Interference riveting method and device based on ultrasonic assistance

An ultrasonic-assisted riveting technology, which is applied in the field of ultrasonic-assisted interference riveting and riveting of aluminum alloy parts, can solve the problems that the quality of riveting cannot meet the requirements and the fluidity of materials cannot be improved, and achieve strong operability and overcome Insufficient anti-fatigue performance, stable and durable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

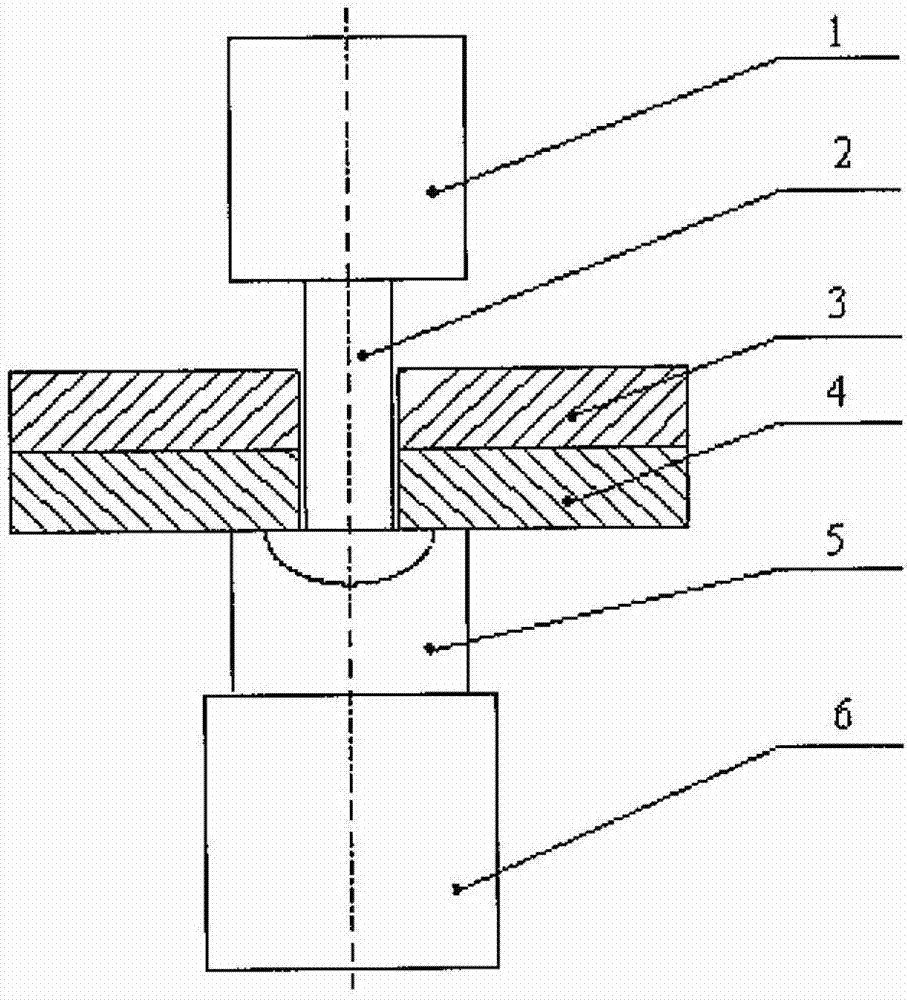

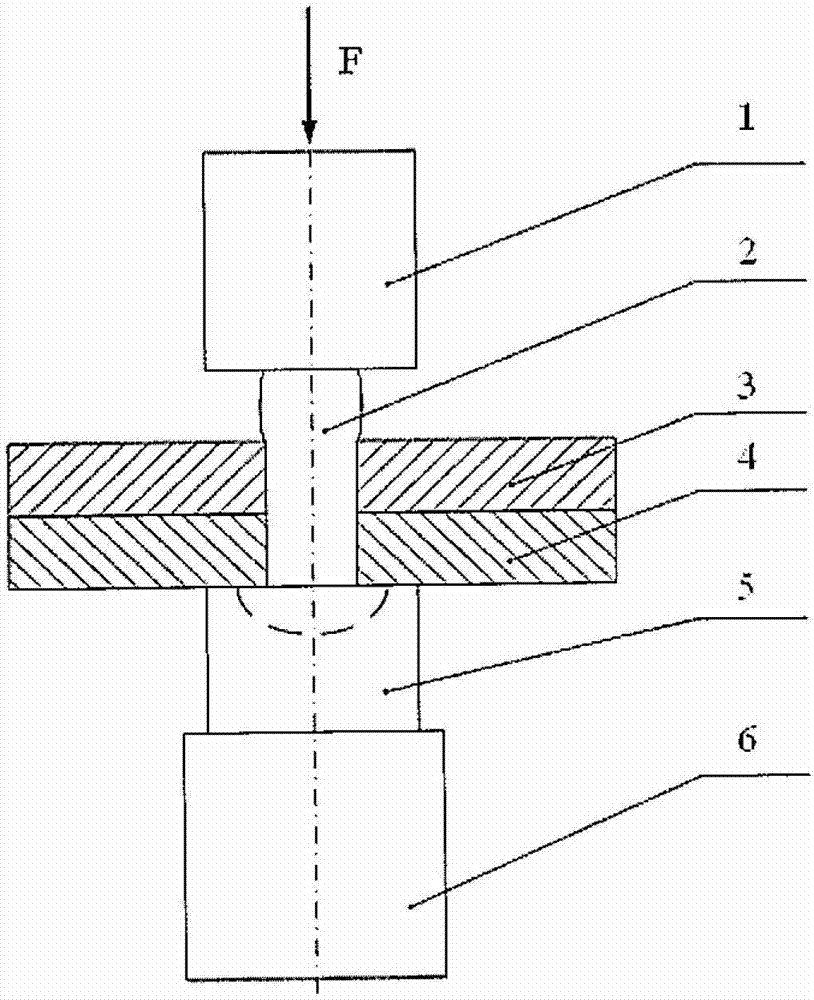

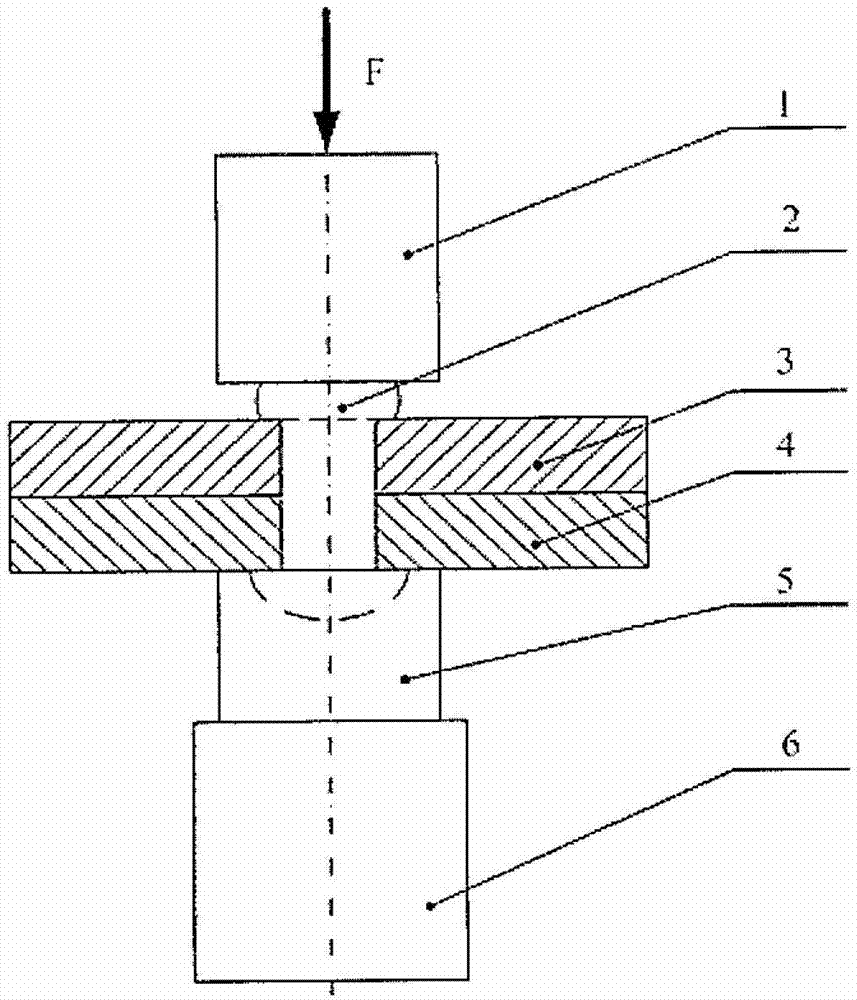

[0028] Such as Figure 1-4 As shown, the ultrasonic-assisted interference riveting device mainly includes: upper riveting die 1, rivet 2, upper connecting plate 3, lower connecting plate 4, lower riveting die 5 and ultrasonic generator 6, upper connecting plate 3 and lower connecting plate 4 Stacked and placed between the upper riveting die 1 and the lower riveting die 5, the rivet 2 is placed in the riveting hole of the upper connecting plate 3 and the lower connecting plate 4, the upper riveting die 1 is in contact with the end surface of the rivet 2, and the lower riveting die 5 is in contact with the nail head of the rivet 2 , the lower riveting die 5 is in contact with the ultrasonic generator 6 , and the ultrasonic wave from the ultrasonic generating device 6 is transmitted to the rivet 2 through the lower riveting die 5 . In this embodiment, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com