Patents

Literature

693results about How to "Improve dust collection efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

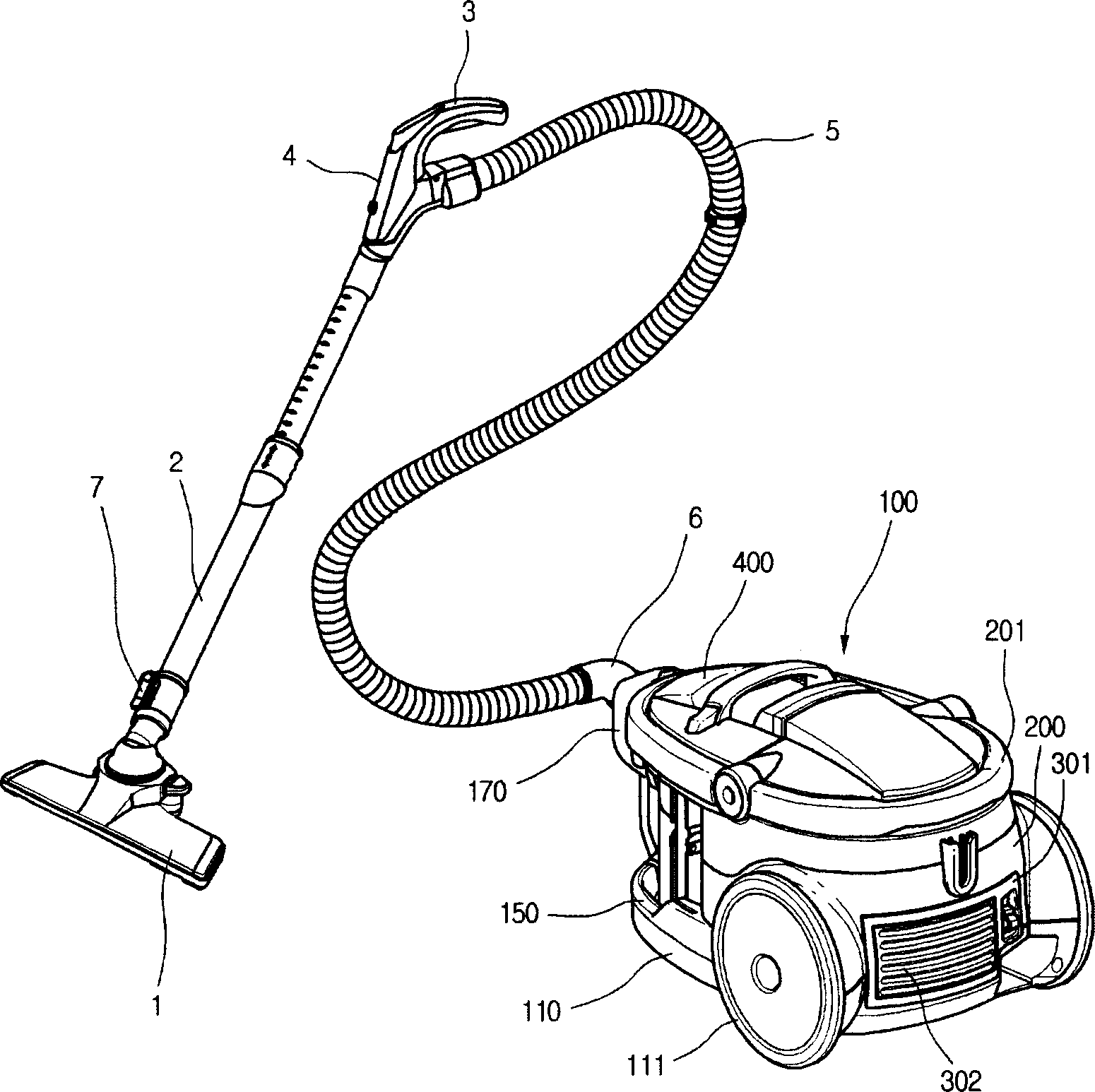

Channel structure of vacuum cleaner

InactiveCN1875855ADoes not affect operating efficiencyImprove cleaning efficiencySuction filtersEngineeringVacuum cleaner

The invention discloses a channel structure of vacuum cleaner, which comprises the following parts: dust collecting device of filtered air, motor rack to lead air of dust collecting device under motor exposing condition, bulk vent on the back of vacuum cleaner to discharge the air through motor. The invention improves the utility rate of vacuum cleaner, which reduces channel resistance.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

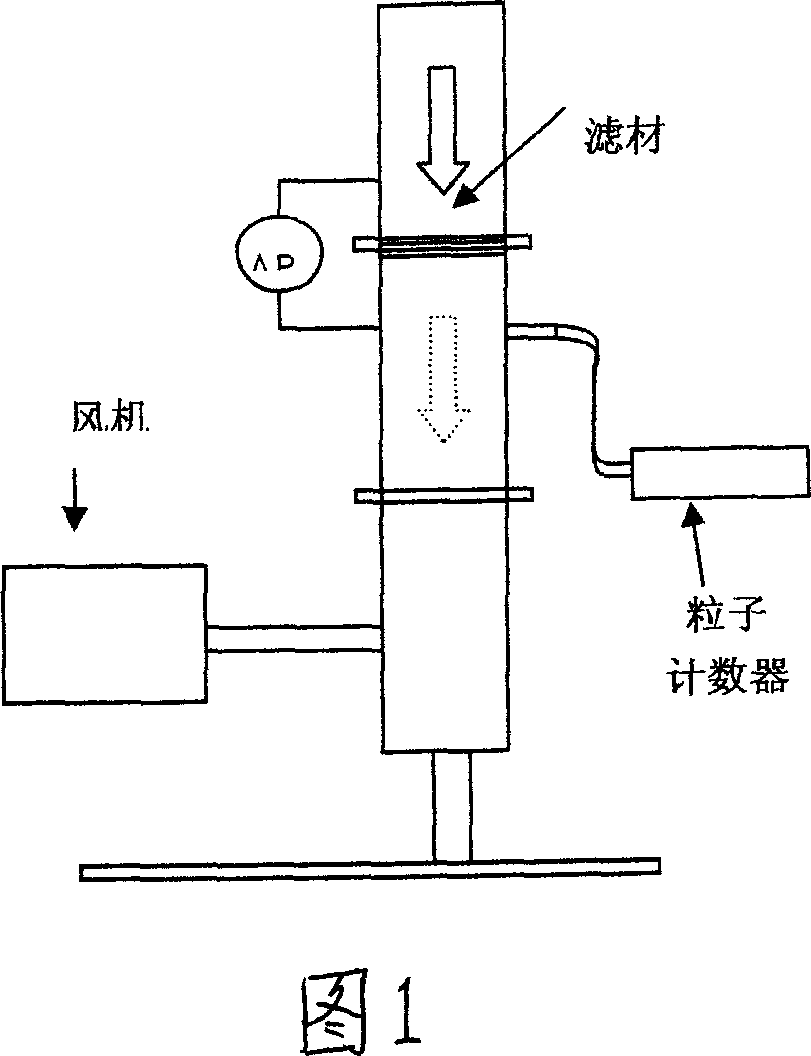

Filtering material of thermal stability and the purpose thereof

InactiveCN101032674AHigh mechanical strengthReduce thermal shrinkageFiltration separationFiberHeat resistance

The present invention discloses one kind of heat resistant filter material and its use. The heat resistant filter material consists of one base material layer and one combined filter layers, the base material layer is made of inorganic fiber and / or heat resistant organic fiber, and at least one filter layer contains both inorganic fiber and heat resistant organic fiber, with the diameter of the inorganic fiber being smaller than that of the heat resistant organic fiber. The heat resistant filter material is used in filter. It has excellent complexing performance between the inorganic fiber and the heat resistant organic fiber, high dust collecting efficiency, high dust impact resistance, high antiwear performance, high heat shrinkage tolerance, etc.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

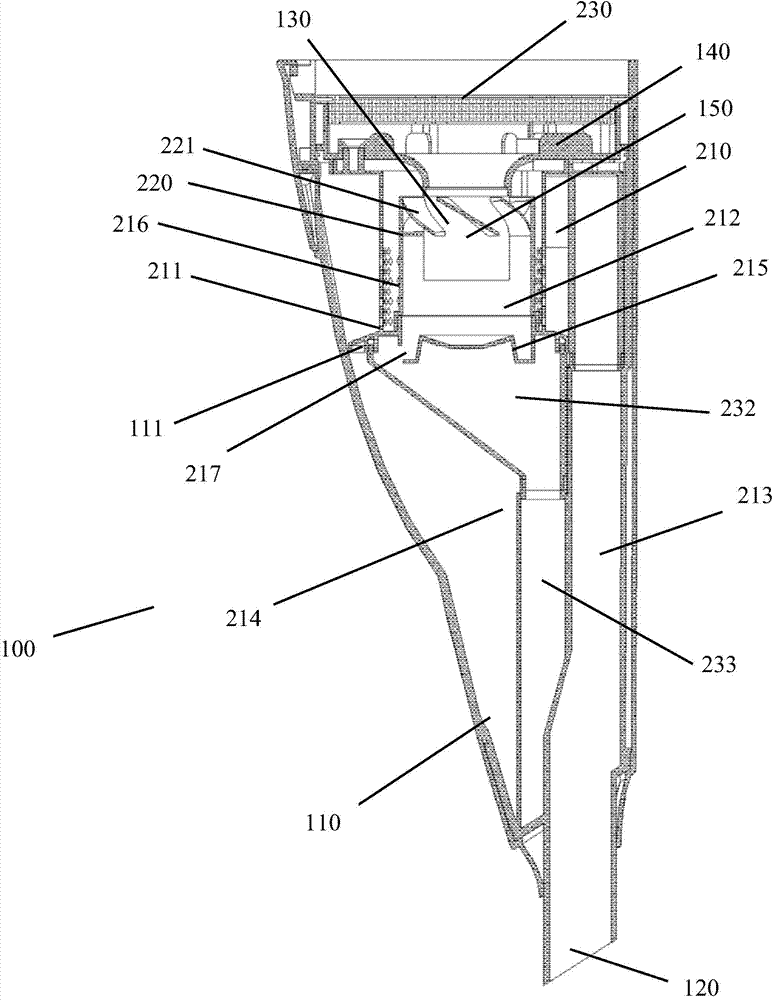

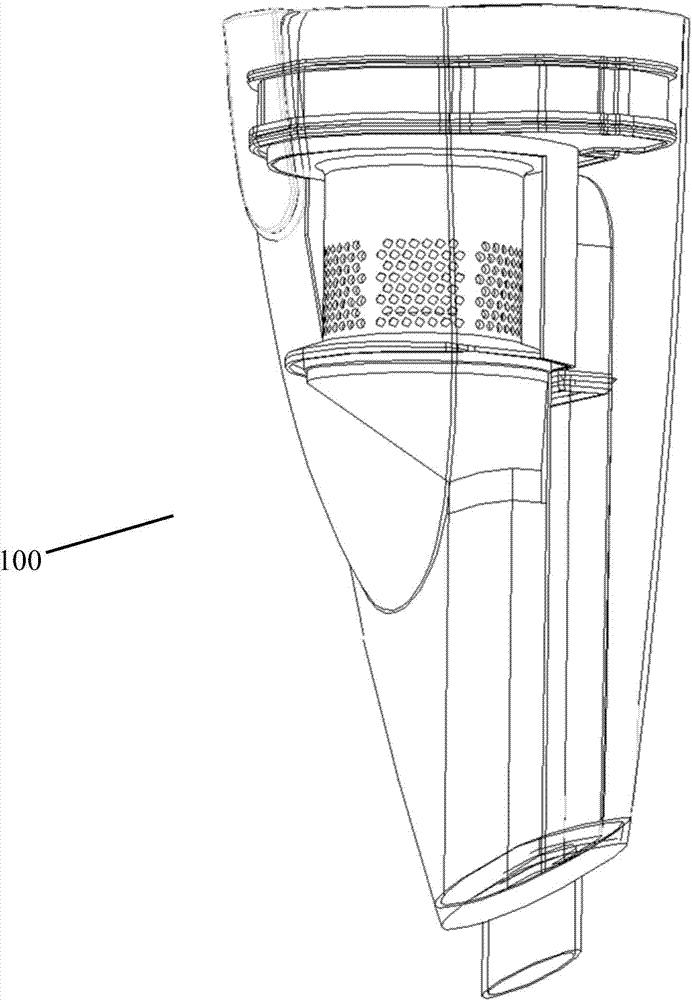

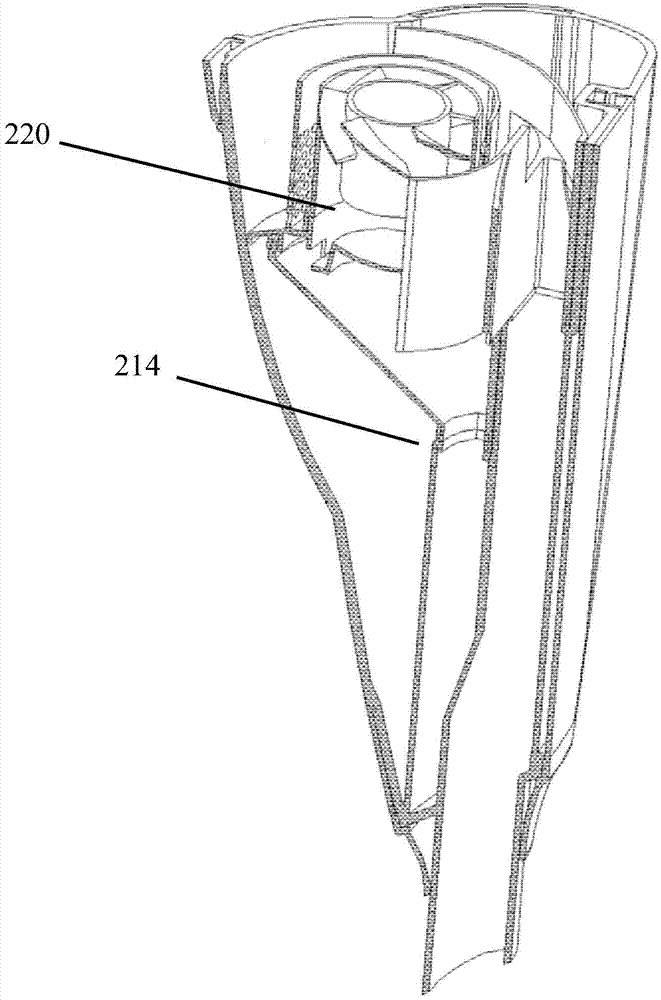

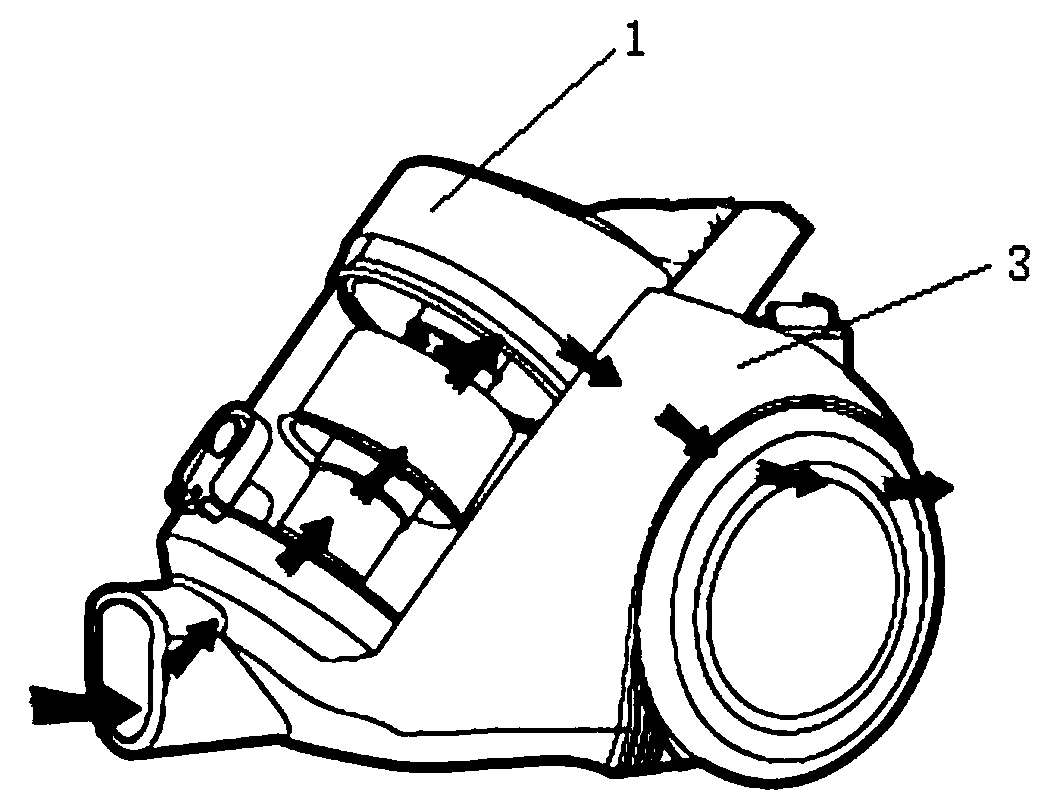

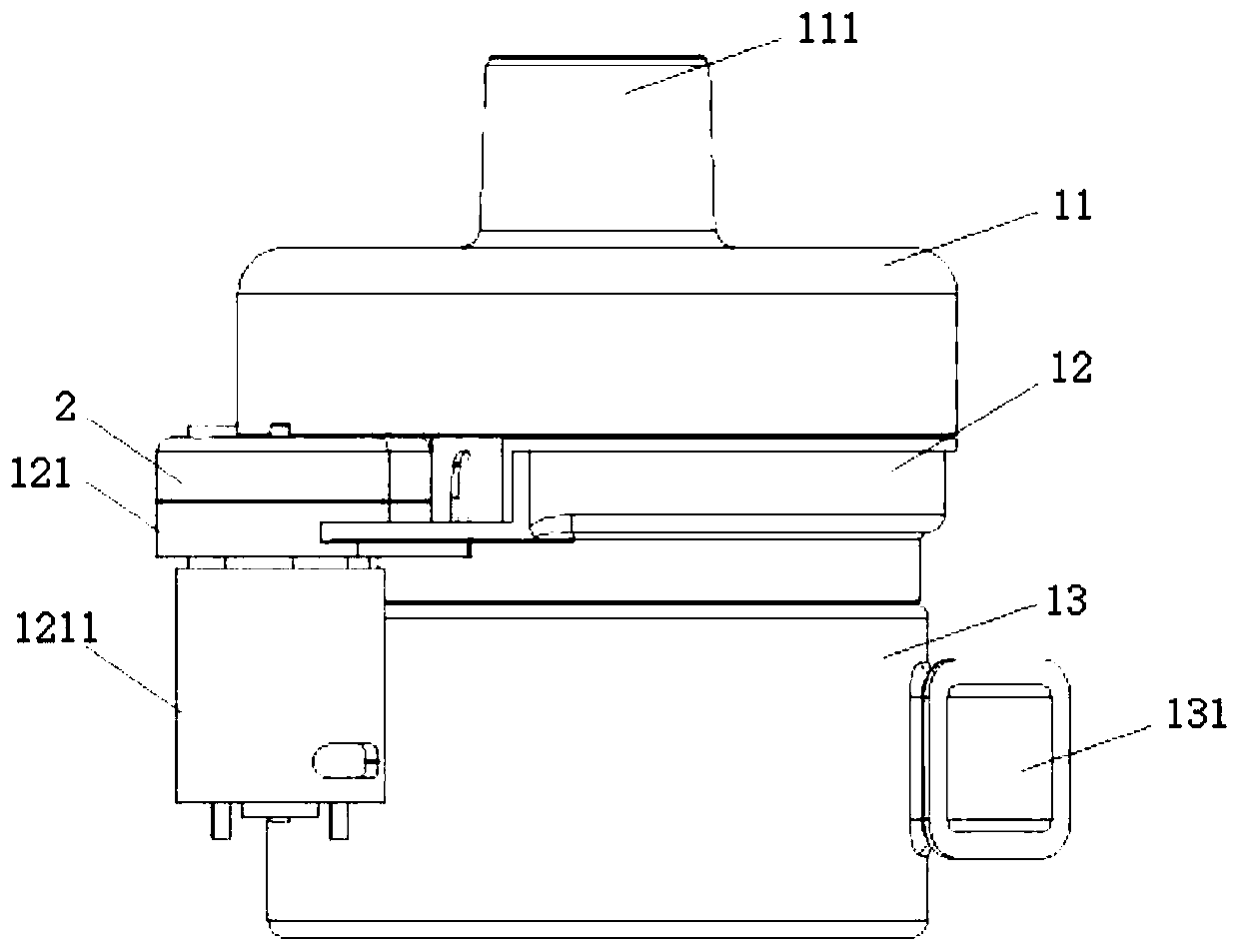

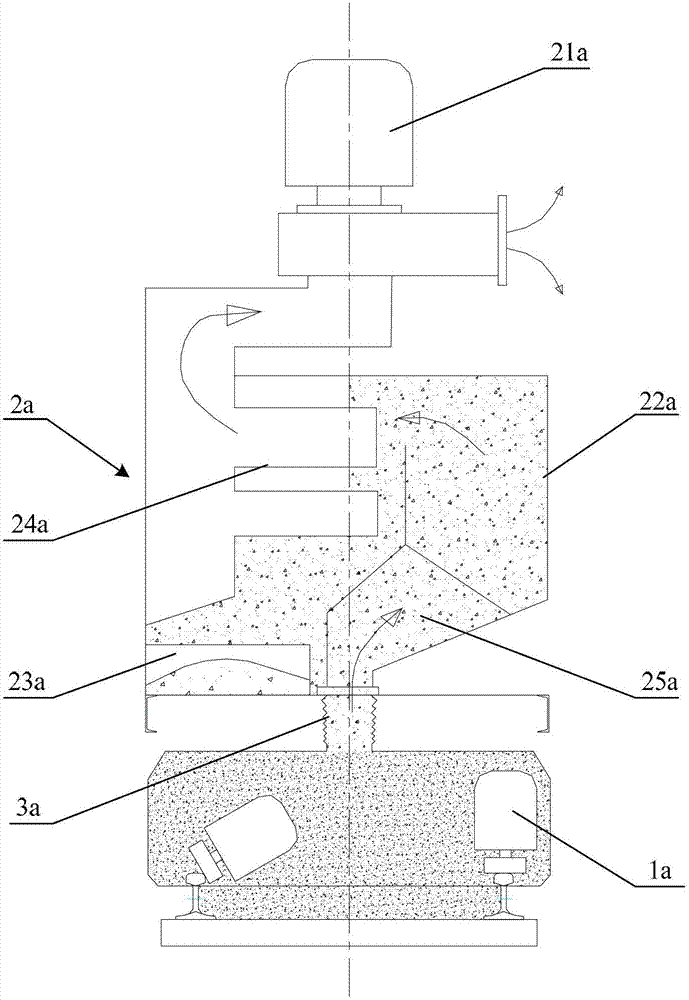

Handheld dust collector with spiral two-level tornado dust-air separation structure

InactiveCN104840152AImprove filtration efficiencyImprove performanceSuction filtersCycloneAir separation

The invention discloses a handheld dust collector, which is characterized in that a body of the dust collector is internally provided with the spiral two-level tornado dust-air separation structure and a one-level dust cylinder, wherein the spiral two-level tornado dust-air separation structure comprises a first-level cyclone cylinder, a second-level cyclone cylinder, a spiral gas-air separation device arranged at the upper end of the second-level cyclone cylinder and a cyclone cover. The first-level cyclone cylinder and the cyclone cover carry out first-level gas-air separation on primary dust-air getting into the spiral two-level tornado dust-air separation structure, and separated two-level dust-air gets into the second-level cyclone cylinder to receive second-level dust-air separation. The dust collector disclosed by the invention is small in number of components, simple in assembling procedure and high in comprehensive performance of the complete machine. Meanwhile, the spiral two-level tornado dust-air separation structure is small in size, can effectively reduce the space of the machine body, and realizes the maximum dust storage volume.

Owner:KINGCLEAN ELECTRIC

Dedusting agent composition and using method thereof

ActiveCN101717617AReduce water consumptionReduce surface tensionOther chemical processesDust removalChlorideCarbon chain

The invention discloses a dedusting agent composition and a using method thereof. The dedusting agent composition is prepared by fully mixing the following components in percentage by weight: 0.04 to 0.06 percent of sodium diisooctylester sulfosuccinate, 0.04 to 0.06 percent of empgen BB, 99.547 percent to 99.91 percent of water and 0.111 to 0.333 percent of calcium chloride, wherein the mixture of the components is pressed into a spraying dust-settling system on a coal mine working surface for spraying. In the method, the sodium diisooctylester sulfosuccinate, the empgen BB, the water and the calcium chloride are fully mixed together; and the sodium diisooctylester sulfosuccinate and the empgen BB are substances with surface activity, the molecules of the sodium diisooctylester sulfosuccinate and the empgen BB consist of hydrophilic groups and hydrophobic groups, the hydrophobic groups generally consist of long organic carbon chains, and the molecules are similar to the characteristics of surface molecule of coal dust and can generate absorption easier than water molecules, so the dust catching efficiency of the water is improved, the dedusting efficiency of the dedusting agent is over 90 percent, and the water consumption for dedusting is saved.

Owner:SHANDONG UNIV OF SCI & TECH

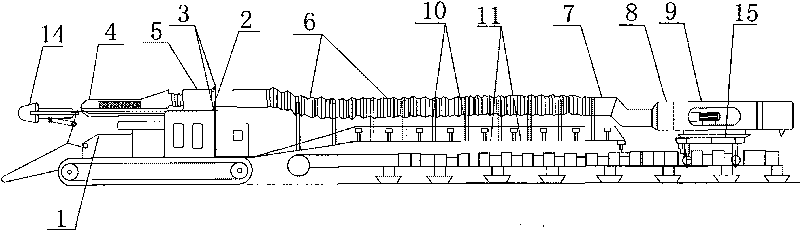

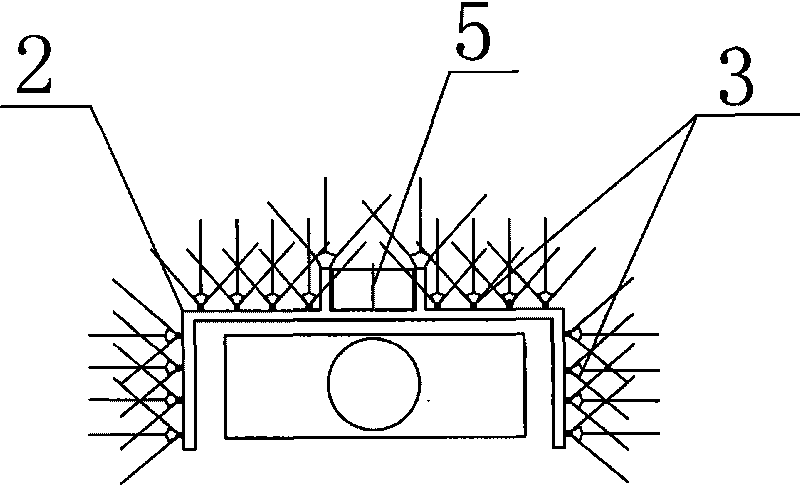

Air curtain sealing dedusting system on fully-mechanized excavating face

InactiveCN101761337AReduce spreadReduce dust concentrationDust removalFire preventionEngineeringOperation safety

The invention discloses an air curtain sealing dedusting system on a fully-mechanized excavating face, comprising a fully-mechanized roadheader body. The fully-mechanized roadheader body is provided with an air curtain generating device; the air curtain generating device is positioned between an excavating head and a driver of the fully-mechanized roadheader body and can spray air flows to the left side and the right side of the fully-mechanized roadheader body in an upright upward direction so as to form a closed air curtain perpendicular to the excavating direction of a fully-mechanized roadheader; a closed space used for accommodating dust generated when the fully-mechanized roadheader body excavates is formed by the closed air curtain and the excavating face of the fully-mechanized roadheader body; and the fully-mechanized roadheader body is also provided with a dedusting device used for absorbing the dust inside the closed space. By arranging the ari curtain generating device on and the dedusting device on the fully-mechanized roadheader to effectively seal the dust in a space with unattended operation, the invention enhances the dust absorption efficiency of the dust positioned on the excavating head, reduces the influence on a visual line of an operator and enhances the operation safety because the operator can clearly view evacavating.

Owner:SHANDONG UNIV OF SCI & TECH

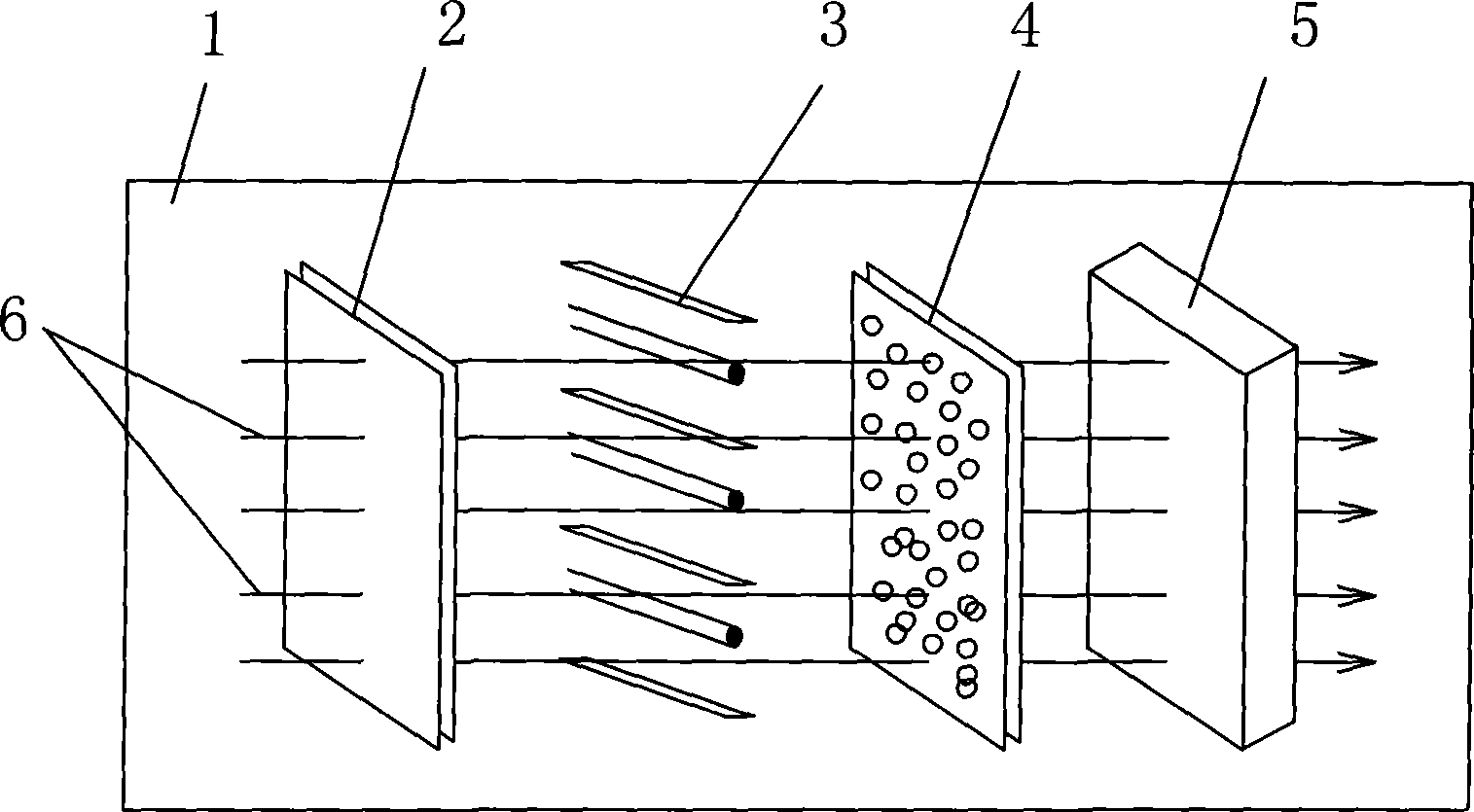

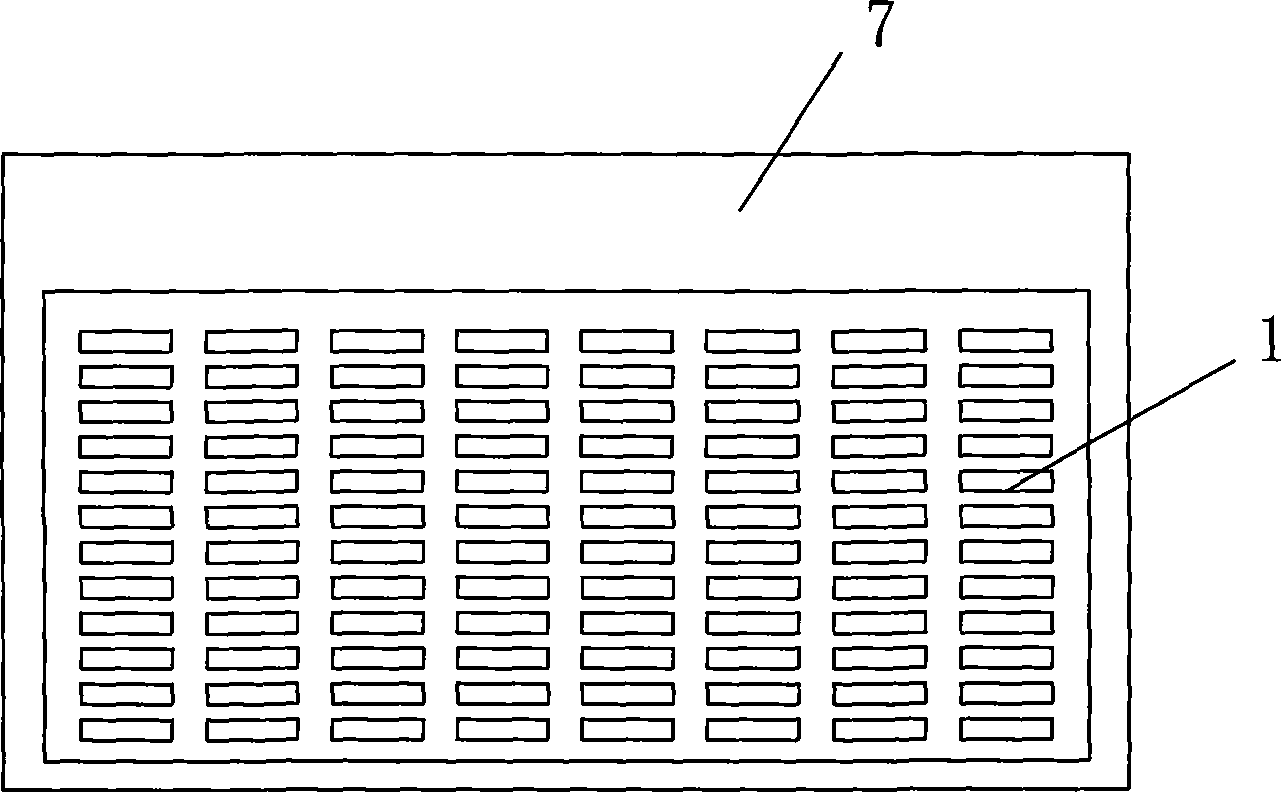

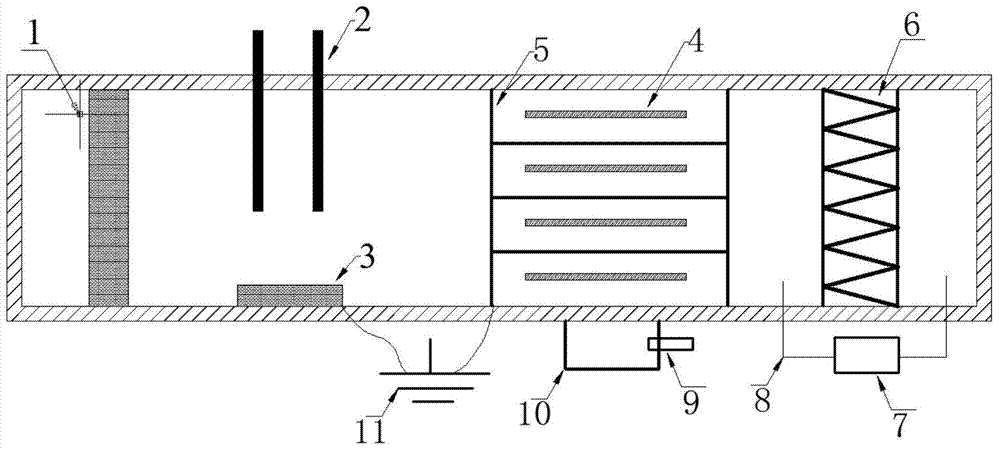

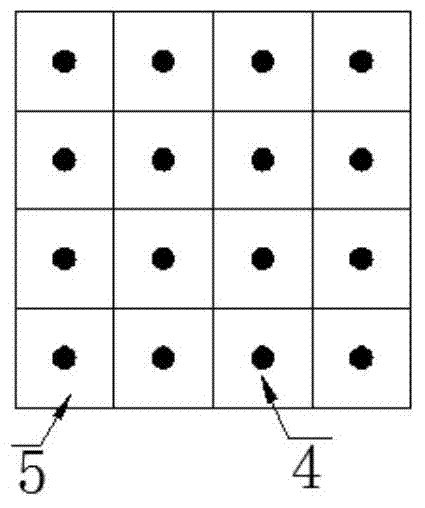

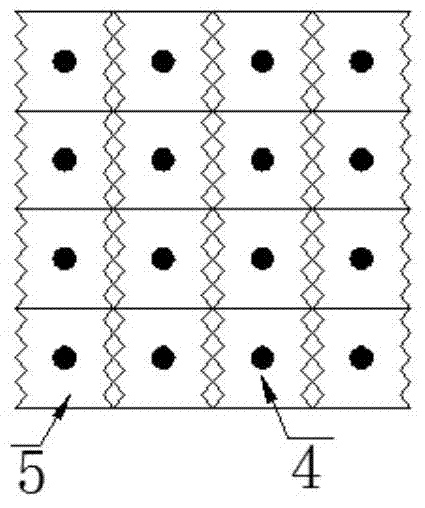

Matrix type honeycomb photocatalysis plasma purifier

InactiveCN101498487AImprove dust collection efficiencyImprove capture efficiencyCombination devicesLighting and heating apparatusHigh concentrationHoneycomb

The invention discloses a matrix-type honeycomb photocatalysis plasma purifier comprising a housing and a purifying unit module arranged and between an inlet and an outlet in the inner cavity. The purifying unit module consist of a primary filter, an electrostatic precipitation filter, a photocatalysis plasma catalyzing and purifying filter and a positive-negative ion stirrer which are sequentially arranged from the inlet to the outlet; then the air sequentially entering from the inlet and having impurities is purified, and fresh air is discharged finally at the outlet. The matrix-type honeycomb photocatalysis plasma purifier integrates the functions of high-efficiency sterilization, virus killing, dedusting, deodorization, formaldehyde removal, decoration gas removal and organic waste gas degradation, realizes large specific surface and high dust collection efficiency and discharges static electricity at the front end and the back end so as to ionize the air with static electricity discharging efficiency higher than the conventional single-area static electricity discharging efficiency; the photocatalysis plasma catalyzing and purifying filter catalyzes and oxidizes harmful chemical odorous gas, and generated plasmas are in high concentration, so that germs can be completely killed; and the matrix-type honeycomb photocatalysis plasma purifier suffers little wind resistance and realizes massive dust collection.

Owner:郑承煜

Wet type dust-laying agent composition and use method thereof

ActiveCN101712861AImprove efficiencyReduce surface tensionOther chemical processesDust removalCarbon chainChloride

The invention discloses a wet type dust-laying agent composition and a use method thereof. According to the percentage by weight, 0.04-0.06% of sodium dodecyl sulfate, 0.04-0.06% of sodium dodecyl benzene sulfonate, 99.547-99.91% of water and 0.111-0.333% of calcium chloride are fully mixed; and the mixed liquid is pressed into a spraying dust-laying system of a working face in the coal mine for spraying. The sodium dodecyl sulfate and the sodium dodecyl benzene sulfonate are the substances with surface activities and the molecules of the two substances are formed by hydrophilic groups and hydrophobic groups. The hydrophobic groups are generally formed by longer carbon chains, have the characteristics close to the characteristics of the molecules on the surface of coal dust and are easierto carry out absorption than water molecules, thereby improving the dust seizing efficiency of water, ensuring the dust-laying rate of the dust-laying agent to exceed 90% and saving the water consumption for dust laying.

Owner:SHANDONG UNIV OF SCI & TECH

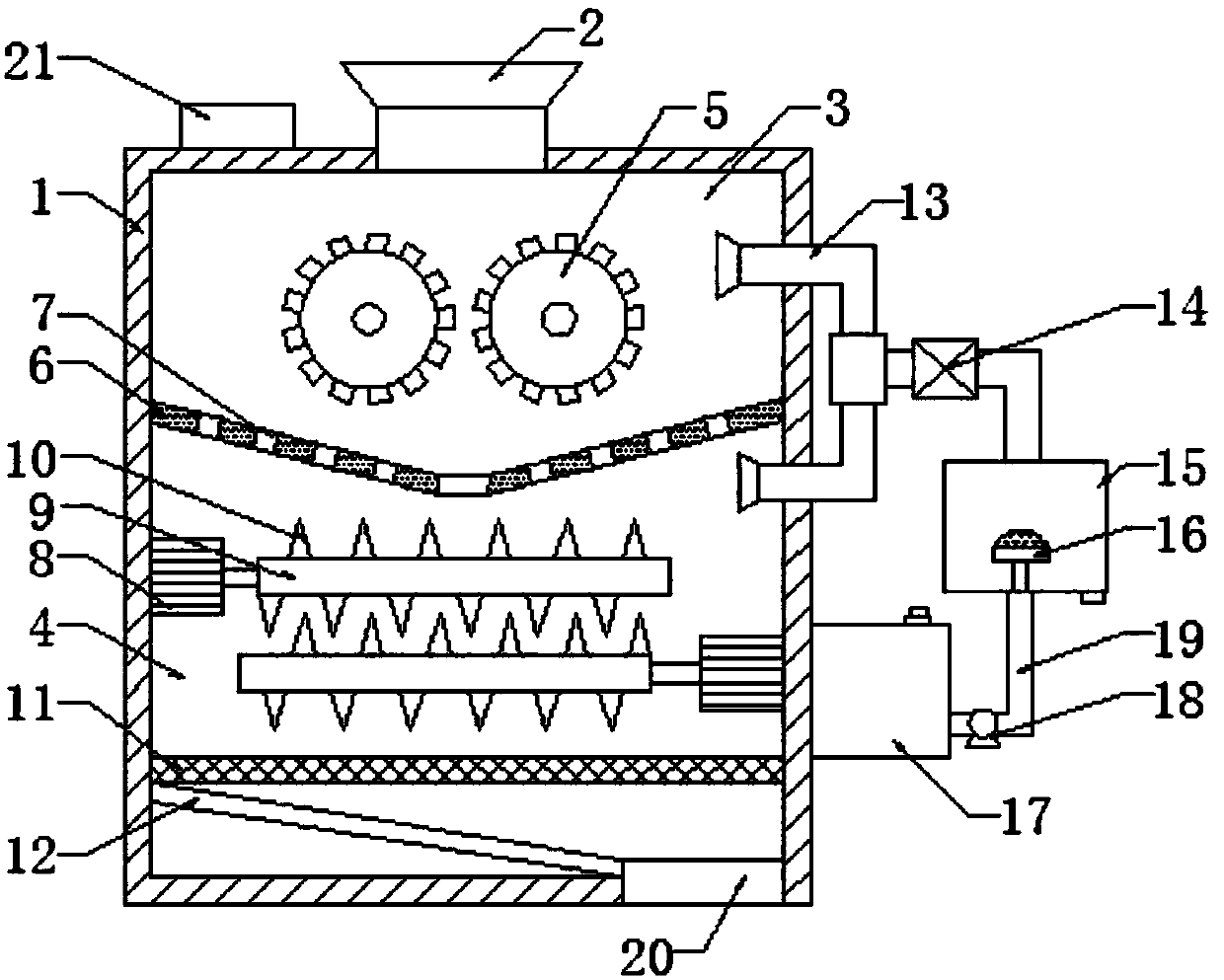

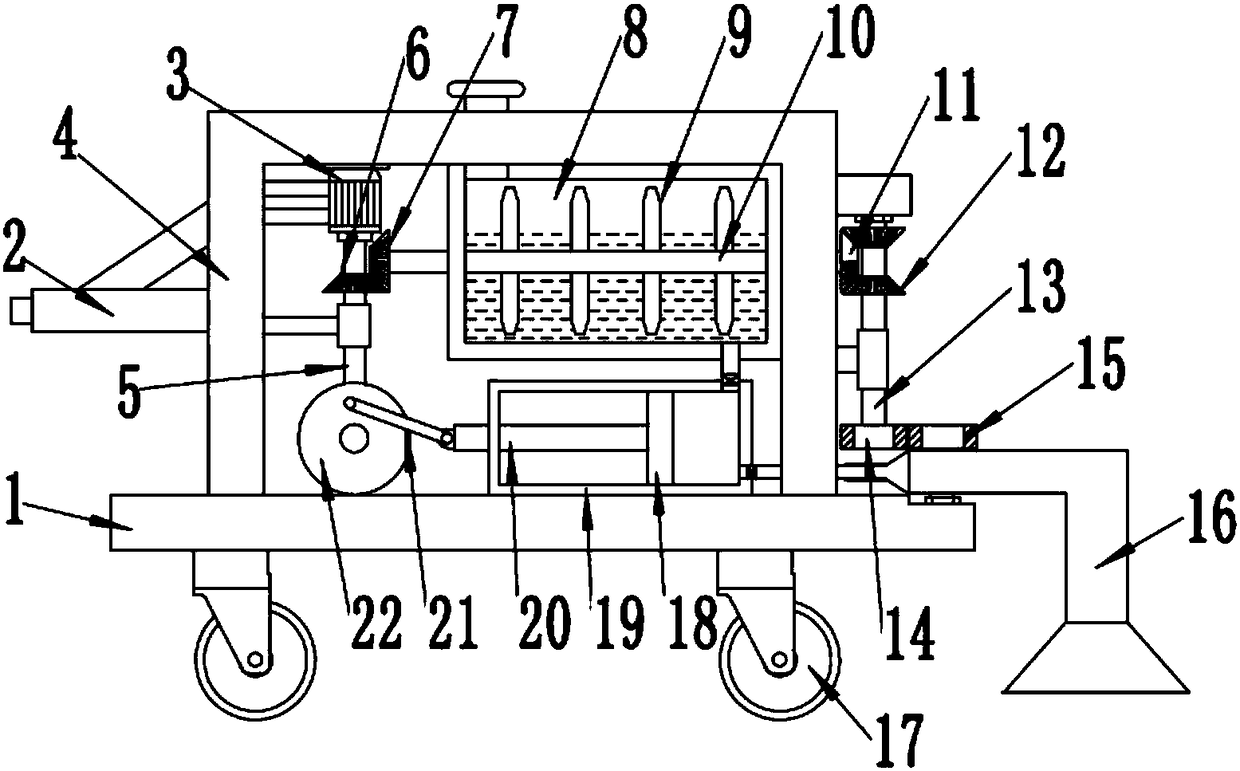

Municipal building waste crushing device with dust removal function

InactiveCN109926145AComplete and compact structural designConvenient whereaboutsUsing liquid separation agentDirt cleaningEngineeringMotor shaft

The invention discloses a municipal building waste crushing device with a dust removal function. The municipal building waste crushing device comprises a crushing box, a coarse smashing chamber, a fine smashing chamber, two servo motors, crushing knives and a dust removal box, the crushing box is internally provided with the coarse smashing chamber and the fine smashing chamber, a feeding inlet isformed in the top of the crushing box, a controller is arranged on one side of the feeding inlet, two crushing rollers are arranged in the coarse smashing chamber in parallel, the coarse smashing chamber and the fine smashing chamber are partitioned by a sieving plate, the sieving plate is evenly provided with a plurality of through holes, the two servo motors are mounted in the fine smashing chamber, motor shafts of the two servo motors are axially connected with two rotating shafts correspondingly, the crushing knives are arranged on the two sides of the two rotating shafts, the directionsof the two rotating shafts are opposite, by arranging the crushing rollers, building waste is preliminarily smashed firstly, coarsely smashed and then smashed by the crushing knives, smashing is morethorough, through mutual action of a water pump, an atomizing nozzle, the dust removal box and a suction ventilator, dust generated in the crushing process is absorbed through water mist, and the effect is good.

Owner:XIAN DONGJIA TRADE CO LTD

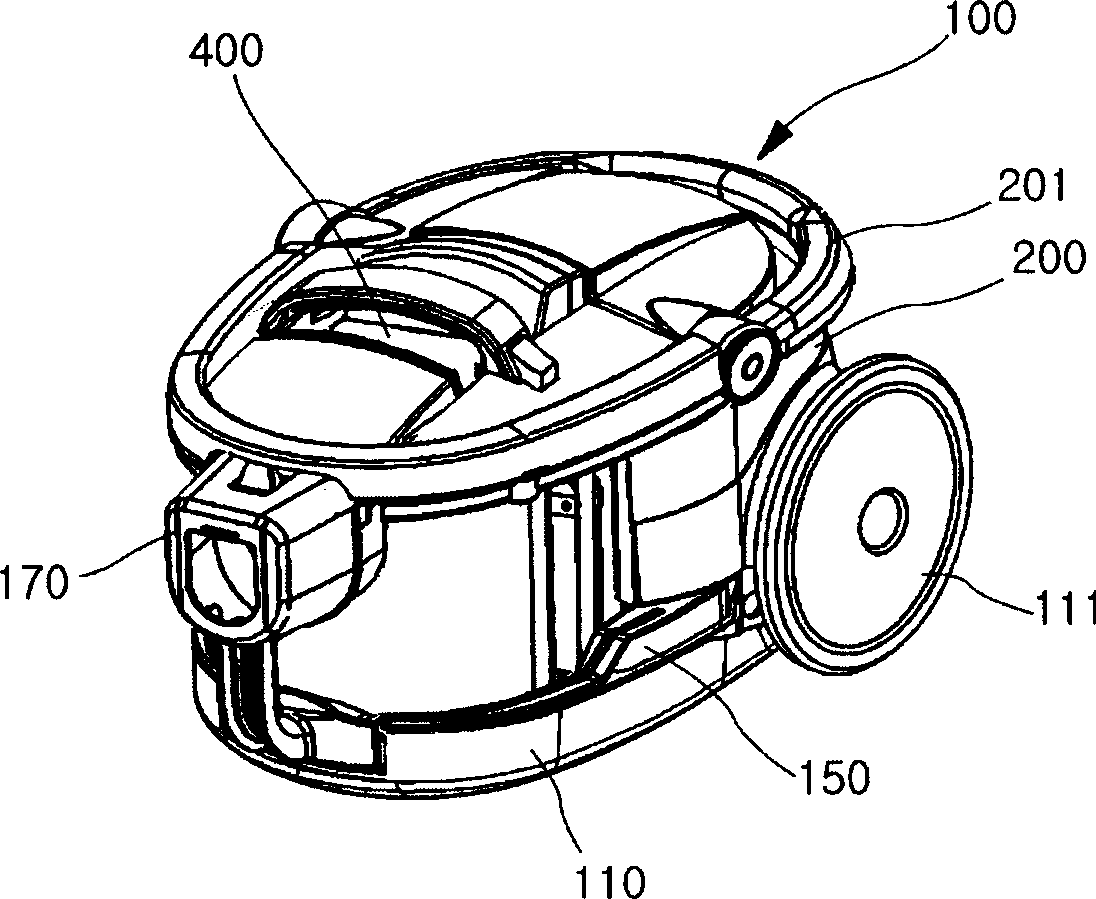

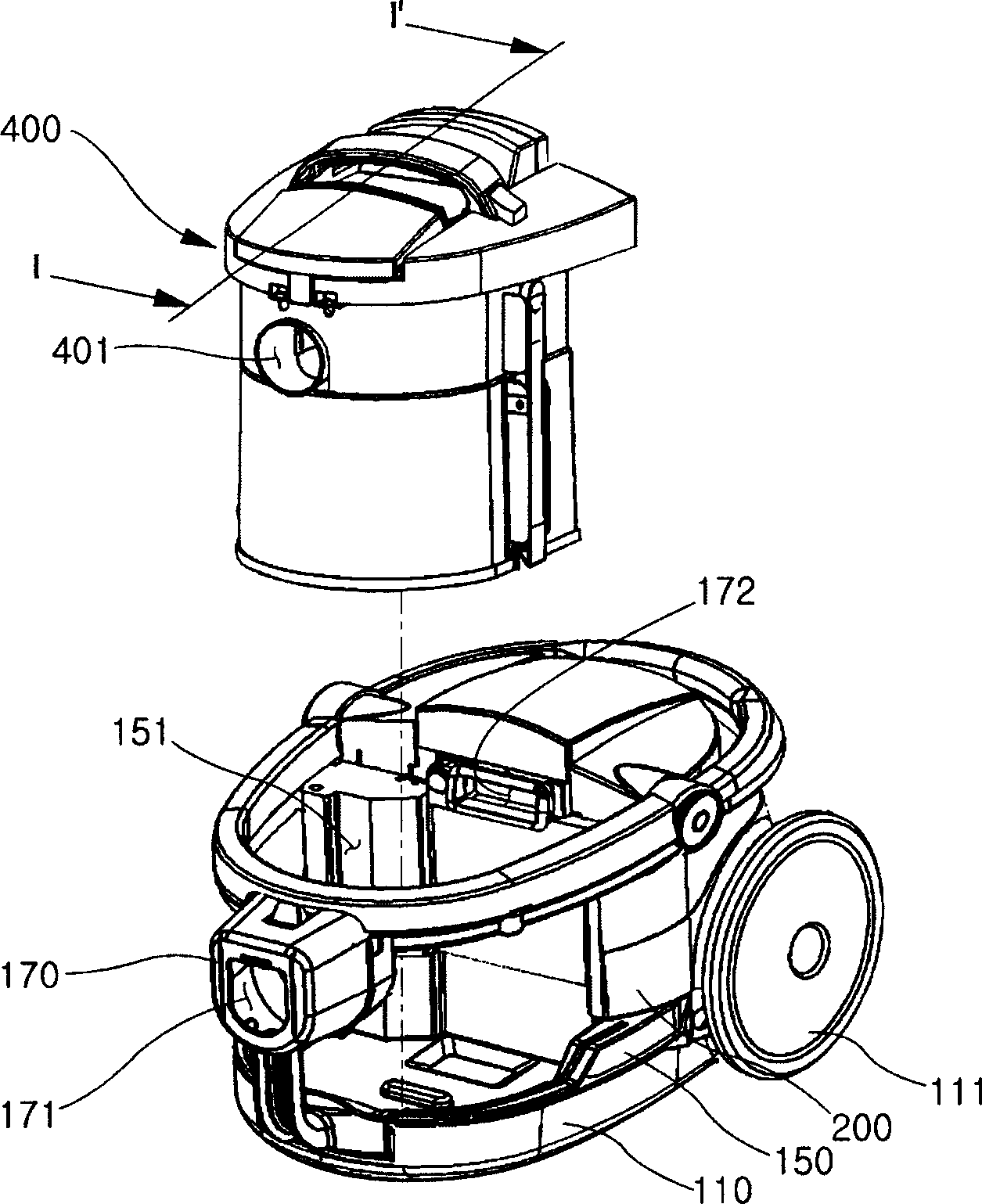

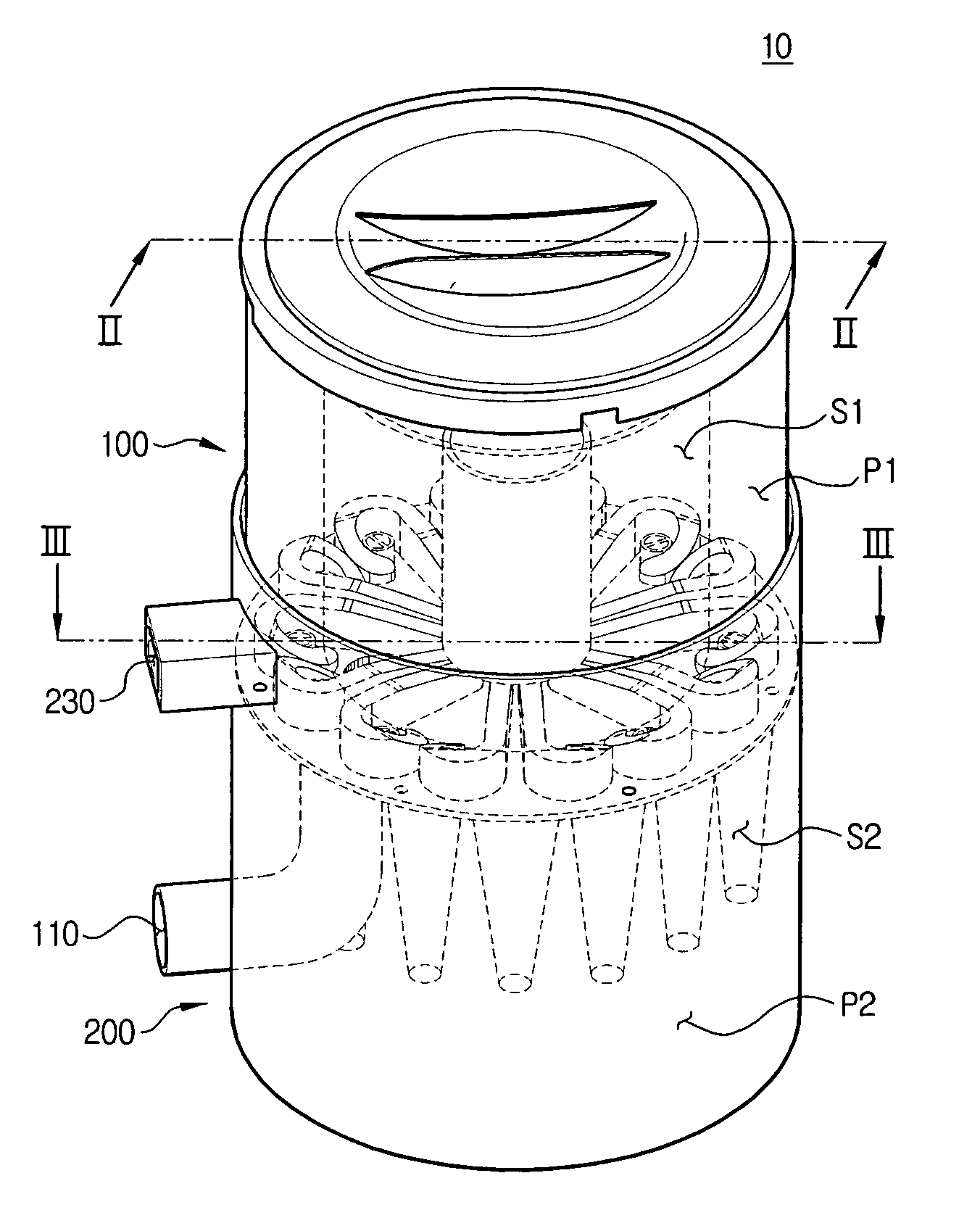

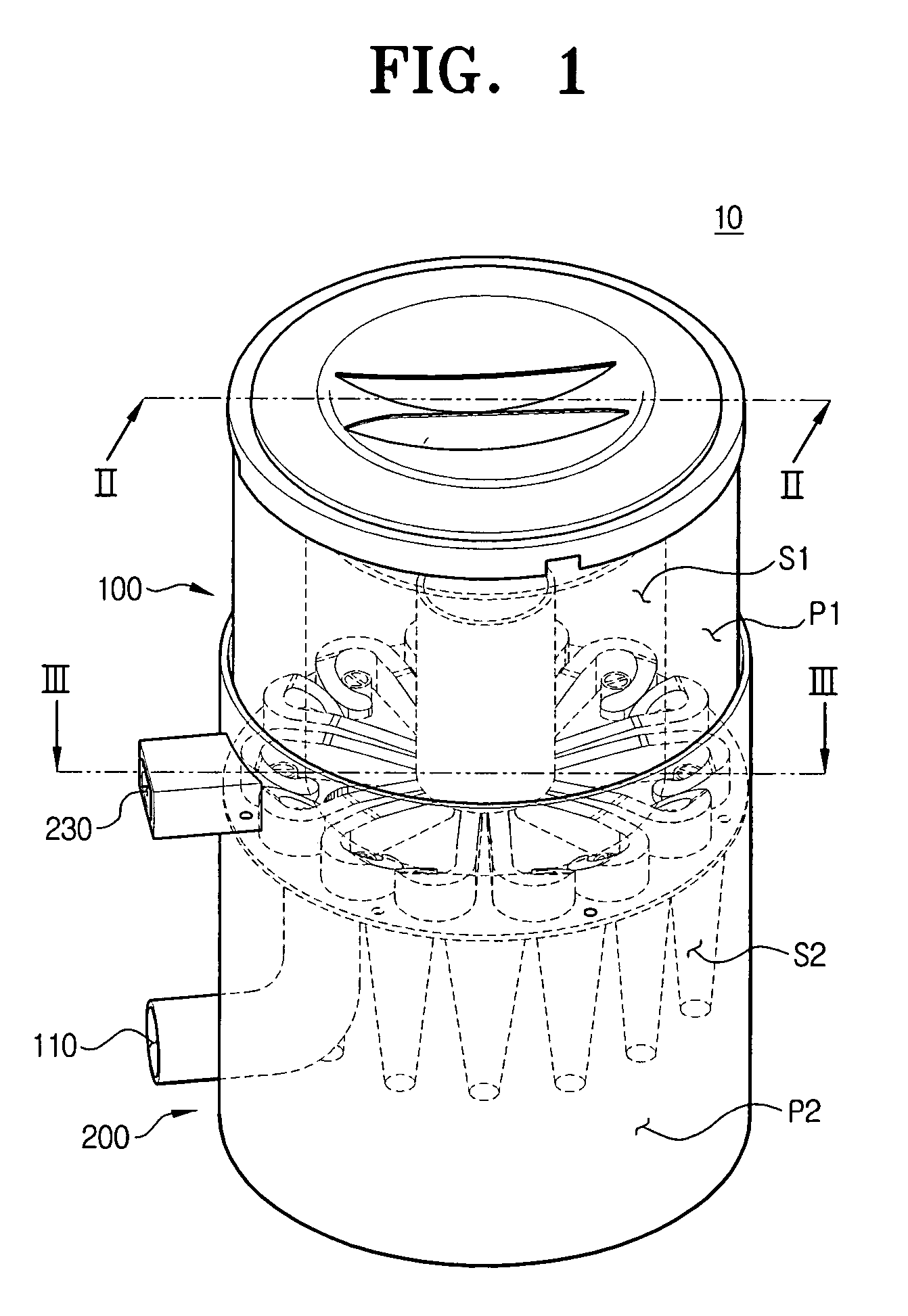

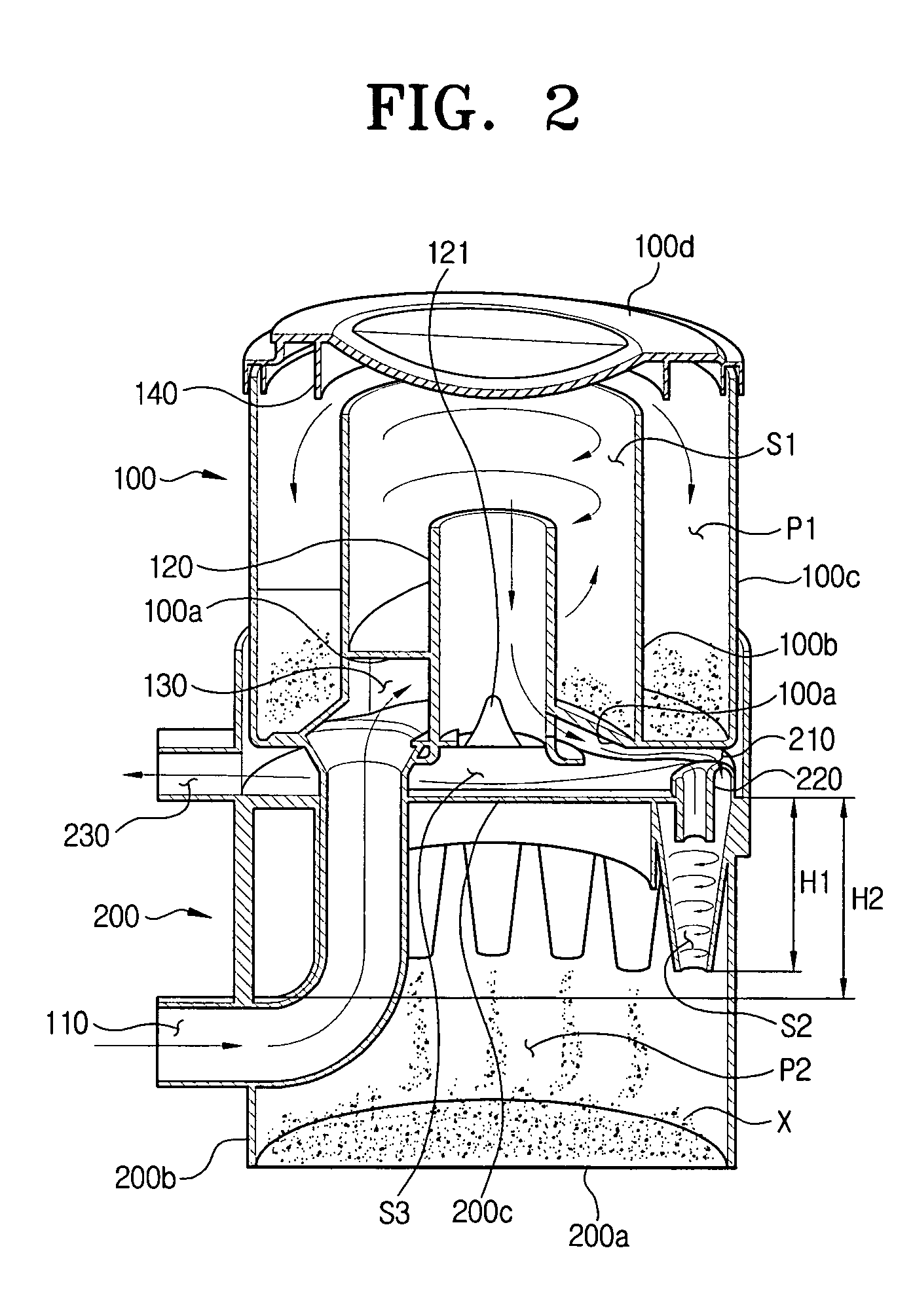

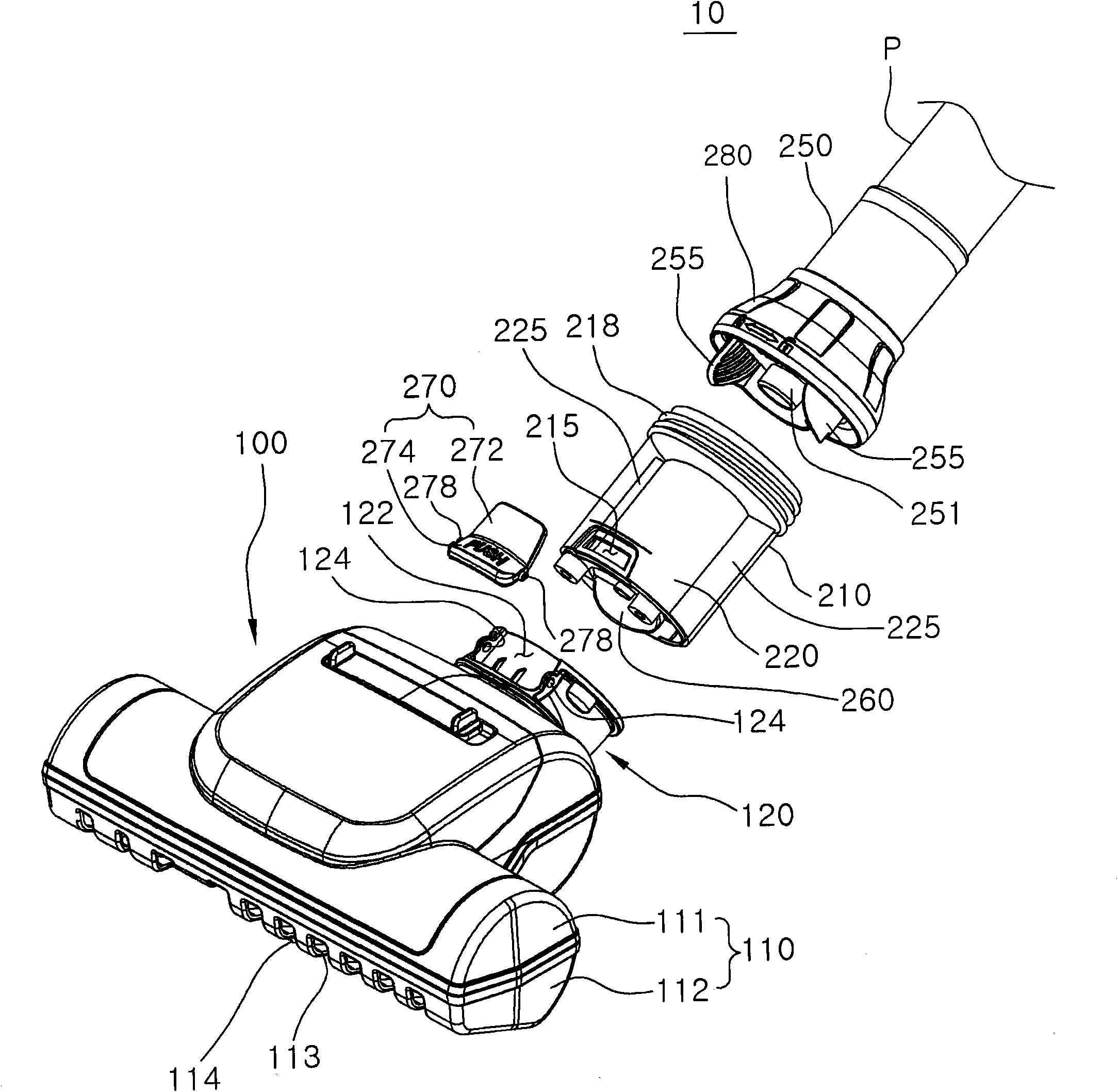

Multi-cyclone dust separator

InactiveUS20060230716A1Improve dust collection efficiencyIncrease the number ofReversed direction vortexSuction cleanersCycloneEngineering

A multi-cyclone dust separator according to an embodiment of the present invention comprises a first cyclone unit having a first cyclone chamber and a first dust receptacle enclosing a circumference of the first cyclone chamber; and a second cyclone unit disposed below the first cyclone unit and having a plurality of second cyclone chambers and a second dust receptacle disposed under the second cyclone chambers to collect dust.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

High-dust holding capacity and high-efficiency composite electrostatic air purification device

InactiveCN103691240AReduced dust holding capacityExtended service lifeCombination devicesBacterial virusAir filter

The invention discloses a high-dust holding capacity and high-efficiency composite electrostatic air purification device, which sequentially comprises a primary filtering screen, a carbon brush charge region, an electrostatic dust removal region, an air filter and a dust hopper, wherein a differential pressure transducer is arranged at the two ends of the air filter; a material level sensor is arranged in the dust hopper. According to the composite electrostatic air purification device, charged particles are collected by the electrostatic dust removal region, so that the air filter is protected, and the service life of the air filter is prolonged; the dust holding capacity of the air filter is reduced, pressure drop is reduced, and labor is saved; the exposure time of air, dust and particles on the air filter is reduced, and secondary pollution to the air caused by gas pollutants and bacterial viruses in a particle filtering process is reduced; the filtering efficiency of the electrostatic dust removal region is insensitive to blast volume changes, and the influence of proper increase of the blast volume to the overall dust removal efficiency of the device is limited, so that the purification device is suitable for blast volume variable buildings.

Owner:TIANJIN UNIV

A vacuum cleaner and a control method thereof

InactiveCN110074724ACompact structureEasy to separateSuction filtersElectric equipment installationDrive motorEngineering

The invention relates to the technical field of dust collectors, and discloses a dust collector and a control method thereof, the dust collector comprises a dust collecting device and a main body, thedust collecting device is detachably mounted on the main body, and the dust collecting device is used for separating and collecting garbage; the dust collecting device comprises a driving motor and aseparator, and the driving motor drives the separator to rotate; an air suction motor is arranged in the main body, when the dust collector is started, the air suction motor falls behind the drivingmotor to be started, and when the dust collector stops, the air suction motor stops earlier than the driving motor. Through arrangement of the driving motor and the air suction motor, the driving motor drives the separator to rotate to reach the preset rotating speed, then the dust collector sucks in fluid under the action of the air suction motor, and the separation effect of the fluid for removing dust and liquid is effectively improved.

Owner:SUZHOU GAMANA ELECTRIC APPLIANCE CO LTD

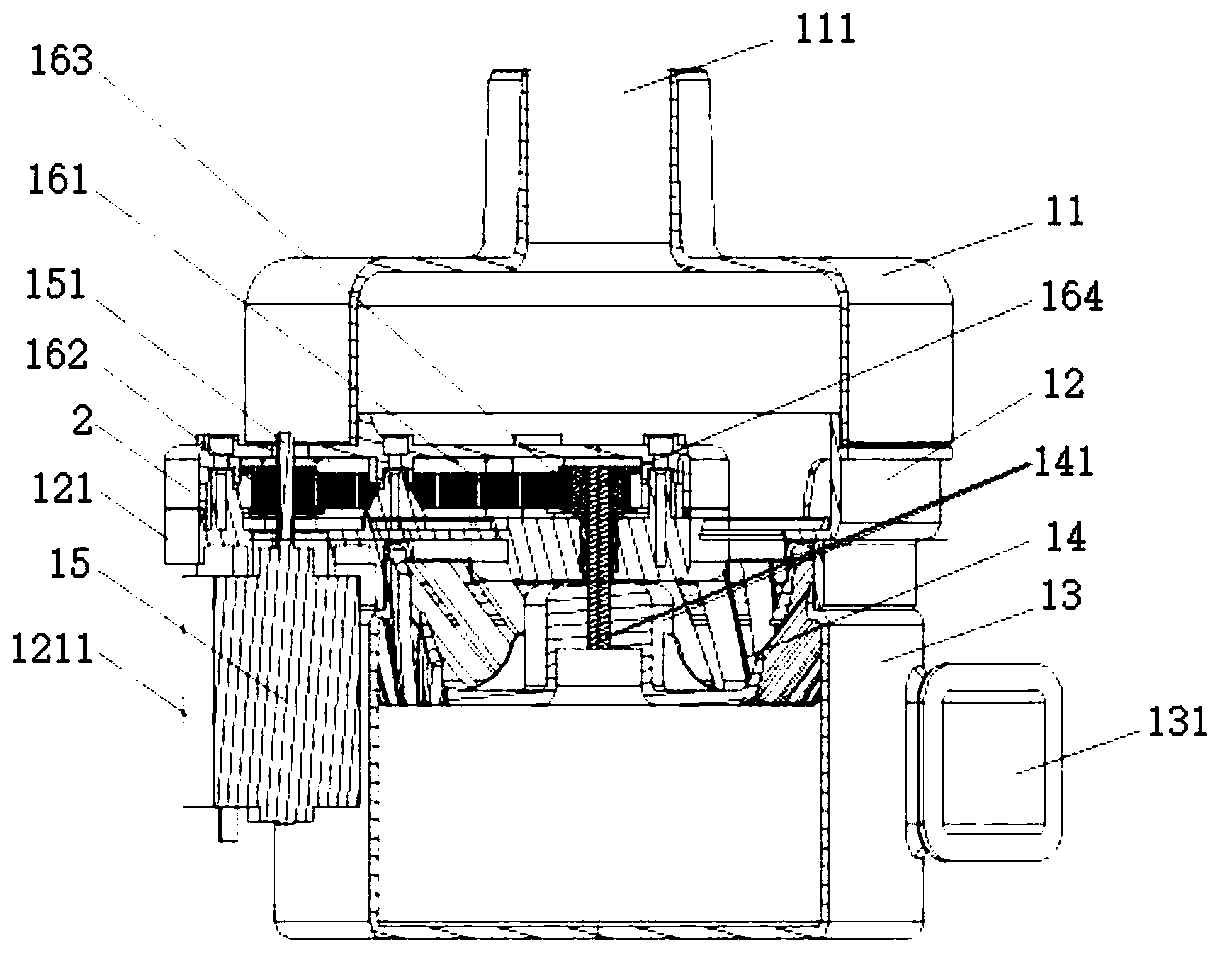

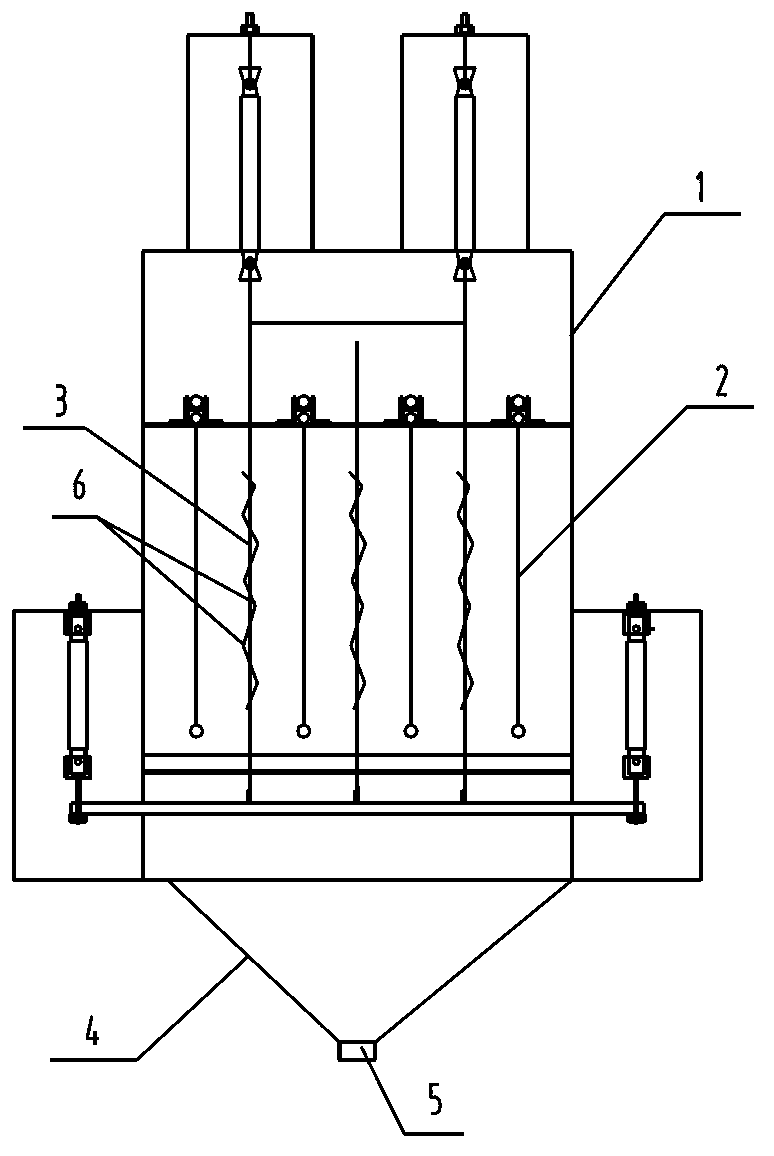

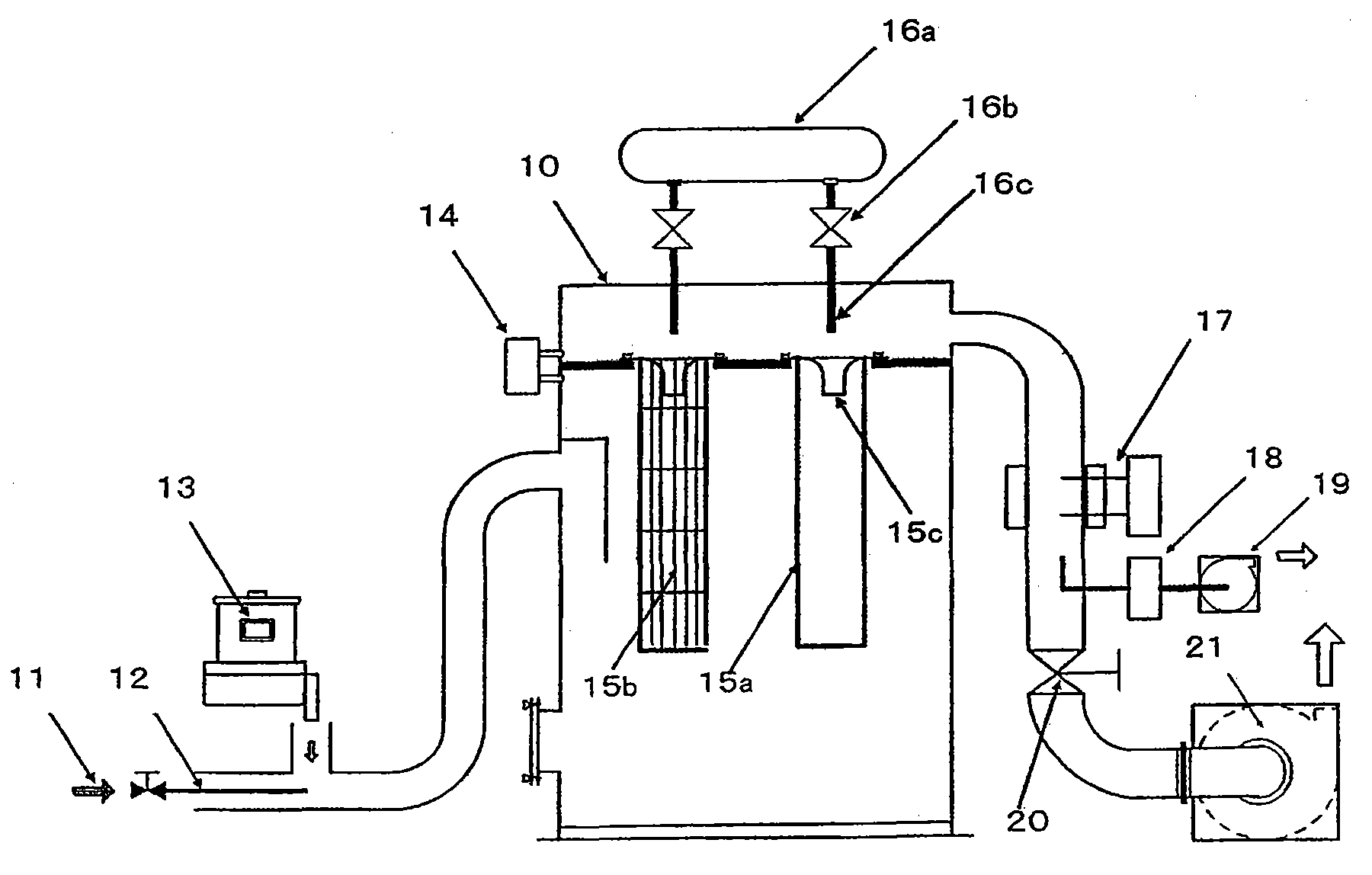

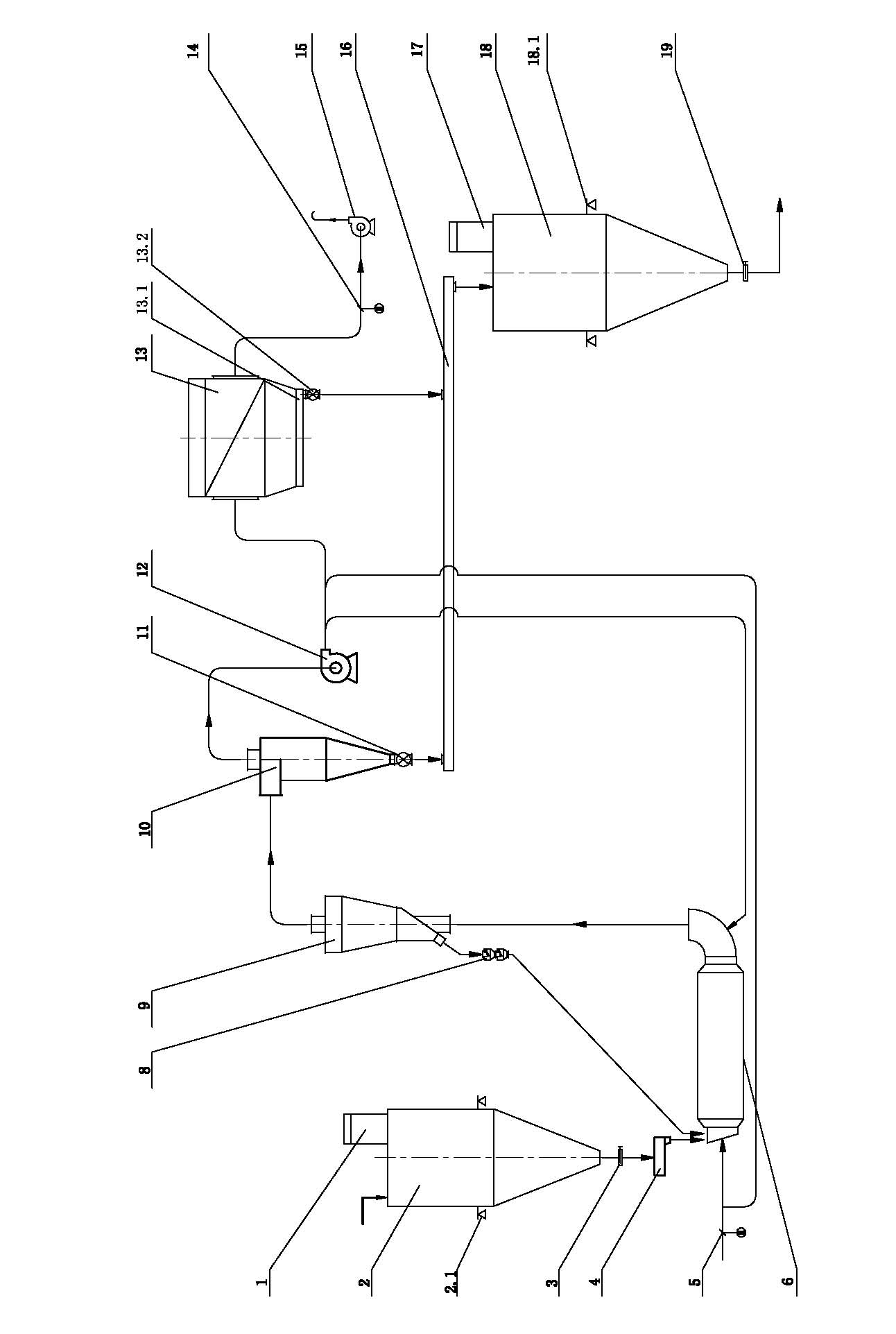

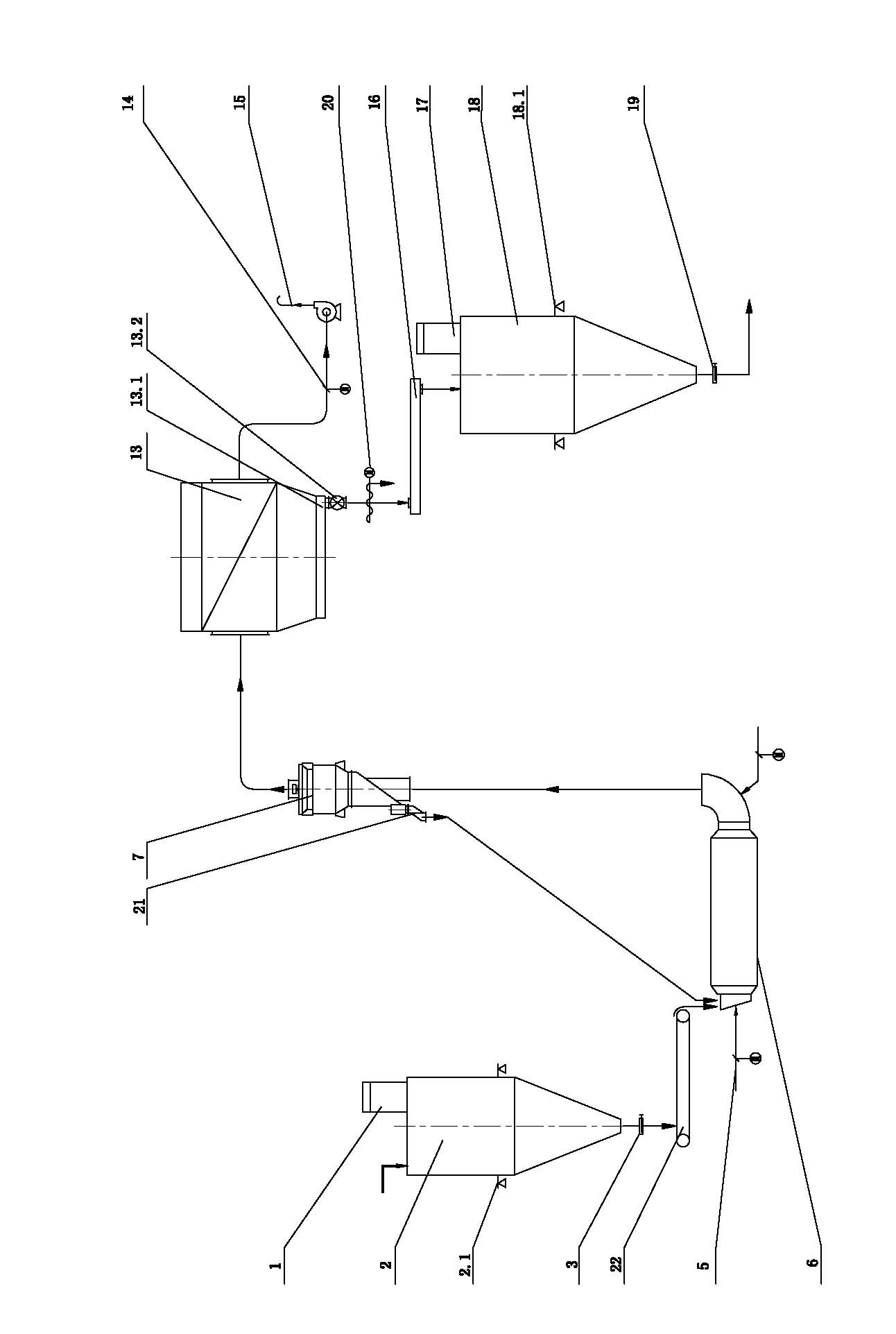

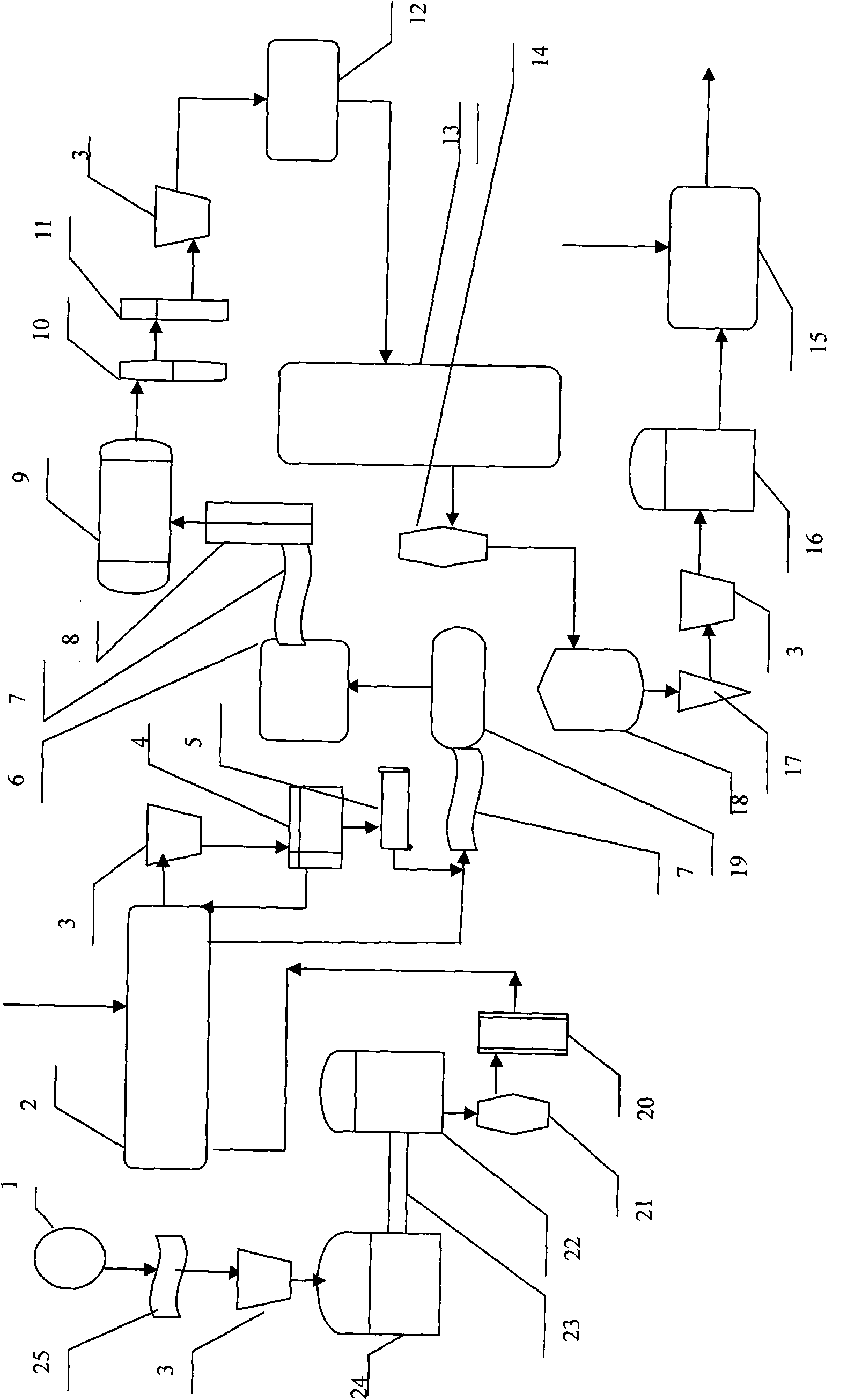

Dust removing system for fully-mechanized coal mining workface

PendingCN107218074AImprove working environmentReduce dust concentrationDust removalFire preventionMining engineeringDust control

The invention discloses a dust removing system for a fully-mechanized coal mining workface. The system includes a dust control system installed on one side of a roadheader, a dust suction system and a dust collecting system installed on the other side of the roadheader, wherein the dust control system comprises a press-in type fan, a press-in type air duct and a wall-attached air duct which are connected with each other in turns; the dust suction system comprises a first suction hood for sucking dust on the cutting head position of the roadheader, a second suction hood for sucking dust on the insertion board position of the roadheader, a third suction hood for sucking dust on the break-of-bulk-point position of a scraper conveyor and belt conveyor, a dust suction air duct and a suction hood assembly box, and the first suction hood, the second suction hood, the third suction hood and the dust suction air duct are all connected to the suction hood assembly box; the dust collecting system comprises an extraction type air duct, a dust remover and an extraction type fan which are connected with each other in turns, and the extraction type air duct is connected to the suction hood assembly box. The dust removing system for the fully-mechanized coal mining workface can effectively control diffusing and spreading of dust in underground roadways, has a good dust suction effect and high dust collecting efficiency, and can greatly reduce the dust concentration of the fully-mechanized coal mining workface.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

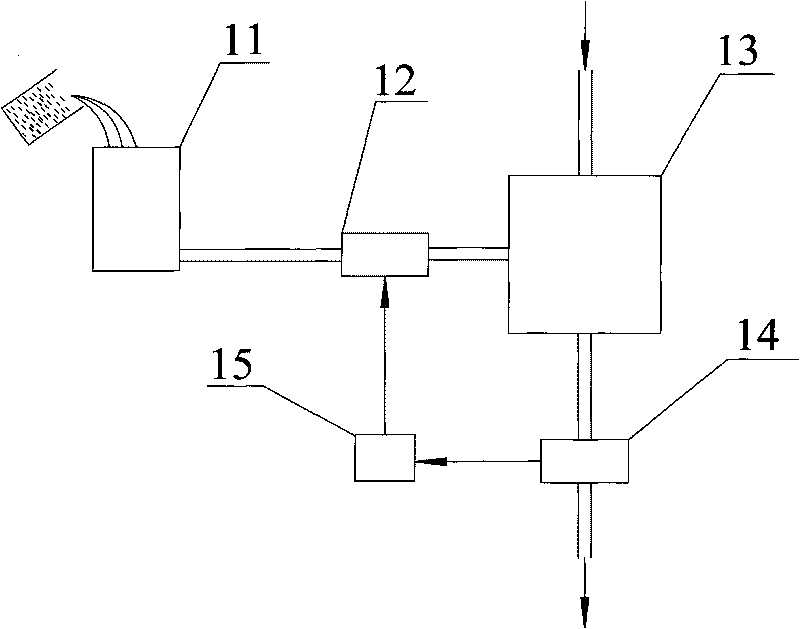

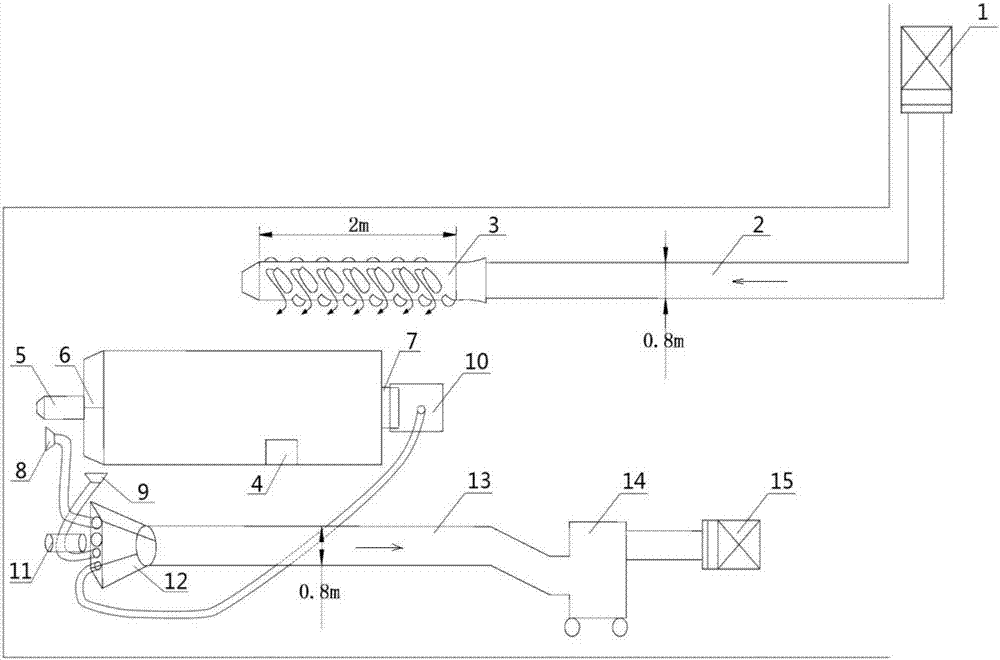

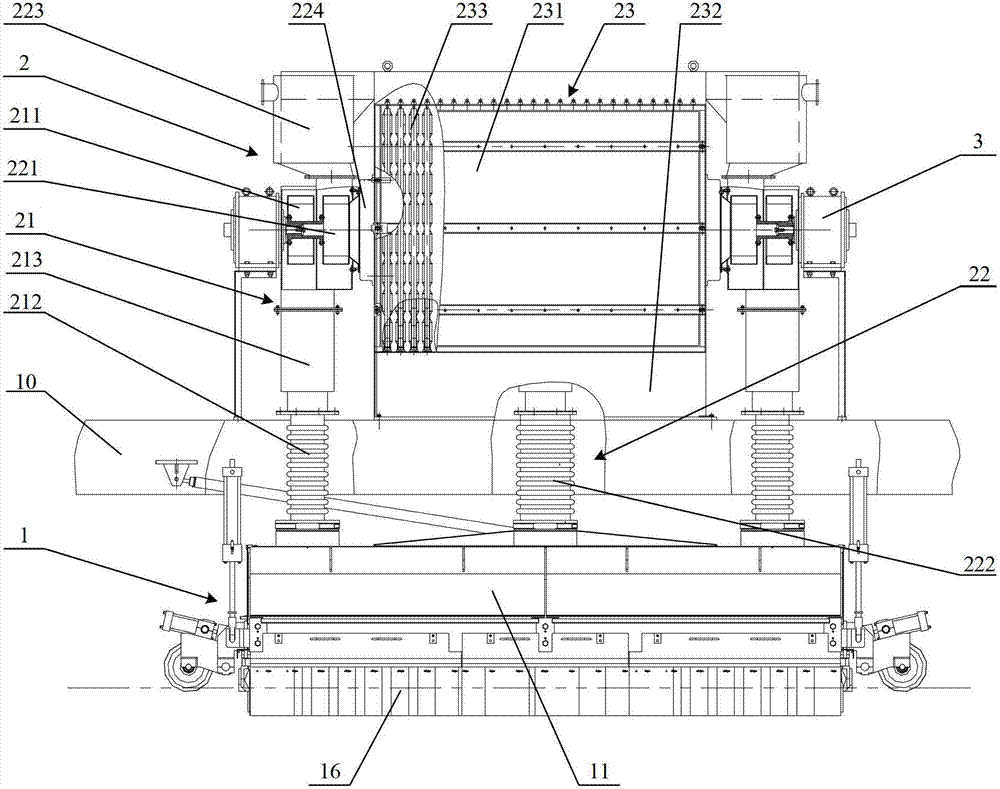

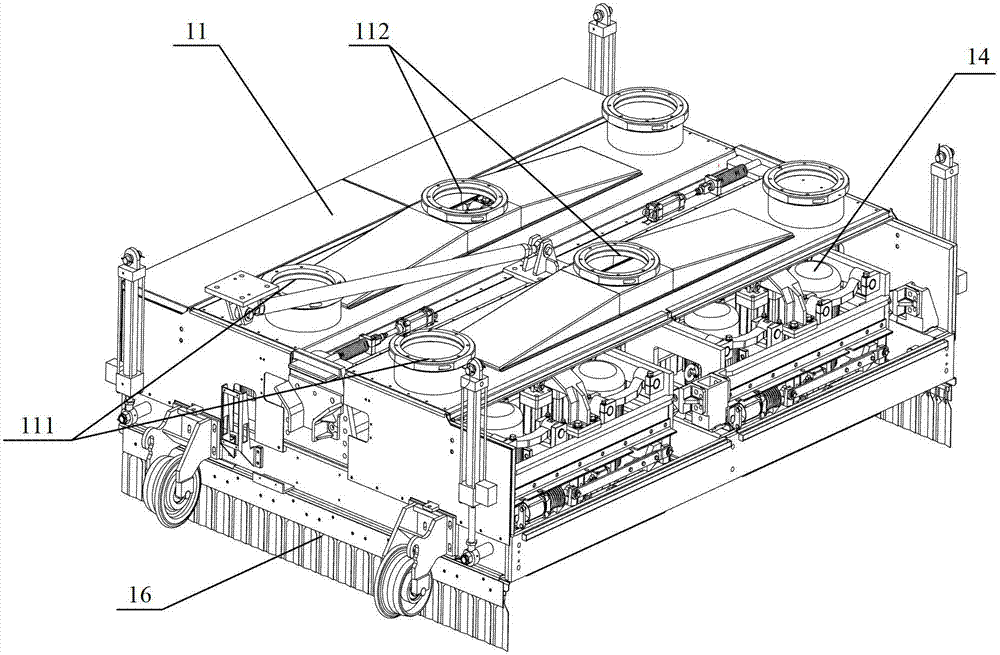

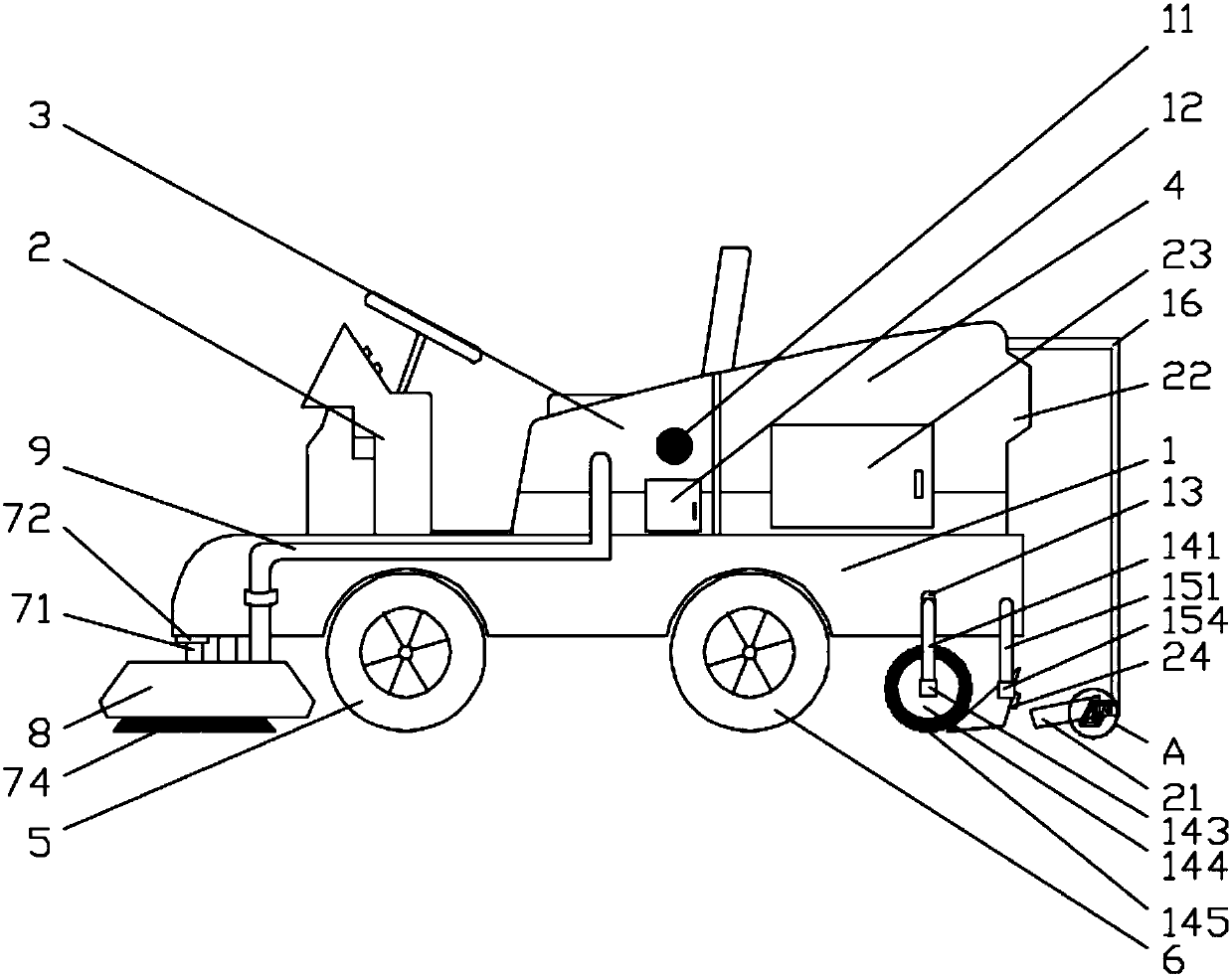

Rail grinding dust-precipitating system and rail grinding wagon

ActiveCN102966014AAvoid damageImprove dust collection efficiencyRailway track constructionFiltrationDust control

The invention provides a rail grinding dust-precipitating system and a rail grinding wagon. The system comprises a grinding device and a dust precipitating device, wherein the dust precipitating device is arranged above the grinding device; the grinding device comprises a box body, a plurality of grinding heads and feeding mechanisms for controlling grinding angles of the grinding heads; the grinding heads and the feeding mechanisms are arranged in the box body; a blowing unit blows wind to the grinding device to blow up sparkles and dust generated by the grinding device when the rail is ground; an air draft unit sucks the sparkles and the dust into a dust filtration unit and filter and precipitate the dust in the dust filtration unit; and the filtered air is exhausted through the air outlet of the air draft unit. By virtue of the blowing unit and the air draft unit, the blowing unit generates powerful airflow to roll up most of the dust, change the motion track of the dust; the air draft unit generates powerful dust precipitating airflow to suck the rolled dust and the other particles into the dust filtration unit, and filter and precipitate the dust in the dust filtration unit, so that the dust control efficiency can be improved.

Owner:太原中车时代轨道工程机械有限公司

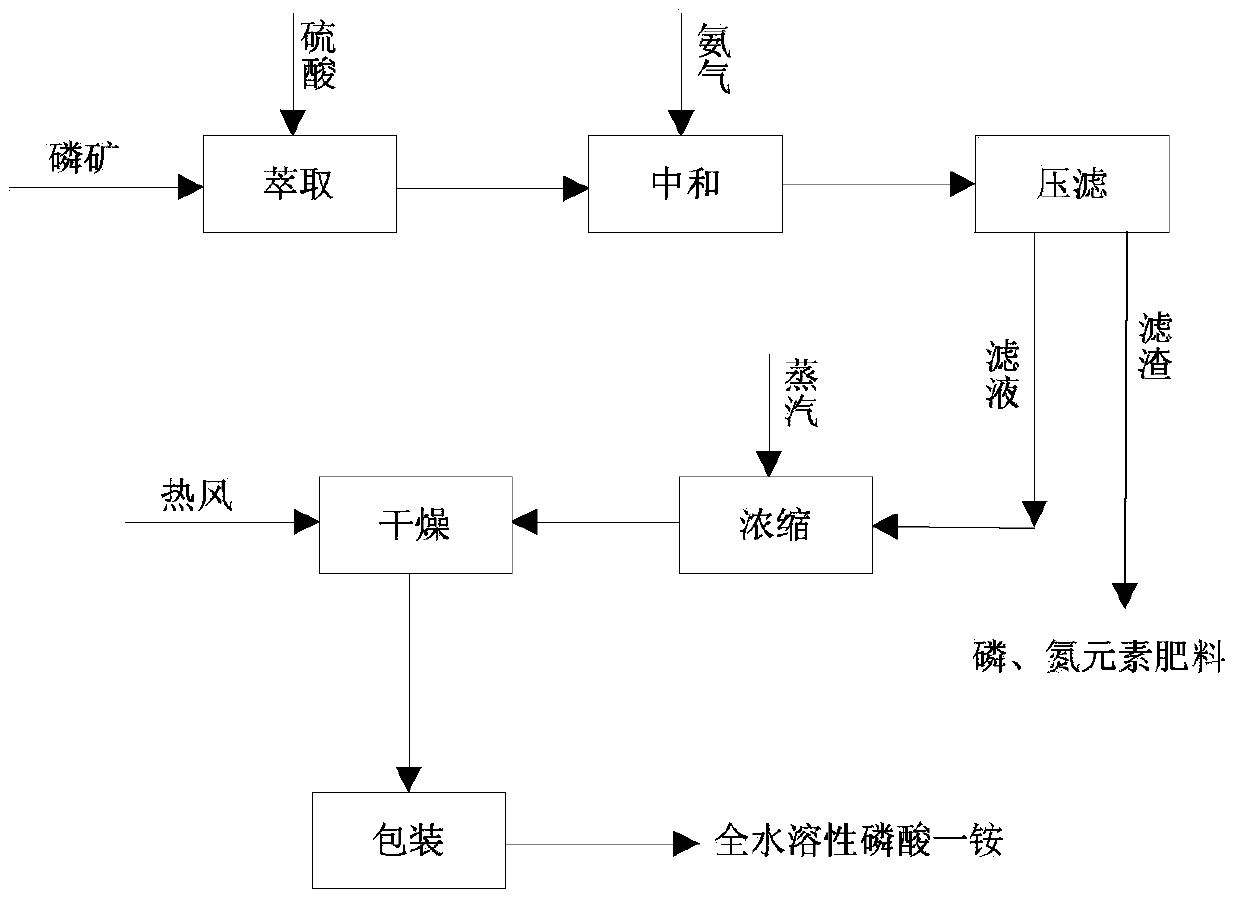

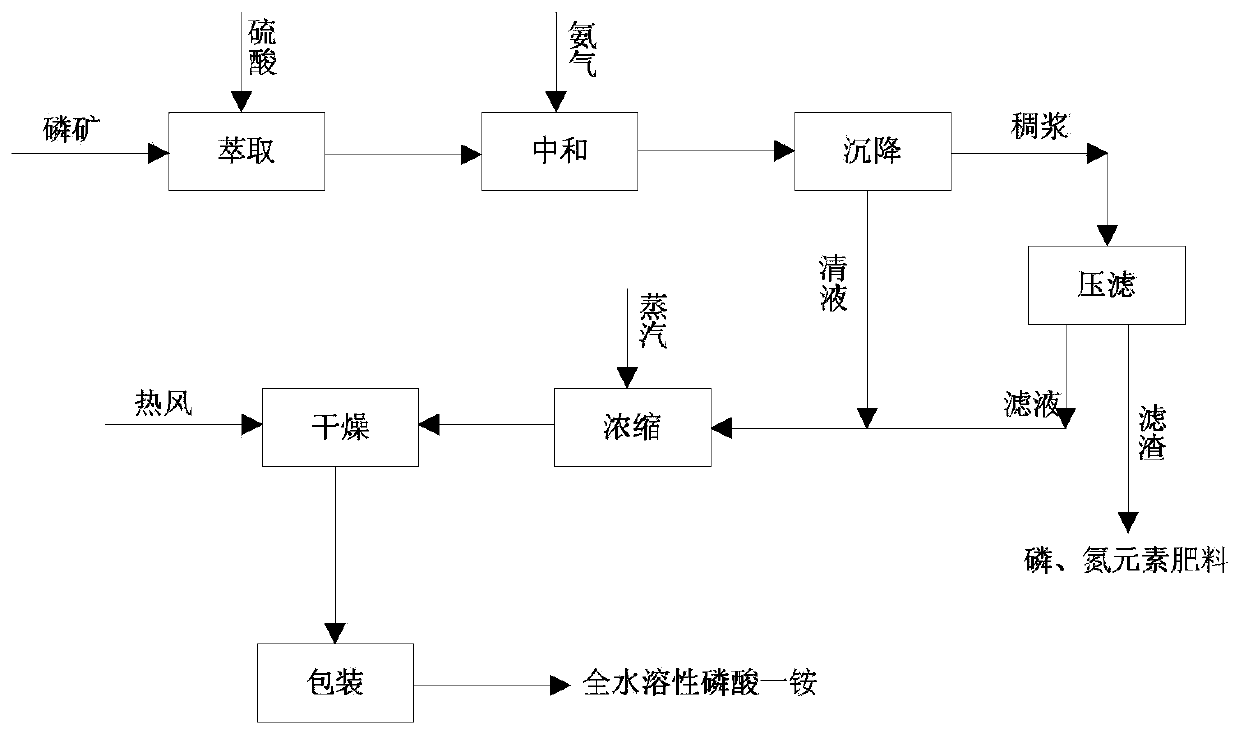

Method for producing full-water-soluble monoammonium phosphate by phosphoric acid by wet process

ActiveCN103466579AImprove dust collection efficiencyAvoid pollutionPhosphatesAlkali orthophosphate fertiliserChemical industryHigh concentration

The invention relates to the field of phosphorus chemical industry, and specifically relates to a full-water-soluble monoammonium phosphate production device which mainly comprises a neutralizing system, a solid-liquid separating system, a concentrating system, a drying system, a finished product collecting system and a tail gas treatment system. The adopted high concentration full-water-soluble monoammonium phosphate production device for producing full-water-soluble monoammonium phosphate has the advantages of high production capacity and low energy consumption. Crystallizing and filtering steps are not needed, and dust in tail gases has minimum influence on the environment, so that the method has a good economic benefit.

Owner:SICHUAN HONGDA

Air purification unit applicable to remove fine particles in the air in the home environment

ActiveCN104566650AImprove charging capacityStable ionizationMechanical apparatusLighting and heating apparatusHome environmentUltraviolet lights

The invention relates to an air purification unit applicable to remove fine particles in the air in the home environment and belongs to the field of electrostatic dust removal. The device comprises an air inducing unit, an air purification unit and an air channel. The air purification unit comprises a positive high-voltage pulse charge region, a negative high-voltage pulse charge region, a static coagulation region under an alternating electric field, a dust particle collection region, a plasma disinfection region and a negative ion region which are arranged successively. A narrow-pulse discharging mode and a negative direct-current high-pressure discharging mode are used, a working voltage below 30KV and a working current below 10mA are used, and the collection efficiency of more than 90% of particles with diameters below 10 microns is achieved in the home environment; the problems of over-large 'wind resistance' and 'secondary pollution' of prior home air conditioners are solved, fine particles in the air can be removed in the home space size range, the air can be disinfected, and the problem of ultraviolet light leakage harms is solved.

Owner:上海安平静电科技有限公司

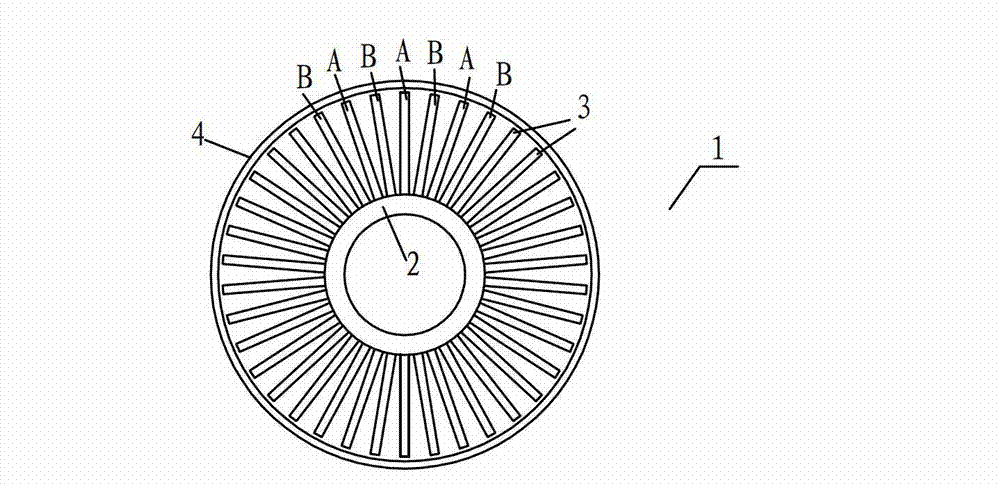

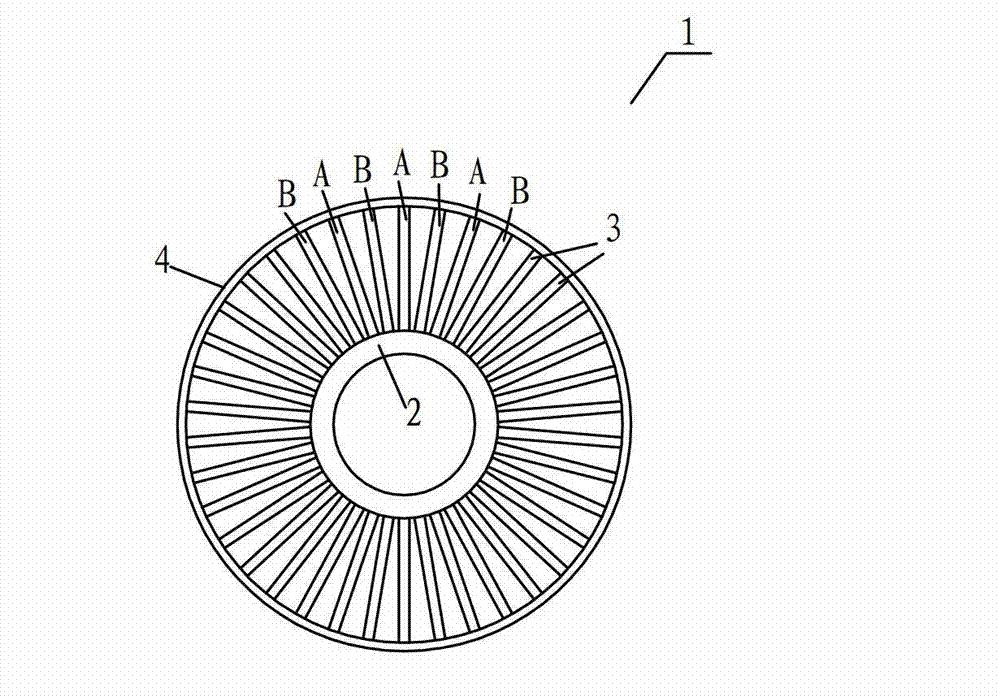

Guide blade or stator blade, and air treatment device having the same

ActiveCN102728470AReduce power consumptionNo pressure dropExternal electric electrostatic seperatorElectrostatic separation detailsLow noiseAir treatment

The invention relates to a guide blade or a stator blade, and an air treatment device having the guide blade or the stator blade. The guide blade or the stator blade comprises a wheel hub, blades and a wheel cover, wherein the blades are distributed on the wheel hub and / or the wheel cover at certain intervals along the circumferential direction. Structural characteristics of the guide blade or the stator blade are that: the blades comprise a first group of blades and a second groups of blades; the two groups of the blades have conductive properties; the first group of the blades and the second group of the blades are staggeredly distributed and insulated, and are not conducted; the first group of the blades and the second group of the blades are respectively applied with high potential and low potential so as to form a charged high voltage space between the first group of the blades and the second group of the blades, the high voltage space forms a dust removing channel, and the dust removing channel can effectively adsorb dust particles flowing through the dust removing channel. The blade and the device of the present invention have characteristics of simple and reasonable structure, high dust absorption efficiency, low resistance, low power consumption, low noise and no pressure loss. In addition, with the blade and the device of the present invention, air delivery, air pressure and efficiency of a fan can be effectively improved.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

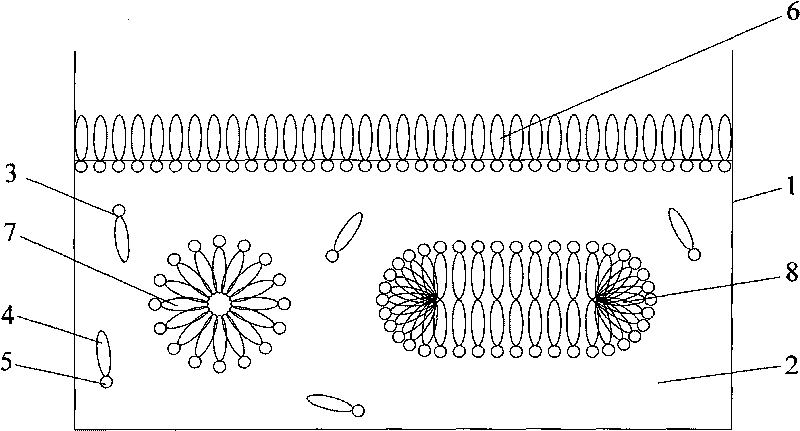

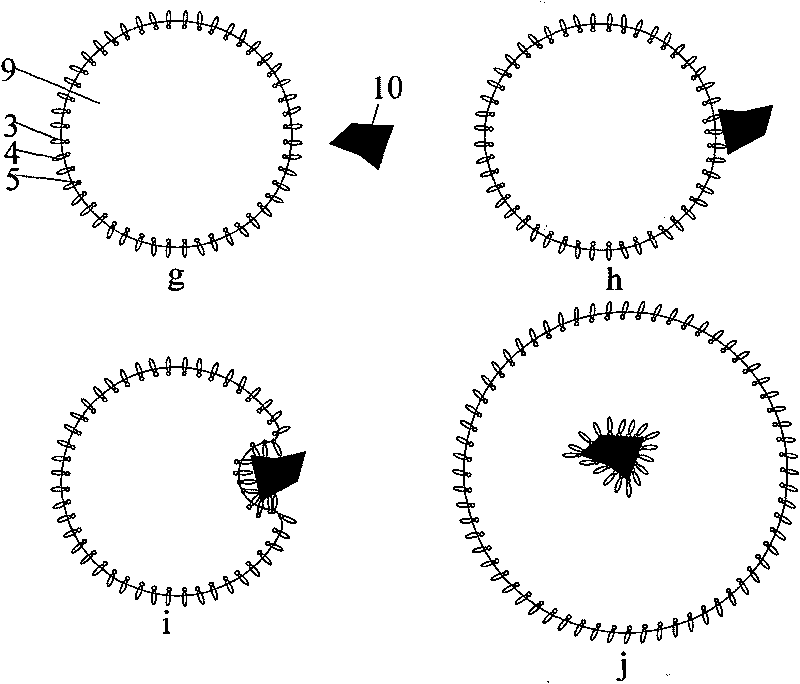

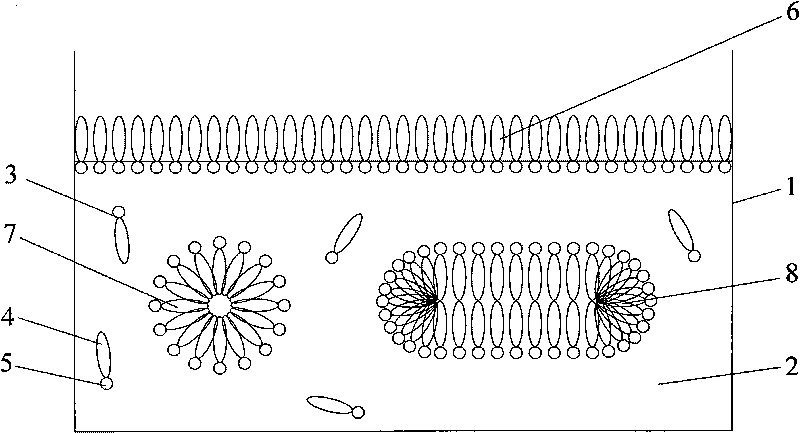

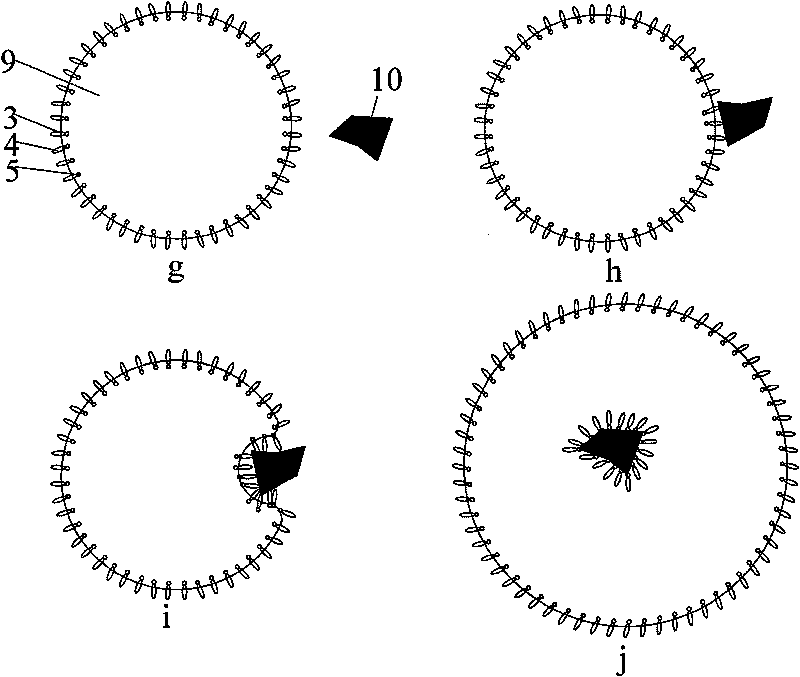

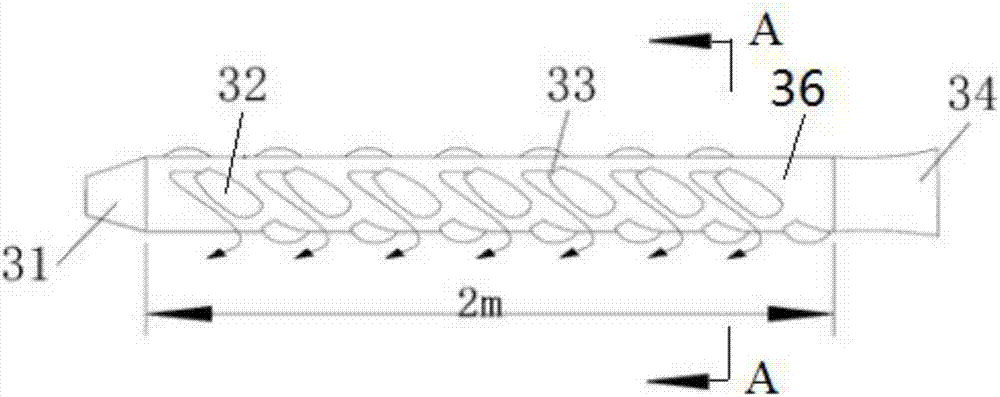

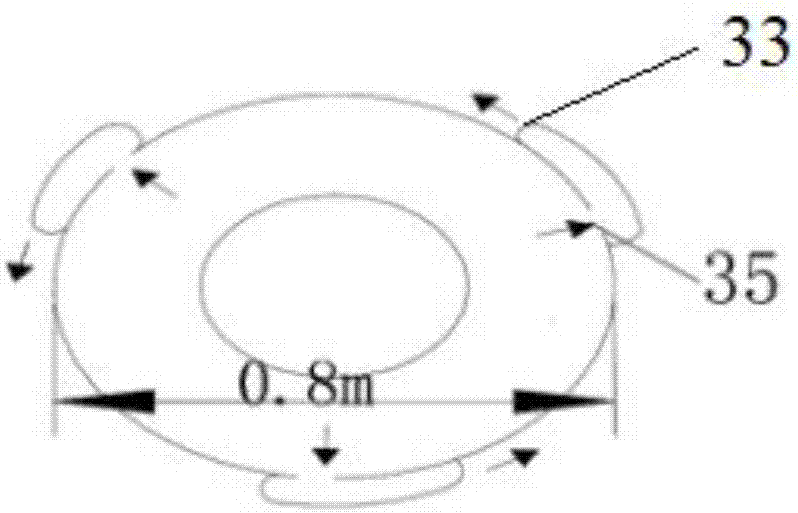

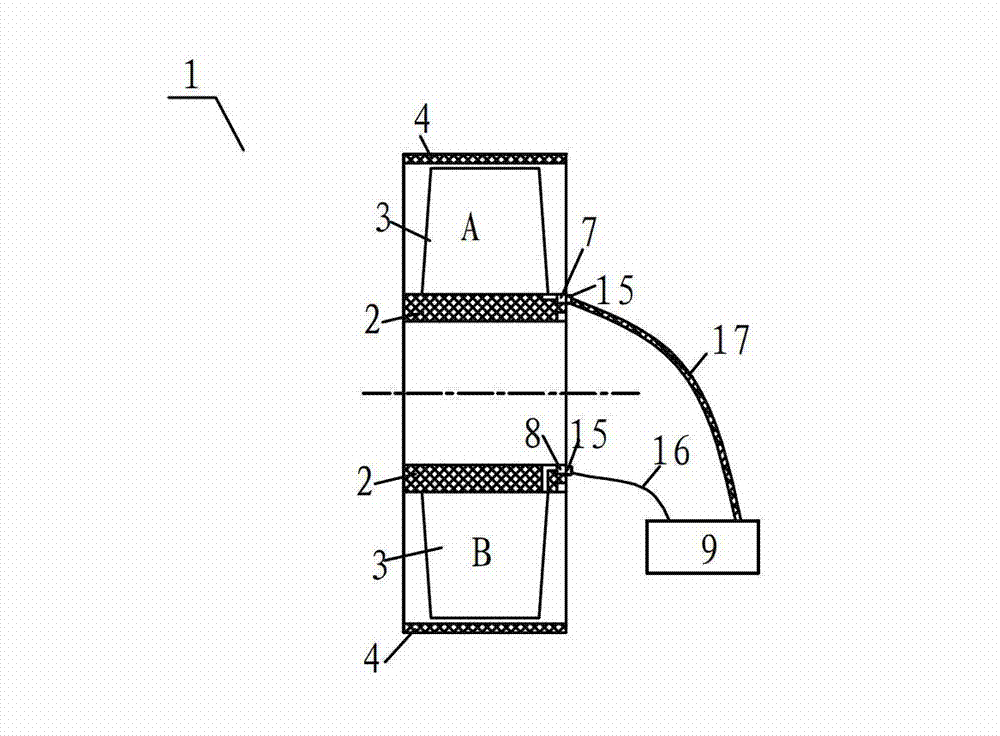

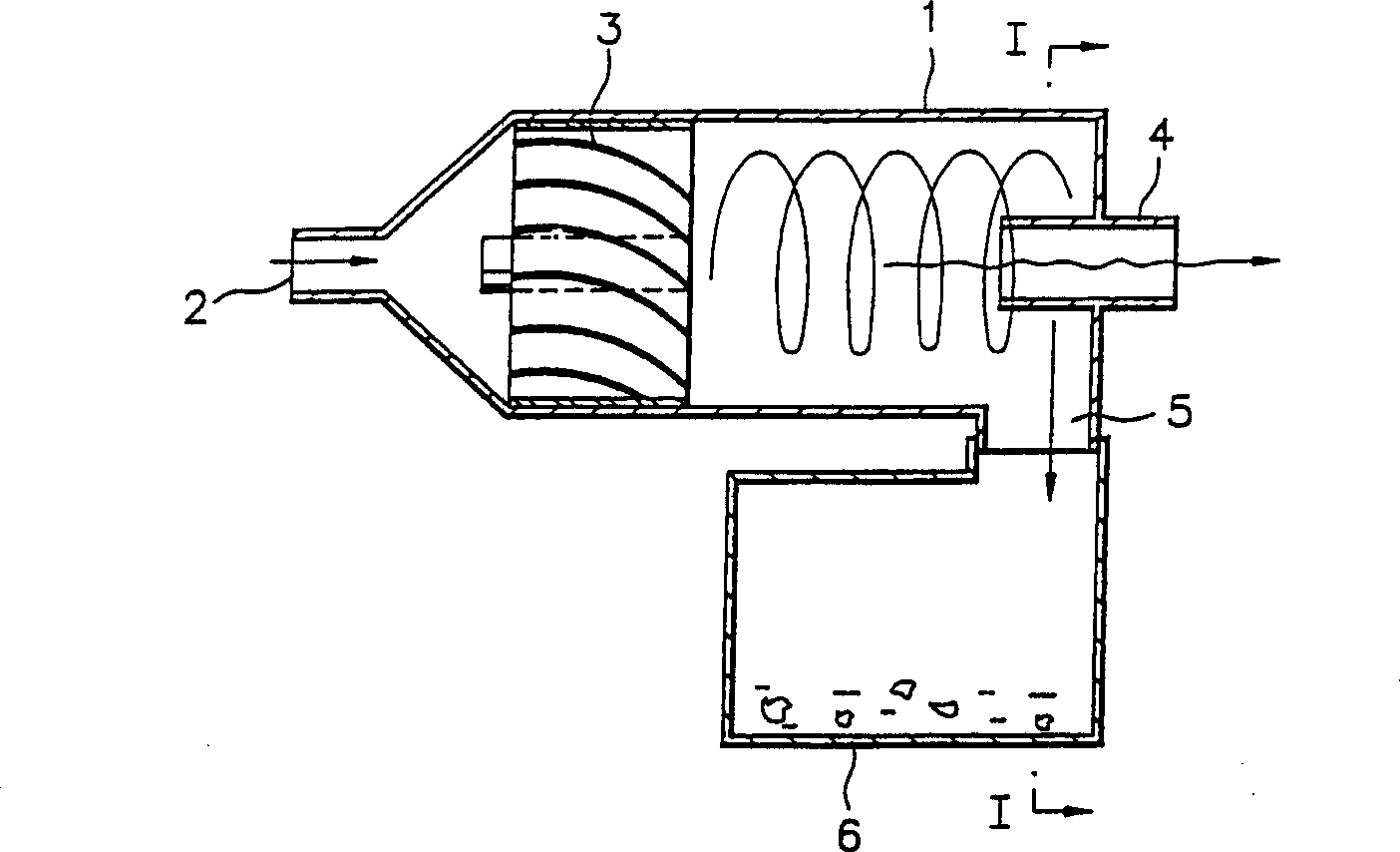

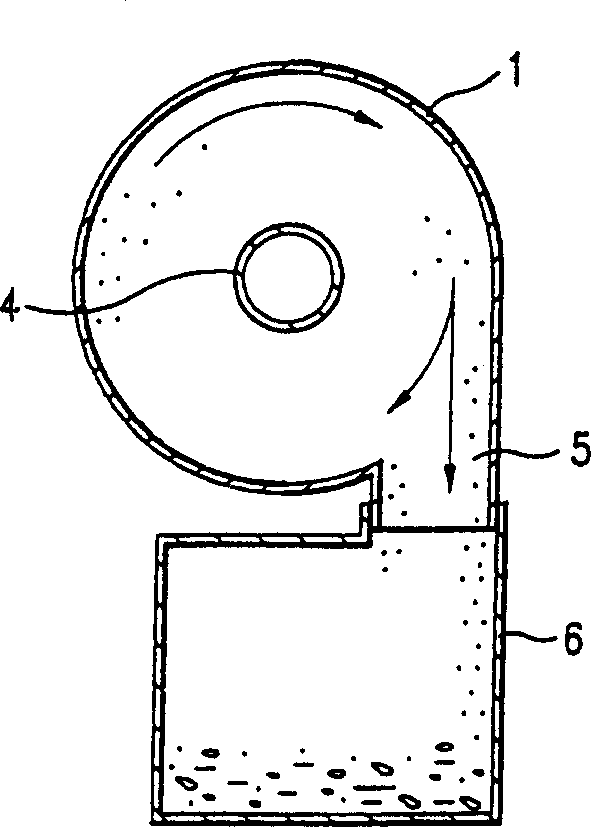

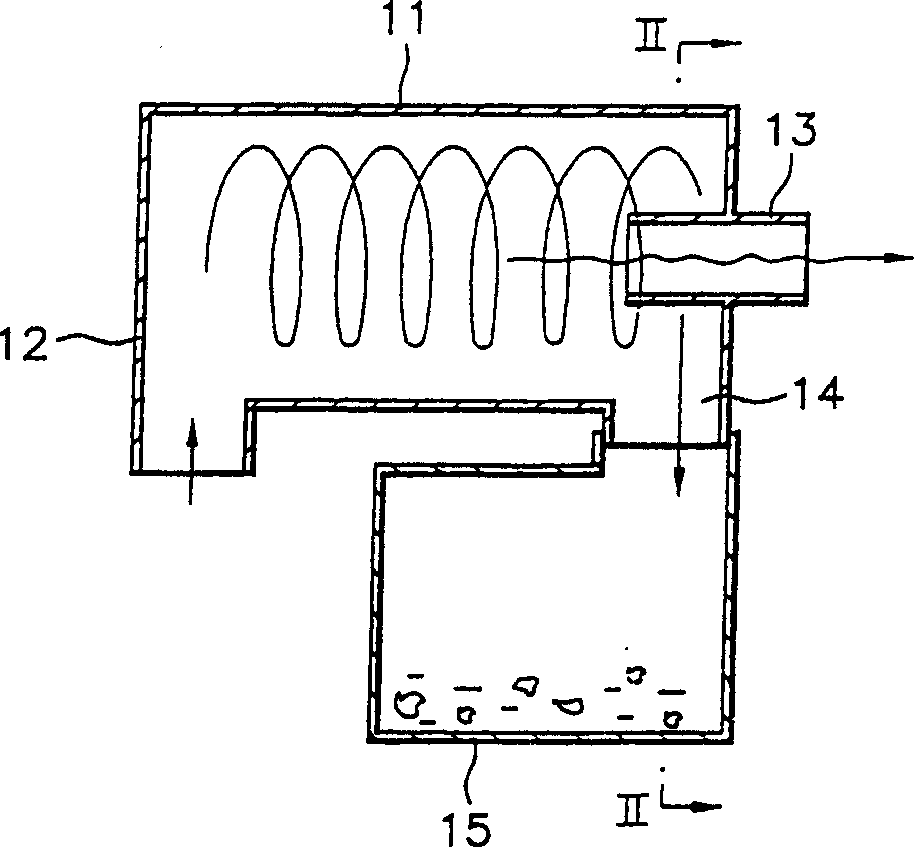

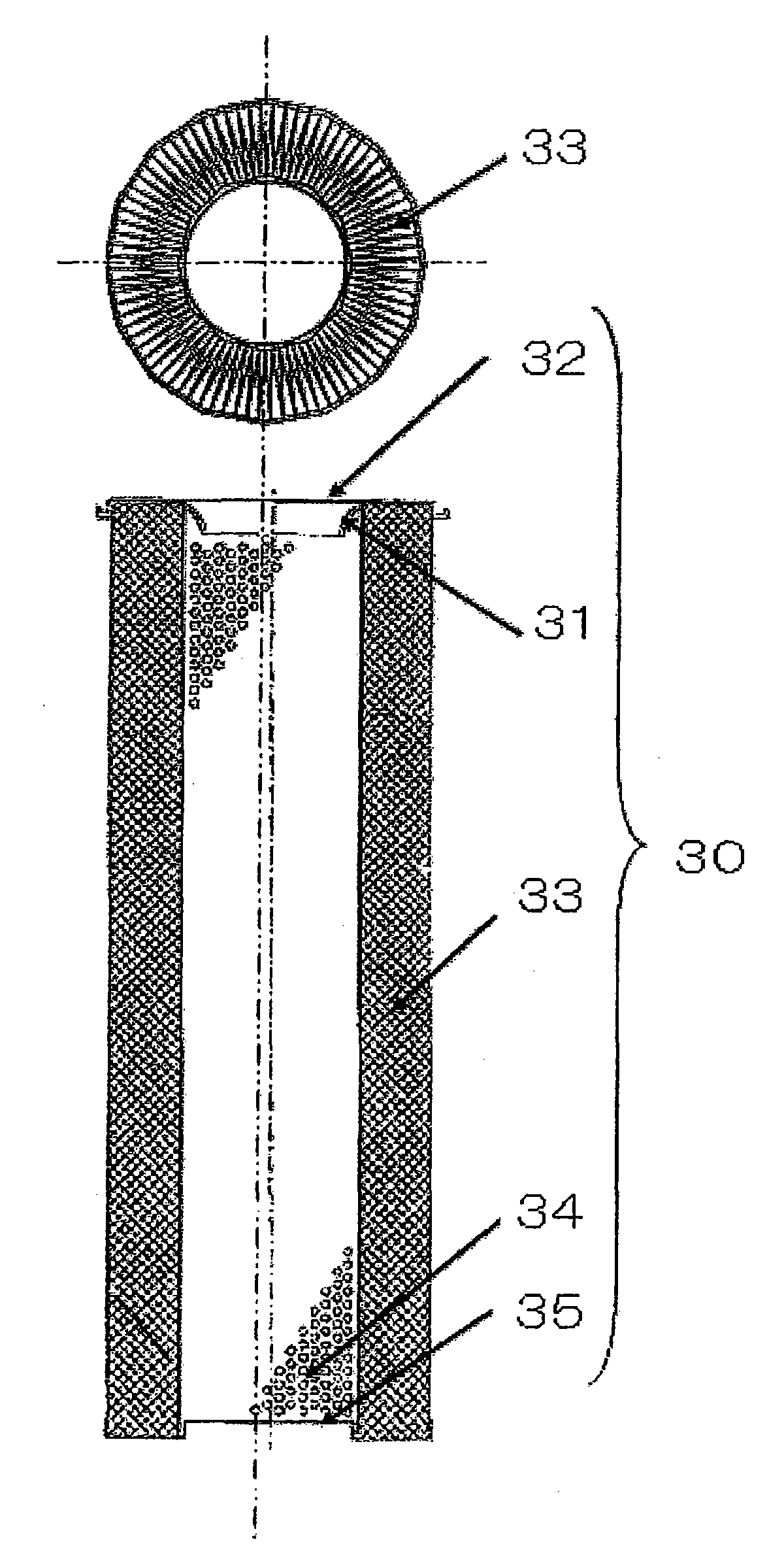

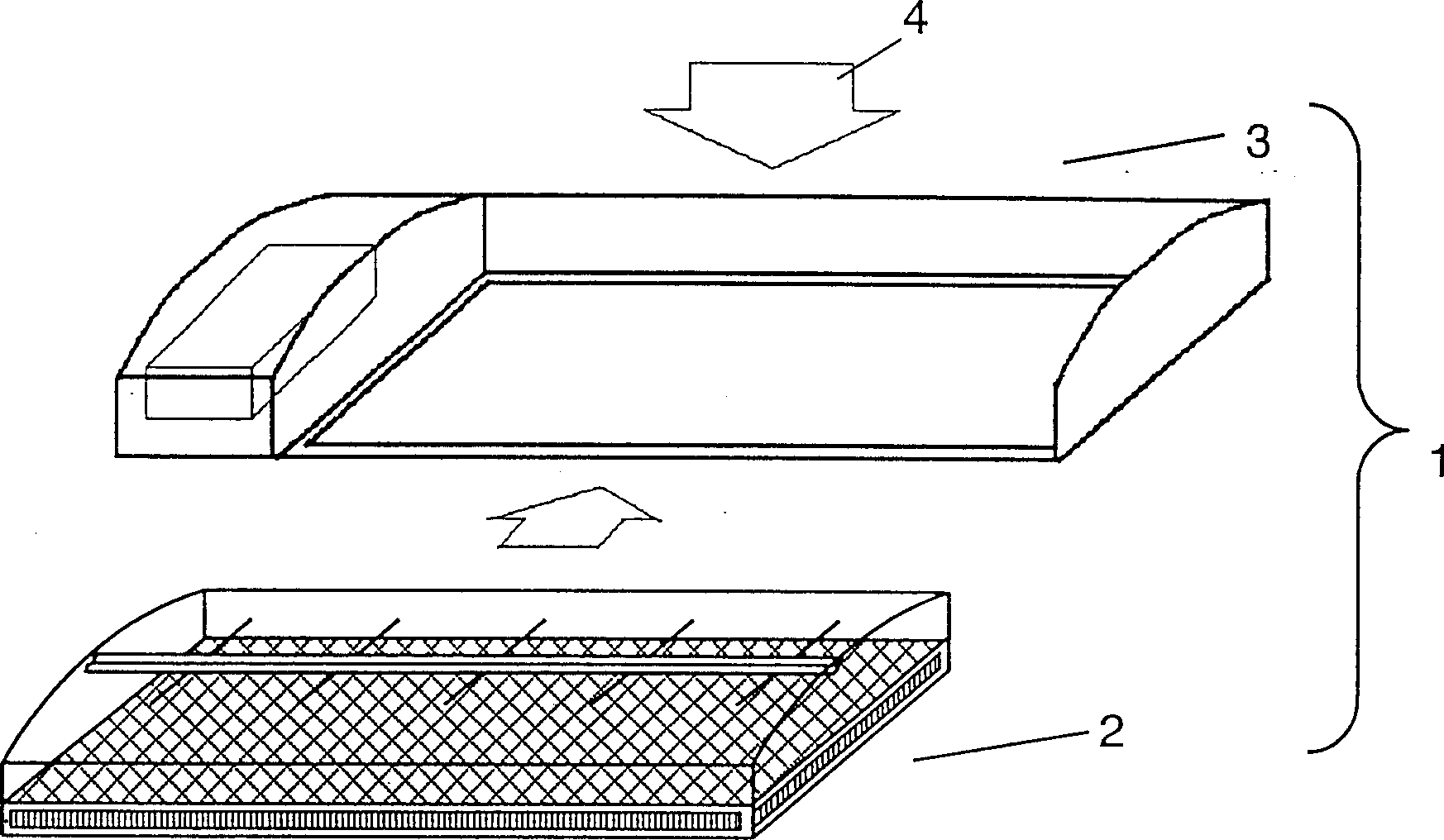

Cyclone collector for vacuum cleaner

InactiveCN1377304AImprove dust collection efficiencyLow flow resistanceSuction filtersReversed direction vortexCycloneAir pollutants

A cyclone dust collector for a vacuum cleaner, comprising a cyclone dust collector body (1, 11, 31), for sucking pollutants and air into the polluted air in the cyclone dust collector body (1, 11, 31) Inlet (2, 12, 32), air outlet (4, 13, 33) for discharging the air purified in the cyclone dust collector body (1, 11, 31), and for connecting with the cyclone dust collector The pollutant outlet (5, 14, 34) from which the pollutants separated by the body (1, 11, 31) are discharged, is characterized in that the cyclone dust collector body (1, 11, 31) includes a flow guiding device (7, 17, 37; 8, 18, 38), the device is arranged relative to the air outlet (4, 13, 33), thereby improving the vortex force in the cyclone dust collector body (1, 11, 31) and preventing the vortex The airflow and exhaust airflow interfere with each other.

Owner:LG ELECTRONICS INC

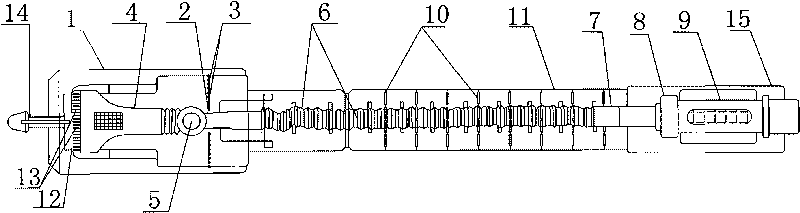

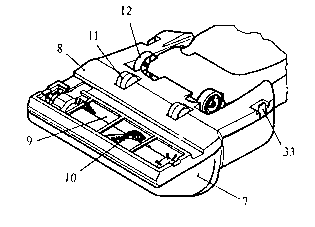

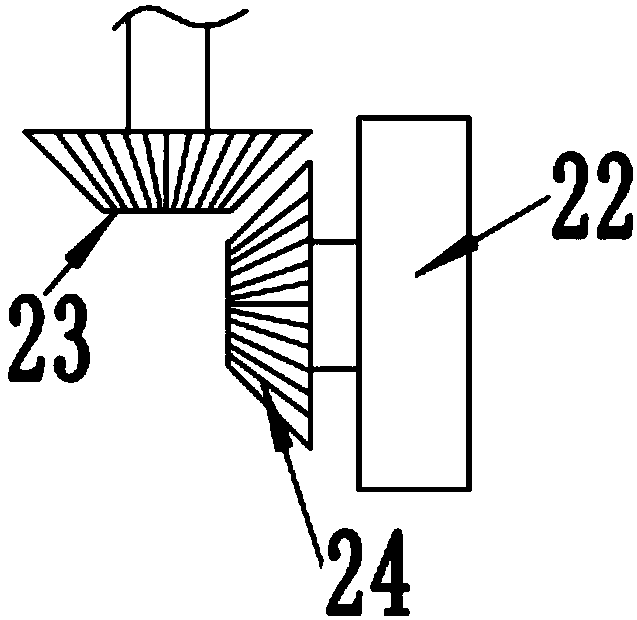

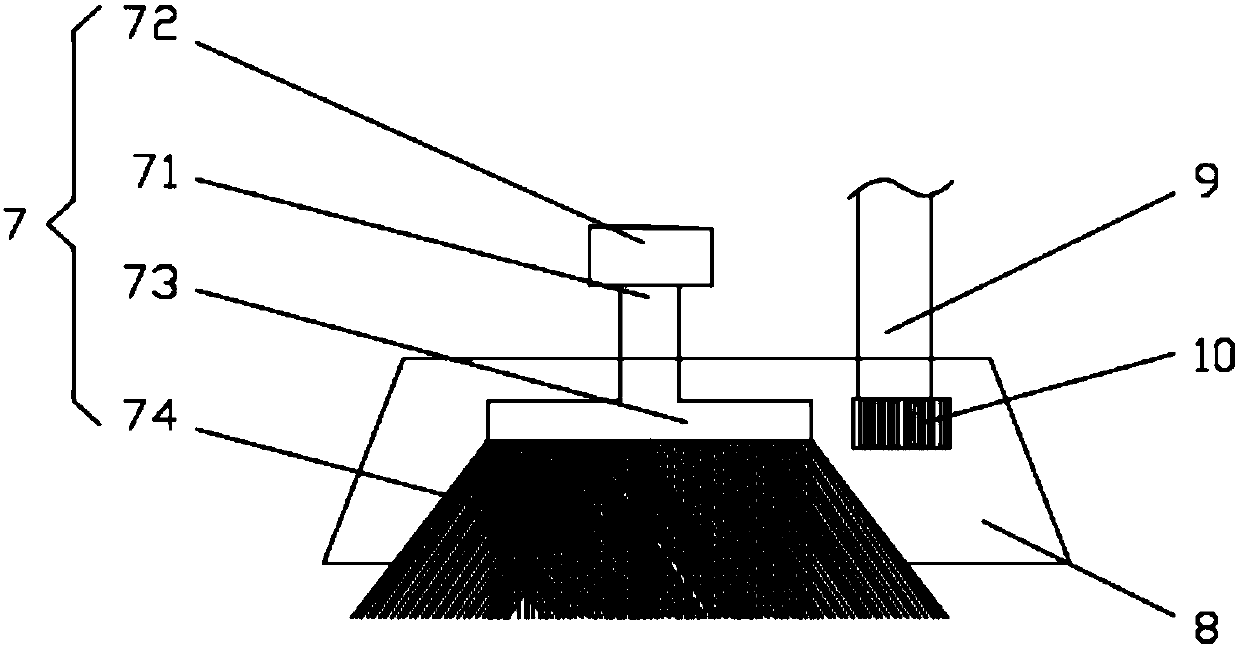

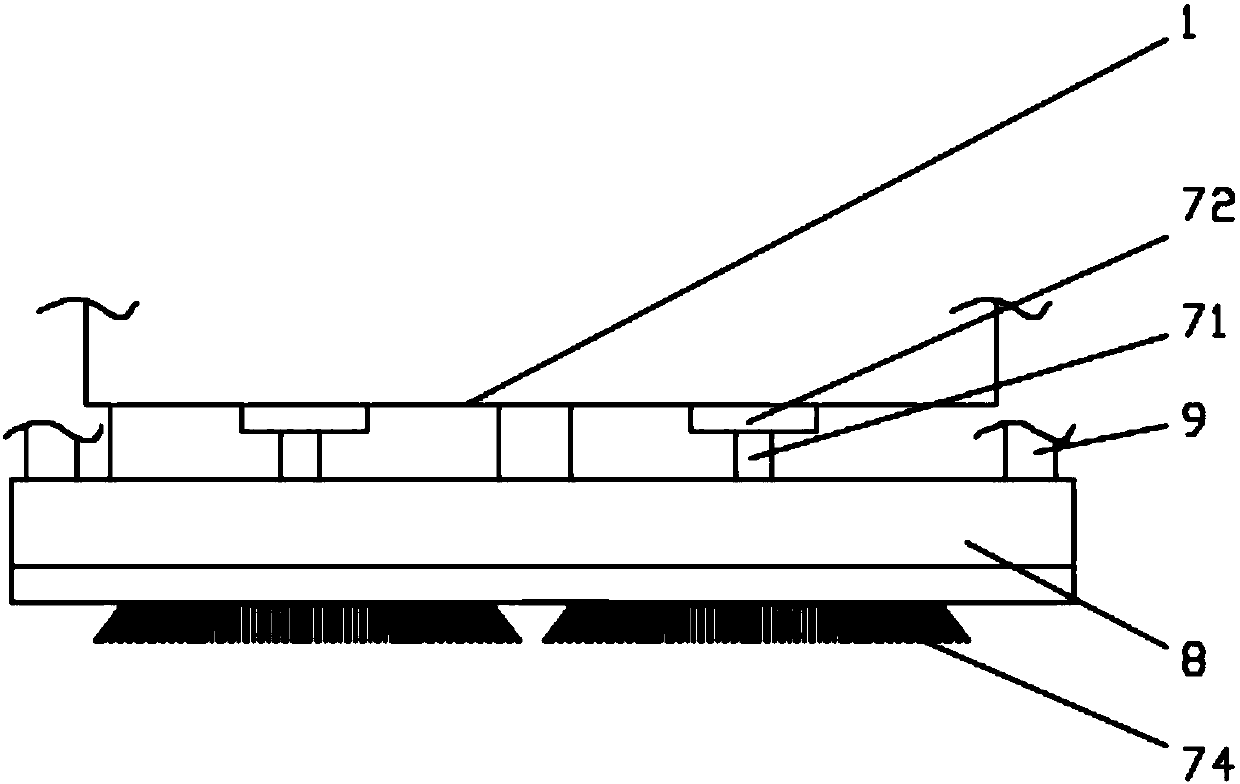

Rolling brush structure with spiral blades

InactiveCN102727136ADoes not increase dragImprove dust collection efficiencySuction nozzlesSpiral bladeHelix

The invention discloses a rolling brush structure with spiral blades. The rolling brush structure comprises a rolling brush body, hairs spirally arranged on the rolling brush body, a left connecting part and a right connecting part, wherein the left connecting part and the right connecting part are arranged at the two ends of the rolling brush body and connected with a suction chassis; the spiral blades are arranged on the rolling brush body; and the external ends of the blades are higher than the external ends of the hairs. The rolling brush structure has the advantages and positive effects that the spiral blades are respectively arranged between every two adjacent rows of hairs on the rolling brush structure, and when the rolling brush body rotates, the blades are rotated together, thus, certain axial flowing is brought to airflow when the spiral blades rotate, dust is blown toward the direction of a suction inlet, and the dust collecting efficiency of a dust collector is improved. Simultaneously, the external ends of the blades are higher than the external ends of the hairs, so that the hairs can be in contact with the ground or a carpet and can clean the ground or the carpet without being influenced, and the resistance occurred along with the rotating of the rolling brush body cannot be increased.

Owner:NANJING LG PANDA APPLIANCES

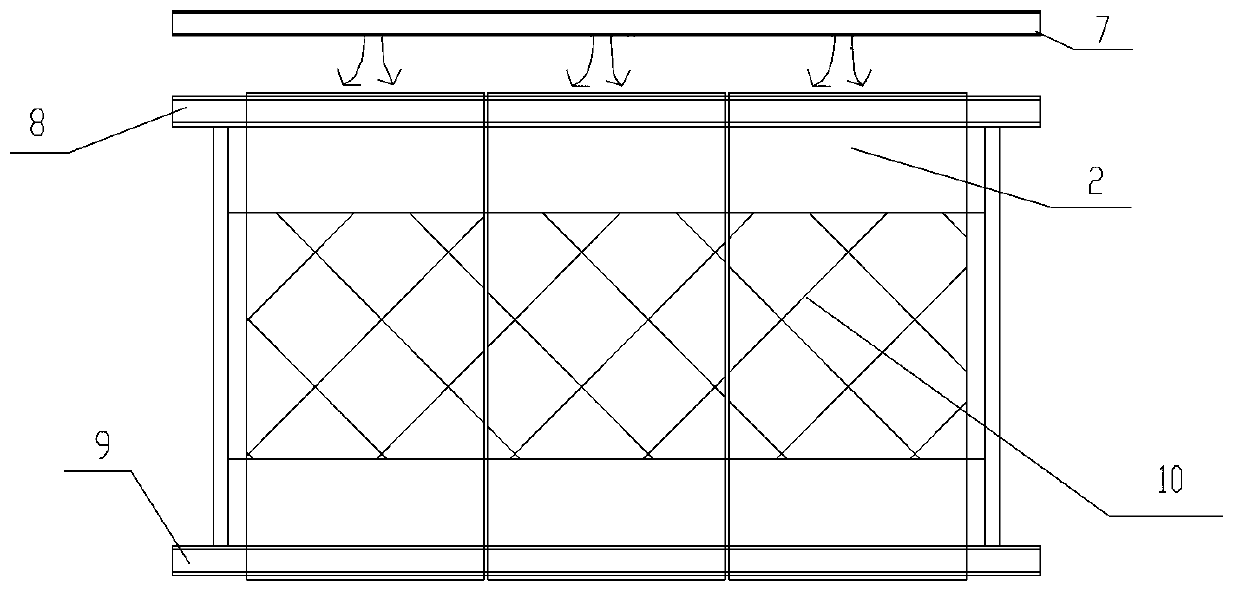

Flexible anode wet dust collector with hard grid layer

ActiveCN102872669APromote atomizationImprove the conductive mediumCombination devicesMetallurgyWind power

The invention provides a flexible anode wet dust collector with hard grid layers, which comprises a case body; an anode and a cathode are separatedly disposed in the case body; the anode is a flexible fabric winding between an upper branch pipe and a lower branch pipe, wherein hard grid layers are disposed outside the two surfaces of the anode. The flexible anode wet dust collector with hard grid layers provided by the invention has the hard grid layers disposed outside the two surfaces of the flexible fabric anode; the flexible fabric bumps the hard grid layers under the action of electric field wind power, which facilitates the atomization of liquid absorbed by the flexible fabric in the electric field, improves gas conducting medium, increases corona power, and thus improves dust collecting efficiency; the bumping of the flexible fabric with the hard grid layers avoids deposited blocks generated by dust and scale formed on the flexible fabric surface.

Owner:ZHEJIANG JIAHUAN ELECTRONICS CO LTD

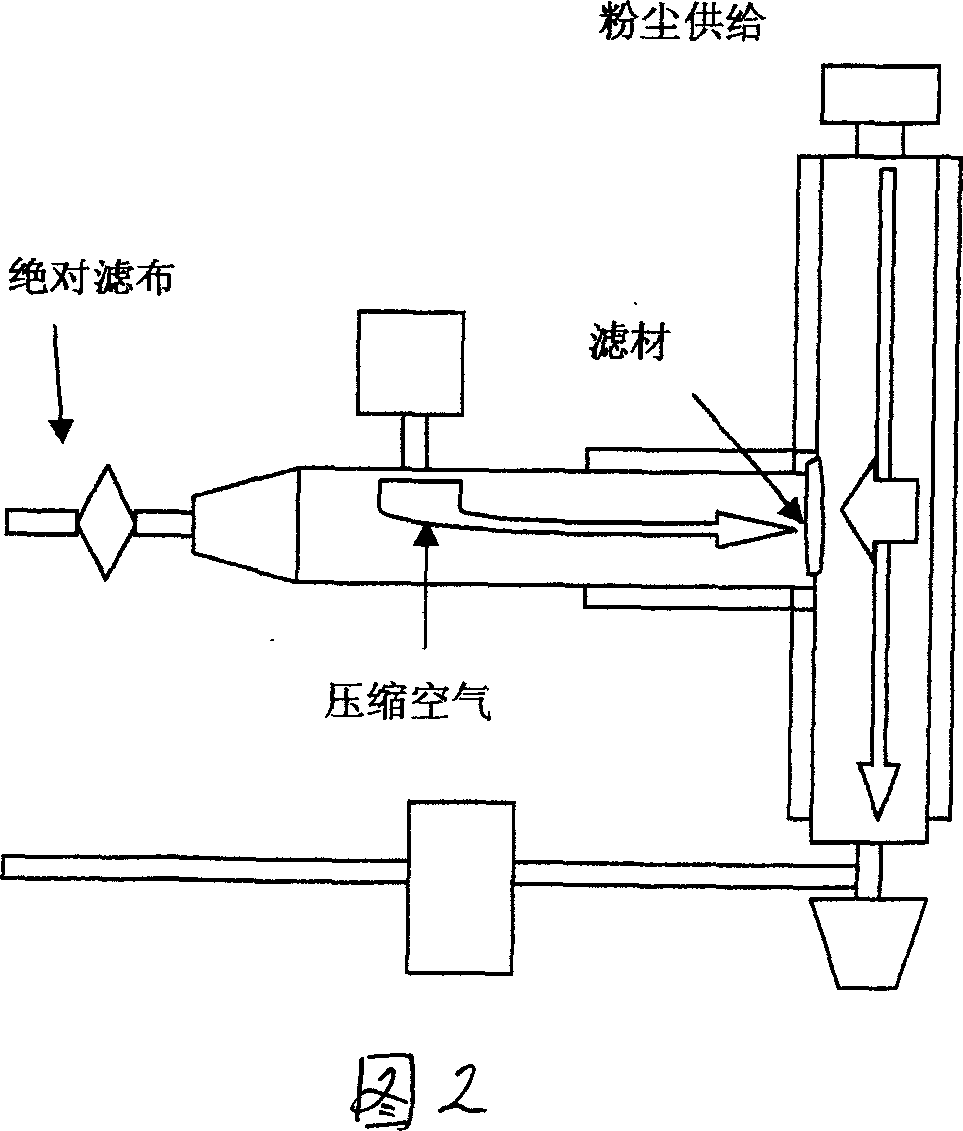

Antistatic filtering cloth in surface filtering mode for dust collector

InactiveCN101816856AIncreased durabilityImprove mechanical strength propertiesDispersed particle filtrationFiltration separationNanometreSurface filter

The invention provides an antistatic filtering cloth in the surface filtering mode for a dust collector. In a filtering cloth for a pulse blow swiping-off dust collector, the filtering cloth for the dust collector, which has numerous dust leakage after swiping off the dust, higher average outlet dust concentration, poor ventilation and dust swiping off performance and bad antistatic performance, is needed to be improved. The side of a soft material filtering surface made of fiber filtering cloth base materials such as non-woven fabric filtering cloth and the like used in the pulse blow swiping-off dust collector is laminated with a micro fine fibre layer formed by a nano carbon fiber with the conductivity, thereby the filtering cloth in the surface filtering mode for the pulse blow swiping-off dust collector, having excellent dust collecting performance and antistatic performance can be provided.

Owner:SINTOKOGIO LTD

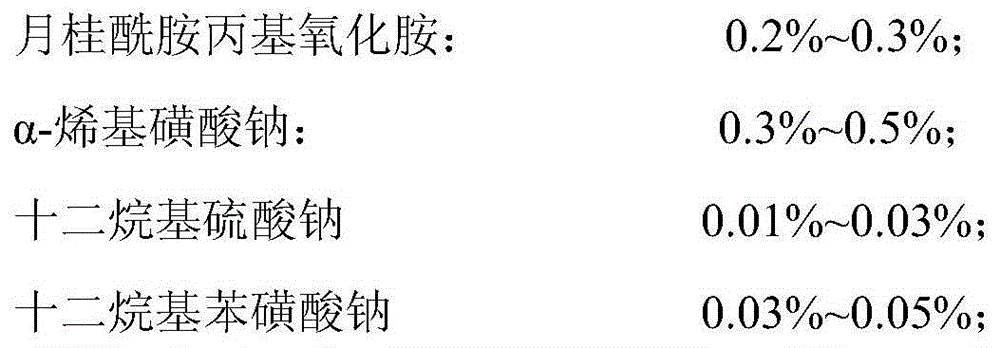

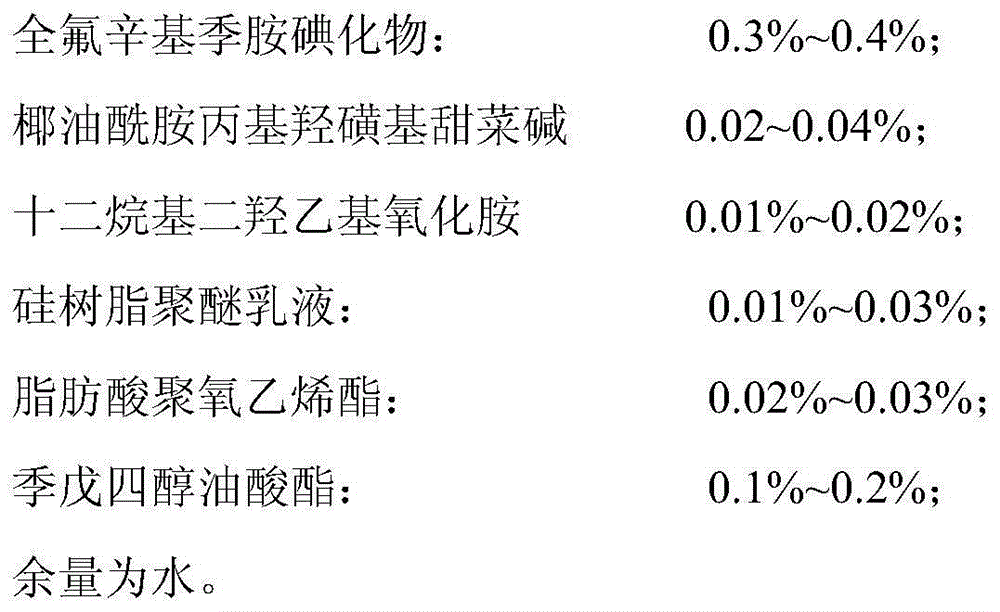

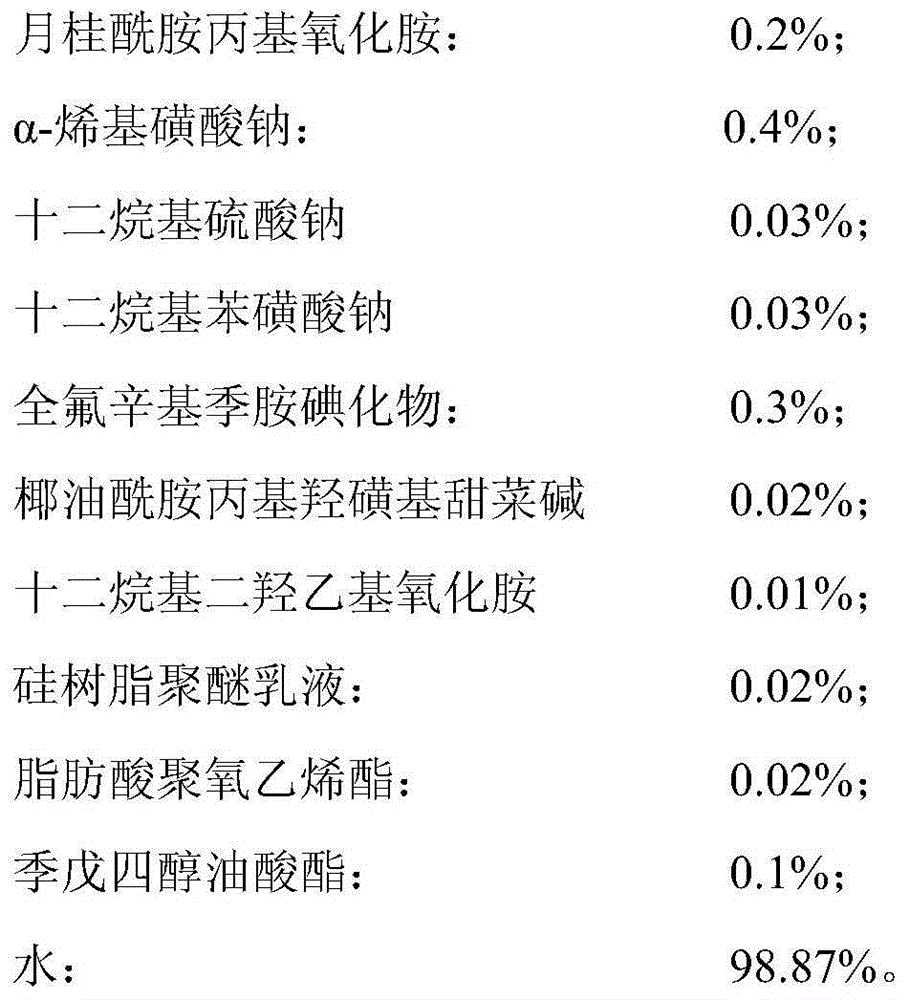

Compound type foam dedusting agent

The invention discloses a compound type foam dedusting agent. The compound foam dedusting agent comprises, by weight, 0.2%-0.3% of alpha olefins, 0.3%-0.5% of alpha-olefin sulfonate, 0.01%-0.03% of lauryl sodium sulfate, 0.03%-0.05% of sodium dodecyl benzene sulfonate, 0.3%-0.4% of trimethyl-1-propanaminium iodide, 0.02%-0.04% of cocoamido propyl hydroxy sulfoBetaine, 0.01%-0.02% of dodecyl dihydroxyethyl amine oxide, 0.01%-0.03% of modified polyethoxylated silicone, 0.02%-0.03% of polyoxyethylene fatty acid, 0.1%-0.2% of pentaerythritol oleate and balance water. Due to the fact that the pentaerythritol oleate was regarded as the corrosion inhibitor and added into the foam dedusting agent, the corrosivity on electromechanical equipment is greatly lowered, and the working environment of the workplace with the high concentration of dust is effectively improved.

Owner:SHANDONG UNIV OF SCI & TECH

Process for preparing carbon forming powder

InactiveCN101972687AImprove dust carrying capacityReduce power consumptionGrain treatmentsProcess engineeringBall mill

The invention relates to a process for preparing carbon forming powder, in particular to a new process for preparing carbon forming powder by adopting an air swept type ball milling system. In the invention, equipment mainly comprises a raw material bin, an air swept type ball mill, a high-efficiency rotor type grader, a gas tank pulse bag type dust collector, a main exhaust fan and a finished powder bin. In the main work process of the invention, a raw material is fed and added to the air swept type ball mill through a feeder and is subjected to rough and fine powder grading through the high-efficiency rotor type grader, rough particles are returned to the ball mill for pulverizing once again, and fine particles enter the gas tank pulse bag type dust collector for collection. The invention has the technological performance advantages of high systemic force supply, low power consumption for unit product, high finished powder purity, and good uniformity and stability, and completely eliminates the phenomena of air leakage and ash flying in the traditional process because of the operation in a negative pressure state. The process is not only suitable for the optimization and technological improvement on the traditional process in the production process of the carbon forming powder, but also suitable for new projects of a carbon forming powder preparation system.

Owner:NANJING UNIV OF TECH

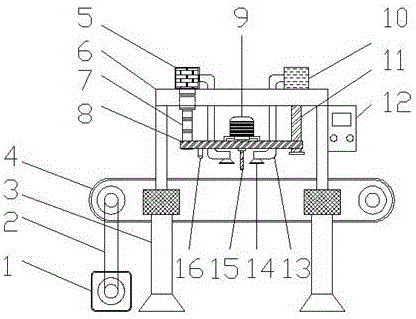

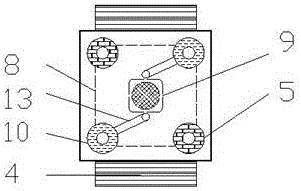

Industrial automation punching device

InactiveCN106272685AHigh degree of automationImprove dust collection efficiencyMetal working apparatusHydraulic cylinderPunching

The invention discloses an industrial automation punching device which comprises a conveying belt motor, a fixing platform, a fixing plate, an air pump, a dust-sucking pipe, a punching head and a height sensor, wherein a transmission belt is arranged on the conveying belt motor; the conveying belt motor is connected with a conveying belt through the transmission belt; a supporting base is arranged below the conveying belt; a hydraulic cylinder is fixedly arranged above the fixing platform; the left end of the fixing plate is fixedly connected with a lifting rod; a punching motor is arranged above the fixing plate; the fixing rod is arranged below the air pump; a controller is fixedly mounted below the right side of the air pump; the upper end of the dust-sucking pipe is connected with the air pump; the punching head is connected with the punching motor; the punching head is arranged on the right side of the height sensor. The industrial automation punching device can perform automatic punching without manual operation, and the automation degree of the whole process is high, so the production efficiency is greatly improved, and manpower and material resources are saved.

Owner:WUXI XINGUANG COMP INSTALLATION

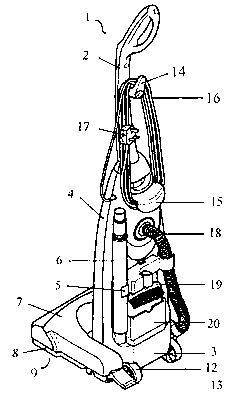

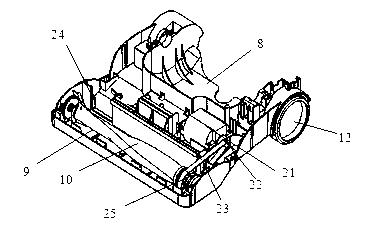

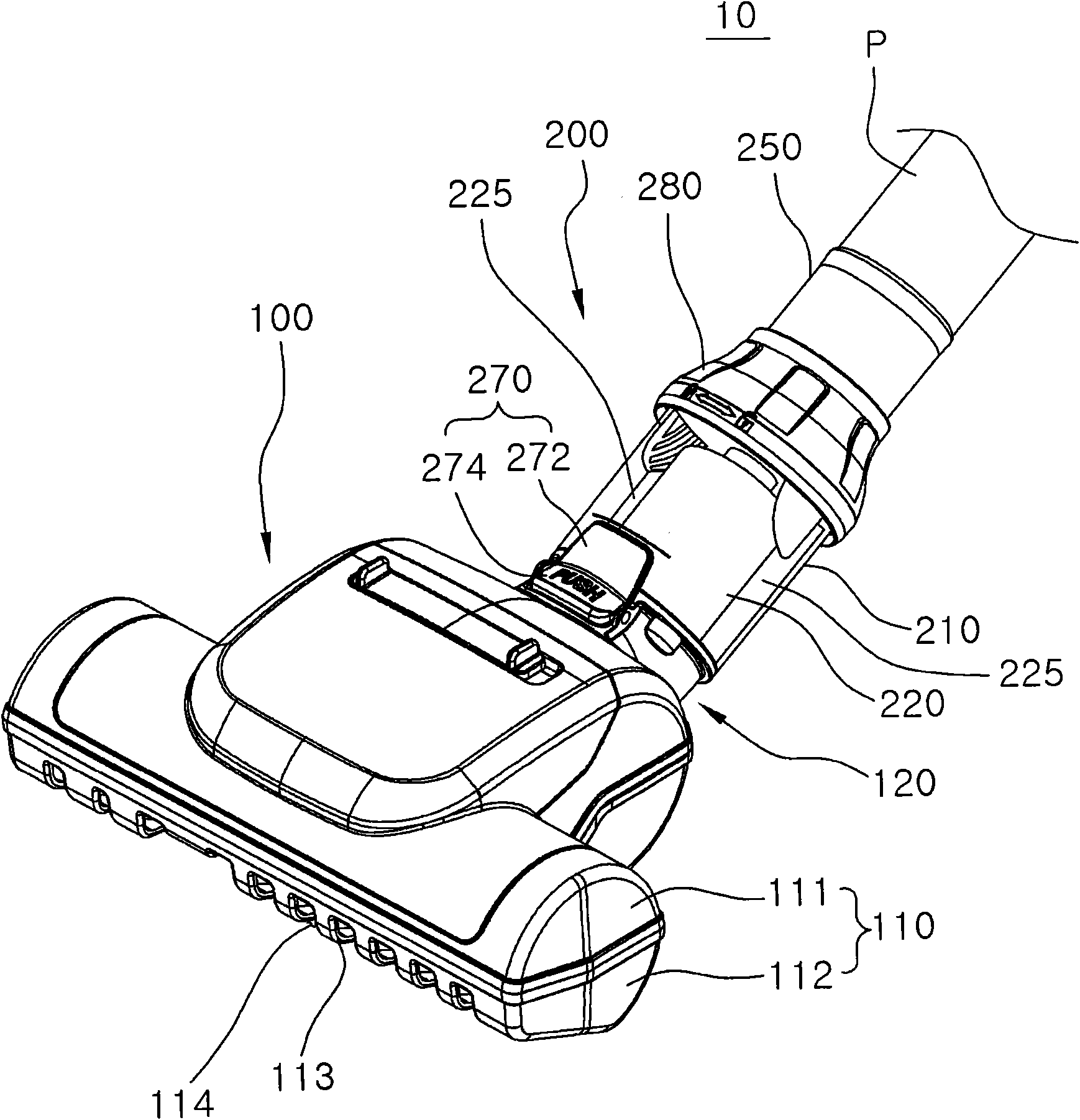

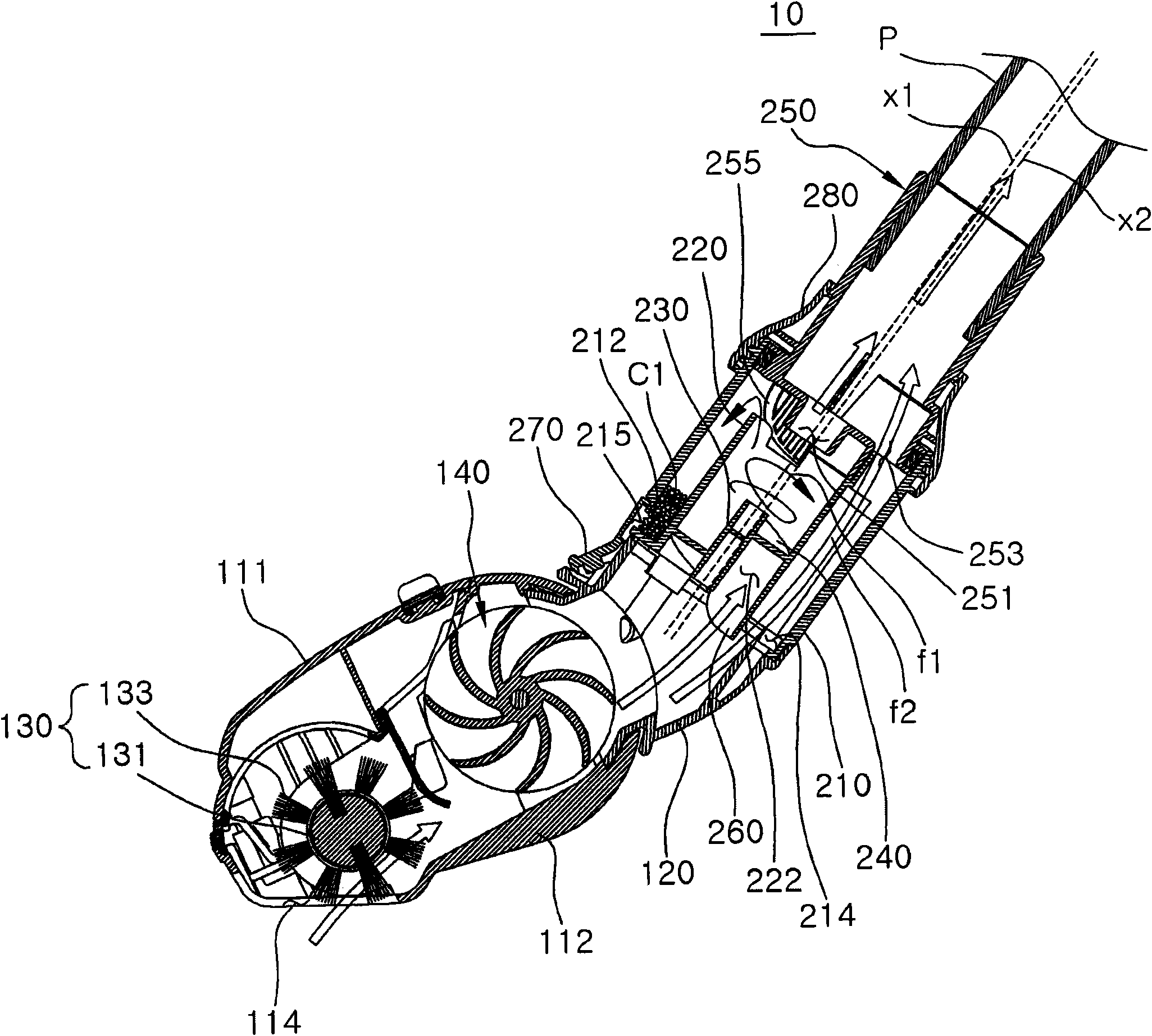

Brush component of vacuum cleaner

The invention provides a brush component of a vacuum cleaner which has a compact bulk and can improve dust separation efficiency and reduce pressure loss. The brush component of the invention is characterized in that the component includes: a brush unit with a housing contacting a cleaned surface; a cyclone dust collecting unit with one end connected to the brush unit and the other end connected to an extending pipe of the vacuum cleaner. The cyclone dust collecting unit includes: a cyclone flow path which allows the inflow of a part of the air discharged from the brush unit and separates the dust in the air by centrifugation; a bypass flow path which allows the rest air discharged from the brush unit to move directly to the extending pipe. Additionally, the central axis of the cyclone flow path is parallel to the central axis of the extending pipe.

Owner:SAMSUNG ELECTRONICS CO LTD

Garden road dust clearing device

ActiveCN108166425AWell mixedImprove adsorption efficiencyUsing liquid separation agentRoad cleaningGear driveArchitectural engineering

The invention discloses a garden road dust clearing device. The garden road dust clearing device comprises a bottom plate, a bracket, a dust falling cavity and a cylinder body; the bracket is fixedlymounted at the upper end of the bottom plate, a motor is mounted on the inner side of the bracket, the output end of the motor is fixedly connected with a rotating shaft, and a bevel gear A is fixedlymounted on the rotating shaft and engaged with a bevel gear B fixedly mounted at the left end of a stirring shaft; and the stirring shaft penetrates through a dust falling box and simultaneously penetrates through the vertical end of the right side of the bracket and is fixedly connected with an incomplete bevel gear, and stirring bars are symmetrically on the stirring shaft of the inner side ofthe dust falling box. The garden road dust clearing device is novel in design, water in the dust falling box is stirred through rotating of the arranged stirring bars, mixing of dust airflow and clearwater is facilitated, the efficiency and effect of dust being adsorbed by the clear water are improved, and the dust is prevented from escaping again with the airflow; and an arranged driving gear drives a dust sucking hood to swing back and forth through a driven gear, the dust sucking range of the dust sucking hood is enlarged accordingly, and the dust sucking efficiency is improved.

Owner:刘华英

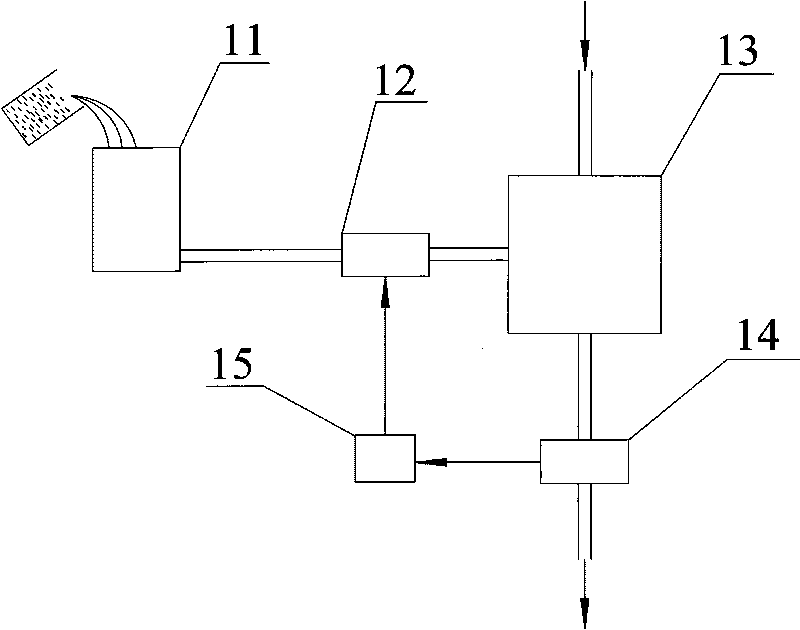

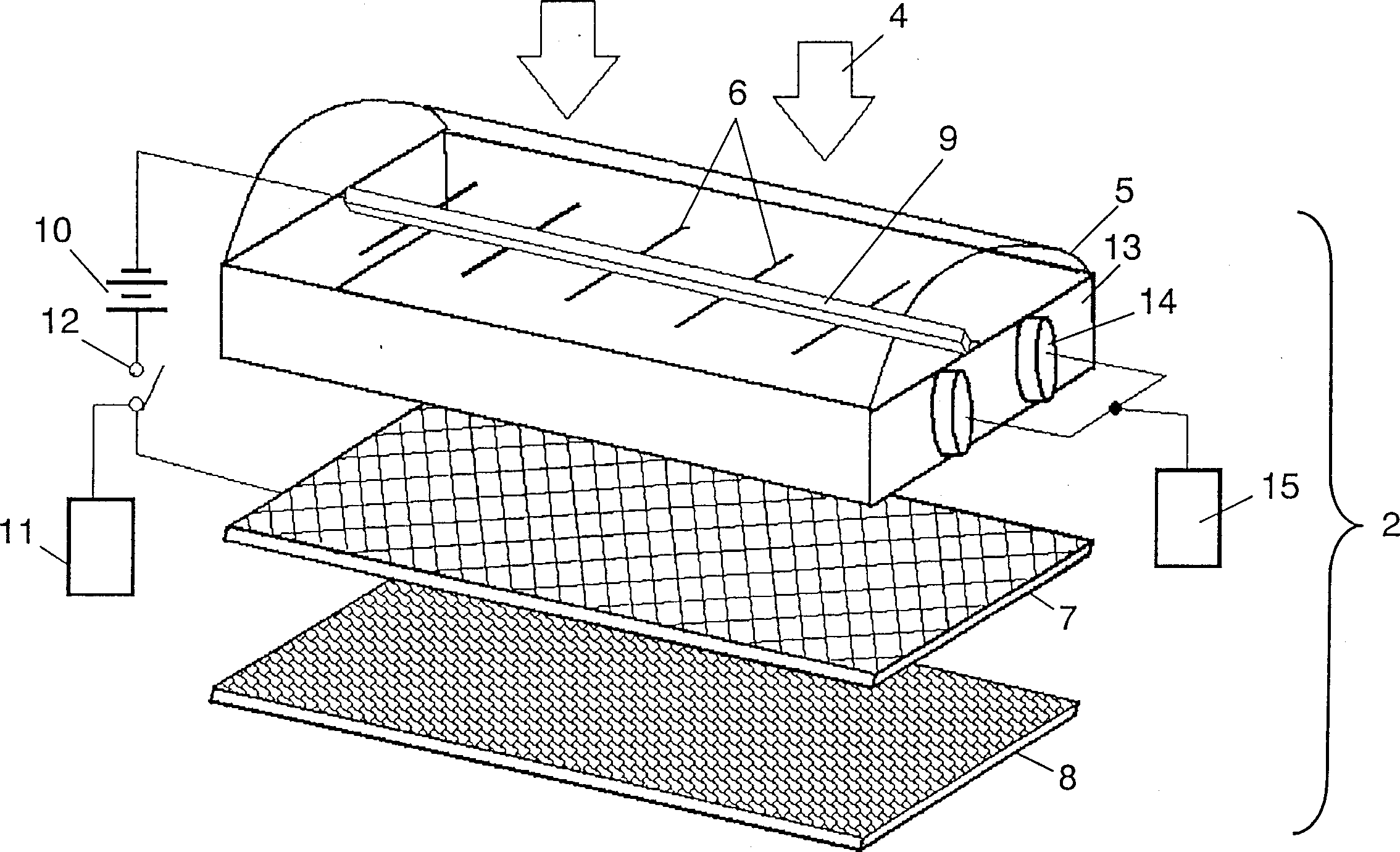

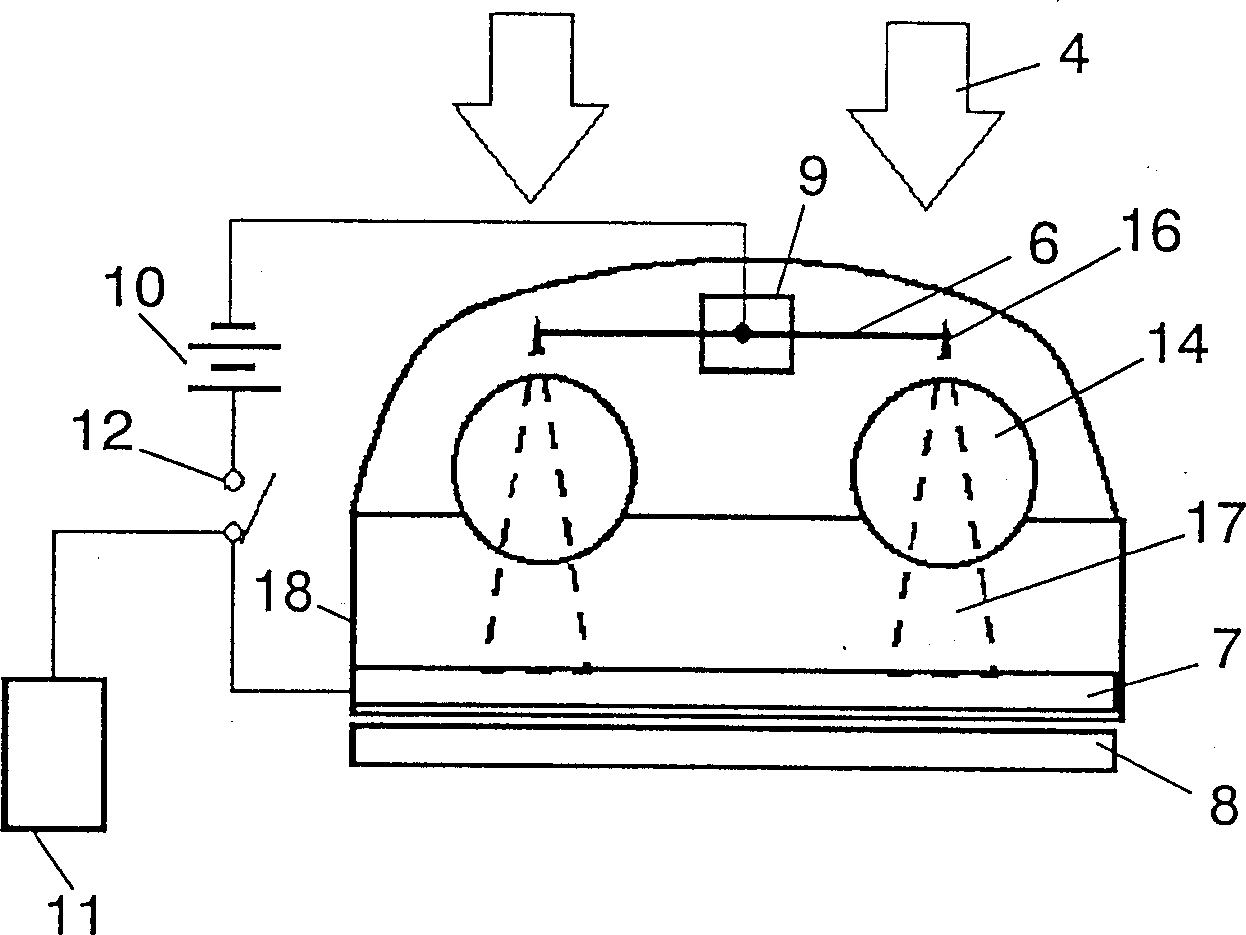

Electric dust collector and method and air supply set using the same

InactiveCN1399103AEffectively chargedImprove dust collection efficiencyDispersed particle filtrationLighting and heating apparatusElectricityCorona discharge

An electric dust collector of a high dust-collection rate is disclosed. The dust collector includes a charging section, a dust collecting section and acoustic wave generating means which irradiates acoustic waves to at least a part of a discharge portion of the charging section. The acoustic wave generating means irradiates the acoustic waves to a corona discharging area, so that an area where corona discharge is generated is enlarged, and at the same time, a probability of collision between particles is increased for accelerating cohesion of the particles. As a result, the dust collection rate is improved.

Owner:PANASONIC CORP

Environmental-friendly road sweeper

The invention discloses an environmental-friendly road sweeper. The environmental-friendly road sweeper comprises a road sweeper chassis and a linear motor. The road sweeper chassis is provided with adriving operating table, a dedusting box and a trash box from left to right in sequence. Brush hair of a disc brush rotating disc sweeps dust on the road surface away, an electric exhaust fan sucks the dust into the dedusting box, a disc brush cover covers a disc brush device and the upper part of the electric exhaust fan, so that the dust is concentrated, the dust sucking efficiency is improved,the dust cannot be raised, larger trash on the road surface is swept by a rolling brush device, a rolling brush rolls so that the trash on the road surface is rolled up and brought into a trash bucket through the rolling brush hair, the trash bucket drives the motor to drive the trash bucket to rotate clockwise, and after the trash is poured into a transport bucket, the trash bucket rotates counterclockwise back to the original position; and the transport bucket is driven by a vertical lifting rod of a lifting bracket to be lifted to the position which is flush with a trash feeding opening, the linear motor is elongated to make the transport bucket be an inclined state, the trash is poured into the trash feeding opening, then the linear motor restores the initial length, and the lifting bracket drives the transport bucket to be lowered to the initial position.

Owner:泉州市知产茂业工业设计有限公司

Technology for preparing cement by dry carbide slag method

ActiveCN101560067ASolve the land occupation of stackingSolve processingClinker productionSlagMoisture

The invention relates to a technology for preparing cement by a dry carbide slag method, which comprises the following steps: raw material storage, transportation, mixture, calcinations, grinding, and the like. Dry carbide slag powder with the moisture from 5 percent to 8 percent, which is discharged by a dry acetylene technical generator, is sealed, transported and stored by a pipe chain machine and a bucket lifting machine; stored raw materials and black raw materials ground in a drying process comprise aeolian sand, sulfate slag and lime slag; carbide ash is transported to a dry pipe by an FU chain transporting machine for initially mixing and drying after being automatically matched and ground by a reservoir bottom microcomputer; raw materials with the moisture which is less than 1 percent are collected by a high-efficiency cyclonic collector and are transported to a raw material homogenizing storehouse to mix by gravity; the raw materials are calcined from a three-grade preheater and a decomposing furnace to a rotary kiln; and after the raw materials are cooled, the raw materials, fly ash, carbide ash and citric acid slag are transported to a cement mill to grind after being metered by a speed-regulating constant feed weigher. The technology increases the participation quantity and the economic benefit of the carbide slag, reduces the environmental pollution and the resource waste, can be used by combining the dry acetylene producing technology and the traditional technology and can be singly used.

Owner:天能水泥有限公司

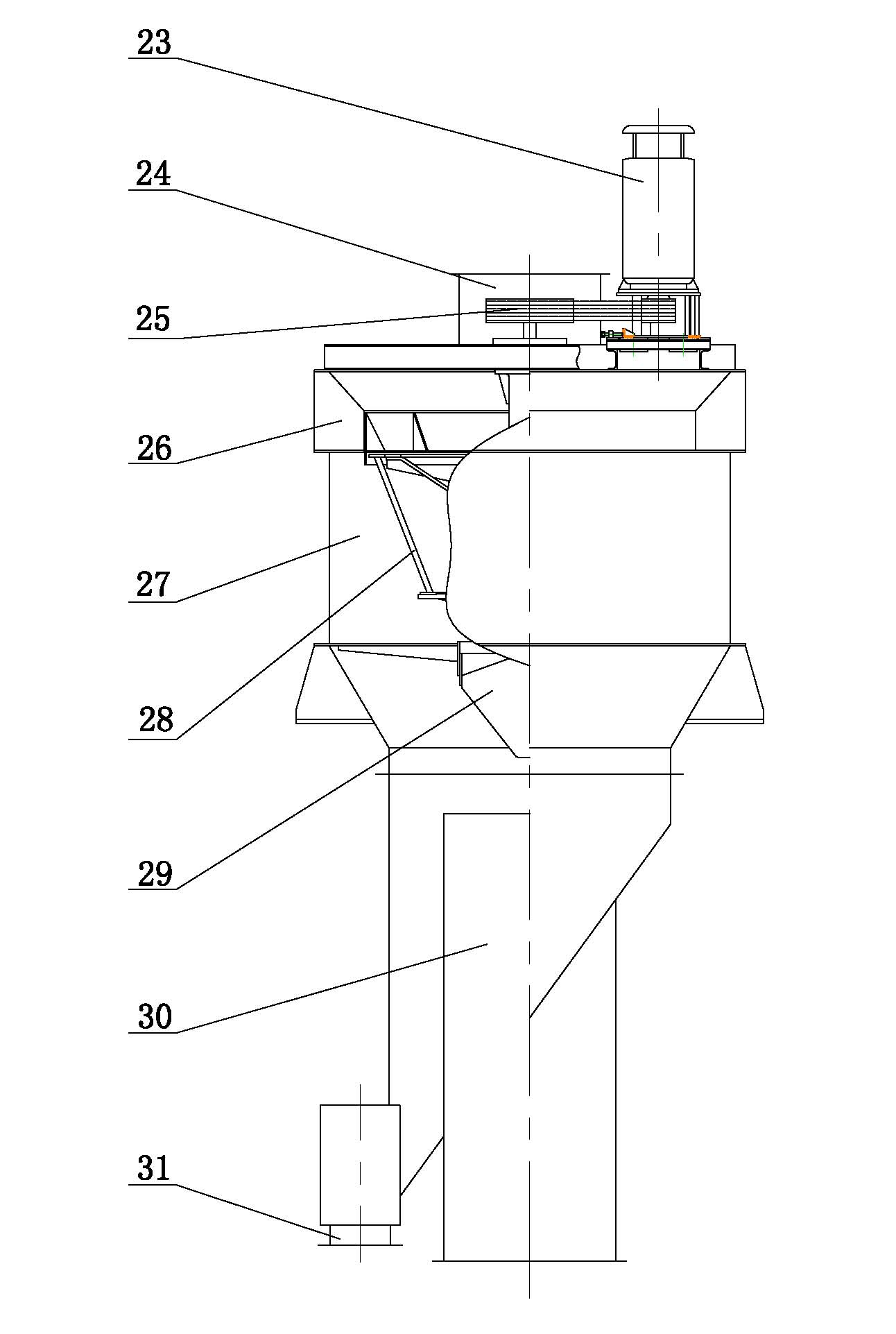

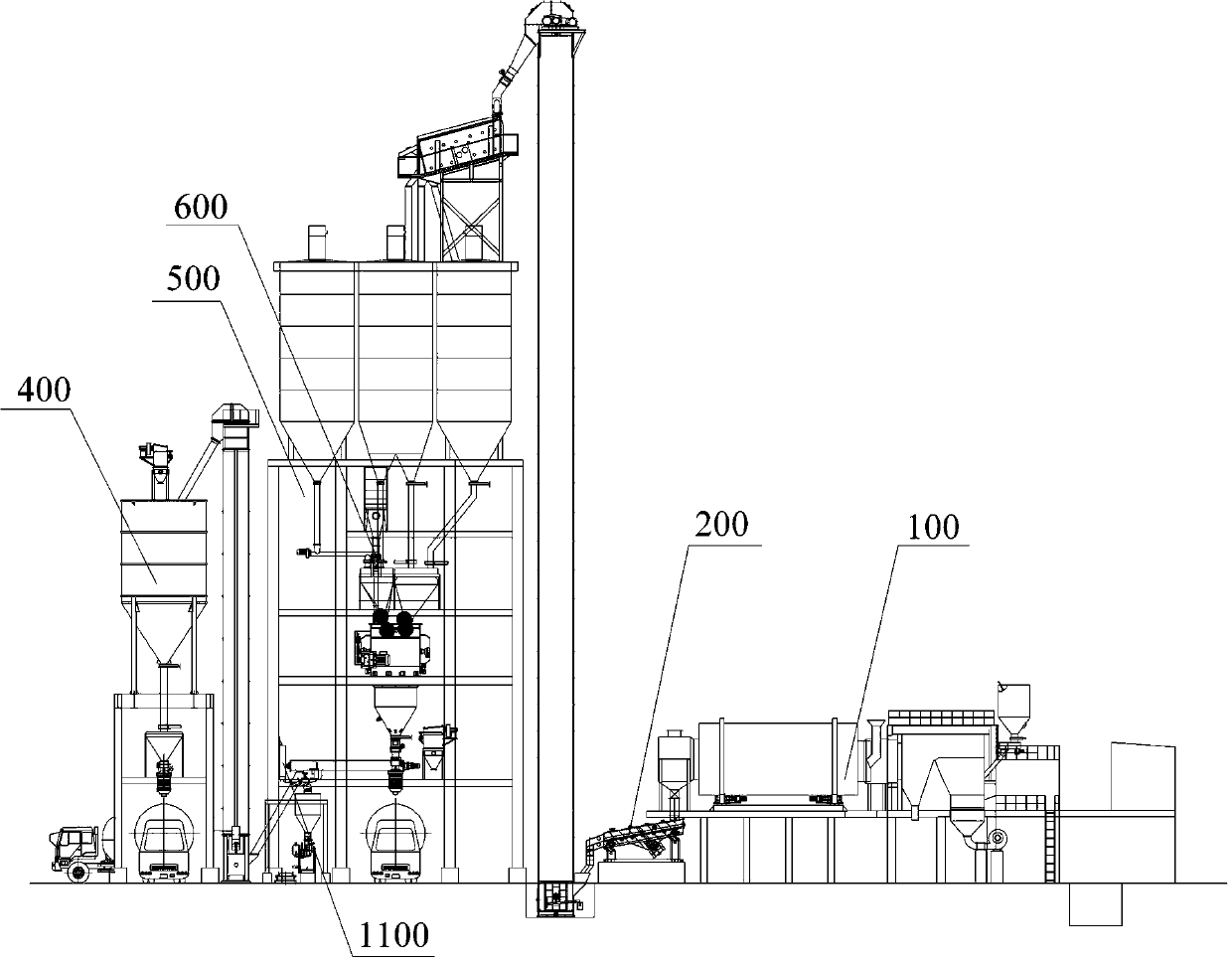

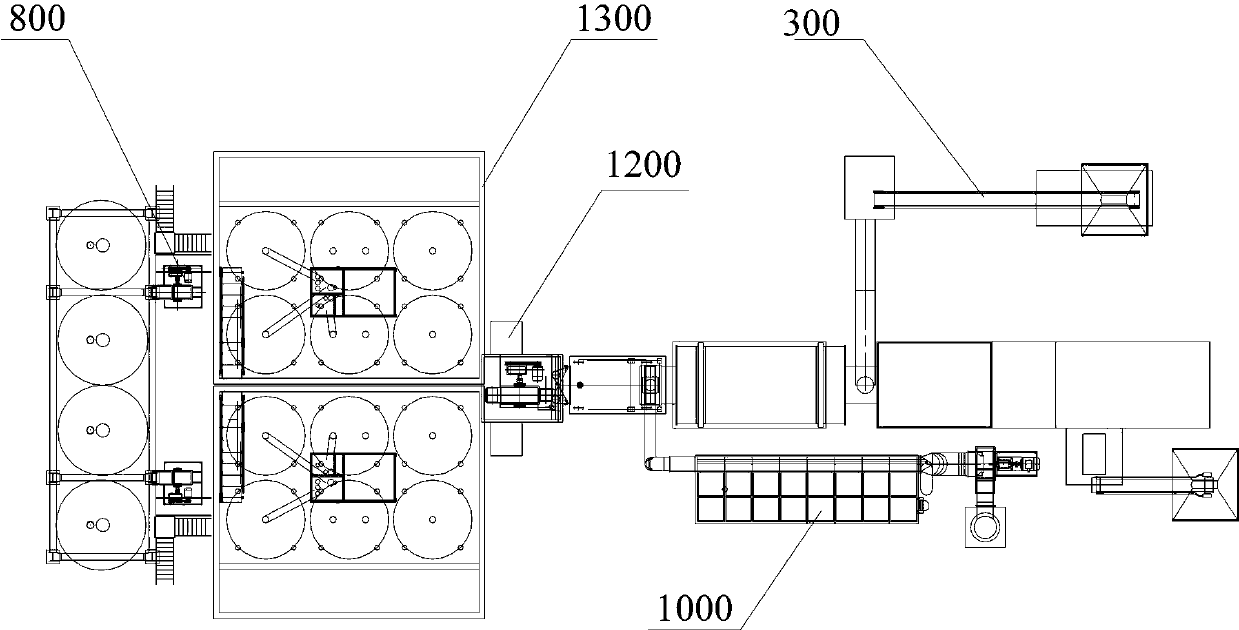

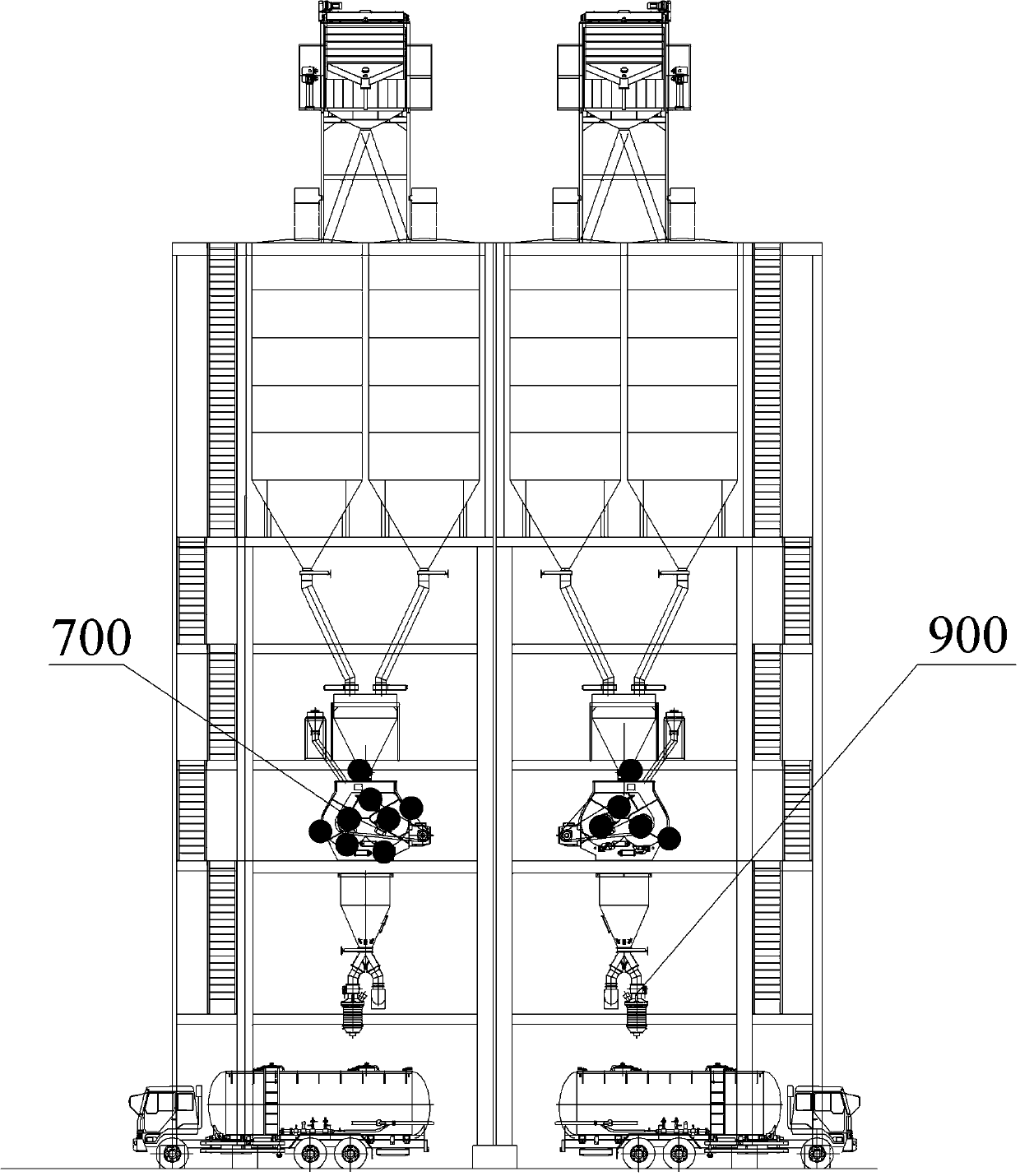

Double-floor type structure dry-mixed mortar station and construction method thereof

InactiveCN103273571AImprove combustion efficiencyRealize stepless speed regulation functionIndustrial buildingsMixing operation plantElastic vibrationSelf locking

The invention provides a double-floor type structure dry-mixed mortar station and a construction method thereof. The double-floor type structure dry-mixed mortar station comprises a drying system, a sieving system, a material supplying system, a storage system, a main body structure, a metering system, a stirring system, a packaging system, a bulking system, a dust-removing system, an electric system, a pneumatic system and an outer packaging system. The double-floor type structure dry-mixed mortar station is characterized in that a variable-frequency feeding device is additionally arranged on a coal cabin charging belt machine in the drying system; aggregates are sieved at a plurality of grades; a primary sieving segregation and sand feeding manner is adopted before bucket lifting; a secondary sieving segregation and sand feeding manner is adopted after the bucket lifting; a sieving machine is provided with an elastic vibration support; a gas tank pulse type automatic dust collector is adopted; a main body adopts a double-floor type structure; two sets of large cubic horizontal double-shaft spiral belt agitating main engines are arranged, one set is standby and the two sets can also be turned on at the same time to use; a multi-finished-product cabin with a manual gate valve and a double-bagging machine are adopted to rapidly bulk and bag to deliver products; and the pneumatic system has bidirectional self-control and self-locking functions so as to guarantee the safety and the reliability of the work of double gas paths and improve the intelligent degree of the whole system.

Owner:上海鸿得利重工有限公司

High-powered dustproof fabric

The invention discloses a high performance dustproof fabric, which is characterized in that the fabric consists of non-dust generating polyester long staple and non-dust generating electrically conductive fiber, wherein, the electrically conductive fiber is distributed inside the fabric in the shape of strips or lattices; the tightness of the fabric is between 2,000 and 4,000. The dustproof fabric has excellent dustproof performance, better antistatic property and air permeability and simplifies the manufacture process of the prior dustproof fabric; moreover, the dustproof fabric which is light, air permeable, comfortable during wearing and convenient for a wearer to work flexibly can be used as dustproof garment fabrics used in industries such as semiconductor, foodstuff and medicine.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com