Process for preparing carbon forming powder

A molding powder and process technology, which is applied in the field of carbon molding powder preparation, achieves the effects of high airflow rotation speed and centrifugal force field strength, convenient fineness adjustment, and high powder selection efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

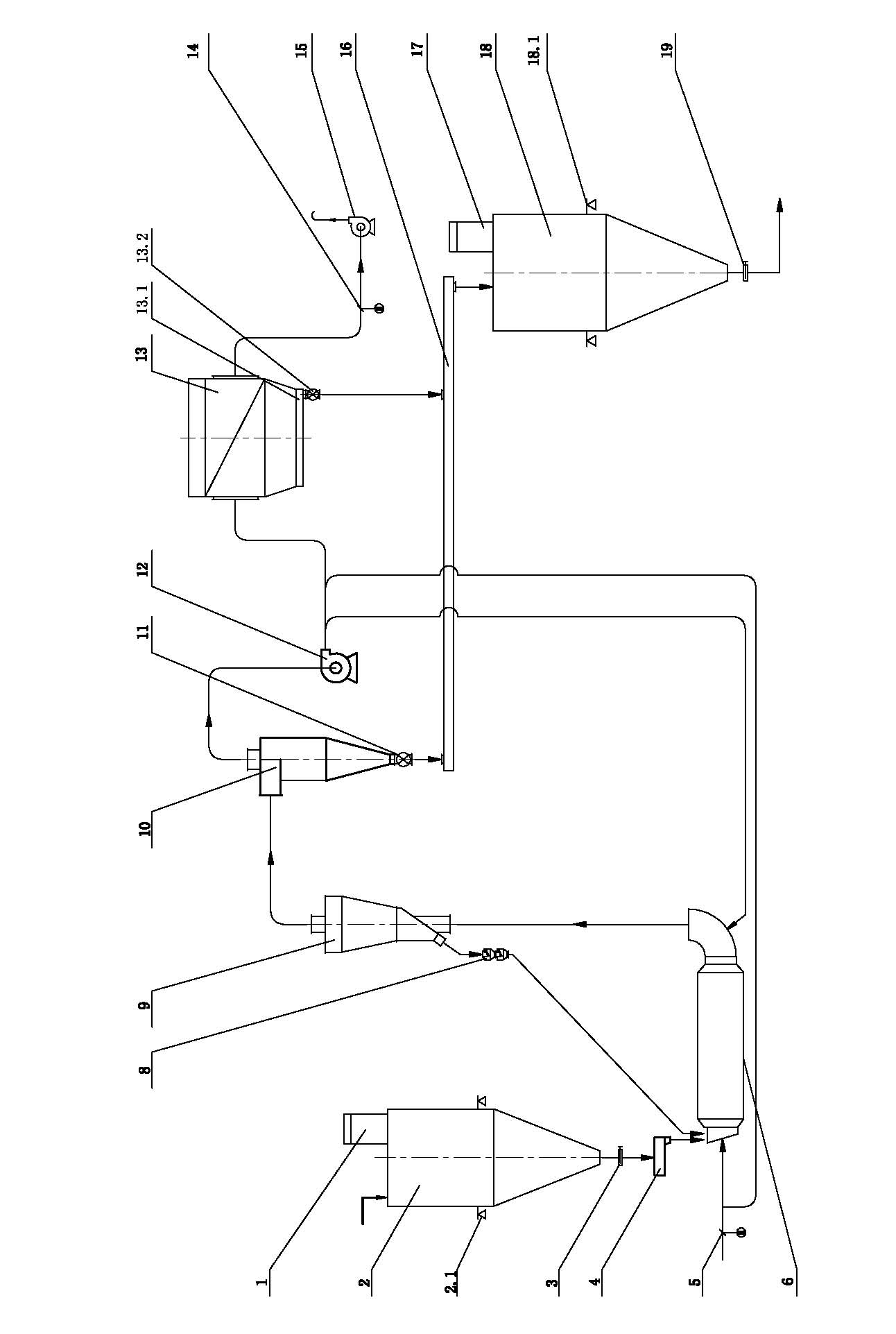

[0041] Example 1 Double fan closed-circuit circulation process transformation

[0042] The invented process is applied to the transformation of the pulverizing system of Luoyang Longquan Tiansong Carbon Co., Ltd. with double blower closed-circuit circulation process. The whole system is an open-circuit system operating at -5860Pa. The raw materials are waste anodes and carbon petroleum coke. The rotor speed (223r / min) of the high-efficiency rotor classifier (NHMF-200) is adjusted, and the air box pulse bag filter ( Model LPM2×5C-920), main exhaust fan (model XY6B-SM1600D, air volume: 48000~63900m3 / h). Effects of the process transformation: 1. The output of the system is greatly improved. The current output of the system is 12t / h. After the transformation, the output of the system is increased by 20% while ensuring the original control fineness (the quality of <80μm is 80%), reaching the original design requirement of 10~12t / h. 2. The stability of the system ...

Embodiment 2

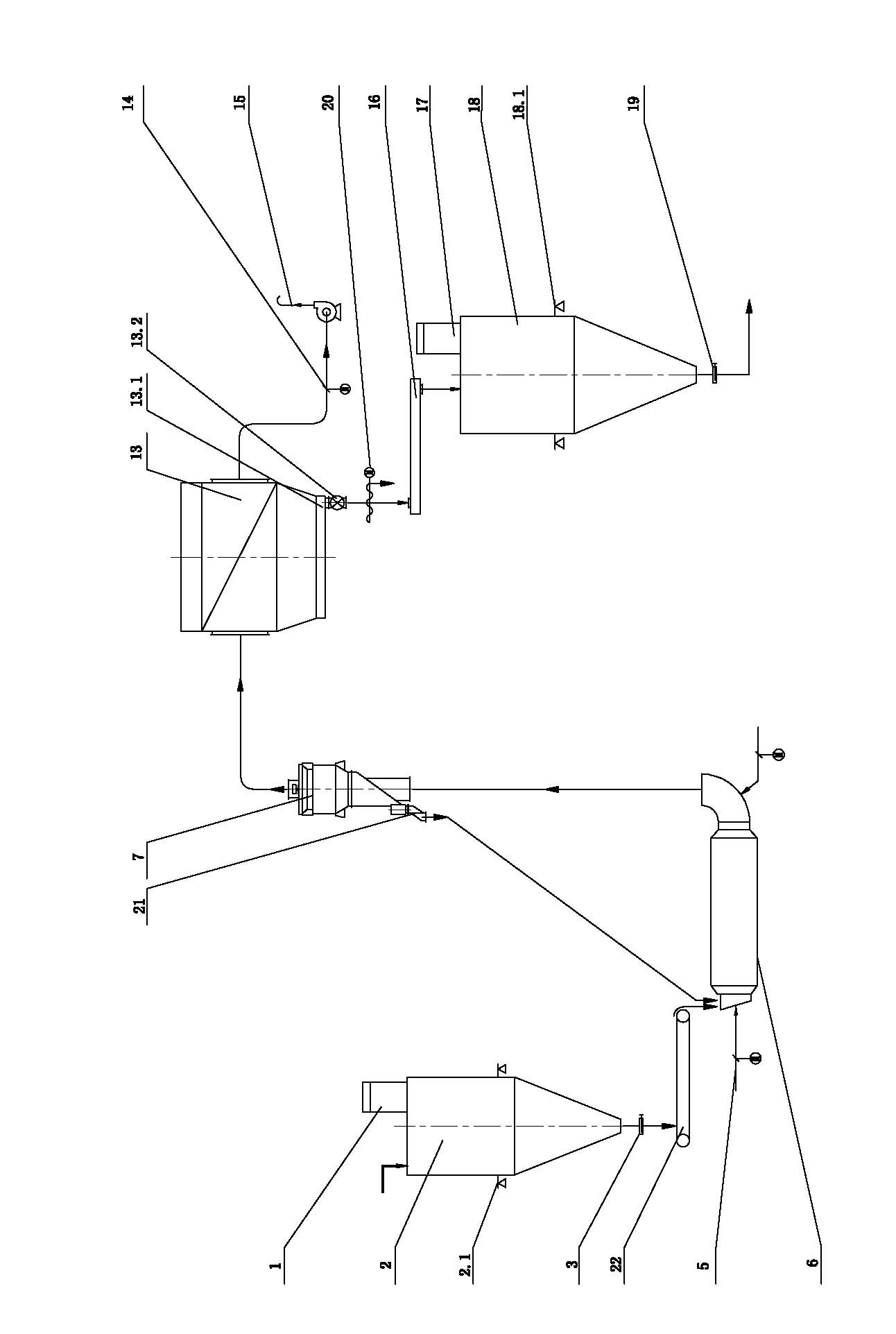

[0043] Embodiment 2 Process new project of the present invention

[0044] This invented process is applied to the newly-built project of grinding system in raw anode workshop of Shandong Nanshan Aluminum Industry Co., Ltd. The whole system is an open circuit system operating at -6500Pa, the raw material is carbon petroleum coke, the rotor speed (265r / min) of the high-efficiency rotor classifier (NHMF-240) is adjusted, and the air box pulse bag filter (model LPM2× 5C-920), main exhaust fan (model 7-29-11 №14.25D, air volume: 50000~70000m3 / h). After the project is completed, the output of the system will be 14t / h, meeting the original design requirement of 12~14t / h. The stability of the system is improved, and the uniformity of the finished powder is good. The average index (n) of its finished powder is 1.30. Adjusting the rotor speed of the high-efficiency rotor classifier through the stepless speed regulation of the frequency converter can easily adjust the finenes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| evenness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com