Folding filter core structure, filter cylinder device and machining method of filter cylinder device

A folding filter element and filter cartridge technology, applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve the problems of easy breeding of bacteria, parasites, difficulty in obtaining filtration accuracy, serious secondary pollution, etc., and achieve enhanced pollution tolerance. ability, improve the effective filter area, and the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

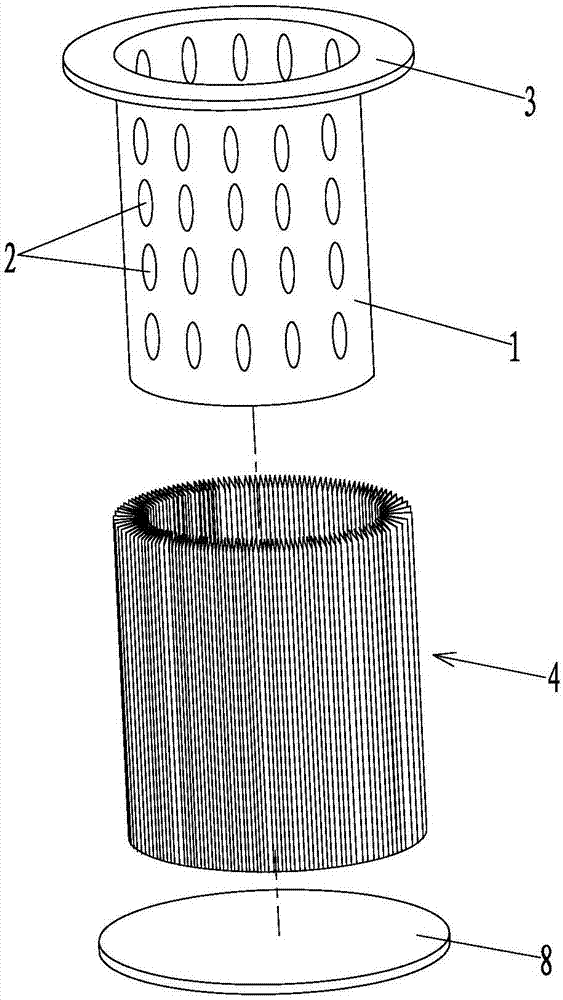

[0039] Such as figure 1 As shown, Embodiment 1 of the pleated filter element structure of the present invention includes a filter element frame 1, which is a cylindrical tube with a plurality of water outlet through holes 2 distributed along the circumferential direction on the surface. The cross-section of the filter core frame 1 is circular or polygonal, and this embodiment adopts a circular shape. The upper end of the filter element frame 1 is welded with an annular upper cover 3 , and the outer surface of the filter element frame 1 is sleeved and connected with an annular folded filter element 4 .

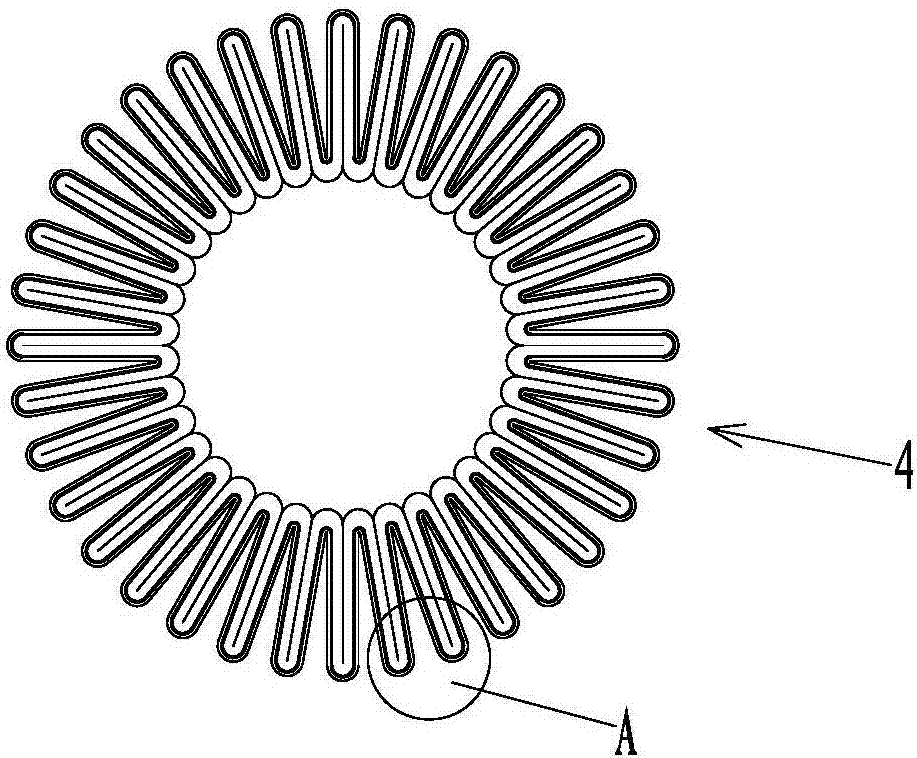

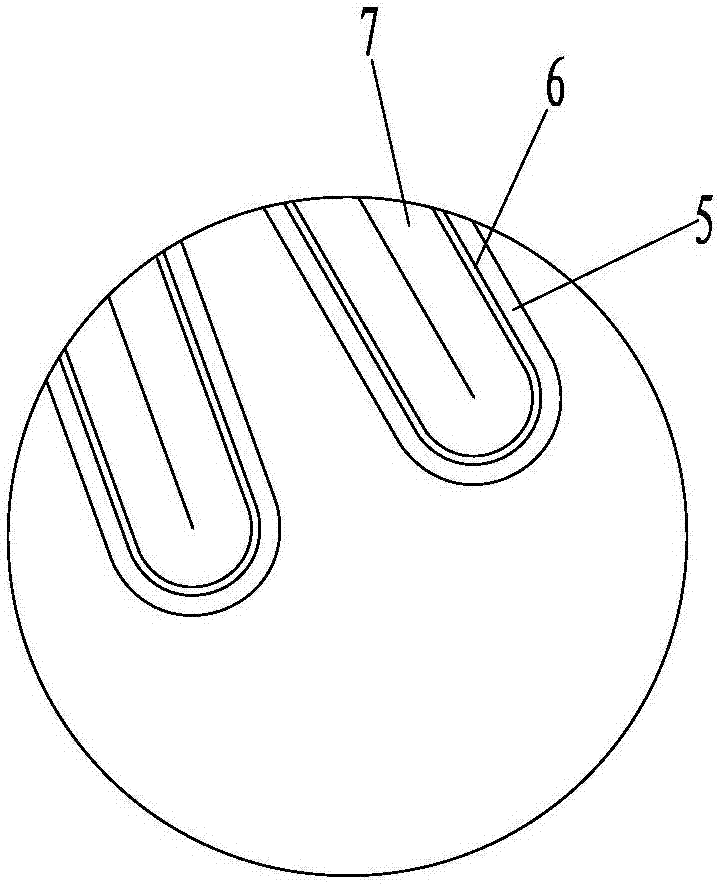

[0040] combine figure 2 As shown, the pleated filter element 4 is a louver-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com