Glass suitable for chemically tempering and chemical tempered glass

一种化学钢化玻璃、化学钢化的技术,应用在玻璃的钢化、玻璃制造设备、运输和包装等方向,能够解决制造工艺难度大、玻璃粘度增大、气泡难以消除等问题,达到熔制温度降低、降低制造难度、抗冲击性能好的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

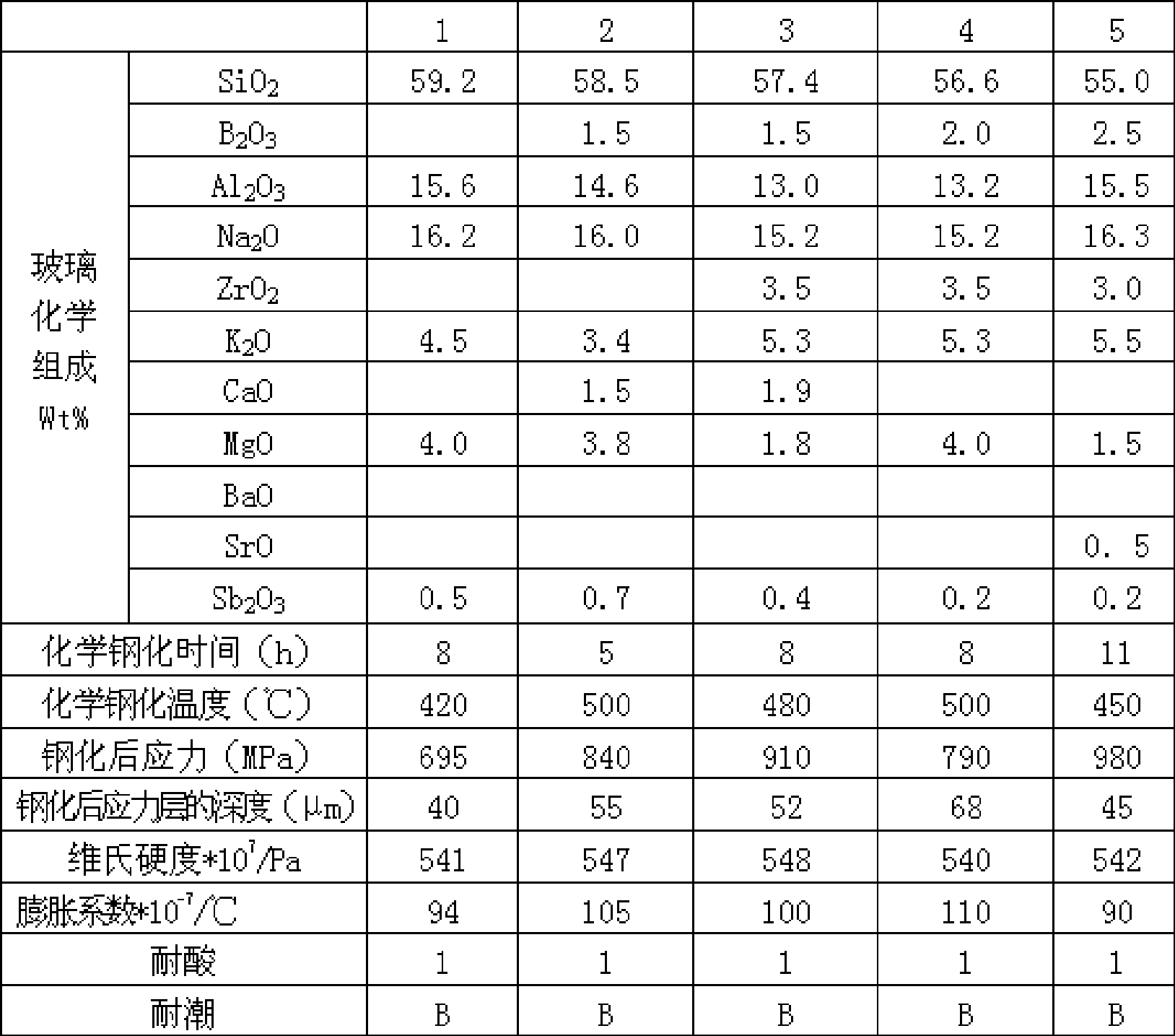

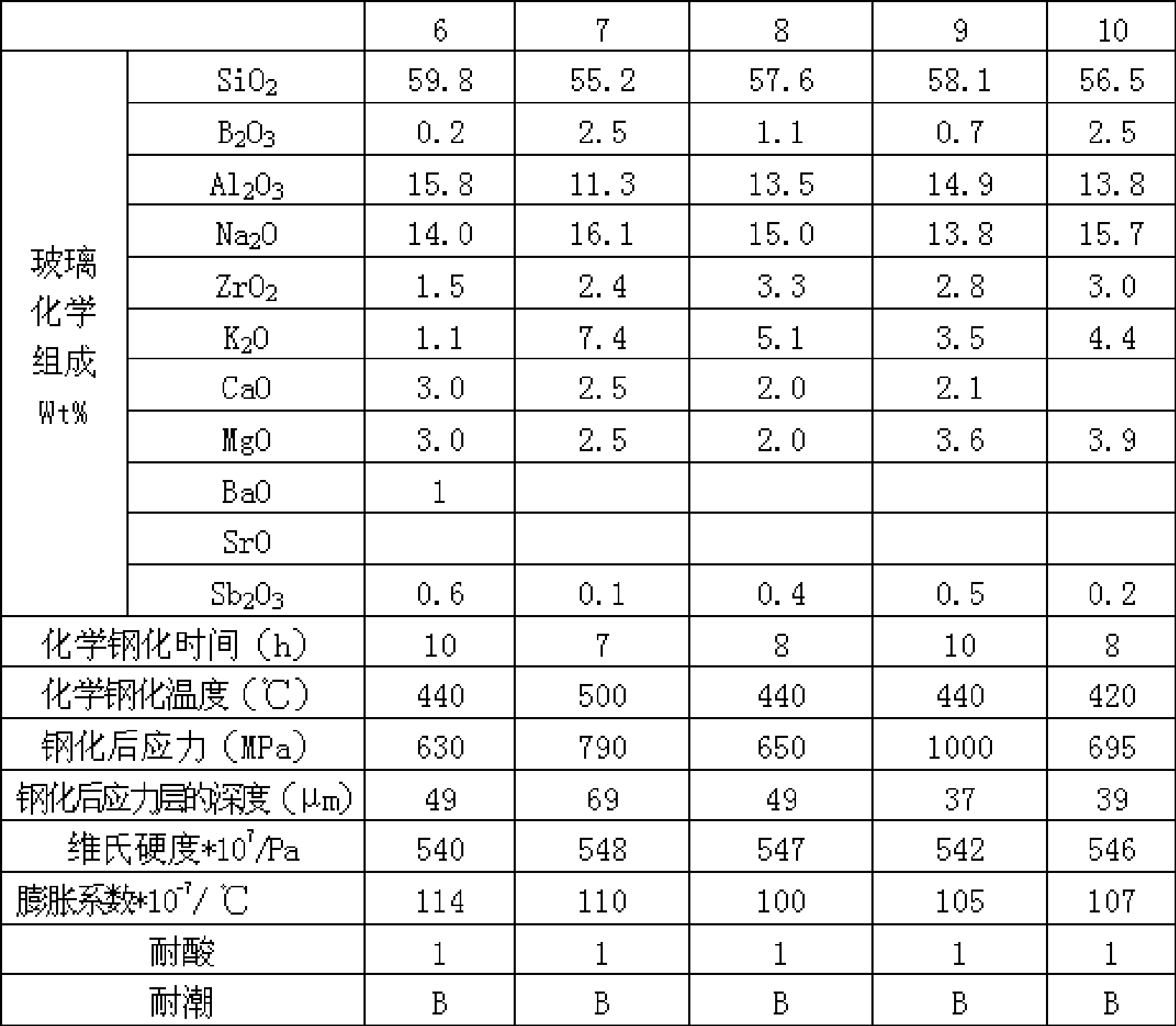

[0032] Components that may be contained in the glass of the present invention will be described below, and the content of each component is shown in % by weight.

[0033] SiO 2 It is the main component to form the glass skeleton. The higher its content, the more it can improve the chemical durability and the mechanical strength of the glass. When the content is below 55%, the chemical stability of the glass is not good, but when the content exceeds 60%, the melting temperature is too high . Therefore, SiO 2 The ratio is limited to 55-60%.

[0034] B 2 o 3 It is an essential ingredient for improving glass melting and reducing viscosity. If the content is too high, the ion exchange rate of glass will be reduced, so its content is limited to 0.1-2.5%, preferably 0.1-1.7%.

[0035] Al 2 o 3 In the glass composition, it provides performance for the ion exchange of the glass surface, and is also a necessary component to improve the chemical stability of the glass, reduce the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| surface pressure | aaaaa | aaaaa |

| surface pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com