Rotary net-filtering tray for cooking fume exhauster

A technology of rotating a filter screen and a range hood is applied in the direction of removing oil fume, applications, and household stoves. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

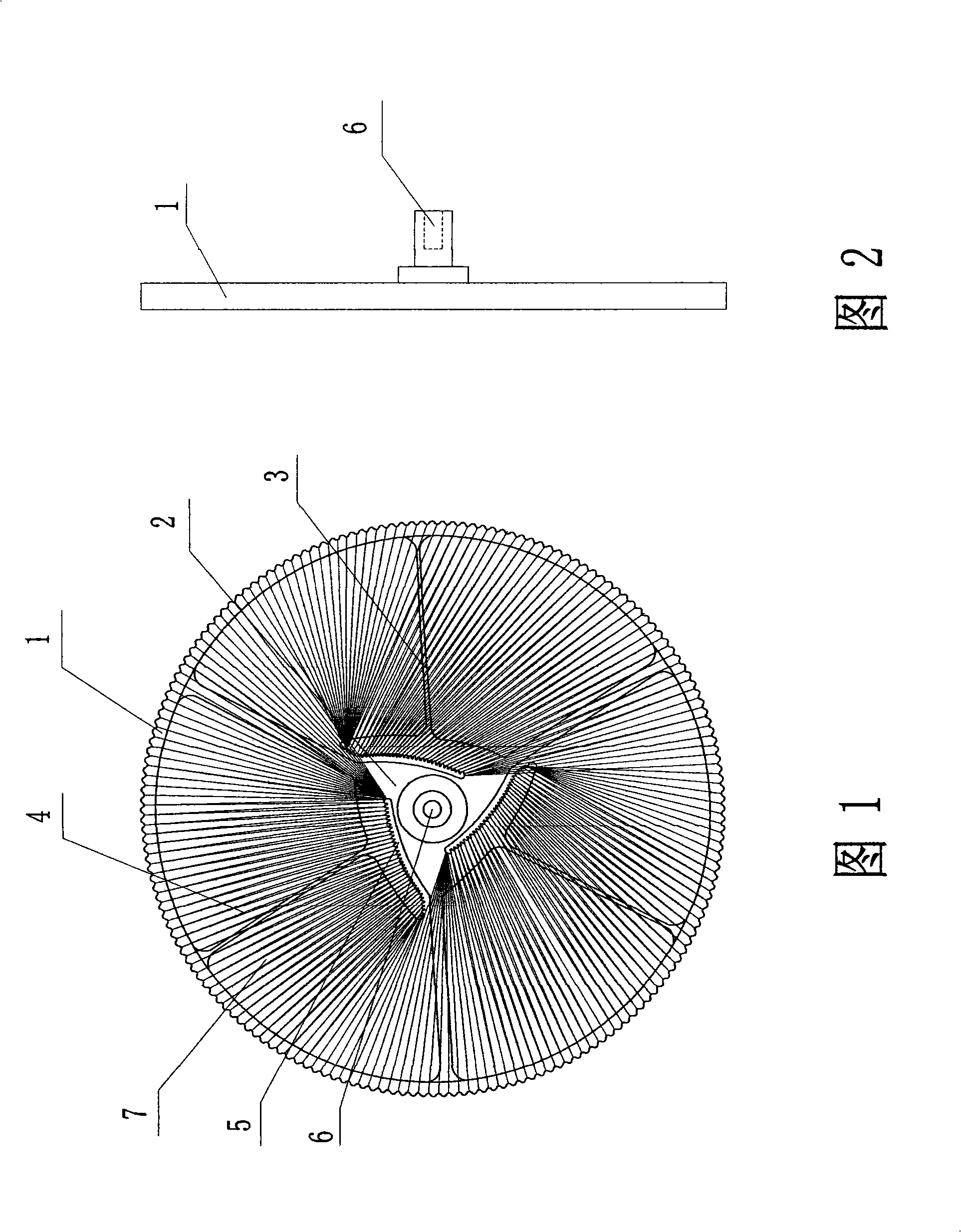

[0013] As shown in Fig. 1 and Fig. 2, the present invention comprises an outer roulette 1 and an inner roulette 2, the outer roulette 1 is circular, its outer peripheral surface is a toothed structure, the inner roulette 2 is a triangular shape, and the inner roulette 2 There are three grooves 5 substantially parallel to the triangular sides, and the side of the grooves 5 opposite to the outer wheel 1 is a tooth-shaped structure. The outer wheel 1 and the inner wheel 2 are connected together by supporting ribs 3. Between the outer wheel disc 1 and the inner wheel disc 2, a filter screen 7 composed of a filter screen wire 4 is provided. 1. The tooth shapes on 1 are formed by synchronous circumferential movement and winding. A shaft sleeve 6 connected with the output shaft of the motor is provided at the center of the inner wheel disc 2 . The diameter of the filter wires 4 is 0.1-0.5 mm, and the angle between adjacent filter wires 4 in the radial direction is 1.5-3.0 degrees. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com