Combined type steel wire rope vibration isolator

A steel wire rope and vibration isolator technology, applied in the field of combined all-metal wire rope vibration isolators, can solve the problems of vibration isolation system design, complex installation, difficult installation and disassembly, and high cost, and achieves improved vibration isolation and impact resistance. Easy assembly and excellent vibration absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

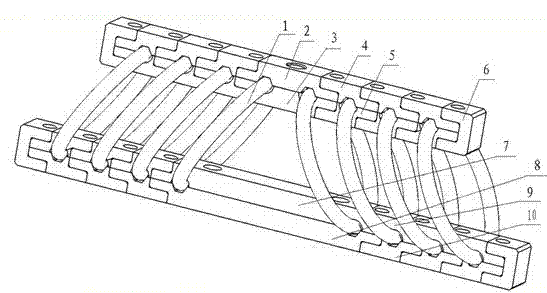

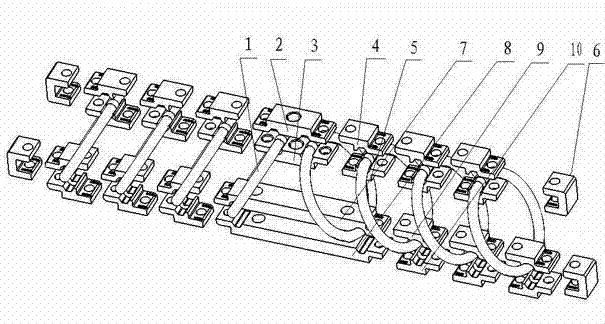

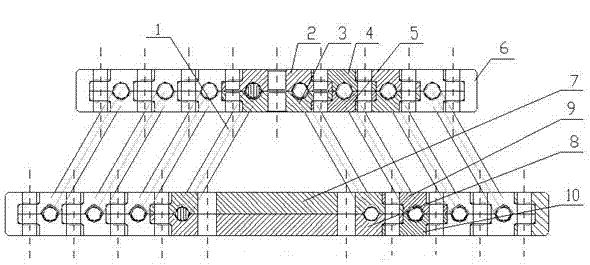

[0045] Specific implementation mode one, refer to the attached figure 1 to attach Figure 9, a combined wire rope ring vibration isolator, including a basic vibration isolation unit, at least one set of expandable vibration isolation units symmetrically fixed on both sides of the basic vibration isolation unit; wherein the basic vibration isolation unit includes a basic vibration isolation upper connection unit, The connection unit under the basic vibration isolation and the two first elastic steel wire rope rings 1 clamped up and down between the two in a figure-eight shape; each group of expandable vibration isolation units includes left and right symmetrical connections between the basic vibration isolation units The expandable vibration-isolation upper connection unit and the expandable vibration-isolation lower connection unit on both sides, and two second elastic steel wire rope circles fixed between the expandable vibration-isolation upper connection unit and the expand...

specific Embodiment approach 2

[0046] Specific implementation mode two, this specific implementation mode discloses two combined structures, such as Figure 10 with 11 Shown is a series type wire rope vibration isolator. The steel wire rope vibration isolator adopts the independent steel wire rope vibration isolators in the first embodiment to be connected in series to form a new vibration isolator, which meets the requirement of being installed in the narrow and long space of the device. According to working conditions, such as Figure 10 As shown, the upper connection unit and the upper connection unit of the basic vibration isolation unit and the expandable vibration isolation unit of the two vibration isolators can be connected by bolts (called positive installation), such as Figure 11 As shown in , the lower connection unit of the basic vibration isolation unit and the expandable vibration isolation unit of the two vibration isolators can also be connected by bolts (referred to as reverse installati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com