Digital microfluidic droplet driving device and method

A digital microfluidic and driving device technology, applied in the direction of fluid controllers, chemical instruments and methods, laboratory appliances, etc., can solve the difficulty of making digital microfluidic droplet driving devices and limit the large-scale flexibility of digital droplets Thread control and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

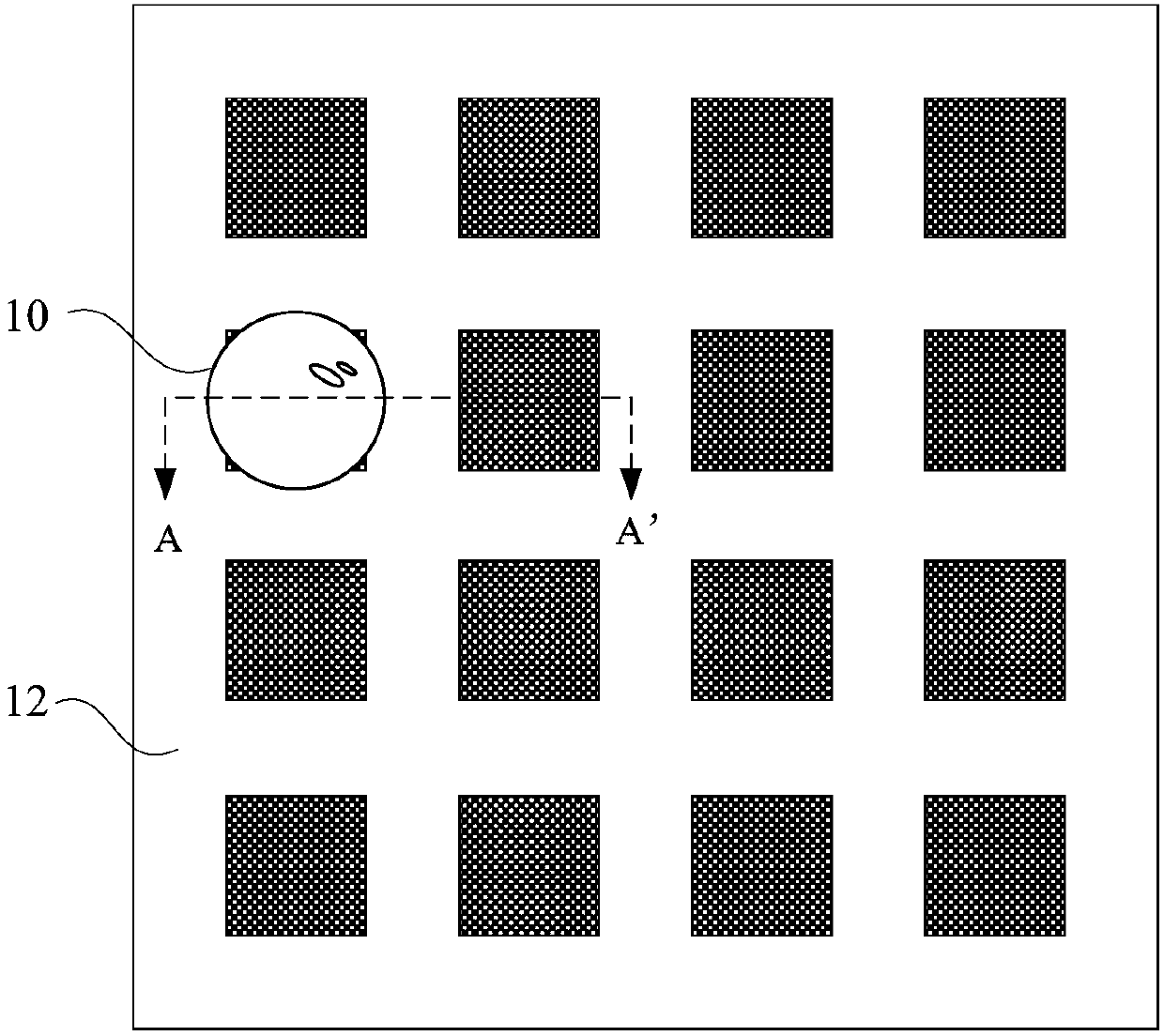

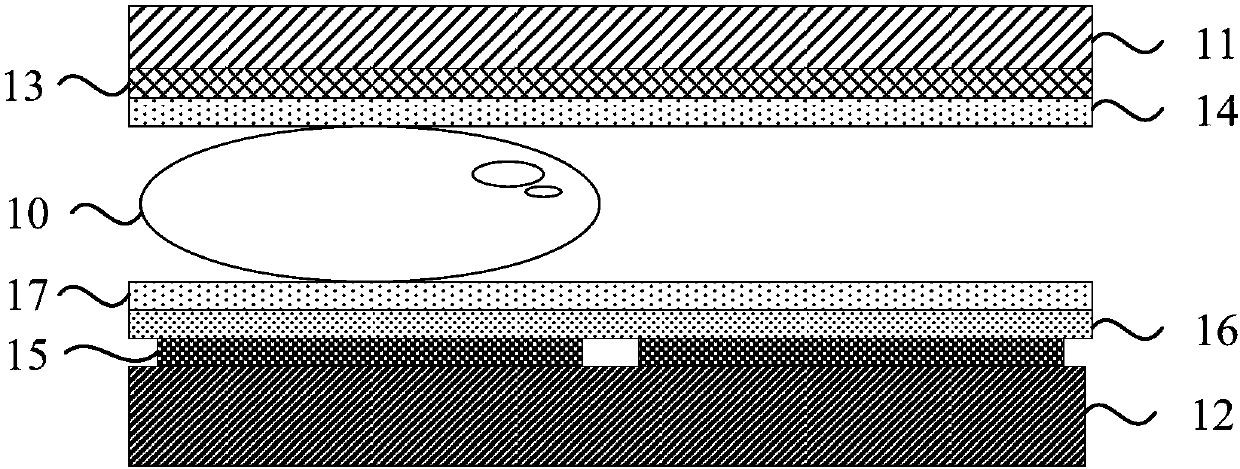

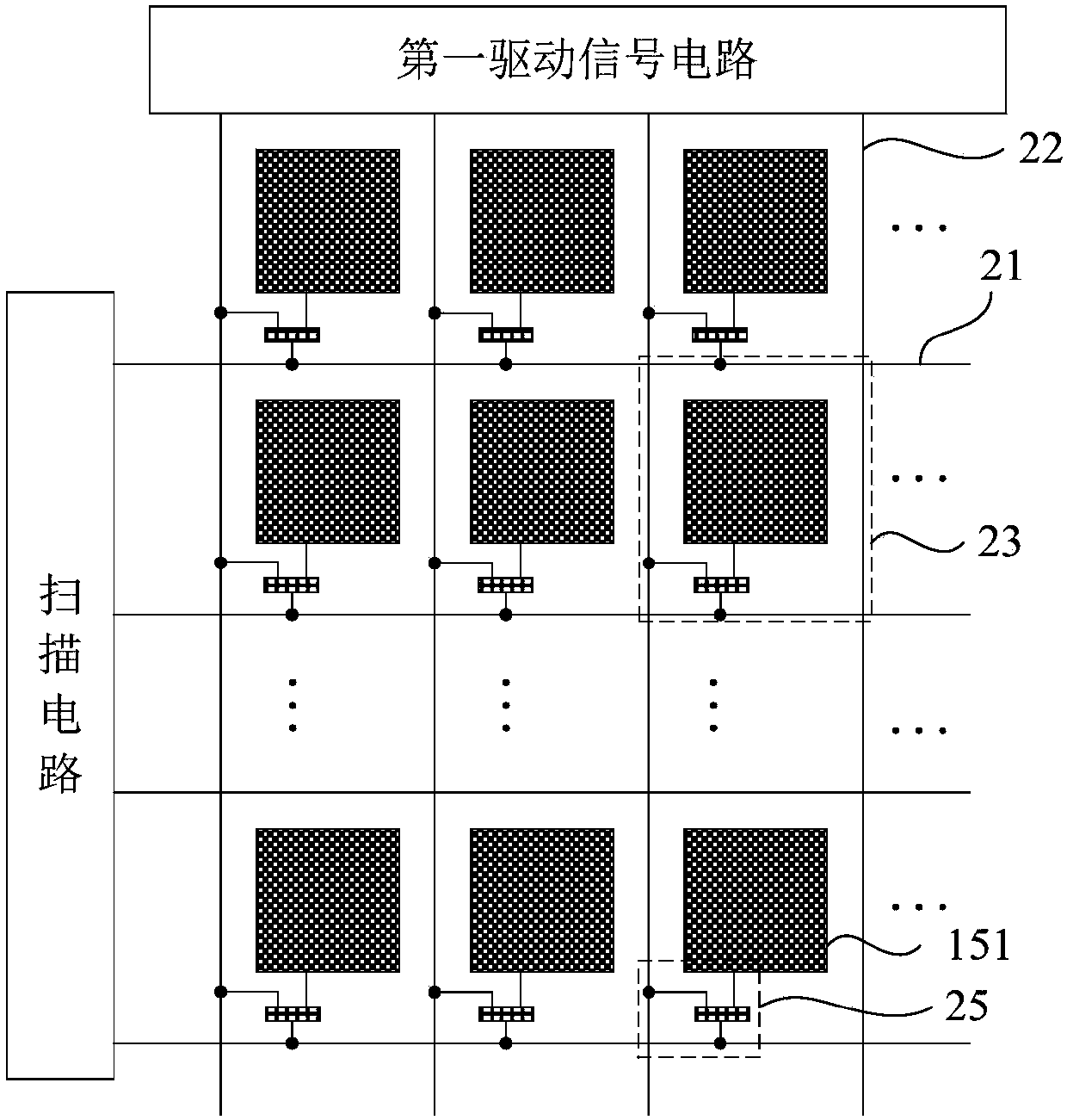

[0046] figure 1 It is a schematic top view structural diagram of a digital microfluidic droplet driving device provided in Embodiment 1 of the present invention, figure 2 is along figure 1 Schematic diagram of the cross-sectional structure of the middle section line A-A', image 3 yesfigure 1 Schematic diagram of the structure of the control circuit layer in the digital microfluidic droplet driving device, Figure 4 yes image 3 Schematic diagram of the control switch. refer to figure 1 , figure 2 , image 3 with Figure 4 , the digital microfluidic droplet driving device specifically includes a first substrate 11, a second substrate 12 ( figure 1 Only the second substrate 12) and the control circuit layer are shown in , and the accommodation space for the droplet 10 is formed between the first substrate 11 and the second substrate 12. Wherein, a reference electrode layer 13 is provided on a side of the first substrate 11 close to the second substrate 12 , and a fir...

Embodiment 2

[0064] Figure 7 It is a circuit diagram of another digital microfluidic droplet driving device provided in Embodiment 2 of the present invention; Figure 8 yes Figure 7 The equivalent circuit diagram of the transistor in the off and on states. Compared with Embodiment 1, in this embodiment, the digital microfluidic droplet driving device further includes a second driving signal line 31 and a third driving signal line 41 . Specifically, see Figure 7 with Figure 8 , the second driving signal line 31 is electrically connected to the reference electrode; the third driving signal line 41 is electrically connected to the driving electrode block.

[0065] Combine below Figure 7 with Figure 8 The driving method of the digital microfluidic droplet driving device provided in this embodiment will be described in detail. The droplet driving method of the digital microfluidic droplet driving device includes:

[0066] S110. After the droplet is dropped into the digital microfl...

Embodiment 3

[0075] Figure 9 It is a schematic cross-sectional view of the digital microfluidic droplet driving device provided in Embodiment 3 of the present invention, Figure 10 It is a circuit diagram of another digital microfluidic droplet driving device provided in Embodiment 3 of the present invention. see Figure 9 with Figure 10 , the digital microfluidic droplet driving device also includes a third substrate 18 opposite to the second substrate 12; the second substrate 12 is located between the first substrate 11 and the third substrate 18; the third substrate 18 includes a The first surface of the substrate 12 and a plurality of connection pins 181; the control circuit layer is integrated on the third substrate 18, the connection pins 181 are located in the first surface of the third substrate 18, and are electrically connected to the output end of the control switch, The connecting pins 181 are arranged in one-to-one correspondence with the driving electrode blocks on the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com