Patents

Literature

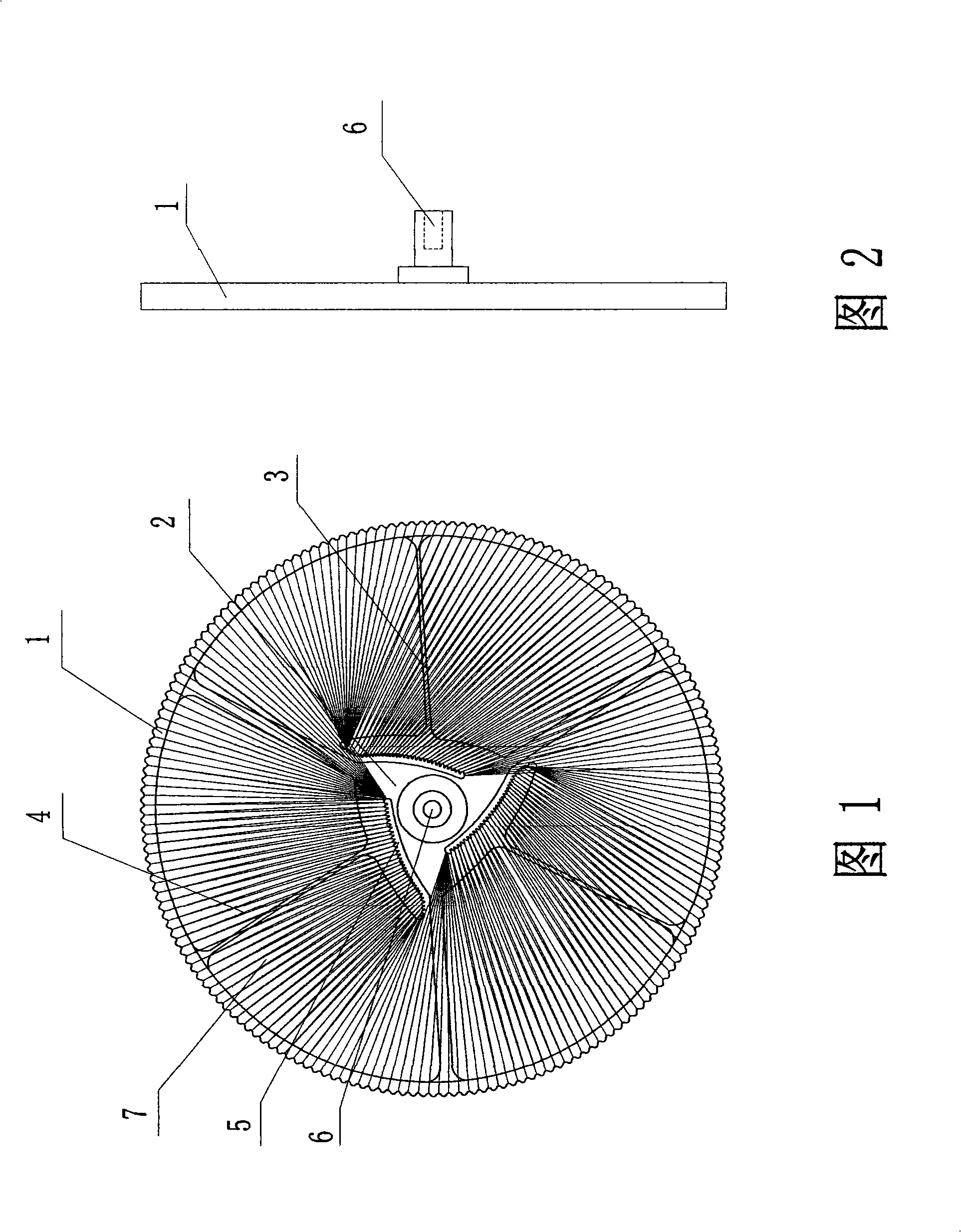

65results about How to "Handling large air volume" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

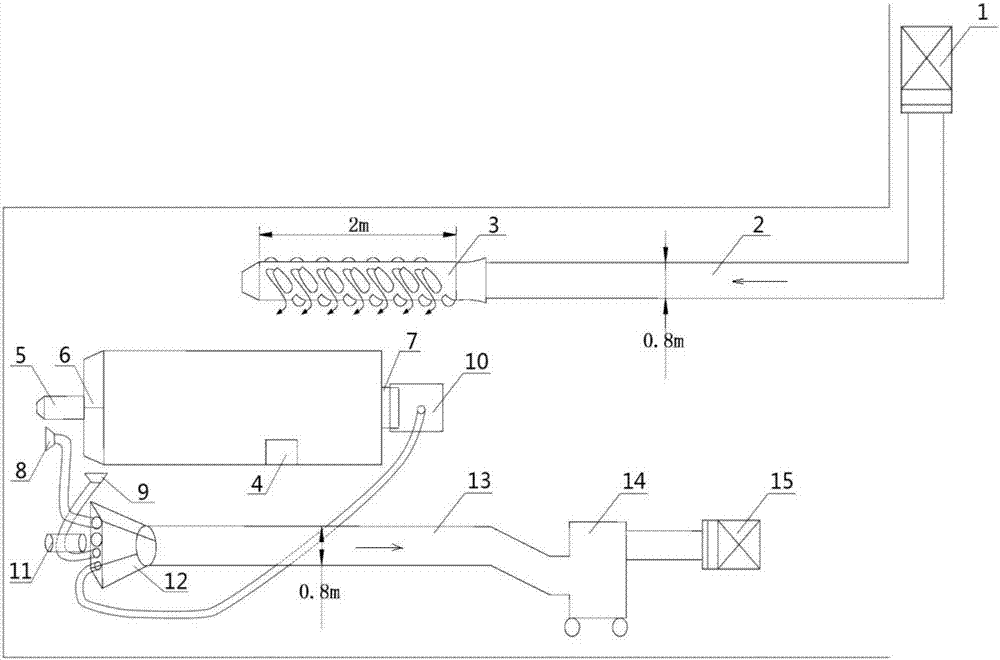

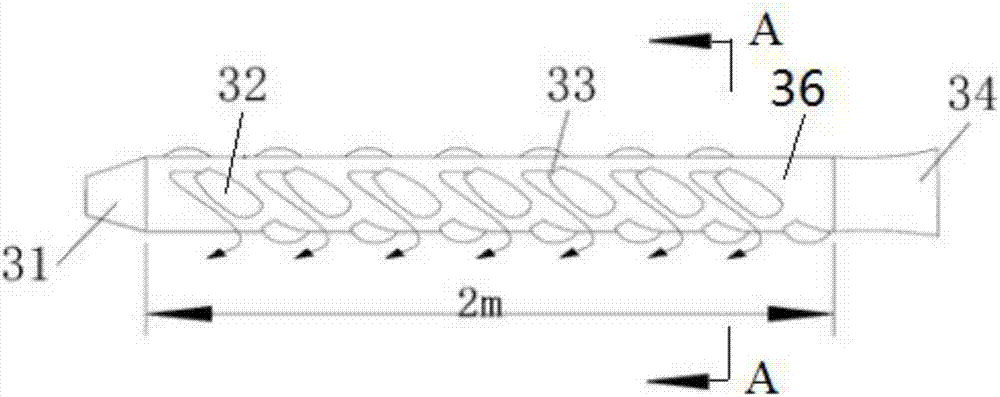

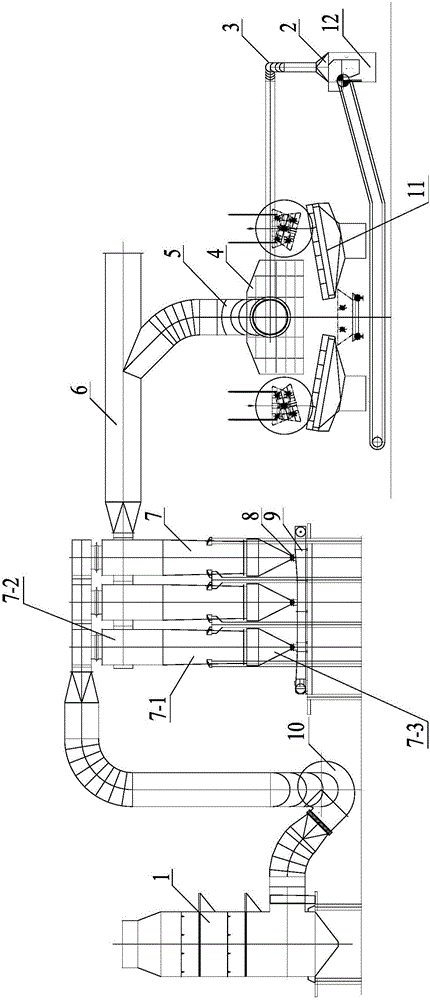

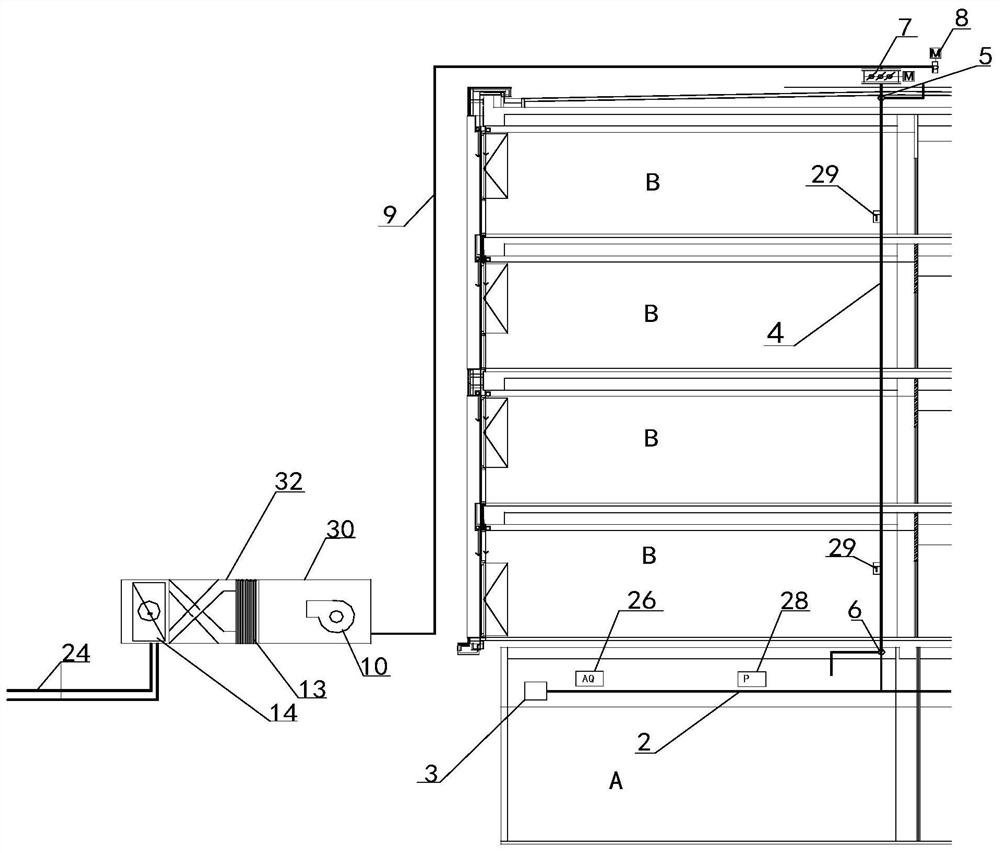

Dust removing system for fully-mechanized coal mining workface

PendingCN107218074AImprove working environmentReduce dust concentrationDust removalFire preventionMining engineeringDust control

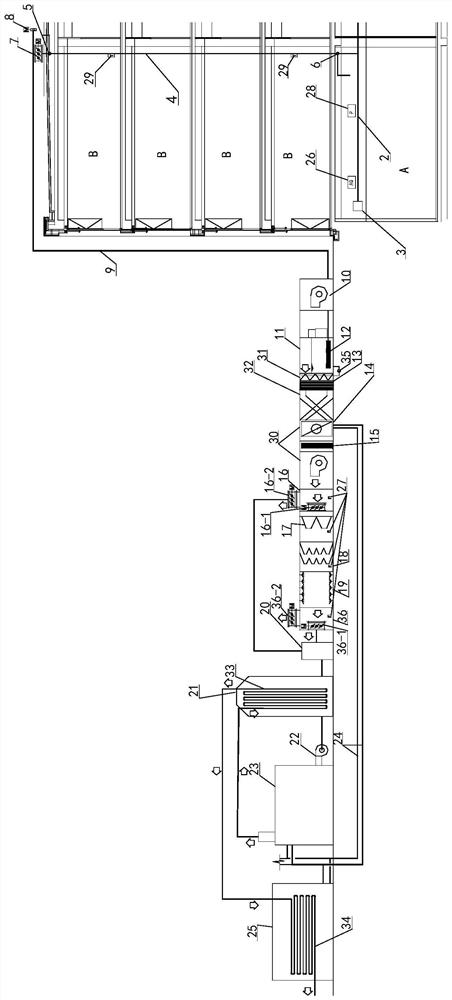

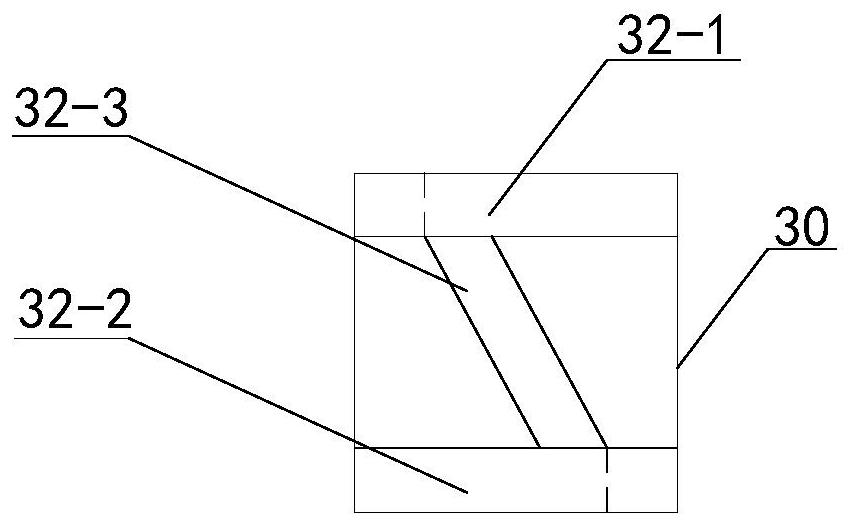

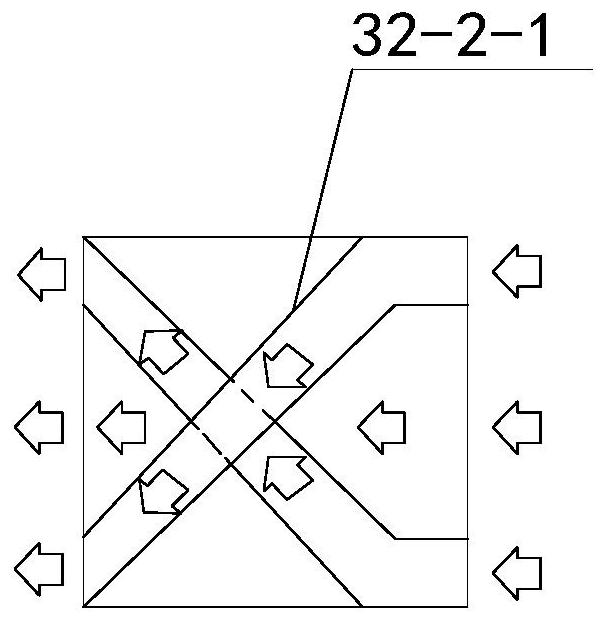

The invention discloses a dust removing system for a fully-mechanized coal mining workface. The system includes a dust control system installed on one side of a roadheader, a dust suction system and a dust collecting system installed on the other side of the roadheader, wherein the dust control system comprises a press-in type fan, a press-in type air duct and a wall-attached air duct which are connected with each other in turns; the dust suction system comprises a first suction hood for sucking dust on the cutting head position of the roadheader, a second suction hood for sucking dust on the insertion board position of the roadheader, a third suction hood for sucking dust on the break-of-bulk-point position of a scraper conveyor and belt conveyor, a dust suction air duct and a suction hood assembly box, and the first suction hood, the second suction hood, the third suction hood and the dust suction air duct are all connected to the suction hood assembly box; the dust collecting system comprises an extraction type air duct, a dust remover and an extraction type fan which are connected with each other in turns, and the extraction type air duct is connected to the suction hood assembly box. The dust removing system for the fully-mechanized coal mining workface can effectively control diffusing and spreading of dust in underground roadways, has a good dust suction effect and high dust collecting efficiency, and can greatly reduce the dust concentration of the fully-mechanized coal mining workface.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

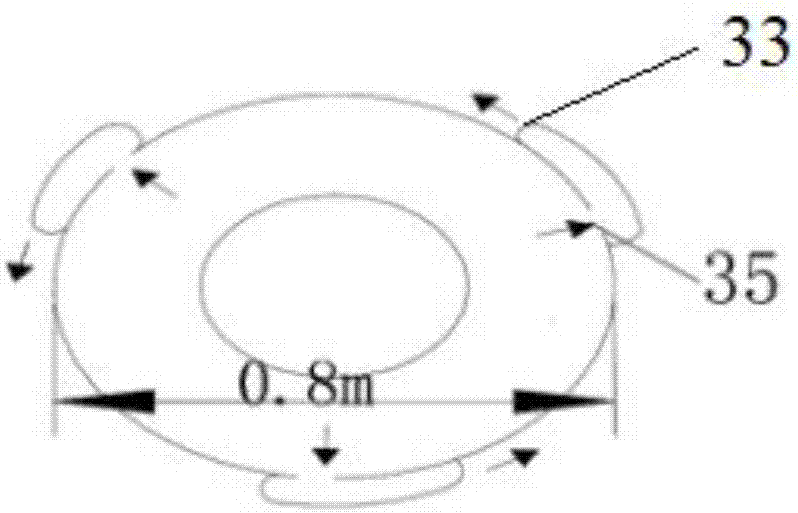

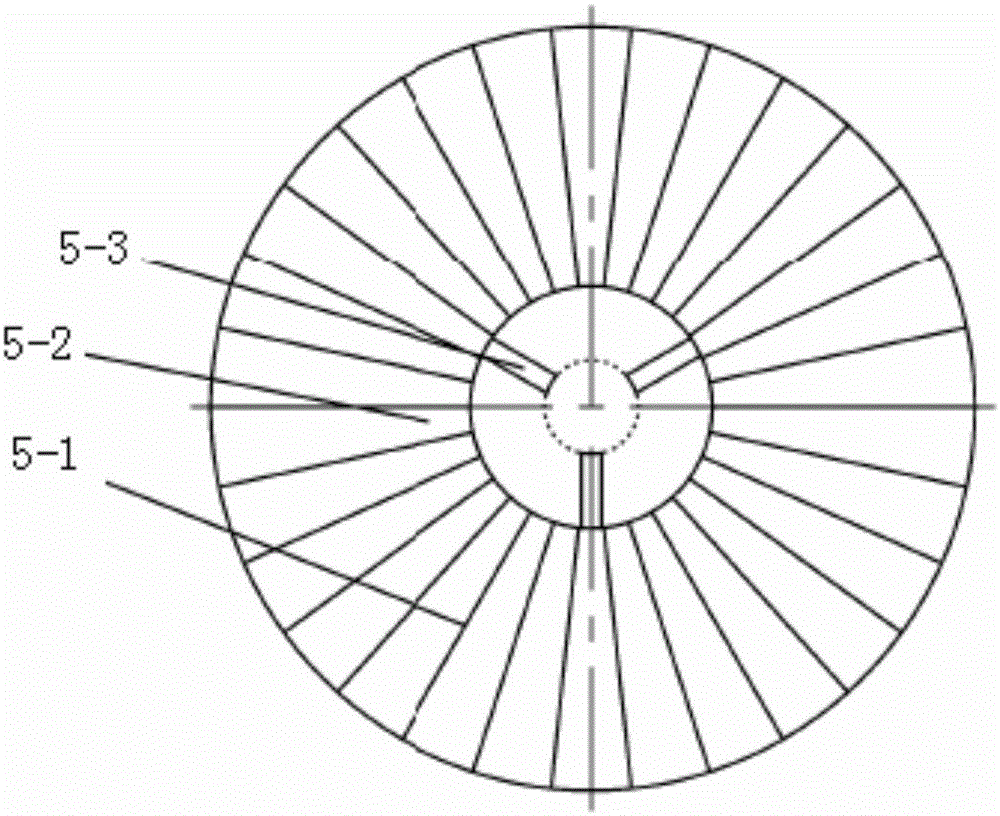

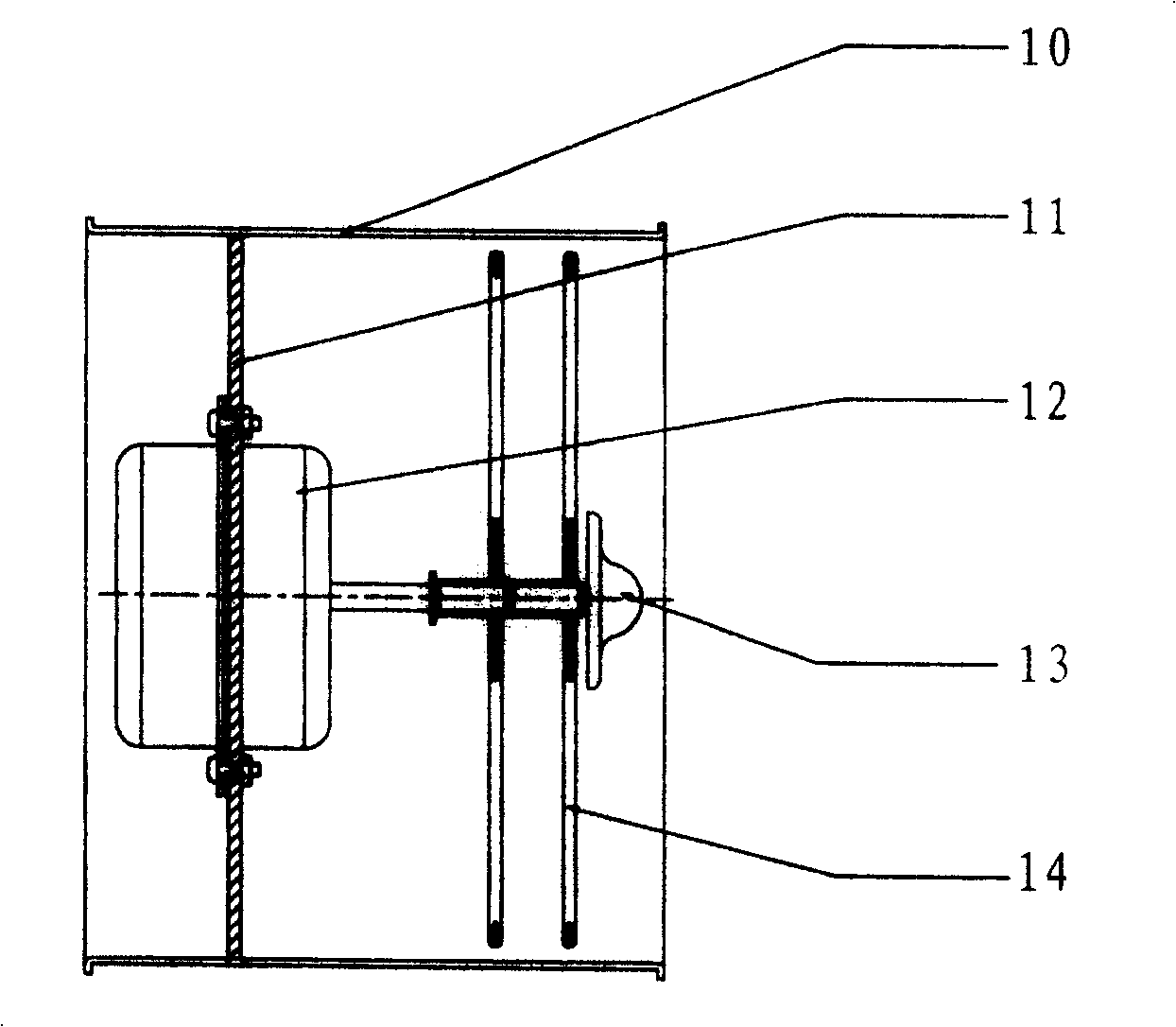

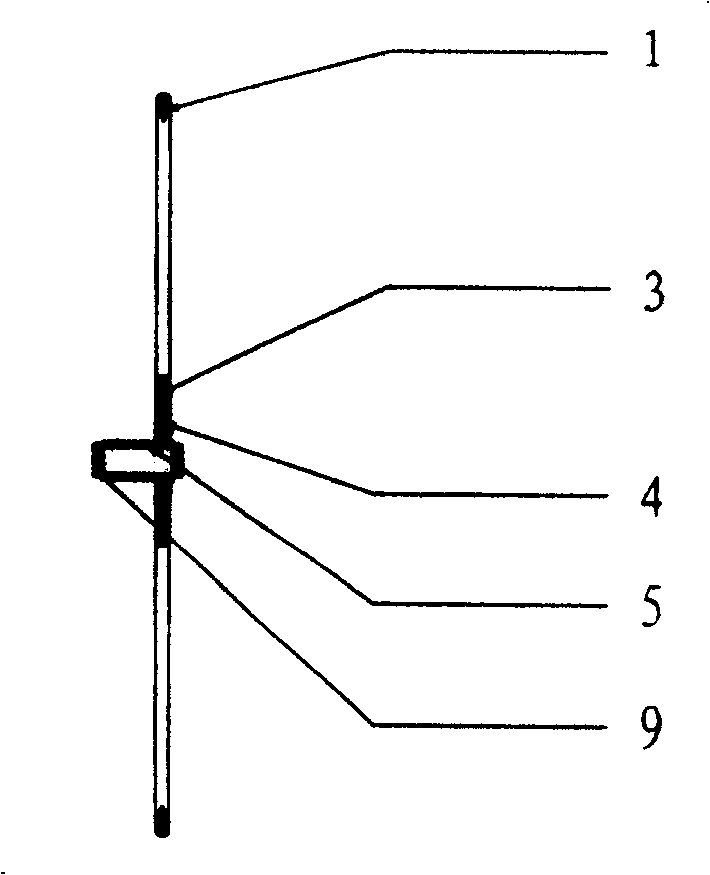

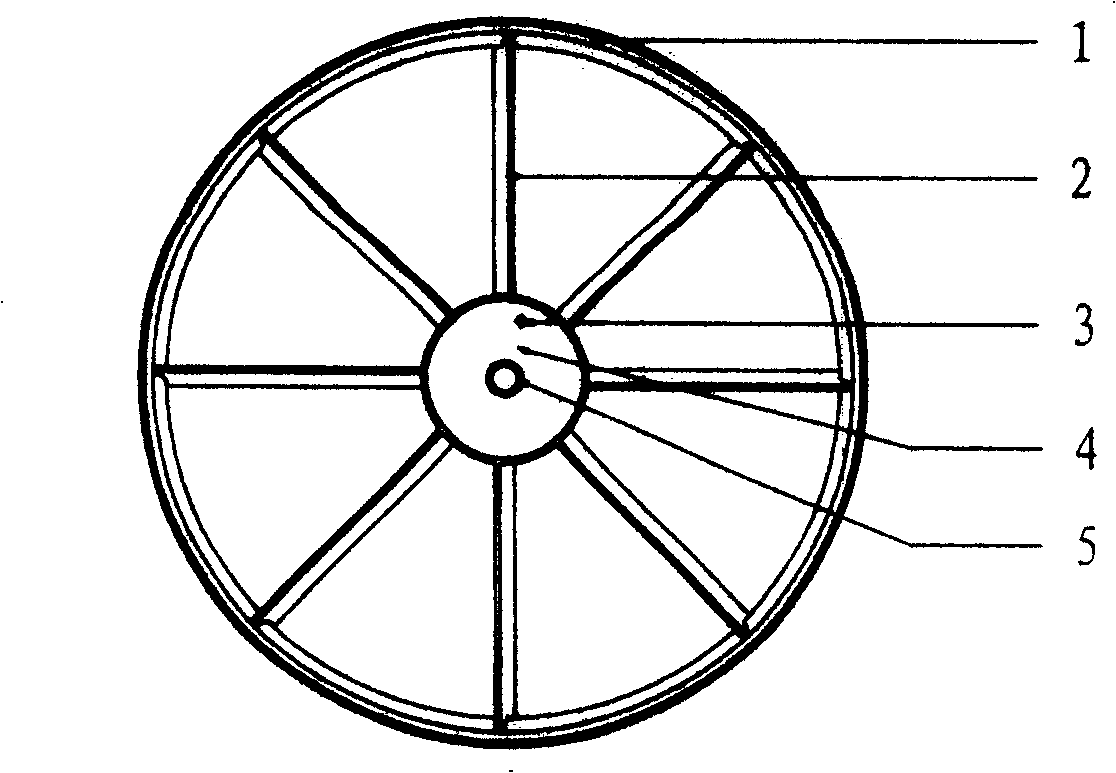

Rotary net-filtering tray for cooking fume exhauster

InactiveCN101329078AHandling large air volumeTo achieve the purpose of purifying the airDomestic stoves or rangesDispersed particle filtrationAir volumeEngineering

The invention discloses a rotary strainer disk used for a range hood, comprising an outer rotary table and an inner rotary table which are connected together through a support rod; a strainer formed by strainer-mesh is arranged between the inner rotary table and the outer rotary table. By adopting the structure, the invention is provided with reasonable design, convenient mounting and maintenance process and low manufacturing cost; the air resistance is small and the disposed air flow is big during running; the oil-smoke containing a plurality of volatile solids can be filtered and cleaned, and the filtering and cleaning efficiency generally can reach more than 90 percent.

Owner:郑吉贤

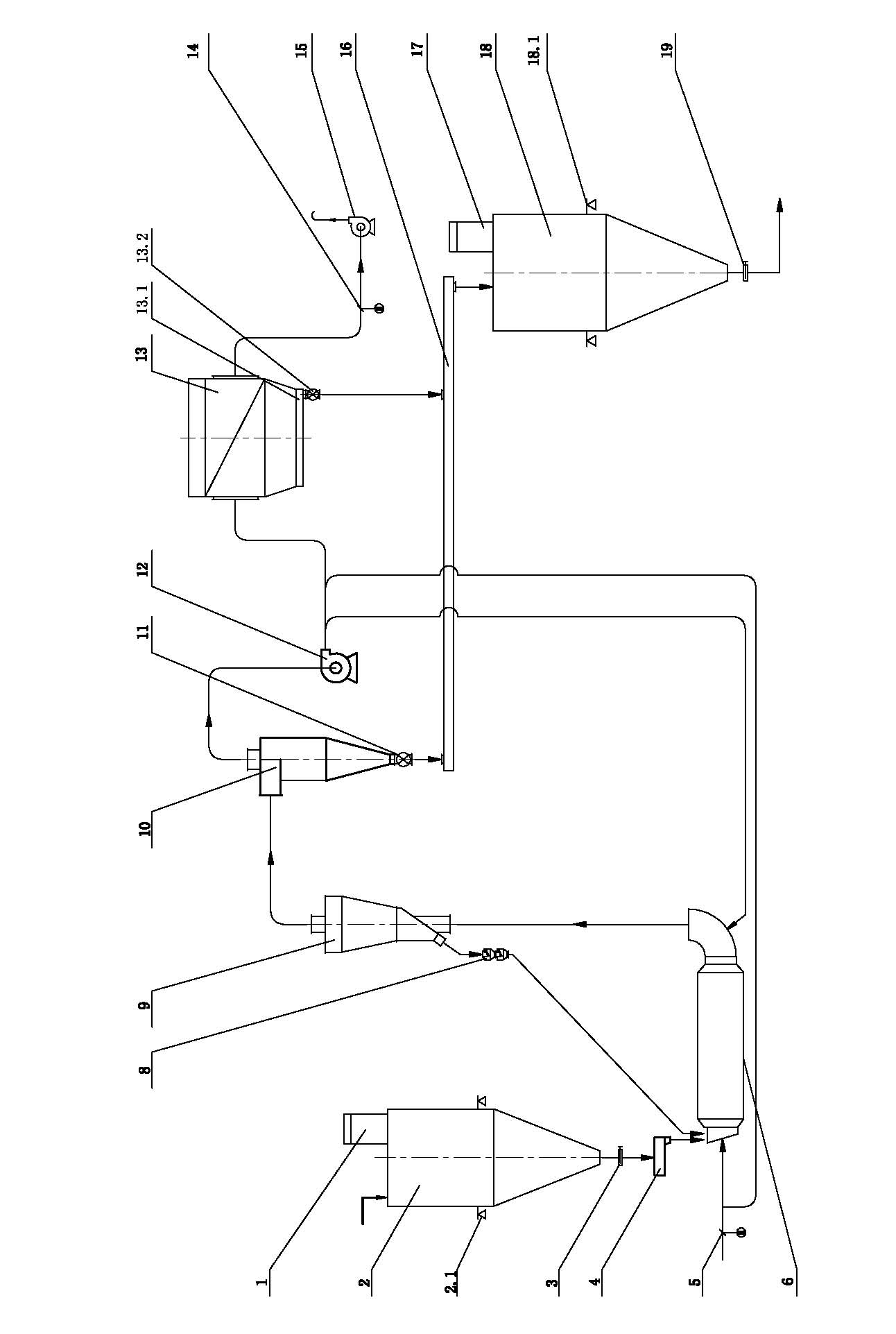

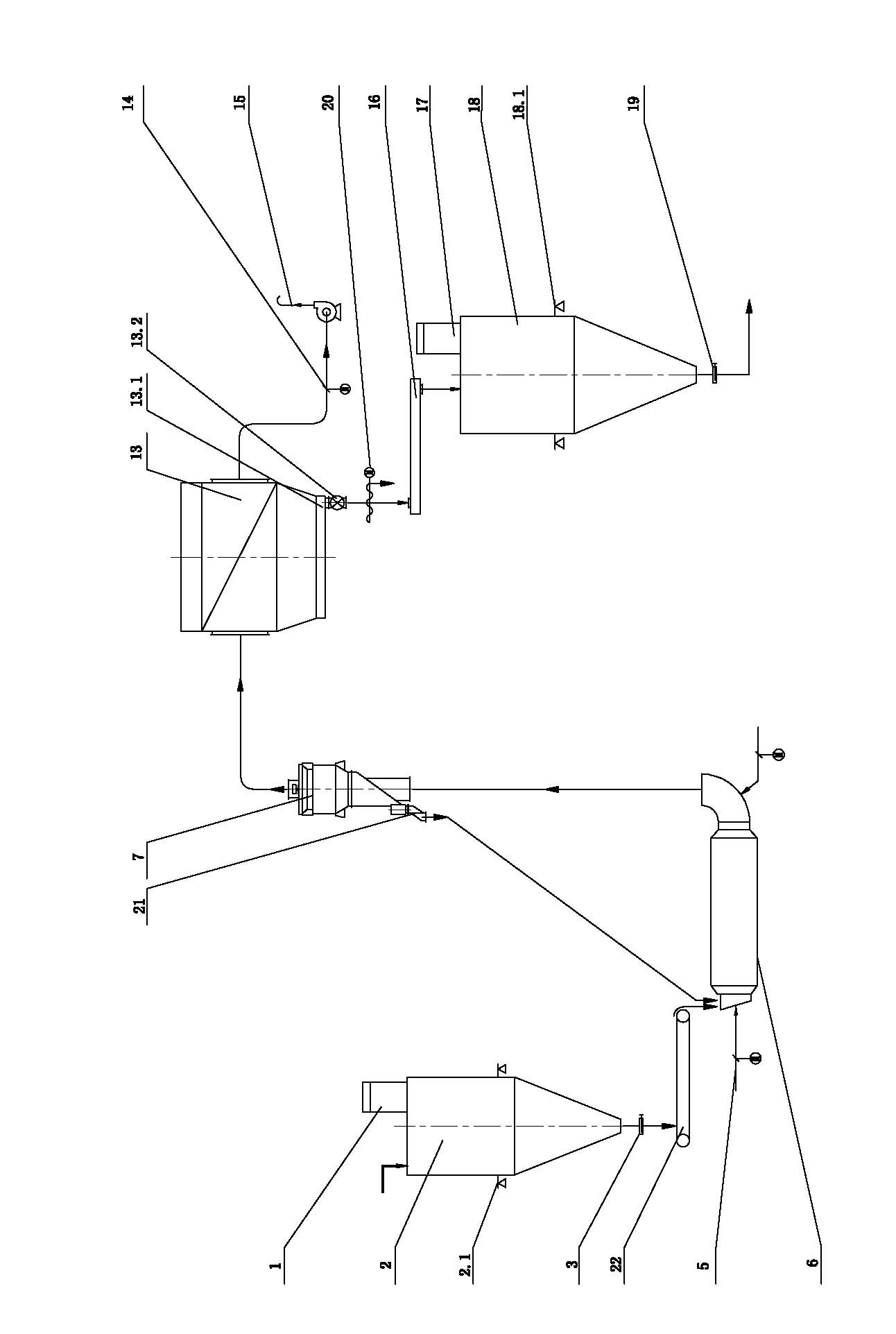

Process for preparing carbon forming powder

InactiveCN101972687AImprove dust carrying capacityReduce power consumptionGrain treatmentsProcess engineeringBall mill

The invention relates to a process for preparing carbon forming powder, in particular to a new process for preparing carbon forming powder by adopting an air swept type ball milling system. In the invention, equipment mainly comprises a raw material bin, an air swept type ball mill, a high-efficiency rotor type grader, a gas tank pulse bag type dust collector, a main exhaust fan and a finished powder bin. In the main work process of the invention, a raw material is fed and added to the air swept type ball mill through a feeder and is subjected to rough and fine powder grading through the high-efficiency rotor type grader, rough particles are returned to the ball mill for pulverizing once again, and fine particles enter the gas tank pulse bag type dust collector for collection. The invention has the technological performance advantages of high systemic force supply, low power consumption for unit product, high finished powder purity, and good uniformity and stability, and completely eliminates the phenomena of air leakage and ash flying in the traditional process because of the operation in a negative pressure state. The process is not only suitable for the optimization and technological improvement on the traditional process in the production process of the carbon forming powder, but also suitable for new projects of a carbon forming powder preparation system.

Owner:NANJING UNIV OF TECH

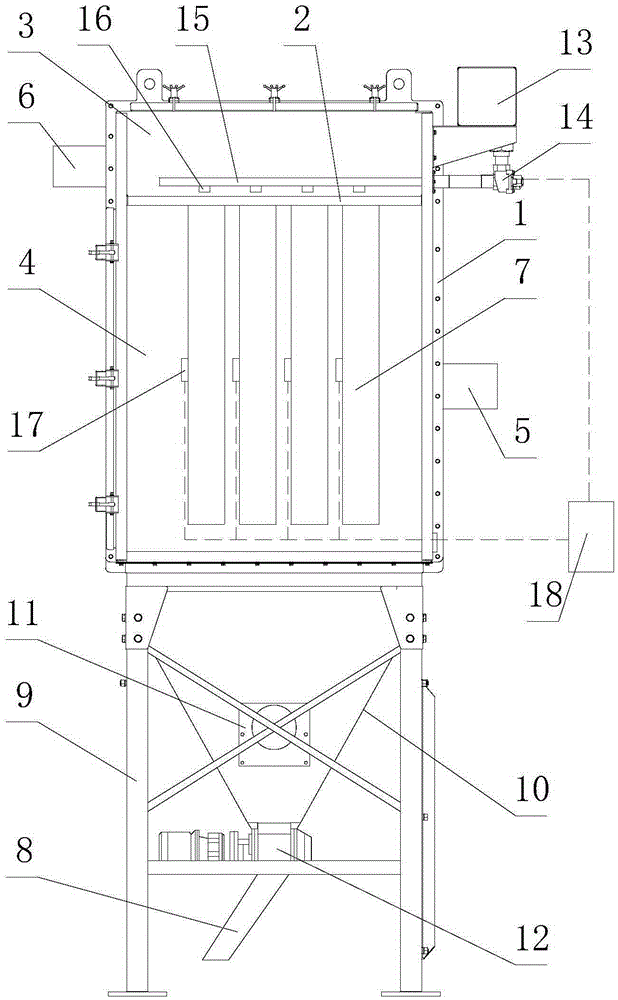

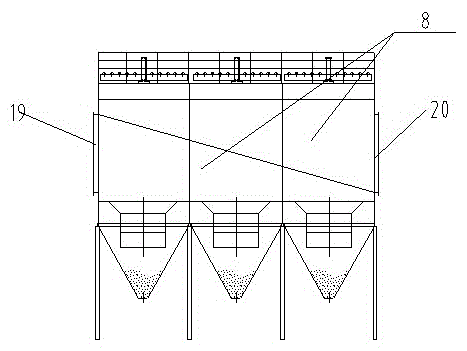

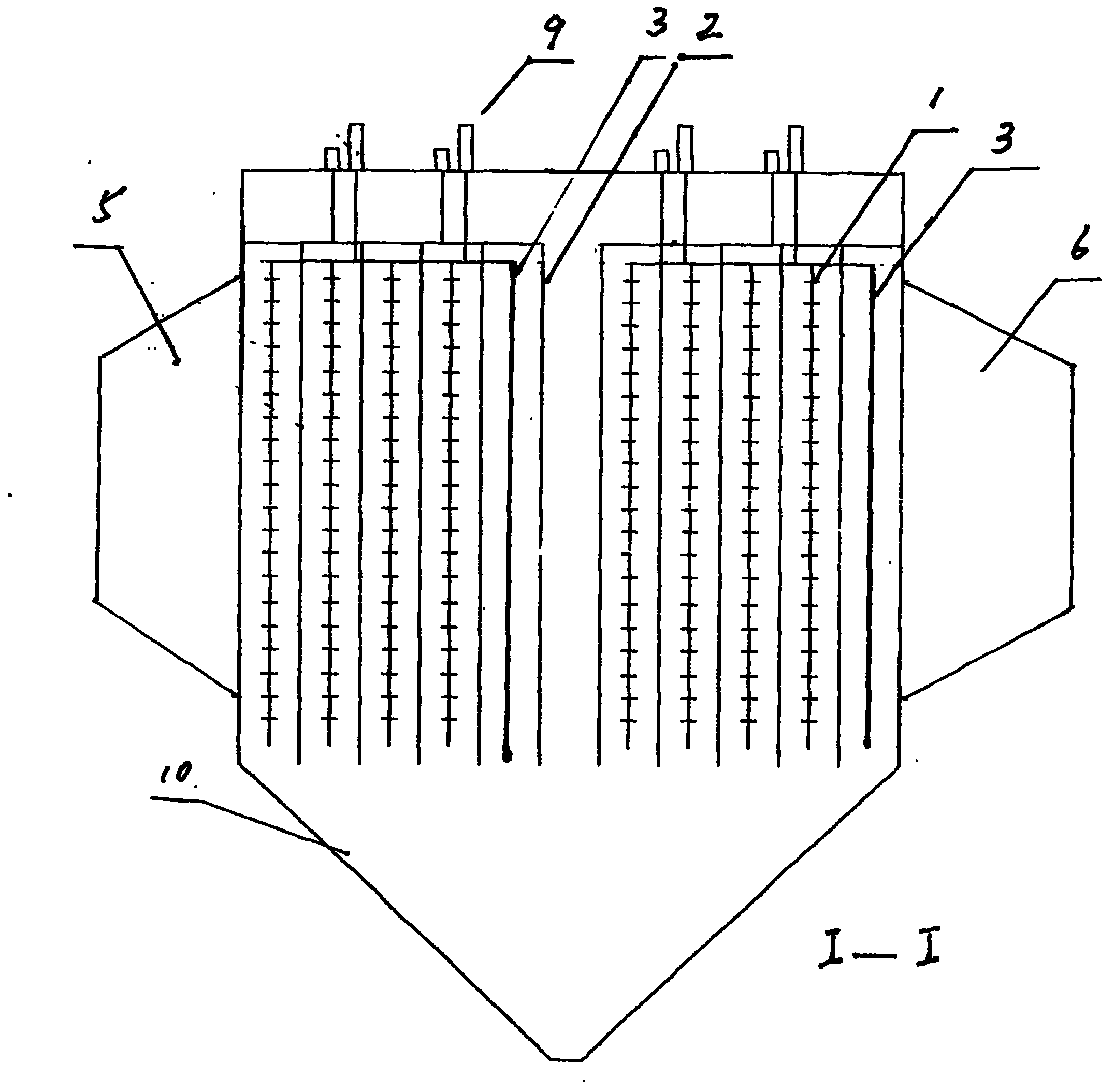

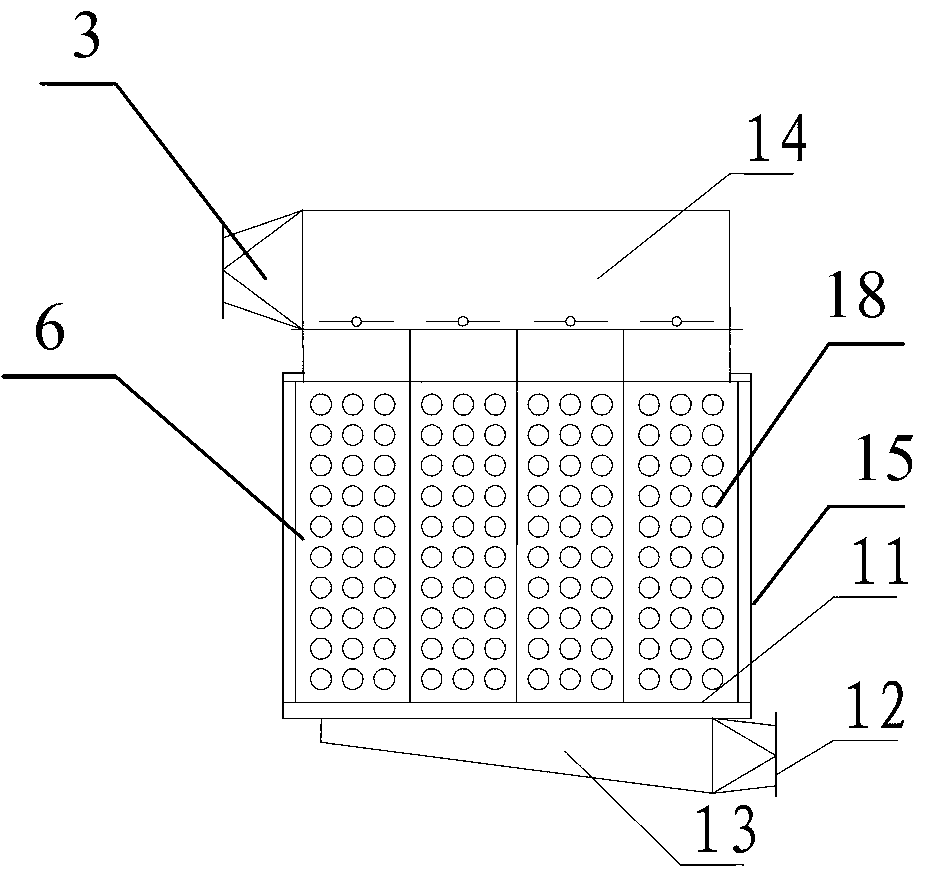

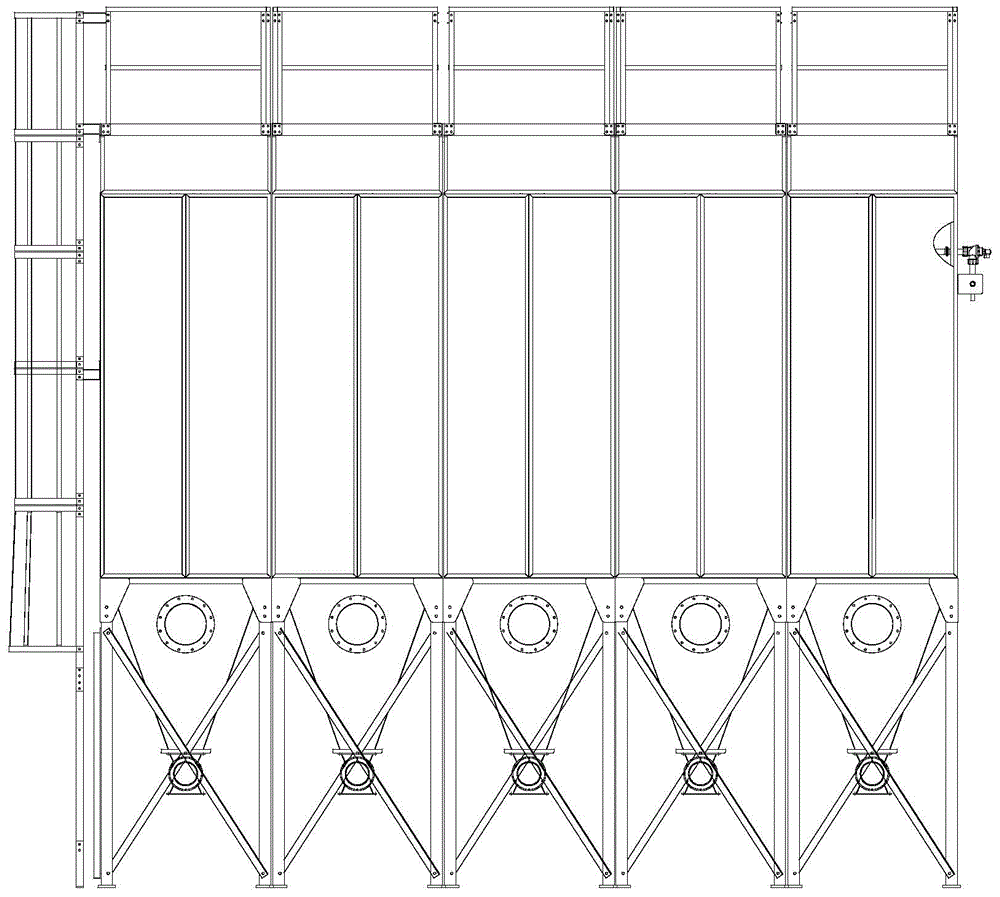

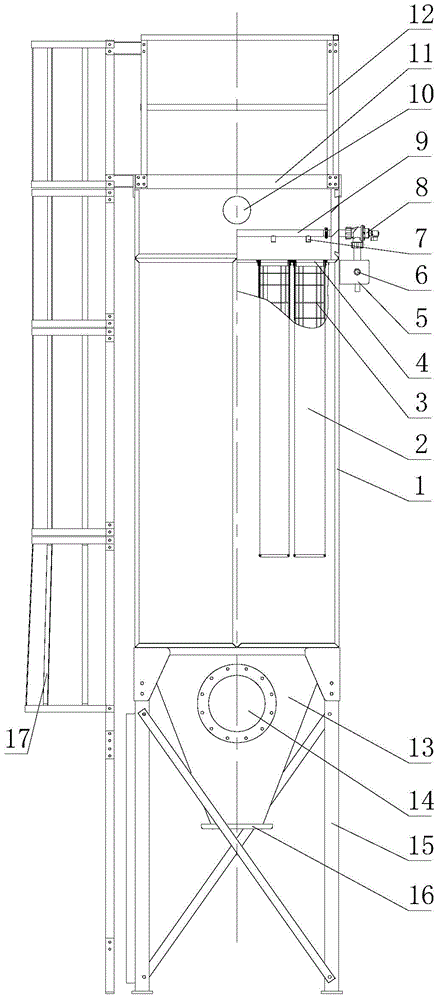

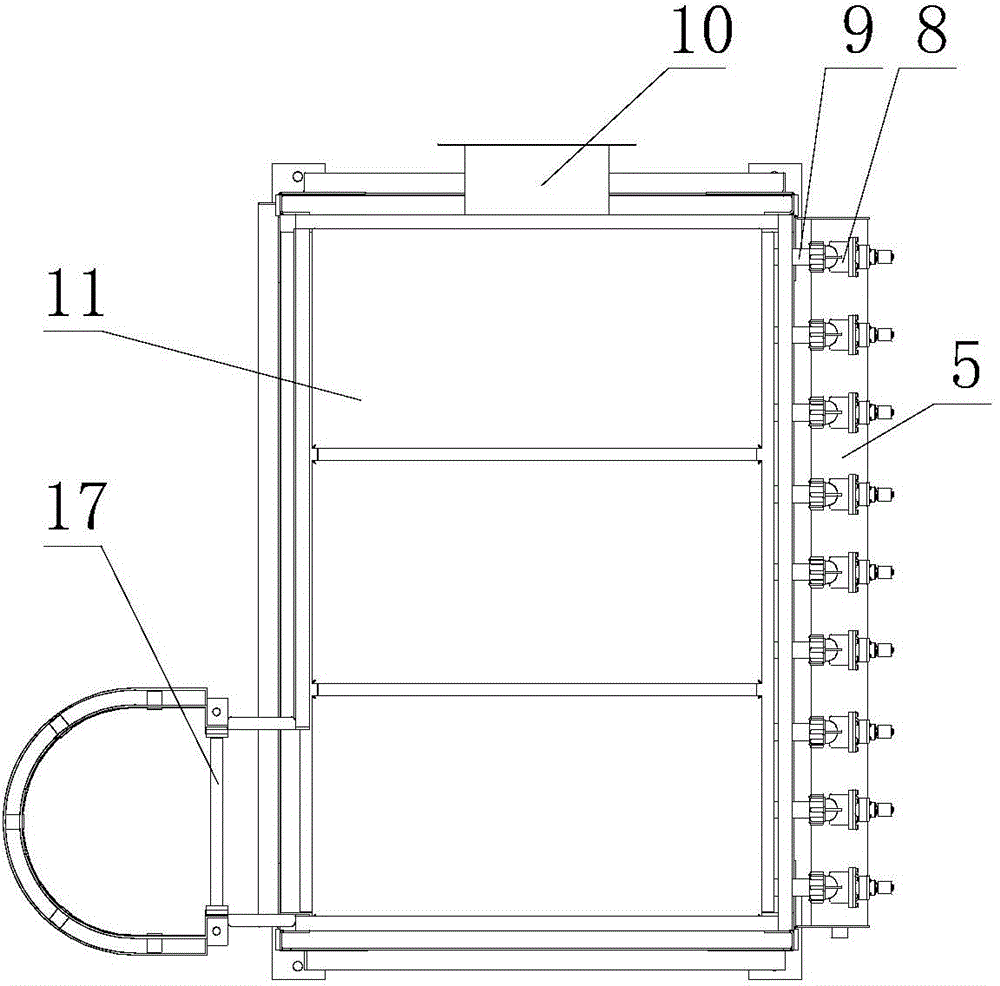

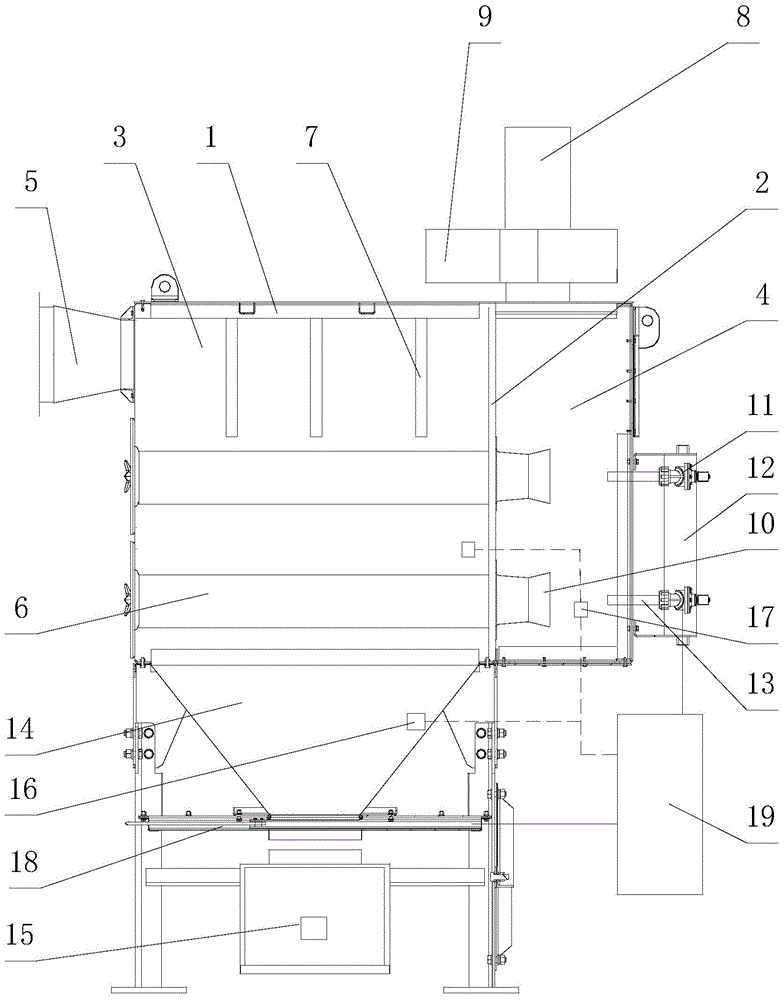

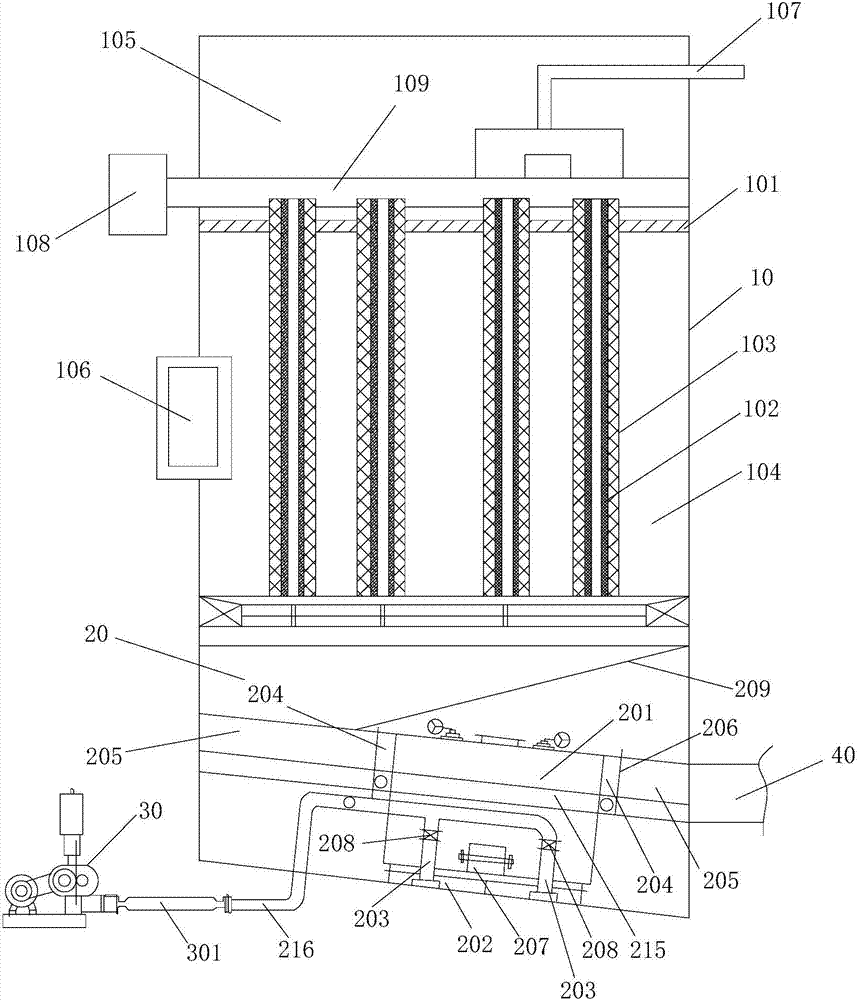

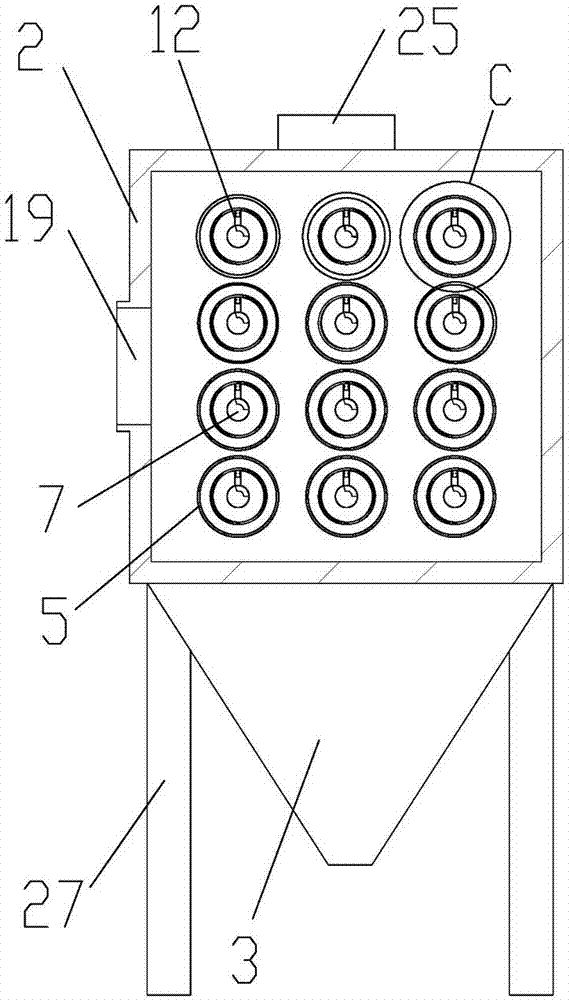

Sintered plate dust collector

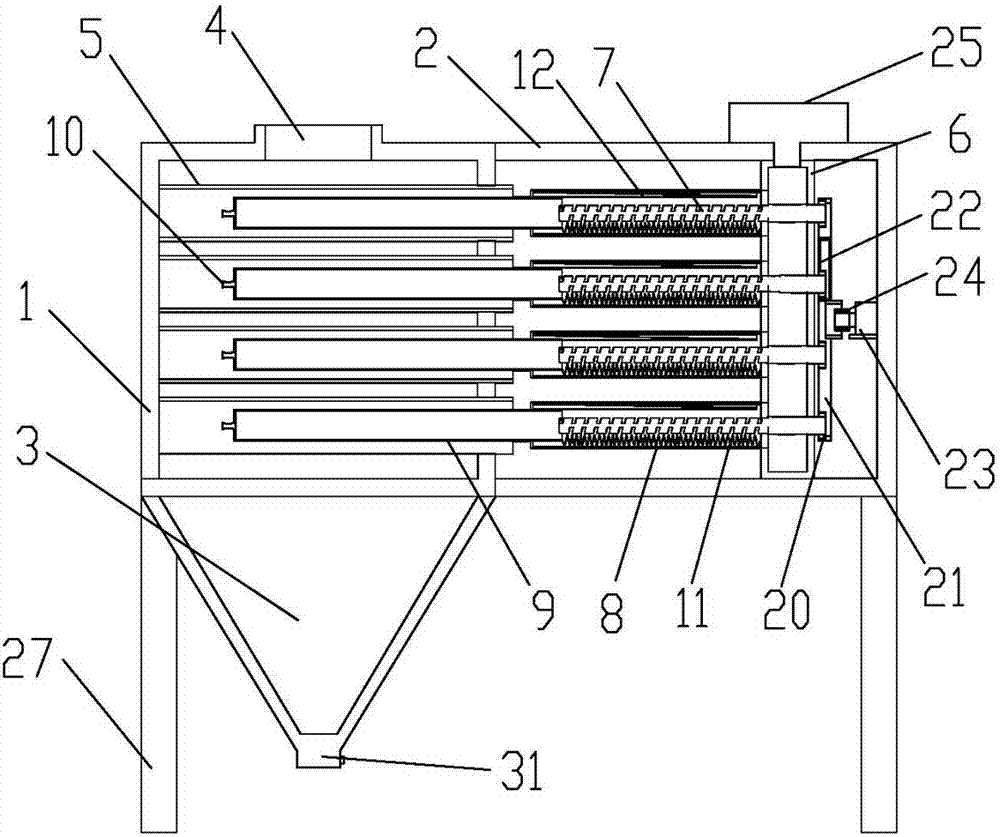

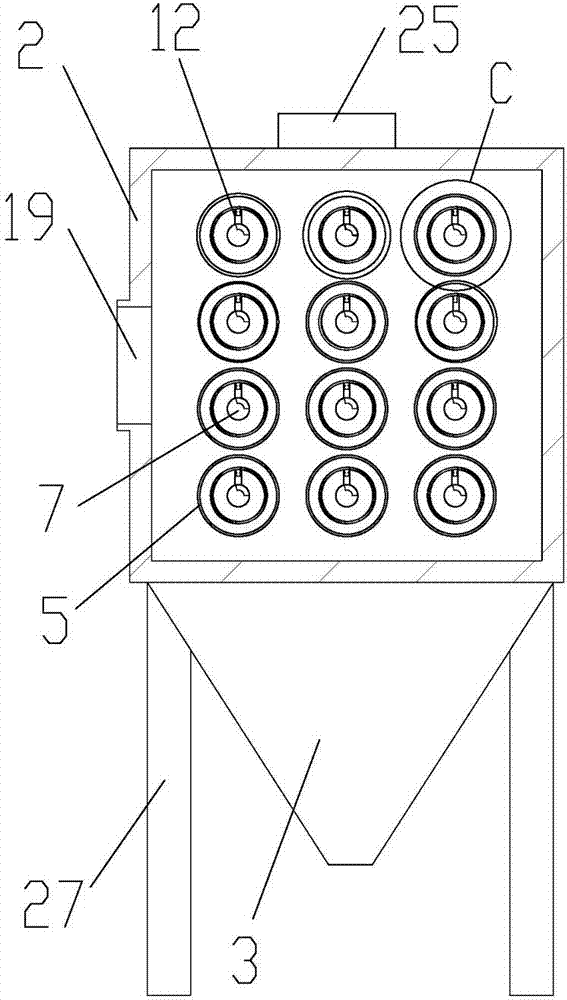

InactiveCN105327562AHigh filtration precisionSolution to short lifeDispersed particle filtrationMembrane filtersMetallurgyProgrammable logic controller

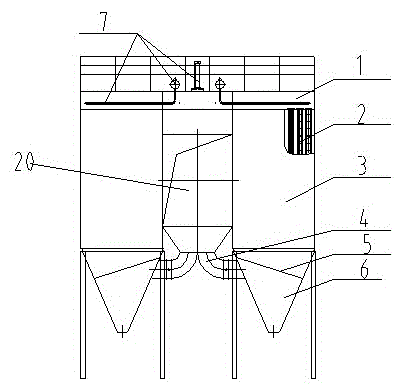

The invention discloses a sintered plate dust collector. The sintered plate dust collector comprises a dust collector box, wherein the dust collector box comprises a cleaning chamber and a filtering chamber which are separated by a porous plate, the cleaning chamber is located above the filtering chamber, multiple sintered plate filter elements are suspended and mounted on the porous plate, a gas outlet for clean gas is formed in the side wall of the cleaning chamber, and a gas inlet for dusty gas introduction is formed in the side wall of the filtering chamber; the lower part of the filtering chamber is connected with a conical dust hopper, a pneumatic hammer is mounted on the side wall of the dust hopper, and a dust outlet is formed in the bottom of the dust hopper; a thickness sensor is mounted on the outer surface of each sintered plate filter element and is in wired or wireless connection with an PLC (programmable logic controller); a pulse-jet dust cleaning device is mounted on the side wall of the cleaning chamber. The sintered plate dust collector is simple in structure, reasonable in design and convenient to operate, the filtering precision of the sintered plate filter elements is high, 0.1 mu m dust can be filtered maximally, and the collection efficiency for the dust larger than 1 mu m is up to 99.99%.

Owner:ZHANGJIAGANG AIER ENVIRONMENTAL PROTECTION ENG CO LTD

High-pollution building space exhaust disinfection and purification system and method

PendingCN111878927AReduce virus contentImprove disinfection effectDucting arrangementsMechanical apparatusVentilation tubeInsulation layer

The invention provides a high-pollution building space exhaust disinfection and purification system and method. The system comprises a pollution region negative pressure metal ventilation pipe, and any position of the pollution region negative pressure metal ventilation pipe is communicated to the inlet end of a high-resistance ventilation pipeline with a heat insulation and insulation layer. Theoutlet end of the high-resistance ventilation pipeline with the heat insulation and insulation layer is connected to the inlet end of an outdoor negative pressure metal ventilation pipe through an electric backflow prevention valve, and the outlet end of the outdoor negative pressure metal ventilation pipe is connected to an extraction opening of an efficient frequency conversion draught fan. A plurality of virus killing devices are sequentially arranged at the rear end of the efficient variable-frequency draught fan. By means of the system and method, air possibly containing viruses in a high-pollution building space is subjected to high-temperature disinfection and sterilization through an electric heating pipeline, then the air subjected to high-temperature disinfection and sterilization is guided to an outdoor multi-virus disinfection and sterilization device through the negative pressure pipeline to conduct diversified thorough disinfection and sterilization on the introduced air,and the viruses in the air in the high-pollution building space can be thoroughly removed.

Owner:CHINA RAILWAY CONSTR GROUP +1

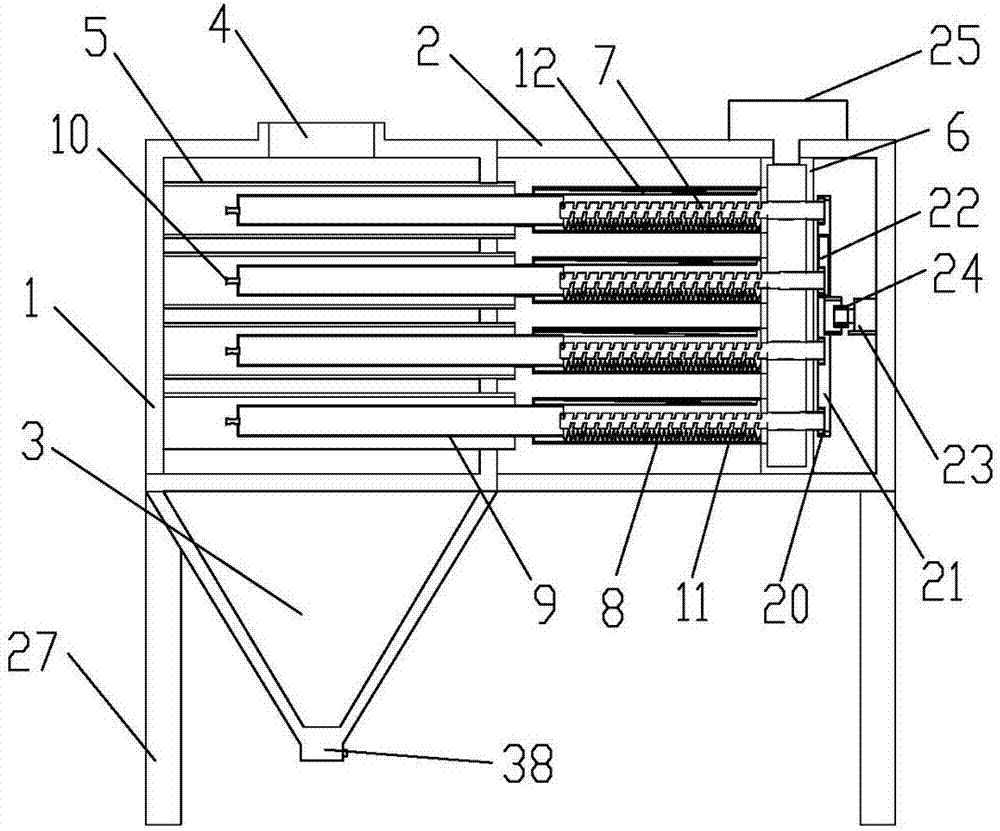

Bag-type dust remover

InactiveCN105080231AHandling large air volumeImprove cleanlinessDispersed particle filtrationBaghouseAir cleaning

A bag-type dust remover consists of an upper box body, a filter bag cage component, a middle box body, a dust hopper air inlet system, an air flow distribution system, a dust hopper, a pulse-jet system, a smoke inlet and outlet passage, an air cylinder, a pulse valve, an atmolysis pocket, a compressed air inlet, an injection pipe, a nozzle, an air cleaning chamber, an off-line valve plate, a tube nest, a filter bag chamber, an air inlet and an air outlet; the bag-type dust remover combines the advantages of sectional reverse-blow and off-line pulse-jet dust cleaning, and is a unit combined dust removing device which is high in treated wind capacity, good in dust removing effect, high in dust removing efficiency, stable in running, convenient to repair, and less in occupied area.

Owner:ANHUI GUONENG YISHENG ENVIRONMENTAL PROTECTION SCI & TECH

Dish type gas decontamination device

ActiveCN105854461ANo accumulation of fouling occursGuaranteed decontamination effectUsing liquid separation agentAir volumeGas phase

The invention relates to a dish type gas decontamination device which comprises a rotating motor. The rotating motor is connected with a rotating shaft, two ends of the rotating shaft are respectively connected with a dish type housing, a gas phase inlet and a gas outlet are formed in two ends of the dish type housing respectively, a liquid distributor is arranged on the shaft wall of the rotating shaft, the tail end of the rotating shaft is connected with a rotating connector, a liquid outlet is formed in the lower end of the dish type housing, the rotating connector is connected with a liquid inlet, and ratable blades and splitter blades are arranged on the rotating shaft. The dish type gas decontamination device can be used for treating dust-containing poisonous and harmful gas, provides a technical guarantee for hazardous chemical leakage and other accidents, aims at dust-containing harmful gas and does not produce dust accumulation or scaling while ensuring a decontamination effect. In addition, the device is simple in structure, strong in stability and large in treating air volume.

Owner:CHINA PETROLEUM & CHEM CORP +1

Cyclone dust removal device with double conical cylinders

ActiveCN106238231AIncrease centrifugal forceSmooth descentReversed direction vortexCycloneEngineering

A cyclone dust removal device with double conical cylinders comprises a cyclone dust remover, a rotary bearing, the movable conical cylinder and the like. A draught fan feeds dusty gas into an air channel box, the dusty gas enters the cyclone dust remover through an air inlet of the cyclone dust remover and forms an outer cyclone flow, when the dusty gas rotates to the movable conical cylinder, dust grains penetrate through thin and long through grooves of the movable conical cylinder through centrifugal force, enter an interlayer formed by the two conical cylinders, descend along the inner wall of the fixed conical cylinder and is collected in a dust hopper, dustless gas spirally ascends (internal rotary flow) along the axis of the conical cylinders and flows out of an air outlet, and gas and the dust grains are separated. The dust grains enter the interlayer, the rebounding dust grains colliding with the fixed conical cylinder are blocked by the rotating movable conical cylinder, the dust grains are prevented from returning a cyclone field, and thus fine dust grains, especially dust grains of PM2.5 or above harmful to the body health are efficiently captured at a low air speed. The device has the advantages of being simple, easy to manufacture, convenient to maintain, low in working noise and the like, and is suitable for families, shopping malls, offices and occasions where clean gas or gas and dust separation is needed in industrial production and the like.

Owner:CHANGSHA UNIVERSITY

Viscose fiber production process exhaust gas treatment method

ActiveCN105597527ARealize local/remote controlRealize interlock controlGas treatmentDispersed particle separationCatalytic oxidationTextile industry

The present invention relates to a viscose fiber production process exhaust gas treatment method, and belongs to the technical field of textile industry exhaust gas treatment. Viscose fiber production process exhaust gas is washed with a first-stage alkali spray tower, then enters a low-temperature plasma apparatus for treatment, then enters a catalytic oxidation treatment bed for exhaust gas catalytic oxidation treatment, and finally is introduced by a glass fiber reinforced plastic centrifugal fan into a second-stage alkali spray tower for absorption of residual small molecules in the exhaust gas. Through the above process, carbon disulfide and hydrogen sulfide exhaust gases can be decomposed into CO2, H2O, N2 and other harmless substances, and are discharged up to standards.

Owner:YIBIN HIEST FIBER

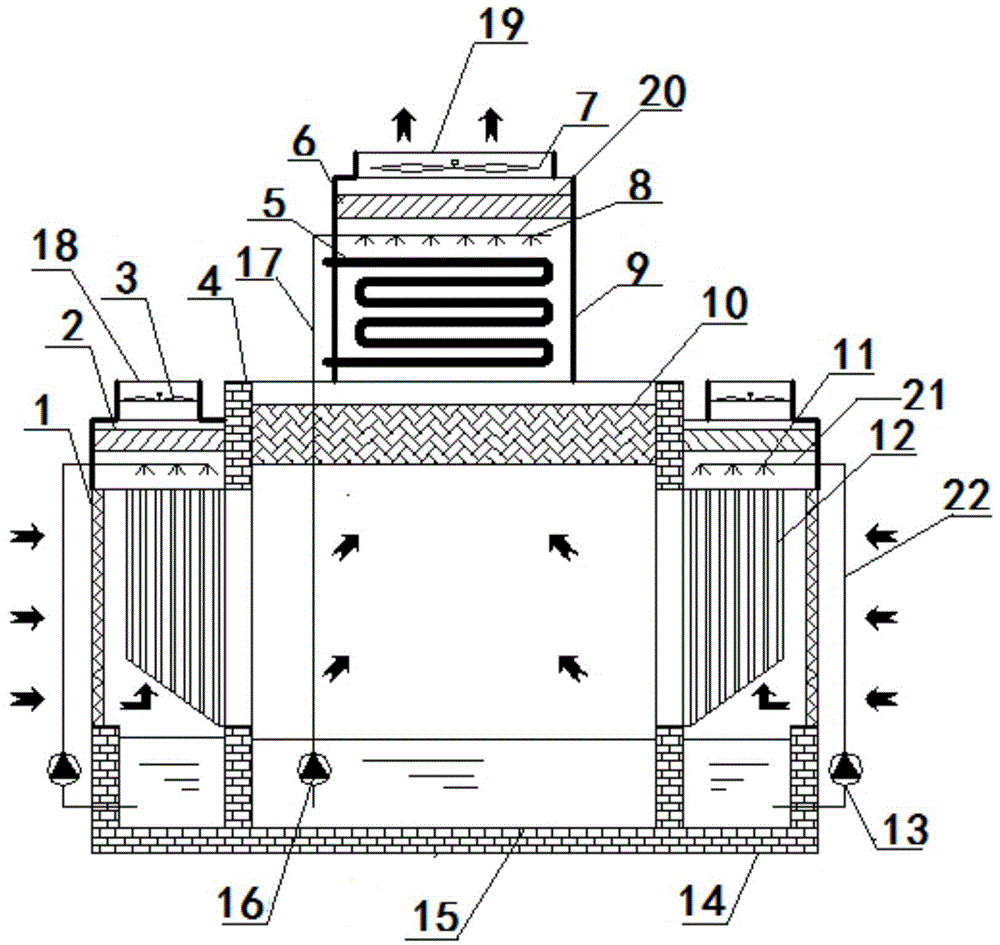

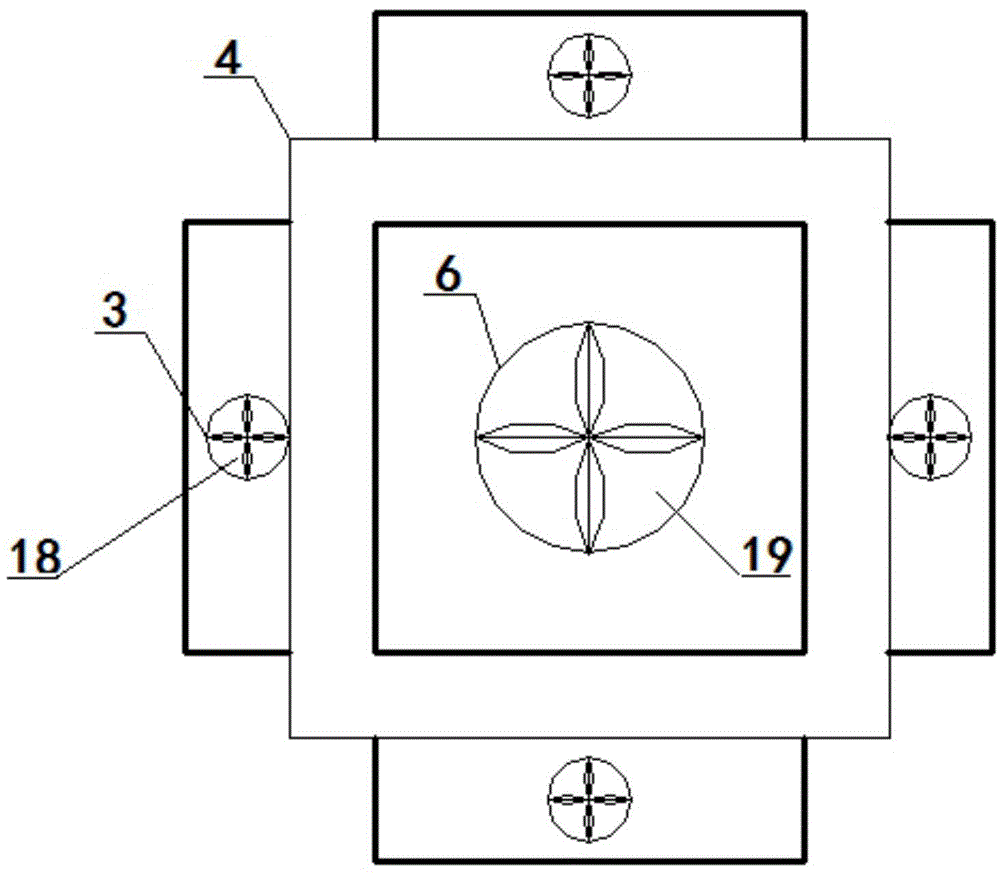

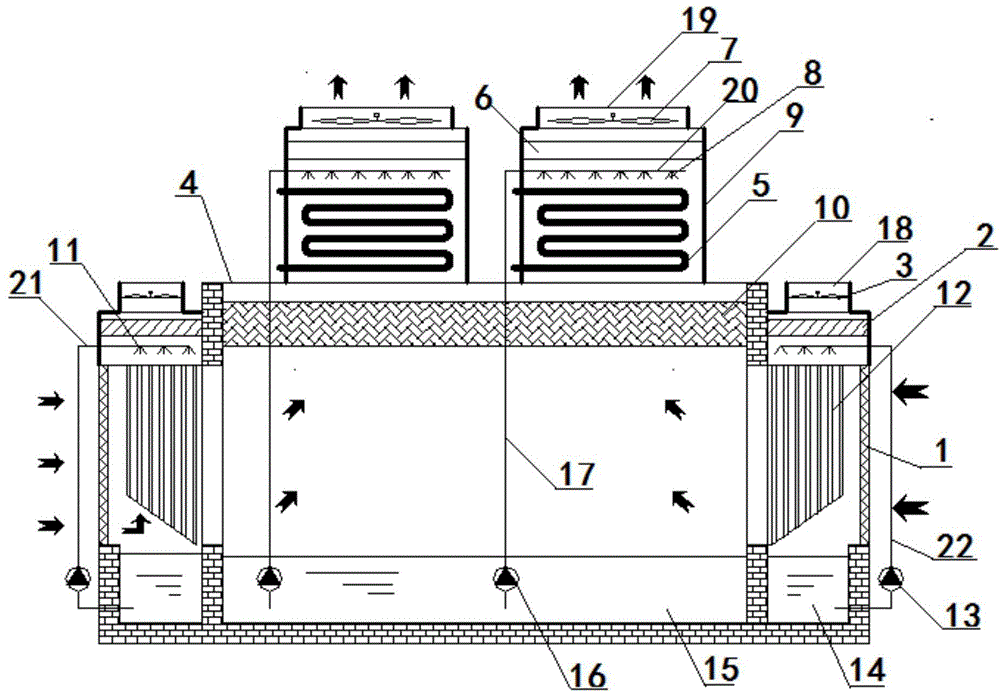

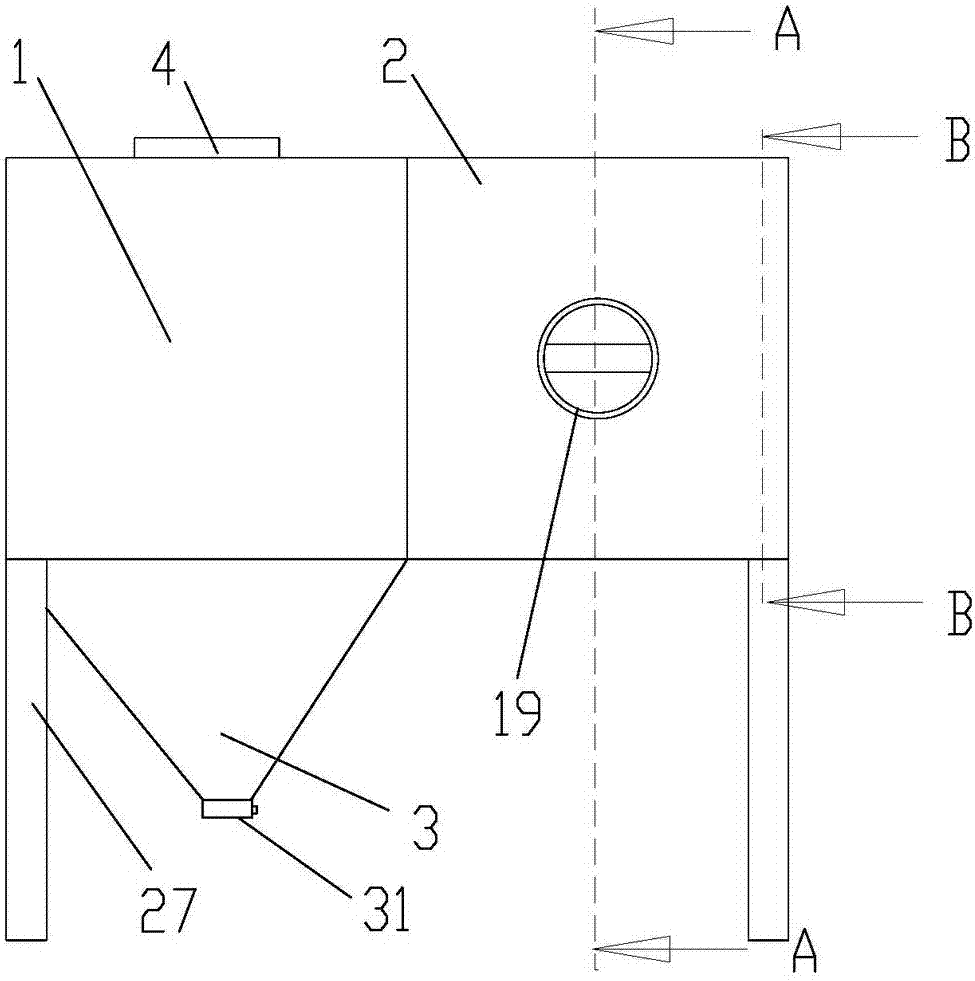

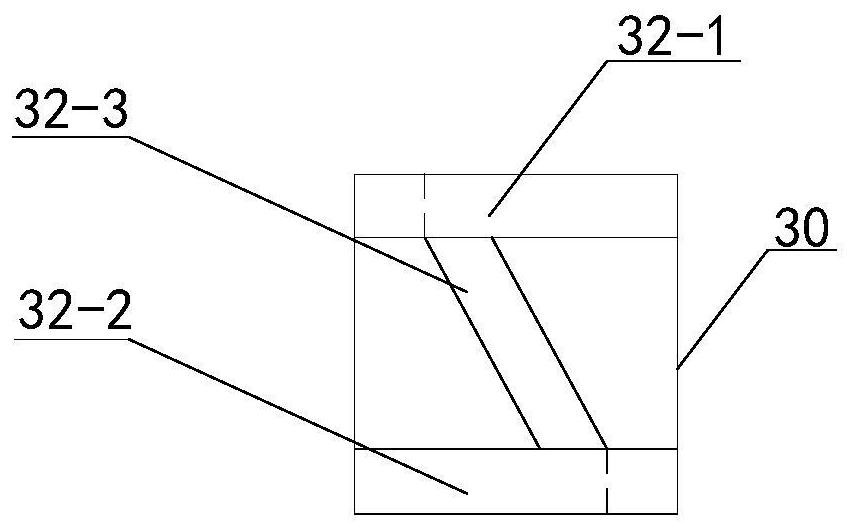

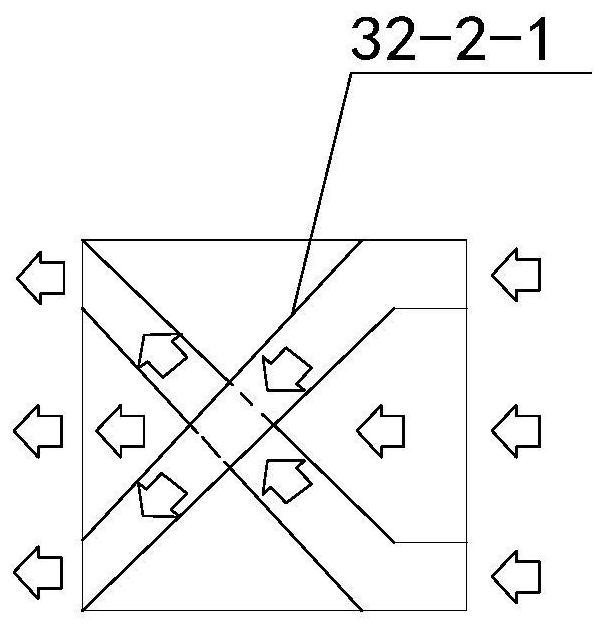

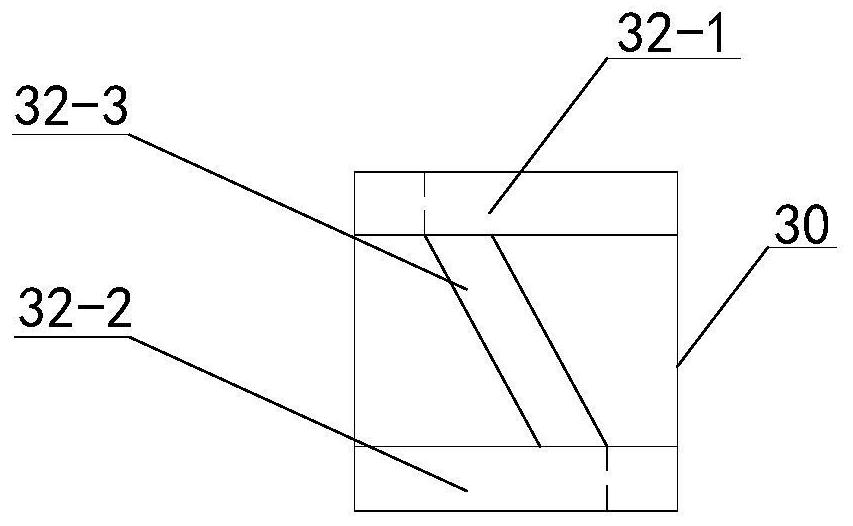

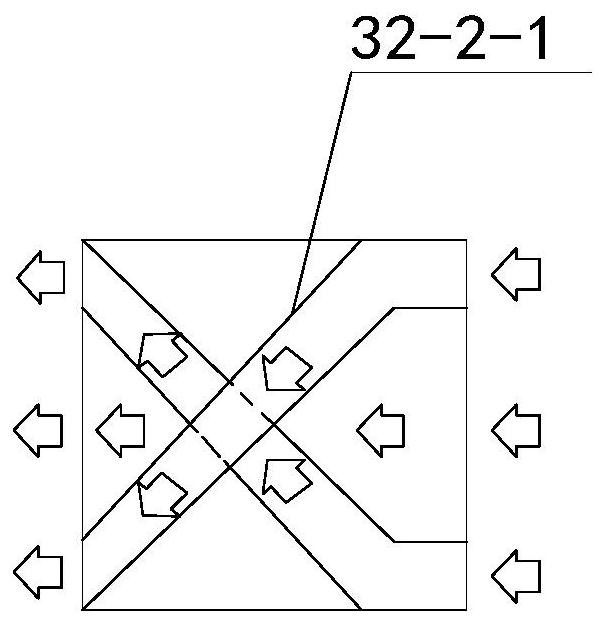

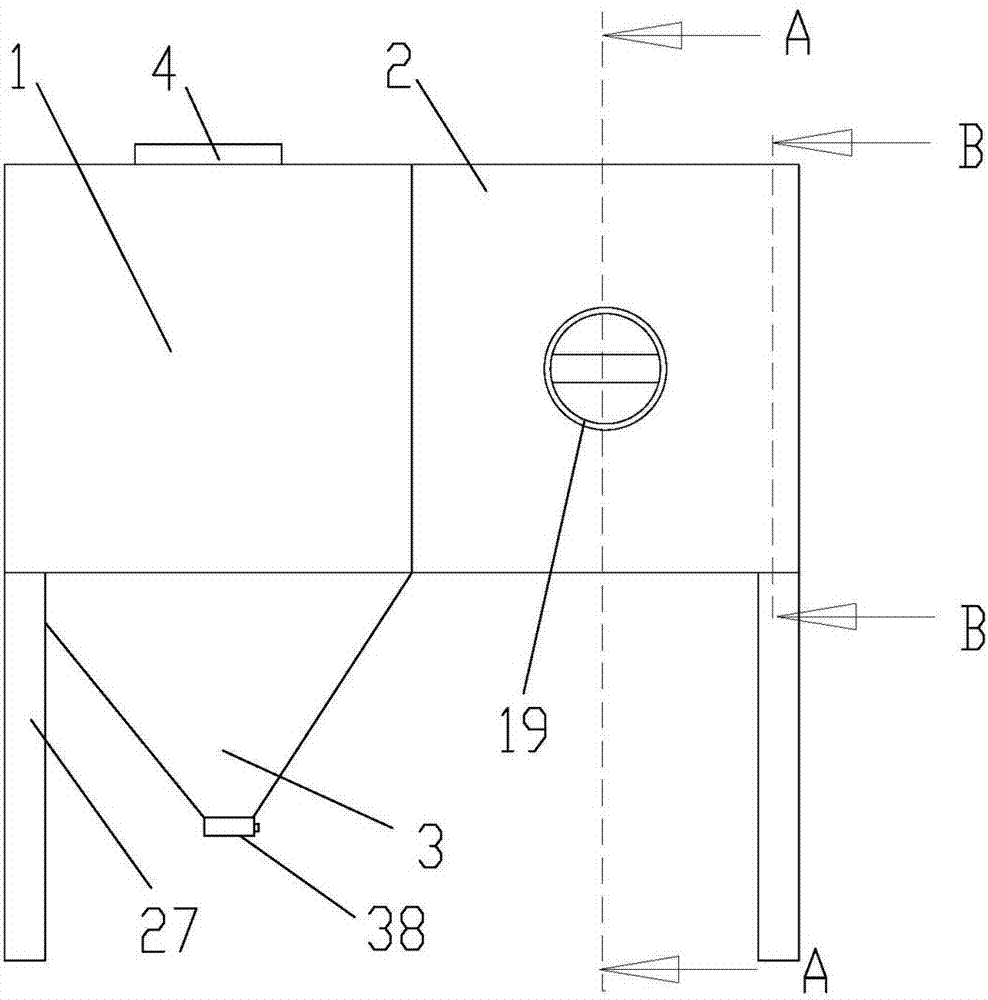

Civil engineering structure and evaporative cooling combined closed evaporative cooling cold water system

InactiveCN104697087AReduce manufacturing costUniform secondary air volumeLighting and heating apparatusSpace heating and ventilation detailsEvaporative coolerAir velocity

The invention discloses a civil engineering structure and evaporative cooling combined closed evaporative cooling cold water system which comprises a civil engineering shell formed by the utilization of a civil engineering structure in a surrounding manner, wherein a closed heat exchange module is arranged at the upper part of the civil engineering shell; a filling type cooling unit is arranged in the civil engineering shell and is connected with the closed heat exchange module; a stand pipe type indirect evaporative cooler is arranged on the periphery of the filling type cooling unit. According to the closed evaporative cooling cold water system disclosed by the invention, as the lower part of a vertical heat exchange tube group is obliquely arranged, the resistance of secondary air is reduced, so that the air pressure of a fan is reduced; with the adoption of a way of air intake from all the directions, more air quantity can be treated, so that the treatment quantity of high-temperature cold water is increased; due to the increase of the area of an air inlet, the windward air velocity of intake air is reduced, the cooling effect on primary air is enhanced, and the efficiency of the stand pipe type indirect evaporative cooler is improved; in addition, the whole system utilizes clean energy dry air energy, so that the system is an energy-saving and environment-friendly cooling system.

Owner:XI'AN POLYTECHNIC UNIVERSITY

Automatic blowback dedusting dust processor

ActiveCN107308748AEasy to cleanExtend working lifeDispersed particle filtrationTransportation and packagingWorking lifeSpray nozzle

An automatic blowback dedusting dust processor effectively solves a problem that existing blowback devices cannot clean up dusts on a filter cylinder. The dust processor includes a dedusting box, the upper end surface of the dedusting box is provided with a wind inlet, a working box is fixedly mounted at the right end of the dedusting box, the side surface of the working box is provided with a wind outlet, a plurality of filter cylinders are uniformly arranged in the dedusting box, one ends of the filter cylinders are fixed on the left side inner wall of the dedusting box, a ventilating box is fixedly mounted in the working box, a plurality of rotating shafts are mounted in the ventilating box in a rotating manner, the left side surface of the ventilating box is fixedly provided with a plurality of large diameter cylinders sleeving outside the rotating shafts and communicating with the internal of the ventilating box, small diameter cylinders sleeving outside the rotating shafts are inserted into the large diameter cylinders, and the left end surfaces of the small diameter cylinders are provided with nozzles. A telescopic blowback device adopted by the dust processor can go deep into the filter cylinders when dusts accumulated on the filter cylinders are too much in order to thoroughly blow away the dusts adsorbed on the filter cylinders, so the working efficiency of the dust processor is greatly increased, the treatment wind capacity is large, the dust processor can safely and reliably run, and the working life of the filter cylinders is greatly prolonged.

Owner:XINXIANG XINYUAN CORROSION INSULATION PROD CO LTD

High voltage electrostatic lampblack purifier

InactiveCN108386885AHandling large air volumeImprove purification efficiencyCombination devicesDomestic stoves or rangesDrive motorLight pipe

The invention discloses a high voltage electrostatic lampblack purifier. The high voltage electrostatic lampblack purifier comprises a purifier shell which is in a rectangular shape; an air inlet is formed in the front end of the purifier shell, and is internally provided with an air sucking device; the portion, located behind a fan driving motor, in the purifier shell is provided with an ultraviolet sterilization device; the portion, located behind a lamp tube support, in the purifier shell is provided with a high voltage electrostatic device; the portion, located behind a charge framework, in the purifier shell is provided with an oil dirt adsorbing device; the portion, located behind an adsorbing framework, in the purifier shell is provided with a silencing plate; the rear end of the purifier shell is provided with an air outlet; a rear filtering device is arranged in the air outlet; a maintaining plate is arranged on one side of the purifier shell; and a power source box is arranged on the other side of the purifier shell, and is electrically connected with the air sucking device, the ultraviolet sterilization device, the high voltage electrostatic device and the oil dirt adsorbing device. The high voltage electrostatic lampblack purifier has the beneficial effects of being simple in structure and high in practicability.

Owner:李博文

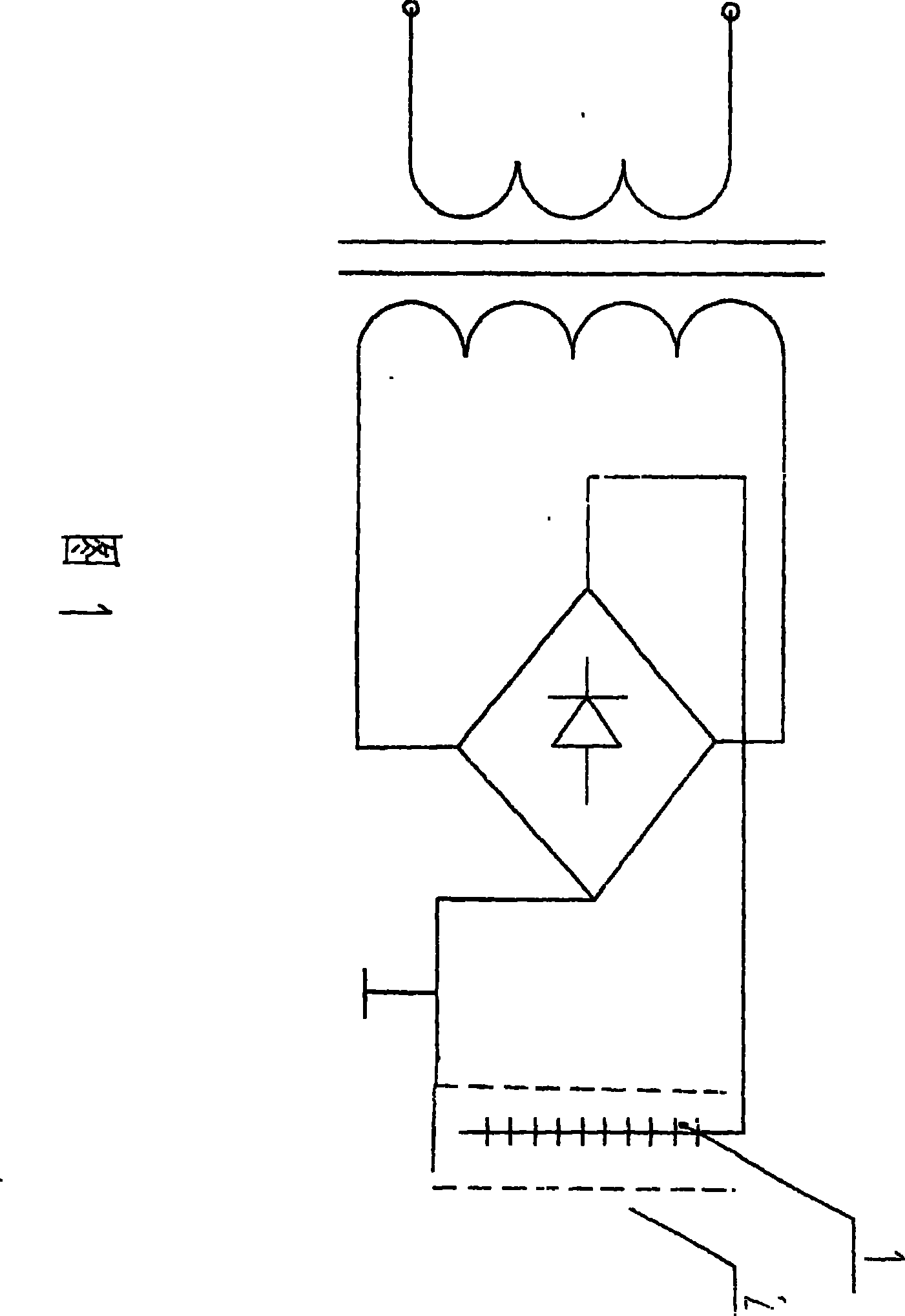

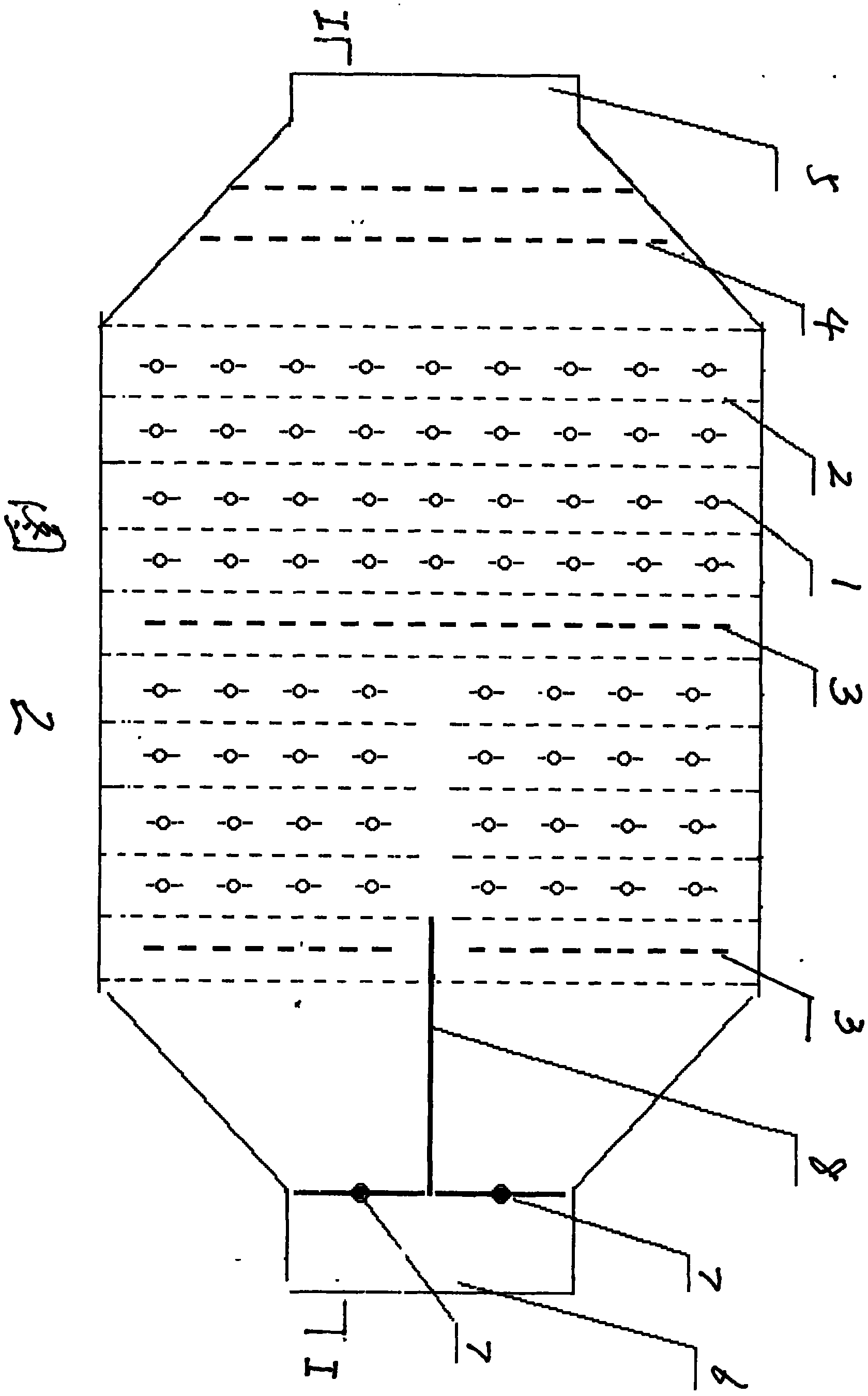

Electric dust collector with ultra- low concentration discharge

InactiveCN101130180BSimple structureLower internal resistanceExternal electric electrostatic seperatorElectrode constructionsElectricityCorona discharge

The invention discloses a hyperlow density discharge electric dedusting device of industrial smoke, which comprises the following parts: box body, intake box and ventilating box at two ends of box, ash bucket at lower part of the box, permeability dust collection block and corona discharge wire in the box body, absorbent electric field with multiple transverse dust collection grids in perpendicular to flow moving direction with equal distance and paralleling alternatively, deashing beating device on the corona discharge wire and dust collection board separately, wherein the dust collection board has multiple ventilation holes; one or more block grid net is set in each block grid of absorbent electric field with damper to seal air-out end at air-out position. The invention eliminates sub-micron graded smoke particle effectively to avoid secondary dust to reduce bulk and cost.

Owner:SHENYANG LONGDA ENVIRONMENTAL PROTECTION

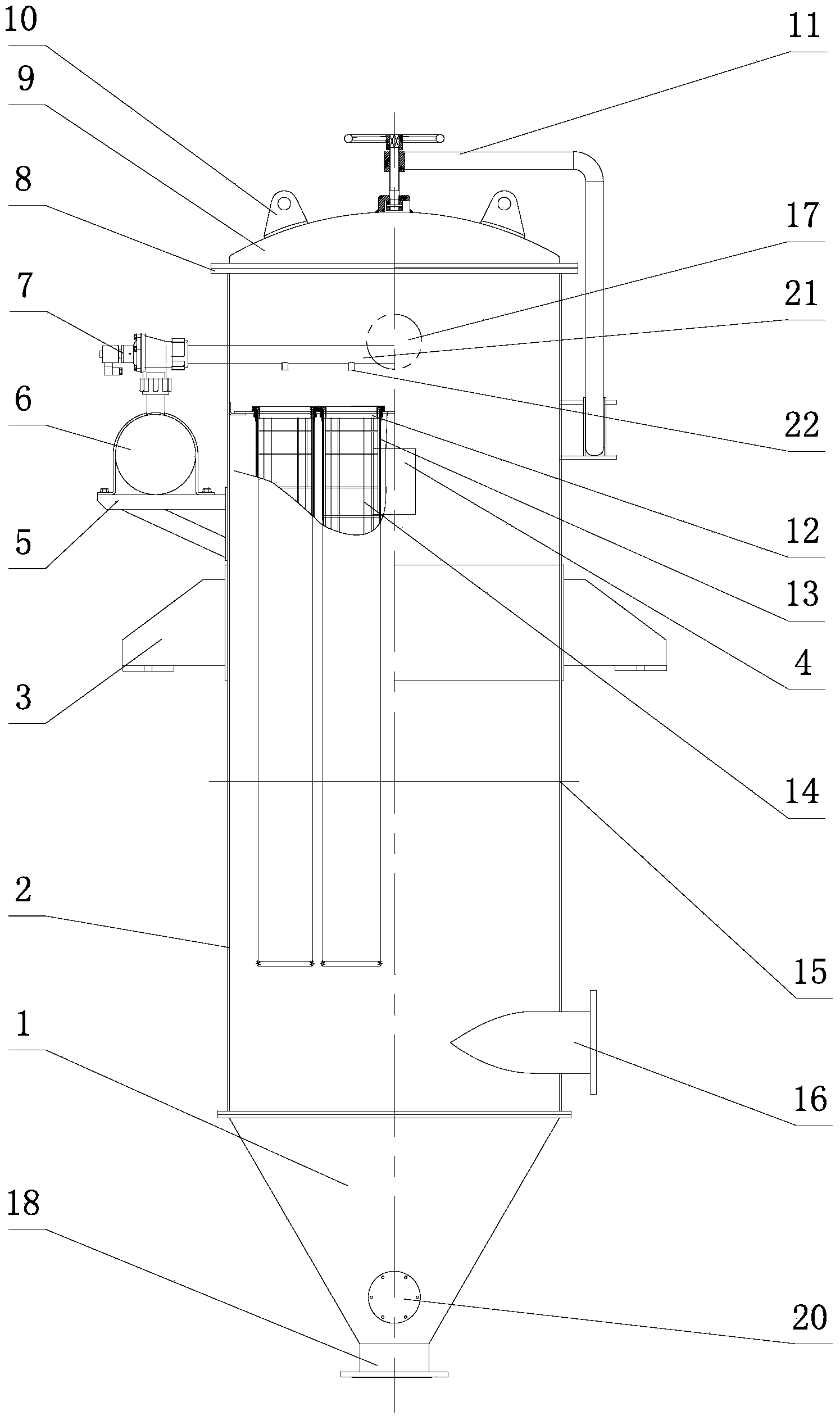

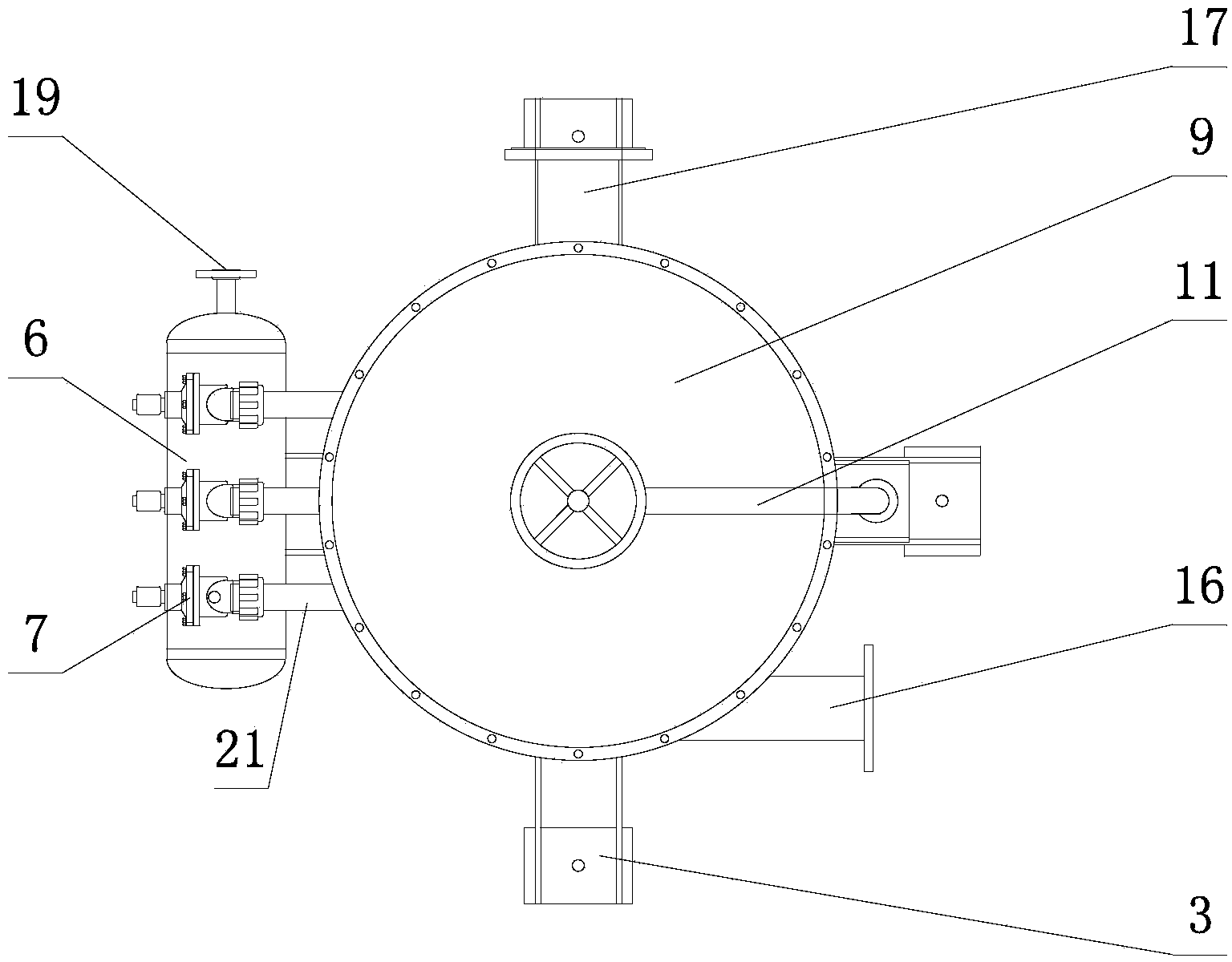

Dust collection filter

InactiveCN104368196ASolution to short lifeSimple structureDispersed particle filtrationElectricityDifferential pressure

The invention discloses a dust collection filter. The dust collection filter comprises a barrel body, wherein a spherical-crown-shaped end socket is arranged above the barrel body; an dust bucket is connected below the barrel body; a dust outlet is formed in the bottom of the dust bucket; a pure gas outlet is formed in the upper part of the outer wall of the barrel body; a dust inlet is formed in the lower part of the outer wall of the barrel body; the barrel body is internally provided with a pattern board; the pattern board is used for dividing the inner cavity of the barrel body into a cleaning chamber and a filtering chamber which are distributed up and down; each of the cleaning chamber and the filtering chamber is provided with a micro-differential pressure sensor; the pattern board is provided with a cage keel in a suspension manner and the cage keel is sleeved by a filtering bag; the outer wall of the barrel body is provided with a pulse dust cleaning device and a control cabinet; and the micro-differential pressure sensors are electrically connected with the control cabinet. The dust collection filter has the advantages of simple structure, reasonable design, good dust cleaning effect, high purification efficiency, great air treatment quantity, long service life of the filtering bag, small working amount for maintenance, and safety and reliability in operation.

Owner:ZHANGJIAGANG AIER ENVIRONMENTAL PROTECTION ENG CO LTD

Compartment stepping washing self-deashing bag-type dust remover and dust removing method

InactiveCN103055617ASimple structureHandling large air volumeDispersed particle filtrationGate valveBag filter

A compartment stepping washing self-deashing bag-type dust remover and a dust removing method belong to the field of environmental protection technology. The dust remover of the invention can not only clear the dust layer on the bag wall surface of a filter bag, but also prevent the dust remover wind amount increase formed during a deashing airflow secondary filter process. The dust remover includes an upper tank body, wherein compartment dividing boards are arranged inside the upper tank body, an air inlet header is arranged at the side portion of the upper tank body, an air inlet window is arranged between the air inlet header and each compartment, and the air inlet window is provided with a gate valve which is connected to a solenoid; a middle tank body arranged under the upper tank body, wherein an upper porous board, a lower porous board and filter bags are arranged inside the middle tank body; and an air outlet header is arranged at the side portion of the middle tank body. The dust removing method of the present invention is as follows: opening a gate valve, so that dust-containing air clears the dust layer on the filter bag, and the other filter bags filter the dust-containing air; and then opening the next gate valve, and closing the other gate valve to form an orderly cycle of filter bag clearing and filtering.

Owner:NORTHEASTERN UNIV

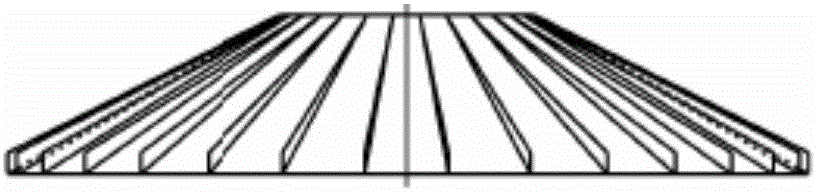

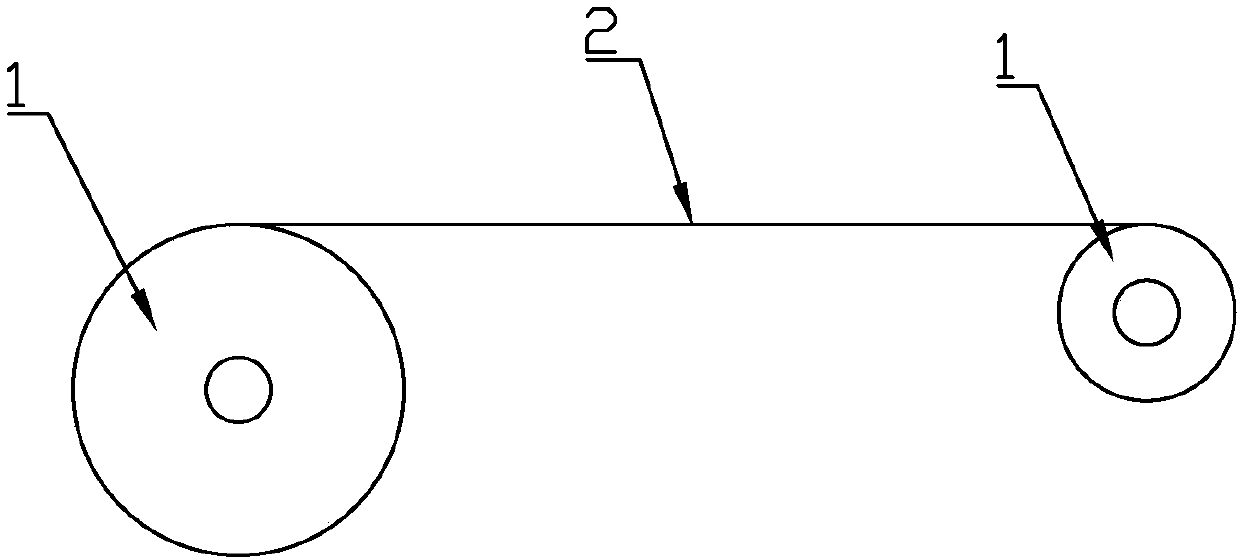

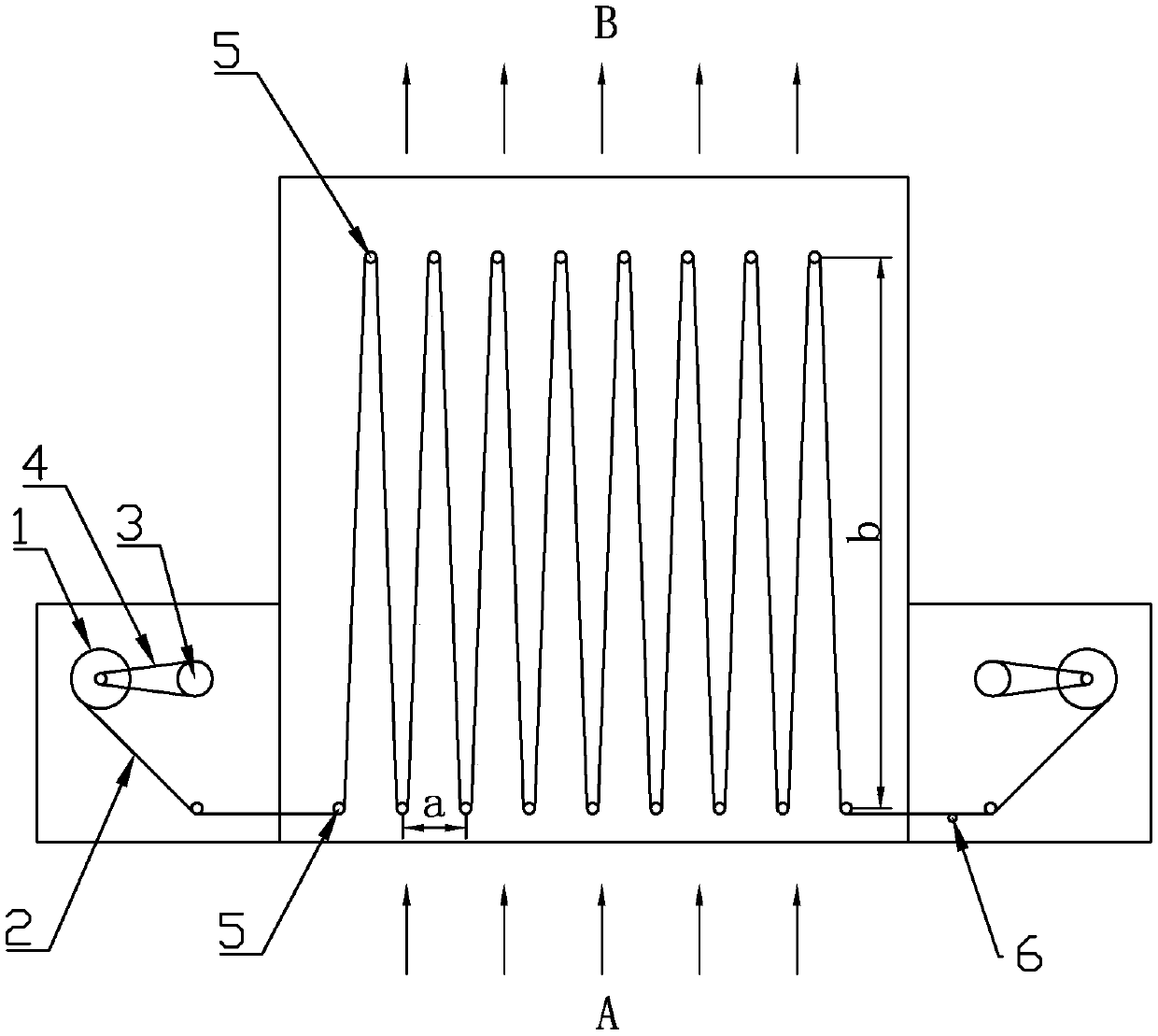

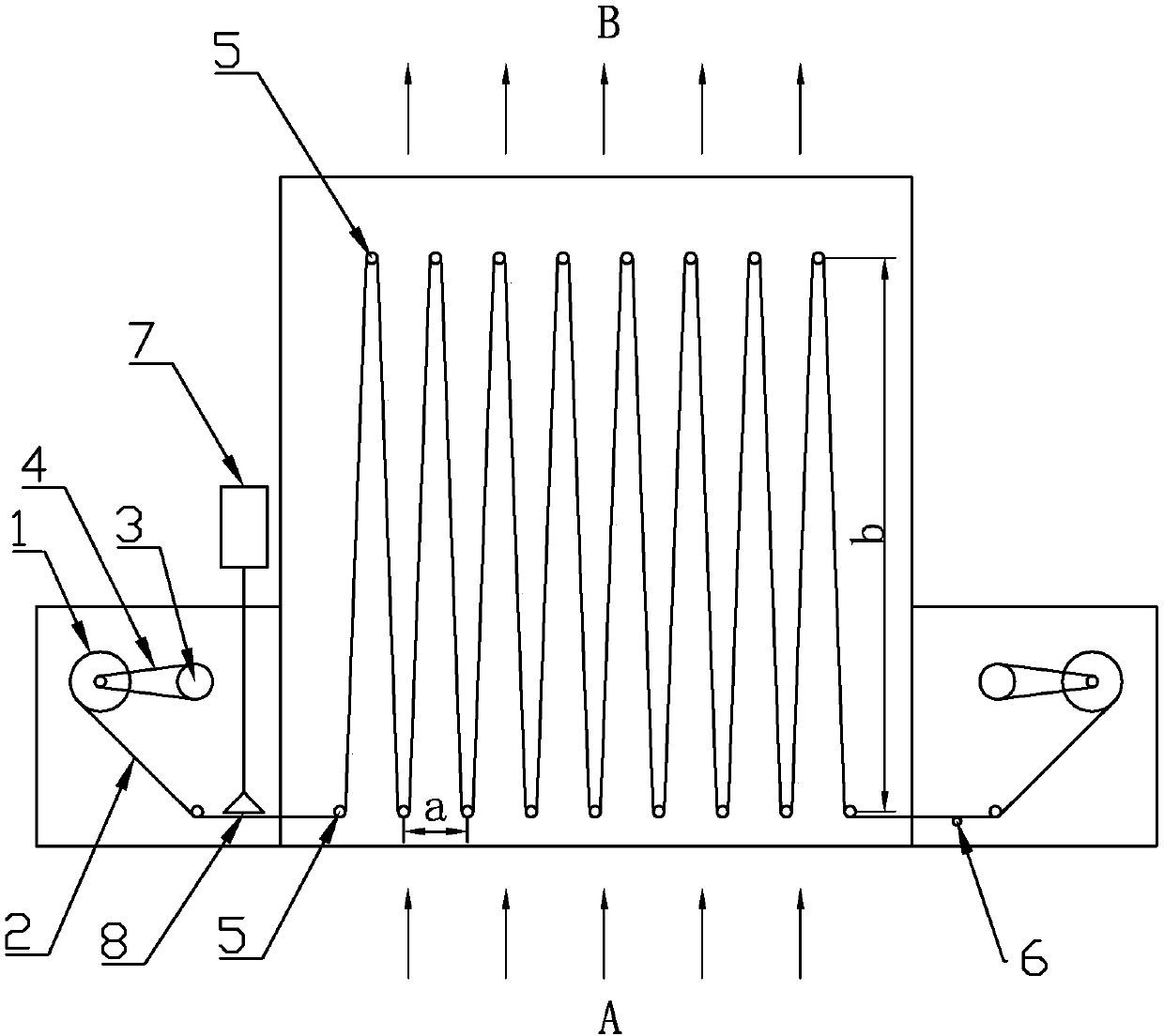

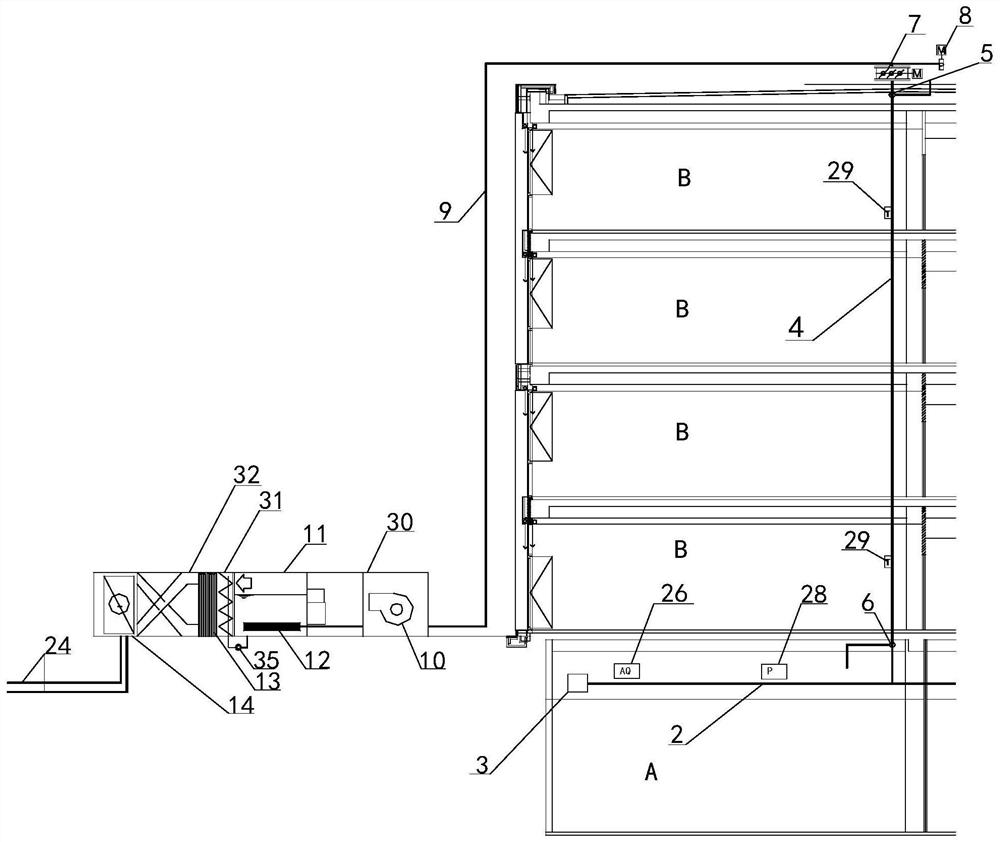

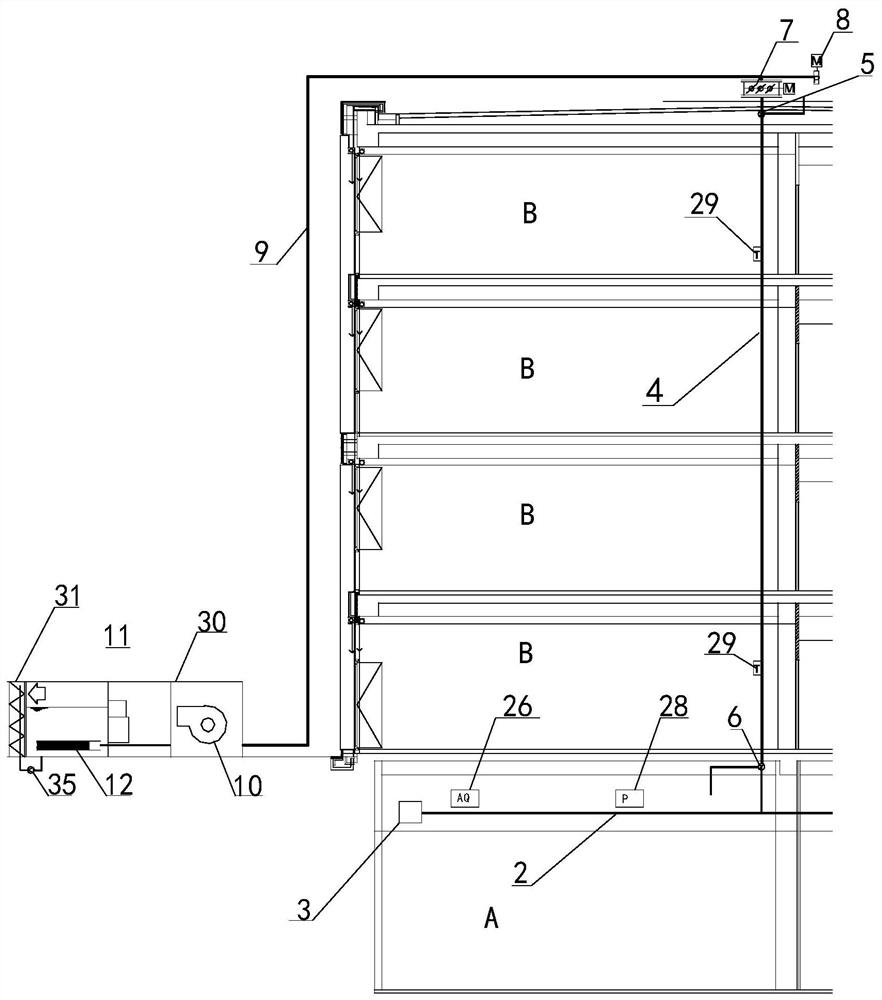

Low-resistance and low-maintenance ventilation purification device and overlapped structure thereof

PendingCN107684783AIncrease the effective filter areaHandling large air volumeGas treatmentDispersed particle filtrationFiltrationBiochemical engineering

The invention provides a low-resistance and low-maintenance ventilation purification device. The low-resistance and low-maintenance ventilation purification device comprises two filter material coilswhich are oppositely arranged, wherein the two filter material coils are respectively driven by a motor, and a filter material is wound between the two filter material coils. The low-resistance and low-maintenance ventilation purification device disclosed by the invention is further provided with two rows of interval limit shafts, one row of the limit shafts are close to the air inlet side, the other row of the limit shafts are close to the air outlet side, and the filter material is sequentially and repeatedly wound among the two rows of the limiting shafts to form a Z-shaped winding path. The low-resistance and low-maintenance ventilation purification device disclosed by the invention can increase an effective filtration area of the filter material; thus, treated air volume is improved,and device resistance is reduced.

Owner:CHINA ACAD OF BUILDING RES +1

Combined type cloth bag dust remover

InactiveCN104353302ASolution to short lifeEasy maintenanceCombination devicesDispersed particle filtrationKeelBaghouse

The invention discloses a combined type cloth bag dust remover which comprises a plurality of cloth bag dust remover units, wherein each cloth bag dust remover unit comprises a barrel body; an overhaul platform is mounted at the top end of each barrel body; the bottom of each barrel body is connected with an ash bucket; pattern plates are arranged in the barrel bodies and divide the inner cavities of the barrel bodies into clean chambers and filtering chambers, which are distributed up and down; the clean chambers are communicated with purified air outlets; the pattern plates are provided with cage keels in a hanging manner; filtering bags sleeve the cage keels; pulse ash cleaning devices are mounted on the outer walls of the barrel bodies. The combined type cloth bag dust remover is simple in structure, and the cloth bag dust remover units can be combined according to a production requirement, so that the type selection is convenient; once one of the cloth bag dust remover units is faulted and needs to be maintained, the unit only needs to be stopped, and other units continuously work; therefore, influence on the production is avoided, and the faulted unit is convenient to maintain.

Owner:ZHANGJIAGANG AIER ENVIRONMENTAL PROTECTION ENG CO LTD

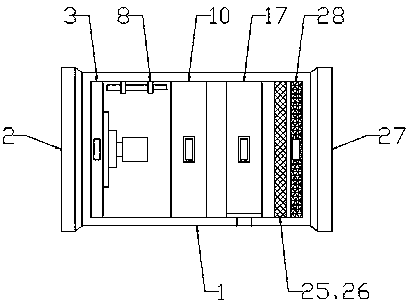

Efficient filter cartridge dust collector

InactiveCN104383767ASolution to short lifeSimple structureCombination devicesDispersed particle filtrationDifferential pressureEngineering

The invention discloses an efficient filter cartridge dust collector. The efficient filter cartridge dust collector comprises a dust collecting box body, wherein a gas inlet is formed in the side wall of the dust collecting box body; the upper surface of the dust collecting box body is provided with a gas outlet; the dust collecting box body is internally provided with a partition plate which separates the inner part of the dust collecting box body into a filtering chamber and a cleaning chamber; the filtering chamber is internally provided with horizontally installed filter cartridges; the cleaning chamber is communicated with a gas outlet; parts, corresponds to the filter cartridges, of the outer wall of the cleaning chamber are provided with pulse dust cleaning devices; a dust bucket is connected to the lower part of the dust collecting box body; the bottom of the dust bucket is provided with a dust discharge valve; the filter cartridges and the cleaning chamber are all provided with micro differential pressure controller connectors. The efficient filter cartridge dust collector is simple in structure, is reasonable in design, and has the advantages of good dust collecting effect, high purifying efficiency, high treatment air rate, low maintenance work load and safety and reliability in running, and the service life of the filter cartridges is long.

Owner:ZHANGJIAGANG AIER ENVIRONMENTAL PROTECTION ENG CO LTD

Plasma catalysis air purification device

InactiveCN104162360AHandling large air volumeSmall air resistanceDispersed particle separationPollutantCarbon dioxide

The invention discloses a plasma catalysis air purification device which comprises a first electrode and a second electrode used for generating plasma, wherein an insulating medium and a catalyst bed layer are arranged between the first electrode and the second electrode; relative motion is generated between the first electrode and the second electrode. With the adoption of the relative motion generated between the first electrode and the second electrode, a plasma discharge area is driven to sequentially act on the whole catalyst bed layer, organic pollutants stored on the catalyst are completely oxidized into carbon dioxide and water through plasma active species, the device is high in treated air quantity, low in power consumption and low in air resistance, and the air purification effect is greatly improved. The plasma discharge area is driven to move through the relative motion of the electrodes, and the whole catalysts are sequentially treated. Therefore, the power consumption is obviously reduced, the problem of high plasma power consumption in the process of simultaneously treating the whole catalyst bed layer is solved, and the relative motion of the electrodes has the advantages of discharge stability, uniformity and high efficiency.

Owner:SHENZHEN PUREMATE TECH +1

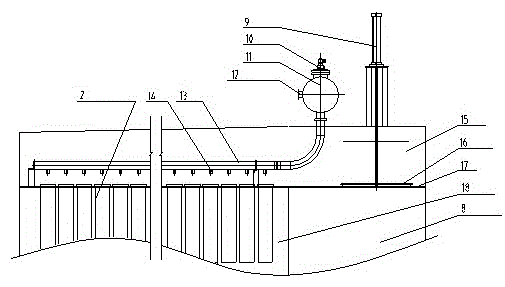

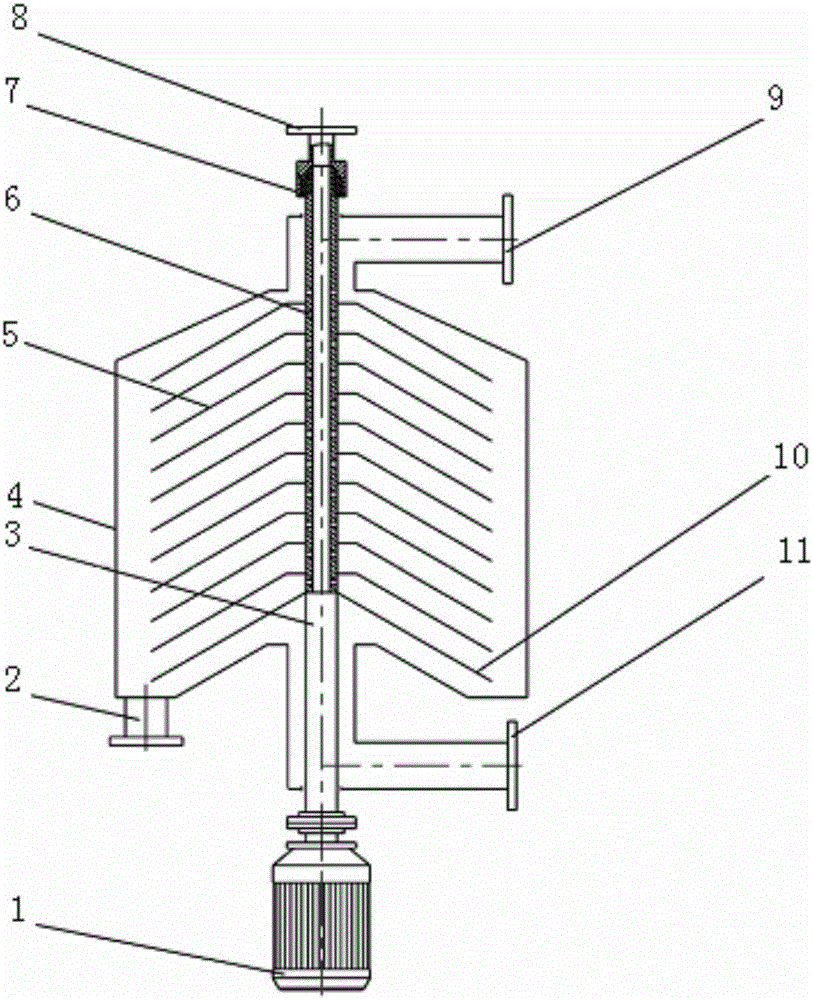

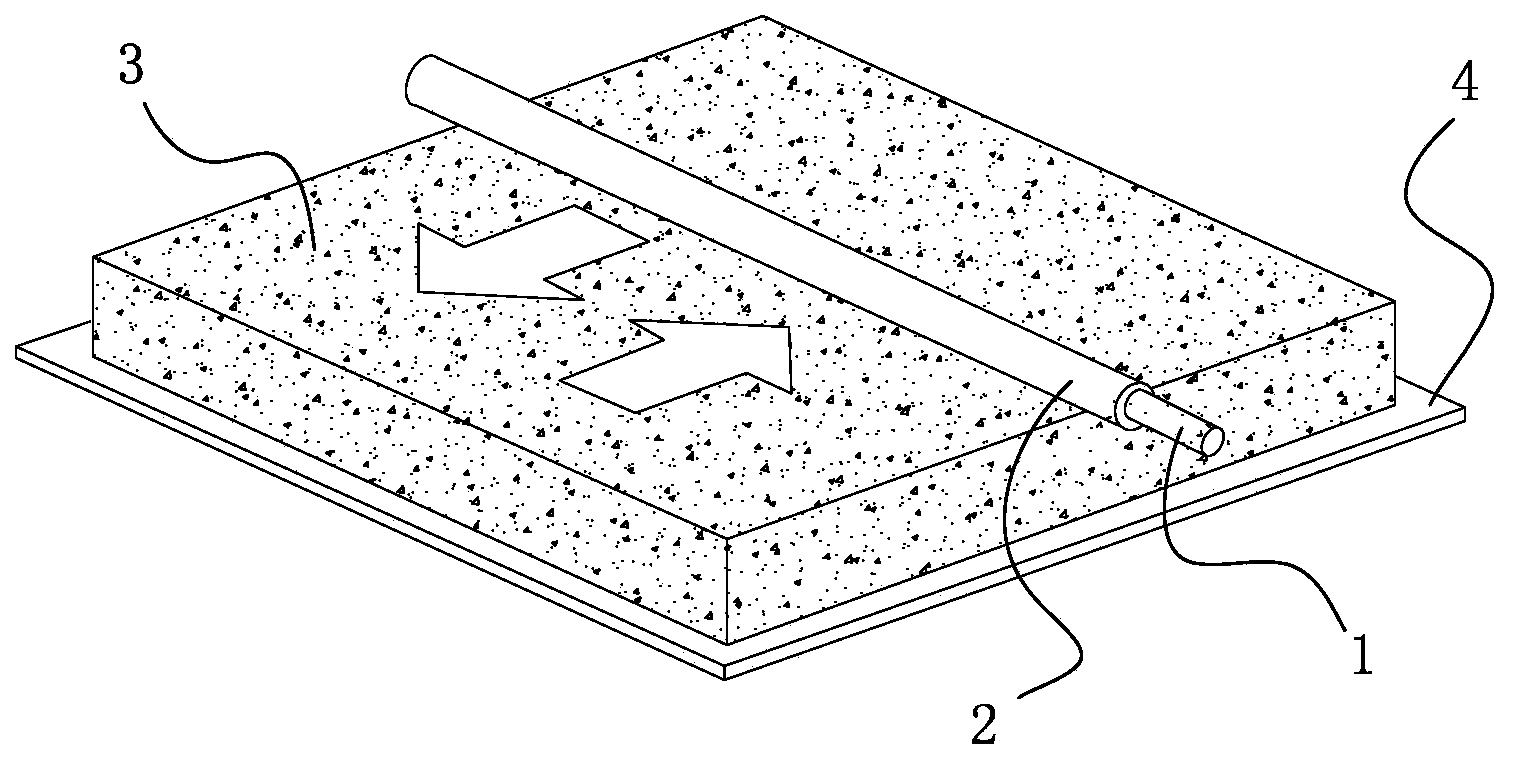

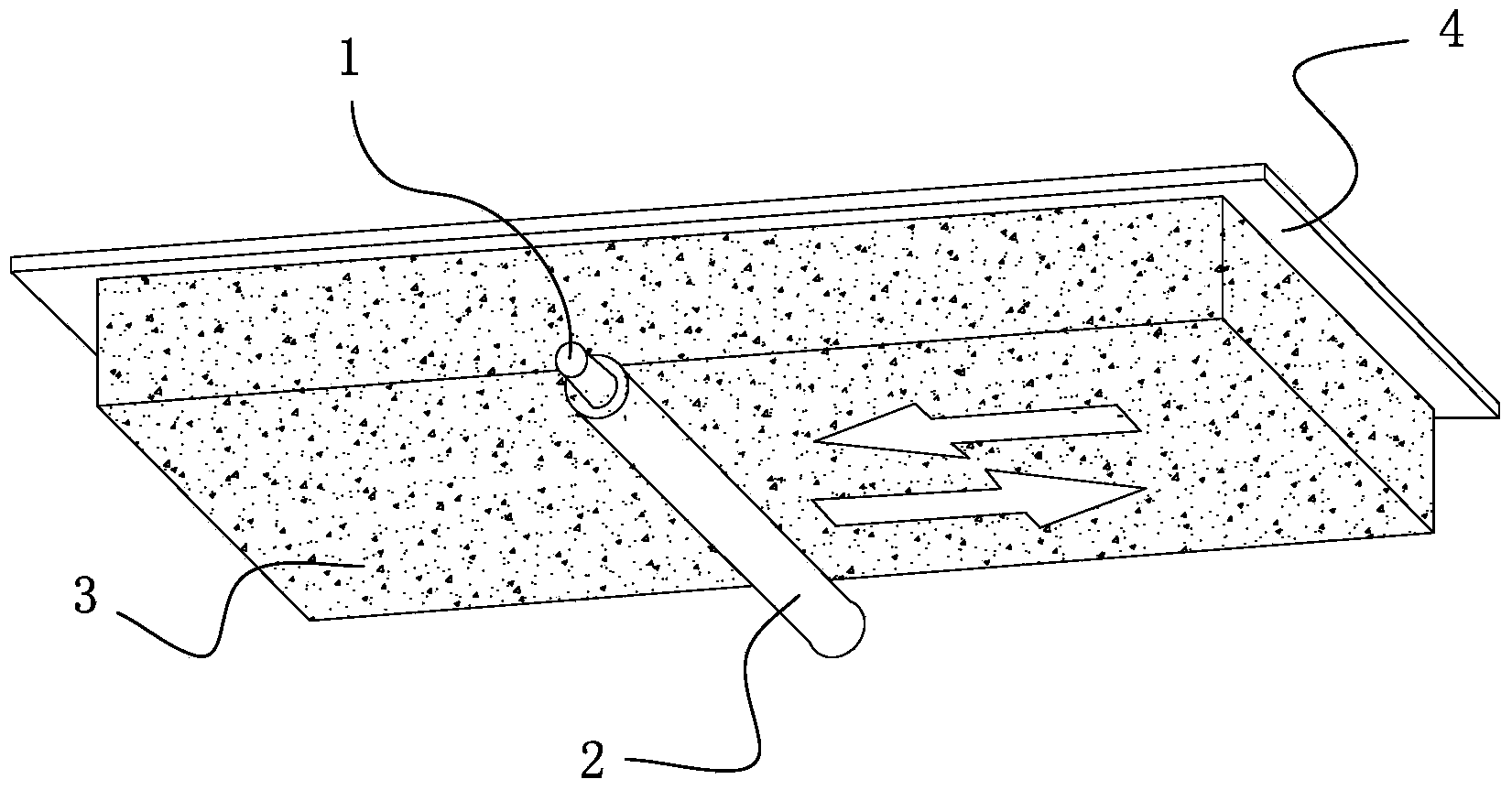

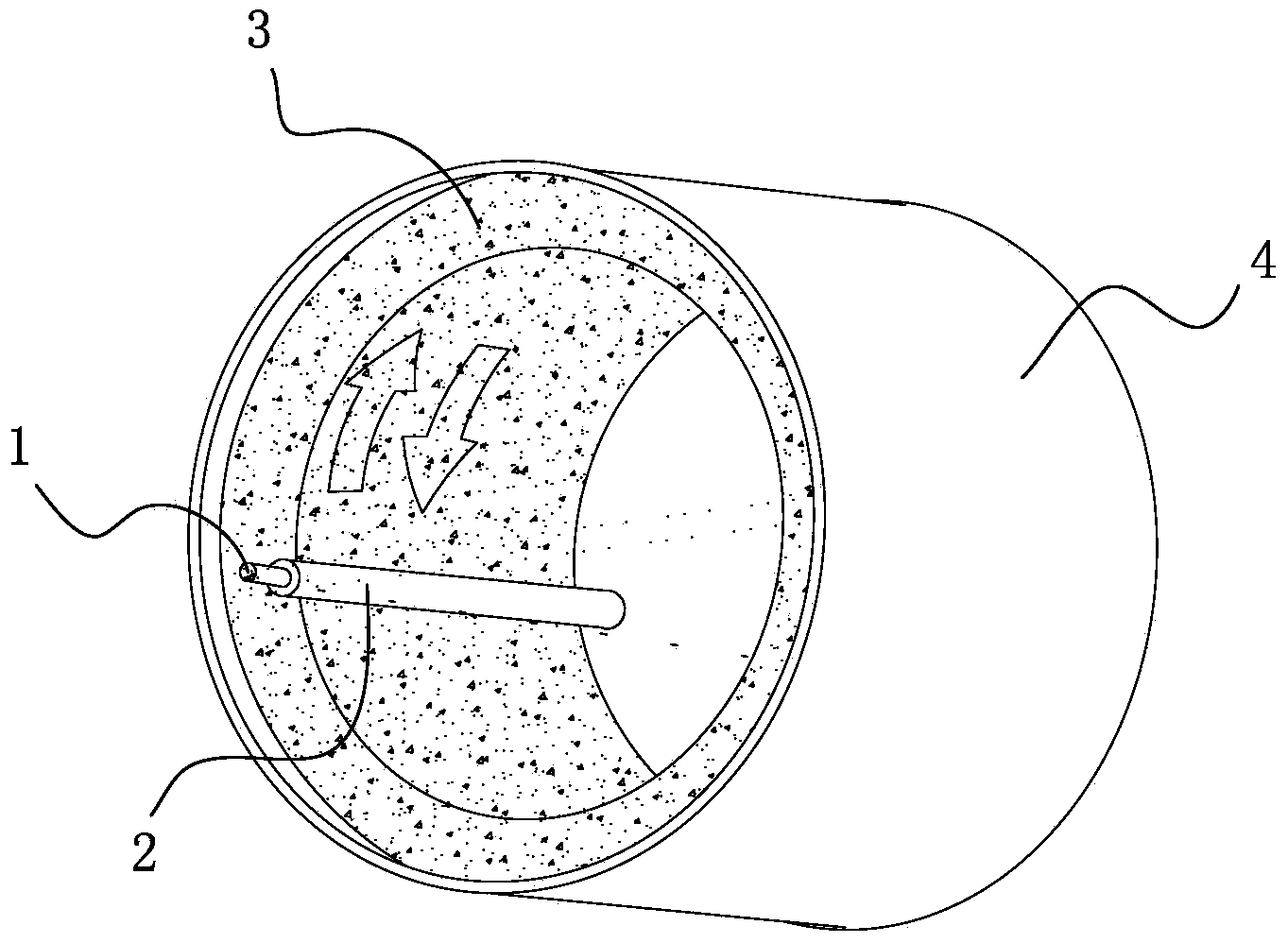

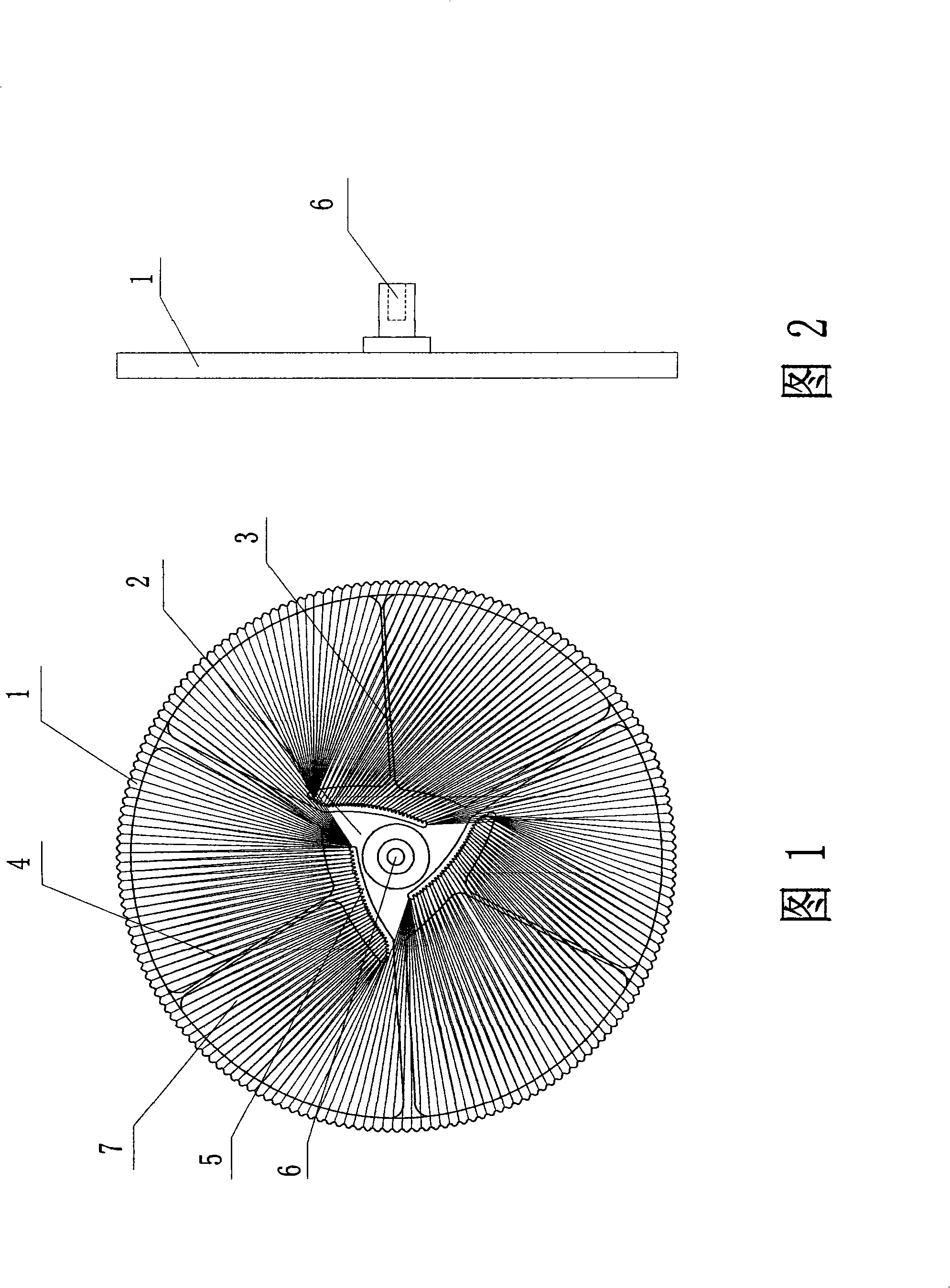

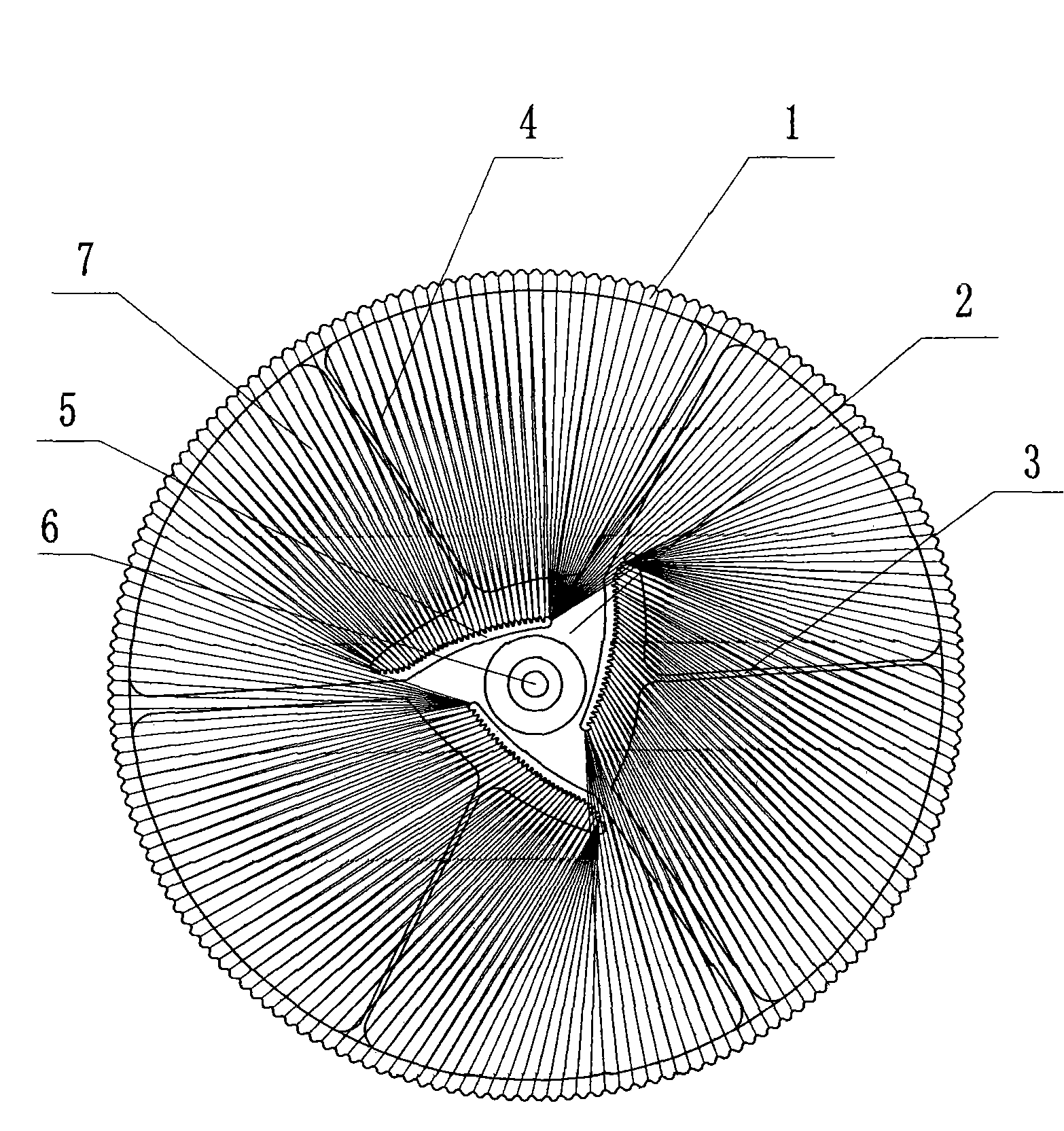

Air dust centrifugal purifier and method for making rotary filter net disk

A centrifugal cleaning apparatus for the air or fume, such as treating oil soot, exchanging air, and desulfurizing fume, features that at least one rotary netted filter disc is arranged to the axle of a motor in an air guiding cylinder. Said rotary netted filter disc is composed of a disc skeleton and a radiant filtering net wound uniformly on said disc skeleton. A method for preparing said rotary netted filter disc is also disclosed.

Owner:武汉创新环保工程有限公司

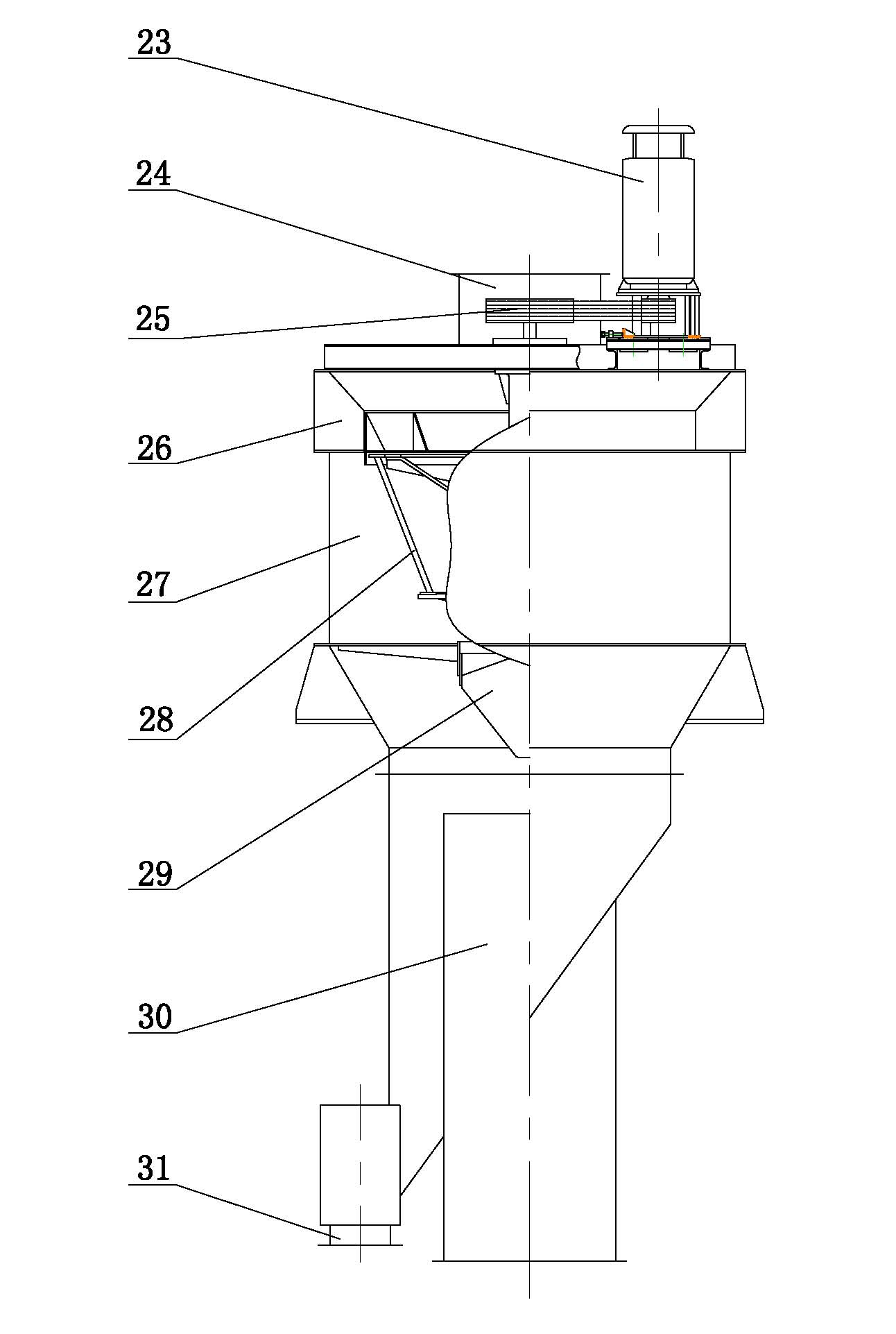

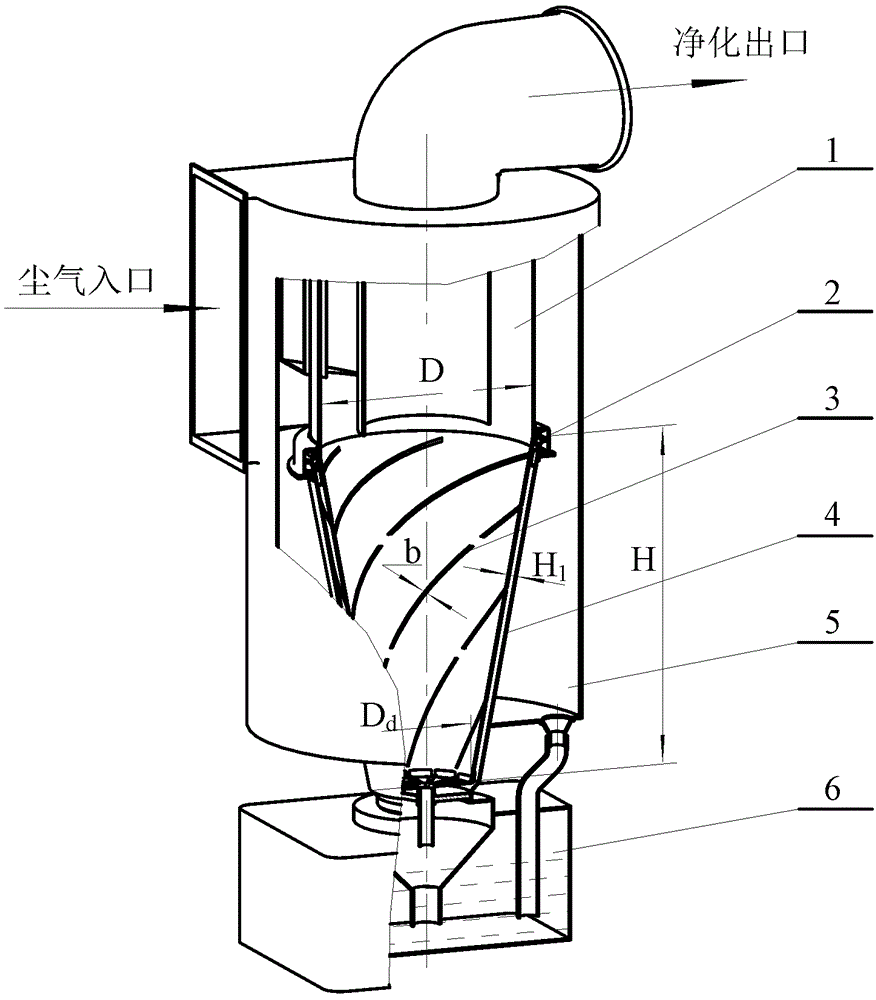

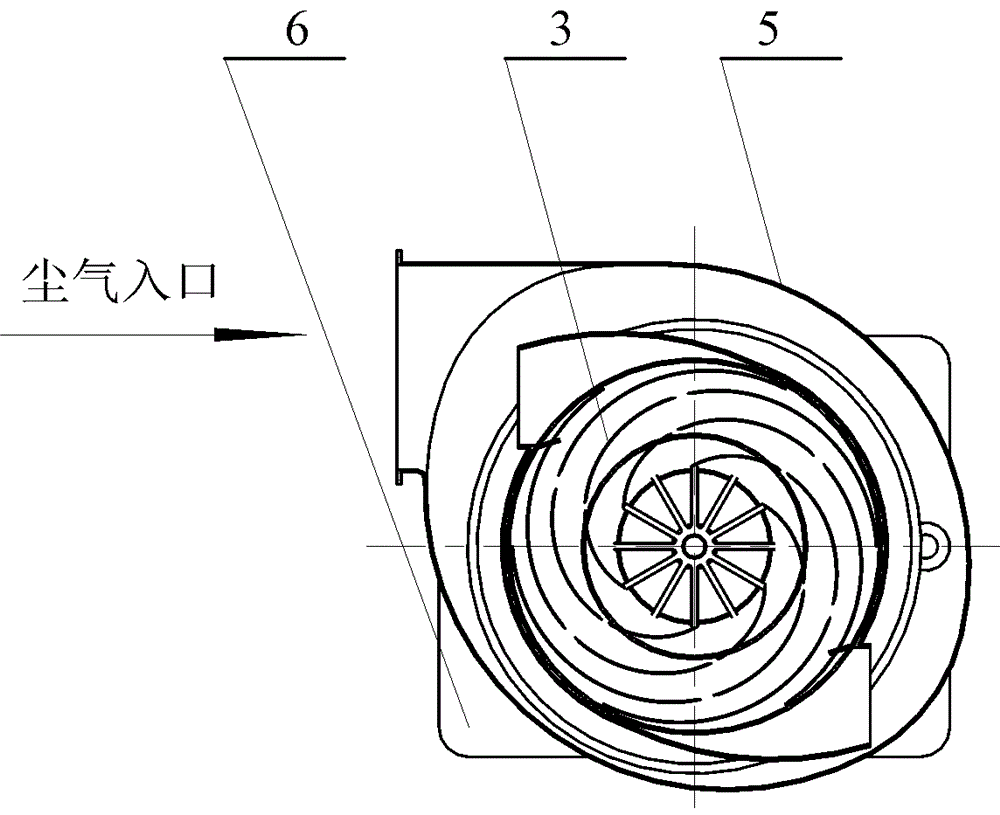

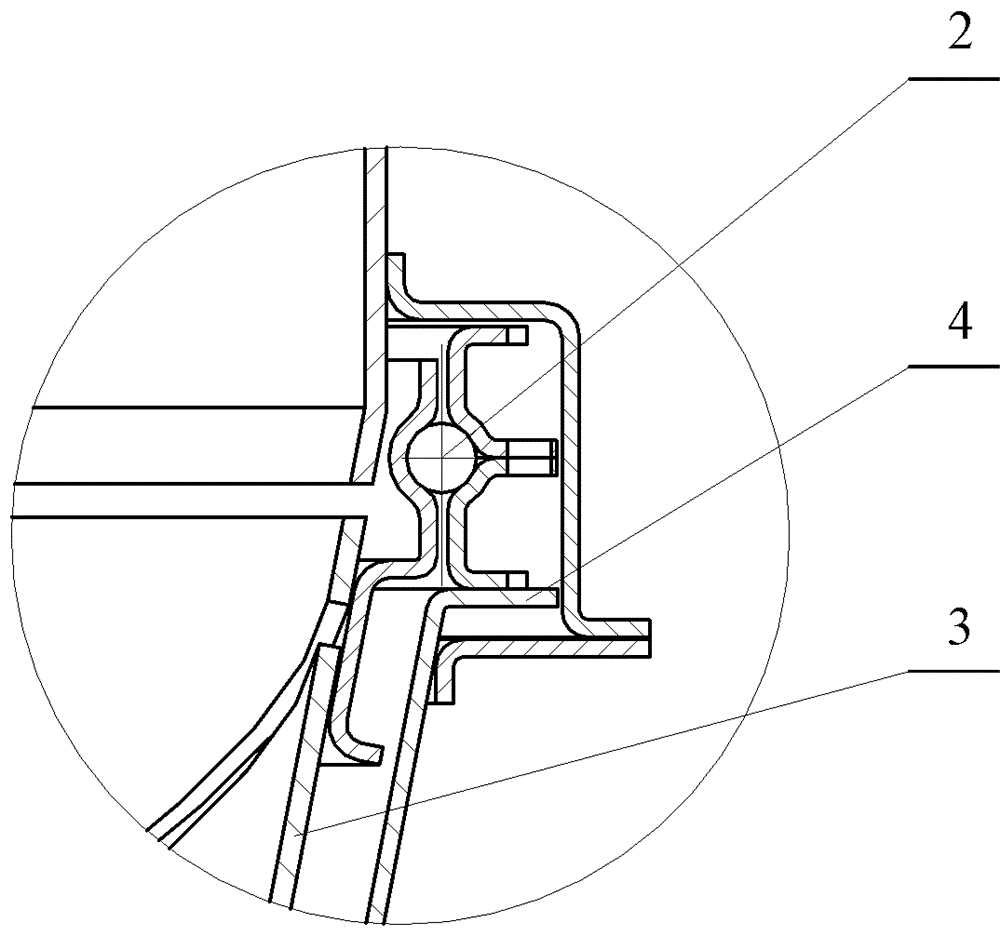

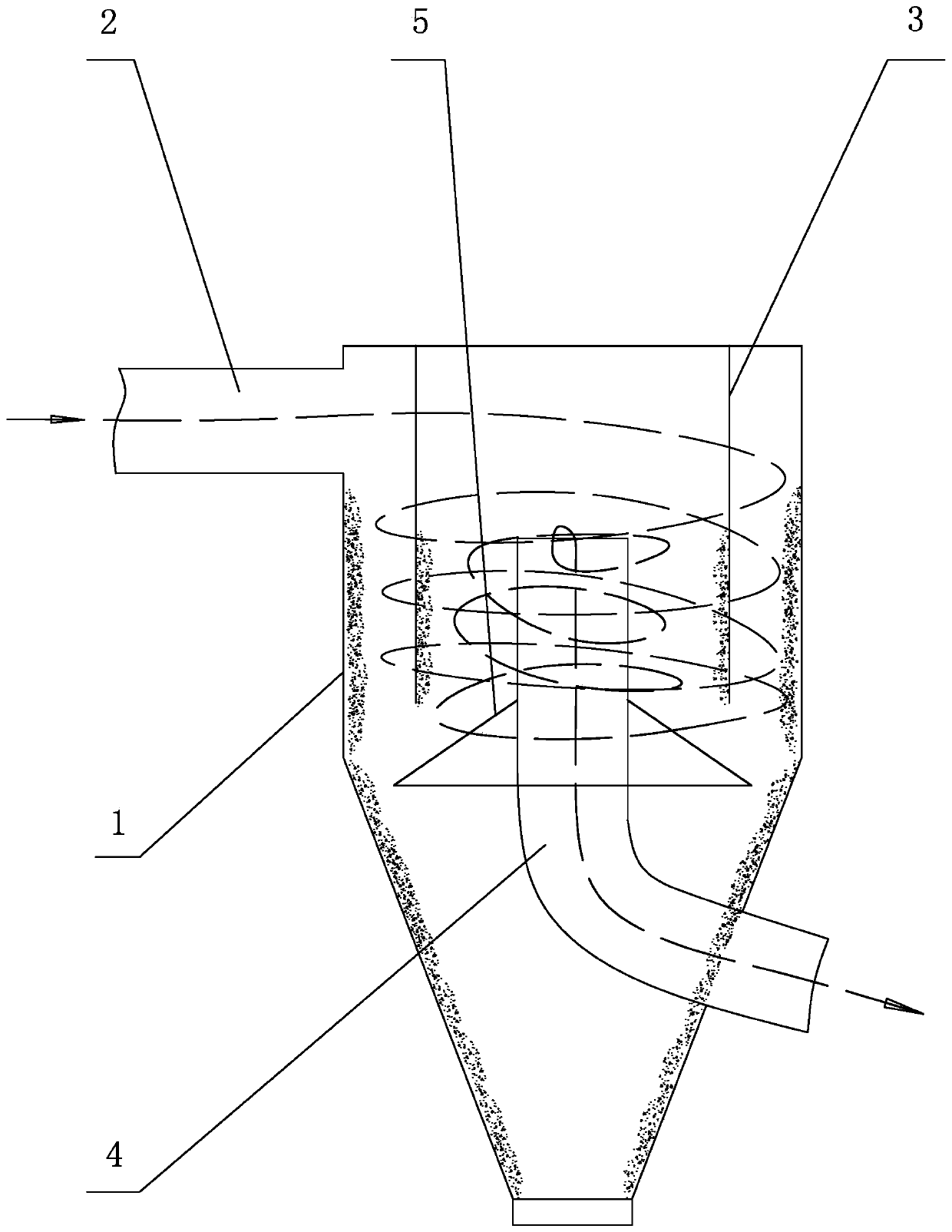

Energy-saving cyclone dust collector

PendingCN110918276AHandling large air volumeSmall wind speed lossReversed direction vortexEngineeringMechanical engineering

The invention discloses an energy-saving cyclone dust collector. The energy-saving cyclone dust collector comprises a separating barrel, wherein the separating barrel comprises an upper cylindrical barrel body and a lower inverted-conical barrel body; an air inlet pipe is tangentially mounted on the cylindrical barrel body; a cylinder opening in the bottom end of the inverted-conical barrel body is a powder outlet; an inner separating barrel is coaxially arranged in the cylindrical barrel body; an annular cavity is formed between the inner separating barrel and the cylindrical barrel body; anexhaust pipe is arranged in the separating barrel; the upper end of the exhaust pipe coaxially extends into the inner separating cylinder; the lower end of the exhaust pipe is bent, then led out of the inverted-conical cylinder body and connected with an air inducing device; and an air guiding and dust blocking plate capable of guiding inlet air of the annular cavity into the inner separating barrel and preventing dust in the inverted-conical barrel body from flowing back to the inner separating cylinder is coaxially arranged on the exhaust pipe outside the inner separating cylinder. The energy-saving cyclone dust collector can solve the problems that an existing dust remover is large in energy consumption, low in separation efficiency and not thorough in separation, can save energy, and improves the separation efficiency.

Owner:桂林矿山机械有限公司

System and method for exhausted air sterilization and aeration and comprehensive heating disinfection of highly-contaminated building space

PendingCN111895550AReduce virus contentImprove disinfection effectDucting arrangementsMechanical apparatusVentilation tubeThermal insulation

The invention provides a system and method for exhausted air sterilization and aeration and comprehensive heating disinfection of a highly-contaminated building space. The system comprises a contaminated area negative pressure metal ventilation pipe, any position thereon communicates with an inlet end of a high-resistance thermal-insulation-layer-carried ventilation pipeline, an outlet end of thehigh-resistance thermal-insulation-layer-carried ventilation pipeline is connected to an inlet end of an outdoor negative pressure metal ventilation pipe through an electric anti-backflow valve, and an outlet end of the outdoor negative pressure metal ventilation pipe is connected with an exhaust port of a high-efficiency variable-frequency fan. Various virus killing devices are sequentially disposed at the rear end of the high-efficiency variable-frequency fan. The system disinfects the air that may contain viruses in the highly-contaminated building space at high temperature through an electric heating pipeline and then guides the air that is disinfected at high temperature to the various outdoor virus killing devices through negative pressure pipelines to diversely and thoroughly disinfect the guided air, thereby thoroughly removing viruses in the air in the highly-contaminated building space.

Owner:CHINA RAILWAY CONSTR GROUP +1

Steelmaking slag treatment dust removing system of AOD furnace

InactiveCN105749686AReduce resistanceHandling large air volumeCombination devicesSteelmakingCyclonic spray scrubber

The invention relates to a steelmaking slag treatment dust removing system of an AOD furnace.The steelmaking slag treatment dust removing system comprises a hopper dust suction hood and a discharging port dust suction hood, and is characterized in that the hopper dust suction hood is arranged on a slag feeding hopper and connected with a hopper dust removing pipeline, the discharging port dust suction hood is arranged at a slag discharging port and connected with a discharging port dust removing pipeline, the discharging port dust removing pipeline is communicated with the hopper dust removing pipeline, the hopper dust removing pipeline is connected with a concentration main pipeline, and the concentration main pipeline is communicated with an air inlet of a cyclone dust remover.An air outlet of the cyclone dust remover is communicated with a draught fan.An air outlet of the draught fan is provided with a water membrane dust remover.The steelmaking slag treatment dust removing system of the AOD furnace is compact in designed structure, capable of saving ground, and high in stability, reliability and dust removing efficiency due to the fact that the unique smoke dust purifying system is arranged oriented to slag features of the AOD furnace.

Owner:WUXI SANDA ENVIRONMENTAL PROTECTION TECH CO LTD

High-contamination exhaust multi-disinfecting-killing system and method

PendingCN111895551AShorten survival timeReduce the risk of residual virusDucting arrangementsMechanical apparatusContamination zoneEnvironmental engineering

The invention provides a high-contamination exhaust multi-disinfecting-killing system and method. The system comprises a contaminated area negative-pressure metal vent pipe, any position on the contaminated area negative-pressure metal vent pipe communicates to the inlet end of a high-resistance tape heat insulating and insulating layer vent pipeline, the outlet end of the high-resistance tape heat insulating and insulating layer vent pipeline is connected to the inlet end of an outdoor negative-pressure metal vent pipe through an electric anti-backflow valve, and the outlet end of the outdoornegative-pressure metal vent pipe is connected to an exhaust port of an efficient variable-frequency fan. Multiple virus disinfecting and killing devices are sequentially arranged at the rear end ofthe efficient variable-frequency fan. Firstly, air probably containing viruses in high-contamination building spaces is disinfected and killed at high temperature through an electric heating pipeline,then the air disinfected and killed at high temperature is exhausted to the outdoor multi-virus disinfecting and killing devices through a negative-pressure pipeline, the introduced air is completelydisinfected and killed diversely, and therefore the viruses in the air of the high-contamination building spaces can be completely removed.

Owner:CHINA RAILWAY CONSTR GROUP +1

Rotary net-filtering tray for cooking fume exhauster

InactiveCN101329078BHandling large air volumeTo achieve the purpose of purifying the airDomestic stoves or rangesDispersed particle filtrationAir volumeEngineering

The invention discloses a rotary strainer disk used for a range hood, comprising an outer rotary table and an inner rotary table which are connected together through a support rod; a strainer formed by strainer-mesh is arranged between the inner rotary table and the outer rotary table. By adopting the structure, the invention is provided with reasonable design, convenient mounting and maintenanceprocess and low manufacturing cost; the air resistance is small and the disposed air flow is big during running; the oil-smoke containing a plurality of volatile solids can be filtered and cleaned, and the filtering and cleaning efficiency generally can reach more than 90 percent.

Owner:郑吉贤

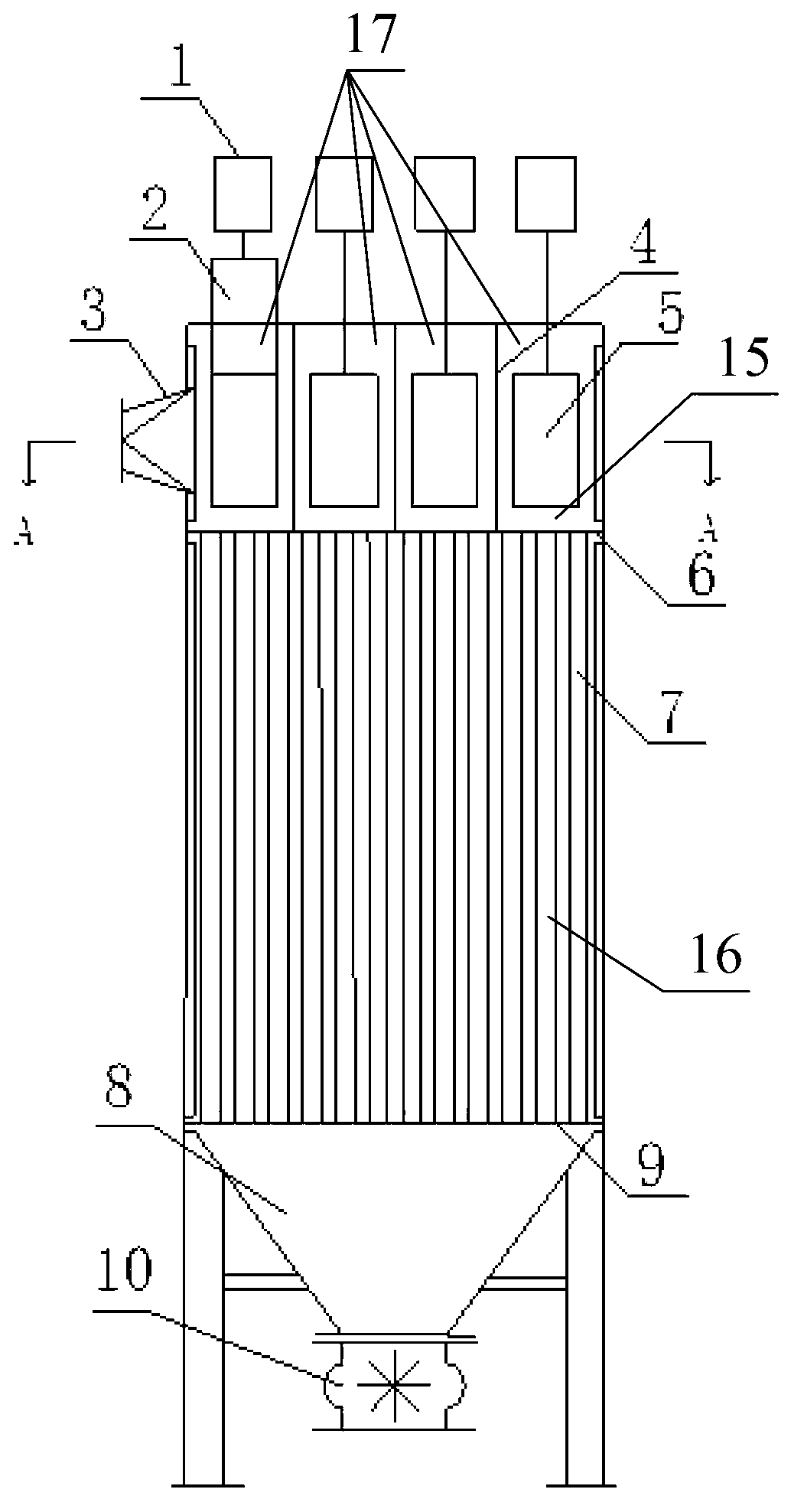

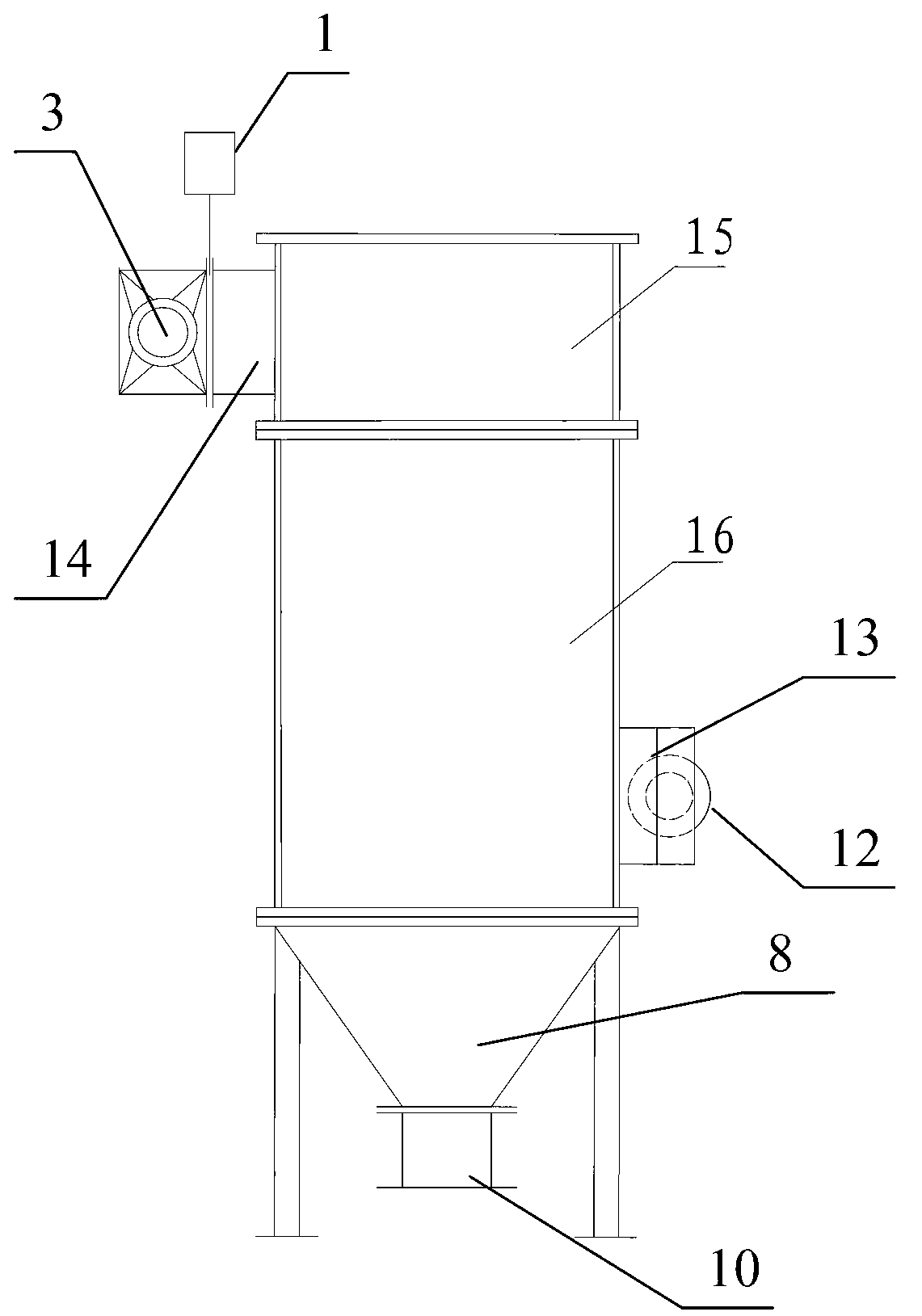

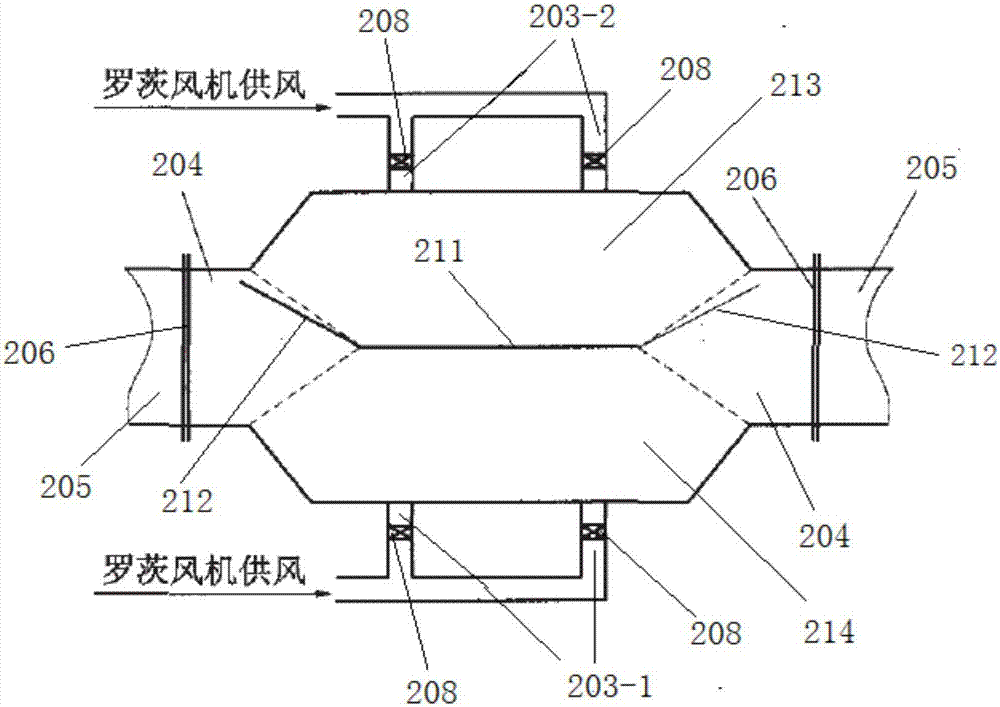

Long-bag low-pressure pulse bag type dust remover

PendingCN107213715AReduce energy consumptionHandling large air volumeDispersed particle filtrationAir volumeBaghouse

The invention provides a long-bag low-pressure pulse bag type dust remover, which comprises a dust remover body and a dust hopper, wherein the dust hoop is positioned under the dust remover body and is connected with the dust remover body; a screening assembly used for screening coarse particle dust is arranged in the dust hopper; the screening assembly comprises a collection box body arranged in the dust hopper in an inclined way; an inflating box with ventilation cloth is arranged at the bottom of the collection box body; an air inlet pipe is arranged on the inflating box body; the air inlet pipe is connected with an air outlet pipe of a Roots blower arranged outside the dust hopper. The long-bag low-pressure pulse bag type dust remover provided by the invention has the advantages that the coarse particle dust can be screened out and can be discharged in a concentrated way after the collection; the pipeline blockage in the subsequent work procedure can be prevented; meanwhile, the characteristics of great treatment air quantity, small occupied area and low energy consumption are realized.

Owner:HONGAN FANGDA ENVIRONMENTAL PROTECTION ENG

Novel high-efficiency dust processor

ActiveCN107321088AEasy to cleanExtend working lifeDispersed particle filtrationTransportation and packagingWorking lifeEngineering

The invention discloses a novel high-efficiency dust processor. The novel high-efficiency dust processor effectively solves the problem that the existing blow-back device cannot fully clean the dust on a filter cartridge. The novel high-efficiency dust processor comprises a dust removal box, the upper end surface of the dust removal box is provided with an air inlet, the right end of the dust removal box is fixedly provided with a working box, the front side of the working box is provided with an air outlet, multiple horizontal filter cartridges are uniformly arranged in the dust removal box, a ventilation box is fixedly installed in the working box, multiple rotation shafts in the center along the axial direction of the filter cartridge are rotatingly arranged in the ventilation box, the left side of the ventilation box is fixedly provided with coarse cylinders sleeving the rotation shafts and communicated with the interior of the ventilation box, fine cylinders sleeving the rotation shafts are inserted into the coarse cylinders and the left end surfaces of the fine cylinders are provided with nozzles. According to the novel high-efficiency dust processor, a telescopic blow-back device is used and can stretch into the filter cartridges when too much dust is accumulated on the filter cartridges so that dust attached to the filter cartridges is thoroughly blown off, dust processing device working efficiency is greatly improved, the processing air amount is large, operation is safe and reliable and the working life of the filter cartridge is greatly prolonged.

Owner:XINXIANG XINYUAN CORROSION INSULATION PROD CO LTD

Exhaust aeration disinfection and sterilization system and method for high-pollution building space

PendingCN111878928AReduce virus contentImprove disinfection effectDucting arrangementsMechanical apparatusInsulation layerThermal insulation

The invention provides an exhaust aeration disinfection and sterilization system and method for a high-pollution building space. The system involves a polluted area negative pressure metal ventilationpipe, wherein any position of the polluted area negative pressure metal ventilation pipe communicates with the inlet end of a high-resistance ventilation pipeline with a thermal isolation and insulation layer, and the outlet end of the high-resistance ventilation pipeline with the thermal isolation and insulation layer is connected to the inlet end of an outdoor negative pressure metal ventilation pipe through an electric backflow prevention valve; and the outlet end of the outdoor negative pressure metal ventilation pipe is connected to an extraction opening of an efficient variable-frequency fan, and a plurality of virus disinfection and sterilization devices are sequentially arranged at the rear end of the efficient variable-frequency fan. According to the exhaust aeration disinfectionand sterilization system and method for the high-pollution building space, air possibly containing viruses in the high-pollution building space is subjected to high-temperature disinfection and sterilization through an electric heating pipeline firstly, then the air subjected to high-temperature disinfection and sterilization is guided to the outdoor through a negative pressure pipeline, and theplurality of virus disinfection and sterilization devices carry out diversified thorough disinfection and sterilization on the introduced air so that the viruses in the air in the high-pollution building space can be thoroughly removed.

Owner:CHINA RAILWAY CONSTR GROUP +1

A treatment method for waste gas in the production process of viscose fiber

ActiveCN105597527BRealize local/remote controlRealize interlock controlGas treatmentDispersed particle separationGlass fiberViscose

The present invention relates to a viscose fiber production process exhaust gas treatment method, and belongs to the technical field of textile industry exhaust gas treatment. Viscose fiber production process exhaust gas is washed with a first-stage alkali spray tower, then enters a low-temperature plasma apparatus for treatment, then enters a catalytic oxidation treatment bed for exhaust gas catalytic oxidation treatment, and finally is introduced by a glass fiber reinforced plastic centrifugal fan into a second-stage alkali spray tower for absorption of residual small molecules in the exhaust gas. Through the above process, carbon disulfide and hydrogen sulfide exhaust gases can be decomposed into CO2, H2O, N2 and other harmless substances, and are discharged up to standards.

Owner:YIBIN HIEST FIBER

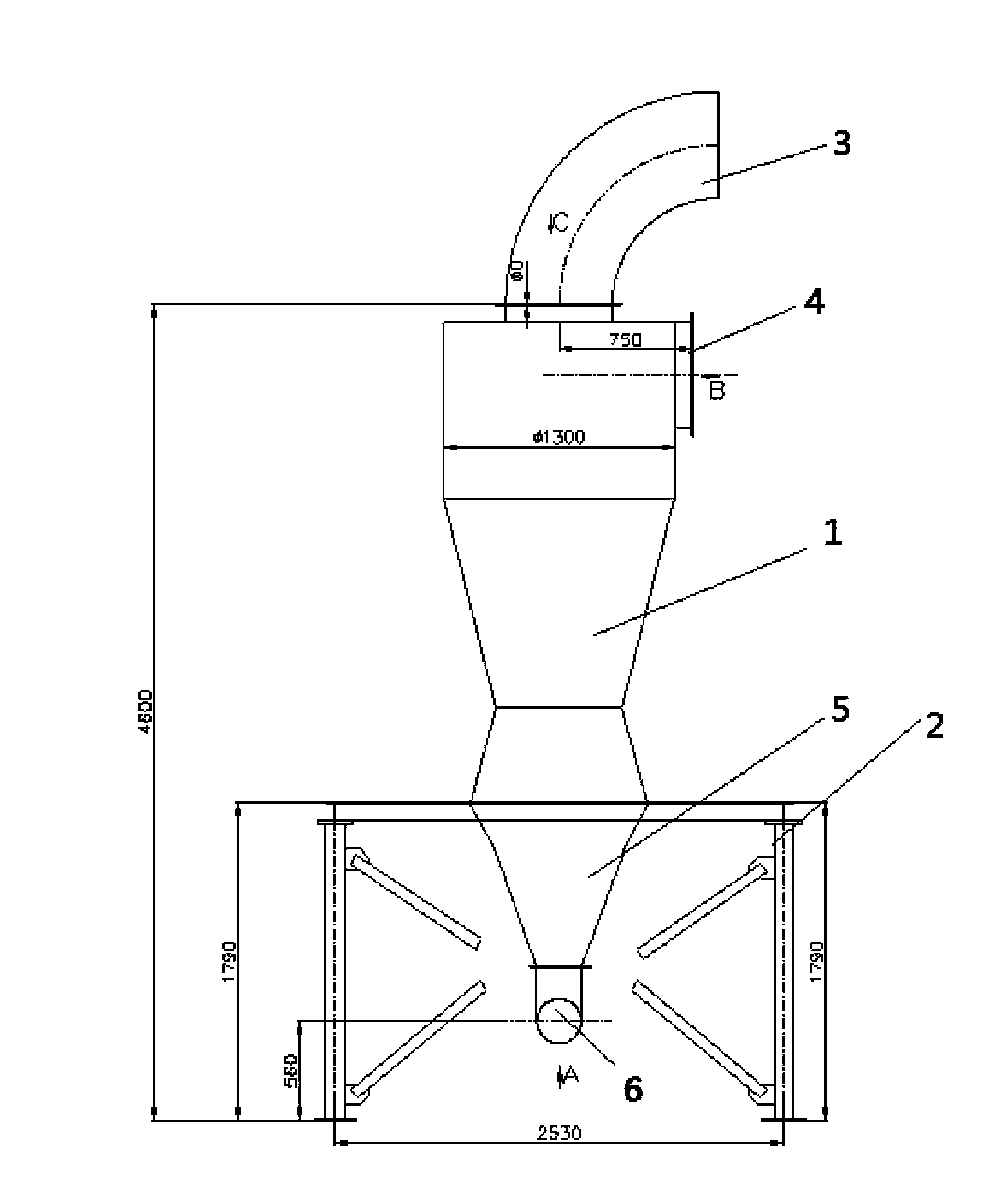

Cyclone dust collector

InactiveCN103721869AImprove dust removal rateHandling large air volumeReversed direction vortexCycloneAir treatment

The invention discloses a cyclone dust collector. The cyclone dust collector comprises a cyclone dust collector body and a support frame used for supporting the cyclone dust collector body; the top of the cyclone dust collector body is provided with an air outlet bend pipe, the middle and upper end of the cyclone dust collector body is provided with an air inlet, and the bottom of the cyclone dust collector body is provided with a flue-dust retainer with an inverted-splayed vertical section; cyclones are arranged in the cyclone dust collector body and at the air inlet of the cyclone dust collector body respectively; and the diameter of the air outlet bend pipe is 1 / 2-1 / 3 of the diameter of the top of the cyclone dust collector body, and the shape of the vertical section of the cyclone dust collector body below the air inlet sequentially transmits from the inverted-splayed shape to a inverted-splayed and then is connected with the flue-dust retainer with an inverted-splayed vertical section. The cyclone dust collector realizes thorough dedusting, has a dedusting efficiency of above 90%, has a large air treatment capacity reaching 28000-50000m<3> / h, has a strong treatment capability, can treat a gas with the dust content of 1000g / m<3>, and has the advantages of simple structure, making convenience and low cost.

Owner:溧阳市化机设备厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com