Cyclone dust removal device with double conical cylinders

A technology of cyclone dust removal and cyclone dust collector, which is applied in the direction of swirl devices and devices in which the axial direction of the swirl can be reversed, etc., which can solve the difficulty of making spiral cones, the inconvenience of post-filter maintenance, and the addition of post-stage filter equipment and other problems, to achieve the effect of easy sealing, low working noise and simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

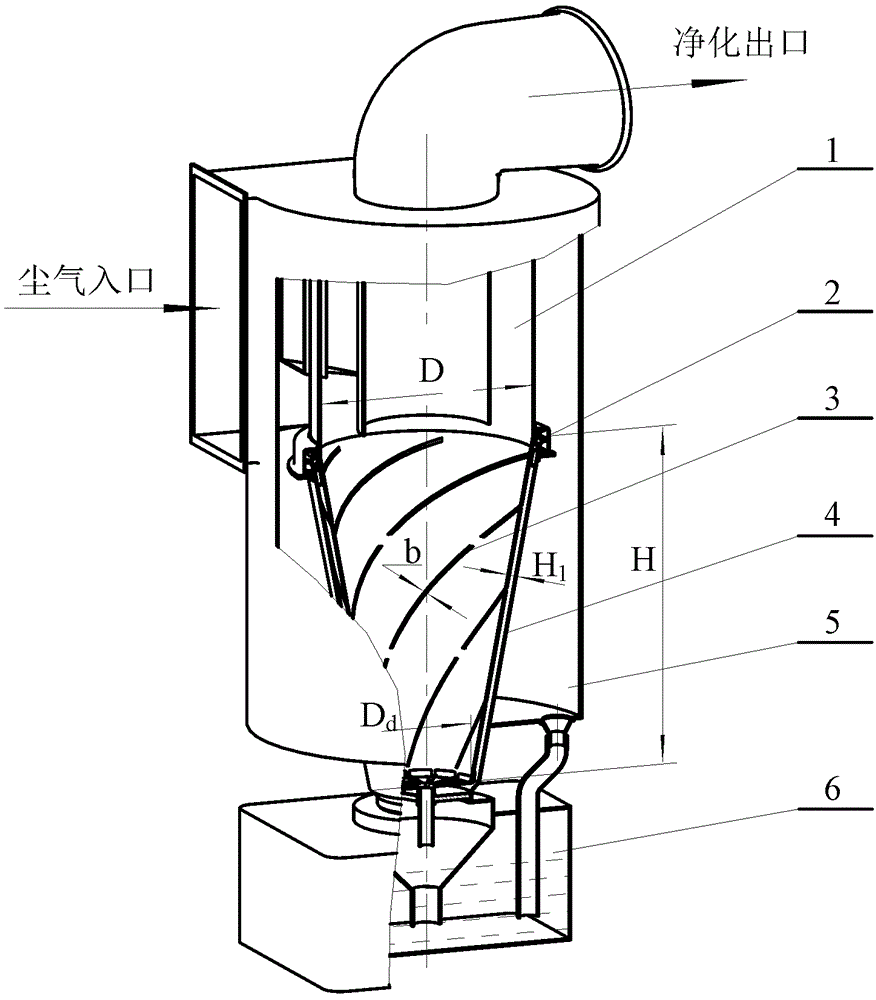

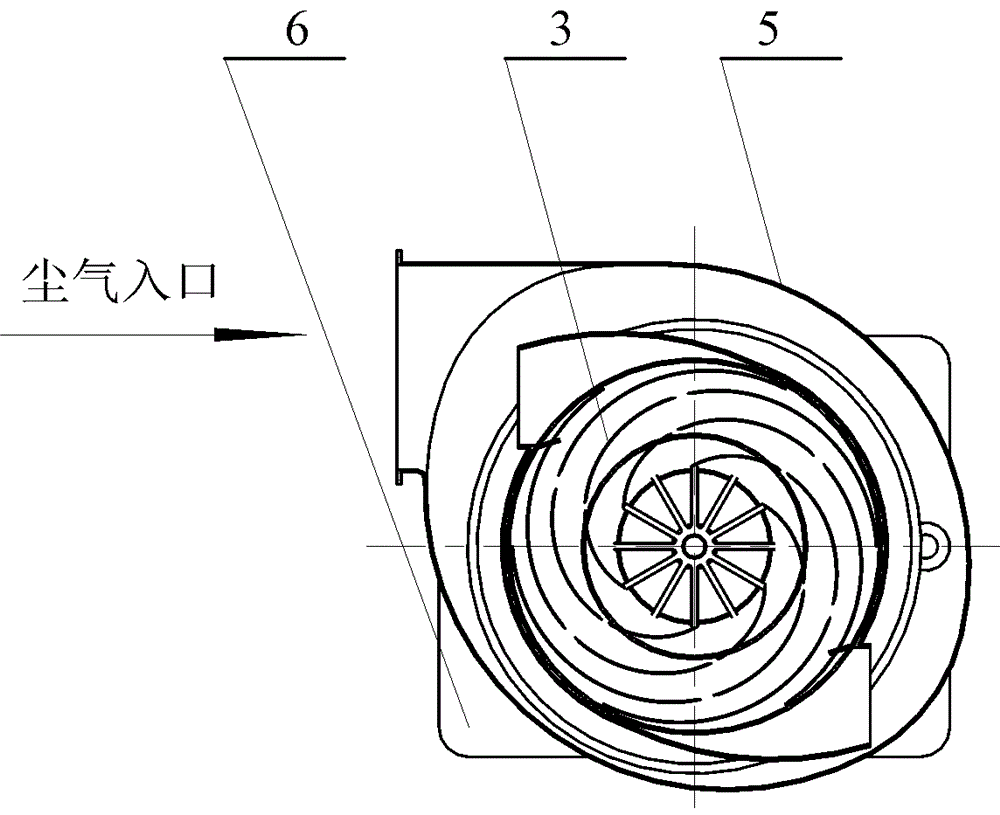

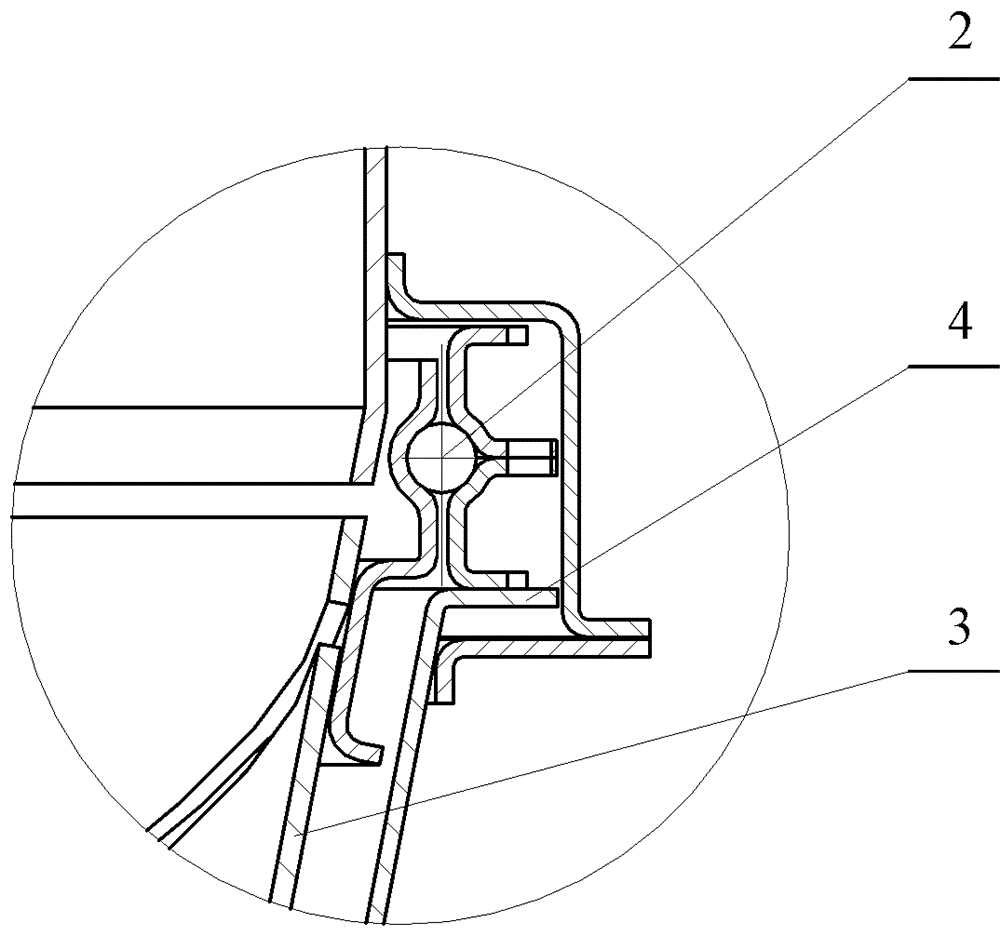

[0017] like figure 1 As shown, a double-cone cyclone dust removal device of the present invention includes: cyclone dust collector (1), slewing bearing (2), movable cone (3), fixed cone (4), air duct box (5) , Dust collecting tank (6).

[0018] When the dust-laden air enters the air channel box (5) from the dust inlet, it enters the upper part of the cylinder body through the two symmetrical air inlets on the cyclone dust collector, forming an external swirl flow that spirals down along the cylinder body, and the air flow passes through the movable cone ( 3) on the inner surface, the dust particles pass through the slender groove on the movable cone (3) under the action of centrifugal force, and enter the interlayer formed by the movable cone (3) and the fixed cone (4). The cylinder (3) is rotating slowly, which preven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com