Low-resistance and low-maintenance ventilation purification device and overlapped structure thereof

A purification device and technology on the air inlet side, applied in the directions of space heating and ventilation details, applications, and household heating, etc., can solve the problems of small effective filtration area, large resistance, and small processing air volume, so as to increase the effective filtration area, The effect of reducing the resistance of the device and increasing the processing air volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

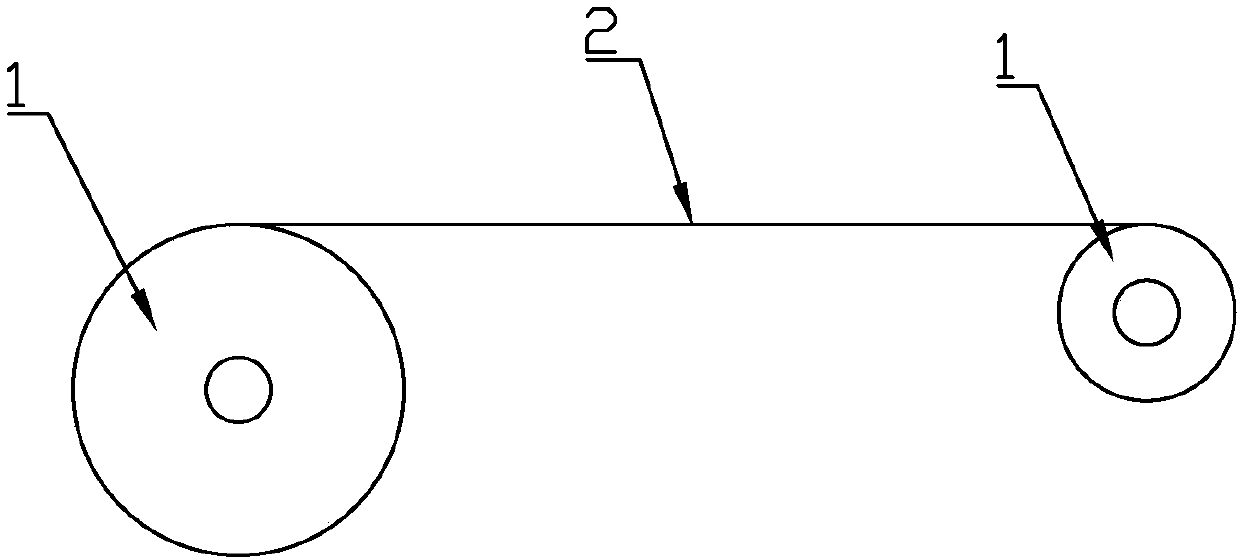

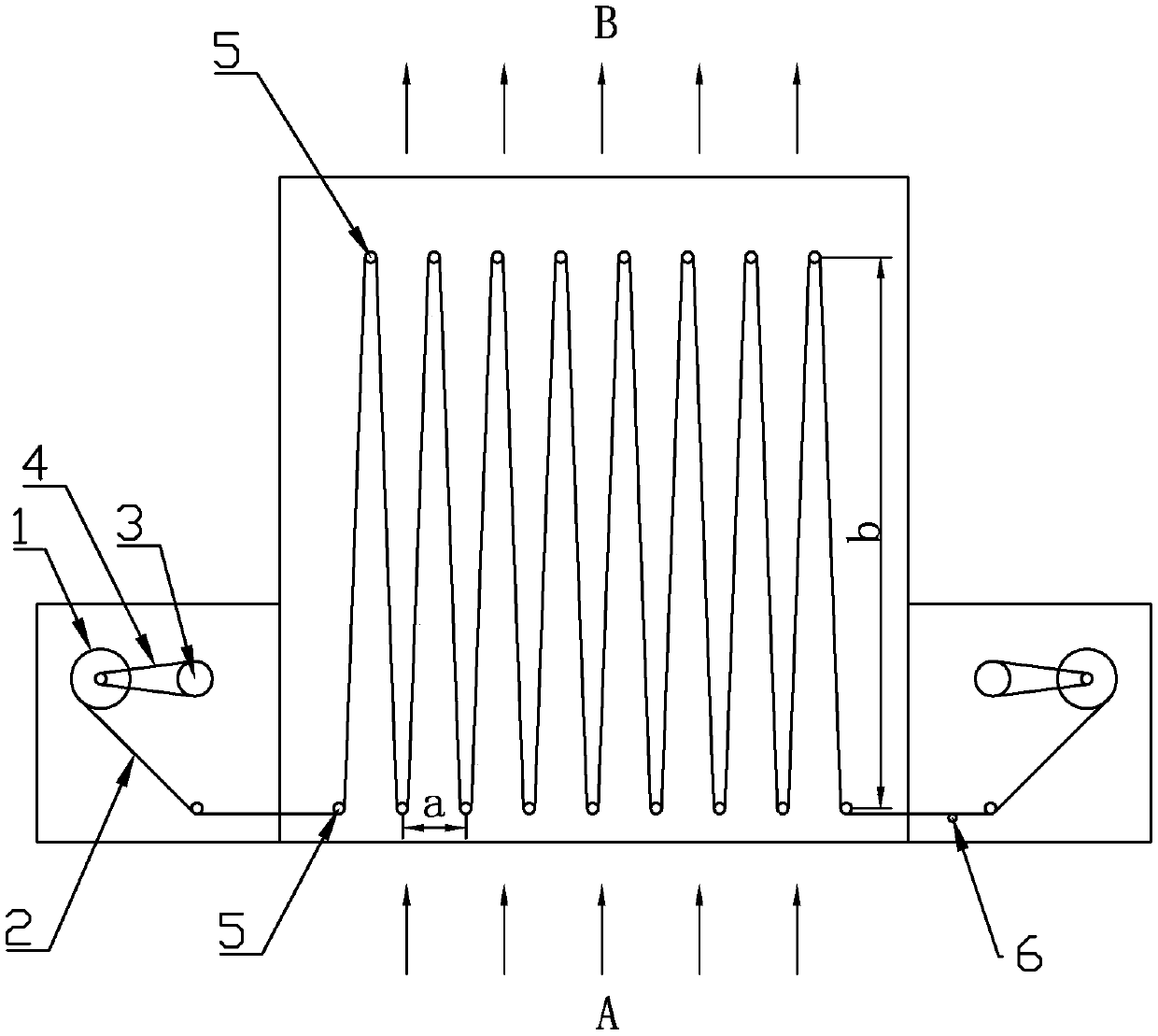

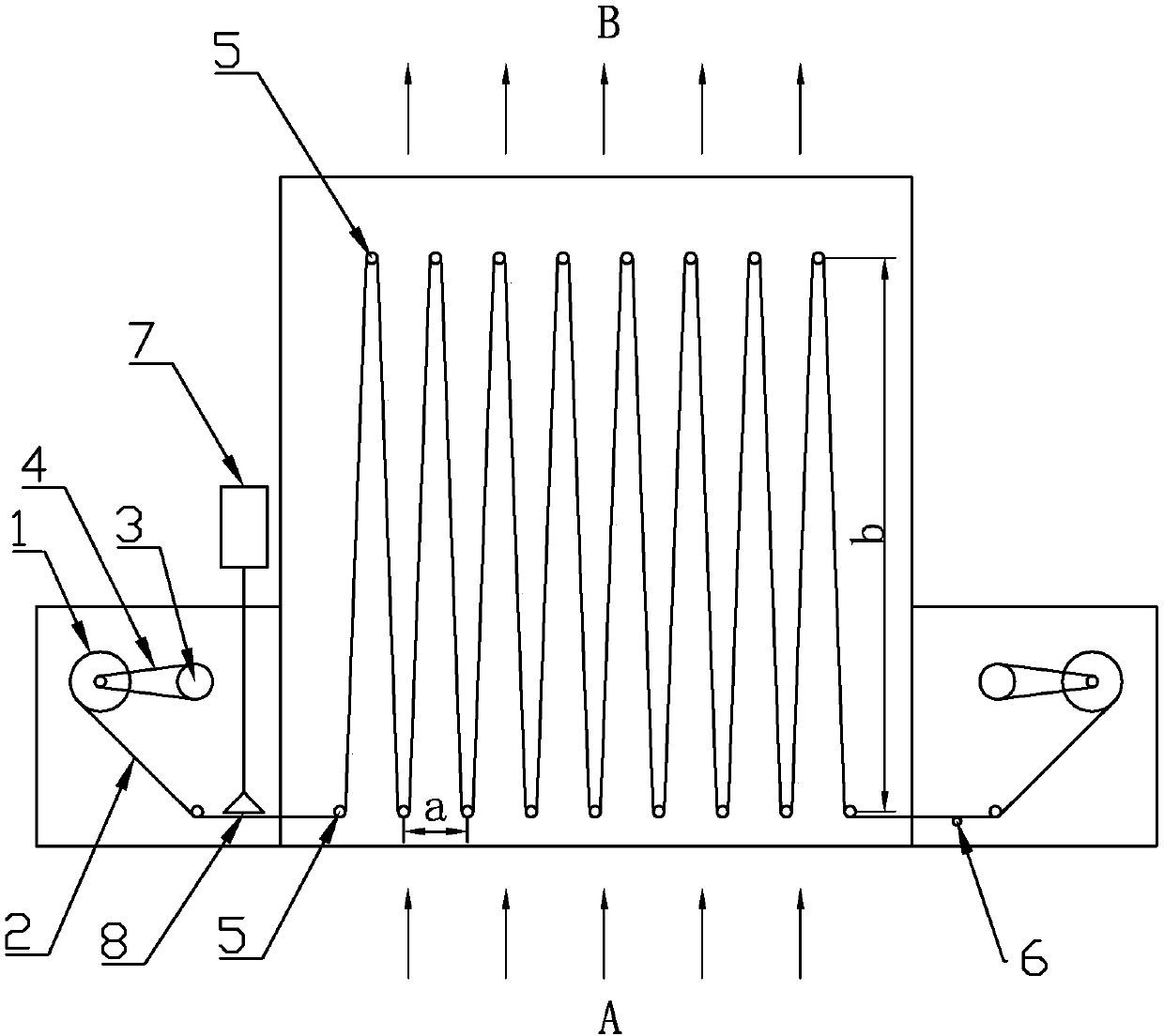

[0026] Such as figure 2 Shown is a schematic structural view of the low-resistance and low-maintenance ventilation purification device provided by the present invention, which has two filter material rolls 1 oppositely arranged, and the two filter material rolls 1 are respectively driven by a motor 3 through crawler belts 4 , a filter material 2 is wound between two filter material rolls 1;

[0027] Different from the prior art, there are also two rows of spacing shafts 5, one row of spacing shafts 5 is close to the air inlet side A, and the other row of spacing shafts 5 is close to the air outlet side B. The filter material 2. Reciprocate and reciprocate sequentially between the two rows of limit shafts 5 to form a "zigzag" winding path to increase the effective filtration area of the filter material 2, thereby increasing the processing air volume and reducing the resistance of the device.

[0028] The present invention has two modes of operation - normal ventilation and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com