High-efficiency spunlace filter material and preparing method thereof

A spunlace, high-efficiency technology, applied in separation methods, chemical instruments and methods, filtration and separation, etc., to achieve high firmness, prolong service life, and increase film firmness and durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

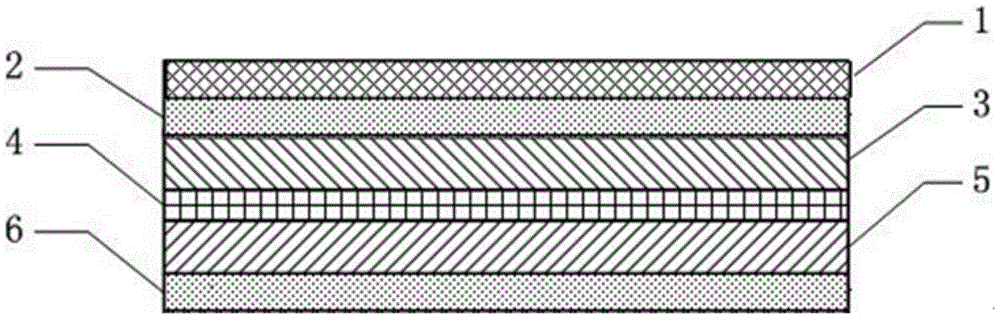

Image

Examples

preparation example Construction

[0027] A method for preparing a spunlace high-efficiency filter material, comprising the steps of:

[0028] (1) Fabrication of the base cloth layer: select high-strength fiber yarns, process through pretreatment, and make the base cloth layer on the loom;

[0029] (2) Fabrication of the fiber web layer and combination with the base fabric: The production of the fiber net layer and the combination with the base fabric are completed by a new spunlace process;

[0030] (3) Introduce the above-mentioned processed product into a polytetrafluoroethylene emulsion dipping tank, and process through dipping, drying, and heat setting to make a spunlace high-efficiency filter material;

[0031] (4) Hot rolling lamination of polytetrafluoroethylene microporous membrane: introduce the impregnated spunlace high-efficiency filter material and polytetrafluoroethylene microporous membrane into the thermal lamination machine, and stretch the microporous membrane by stretching , and then combine...

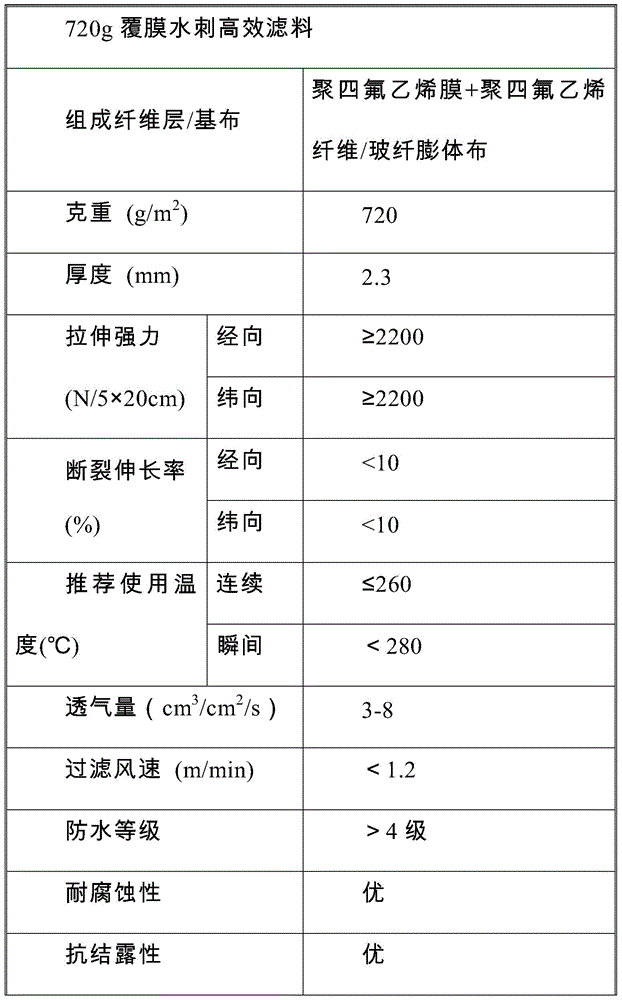

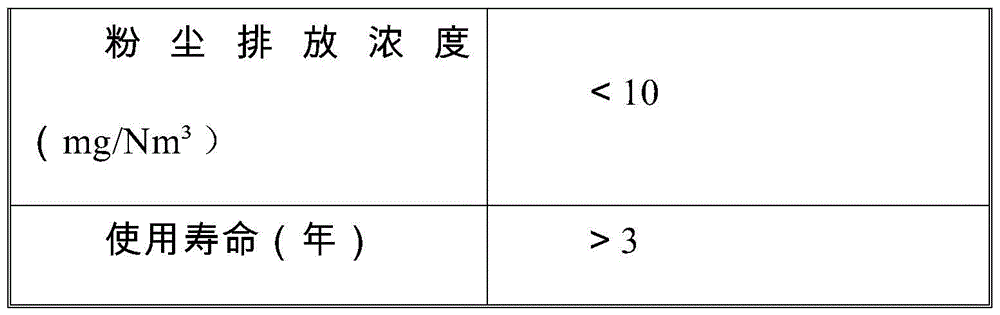

Embodiment 1

[0040] 1. Ultra-fine glass fiber drawing molding, PTFE emulsion impregnation treatment, bulking process treatment, the treated glass fiber thread is woven into 320g / m 2 fiberglass puffed cloth.

[0041] Its longitudinal strength is ≥1700N; weft strength is greater than or equal to 1600N.

[0042] 2. Unpack the PTFE short fiber raw material, spread it evenly, spray the aqueous solution containing 1% antistatic agent, and after standing for 12 hours, go through the following procedures:

[0043] Pre-opening→Main opening→Cotton box mixing→Carding→Make 180g / m 2 ~200g / m 2 PTFE fiber mesh → pre-needle punching → spunlace → trimming, inspection and rolling into rolls, etc., to make 700g / m 2 Spunlace high-efficiency filter material.

[0044] Spunlace process parameters are as follows:

[0045] serial number

main project

Process parameters

1

Spout Diameter

0.10mm

2

Nozzle specification and quantity

Double row 25 holes

3

...

Embodiment 2

[0054] 1. After pretreatment, the high-strength PTFE filament is made of rapier loom and plain weaving process to make 150g / m 2 High-strength PTFE base cloth.

[0055] Its warp strength is ≥800N / 5×20cm; weft strength is ≥900N / 5×20cm.

[0056] 2. Unpack the PPS short fiber and PTFE short fiber raw materials, spread them evenly, spray an aqueous solution containing 1.5% antistatic agent, and after standing for 14 hours, go through the following procedures:

[0057] The mixing ratio of PPS staple fiber and PTFE staple fiber is 1:1→pre-opening→main opening→cotton box mixing→carding→made into 180g / m 2 ~200g / m 2 PTFE fiber mesh → pre-needling → spunlace → trimming inspection roll process, made 550g / m 2 composite spunlace felt.

[0058] Spunlace process parameters are as follows:

[0059]

[0060] .

[0061] 3. Introduce the composite spunlace felt into the PTFE emulsion dipping tank, and process it through dipping treatment, volatilization treatment, drying treatment, sinte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dust removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com