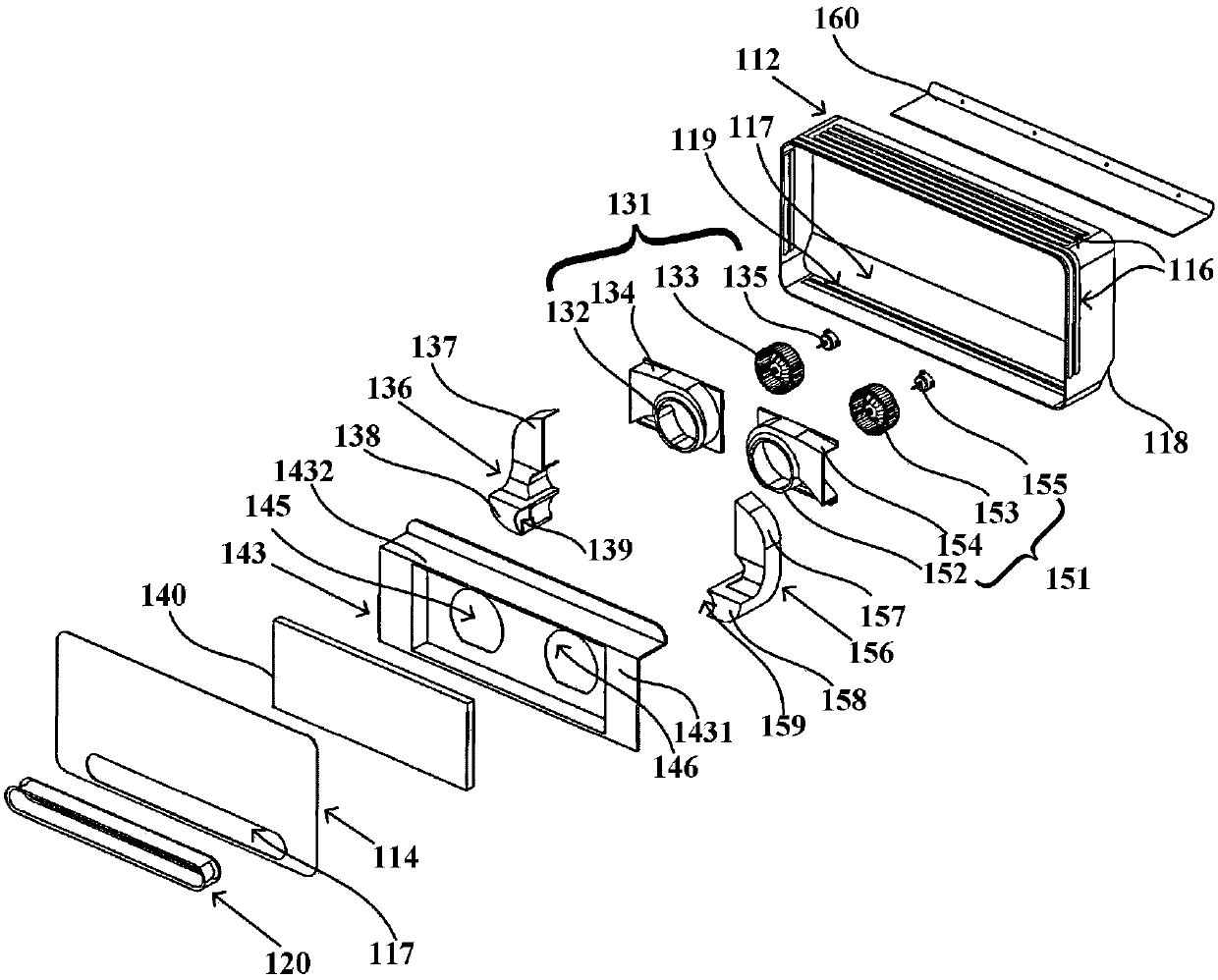

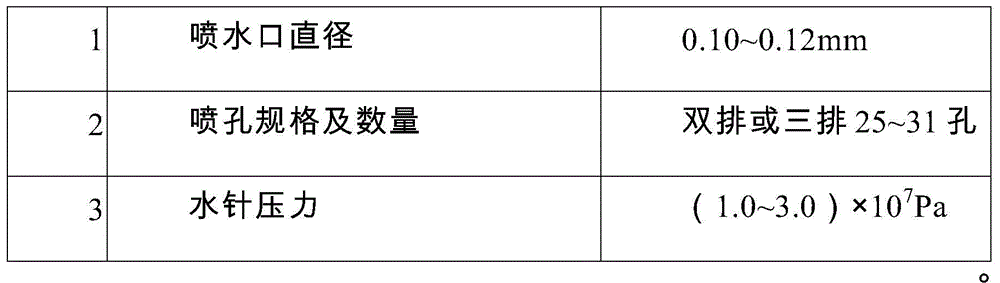

Wall-mounted air conditioner indoor unit

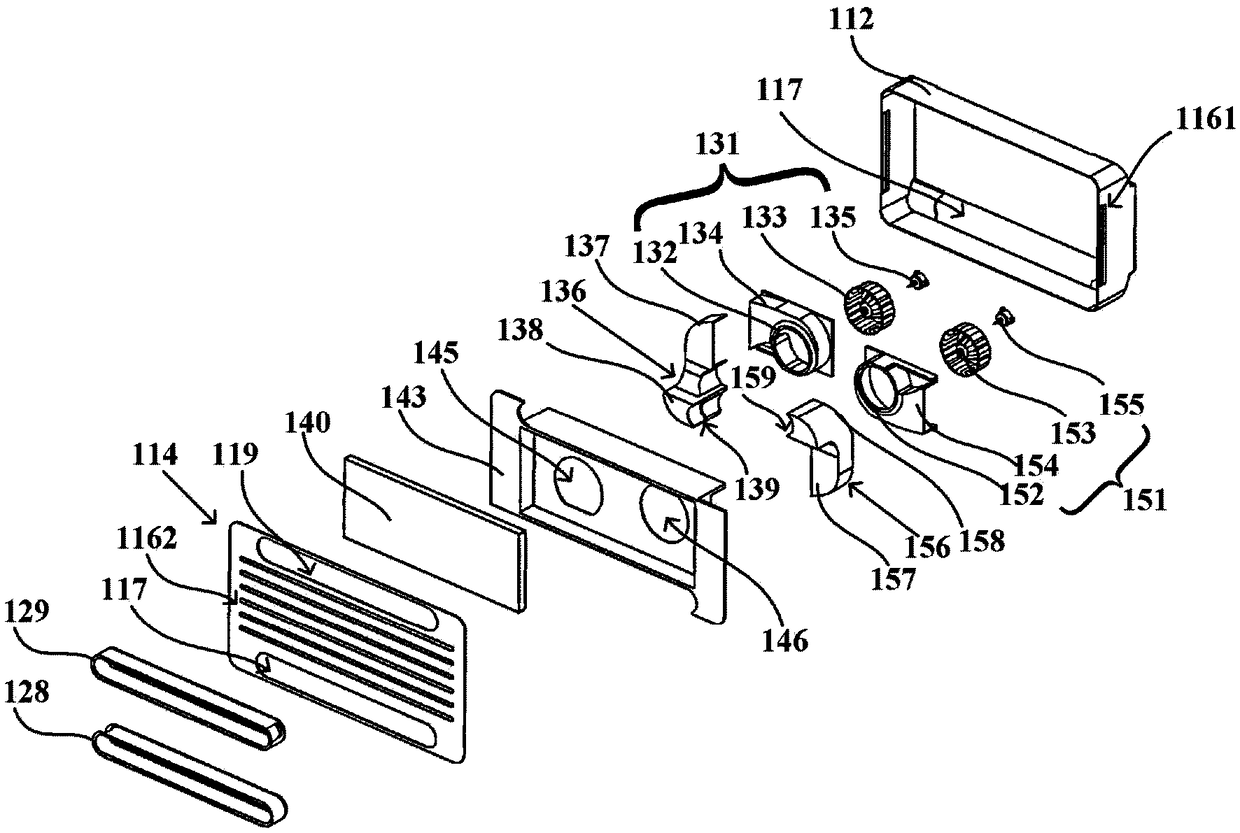

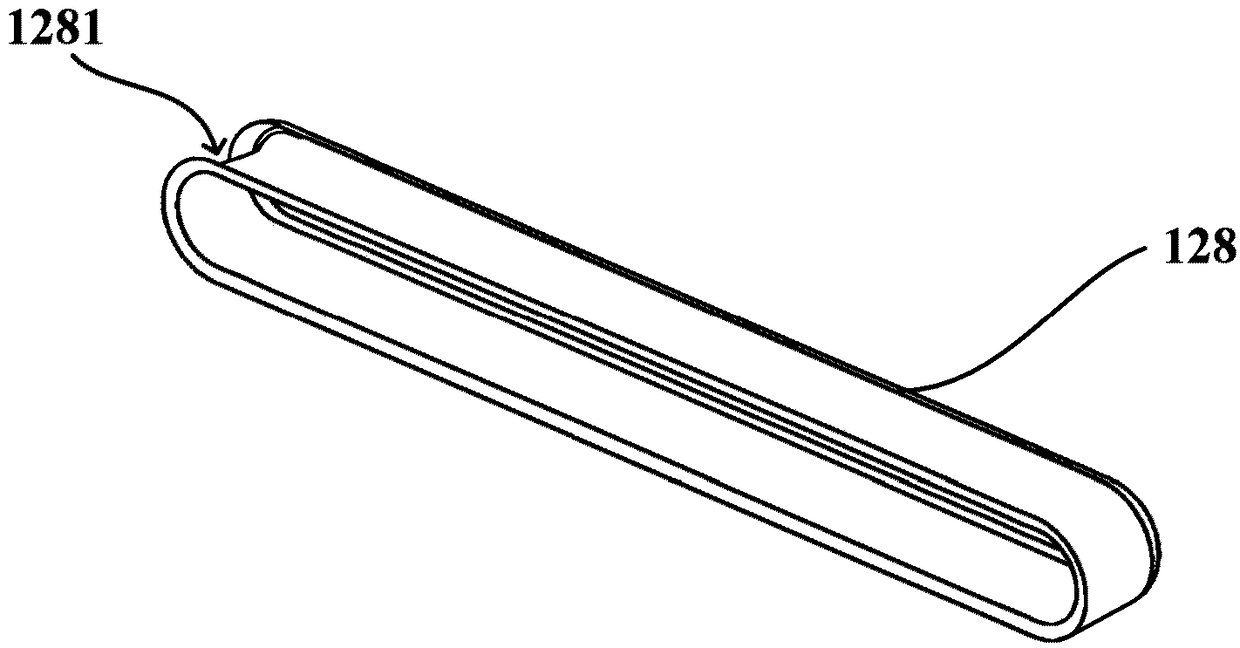

PendingCN107655075AFeel comfortableIncrease air volumeLighting and heating apparatusAir conditioning systemsAir volumeInjection air

The invention provides a wall-mounted air conditioner indoor unit. The wall-mounted air conditioner indoor unit comprises a shell, a heat exchanger, an air injection assembly, a first air supply assembly and a second air supply assembly, wherein the shell comprises a cover enclosure and a front panel arranged on the front portion of the cover enclosure; the top wall and the sidewalls of the coverenclosure are all provided with air inlets, and the lower portion of the front panel is provided with an oblong air supply outlet; the heat exchanger is provided with a first heat exchange section anda second heat exchange section; the air injection assembly is arranged in the air supply outlet and comprises a first air injection part and a second air injection part which are arranged transversely; the first air injection part and the second air injection part are used for injecting airflow in the air injection parts forwards and driving ambient air in air suction holes defined by the inner peripheral walls of the air injection parts to be sent forwards; the first air supply assembly is used for producing first heat exchange airflow flowing in from the air inlets, conducting heat exchangewith the heat exchanger and then supplied into the first air injection part; the second air supply assembly is used for producing second heat exchange airflow flowing in from the air inlets, conducting heat exchange with the heat exchanger and then supplied into the second air injection part. By adopting the wall-mounted air conditioner indoor unit, the air supply amount is increased, and the indoor temperature is lowered uniformly.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD

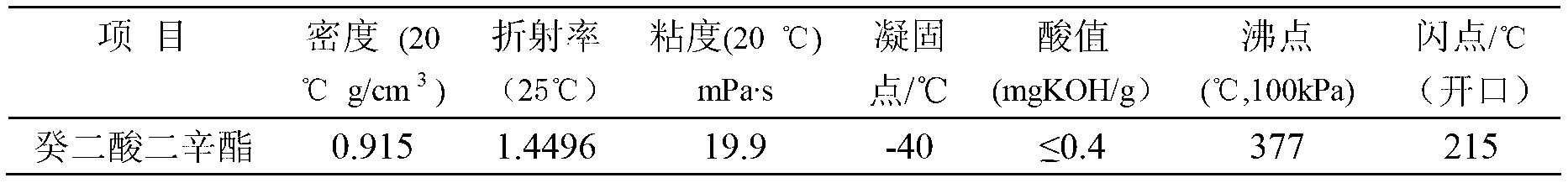

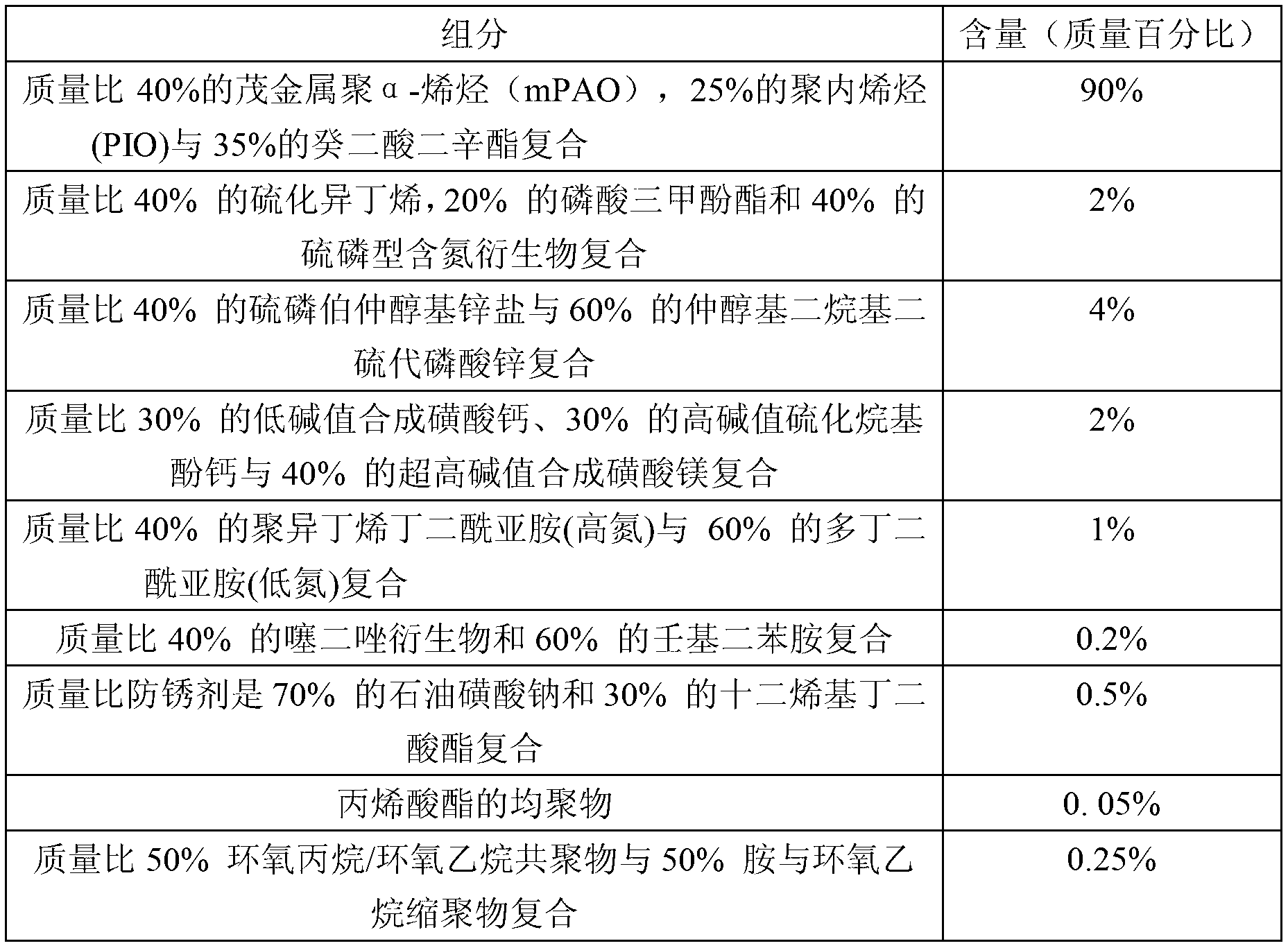

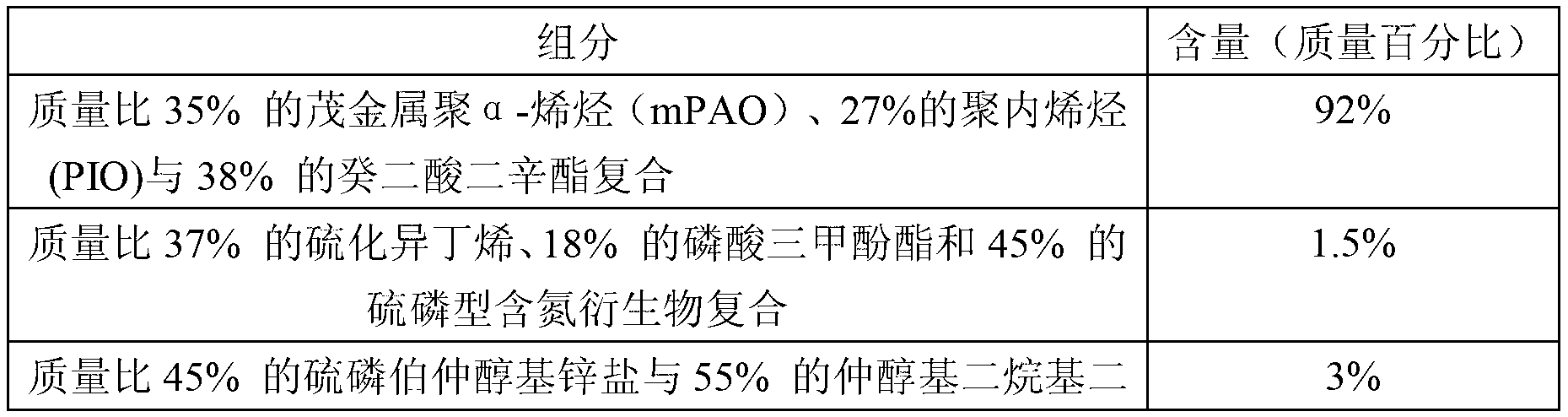

Environment friendly energy-efficient heavy-load compression machine oil

ActiveCN103232880AMeet the requirements of different working conditionsAchieve qualityBase-materialsEngineeringCrankcase

The invention provides environment friendly energy-efficient heavy-load compression machine oil, which comprises the following components by mass percentage: 90-95% of base oil and 10-5% of other additives. Metallocene poly alpha-olefins (mPAO), poly internal olefin (PIO) and dioctyl sebacate are composited as base oil of heavy-load compressor oil. One main component of the base oil of the compressor oil is dioctyl sebacate which has a sufficient raw material source, and the product is a reproducible resource with high economic benefit and social benefit, and the preparation technology is simple. Each physical and chemical index of the heavy-load compressor oil reaches the usage requirement, and the polyisobutylene can be blended with the product for producing a product which meets the performance requirements of L-DAC heavy-load compressor oil with viscosity grades as follows: N32, N46, N68, N100 and N150. The product is suitable for lubricating, cooling and sealing the cylinder and the crankcase of the middle and heavy-load piston compressor and the large-scale rotary compressor.

Owner:GUANGXI UNIV

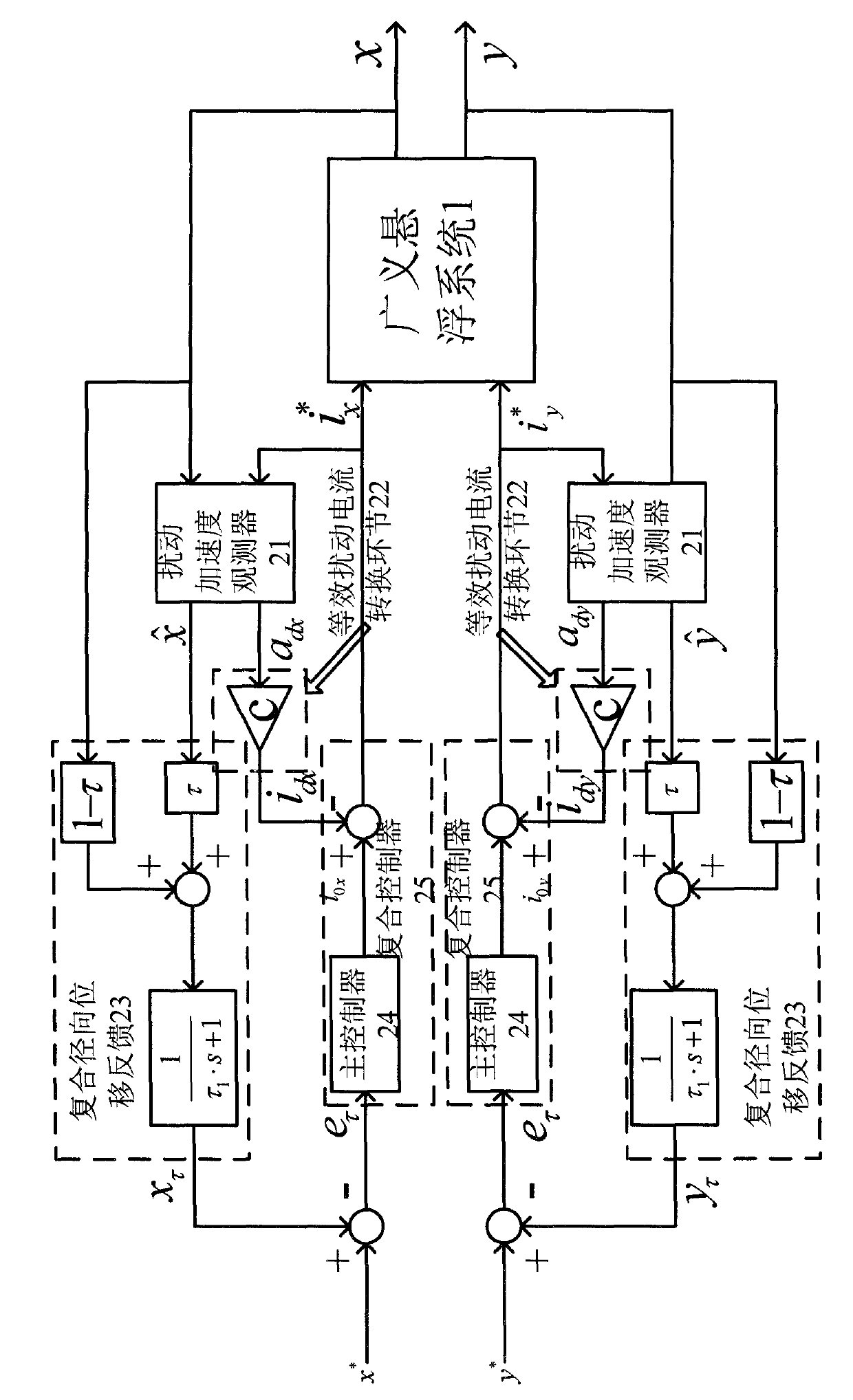

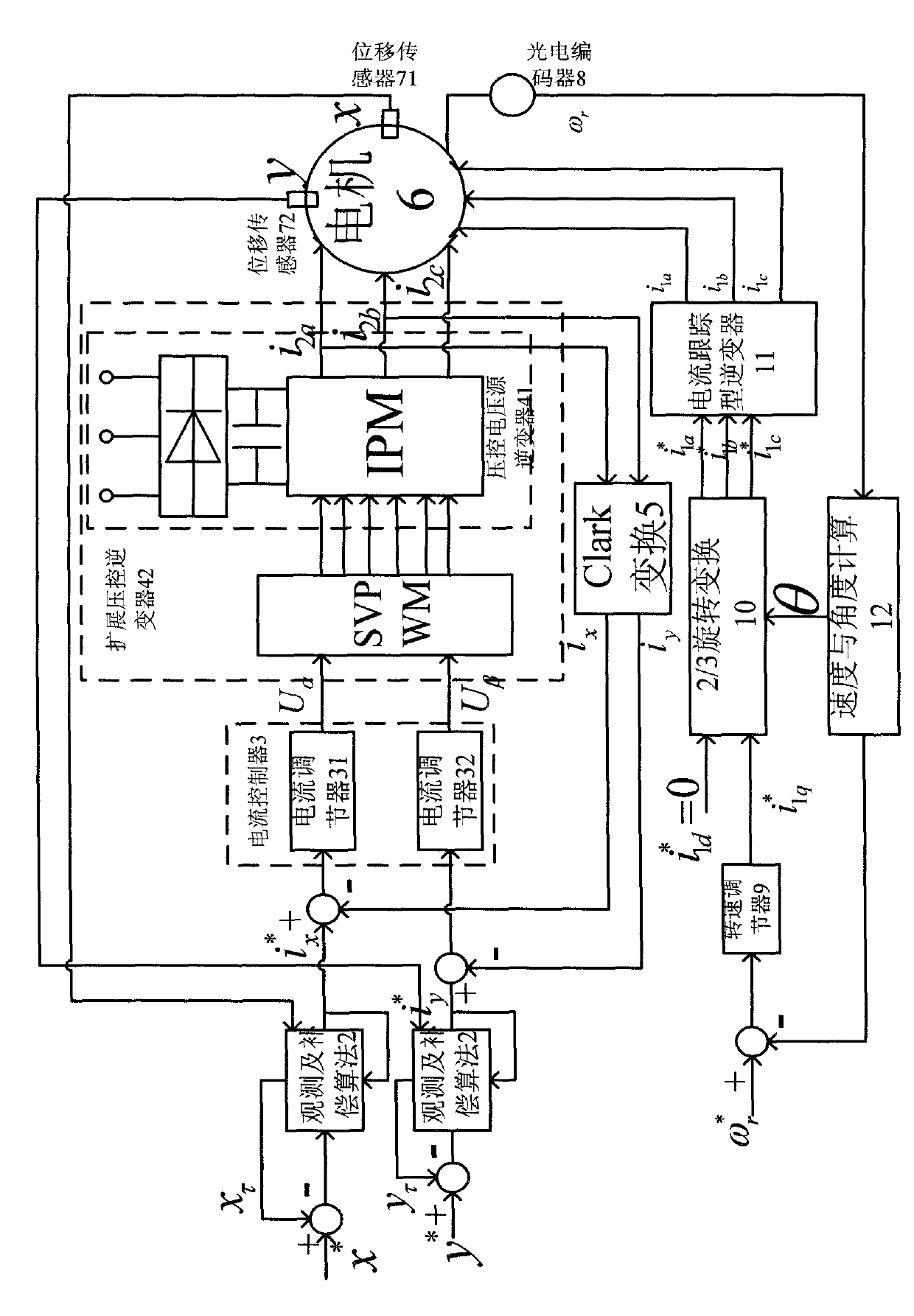

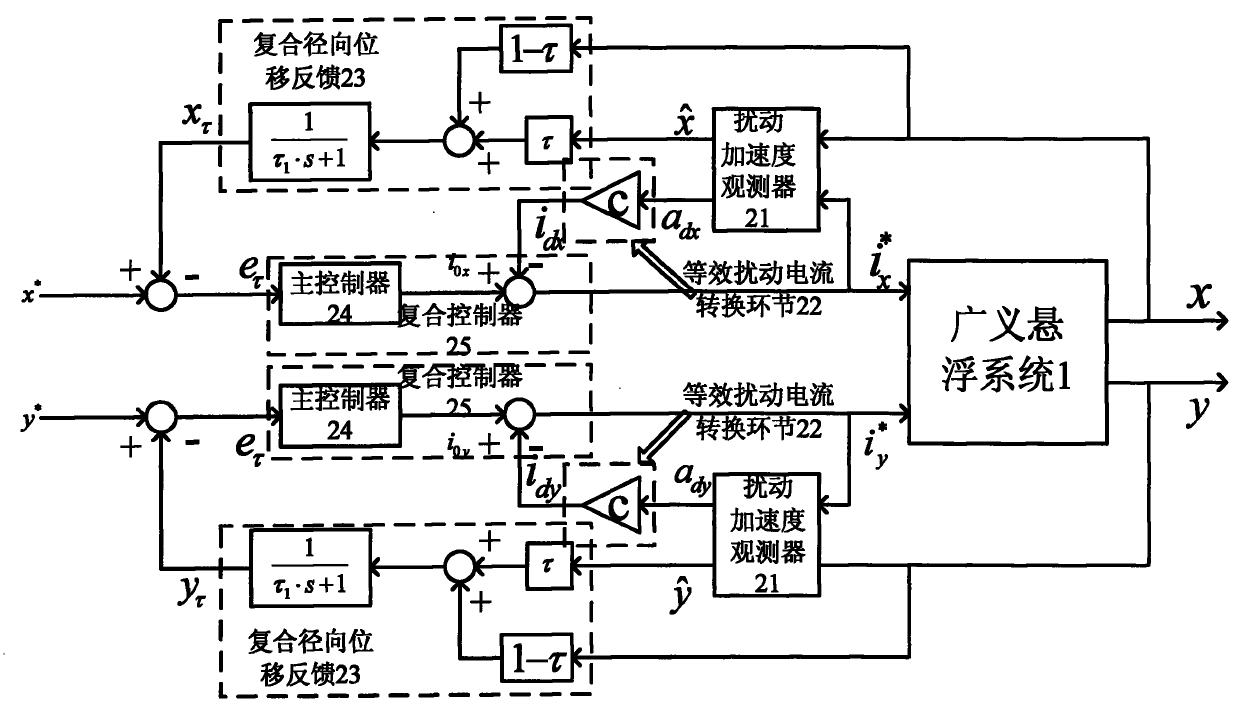

Suspension rotor equivalent disturbance current compensation control device for bearing-free permanent magnet synchronous motor

ActiveCN101795105APrecise control of radial displacementSmall pulsationSingle motor speed/torque controlObserver controlComposite controllerControl mode

The invention discloses a suspension rotor equivalent disturbance current compensation control device for a bearing-free permanent magnet synchronous motor. The control device is characterized in that: a generalized suspension system consists of an expended voltage controlled inverter, a current controller, a Clark transformer, a motor and a displacement sensor; observation and compensation algorithms are formed by connecting disturbance acceleration observers, equivalent disturbance current transforming links, composite radial displacement feedback, main controllers and composite controllers in sequence; two paths of observation and compensation algorithms are connected in series in front of the generalized suspension system and form a close-loop structure; and the control device is used for controlling a motor suspension system in a displacement ring of a bearing-free permanent magnet synchronous motor. The control device carries out the close-loop control on the displacement ring of the bearing-free permanent magnet motor suspension system of the consequent pole, and suppresses disturbance acting on the suspension system in a control mode of feedforward compensation. The control device observes disturbance acceleration generated by the suspension rotor of the motor because of disturbance effect through the disturbance observation algorithm in real time, and the algorithm does not dependent on a mathematical model of the suspension system and does not need to acquire specific forms of the disturbance in advance, so that the control device has wider adaptive range.

Owner:KUNSHAN PANGOLIN ROBOT

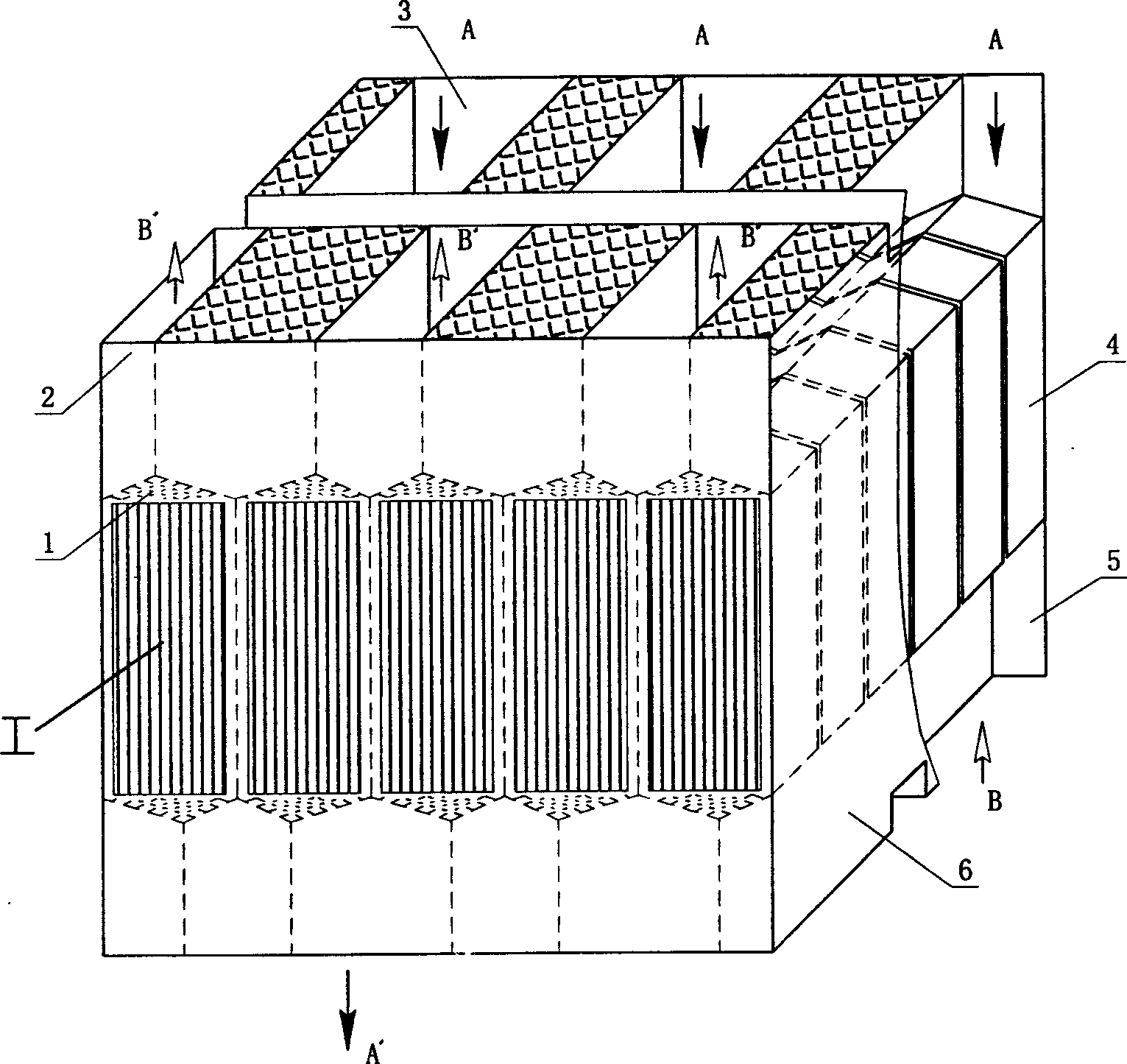

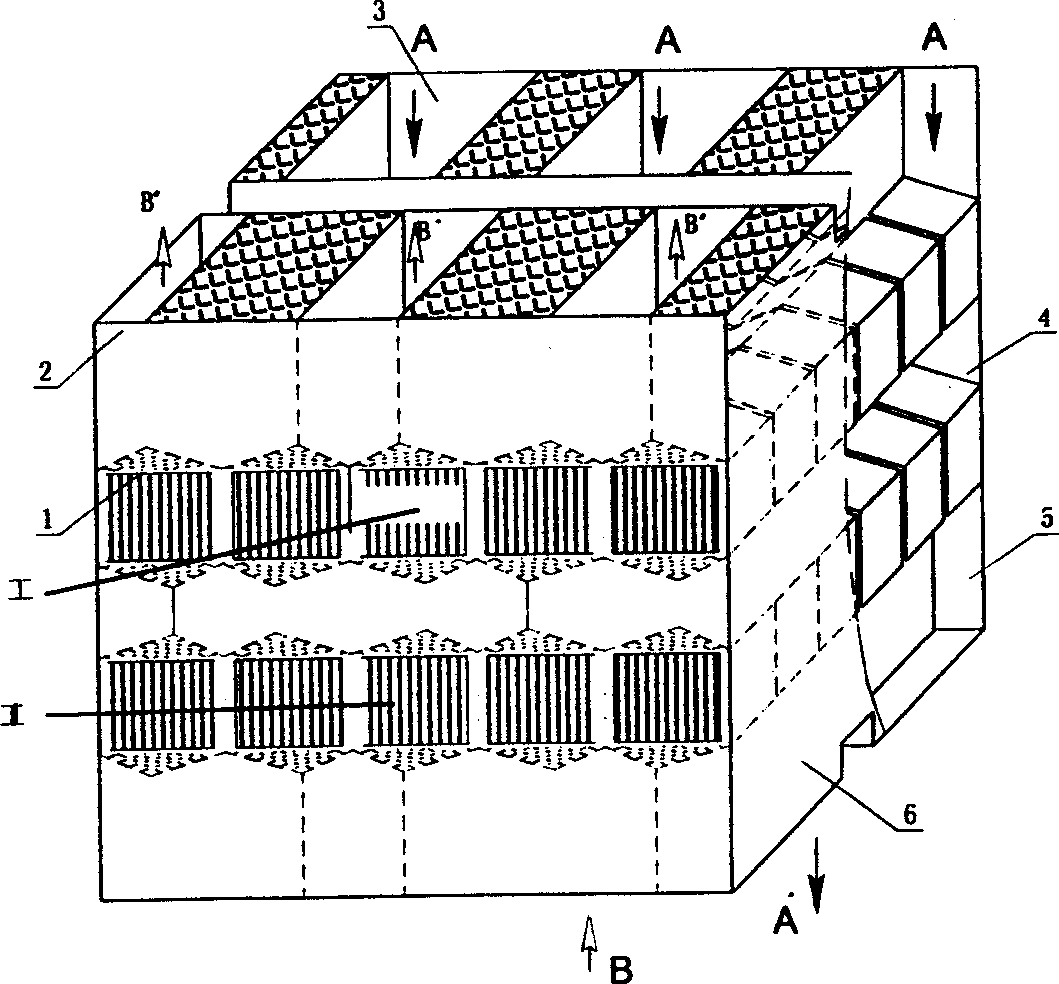

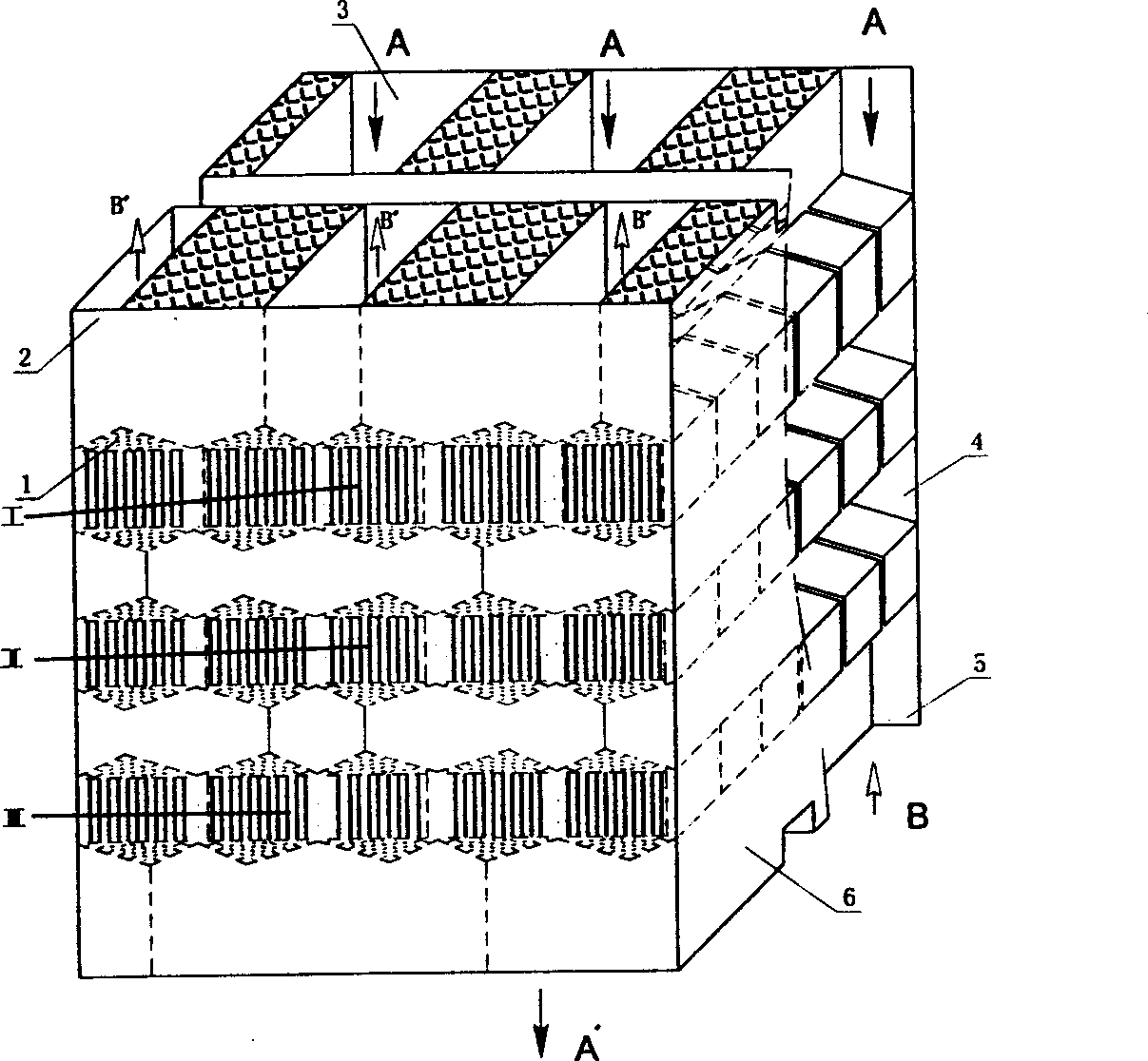

Plate type air preheater

ActiveCN1884915AEasy to blow sootSolve the problem of equipment dust accumulationCombustion processIndirect carbon-dioxide mitigationHeat transfer efficiencyEngineering

The invention relates to a sheet air preheating device, which comprises: a box, a heat exchange element, and an air-smoke entrance tubular box, wherein said box is arranged with sheet heat exchange element formed by sheet beam with at least one layer of one sheet beam module; the upper end of sheet beam is through to the smoke inlet tubular box and the air outlet tubular box, while the lower end is through to the smoke outlet tubular box and the air inlet tubular box; the sheet beam module is formed by layered ripple sheets; the air-smoke channels of sheet beam module are sealed channels with reversed direction. The invention uses reverse flow to exchange heat, with high efficiency, small volume, light weight and low cost.

Owner:GANSU LANPEC TECH +2

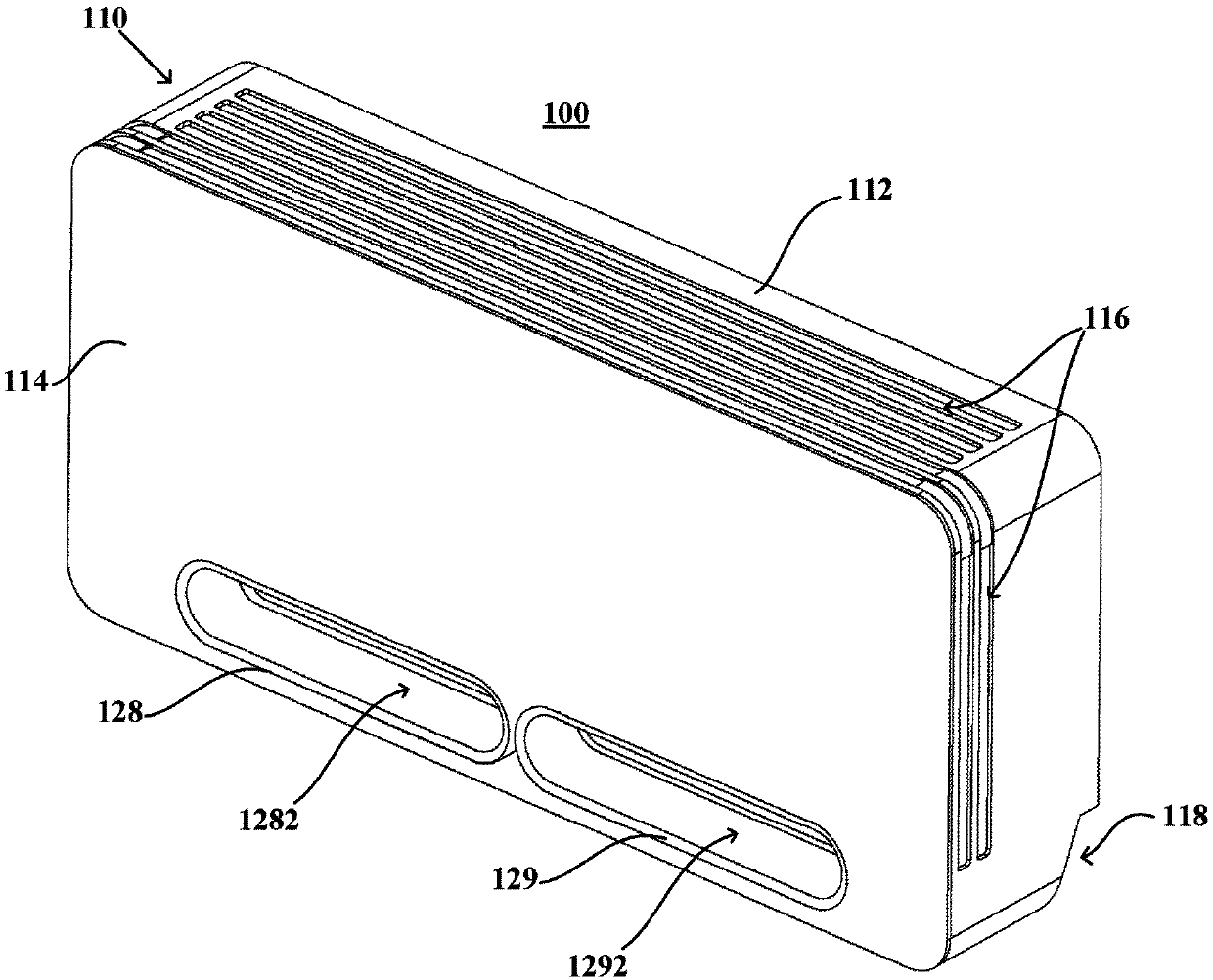

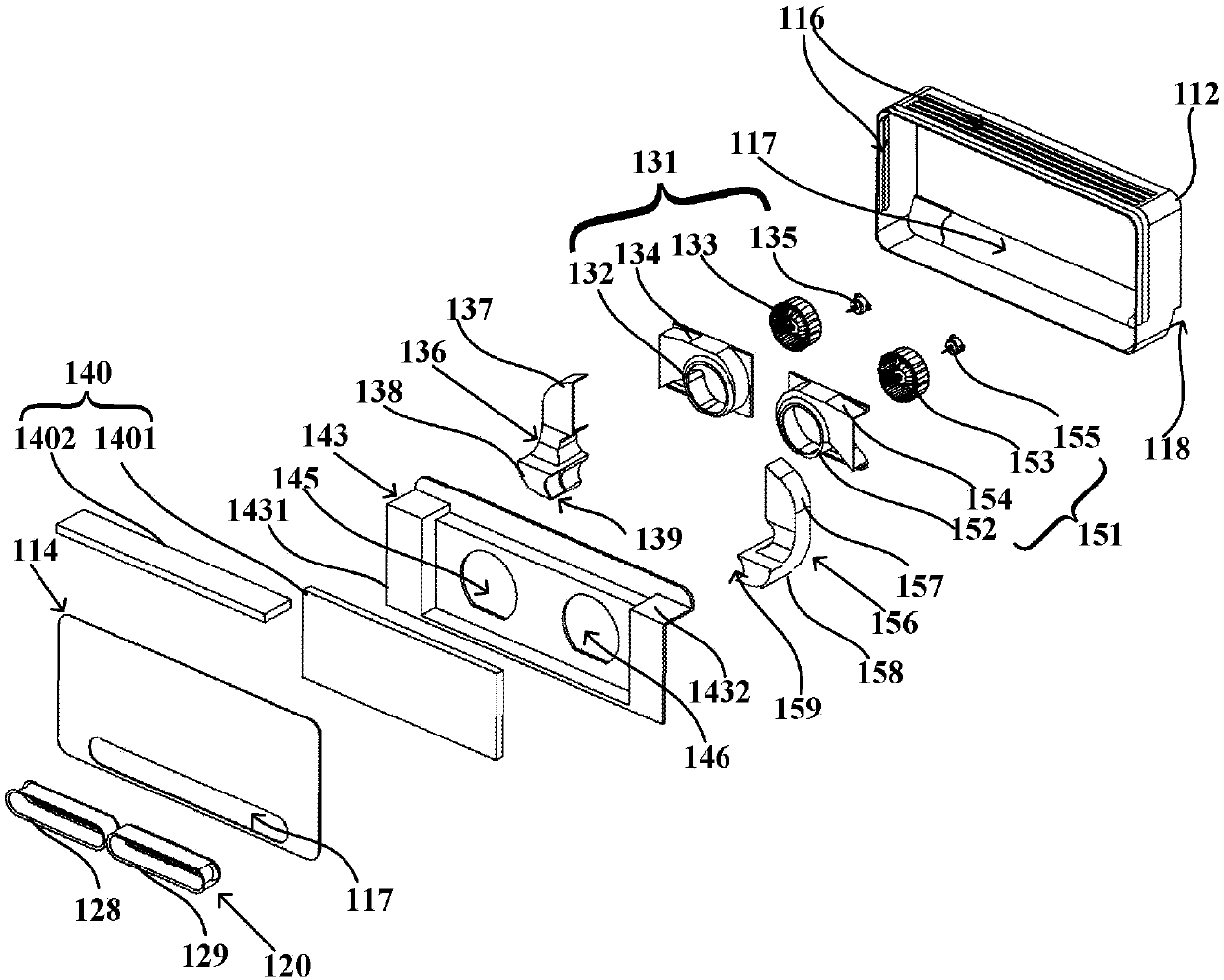

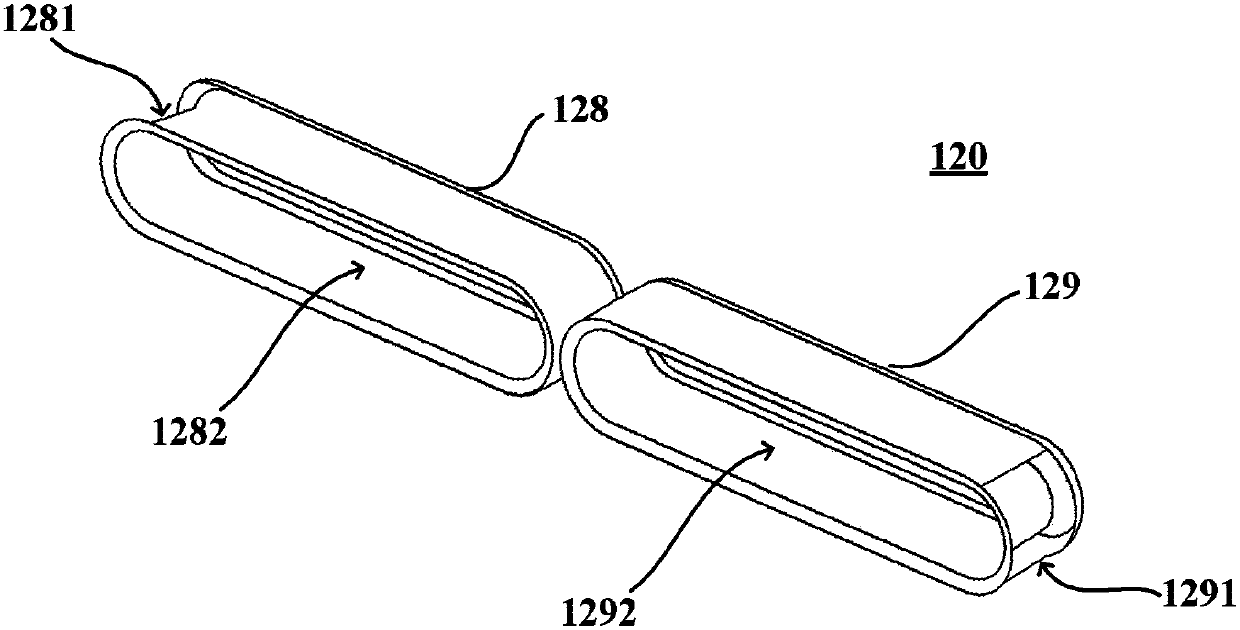

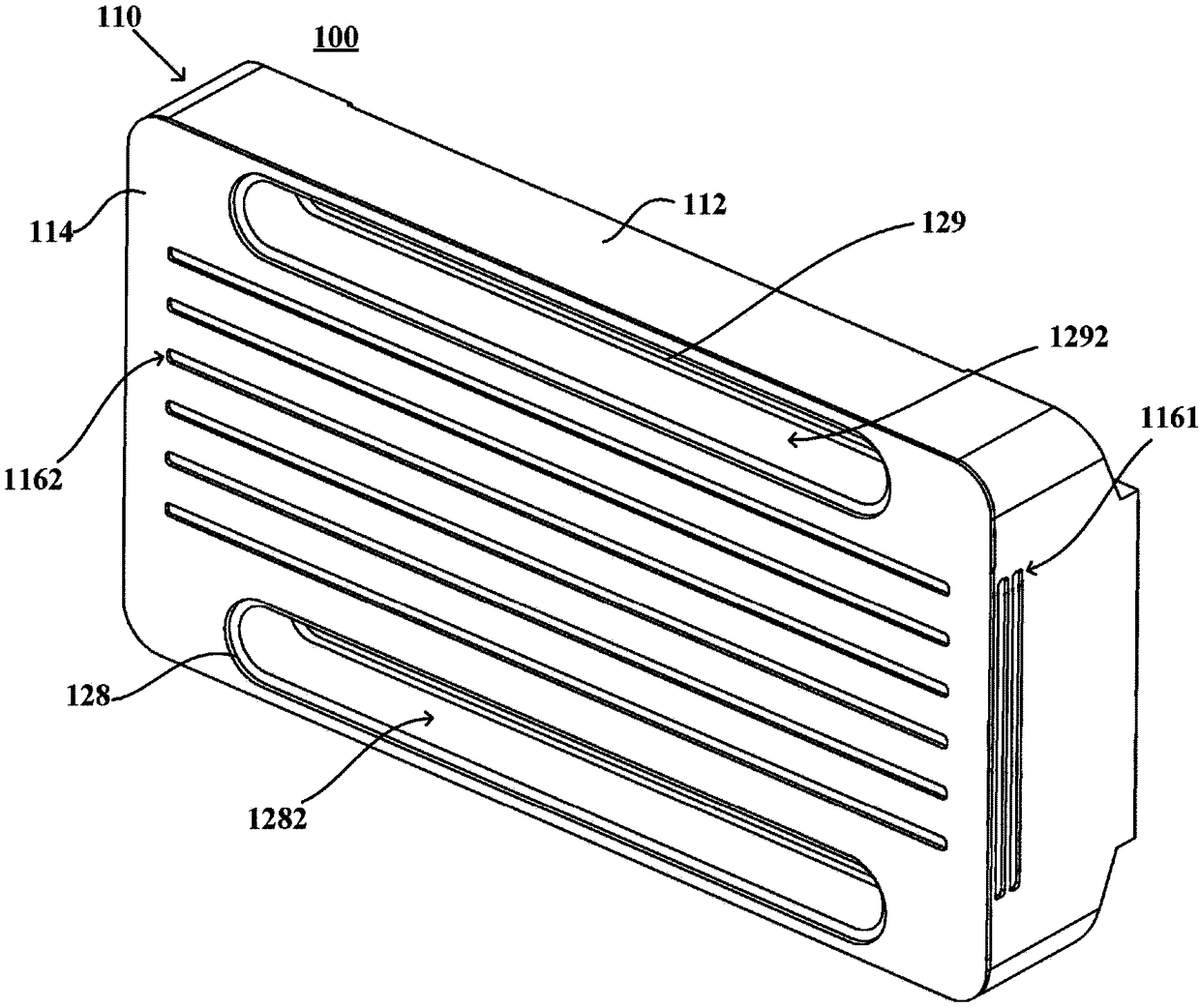

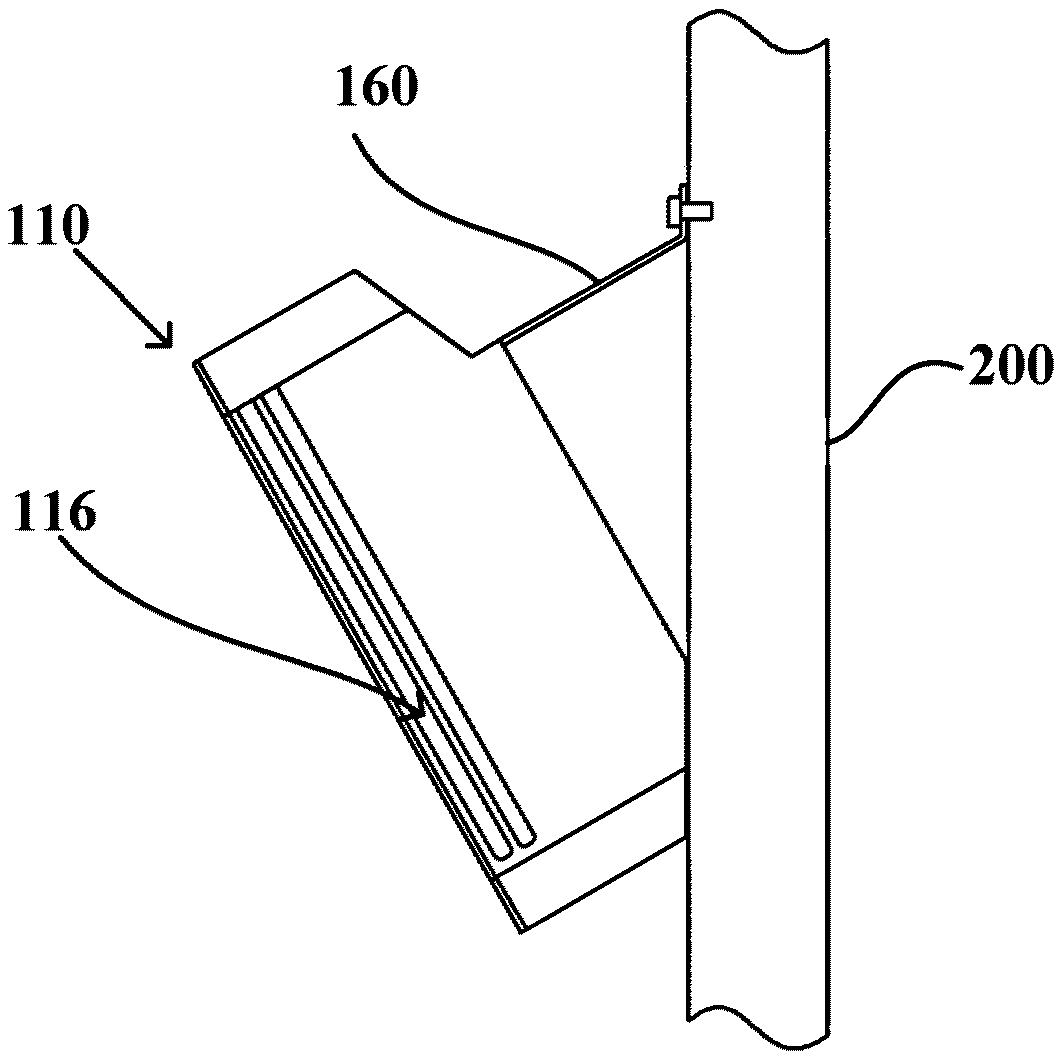

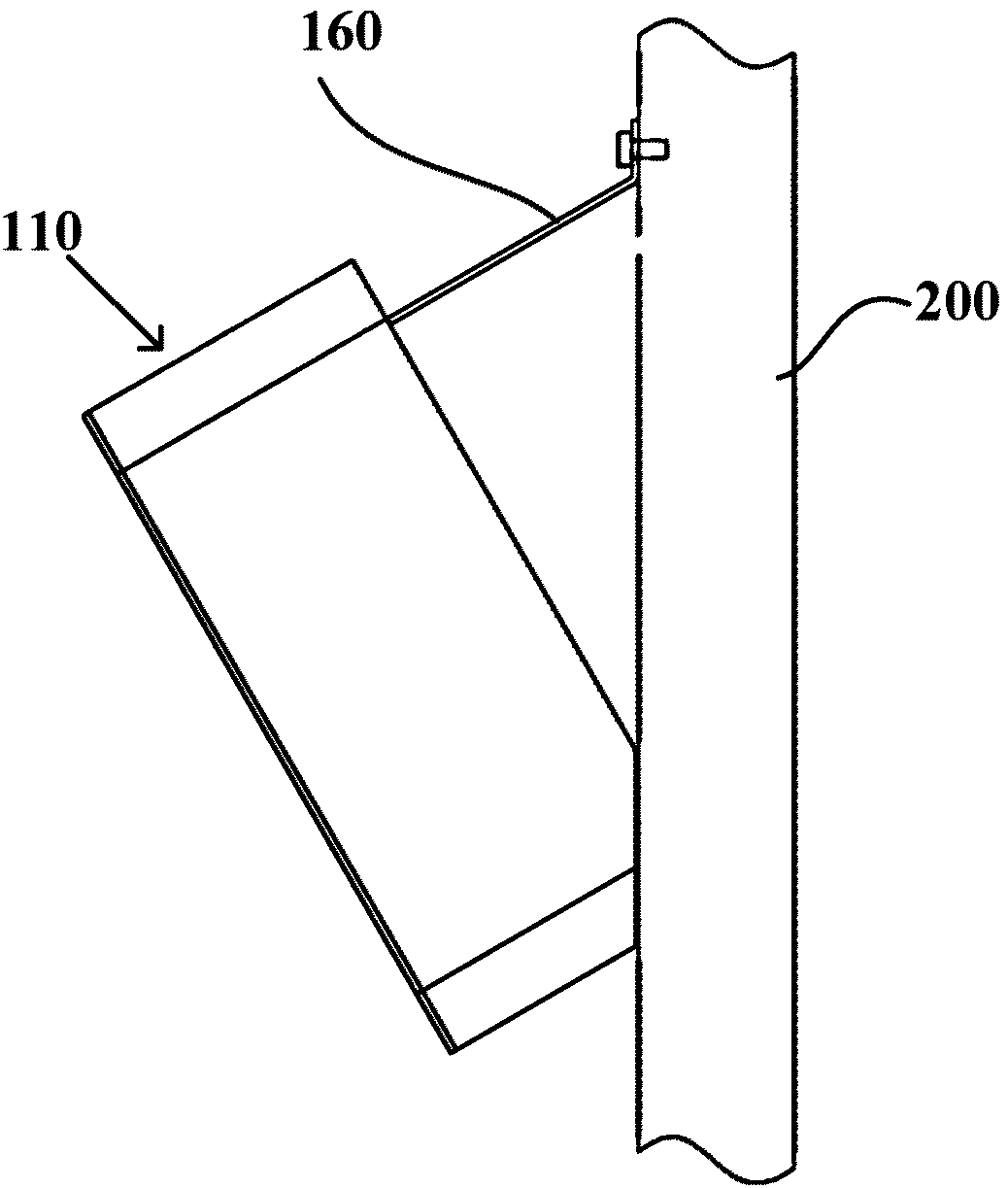

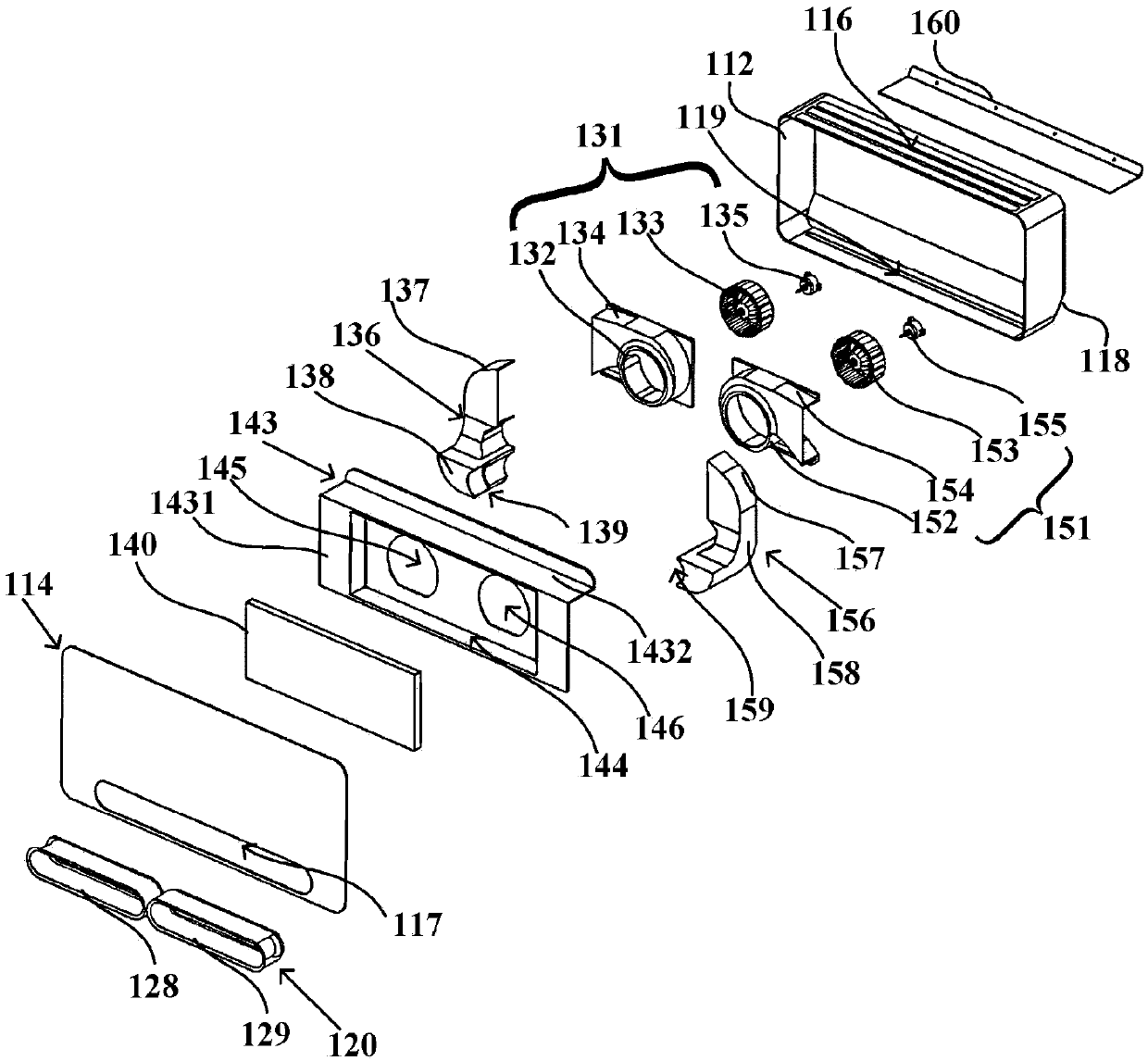

Wall-mounted air conditioner indoor unit

ActiveCN108050588ACompact structureGuaranteed unobstructedLighting and heating apparatusAir conditioning systemsWall mountWaste management

The invention provides a wall-mounted air conditioner indoor unit. The indoor unit comprises a shell, a heat exchanger, a first air jetting part, a second air jetting part, a first air supply assemblyand a second air supply assembly; the shell comprises a cover shell and a front panel arranged in front of the cover shell, the front panel is provided with a first air supply port and a second air supply port which are in long circle shapes, and the shell is arranged obliquely downward relative to a supporting wall so as to make the air supply ports be inclined downward; the heat exchanger is arranged in the shell, and the position of the heat exchanger communicates with an air inlet; the first air jetting part is arranged in the first air supply port, the second air jetting part is arrangedin the second air supply port, the inner circumferential wall of the first air jetting part and the inner circumferential wall of the second air jetting part are provided with a first air jetting port and a second air jetting port which allow the air flow subjected to heat exchange to be discharged correspondingly, and the air flow subjected to heat exchange drives the air in center air draft hole of the first air jetting part and the air in the center air draft hole of the second air jetting part to be sent out obliquely downward; and the first air supply assembly and the second air supply assembly are arranged in the shell at intervals, and are used for providing heat exchange air flows for the first air jetting part and the second air jetting part respectively. According to the scheme,the air supply amount is increased, so that the temperature of the indoor temperature is reduced integrally and uniformly.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD +1

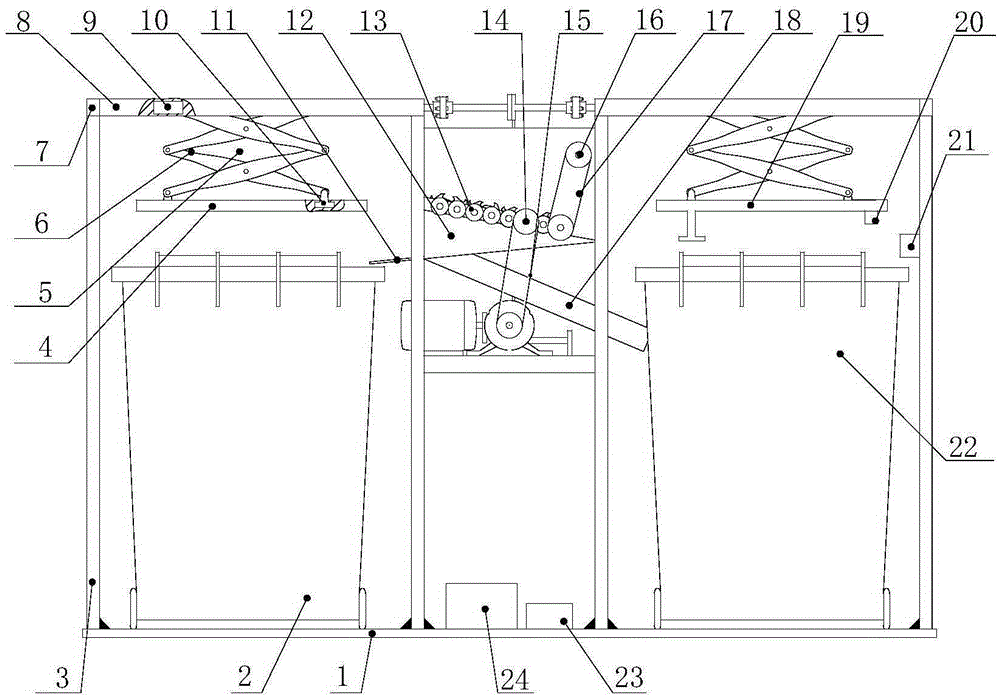

Rubbish compression device with automatic classification function

InactiveCN105292855AEasy to follow upImprove storage rateRefuse receptaclesCompression deviceEngineering

The invention provides a rubbish compression device with an automatic classification function, and relates to the field of environmental protection machines. The rubbish compression device is mainly used for classified recycling of thrown-in rubbish and comprises a bottom plate, a supporting frame, a rubbish can, a crushing and classifying mechanism, a compression mechanism, a power source, a belt wheel, a coupler, a speed reducer, a control device and the like. The compression mechanism and the crushing and classifying mechanism are mounted on the supporting frame. A direct-current motor is used for providing power needed by the device. The rubbish compression device can be used for accurately classifying and recycling the thrown-in rubbish, classified recycling of the rubbish is achieved, and conditions are provided for follow-up disposal of the rubbish.

Owner:绿亚科技服务(浙江)有限公司

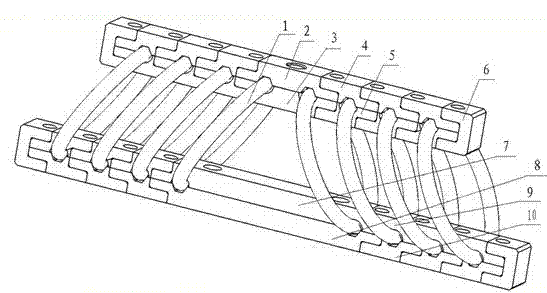

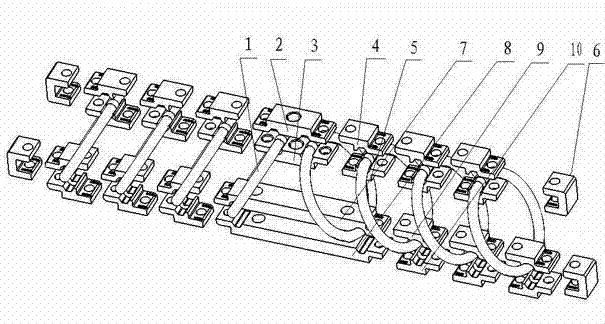

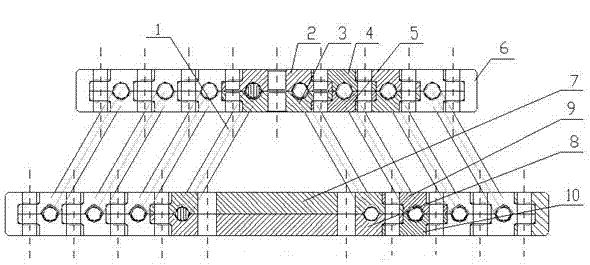

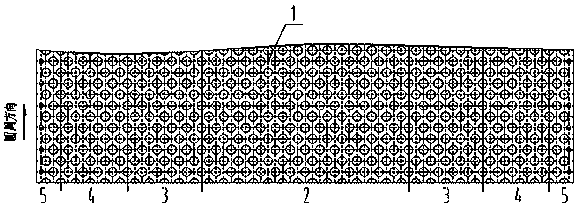

Combined type steel wire rope vibration isolator

InactiveCN102401056AGood for studying stiffnessGood for studying damping characteristicsShock absorbersShock resistanceBroadband

The invention discloses a combined type all-metal steel wire rope vibration isolator which is easy to disassemble, has various types of vibration isolation units with strong replaceability, variable rigidity and variable damping, reduces vibration quickly, has a simple structure and is convenient to install and maintain. The combined type steel wire rope vibration isolator mainly comprises a basic vibration isolating unit, an expandable vibration isolating unit and a buckle. The units are connected together through bolts. The vibration isolator has the characteristics of strong vibration isolation and reduction capacity in any direction, large damping, strong impact resistance capacity, good broadband vibration absorbing performance, obvious nonlinear characteristics, various combination modes and the like, is convenient to assemble and disassemble, convenient to package and easy to maintain and is suitable for mass production and single-piece character assembly. So the vibration isolator is widely applied in the fields of vibration reduction, vibration isolation and impact resistance of machinery and instruments under dynamic load.

Owner:CHONGQING UNIV

Column nail type high-pressure grinding roller roll surface and production method thereof

The invention discloses a production method of a column nail type high-pressure grinding roller roll surface. The production method comprises the following steps that molten steel refining, external refining, modification or spheroidizing are conducted on a working layer material and a core layer material; centrifugal pressure casting is conducted on a roller shell; then rough machining, annealing, quenching, tempering and finish machining are conducted on a roller shell workblank; blind holes are machined in the excircle surface of the roller shell blank; the textures of column nails at a first area in the middle of the roll surface are determined, and the hardness of the textures of the column nails at areas which are symmetrically distributed on the two sides of the first area is sequentially reduced by HRA 0.5-HRA 2; and the column nails at all the areas are installed into the blind holes of all the areas of the roll surface in transition fit and adhesive bonding modes. The production method has the advantages that treatment of a roller shell thermotechnical stage is completed at a time, a heat treatment link after machining is omitted, matching of column nail abrasive resistance is conducted through a roller shell abrasive resistance test, the textures of the column nails at all the areas are selected, and even abrasion of the roll surface is achieved; and the column nailsare installed by adopting the transition fit and adhesive bonding modes, and therefore installation and replacement of the column nails are convenient.

Owner:CHENGDU LEEJUN IND +1

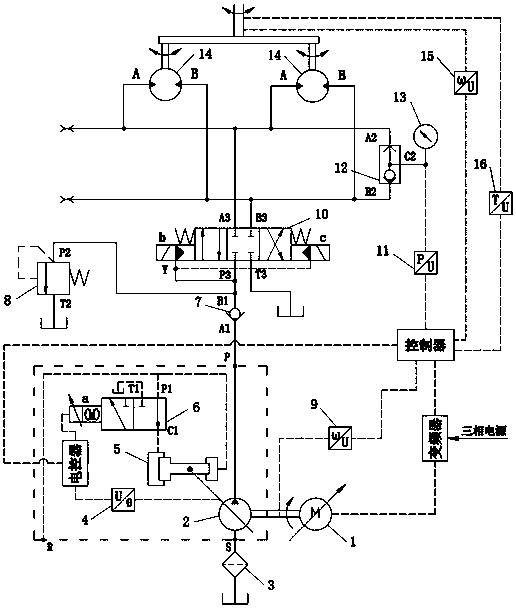

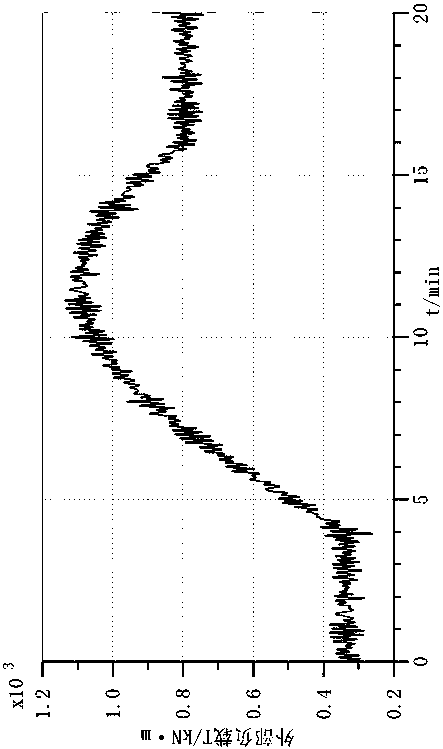

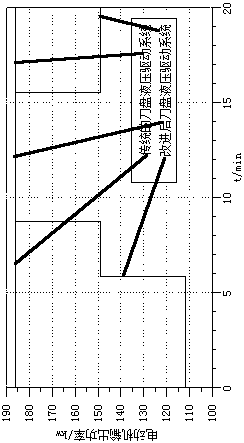

Shield knife disc hydraulic driving system and method in intelligent variable power control mode

Disclosed are a shield knife disc hydraulic driving system and method in an intelligent variable power control mode. The shield knife disc hydraulic driving system includes a motor, a variable pump and a one-way valve connected with one another in sequence. The one-way valve is connected with an overflow valve and a three-position four-way electro-hydraulic directional valve. The three-position four-way electro-hydraulic directional valve is connected with a constant displacement motor and a shuttle valve. The motor is a three-phase asynchronous motor. An input shaft and an output shaft of themotor are provided with a frequency converter and a first revolution speed transducer. An angular transducer in a swash plate of the variable pump is connected with a variable pump electric controller. A left cavity of a servo plunger piston of the variable pump communicates with a control oil port C1 of a two-position three-way high-speed switch valve. a right cavity of the servo plunger pistoncommunicates with an external pilot pressure oil port R. an oil inlet P1 and an oil returning mouth T1 of the two-position three-way high-speed switch valve communicates with the external pilot pressure oil port R and an oil box correspondingly. A second revolution speed transducer, a torque transducer, a frequency changer on the shield knife disc, an electric controller of the variable pump, a second revolution speed transducer and a pressure sensor of a shuttle valve oil outlet C2 pipe are all connected with a controlling device.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

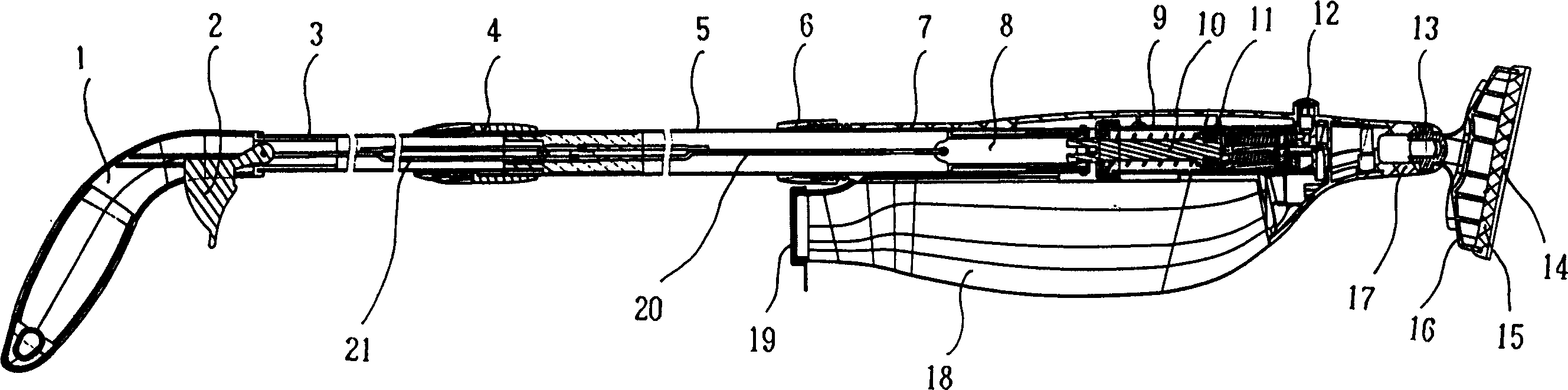

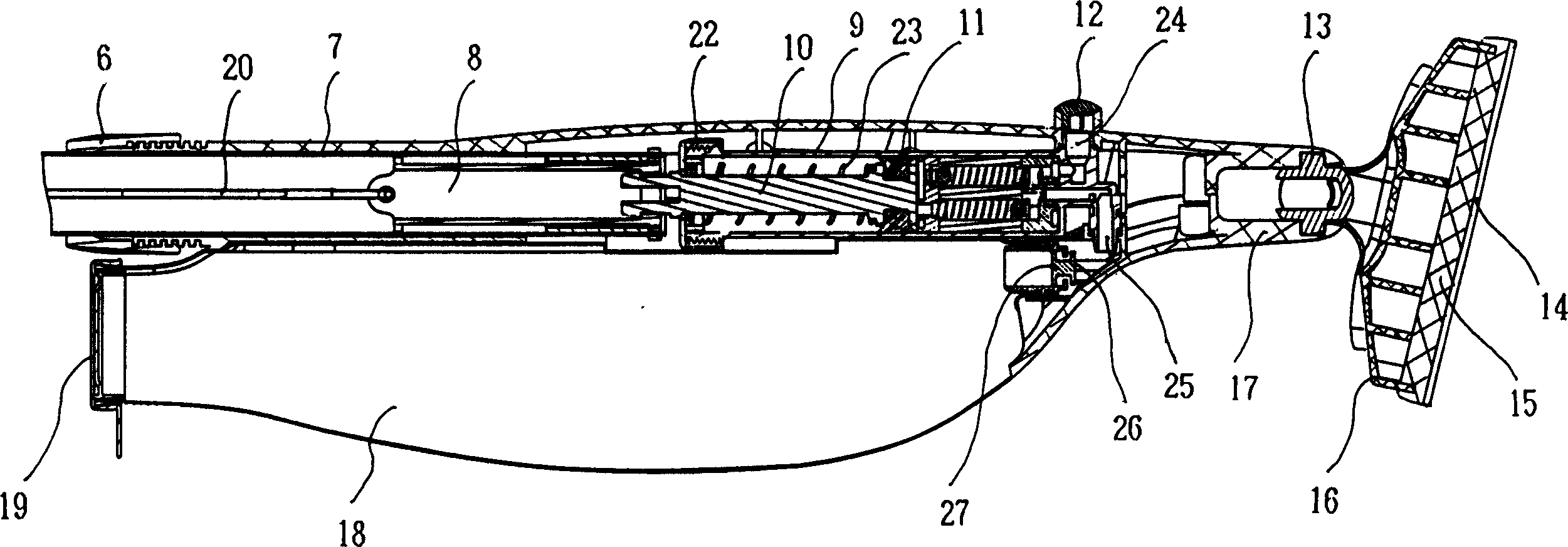

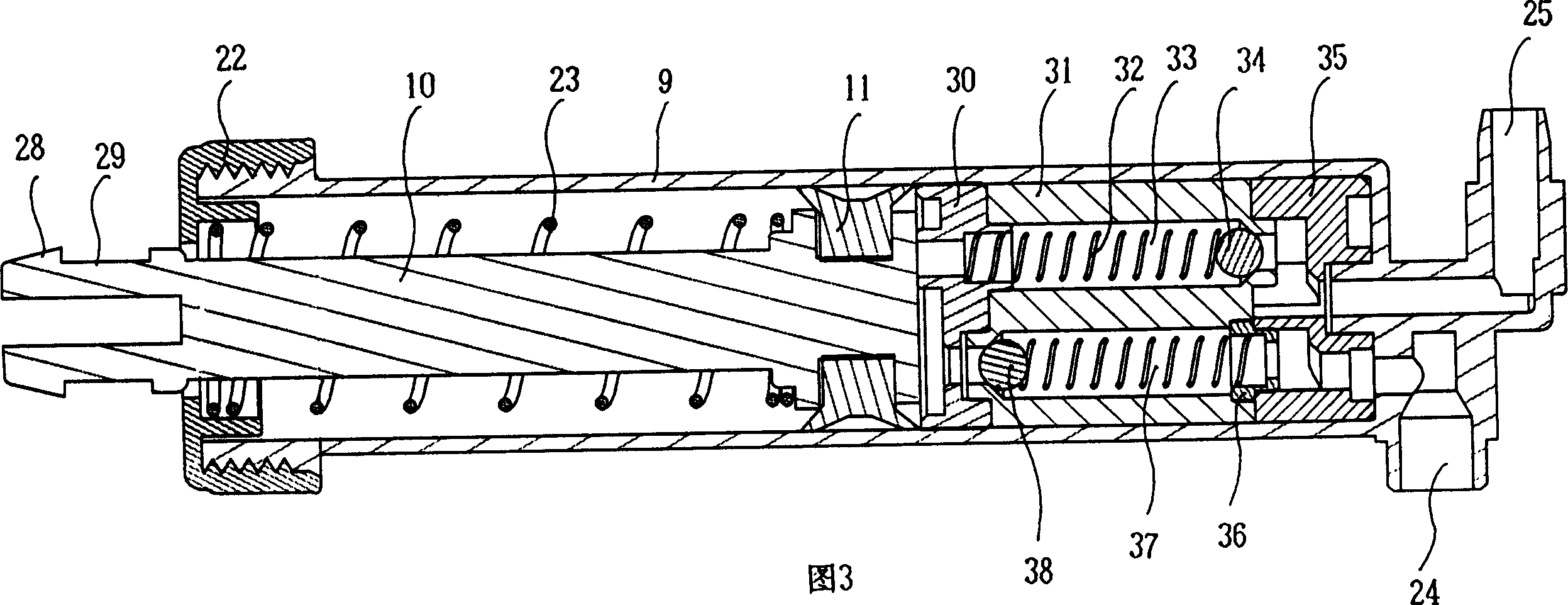

Mop with liquid-sprayer

InactiveCN1559335AGreat advantageLarge amount of waterCarpet cleanersFloor cleanersSprayerWater flow

A mop able to spray liquid is composed of mop handle, liquid spraying unit consists of liquid spray manipulating mechanism, liquid sucking-discharging mechanism and liquid storage bottle, and cleaning part. The amount of sprayed liquid and the speed and direction of spraying liquid are controll able.

Owner:李爱良

Boracic wear-resisting alloy steel and preparation method thereof

The invention discloses boracic wear-resisting alloy steel and a preparation method thereof. The boracic wear-resisting alloy steel is prepared from, by mass percent, 0.20%-0.5% of C, 2%-6% of Cr, 0.4%-1.0% of Si, 3.0%-5.0% of Mn, 0.3%-2.5% of B, 0.2%-1.2% of Cu, 0.2%-0.6% of Ti, 0.05%-0.25% of Ca, 0.03%-0.3% of ReSiMg, 0.02%-0.18% of N, 0.05%-0.3% of Nb, 0.03%-0.08% of Al, 0.04%-0.13% of K, smaller than 0.03% of S, smaller than 0.04% of P and the balance Fe. Melting is carried out through an intermediate frequency furnace until the temperature ranges from 1,560 DEG C to 1,620 DEG C, ferrovanadium, ferrotitanium, potassium oxide, a silicon-calcium-barium alloy and nitrogen containing ferrochromium which are 60 meshes to 100 meshes, BC, BN, B2O3, Si3N4, Al and ReSiMg are matched according to the mass percent and then rolled into a metal cored wire with the diameter ranging from 8 mm to 15 mm through low-carbon steel with the thickness ranging from 0.12 mm to 0.25 mm, the metal cored wire is added into smelted molten steel as a boron supplying agent for boron supplying and metamorphic inoculation treatment, and the casting temperature of the molten steel ranges from 1,400 DEG C to 1,450 DEG C; and a casting is subjected to heat preservation for 2-4 hours at the temperature ranging from 920 DEG C to 1,150 DEG C, and air cooling is carried out to room temperature. The boracic wear-resisting alloy steel is good in strength, hardness, toughness, heat fatigue resistance and wear resistance and low in production cost.

Owner:DANYANG JIAWEI WEAR RESISTANT MATERIAL TECH CO LTD

Early overflow and leakage monitoring system for well drilling

ActiveCN109403894AImprove monitoring accuracyMeet the measurementSurveyFlushingWater basedDischarge measurements

The invention discloses an early overflow and leakage monitoring system for well drilling. The early overflow and leakage monitoring system for the well drilling comprises a Y-shaped elevated pipe; the Y-shaped elevated pipe comprises a main pipe and two measuring pipes, the two measuring pipes are symmetrically welded to the main pipe, an elevated hose-pipe is connected to one end of the Y-shapedelevated pipe, a pneumatic shut-off valve and an elevated pipe are connected to the other end of the Y-shaped elevated pipe through a flange, and shut-off valves and mass flow meters are correspondingly installed on the two measuring pipes; two buffer tanks are symmetrically distributed on both sides of the elevated pipe; and measurement signals of the mass flow meters, a mud pool level gauge, abell mouth level gauge, a pump stroke sensor, a turntable torque sensor, a turntable rotary speed sensor, a stand pressure sensor and a casing pressure sensor are transmitted to a monitoring control alarm device through signal cables, and the monitoring control alarm device controls a switch of the pneumatic shut-off valve and performs pre-alarm of overflow and leakage. The early overflow and leakage monitoring system for the well drilling is suitable for flow measurement of water-based and oil-based mud, and the monitoring accuracy of the wellbore outlet flow is improved.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD +1

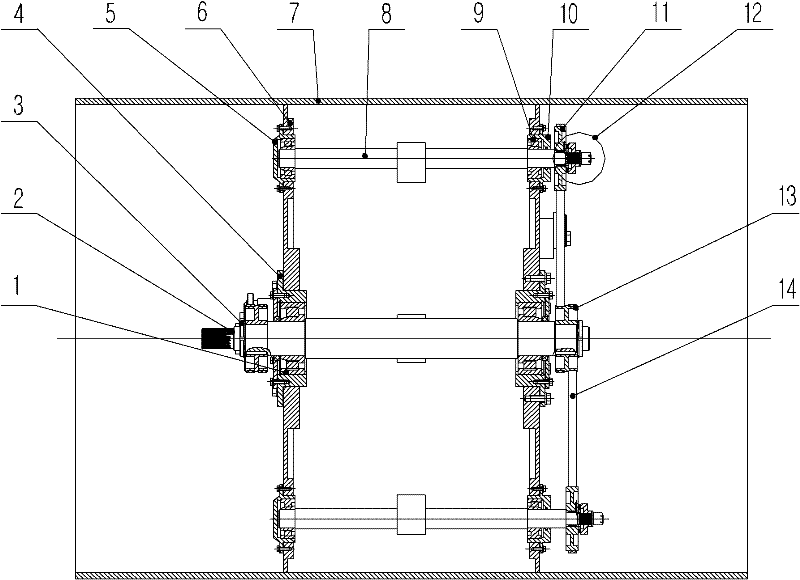

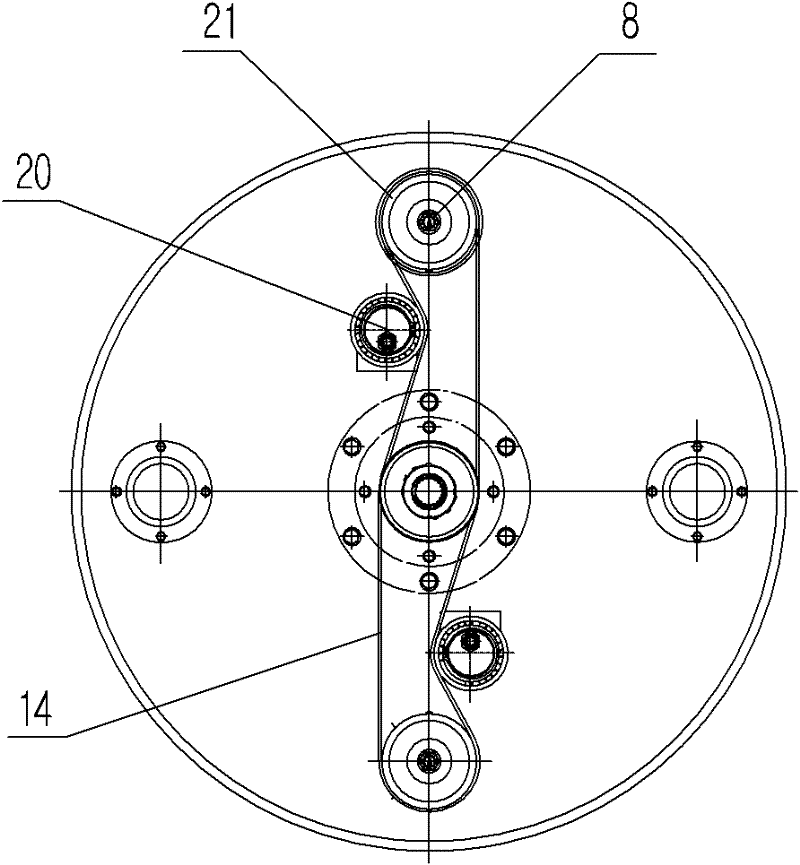

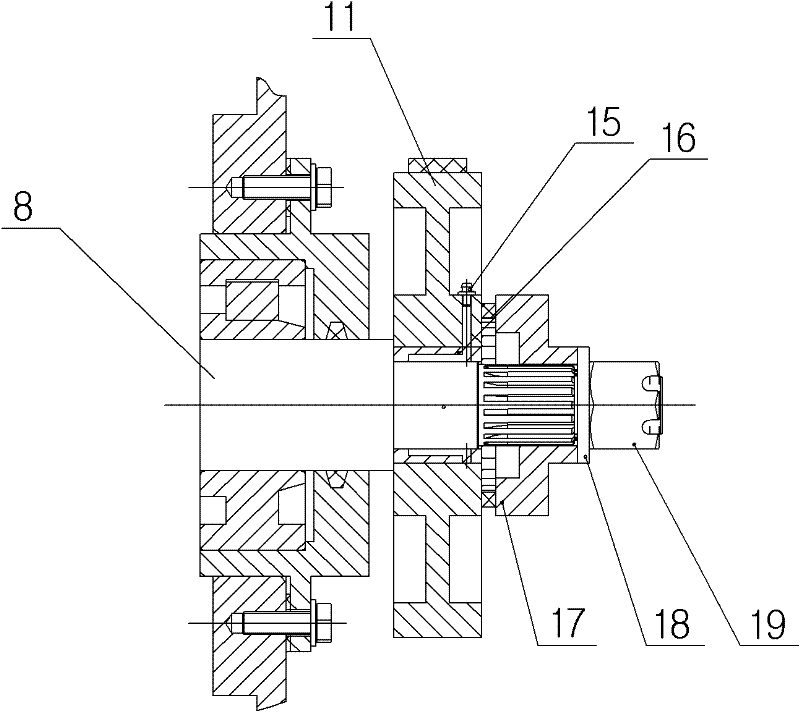

Road roller combining vibration, oscillation and complex excitation as whole

ActiveCN102454151ADense and flat surfacePrevent looseningRoads maintainenceWheel cylinderEngineering

The invention discloses a road roller combining vibration, oscillation and complex excitation as a whole, which comprises a frame; an engine, a vibrating wheel, and a transmission part connected with the engine are disposed in the frame; a cab is disposed above the frame; the vibrating wheel comprises a vibrating wheel cylinder body; a center shaft is disposed at the center of the vibrating wheel cylinder body; four eccentric shafts are disposed around the center shaft with equal angles; the eccentric shafts are mounted on a supporting plate disposed on the vibrating wheel cylinder body; the end parts of the eccentric shafts are movably connected with driven pulleys; the driven pulleys are connected by a driving belt with driving pulleys which are disposed at the end part of the center shaft and at the same side as the driven pulleys; the driven pulleys are connected with a phase adjusting mechanism by gears at the end surfaces. The invention combines vibration, oscillation and complex excitation functions as a whole, enhances the application effect, expands the application scope, has a simple structure, is convenient for using, and is convenient for popularization and application.

Owner:SHAANXI JOINTARK MASCH GRP CO LTD

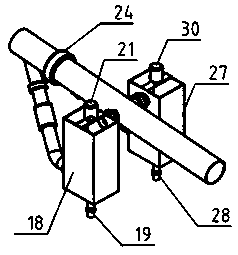

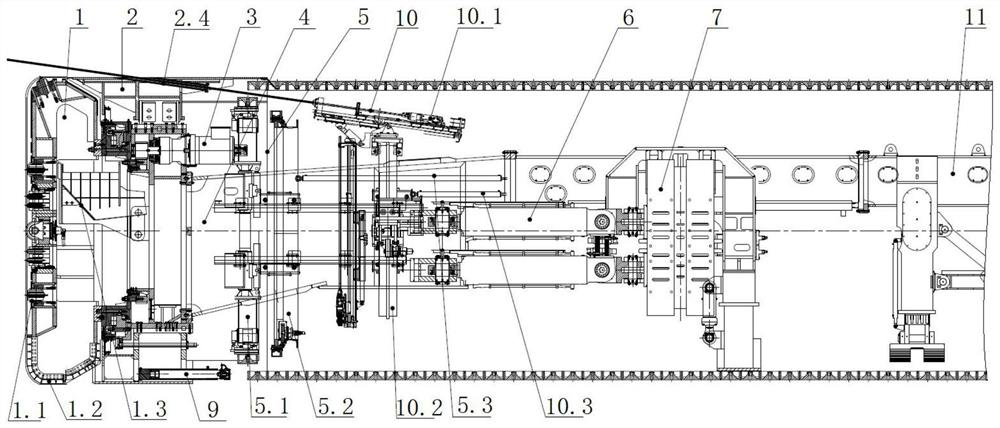

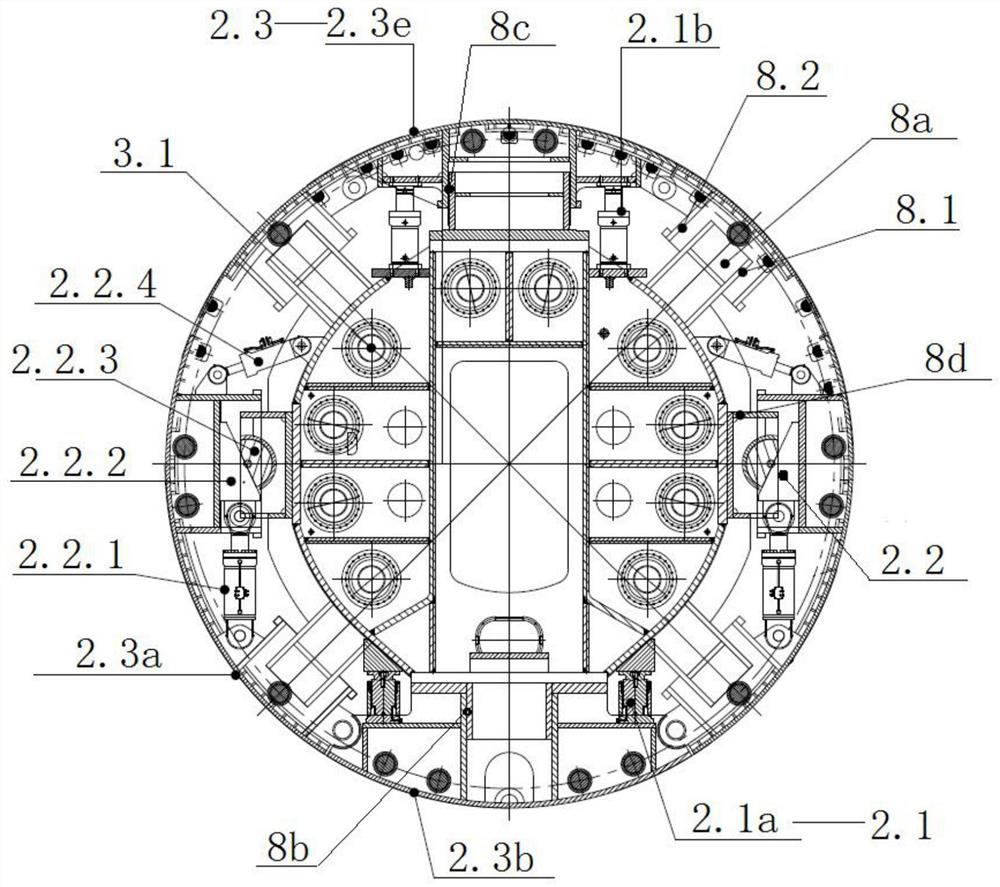

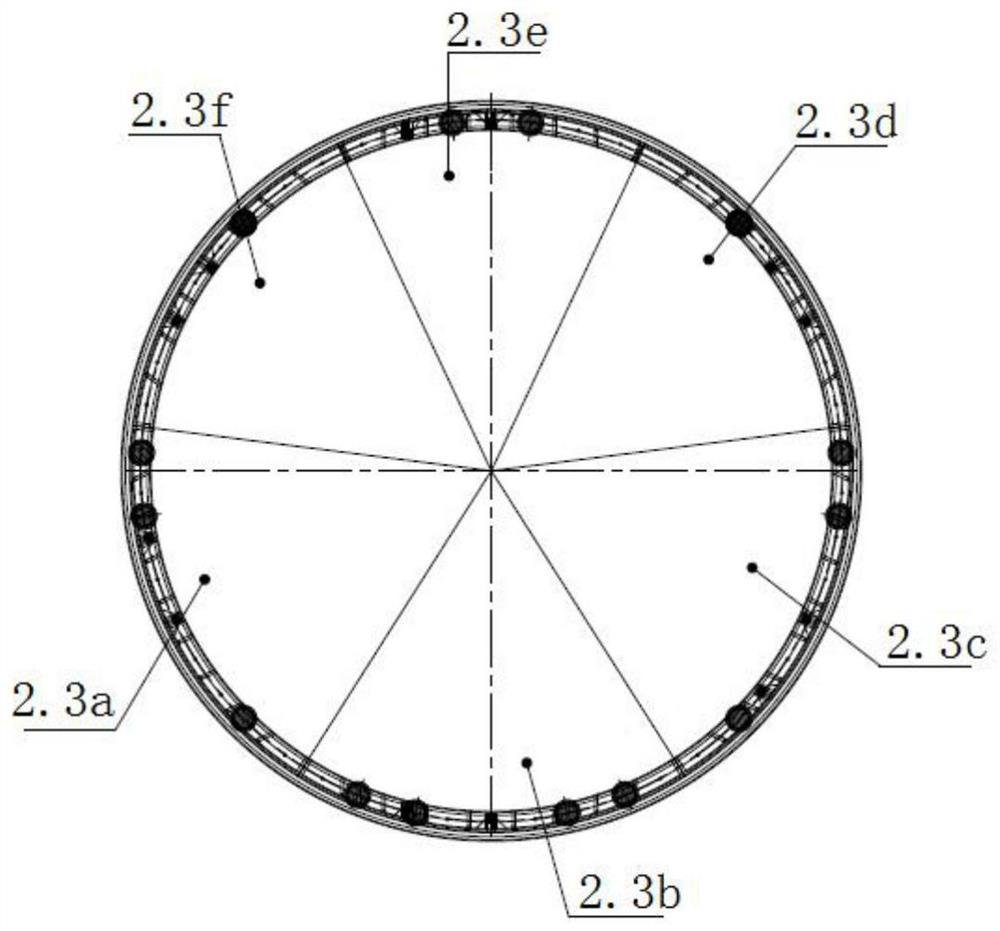

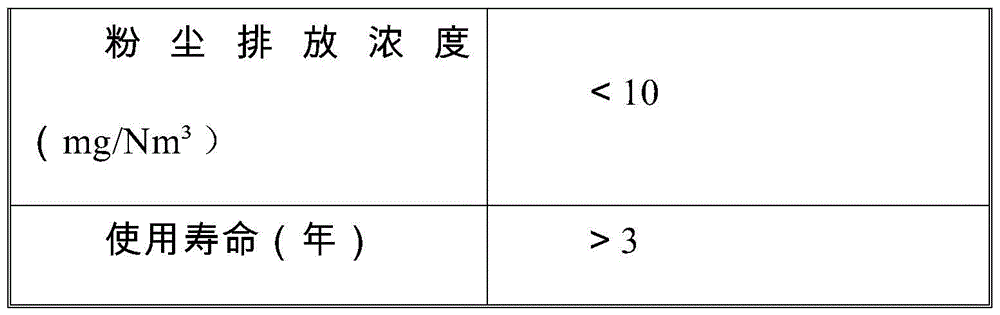

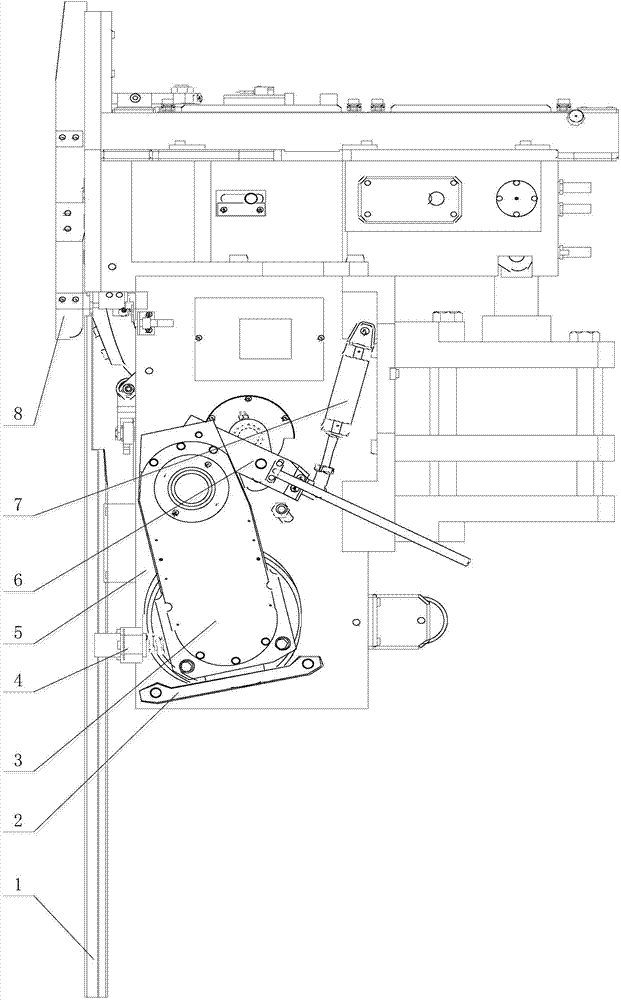

Hard rock tunnel boring machine

ActiveCN112554899ARapid expansionSmooth liftUnderground chambersTunnel liningTunnel boring machineRock tunnel

The invention provides a hard rock tunnel boring machine. The hard rock tunnel boring machine comprises a cutter head, a front shield, a main drive, a connecting bridge, a multifunctional assembling machine, a main propelling system and a tight supporting shield; the cutter head and the front shield are both connected with the main drive and used for driving the cutter head to work and protectingthe main drive; one end of the connecting bridge is connected with the front shield, and the other end of the connecting bridge is connected with the tight supporting shield; one end of the main propelling system is connected with the connecting bridge, and the other end of the main propelling system is connected with the tight supporting shield and used for providing thrust in the tunneling process; the connecting bridge is connected with the multifunctional assembling machine in a sliding manner; and the multifunctional assembling machine comprises a segment assembling machine body and a steel arch assembling machine body and is used for assembling segments, steel tiles and steel arches. The multifunctional assembling machine is installed on the connecting bridge and comprises the segment assembling machine body and the steel arch assembling machine body, and therefore different supporting modes can be selected according to different geologies when tunnel boring is conducted under the complex geological conditions.

Owner:CHINA RAILWAY CONSTR HEAVY IND

Wall-mounted air conditioner indoor unit

InactiveCN108072108ASpeed up the flowSoft airflowLighting and heating apparatusHeating and ventilation casings/coversAir volumeAmbient air

The invention provides a wall-mounted air conditioner indoor unit. The indoor unit comprises a casing, a heat exchanger, a first air spraying part, a second air spraying part, a first air supplying assembly and a second air supplying assembly; the casing comprises a housing and a front panel arranged in front of the housing; a long and round first air supplying opening and a long and round secondair supplying opening which are formed at an interval are formed in the front panel; side wall air inlets are formed in two sides of the housing; panel air inlets are formed between the first air supplying opening and the second air supplying opening; the heat exchanger is arranged in the casing; the first air spraying part is arranged in the first air supplying opening; the second air spraying part is arranged in the second air supplying opening; a first air spraying opening and a second air spraying opening which supply air flows after heat exchange are correspondingly formed in the inner circumferential wall of the first air spraying part and the inner circumferential wall of the second air spraying part; heat-exchange air flows drive the ambient air in central air drawing holes of thefirst air spraying part and the second air spraying part to be sent out; the first air supplying assembly and the second air supplying assembly are arranged inside the casing at an interval and are used for providing the heat-exchange air flows for the first air spraying part and the second air spraying part correspondingly. According to the scheme, the air supplying volume is increased, and the indoor temperature is reduced in an overall even manner.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD

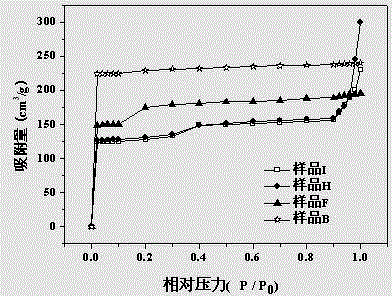

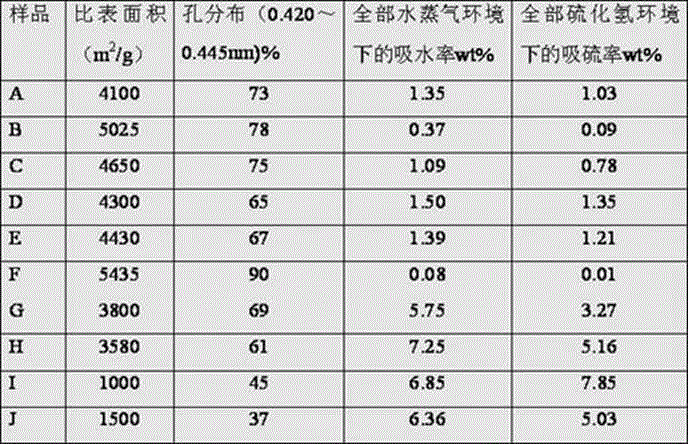

Preparation method of ferrous metal organic framework material and application of ferrous metal organic framework material

ActiveCN104549161AHigh affinityHigh selective adsorption capacityOther chemical processesGaseous fuelsIonSelective adsorption

The invention relates to a preparation method of a ferrous metal organic framework material. The preparation method comprises the following steps of dissolving ferrite and 2, 6-naphthalenedicarboxylic acid into deionized water; adding tartaric acid and acetic acid under a stirring condition; adding the obtained precursor solution into a stainless steel high-pressure reaction kettle for hydrothermal reaction to obtain precipitates, then washing the precipitates sequentially by deionzed water, N, N-dimethylformamide and acetone respectively; and centrifuging, filtering and drying so as to obtain the ferrous metal organic framework material. The invention also relates to the application of the ferrous metal organic framework material prepared by the method disclosed by the invention in adsorbing methane in natural gas. The ferrous metal organic framework material obtained by the method is large in specific surface area, is reasonable in pore volume distribution, is obviously intensified in the affinity with a methane molecule, and is relatively high in sulfur pollution resistance, the severity of the operation condition for selectively adsorbing methane from natural gas is further reduced, the flexibility of a small LNG device is greatly improved, and the cost is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Wall-mounted air conditioner indoor unit

PendingCN108050586ASoft airflowFeel comfortableLighting and heating apparatusHeating and ventilation casings/coversAir volumeAirflow

The invention provides a wall-mounted air conditioner indoor unit. The wall-mounted air conditioner indoor unit comprises a shell, an air jetting component, a first air supplying assembly and a secondair supplying assembly, the shell is provided with a housing and a front panel, and air inlets are formed in the top wall and the side wall of the housing correspondingly. A long circular air supplyopening is formed in the lower portion of the front panel. The shell is arranged to be obliquely downward relative to a support wall so as to enable the air supplying opening to face downwards and obliquely. The air jetting component is arranged in the air supplying opening, an air exhausting hole is defined in the inner side of the annular inner wall of the air jetting component, an air supplyingcavity is defined by the annular outer wall and the annular inner wall jointly, and an air jetting opening is formed in the connected edges of the annular outer wall and the annular inner wall. A first air inlet and a second air inlet which are used for supplying heat exchange air flows to the air supplying cavity are formed in the transverse two ends of the annular outer wall correspondingly. The air jetting opening is used for jetting air of the air supplying cavity out and enabling environment air to be exhausted to penetrate through the air supplying opening. The first air supplying assembly and the second air supplying assembly are used for generating the heat exchange air flows supplied into the air supplying cavity through the first air inlet and the second air inlet correspondingly. According to the wall-mounted air conditioner indoor unit, the air supplying quantity is increased to enable the indoor temperature to be overall evenly decreased.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD

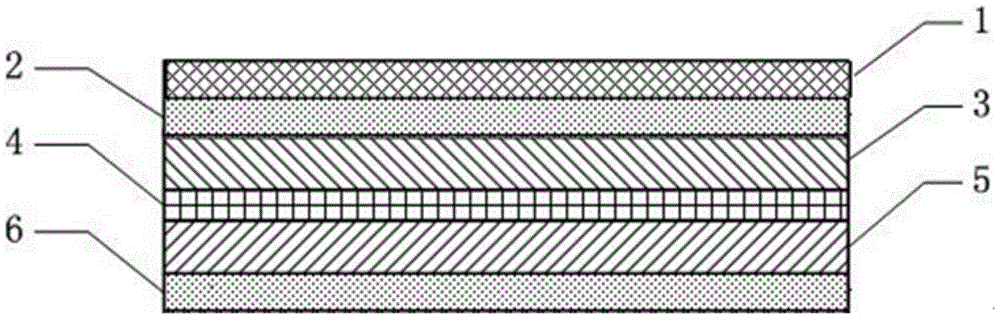

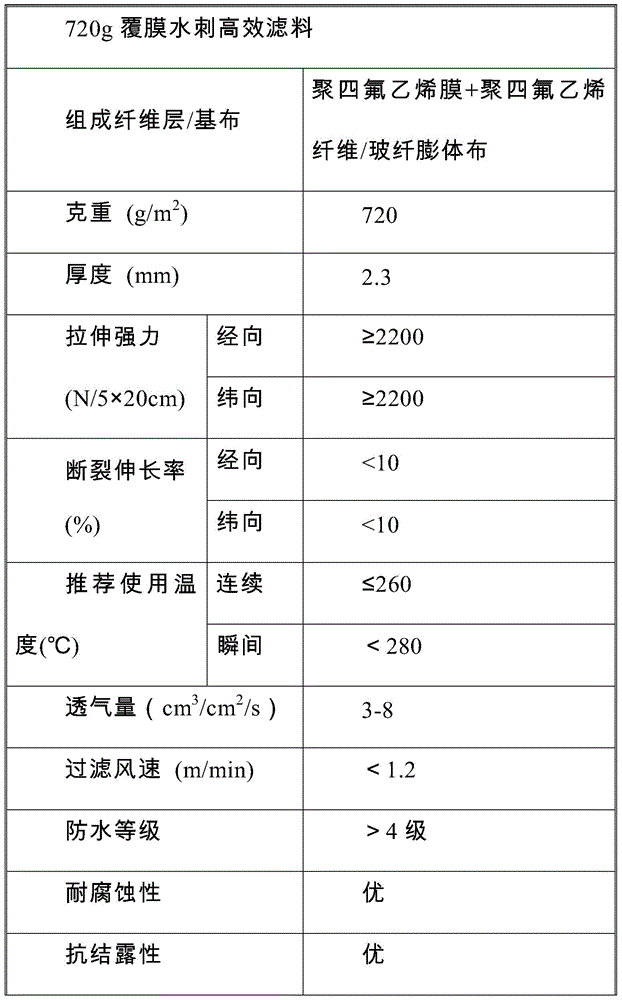

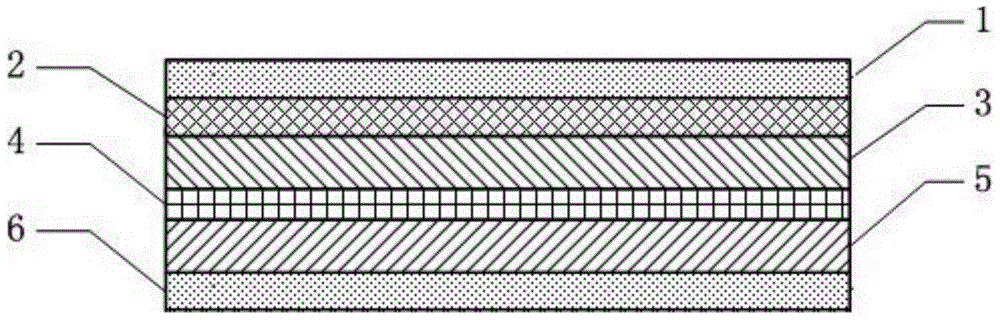

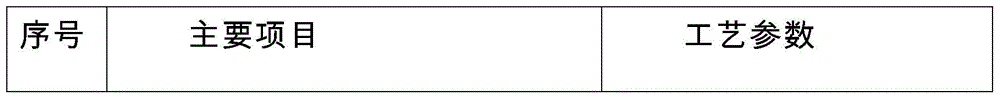

High-efficiency spunlace filter material and preparing method thereof

InactiveCN105709504AEasy to collectImprove cleanlinessSynthetic resin layered productsFiltration separationFiberPolytetrafluoroethylene

The invention provides a high-efficiency spunlace filter material. The high-efficiency spunlace filter material is mainly composed of a base cloth layer, an upper fiber web layer, a lower fiber web layer, an upper immersion treatment layer, a lower immersion treatment layer and a teflon microporous film layer or a teflon intumescent coating. High-performance woven fabric is adopted as the base cloth layer. According to the upper fiber web layer and the lower fiber web layer, after being subjected to pretreatment, pre-opening, carding and web forming, stable fiber is subjected to spunlace machining and combined with the base cloth layer to form spunlace felt; the spunlace felt is subjected to teflon emulsion immersion treatment, and the upper immersion layer and the lower immersion layer are formed; according to the teflon microporous film layer or the teflon intumescent coating, a teflon microporous film and the spunlace felt are combined or the surface of the spunlace felt is coated with teflon resin, and finally the high-efficiency spunlace filter material is prepared. The high-efficiency spunlace filter material is stable in structure, high in filter precision and resistant to high temperature and corrosion, and can be used for smoke filtering at various complex environments.

Owner:ZHEJIANG HONGSHENG NEW MATERIAL TECH GRP CO LTD

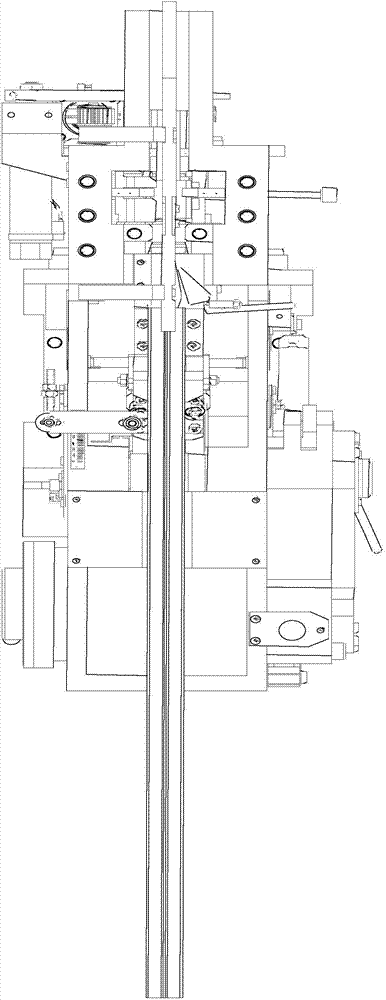

Full-automatic pneumatic steel coil bundler

InactiveCN104773323ACompact structureShort baling timeBinding material applicationBundling machine detailsDrive motorEngineering

The invention provides a full-automatic pneumatic steel coil bundler which is mainly used for completing a series of actions of feeding, tensioning, cutting-off and the like of a steel belt. The full-automatic pneumatic steel coil bundler comprises a housing, a gripper arm mechanism, a steel belt leading-in mechanism, a steel belt pumping mechanism, and a snap joint leading-in mechanism, wherein the housing is used for bearing a parent body of each part of the bundler and providing connecting interfaces for other auxiliary equipment (for example an outer guide rail and a snap joint storage box); the gripper mechanism is used for completing a series of actions of lock catch gripping, clamping, cutting-off of the steel belt, and the like; the steel belt leading-in mechanism is used for controlling the steel belt to accurately enter a lock catch position, and assisting the leading-in, positioning, pressure-buckling, and the like of the steel belt; the steel belt pumping mechanism is used for driving a motor to rotate actively and passively, and feeding or withdrawing the steel belt by two wheels through friction-force pressure-feeding; the snap joint leading-in mechanism is used for completing actions of leading-in, pressing and the like of a snap joint. The full-automatic pneumatic steel coil bundler completes bundling once within 10 seconds due to short bundling time, is suitable for different plate rolling specifications and capable of realizing peripheral bundling and perforated bundling, and has the characteristics of being compact in structure, simple to operate and flexible.

Owner:BEIHANG UNIV

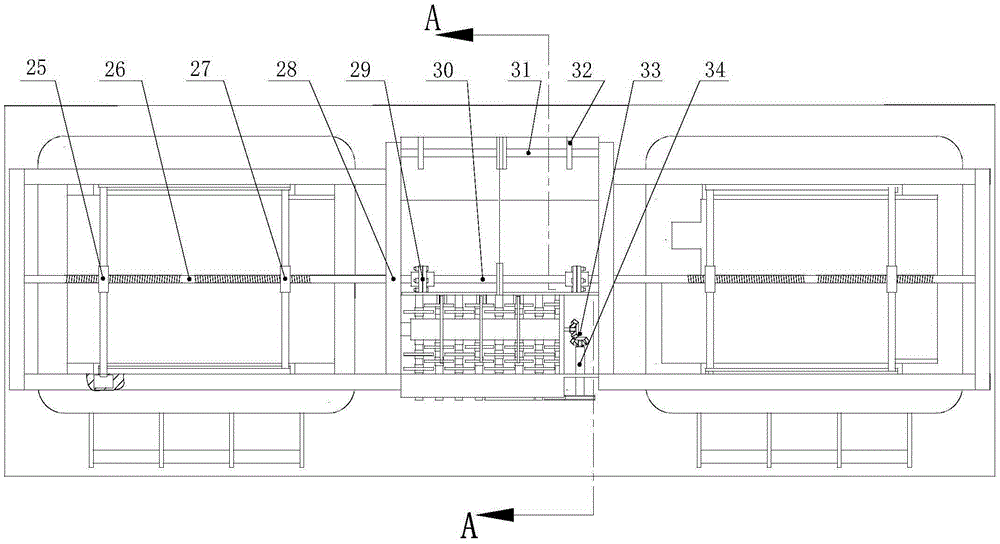

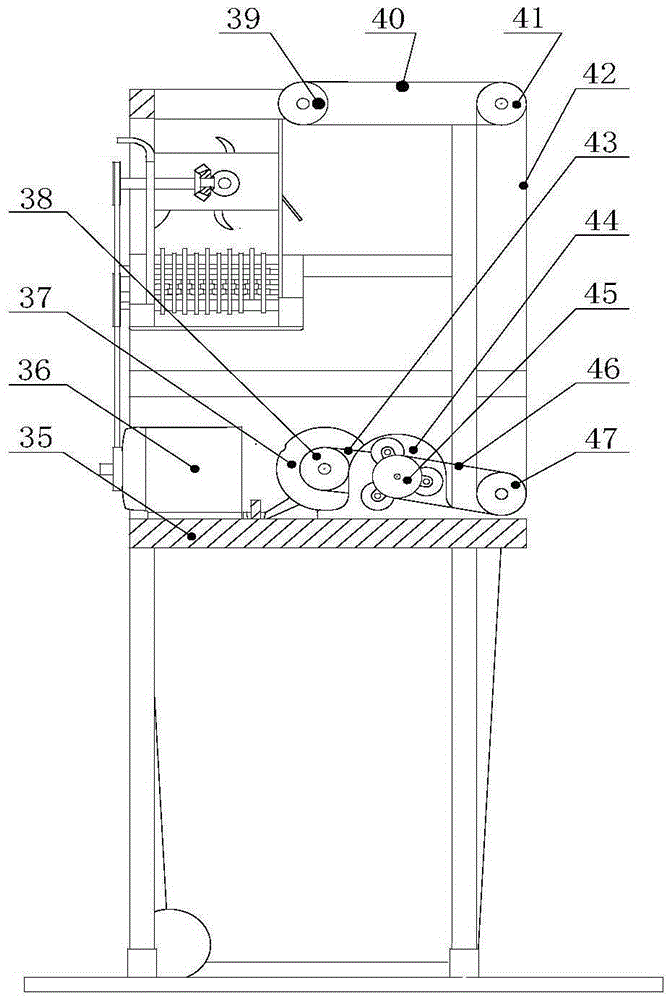

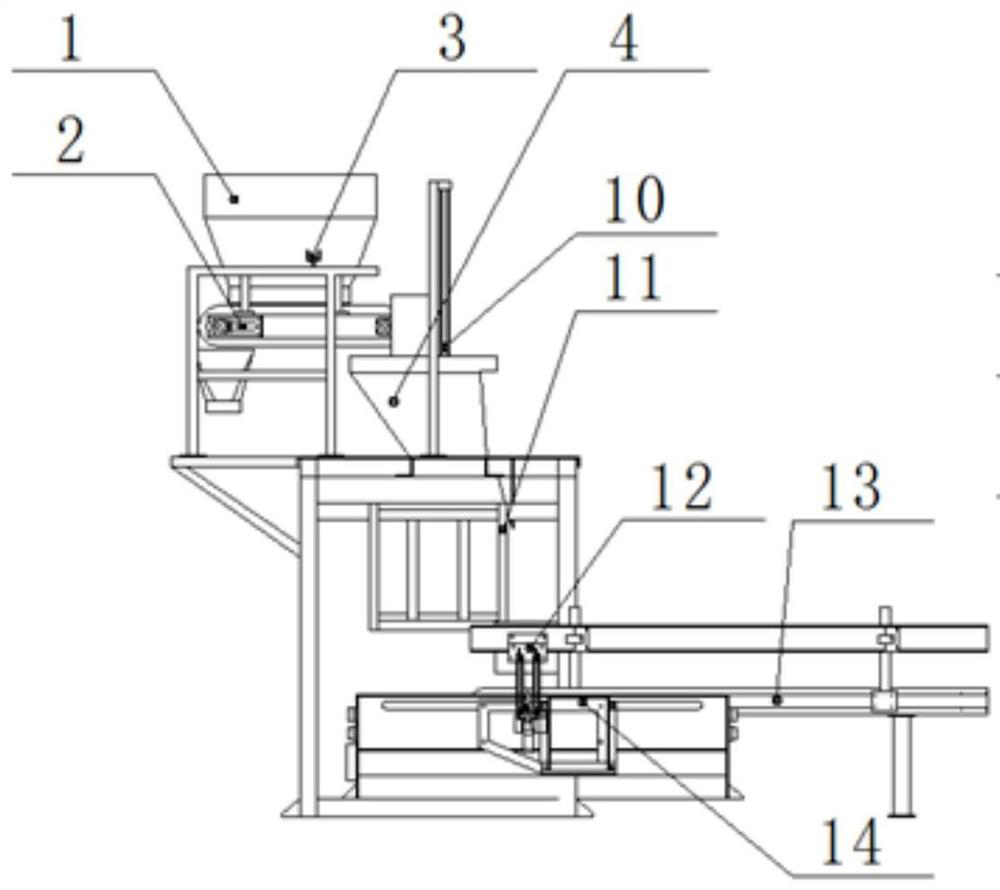

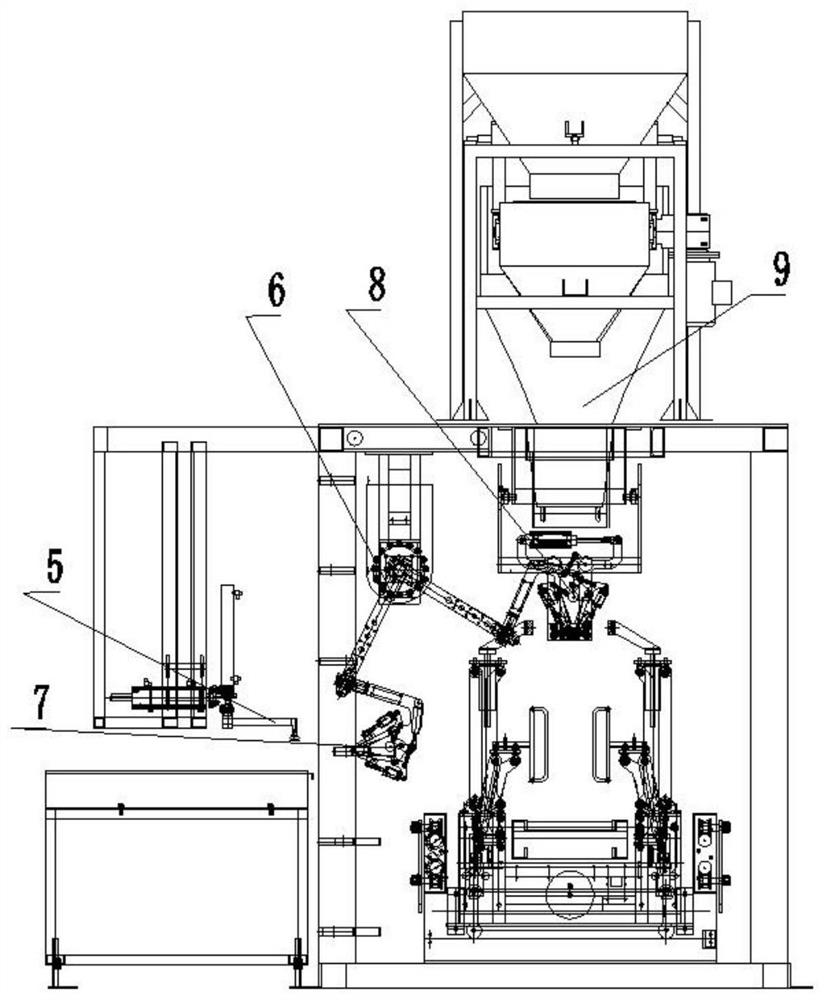

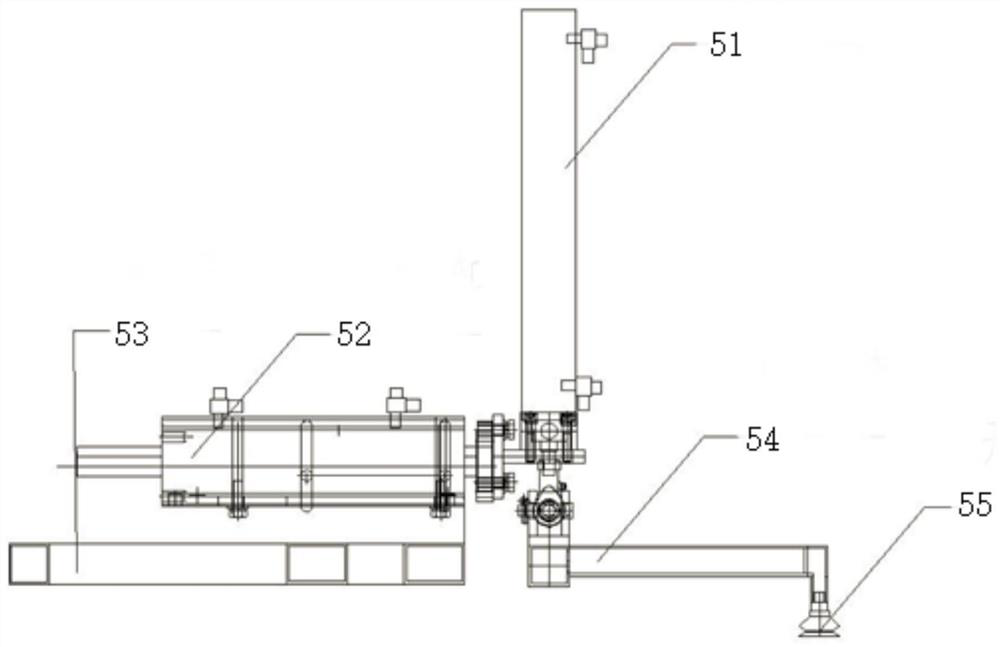

Soft waste full-automatic packaging system

PendingCN112644786AHigh degree of automationReduce manual labor intensityWrapper twisting/gatheringSolid materialProcess engineeringAutonomation

The invention relates to a soft waste full-automatic packaging system which comprises a weighing, metering and feeding system, a bag feeding system, a compacting system, a filling treatment system and an auxiliary system. The weighing, metering and feeding system is composed of a material bin, a feeding belt conveyor, a weighing system and a discharging hopper, the feeding belt conveyor and the weighing system are located below the material bin, and the discharging hopper is positioned on one side of the end of the feeding belt conveyor. The bag feeding system is composed of a bag feeding mechanism, a pushing mechanism, a bag opening mechanism and a guiding mechanism. The compacting system is composed of a material chute, a compacting mechanism and a frame. The filling treatment system is composed of a bag opening treatment system, a finished bag conveying mechanism and a lifting platform, the bag opening treatment system is located above the lifting platform, and the finished bag conveying mechanism is located on one side of the bag opening treatment system. The system is high in automation degree, the whole process of metering, feeding, bag feeding, compacting, filling and the like of various kinds of soft waste can be achieved, the labor intensity of manpower is reduced, and the working efficiency is improved.

Owner:CHINA INST FOR RADIATION PROTECTION

Gas heat blower

The invention relates to a gas heat blower, belonging to the technical field of industrial hot-blast air. The gas heat blower has the main technical characteristics that a gas distributor is installed at the front end of the cavity in the case and is sheathed on the outer diameter of the front end of the gas distributor; a casing pipe with a flange is installed on one side of a wind outlet tube; the wind outlet tube, the air distributor flange and the case are fixedly connected and fixed; the upper end of the case is provided with an air inlet; and the lower end of the case is provided with a gas inlet. The invention mixes and burns gas and air to generate gas hot-blast air with large flow and high calorific value; compared with the method that air is only heated to generate hot-blast air, the device utilizes the advantages of large flow and high calorific value of the hot-blast air generated by chemical reaction so as to effectively reduce fan volume; because the air inlet and the gas outlet are respectively connected with the control pipeline of an electric control valve, the air inflow and supply air rate of the gas distributor and the air distributor can be independent and adjustable and can satisfy different working condition requirements.

Owner:SHANXI ALEX ENVIRONMENTAL PROTECTION TECH

Metallurgical bonding stainless steel cladding thermometal profile steel and preparing technology

The invention discloses a metallurgically bonded stainless steel-coated bimetallic section steel and its preparation process, which includes a carbon steel core and a stainless steel cladding. Its composite forming process includes using an induction heater to integrally heat the outer stainless steel pipe to 600-1000°C. The inner layer of carbon steel is poured into molten metal and cast to produce a clad bimetal composite billet with a metallurgical bonding interface; the cast bimetal billet is hot-rolled into a clad bimetal steel section. The metallurgical bonding interface between the stainless steel layer and the carbon steel core is formed by melting and casting, and has the advantages of high bonding strength, excellent process performance, dense structure, good quality, few processes, low cost, and high efficiency. The present invention uses bimetallic section steel to replace the integral stainless steel section steel. On the premise of ensuring the corrosion resistance properties of the section steel, it not only saves stainless steel materials and reduces project costs, but also effectively improves the strength of steel bars, reduces waste of resources and energy and environmental pollution, and has Broad application prospects.

Owner:丹阳恒庆复合材料科技有限公司

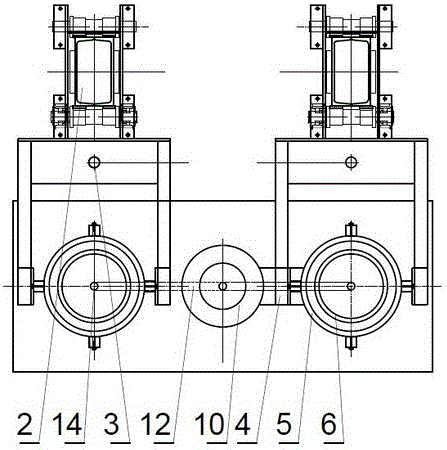

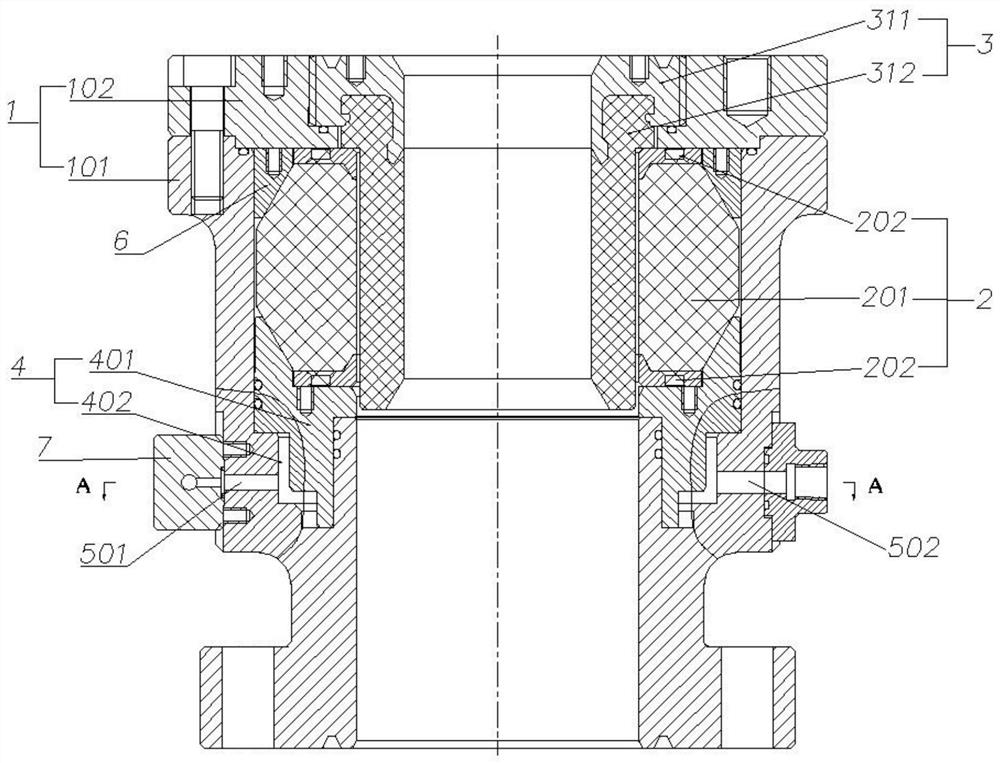

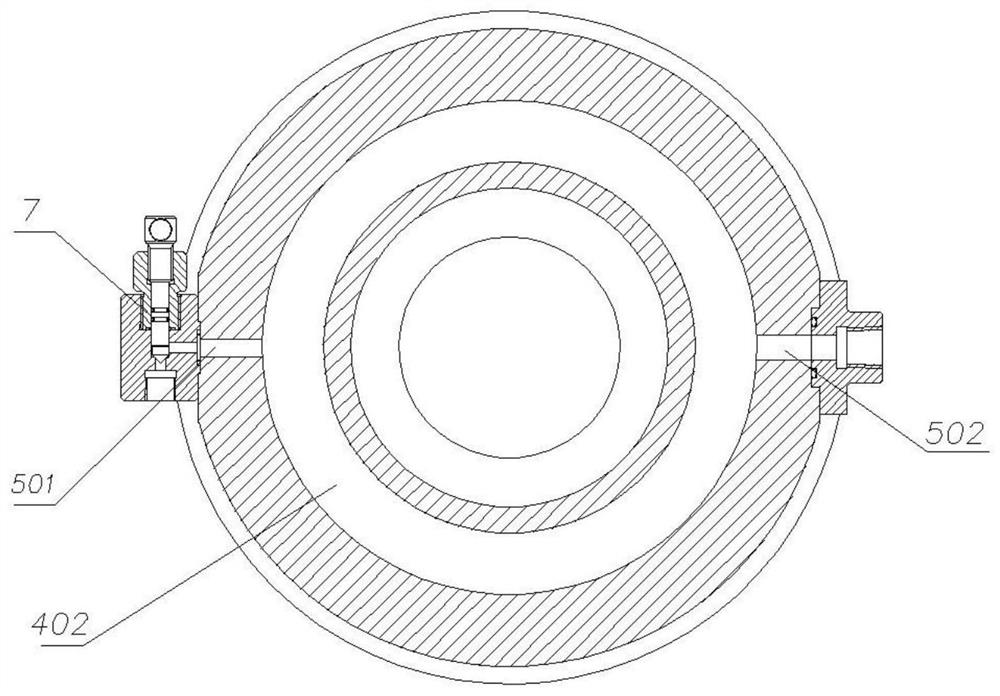

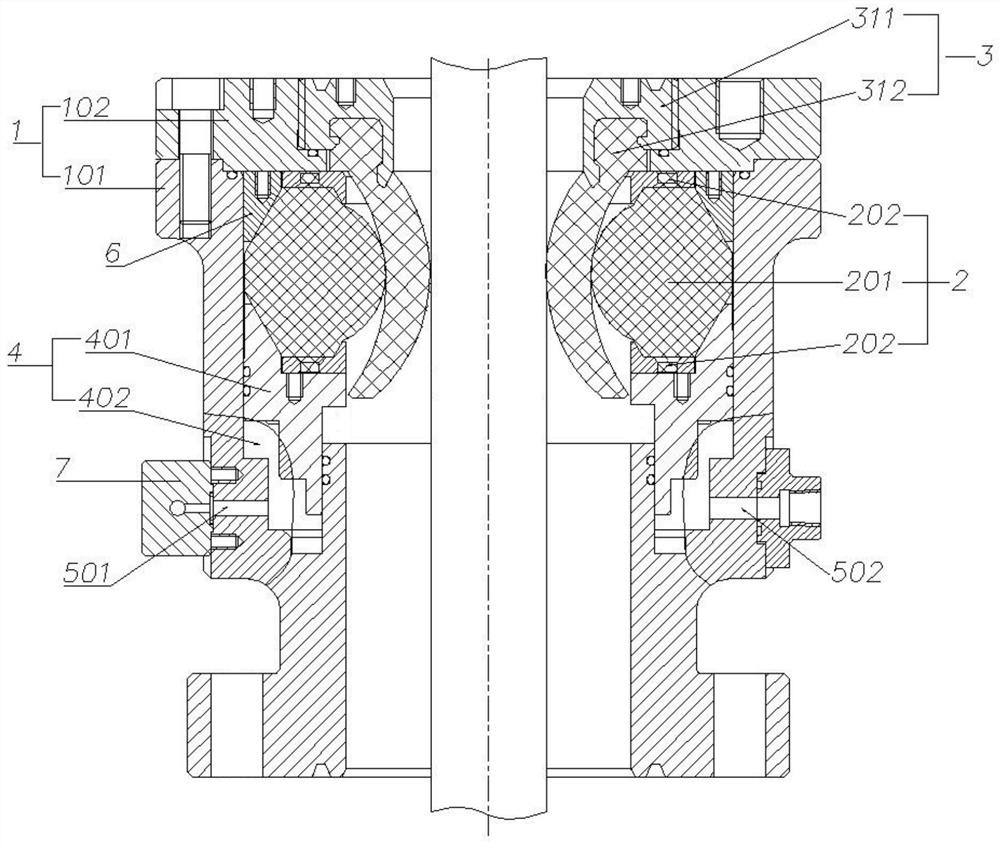

Compensation type multipurpose annular blowout preventer

PendingCN112112598AReduce volumeLight in massDrilling rodsSealing/packingEngineeringBlowout preventer

The invention relates to an oil well blowout preventer, in particular to a compensation type multipurpose annular blowout preventer so as to solve the problems that an existing blowout preventer is large in size, complex in rubber sleeve replacement and high in cost, a self-sealing rubber sleeve is low in pressure resistance, the self-sealing well sealing capacity cannot be adjusted, an annular main rubber sleeve is prone to being damaged, and after an inner bush is annularly held, an inner hole of the inner bush is not round, and consequently the well pressure cannot be sealed. The annular blowout preventer comprises a shell, a main rubber sleeve assembly, an auxiliary rubber sleeve assembly, a piston assembly and an oil way, all of which are coaxially arranged in sequence from outside toinside, the piston assembly is located on the inner side of the shell, arranged below the main rubber sleeve assembly and used for extruding the main rubber sleeve assembly, and the oil way is arranged on the shell and communicates with the piston assembly. The auxiliary rubber sleeve assembly comprises an auxiliary rubber sleeve and an auxiliary rubber sleeve framework, the auxiliary rubber sleeve is arranged on the inner side of the main rubber sleeve assembly, the upper end of the auxiliary rubber sleeve is fixedly connected with the auxiliary rubber sleeve framework, the auxiliary rubbersleeve framework is detachably connected with the upper end of the shell, and the auxiliary rubber sleeve assembly is used for tightly holding an oil pipe, a workover tool, a cable, a steel wire ropeor a sucker rod under extrusion of the main rubber sleeve assembly.

Owner:西安宇星石油机械新技术开发有限公司

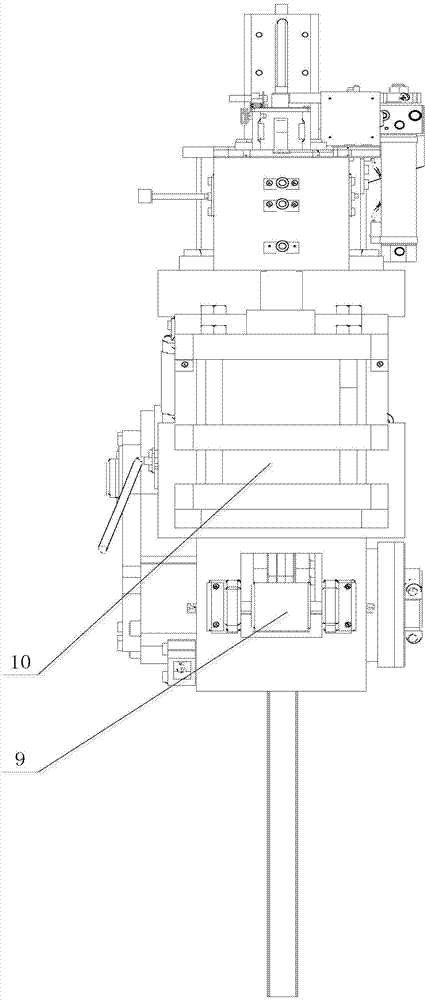

Spunlace precise surface filter material and preparation method thereof

InactiveCN105688512AImprove cleanlinessEasy to collectSynthetic resin layered productsMembrane filtersFiberEmulsion

The invention provides a spunlace precise surface filter material which comprises the following six parts from a dust-coming side to an air-purifying side: a precise surface layer, an upper fiber web layer, a base cloth layer and a lower fiber web layer as well as immersion treatment layers arranged on the two sides of the filter material, wherein the upper and lower fiber web layers are formed by pre-processing, pre-loosening, carding and netting short fibers and then are fixedly adhered to the base cloth layer through spunlace processing, so as to form a spunlace felt; the precise surface layer is formed by pre-processing, pre-loosening, carding and netting fine denier fibers and then is fixedly adhered to the surface of the spunlace felt, so as to form a spunlace precise surface felt; the spunlace precise surface felt is subjected to immersion treatment in polytetrafluoroethylene emulsion, thereby forming the upper and lower immersion layers; the spunlace precise surface filter material is lastly formed. The spunlace precise surface filter material provided by the invention is stable in structure, has the characteristics of high filtering precision, high temperature resistance, excellent corrosion resistance, and the like, and can be used for filtering smoke under various complex environments.

Owner:ZHEJIANG HONGSHENG NEW MATERIAL TECH GRP CO LTD

Wall-mounted air conditioner indoor unit

PendingCN107655076AFeel comfortableIncrease air volumeLighting and heating apparatusAir conditioning systemsAmbient airWall mount

The invention provides a wall-mounted air conditioner indoor unit. The wall-mounted air conditioner indoor unit comprises a shell body, a heat exchanger, a jet assembly, a first air supplying assemblyand a second air supplying assembly, wherein the shell body comprises a cover shell and a front panel arranged on the front of the cover shell, and the shell body is arranged obliquely downwards relative to a supporting wall body to make an air supplying opening face the oblique lower portion; an air inlet is formed in the top wall of the cover shell; the jet assembly is arranged in the air supplying opening, the jet assembly comprises a first jet part and a second jet part which are arranged transversely, a first jet opening and a second jet opening are formed in the inner peripheral walls of the first jet part and the second jet part correspondingly, and the first jet opening and the second jet opening are correspondingly used for jetting airflow in the jet parts forward to drive ambient air in an air pumping hole defined by the inner peripheral walls of the jet parts to be sent to the oblique lower portion; and the first air supplying assembly and the second air supplying assemblyare correspondingly used for generating second heat exchanging airflow which enters from the air inlet, conducts heat exchanging with the heat exchanger and then is supplied to the interior of the corresponding jet part. According to the scheme of the wall-mounted air conditioner indoor unit, the air supplying volume is increased, and the whole indoor temperature is made to be decreased uniformly.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD

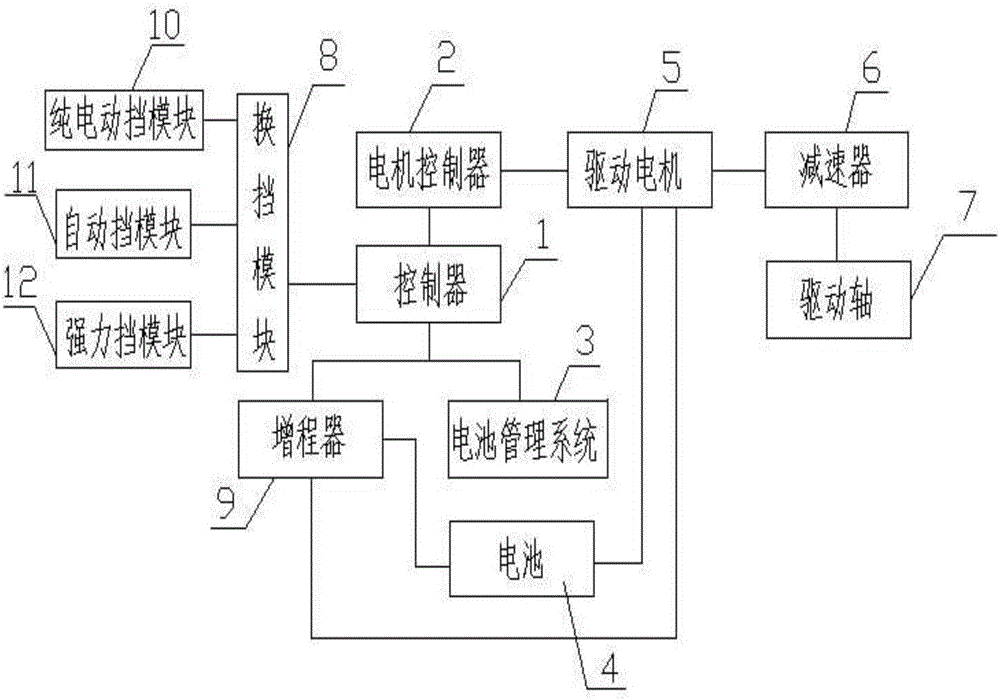

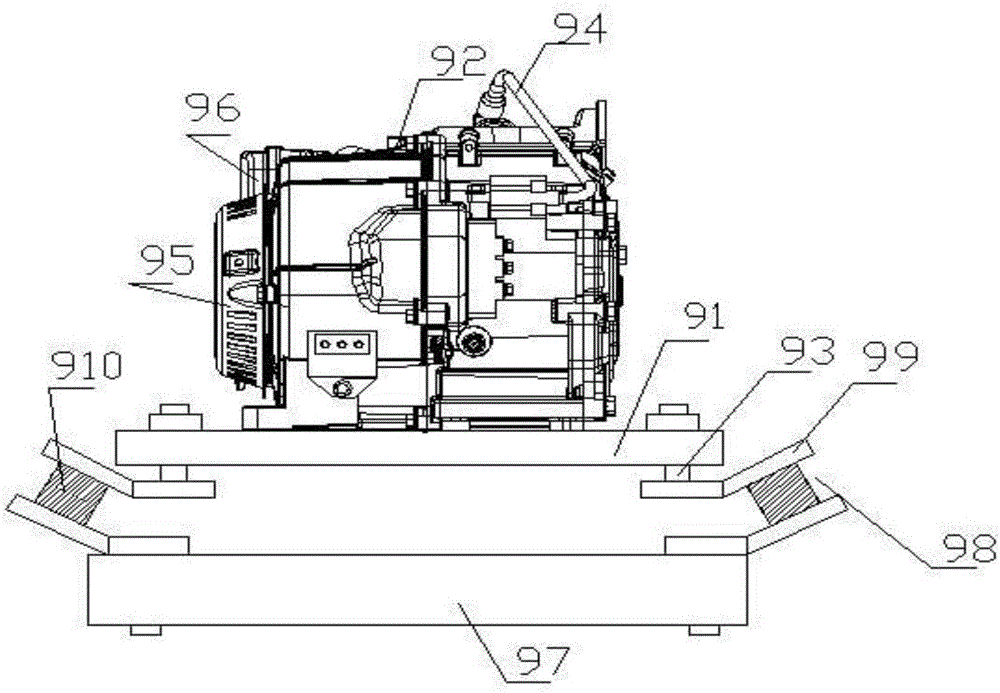

Control system used for electric vehicle

InactiveCN105857298AImprove battery lifeImprove carrying capacityHybrid vehiclesPropulsion using engine-driven generatorsReduction driveDrive motor

The invention relates to a control system used for an electric vehicle. The control system comprises a controller, a motor controller, a battery management system and a battery. The controller is connected with the motor controller and the battery management system; the motor controller is connected with a driving motor; the driving motor is connected with a driving shaft through a speed reducer; the battery management system is connected with the battery; the controller is connected with a gear-shifting module through a gear position line; the controller is further connected with a range extender; and the range extender is connected with the battery and the driving motor. When battery capacity is smaller than or equal to 20%, the range extender is started so that the electric energy can be provided for driving of the whole vehicle in time, and accordingly, the endurance mileage of the electric vehicle is increased and the climbing and bearing capacity of the vehicle is improved within the capacity range of the driving motor; and starting voltage of the range extender is set, the electric energy is provided for the whole vehicle in time, and additional charge for the storage battery is performed, so that the endurance mileage of the whole vehicle is increased and the service life of the battery is prolonged.

Owner:DONGGUAN RUIDA ELECTRIC VEHICLE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com