Patents

Literature

131results about How to "Improve dust removal rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

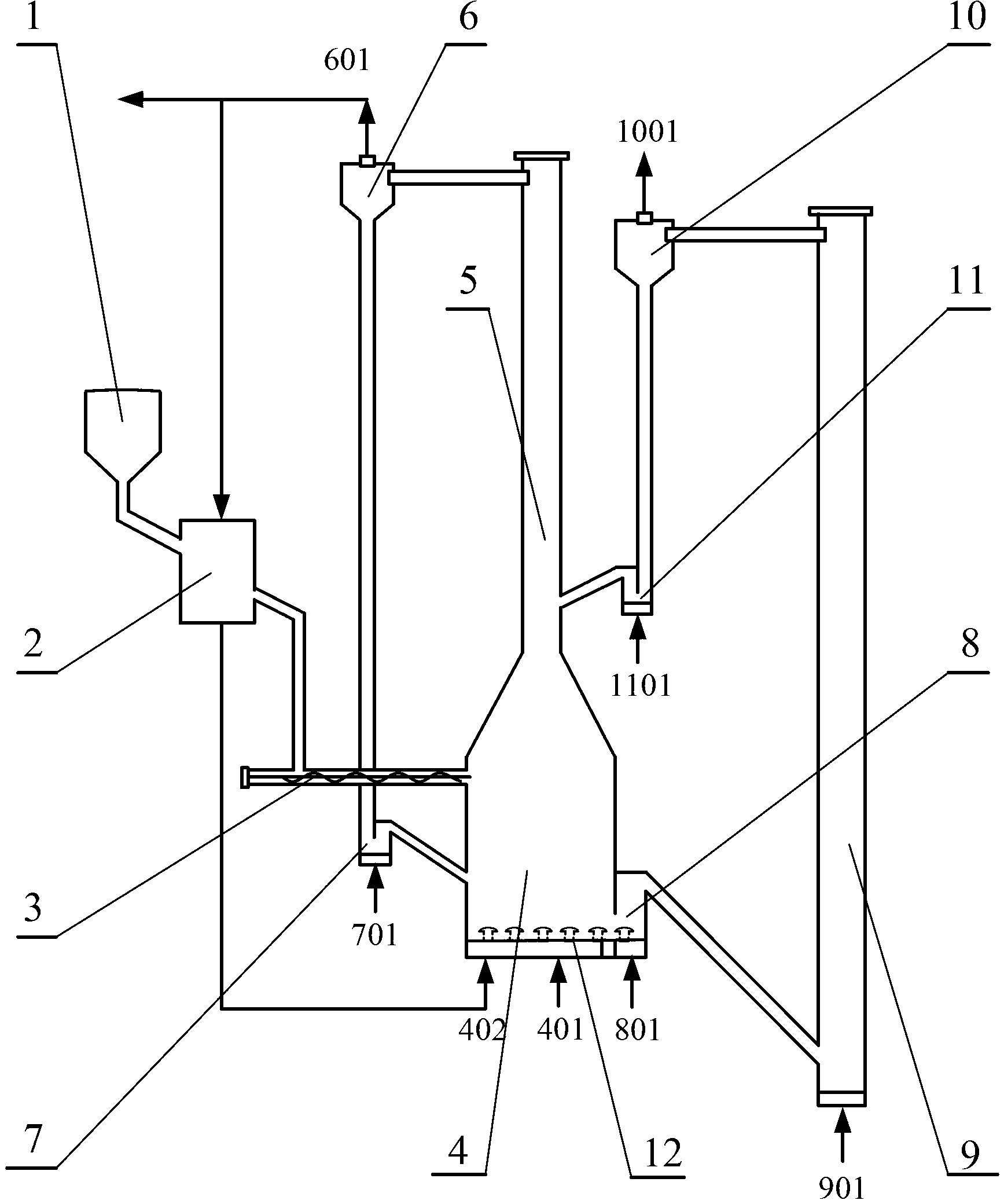

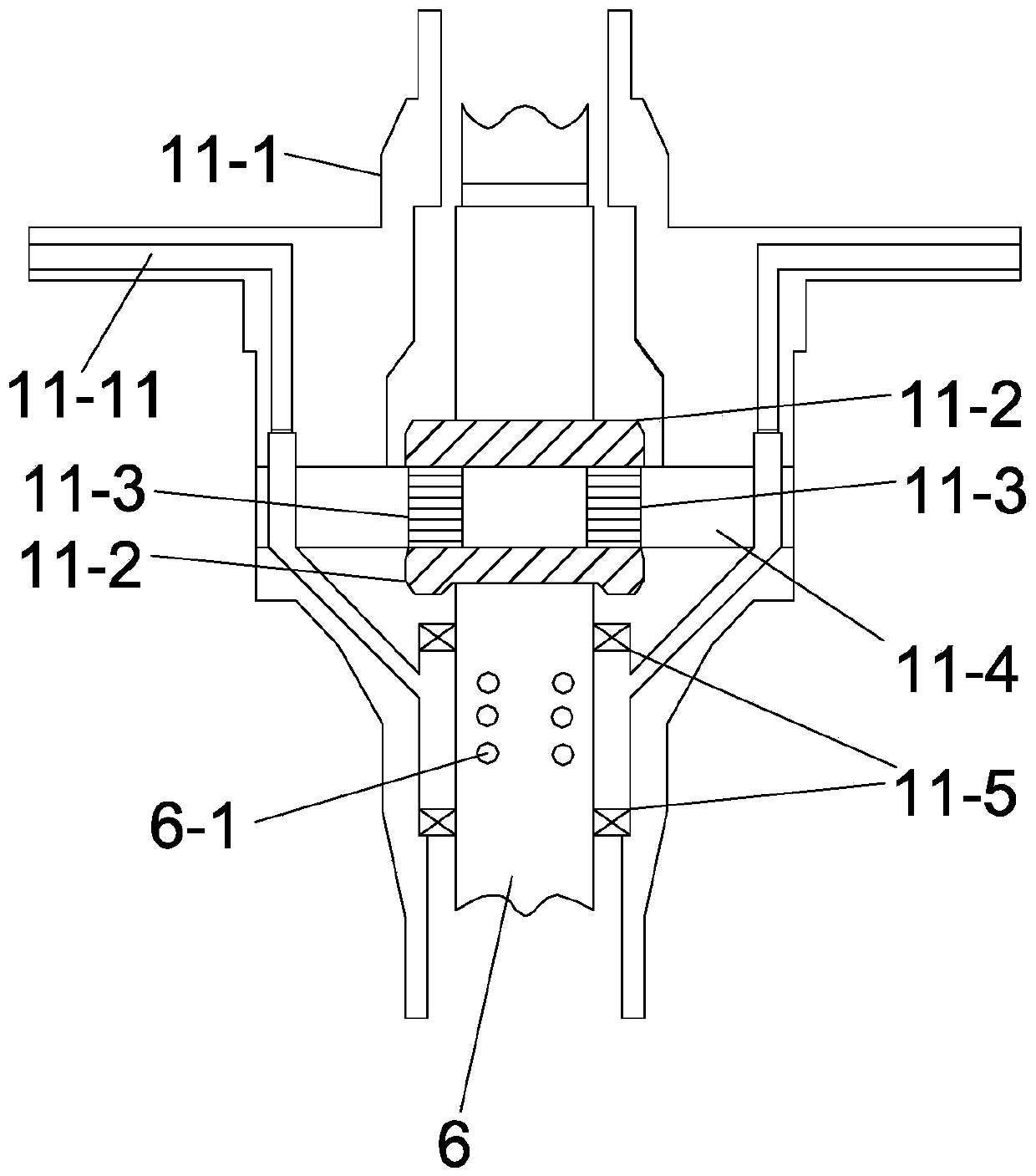

Apparatus for preparing synthesis gas based on dual fluidized bed biomass gasification and preparation method thereof

InactiveCN102977927AReduce outputHigh calorific valueBulk chemical productionGranular/pulverulent flues gasificationCycloneGas phase

The present invention discloses an apparatus for preparing synthesis gas based on dual fluidized bed biomass gasification, including a hopper, a dryer, a screw feeder, a pyrolysis fluidized bed, a reforming fluidized bed, a reforming cyclone separator, a calcination fluidized bed, a calcination cyclone separator, a first U-shaped refeeder, a second U-shaped refeeder and a third U-shaped refeeder. The method of the apparatus for preparing synthesis gas includes: feeding biomass into the hopper, feeding the dried biomass to the pyrolysis fluidized bed, pyrolyzing and gasifying, and feeding carbon residue into the calcination fluidized bed. In the calcination fluidized bed, the coke in solid residue is combusted with oxygen to decompose calcium carbonate. The products of gas phase and solid phase are separated by the calcination cyclone separator. The heat-carrying agent calcium oxide is fed into the reforming fluidized bed. The pyrolysis gas carries calcium oxide to increase to promote catalytic cracking of tar. The reformed gas is obtained by reforming the pyrolysis gas. The synthesis gas is obtained from a synthesis gas outlet. The apparatus for preparing synthesis gas can reduce the tar yield, and improve the synthesis gas heat value ?and gasification efficiency.

Owner:SOUTHEAST UNIV

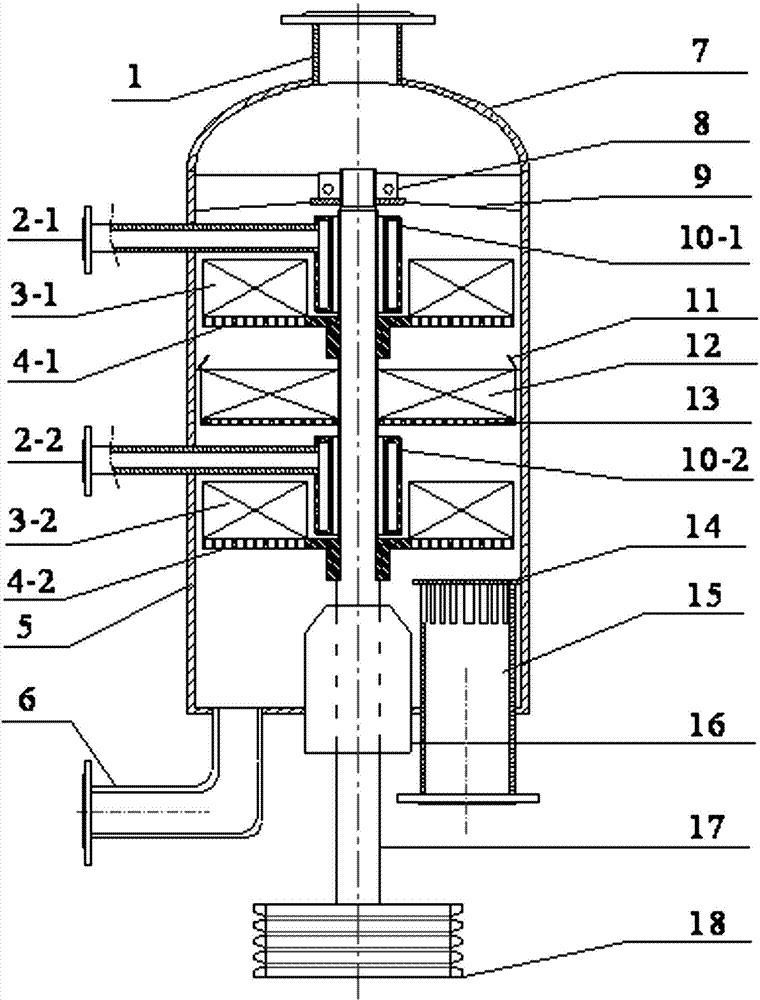

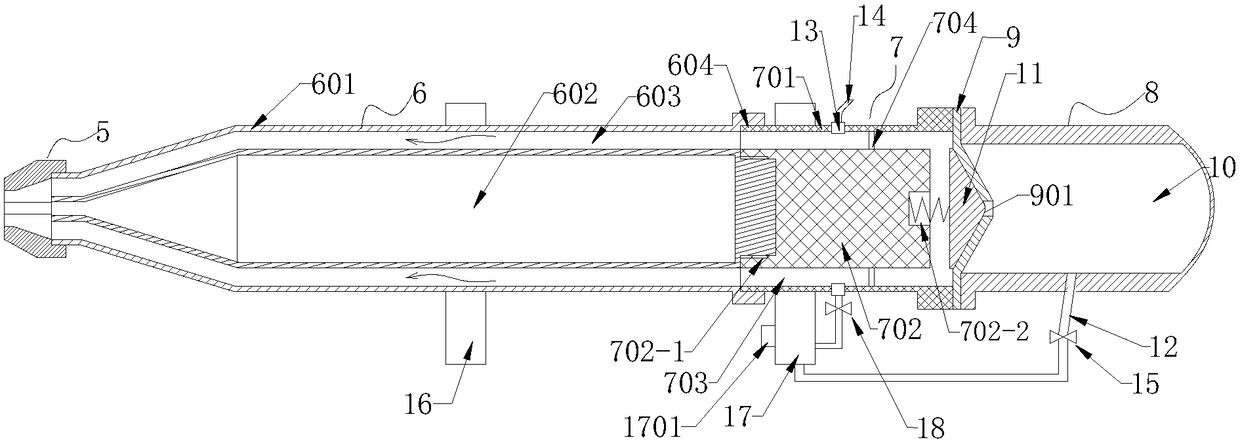

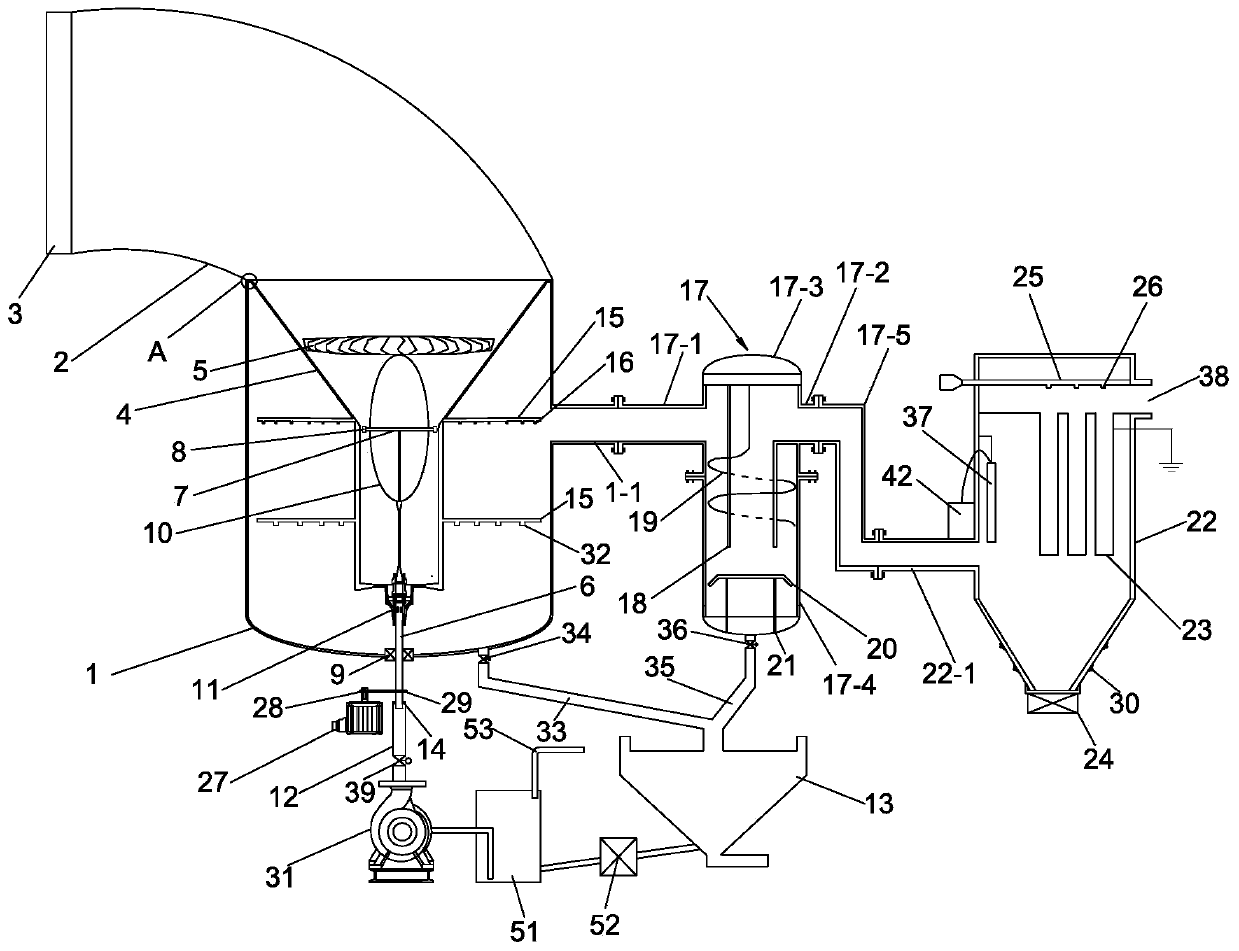

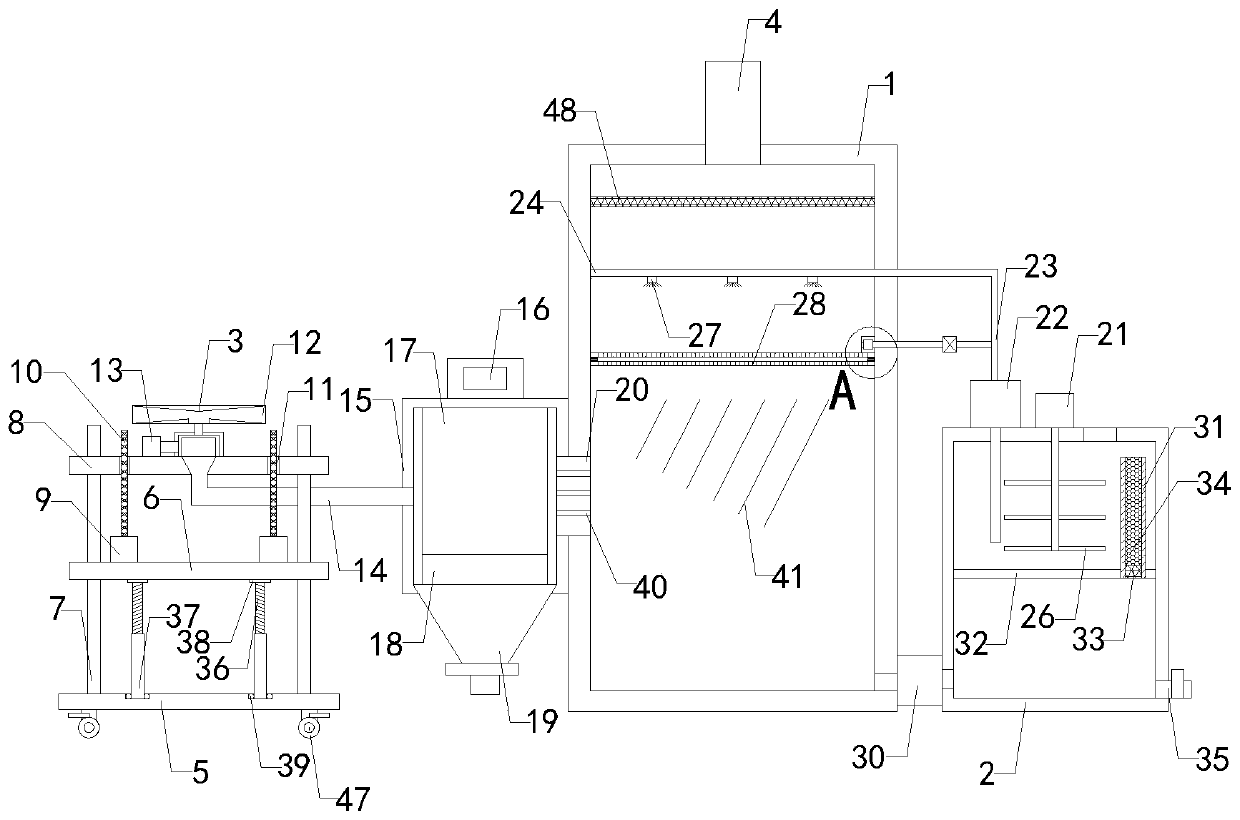

Flue gas desulfurization and dust removal technology and integrated apparatus applicable to ship

ActiveCN104492210AEnhanced mass transferIncrease capture rateCombination devicesGas treatmentFlue gasDust control

The invention belongs to the technology of flue gas desulfurization and dust removal, and in particular relates to a flue gas desulfurization and dust removal technology and an integrated device applicable to ships, and solves the problems in the flue gas desulphurization technology and equipment for ships of the prior art. The flue gas desulfurization and dust removal apparatus includes a multi-stage cross flow rotating packed bed, a barren liquor tank, a barren liquor circulating pump and an aeration tank. The flue gas desulfurization process includes an open seawater method flue gas desulphurization technology and a enclosed alkali method flue gas desulfurization technology. Two technologies can be combined with the rotating packed bed, and the invention has the advantages of high desulfurization efficiency, low energy consumption, simple process, low investment and operation cost, stable operation, convenient startup and shutdown, and integrated desulphurization and dust removal.

Owner:ZHONGBEI UNIV

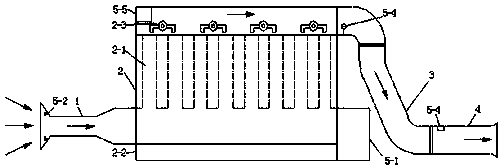

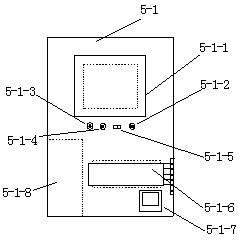

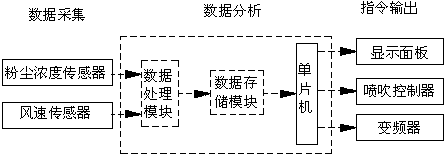

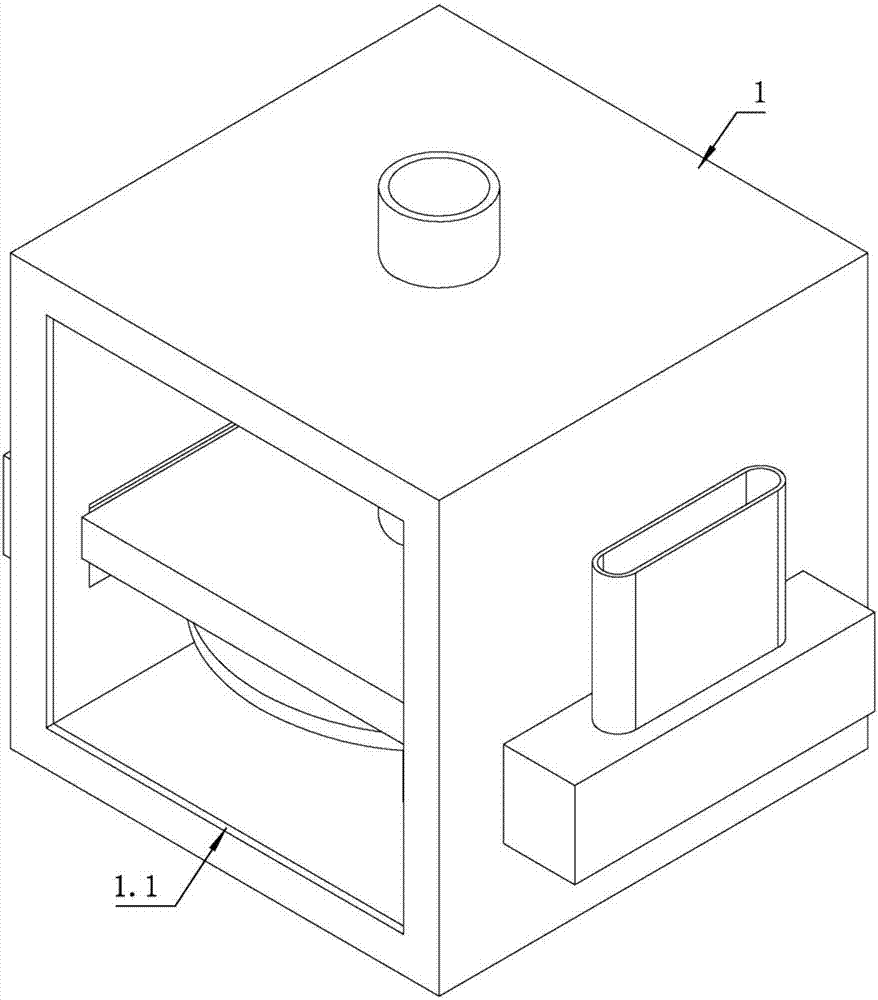

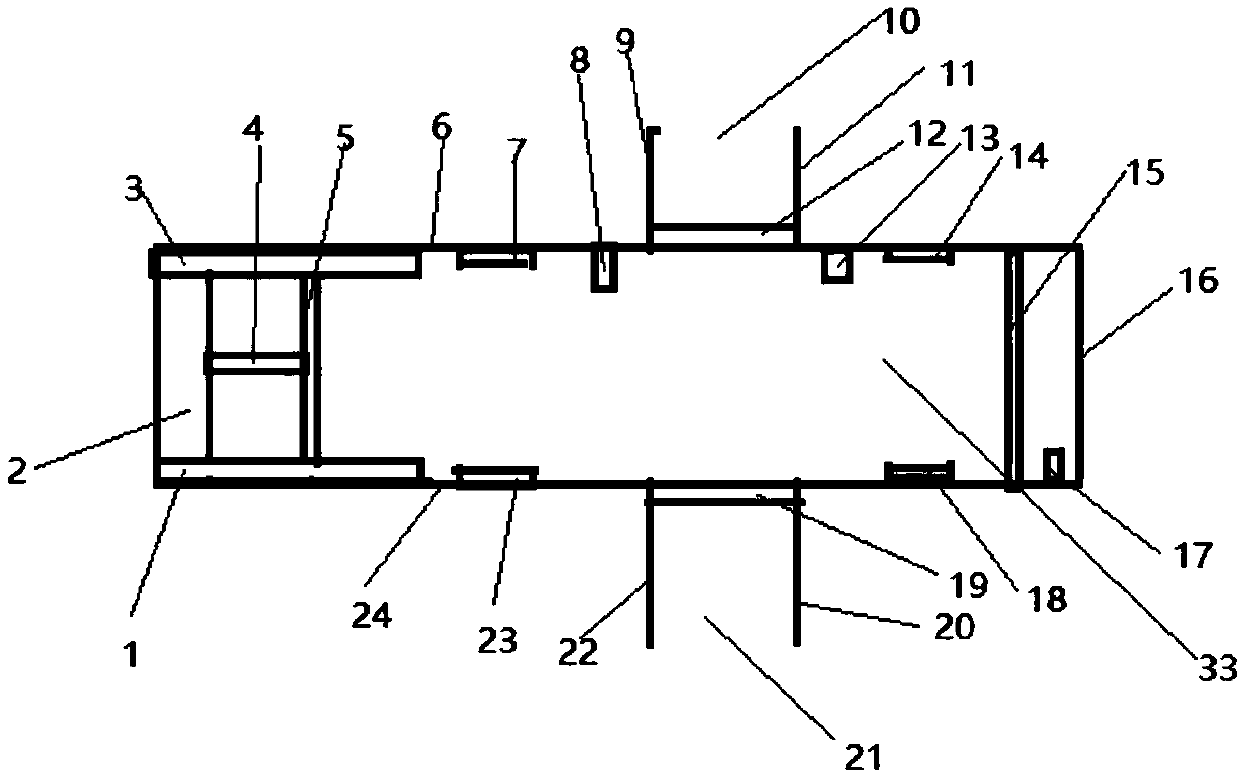

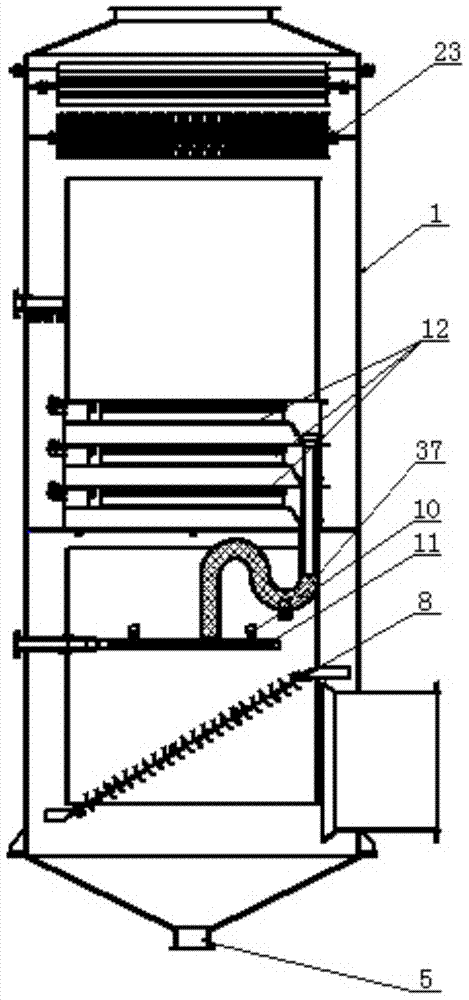

Integrated control system and integrated control method for mining dry dust remover

ActiveCN103830979AImprove dust filtration efficiencyOptimize the intake air volume of dust extractionDispersed particle filtrationControl systemEngineering

The invention discloses an integrated control system and an integrated control method for a mining dry dust remover. An air inlet device is arranged on one side of a dry dust removal box, a connecting cylinder, a fan and an integrated controller are sequentially connected to the other side of the dry dust removal box, a dust discharging box is arranged at the bottom of the dry dust removal box, and a filter cartridge is arranged in the dry dust removal box, wherein a pulse valve is connected to the upper part of the filter cartridge in the dry dust removal box; a blowing controller is connected to the upper end of the pulse valve; a dust concentration sensor is arranged at an inlet of the air inlet device; an air speed sensor is arranged at an outlet of the dry dust removal box; a frequency converter is arranged on the fan; the blowing controller is connected with the pulse valve; the dust concentration sensor and the air speed sensor are connected with the integrated controller through a wire, and transmits monitoring data to the integrated controller in real time. The system and the method have the advantages that the frequency of the fan can be automatically adjusted according to the dust concentration of an underground dust production operating site, the dust suction air inflow is optimized, and whether blowing dust removal operation is started is analyzed according to the air speed of the outlet of the dry dust removal box, so that the dust filtering efficiency of the filter cartridge is improved.

Owner:CHINA UNIV OF MINING & TECH +1

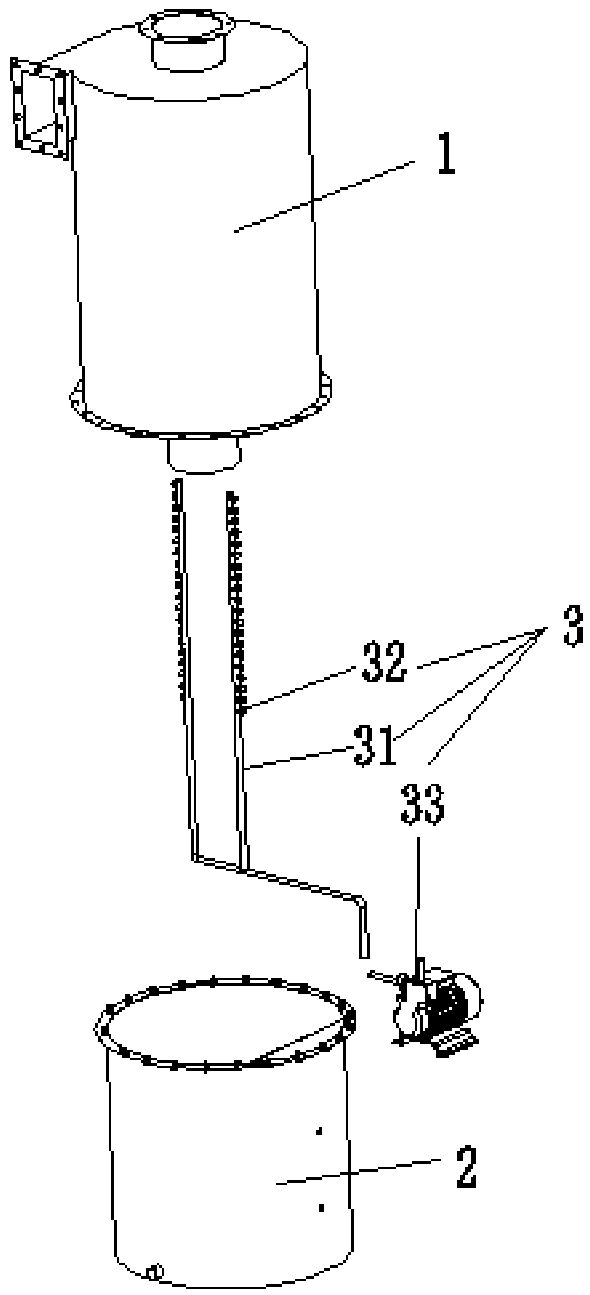

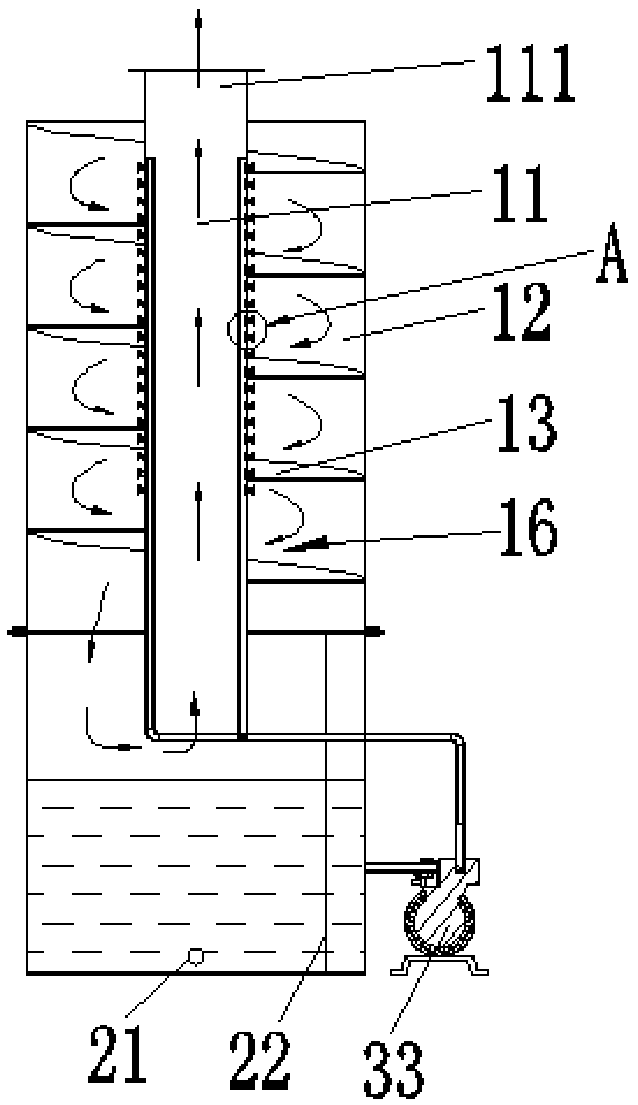

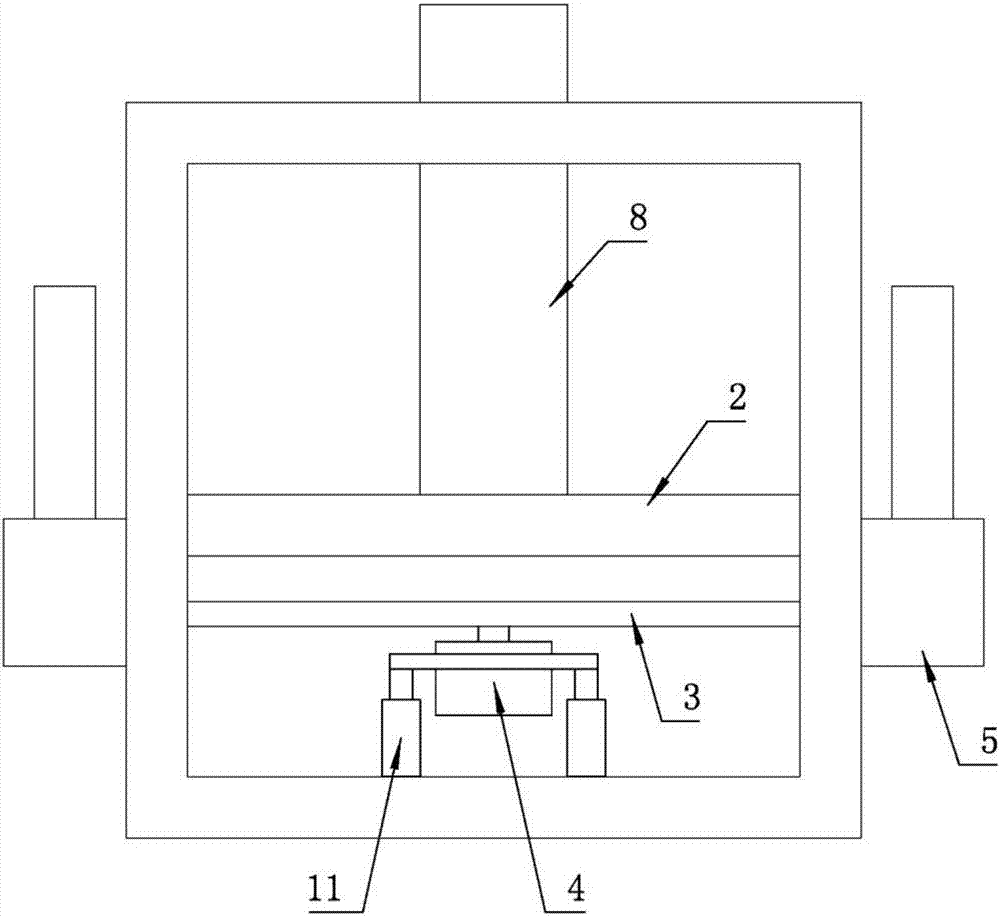

Wet dust removal device

PendingCN108905478AImprove dust removal rateExtended cycleCombination devicesSpray nozzleGas passing

The invention discloses a wet dust removal device. The wet dust removal device comprises an air duct tube and a spraying mechanism. The bottom of the air duct tube is connected to a water tank. The air duct tube is provided with an air outlet pipe. The inner wall of the air duct tube is provided with a spiral air duct blade. The inner wall of the air duct tube and the spiral air duct blade form aspiral air duct. The top of the spiral air duct is provided with an air inlet. The bottom of the spiral air duct is communicated with an air outlet tube. The spraying mechanism comprises multiple spray nozzles. The spray nozzles are installed at the middle shaft of the spiral air duct. Air flows through the spiral air duct and rotates in the spiral air duct, then the spraying mechanism sprays water mist so that dust in air contacts with water mist and then is spun down to the inner wall of the air duct tube under the action of a centrifugal force, and through the centrifugal force of multiplerings of the spiral air ducts, the dust in air is separated so that a dust removal rate is high.

Owner:佛山市华展舜业环保设备有限公司

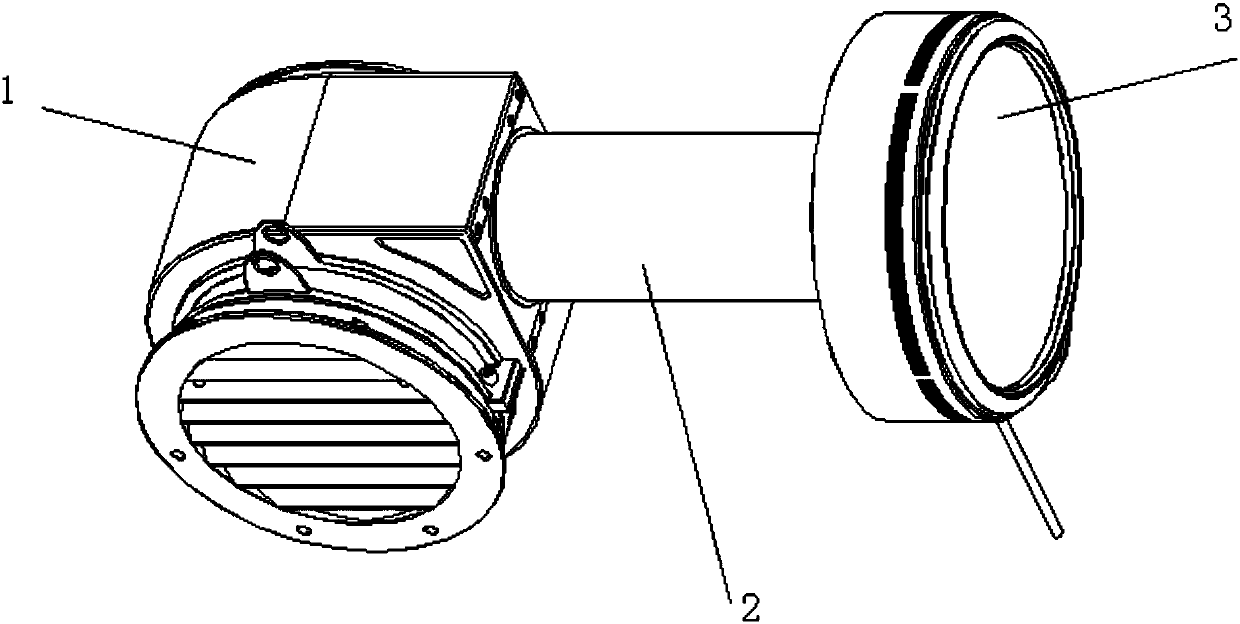

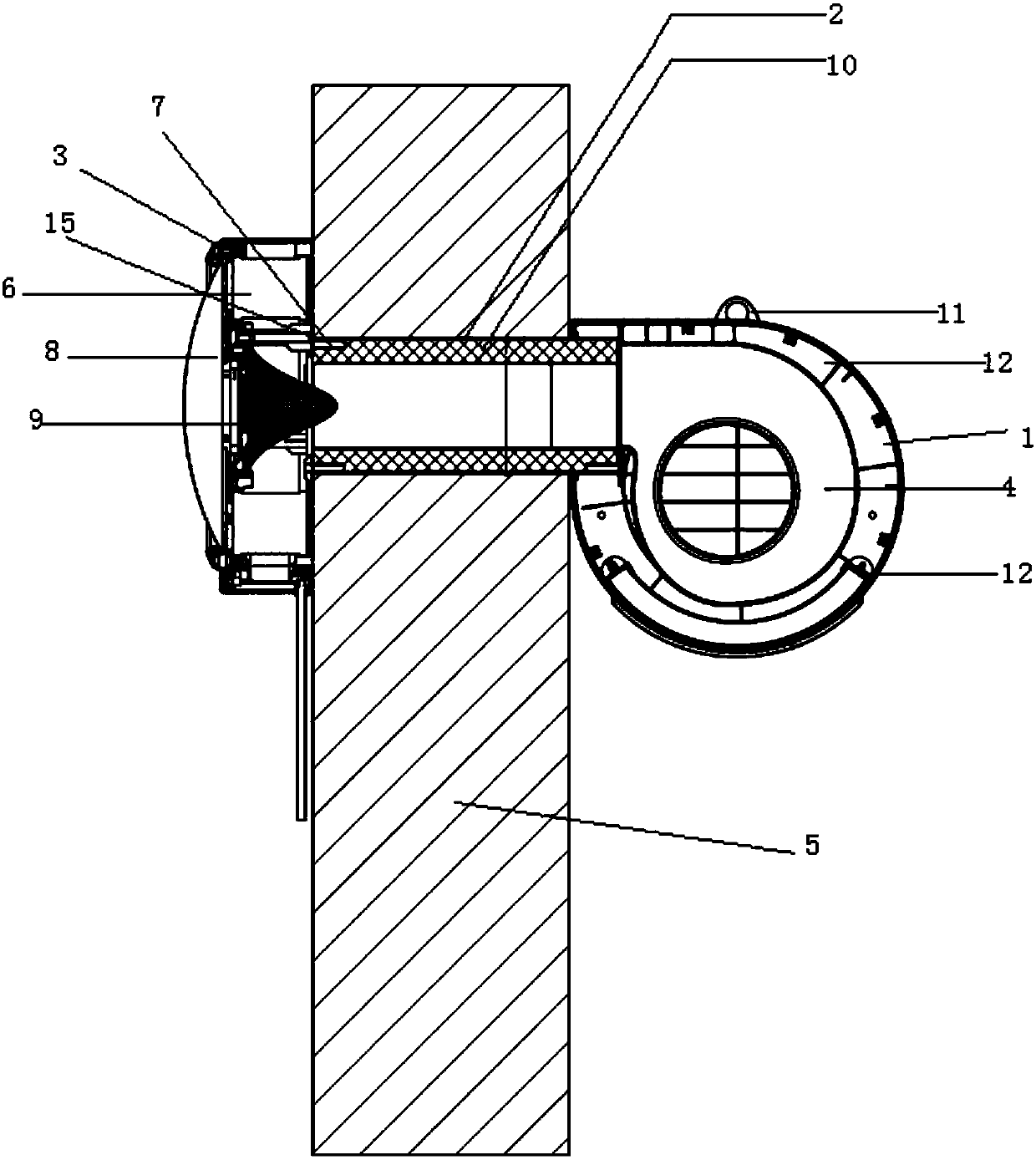

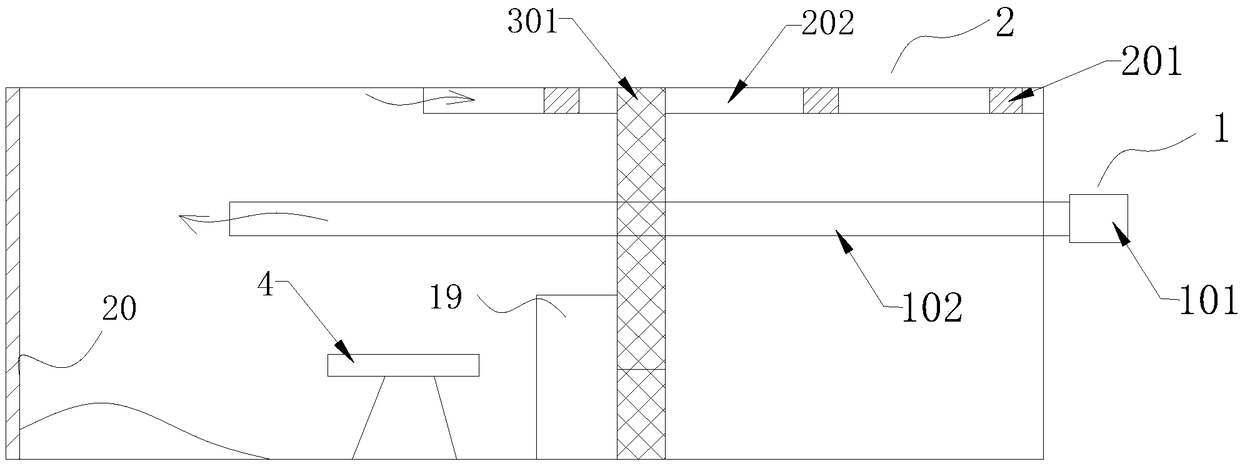

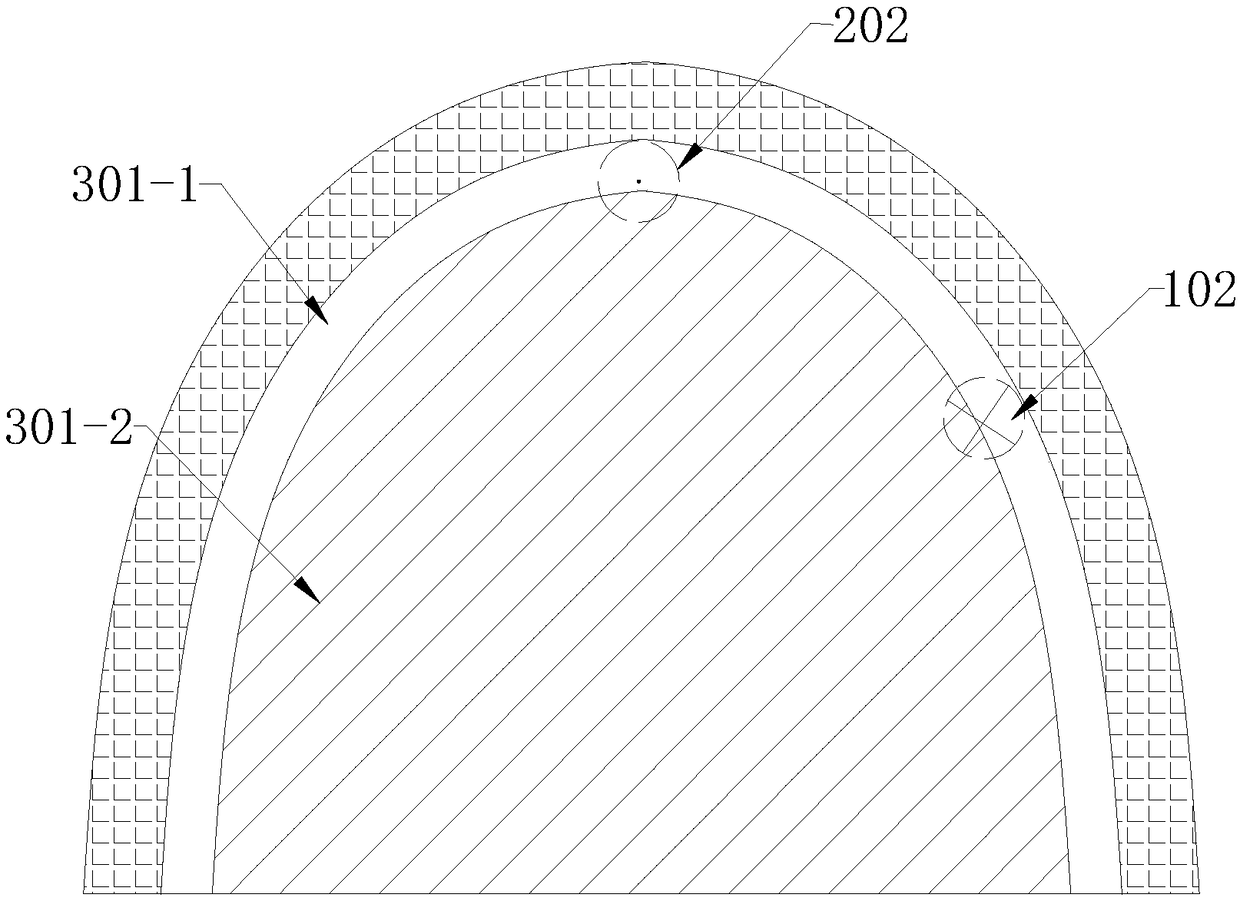

Fresh air system with indoor unit and outdoor unit of separated structure and mounting method

PendingCN107702266AReduce concentrationPrevent mildewLighting and heating apparatusNoise suppressionFresh airEnvironmental engineering

The invention discloses a fresh air system with an indoor unit and an outdoor unit of a separated structure and a mounting method. The fresh air system with the indoor unit and the outdoor unit of theseparated structure comprises a filter and a fan, and is characterized in that the fresh air system further comprises the indoor unit, the outdoor unit and a connecting pipe; the indoor unit is arranged indoors, the filter is arranged in the indoor unit, and a filter screen is arranged in the filter; the outdoor unit is arranged outdoors, and the fan is arranged in the outdoor unit; and the indoor unit and the outdoor unit are connected through the connecting pipe penetrating through a wall. According to the fresh air system with the indoor unit and the outdoor unit of the separated structure, the indoor unit and the outdoor unit are designed independently and connected through the connecting pipe, a noise source can be isolated through the wall, and thus a high-power fan can be adopted;noise can be effectively lowered, the air purification effect is good, and the fresh air system can be mounted conveniently and safely and fully meets the requirement for domestic air purification; and the filter screen is arranged in the indoor unit and thus can be replaced easily.

Owner:苏州纽塔克净化服务有限公司

Novel tunnel smoke and dust removal system device

PendingCN108442968AReasonable designPromote circulationDust removalFire preventionFresh airEngineering

The invention discloses a novel tunnel smoke and dust removal system device. The novel tunnel smoke and dust removal system device comprises a blowing-in mechanism, an air draft mechanism, a dust removal mechanism and an after-damp diffusion preventing mechanism. The dust removal mechanism comprises at least one automatic spraying device, and the automatic spraying device is arranged at a tunnel face. The after-damp diffusion preventing mechanism is located at a tunnel mouth and includes an isolation device. According to the novel tunnel smoke and dust removal system device, the design is reasonable, on-site equipment can be fully used, the blowing-in mechanism is matched with the air draft mechanism, the circulation of air in the tunnel is facilitated, exhaust gas can be discharged outwards in time, fresh air can enter into the tunnel, and the air quality in the tunnel is maintained; and the automatic spraying device is additionally arranged, the after-damp produced after blasting isprevented from diffusing into the air outside the tunnel, the after-damp and harmful gas particles are adsorbed and combined, and then settle to the ground, so that the dust removal rate is further improved.

Owner:广东矿发节能环保科技有限公司

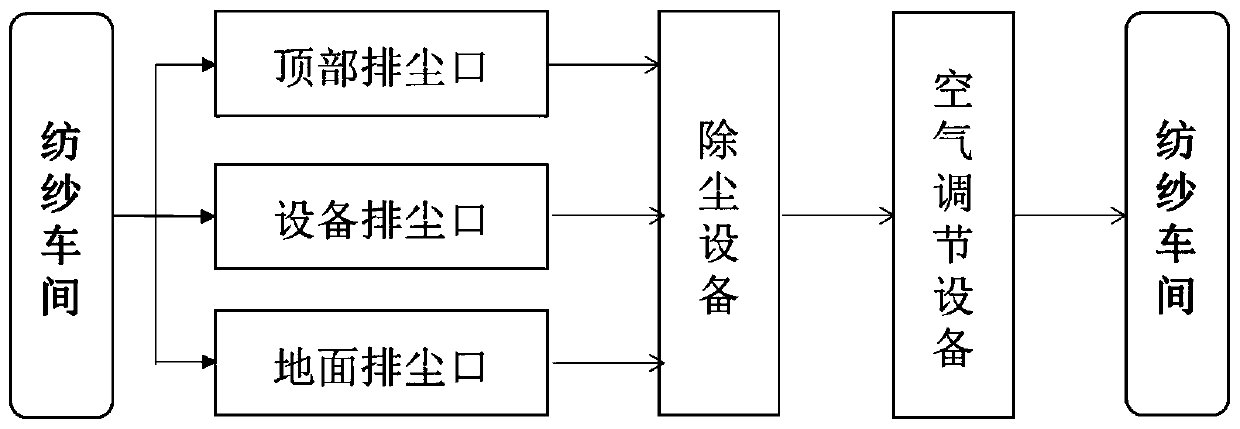

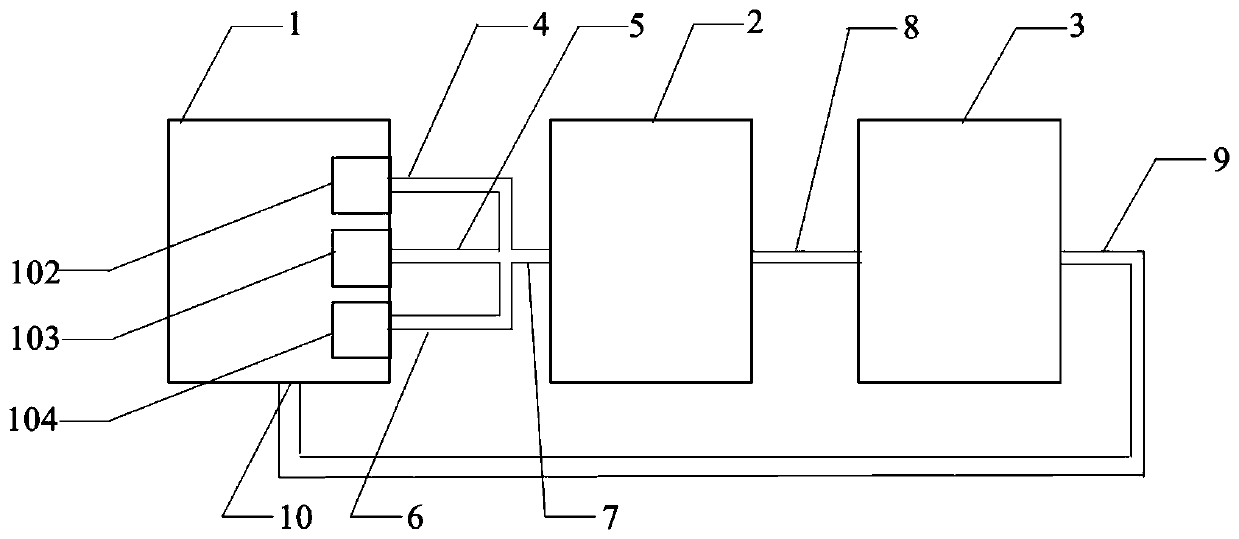

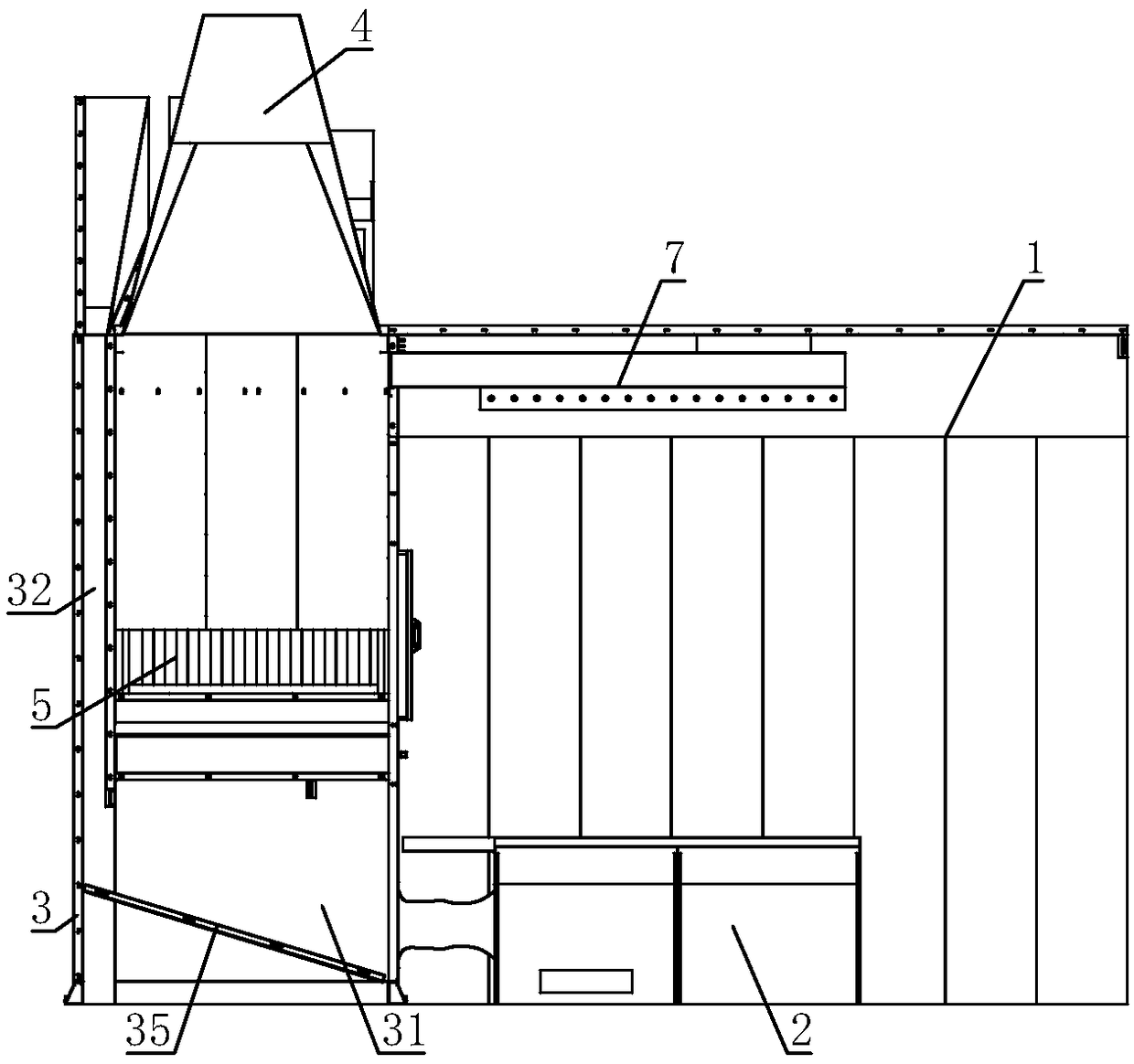

Intelligent dust removal system for spinning workshop

PendingCN110375393AReduce dust contentRealize all-round dust removal without dead endsMechanical apparatusLighting and heating apparatusFiberAir conditioning

The invention provides an intelligent dust removal system for a spinning workshop. The intelligent dust removal system comprises the spinning workshop, a dust removal chamber and an air conditioning chamber. A ground dust discharge port, an equipment dust discharge port and a workshop top dust discharge port are formed in the spinning workshop, and air inlets are formed in the top of the workshopand the position close to the ground. The dust removal chamber is provided with at least one piece of dust removal equipment, fibers or dust in the workshop enters the dust removal chamber through thedust discharge ports to be treated and recycled in the dust removal chamber, residual air enters the air conditioning chamber, and the air conditioning chamber is provided with air conditioning equipment capable of purifying the air and then introducing the air into the spinning workshop to be recycled. By means of the dust removal system, omnibearing dead-corner-free dust removal and purification of the workshop can be achieved, and the beneficial effects of being high in dust removal efficiency, low in energy consumption and free of pollution to the environment are achieved.

Owner:武汉裕大华纺织服装集团有限公司

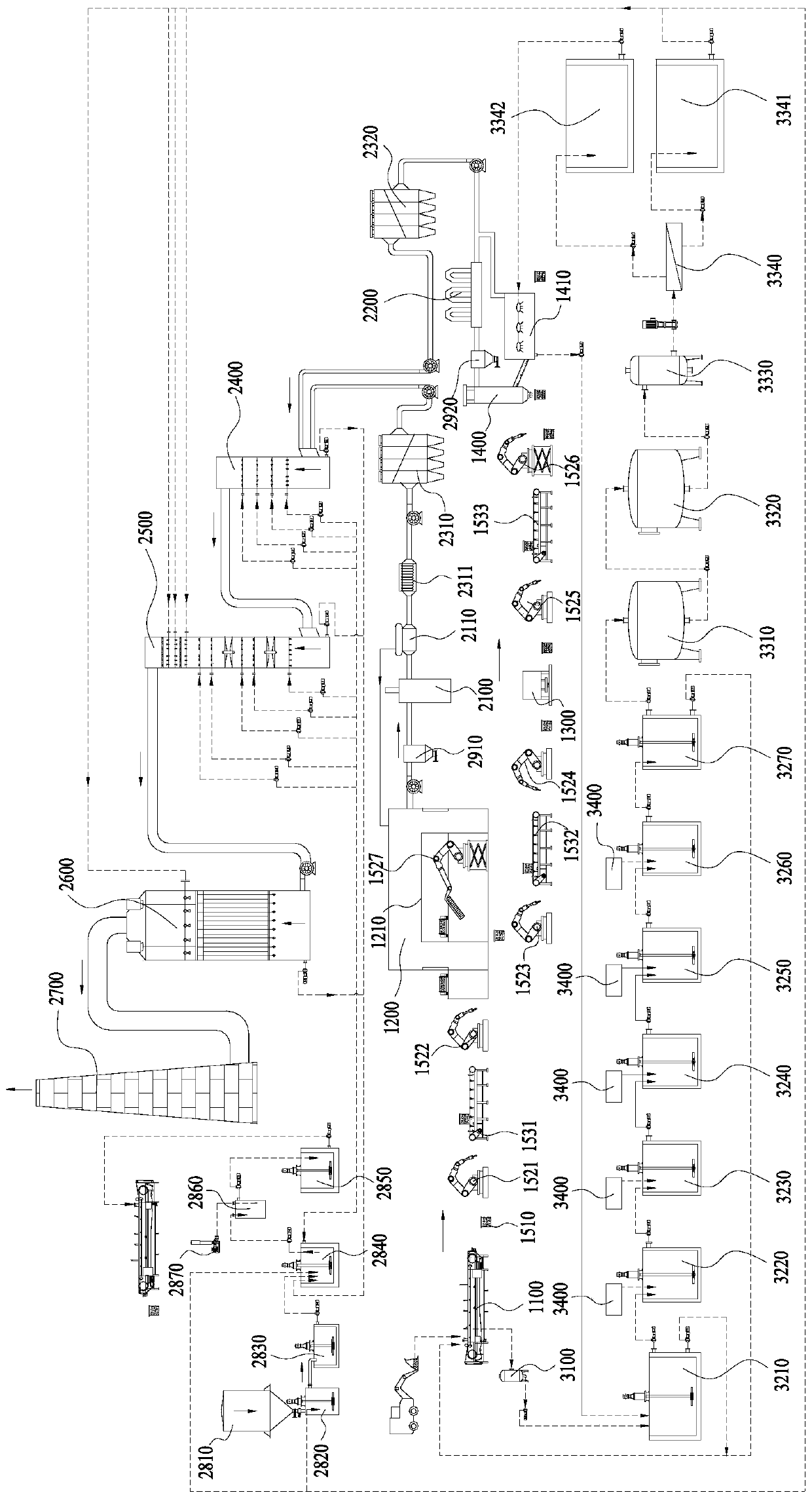

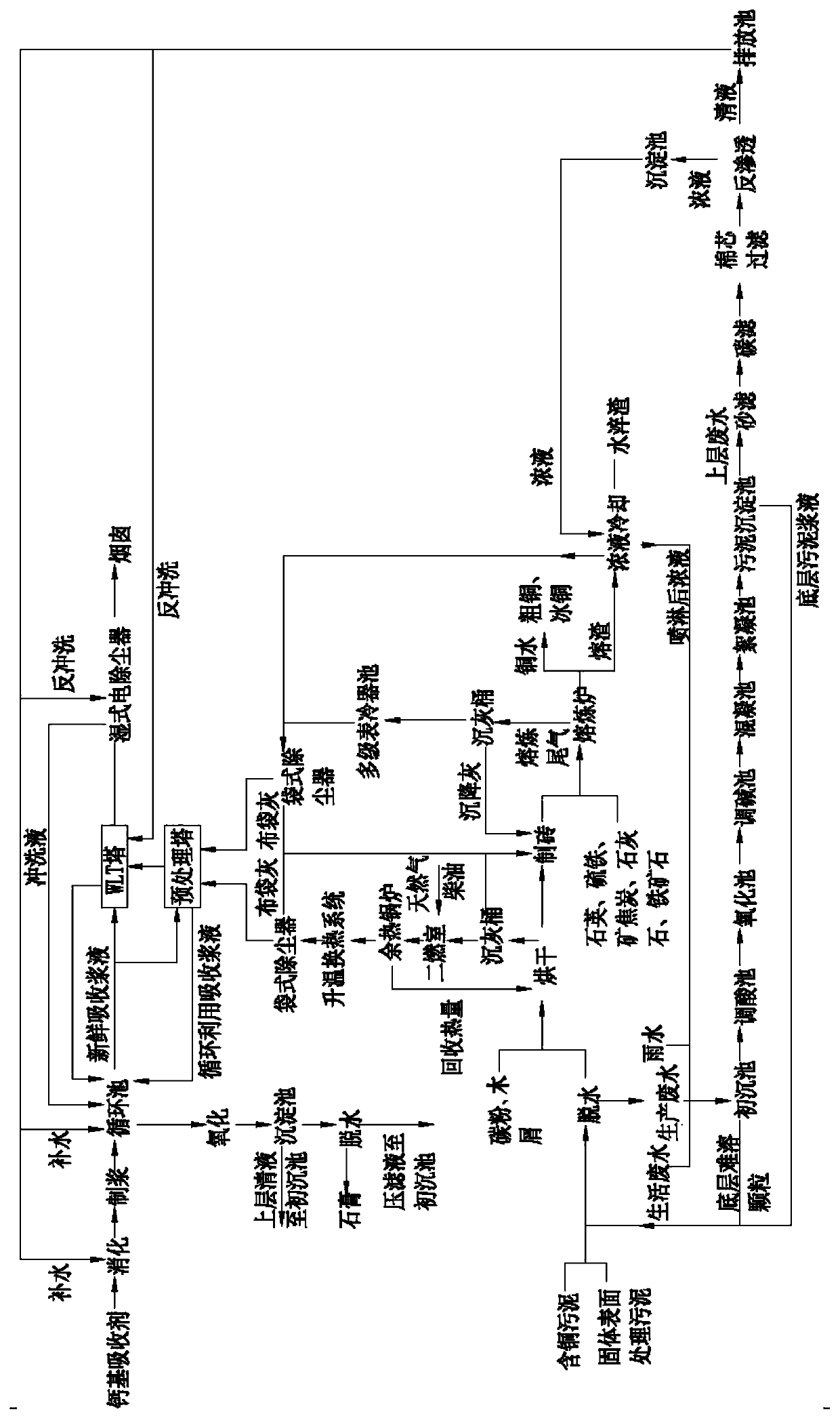

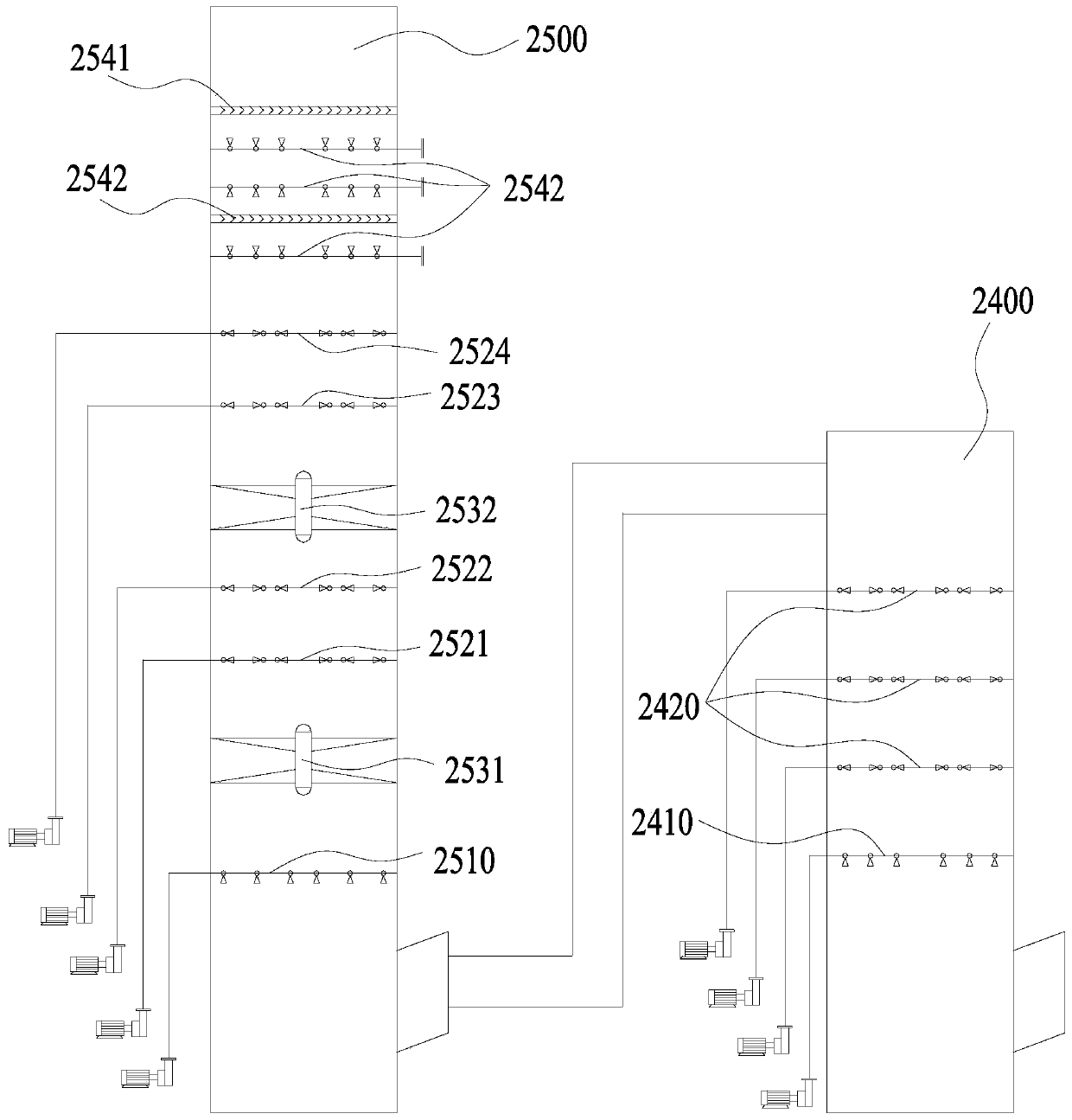

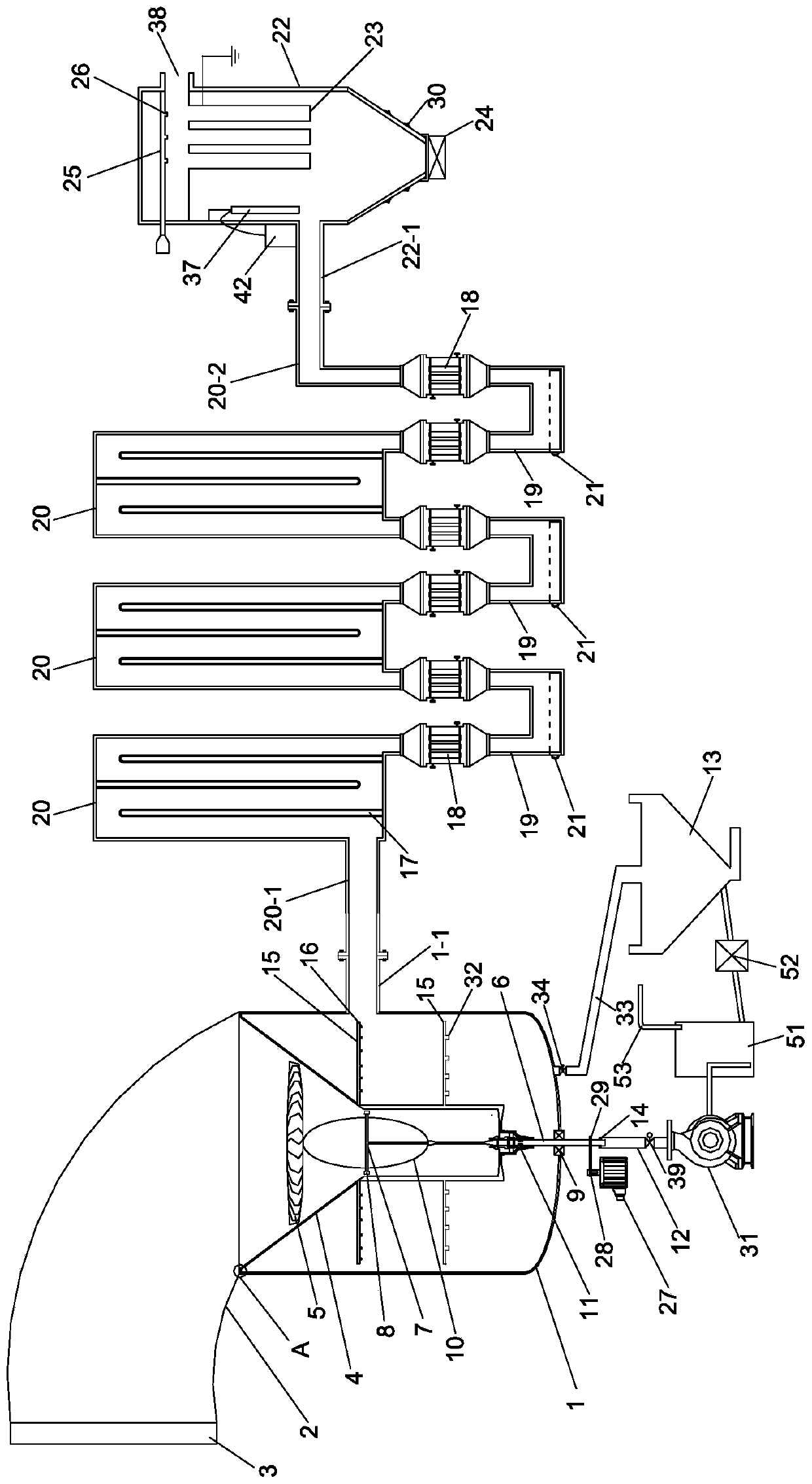

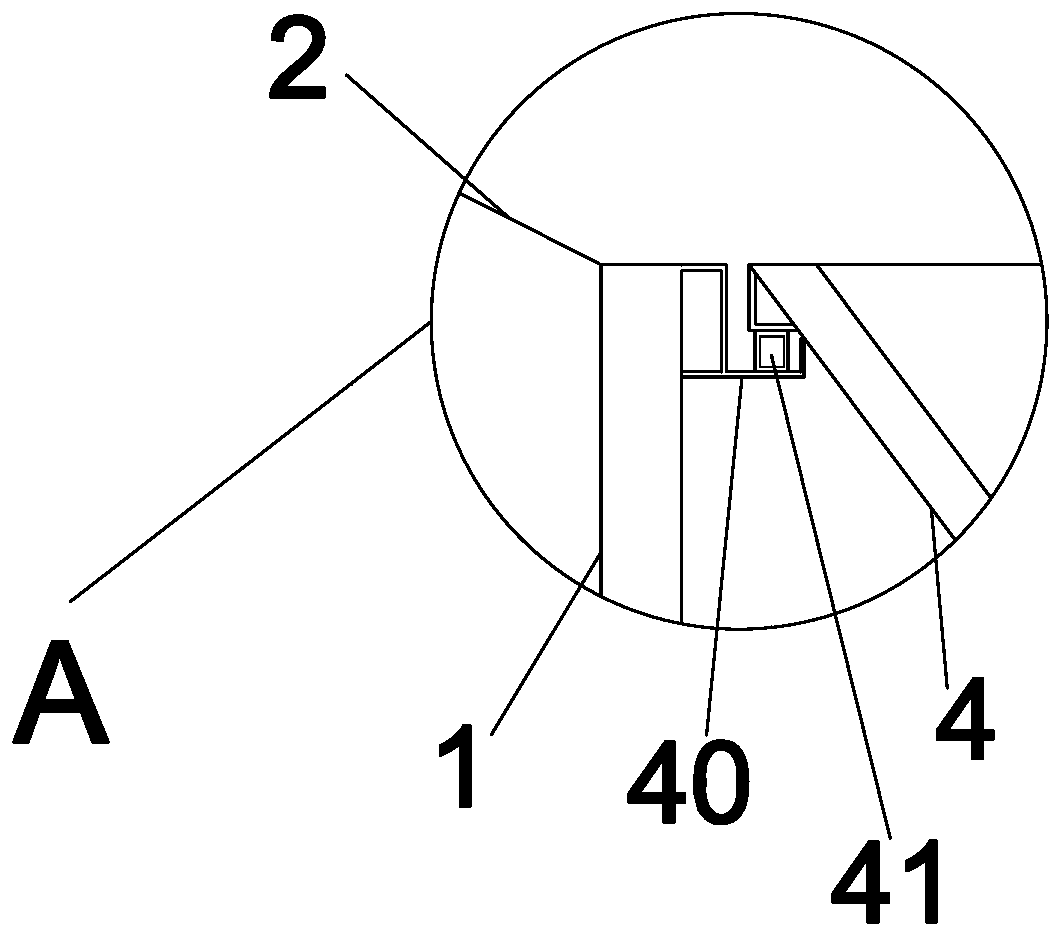

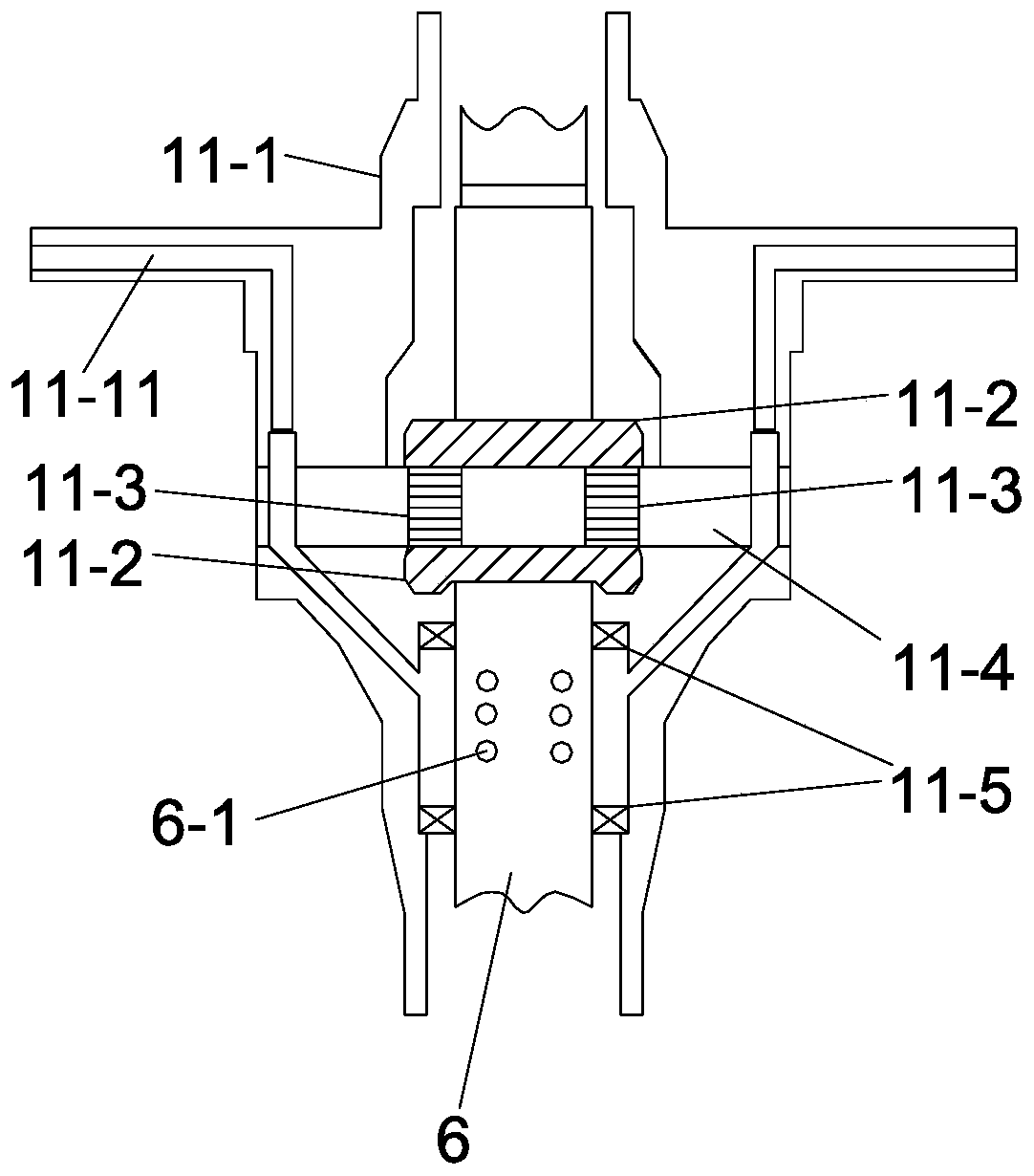

Comprehensive treatment system and method for three wastes of copper-containing industrial sludge

PendingCN110052106AContinuous smelting processConsistent dryingCombination devicesSludge treatment by de-watering/drying/thickeningGas phaseSludge

The invention relates to a comprehensive treatment system and method for three wastes of copper-containing industrial sludge, and belongs to the technical field of environmental protection. The treatment equipment comprises solid waste treatment equipment, waste gas treatment equipment and sewage treatment equipment, according to the comprehensive treatment system for the three wastes of the copper-containing industrial sludge, the solid waste treatment equipment, the waste gas treatment equipment and the sewage treatment equipment are matched, and purposes of reduction, hazard-free treatmentand recycling of the three wastes of hazardous waste sludge are achieved through a process capable of effectively carrying out comprehensive treatment on solid, liquid and gas phases of the hazardouswaste sludge containing heavy metal. In addition, by cooperation of a pretreatment tower and an absorption tower (WLT tower), waste gas is treated, while the desulfurization rate and the dust removalrate are increased, the bad property of flue gas is adjusted through the pretreatment tower, part of soot and sulfur dioxide are removed in advance, the smoke temperature is reduced, internal equipment of the subsequent WLT tower is protected, and the comprehensive treatment system has the advantage that the service life of the subsequent equipment is prolonged.

Owner:广东允诚再生资源有限公司

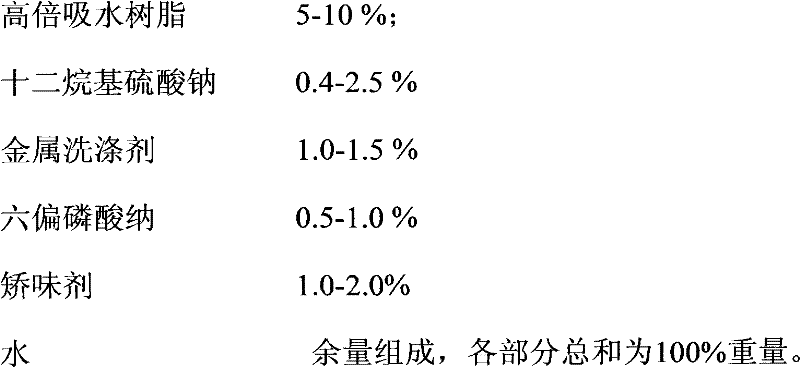

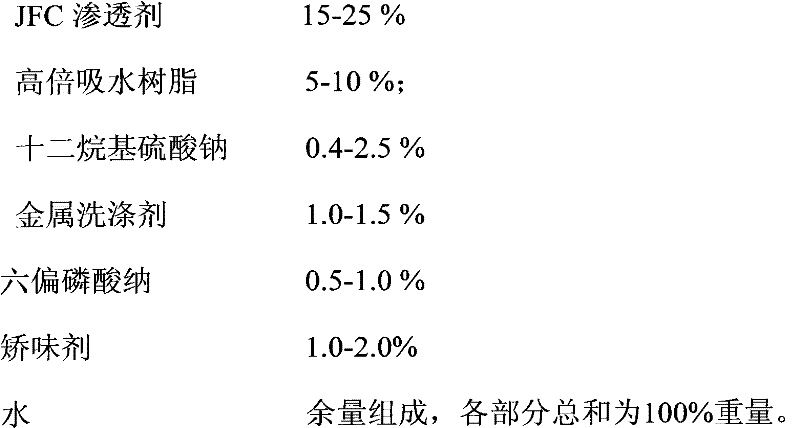

Mining high efficiency blister mud dedusting additive

InactiveCN102408875AStrong dust suppression abilityImprove dust removal rateOther chemical processesRespirable dustSolvent

Belonging to the field of blast mining, the invention specifically relates to a mining high efficiency blister mud dedusting additive, which is composed of 15-25% of a JFC penetrating agent, 5-10% of superabsorbent resin, 0.4-2.5% of sodium dodecyl sulfate, 1.0-1.5% of a metal washing agent, 0.5-1.0% of sodium hexametaphosphate, and the balance water. The additive is prepared by the steps of: first adding 5-10% of superabsorbent resin into a solvent and stirring them to form a homogeneous solution; then adding 15-25% of a JFC penetrating agent and 0.4-2.5% of sodium dodecyl sulfate into the above saturated solution in proportion; and adding 1.0-1.5% of a metal washing agent, 0.5-1.0% of sodium hexametaphosphate, and the balance water into the mixture, and continuing stirring for half an hour. With strong dedusting capability, the additive of the invention has a comprehensive dedusting rate up to over 80%, and the removing rate for respirable dust less than 5 micrometers can reach over 70%. Thus, the additive provided in the invention is suitable for dedusting in mine exploitation and stone removal, as well as coal mine explosion and exploitation.

Owner:韩林华

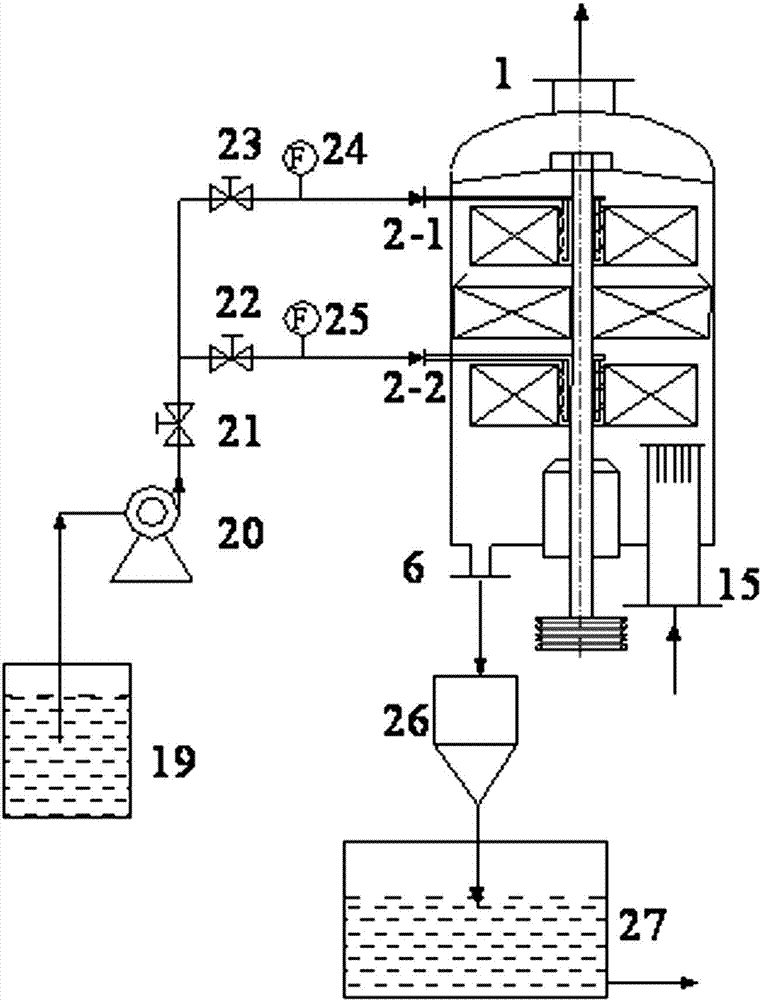

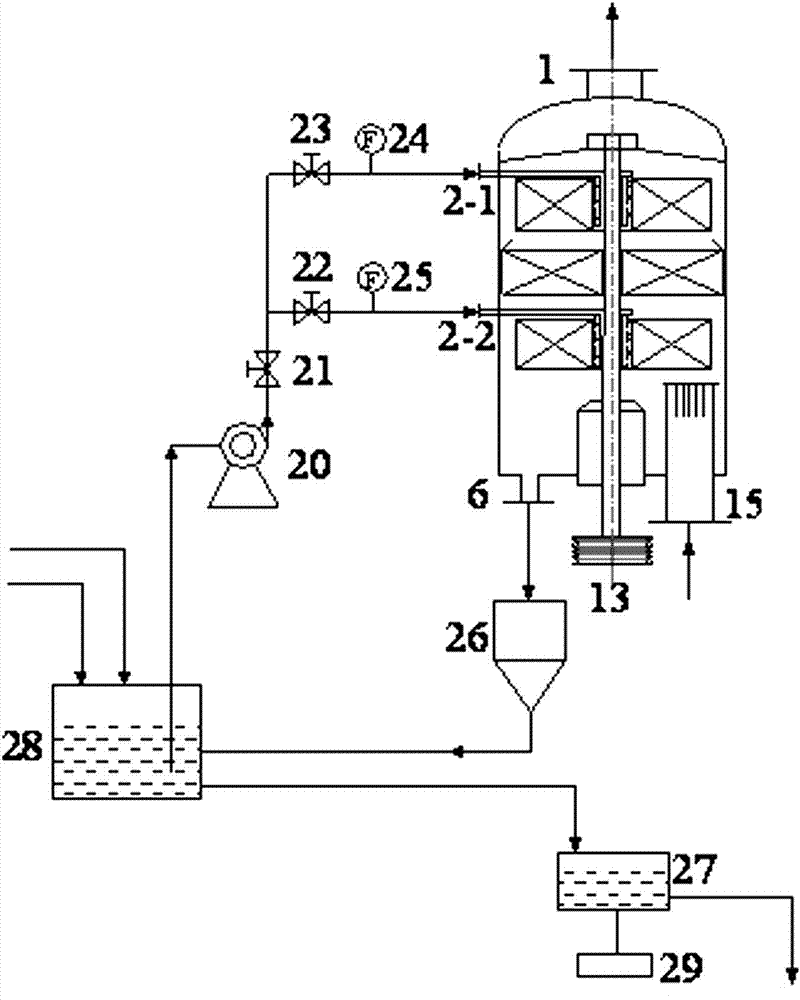

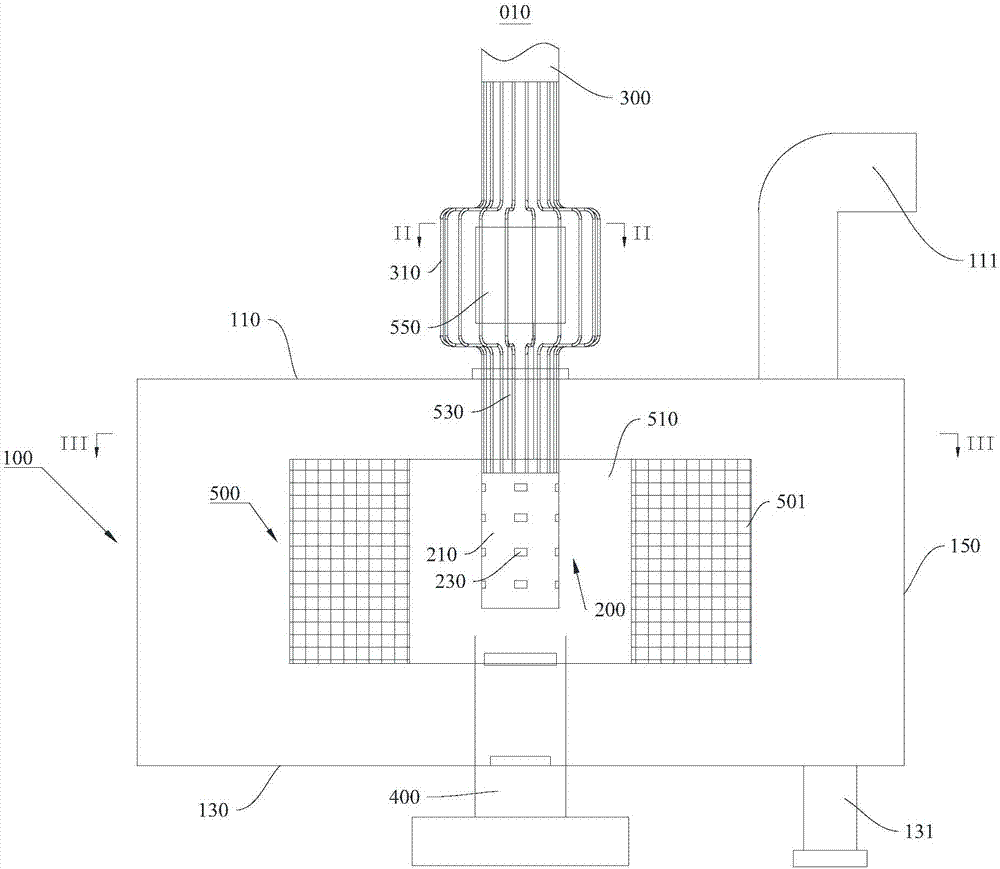

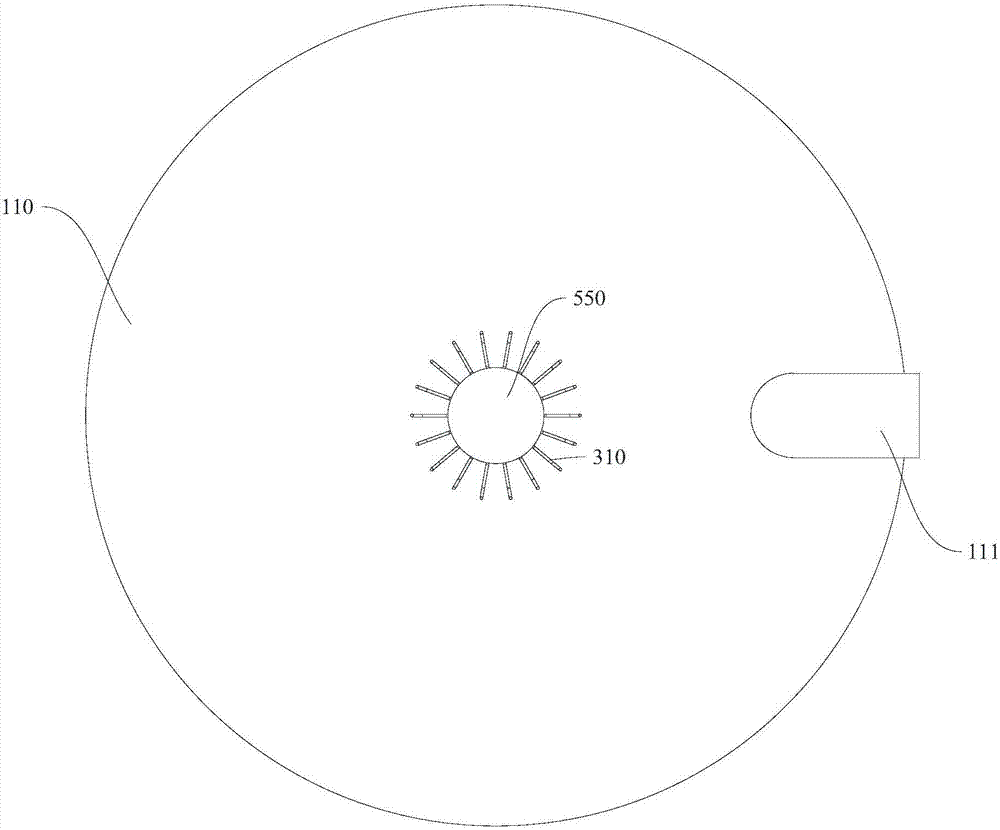

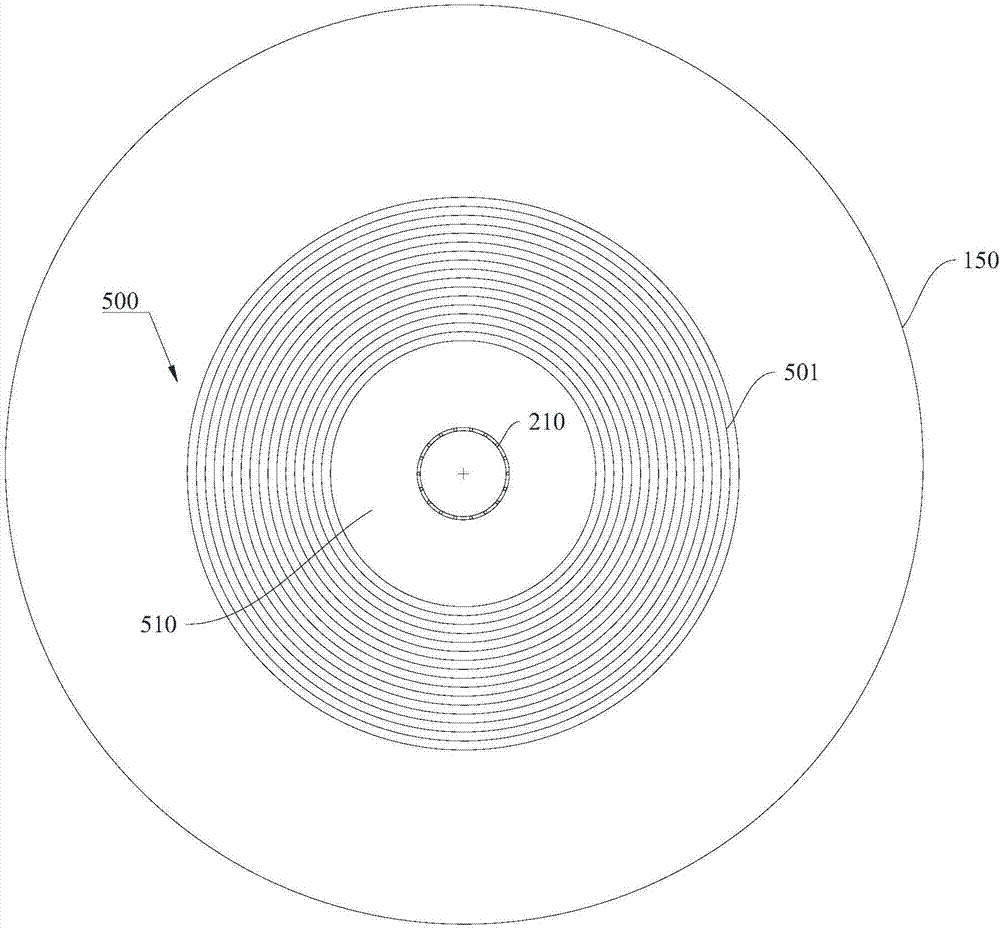

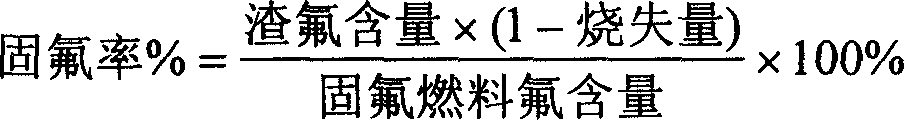

Supergravity waste gas treatment device, waste gas treatment circulating system and desulphurization and dust removal method

PendingCN106925101AImprove dust removal rateImprove desulfurization effectUsing liquid separation agentComing outFlue gas

The invention provides a supergravity waste gas treatment device, a waste gas treatment circulating system and a desulphurization and dust removal method, and belongs to the field of flue gas purification. The supergravity waste gas treatment device comprises an alkali liquor spray device, an alkali liquor delivery pipe used for alkali liquor input and a waste gas pipe used for waste gas input; the alkali liquor spray device comprises a center pipe and multiple spray through holes, the center pipe is connected with the alkali liquor delivery pipe, and the spray through holes are formed in the outer wall of the center pipe; a waste gas pipe outlet and the center pipe are coaxial. Waste gas coming out of the waste gas pipe is subjected to first dust removal and desulphurization directly through an atomization area formed by the alkali liquor spray device, and the very high efficiency is achieved. The waste gas treatment circulating system comprises the supergravity waste gas treatment device and an alkali liquor circulation part, by means of circulating utilization of alkali liquor the cost is reduced, and the automation level is improved.

Owner:YANCHENG INST OF TECH

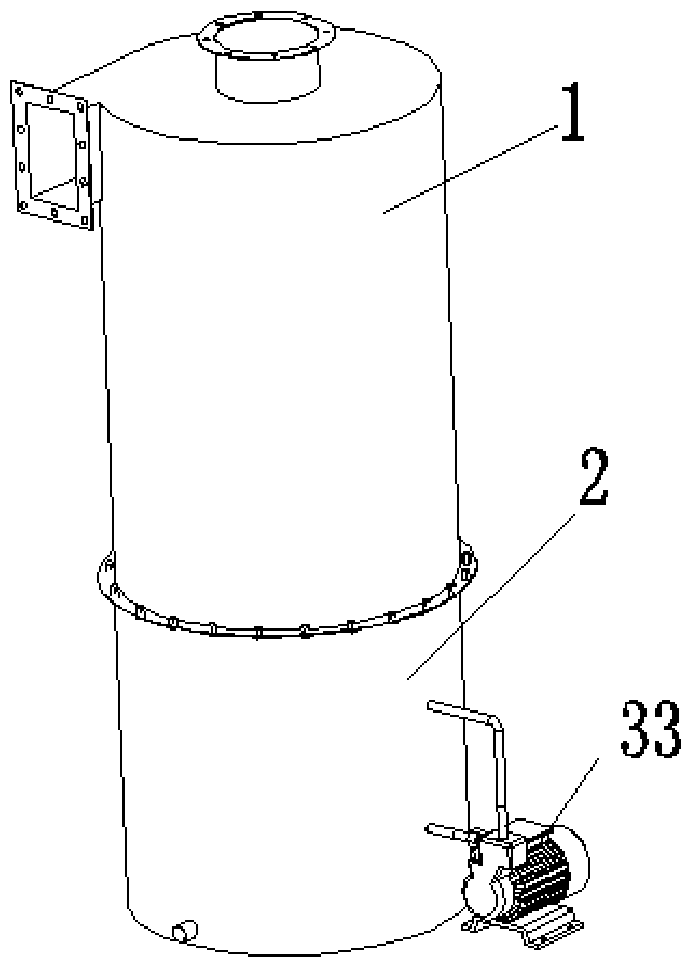

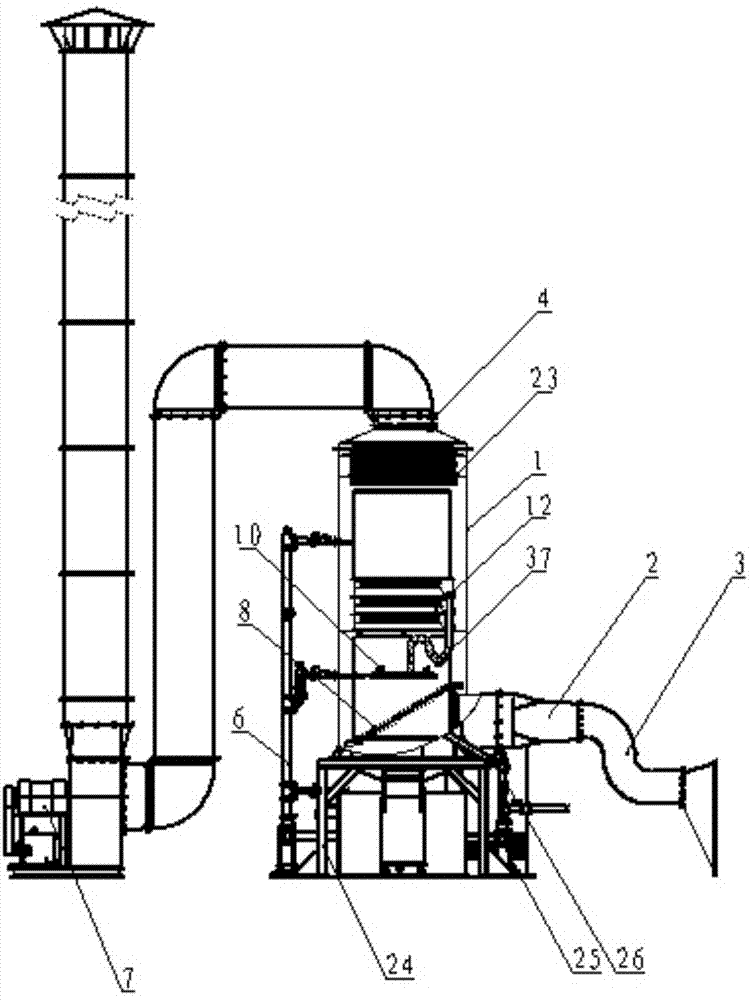

A washing type flue dust collector having a high dust collection efficiency

InactiveCN104606986AImprove dust removal rateUsing liquid separation agentSeparation devicesFlueEngineering

The invention relates to a washing type flue dust collector having a high dust collection efficiency. The flue dust collector comprises a cylinder. The top of the cylinder is provided with a gas outlet. The upper part of the inner cavity of the cylinder is provided with a demister. A spraying pipe is disposed below the demister. The side wall of the cylinder, which is below the spraying pipe, is provided with a gas inlet. One end of the spraying pipe is fixed to the inner side wall of the cylinder, and the other end of the spraying pipe penetrates the side wall of the cylinder and protrudes outside. The lower side of the spraying pipe in the cylinder is evenly provided with spraying heads. The spraying pipe outside the cylinder is connected to a water tank through a pipeline. The pipeline is provided with a water pump. The flue dust collector is characterized in that: the bottom of the cylinder is provided with a washing chamber, the bottom of the washing chamber is provided with a sewage draining outlet, and the sewage draining outlet is provided with a valve. A gas feeding pipe is provided at the gas inlet. One end of the gas feeding pipe is outside the cylinder, and the other end of the gas feeding pipe penetrates to a position below the liquid surface in the washing chamber. At least two baffle plates are disposed in the inner cavity of the cylinder below the spraying pipe from top to bottom. During dust collection, the stay time of dust containing gas in the cylinder is long, and the dust collection efficiency is high.

Owner:WUXI CITY NANCHANG DISTRICT TECH INNOVATIONSERVICE CENT

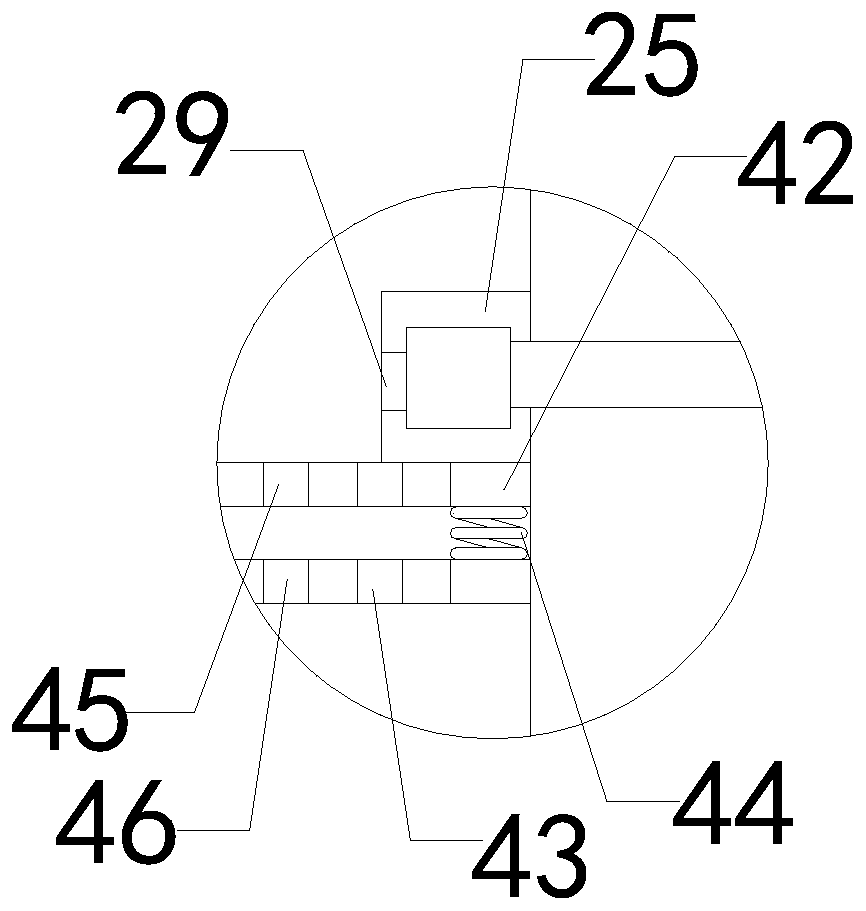

Chip dust removal device

The invention discloses a device for chip dust removal, which comprises a box body, the front side of the box body is open and a box door is arranged at the opening; it also includes: an air pump; a disc nozzle, which is arranged in the box; In the box; the turntable is rotatably set in the box driven by the motor; the dust collection room is set outside the two sides of the box body; the fan is set in the dust collection room; the lower clip is set on the turntable; the upper clip a bar, adjustably positioned above the lower bar; a bolt, with a threaded section that secures the lower bar and a non-threaded section that slidably connects the upper bar; a clamping spring, one end connected to the upper bar and the other end connected to the bolt to The chip is clamped between the upper clamping bar and the lower clamping bar; the disc nozzle is connected to the air pump and is located on the upper side of the turntable and is set facing the turntable; the box body is communicated with the dust collection room, and the dust collection room has an air outlet pipe. The invention has the beneficial effect that the chips are blown by the high-pressure airflow, and the dust removal process does not generate any loss to ensure a high dust removal rate.

Owner:江苏芯力特电子科技有限公司

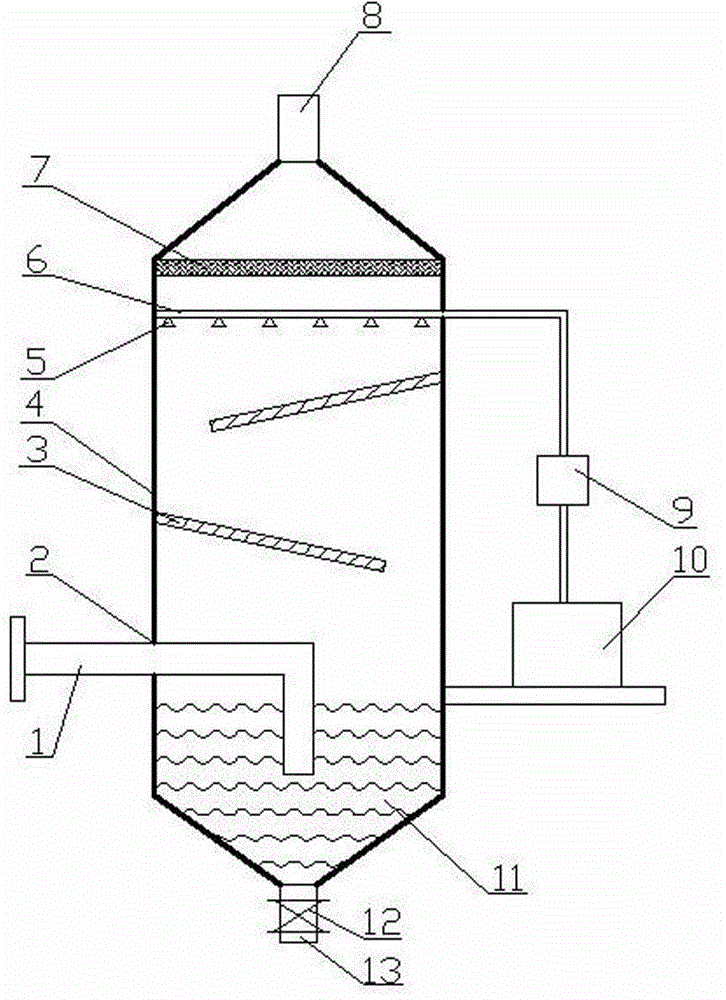

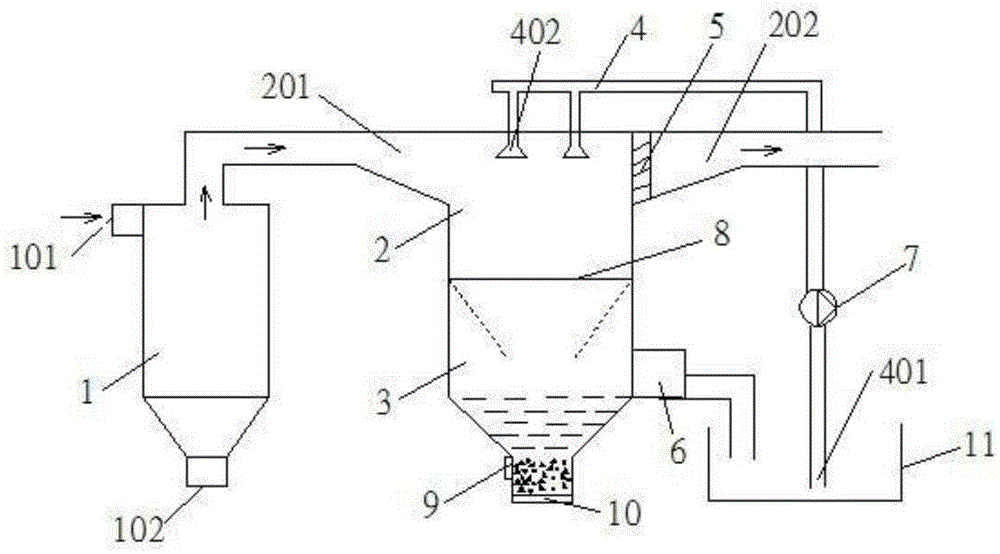

Waste gas dedusting device and method for tunnel kiln

The invention relates to a waste gas dedusting device and method for a tunnel kiln. The dedusting device comprises a cyclone separator for performing primary dedusting on waste gas, a spraying chamber and a dust collection chamber, wherein the spraying chamber is connected with the cyclone separator and used for performing secondary dedusting on the waste gas; the dust collection chamber is arranged at the lower end of the spraying chamber, communicated with the spraying chamber and used for concentrated treatment of secondary dedusting dust; a waste gas inlet, a primary dedusting dust discharge port and a primary dedusting waste gas outlet are formed in the cyclone separator; an atomization sprayer for performing spraying dedusting on primary waste gas, a primary dedusting waste gas inlet and a secondary dedusting waste gas outlet are formed in the spraying chamber; an inlet channel and an outlet channel which extend obliquely towards the dust collection chamber are formed in the primary dedusting waste gas inlet and the secondary dedusting waste gas outlet of the spraying chamber respectively. The dedusting method comprises primary dedusting by the cyclone separator and secondary dedusting by the atomization sprayer. The cyclone separator and the atomization sprayer are combined for use, dust falling is specifically performed on dust in the waste gas, and the dedusting effect is excellent.

Owner:盐城易动科技服务有限公司

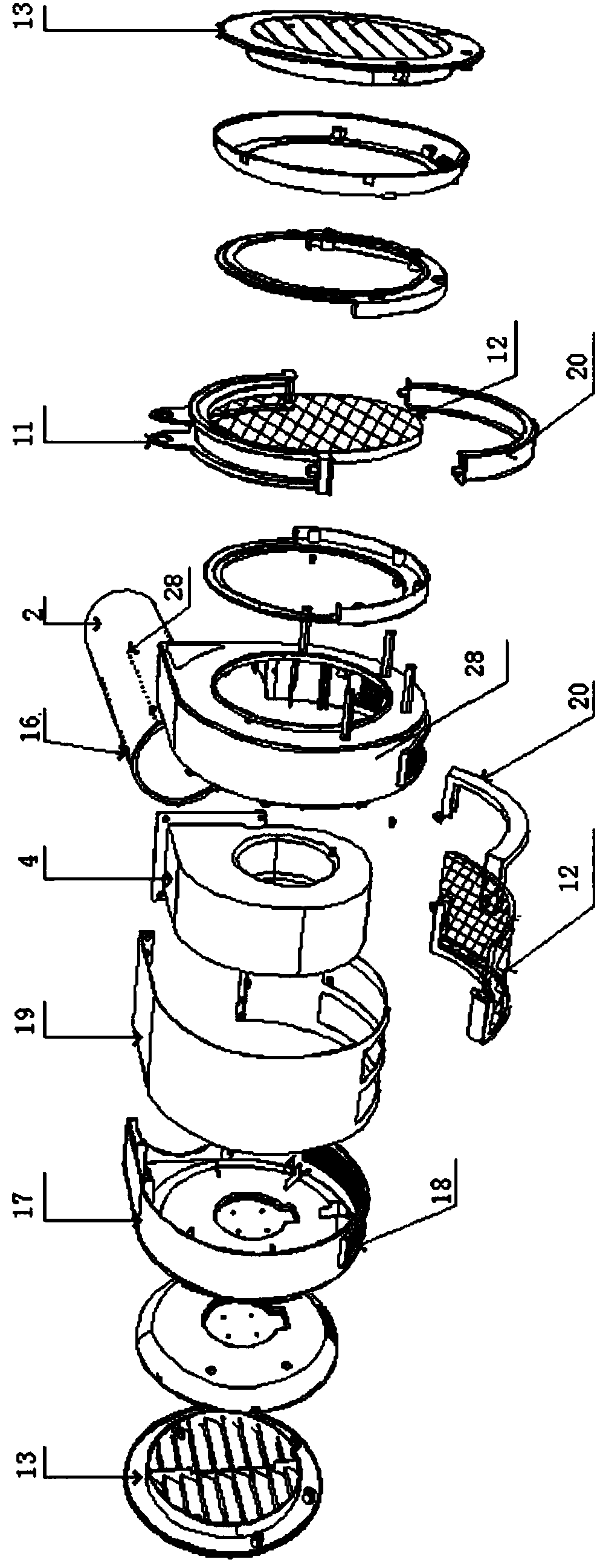

Multistage combined tunnel dust removal system and dust removal method thereof

ActiveCN109915196ARealize the purpose of multi-stage joint dust removalImprove dust removal rateDust removalFire preventionWater storageThree stage

The invention discloses a multi-stage combined tunnel dust removal system and a dust removal method thereof. The dust removal system comprises a first-stage dust removal device, a second-stage dust removal device, a third-stage dust removal device, a sedimentation filter tank and a water storage device, the first-stage dust removal device comprises a first-stage dust removal outer barrel, an air inlet barrel and a rotary dust removal mechanism; an air inlet grid is arranged at an inlet of the air inlet barrel; the rotary dust removal mechanism comprises a first-stage dust removal inner barrel,a turbofan, a water mist spraying mechanism and a rotary power transmission mechanism; the second-stage dust removal device comprises a second-stage dust removal cylinder, a U-shaped pipe and a tubenest type condenser; the three-stage dust removal device comprises a three-stage dust removal cylinder, a corona electrode, a filter bag type dust remover and a rectification power supply, the filterbag type dust remover comprises a dust removal framework and a dust removal filter bag, a blowback pipe is arranged in the three-stage dust removal cylinder, and a plurality of pulse blowback valves are arranged on the blowback pipe. The dust removal system is novel and reasonable in design, convenient to implement, capable of efficiently removing dust generated in tunnel construction and reducingharm to human beings, high in practicability, good in using effect and convenient to popularize and use.

Owner:XIAN UNIV OF SCI & TECH

Air dust removal device for radiator and harvester

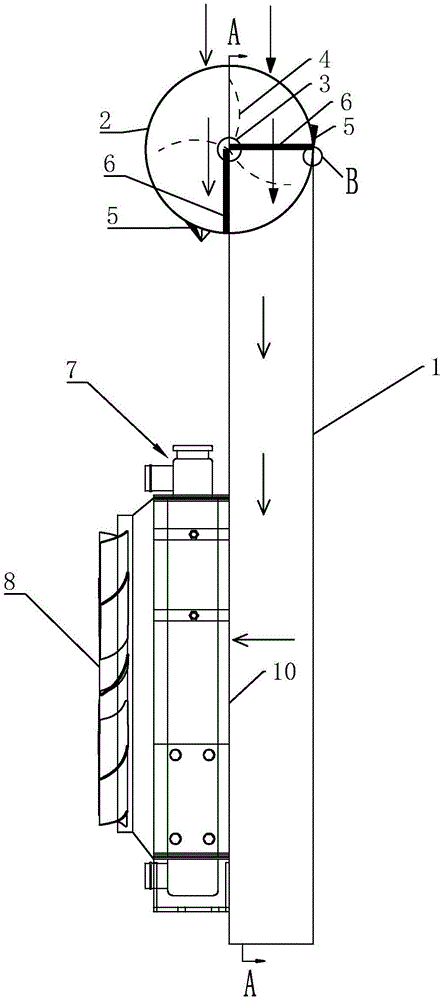

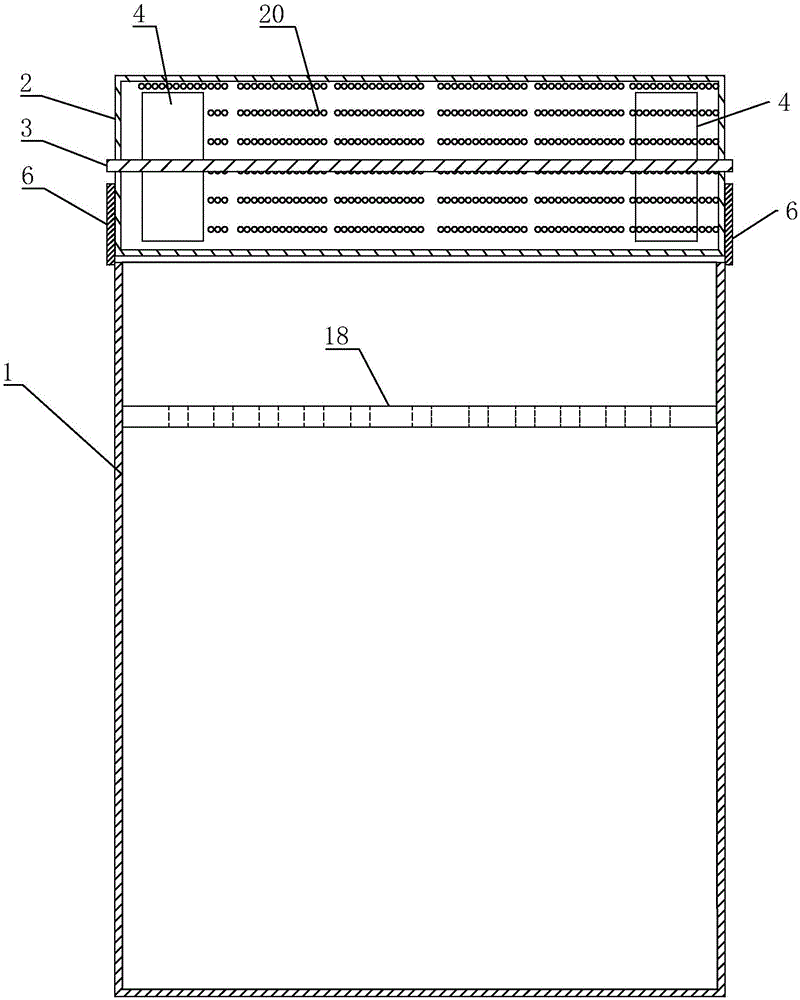

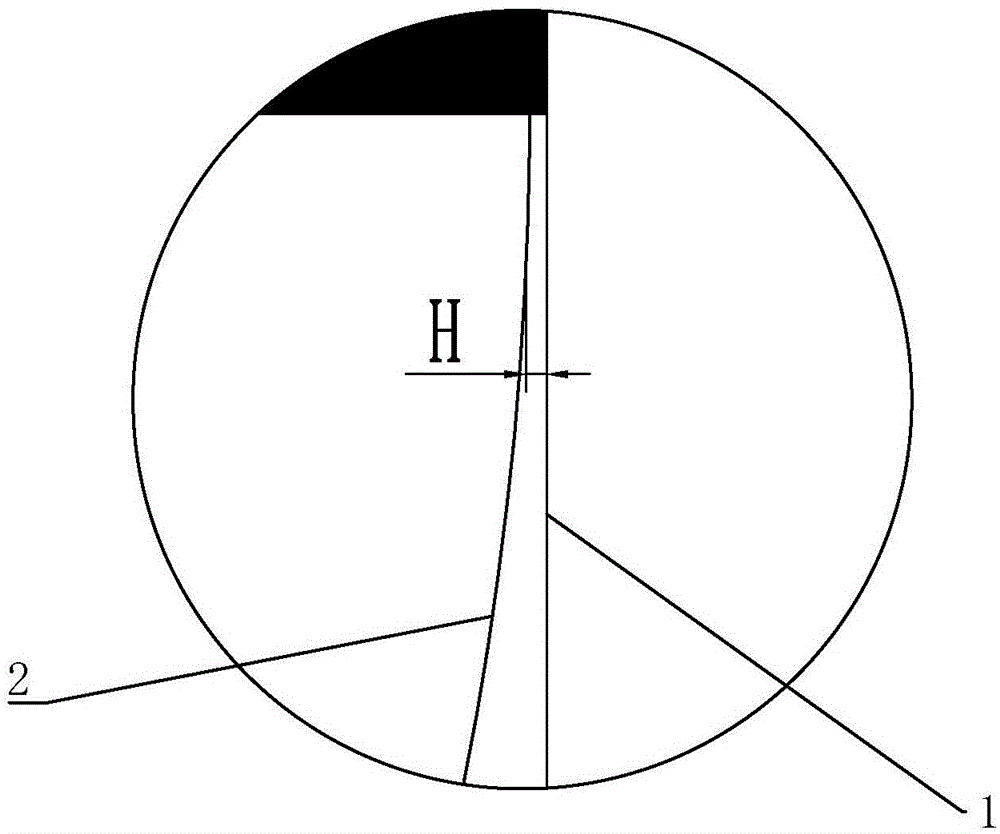

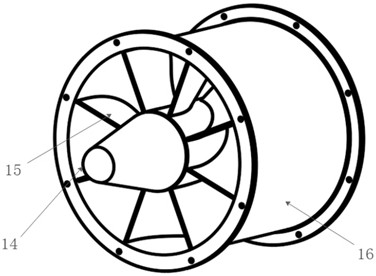

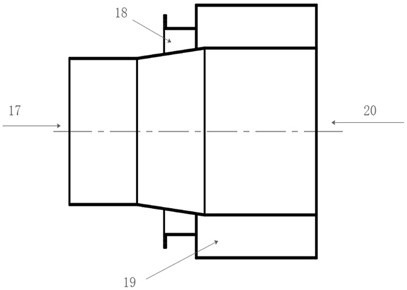

ActiveCN105126493AEasy to useGuaranteed design height requirementsDispersed particle filtrationHarvestersDifferential pressureEngineering

The invention discloses an air dust removal device for a radiator. The air dust removal device comprises a vertical air director with an opening in the upper end, wherein an air outlet is formed in one side of the air director, a suction fan is arranged in the position, corresponding to the air outlet, of the air director, a dust removal mesh cover is arranged correspondingly at the opening in the upper end of the air director, the dust removal mesh cover covers the opening in the upper end of the air director, and first hairbrushes used for cleaning the outer surface of the dust removal mesh cover are arranged on the periphery of the dust removal mesh cover; the dust removal mesh cover is connected with a rotating shaft, and fan blades driven through differential pressure generated by the suction fan are arranged on the rotating shaft. Few components are used, the use cost is reduced, and the dust removal effect is remarkable. The invention further discloses a harvester provided with an automatic dust removal and prevention structure. The overall use performance of the harvester is greatly improved, and the maintenance time is saved.

Owner:LOVOL HEAVY IND CO LTD

Coal mine dust removal system and dust removal method

ActiveCN111878153AReasonable matchingReduce volumeHuman health protectionCombination devicesMining engineeringSlag

The invention discloses a coal mine dust removal system and dust removal method. The coal mine dust removal system comprises a trapping device, a pneumatic suction device, an entrainment dust removaldevice, a cyclone separation device, a multi-phase flow division device and a dust exhauster which are connected in sequence, wherein the trapping device, the pneumatic suction device, the entrainmentdust removal device, the cyclone separation device and the multi-phase flow division device are all of tubular structures, every two adjacent devices are integrally connected through a flange, and the pneumatic suction device is connected with a coal mine ventilation pipe through a telescopic hose; a slag discharge port of the multi-phase flow division device is connected with a coal mine slag discharge system through a telescopic pipeline, the entrainment dust removal device is connected with a coal mine water supply system through a hose, and stop valves are arranged on the telescopic hoseand a pipeline of the hose. The coal mine dust removal system is reasonable in unit combination design and small in size, and has the advantages of being small in investment, small in occupied area, low in energy consumption, high in dust removal rate and the like, and the coal mine dust removal method has the advantages of being short in process, low in operation cost and the like.

Owner:DALIAN EAST REFRIGERATION EQUIP

Rapid dust removal method and device in tunnel

InactiveCN101387203AImprove dust removal rateQuick dustDust removalFire preventionEngineeringHigh pressure

The invention relates to a downhole quick dustfall method and a downhole quick dustfall device, which are characterized in that a drilling position of a heading is provided with a front-end hole by utilization of a drill; an annular area between a drill rod and the rock wall of the front-end hole is taken as a dustfall area in the front-end hole, and spray which is formed by inlet of compressed air and water together is led into the dustfall area; and the spray is maintained when the drill rod drills simultaneously. The downhole quick dustfall method and the downhole quick dustfall device can maintain using high-pressure blast to quicken normal drilling construction, and simultaneously effectively reduce the discharge capacity of downhole dust, thereby solving the problem of the hazard of the dust on the health of workers and the safety threat of the dust on mines.

Owner:HUAINAN MINING IND GRP

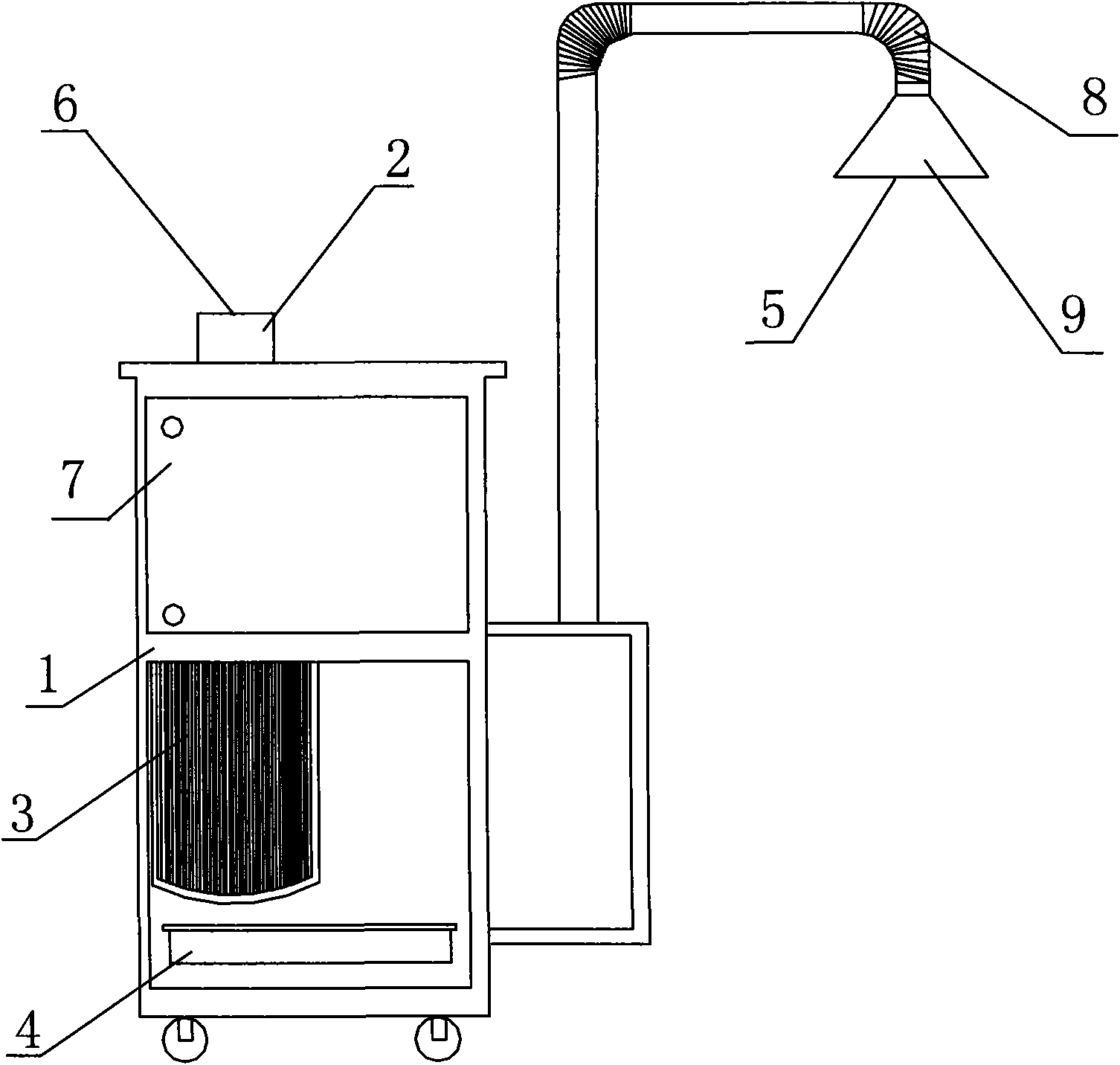

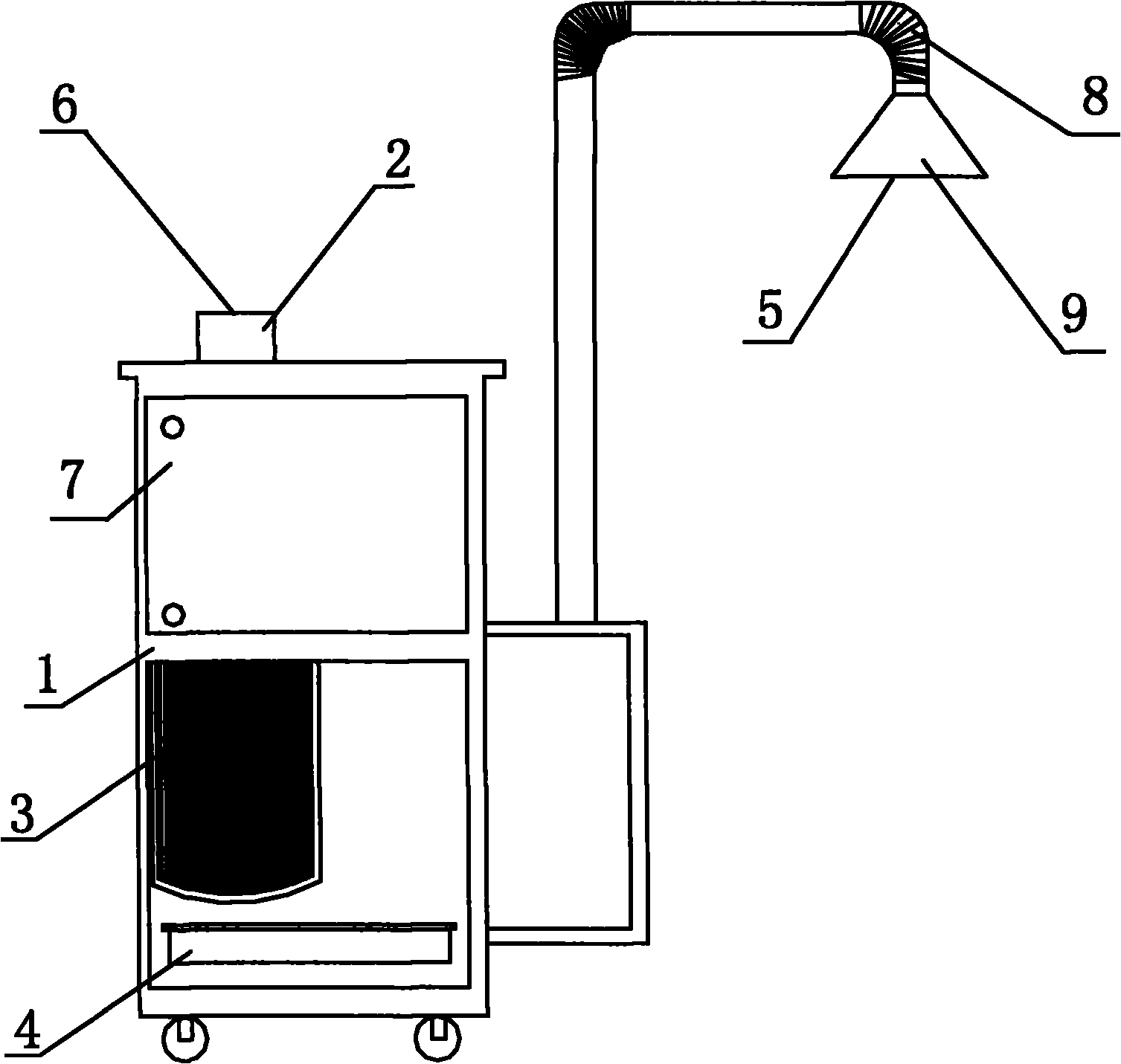

Filtering cylinder type dust-removing purification machine

The invention provides a filtering iltering cylinder type dust-removing purification machine which comprises a box body, a fan, a filtering cylinder, an ash containing drawer, an air inlet, an air outlet and an electric appliance control device, wherein the electric appliance control device is installed at the upper part in the box body; the top of the box body is provided with an air outlet which is provided with the fan; the air inlet is communicated with the interior of the box body by a hose; the filtering cylinder is positioned in the box body; and the bottom in the box body is provided with the ash containing drawer. The filtering cylinder type dust-removing purification machine has stable technical performance, low noise, electricity conservation, attractive appearance, flexible use, simple and convenient ash removal, small occupied area, wide application scope, high dust removal rate (99%) and recycle of fiber.

Owner:苏登宽

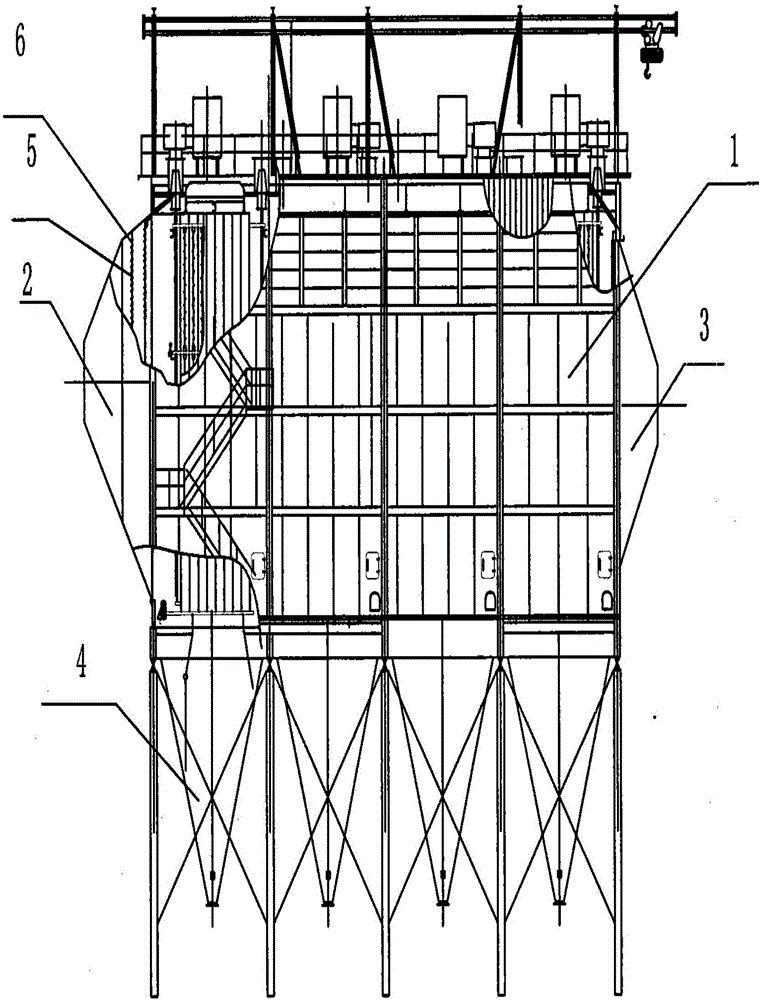

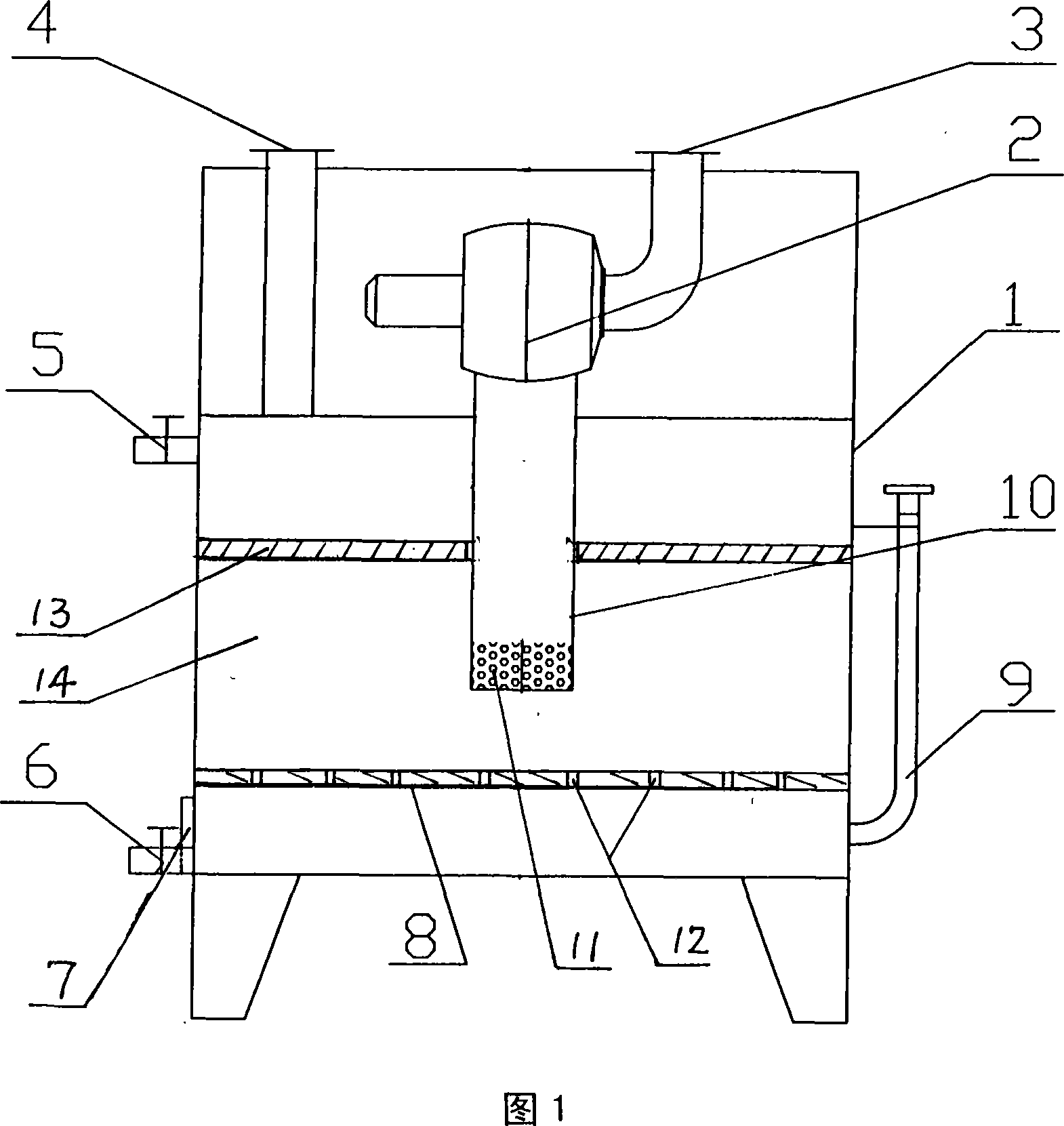

Electric dust remover with inlet airflow distribution plate

InactiveCN106076637ASimple structureImprove dust removal rateExternal electric electrostatic seperatorVapor flow controlWaste managementAirflow

The invention discloses an electric dust remover, and particularly relates to an electric dust remover with an inlet airflow distribution plate. The electric dust remover comprises a shell, wherein an airflow inlet is arranged in one end of the shell, and an airflow outlet is arranged in the other end of the shell; an ash outlet hopper is arranged at the bottom of the shell; the inlet airflow distribution plate is arranged at the airflow inlet; and guide layers which are uniformly distributed are arranged on the inlet airflow distribution plate. The electric dust remover is simple in structure, and capable of increasing the dust removal rate.

Owner:TIANJIN WANYATONG TECH

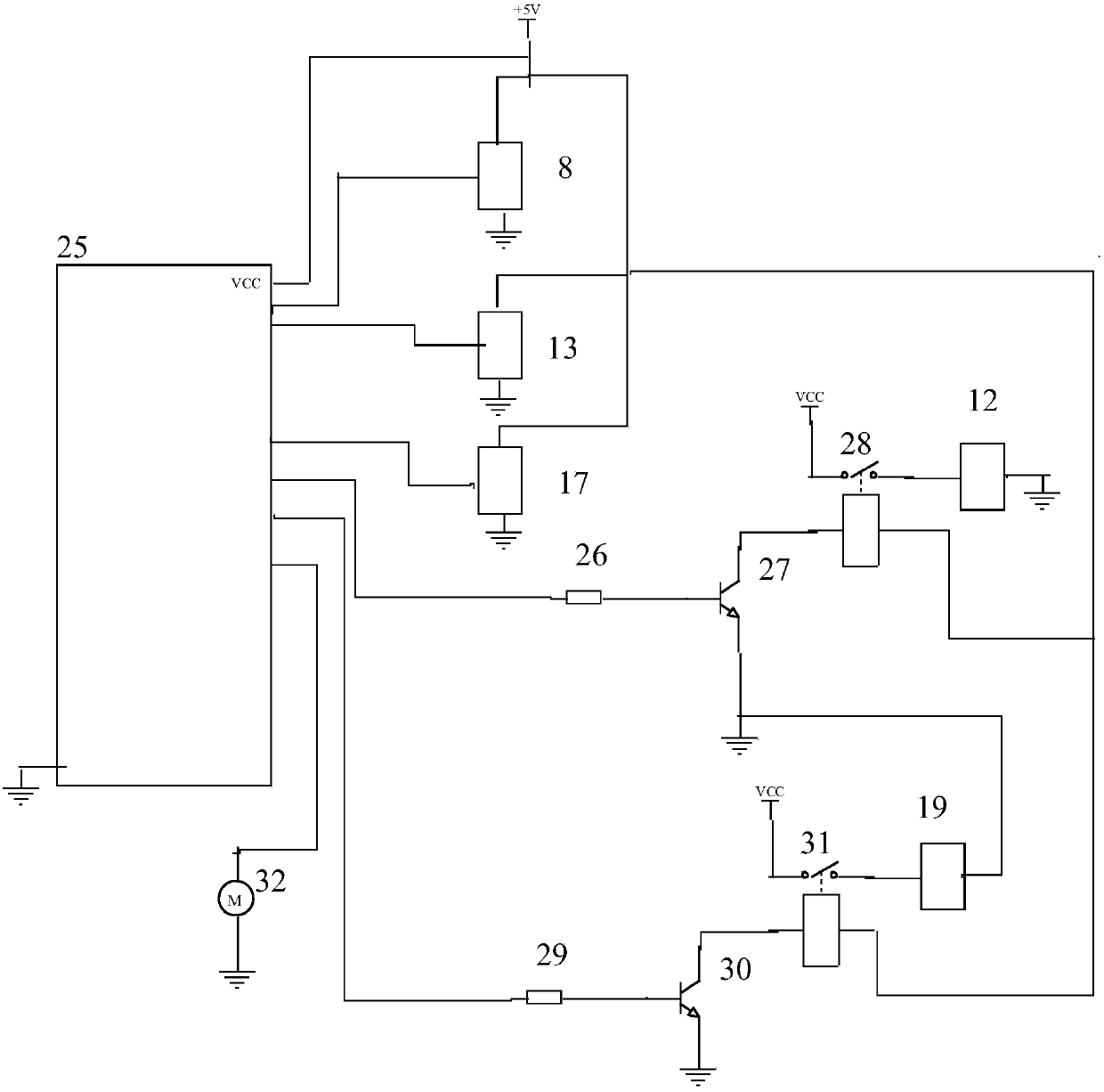

Fine dust particle convergent resonant cavity based on multiple sensors

InactiveCN107899746AExtended stayImprove aggregation performanceElectrostatic separation detailsMultiple sensorPush pull

The invention relates to a fine dust particle convergent resonant cavity based on multiple sensors, and belongs to the field of electrostatic dust collection. The fine dust particle convergent resonant cavity mainly aims to extend the standing time of fine particles in a convergent electric field in limited space, so that the convergent effect of the fine particles is increased, and the dust collection rate is increased. The fine dust particle convergent resonant cavity is composed of a lower slideway, a tractor, an upper slideway, a push-pull rod, a compression plate, an upper cavity wall, aleft positive convergent plate electrode, an upper pressure sensor, a branch outlet flue left wall, a branch outlet flue, a branch outlet flue right wall, a branch flue outlet electromagnetic valve, aparticle distribution sensor, a right negative convergent plate electrode, filter cloth, a right cavity wall, a lower pressure sensor, a right positive convergent plate electrode, a branch flue inletelectromagnetic valve, a branch flue inlet right wall, a branch flue inlet, a branch flue inlet left wall, a left negative convergent plate electrode, a lower cavity wall, a single chip microcomputer, a first resistor, a first triode, a first relay, a second resistor, a second triode and a tractor stepping motor. The fine dust particle convergent resonant cavity is mainly used in the field of theelectrostatic dust collection.

Owner:NORTHEAST NORMAL UNIVERSITY

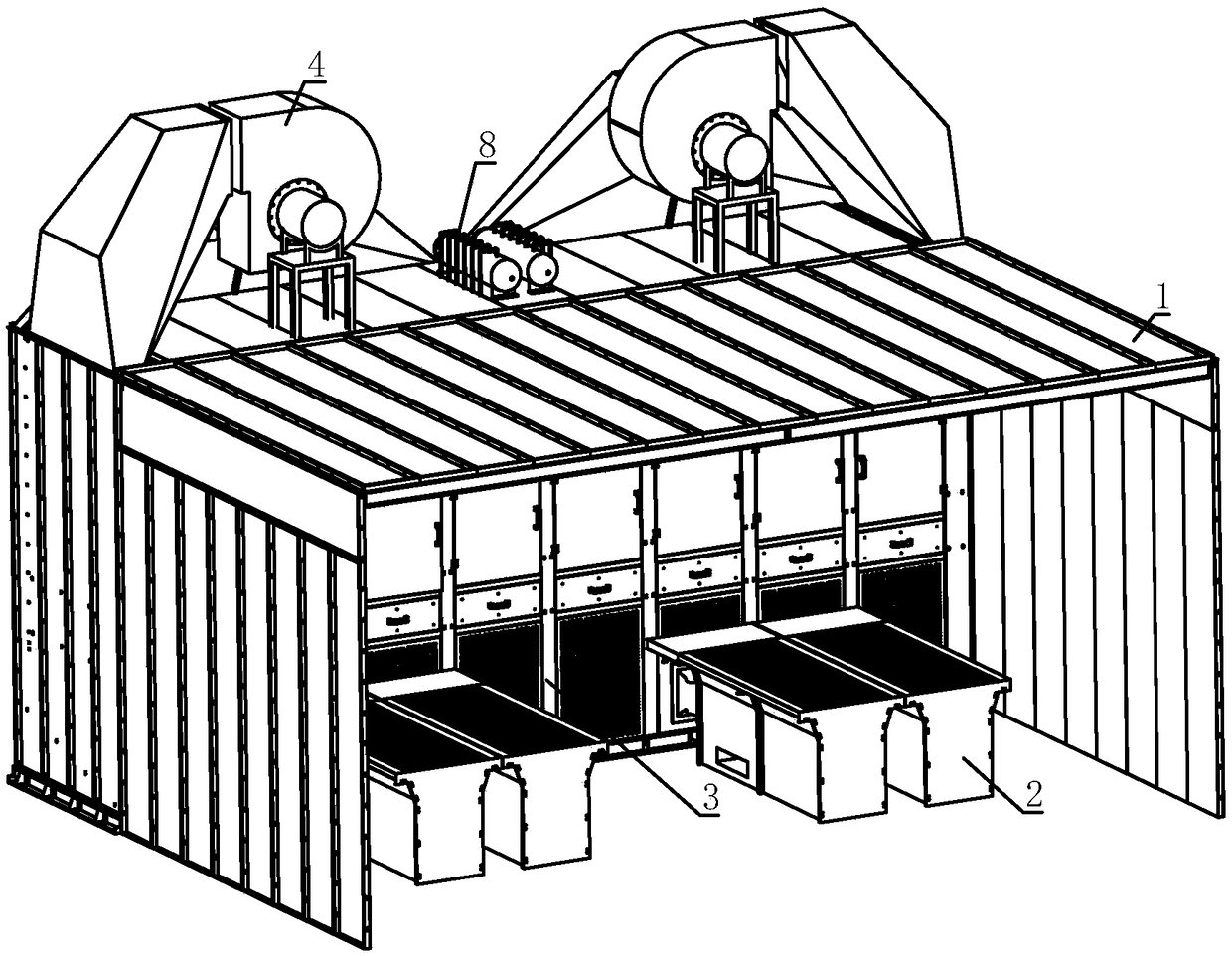

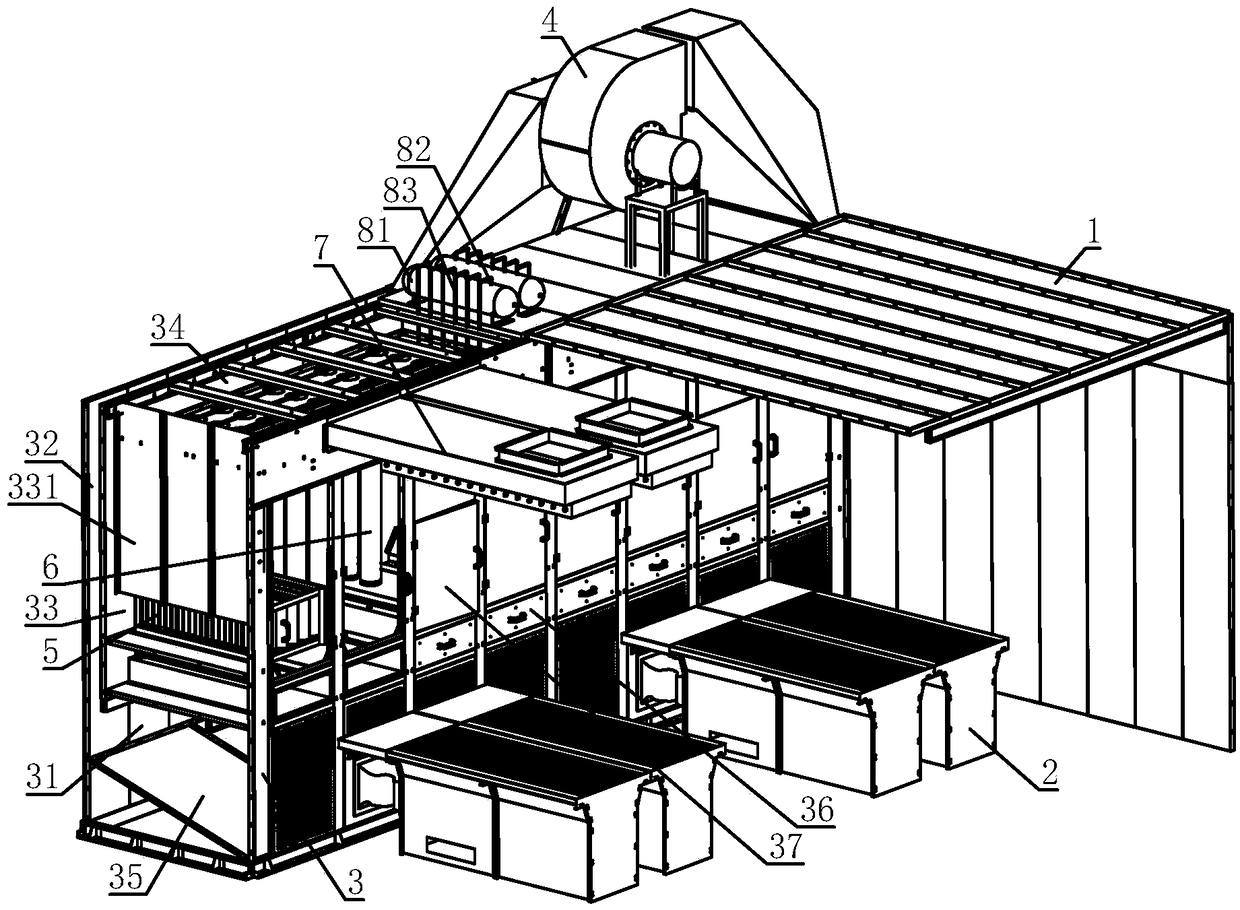

Polishing room with high dust removal rate

PendingCN109048673AImprove air intakeImprove dust removal rateCombination devicesGrinding/polishing safety devicesEngineering

The invention relates to the field of polishing rooms, in particular to a polishing room with a high dust removal rate. The polishing room with the high dust removal rate comprises a polishing room body. Polishing tables are mounted in the polishing room body. A dust removal frame is arranged in the polishing room body. An air inlet cavity is formed in the bottom of the dust removal frame. An airinlet interlayer cavity is formed in the dust removal frame. The air inlet cavity communicates with the air inlet interlayer cavity. An exhaust fan is mounted at the top of the dust removal frame. Anair inlet of the exhaust fan communicates with the air inlet interlayer cavity. A filter cavity is formed in the dust removal frame and communicates with an air outlet of the exhaust fan. Baffle plates and filter cloth bags are sequentially arranged in the filter cavity. A top air cavity is formed in the top of the dust removal frame. Openings of the filter cloth bags communicate with the top aircavity. An air outlet mechanism is mounted on the dust removal frame and communicates with the top air cavity. An air guide plate used for adjusting the air outlet direction is mounted on the air outlet mechanism. According to the polishing room, more dust can be sucked away, and thus, the dust removal rate is increased.

Owner:QUANYOU FURNITURE

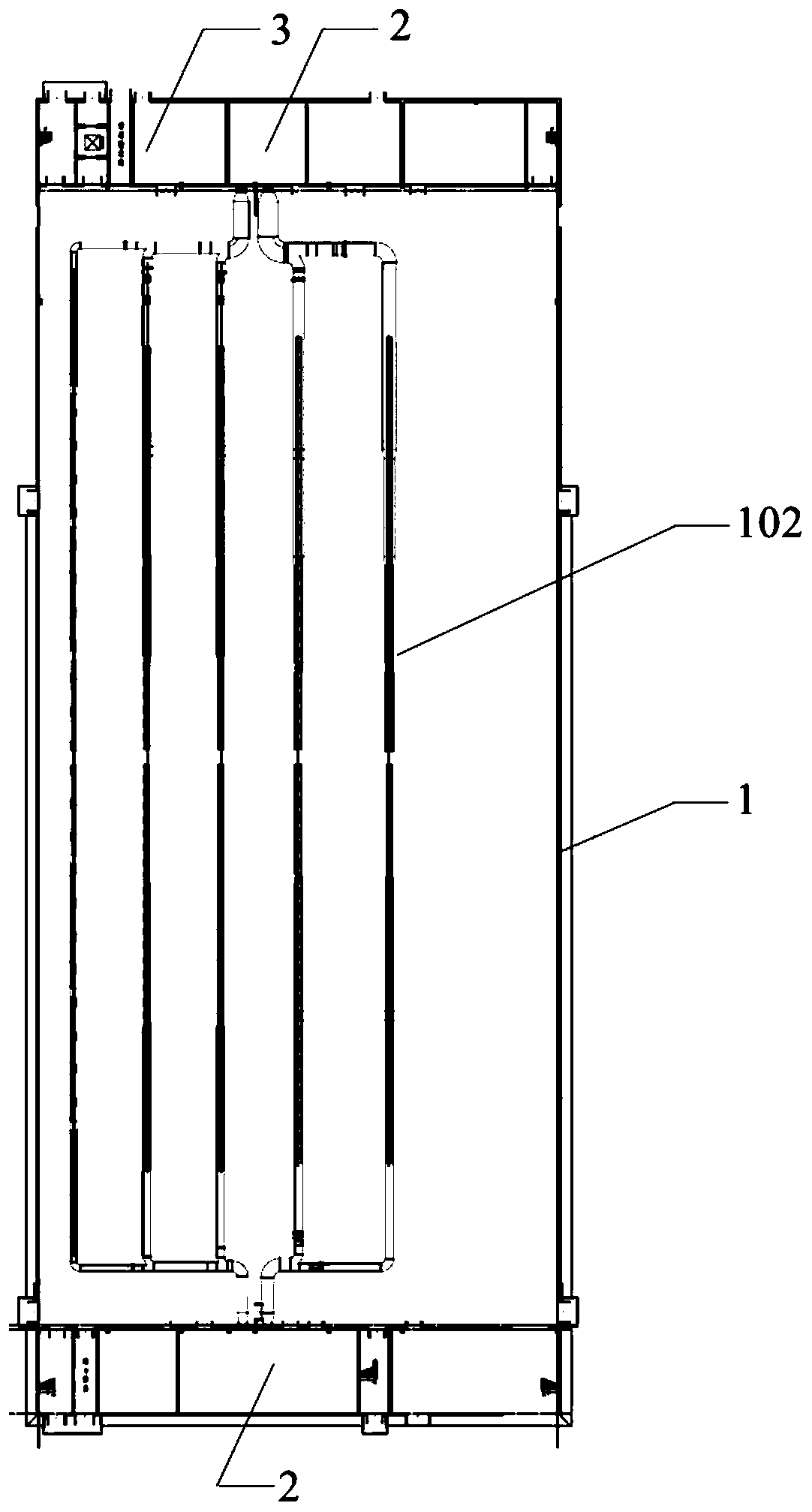

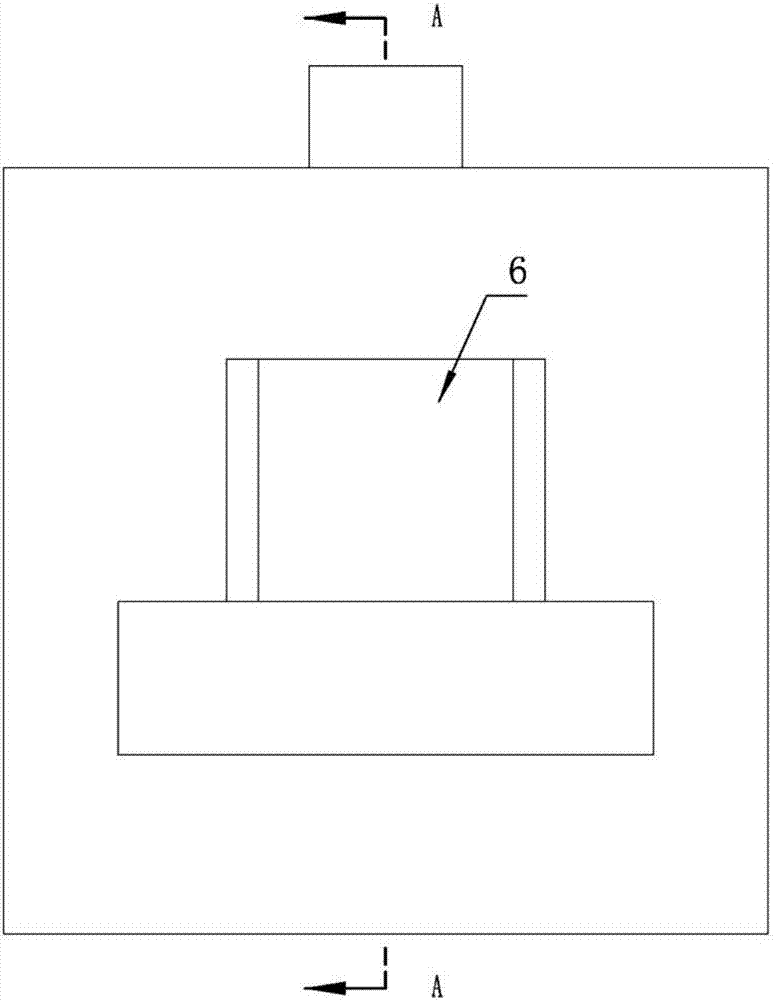

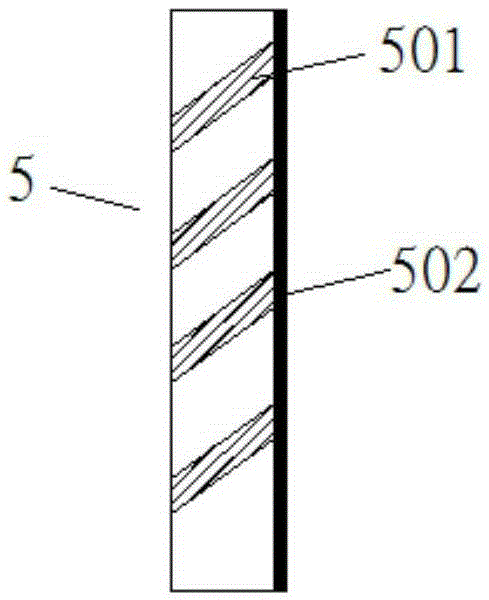

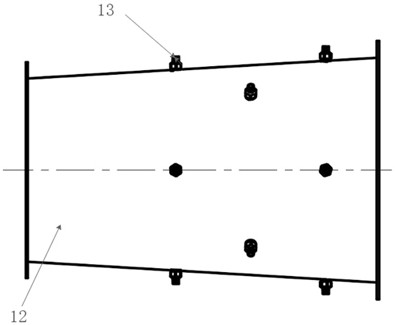

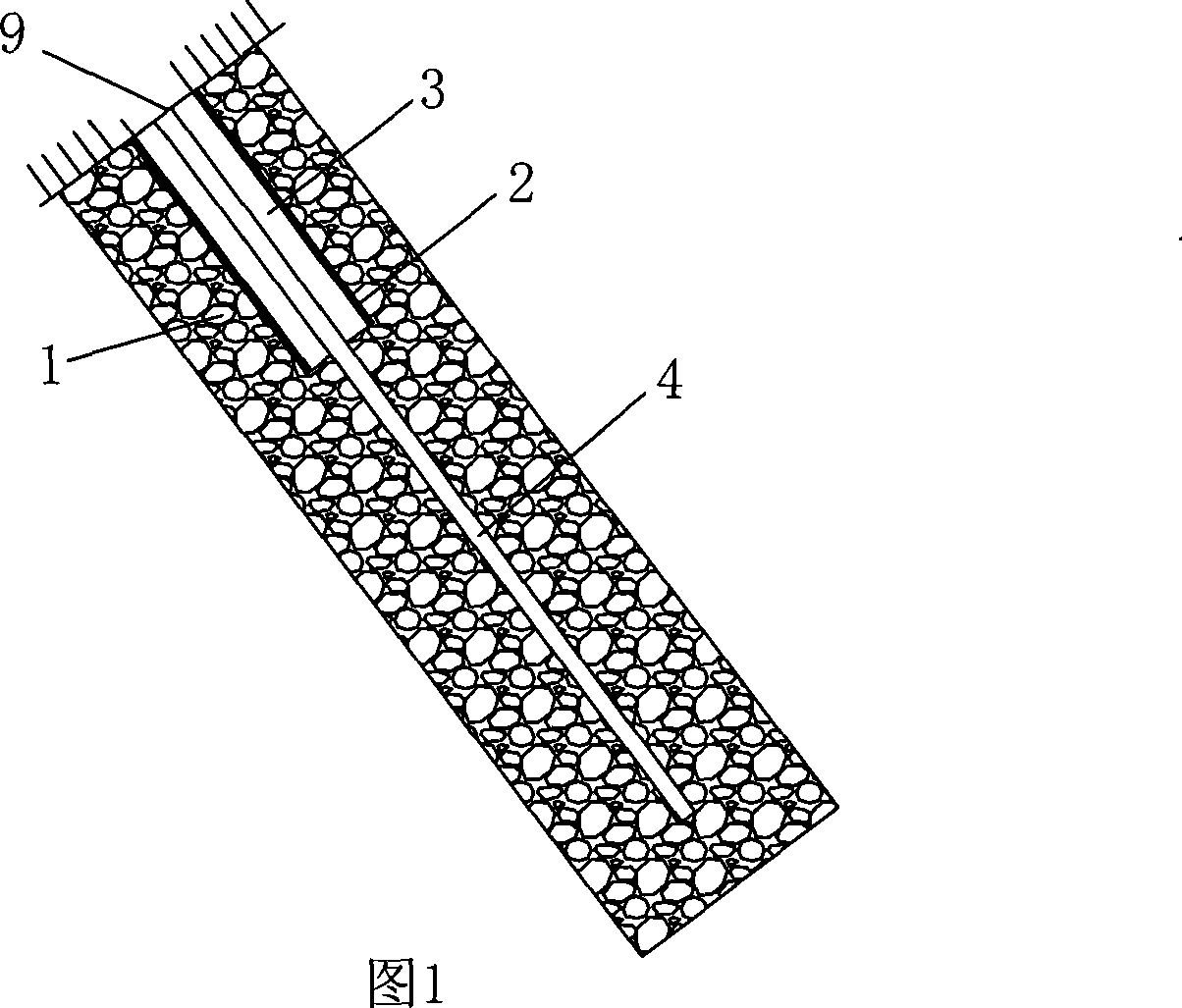

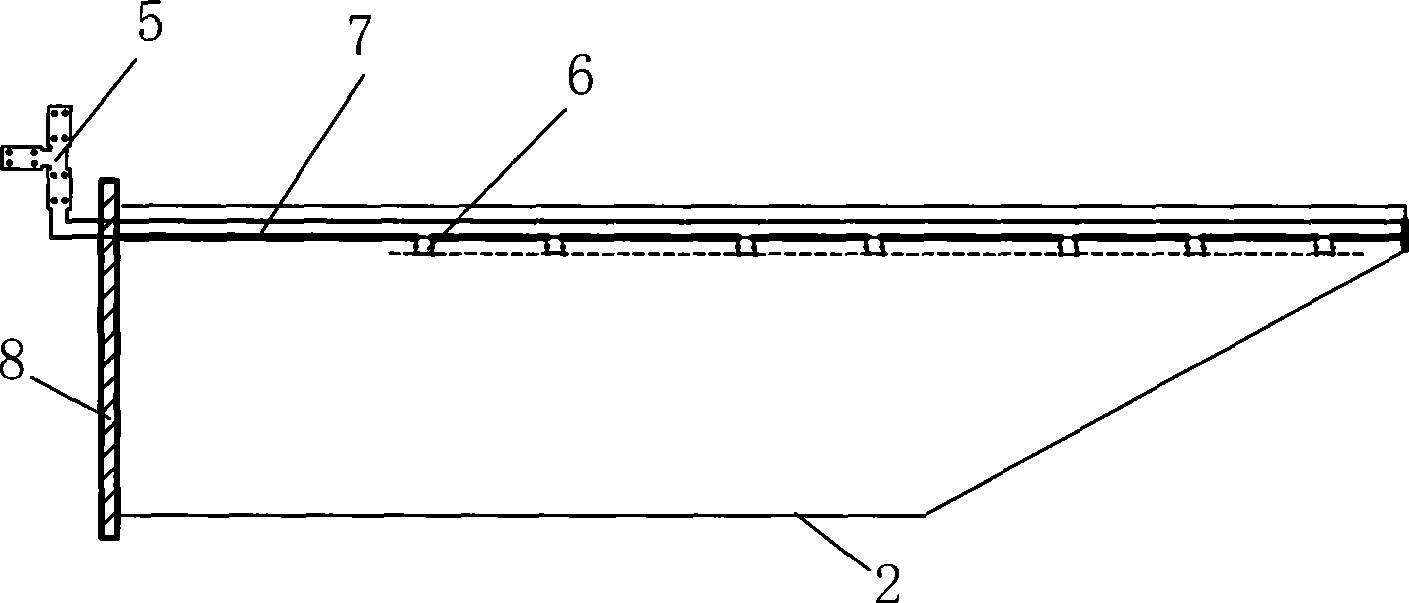

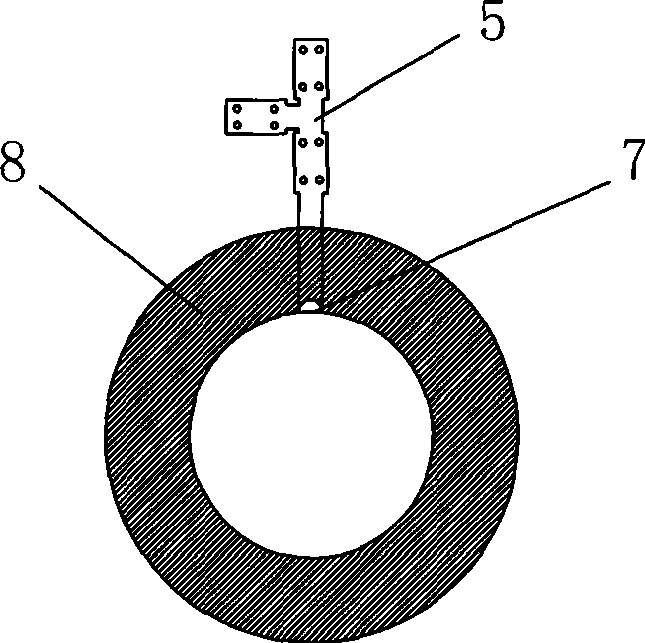

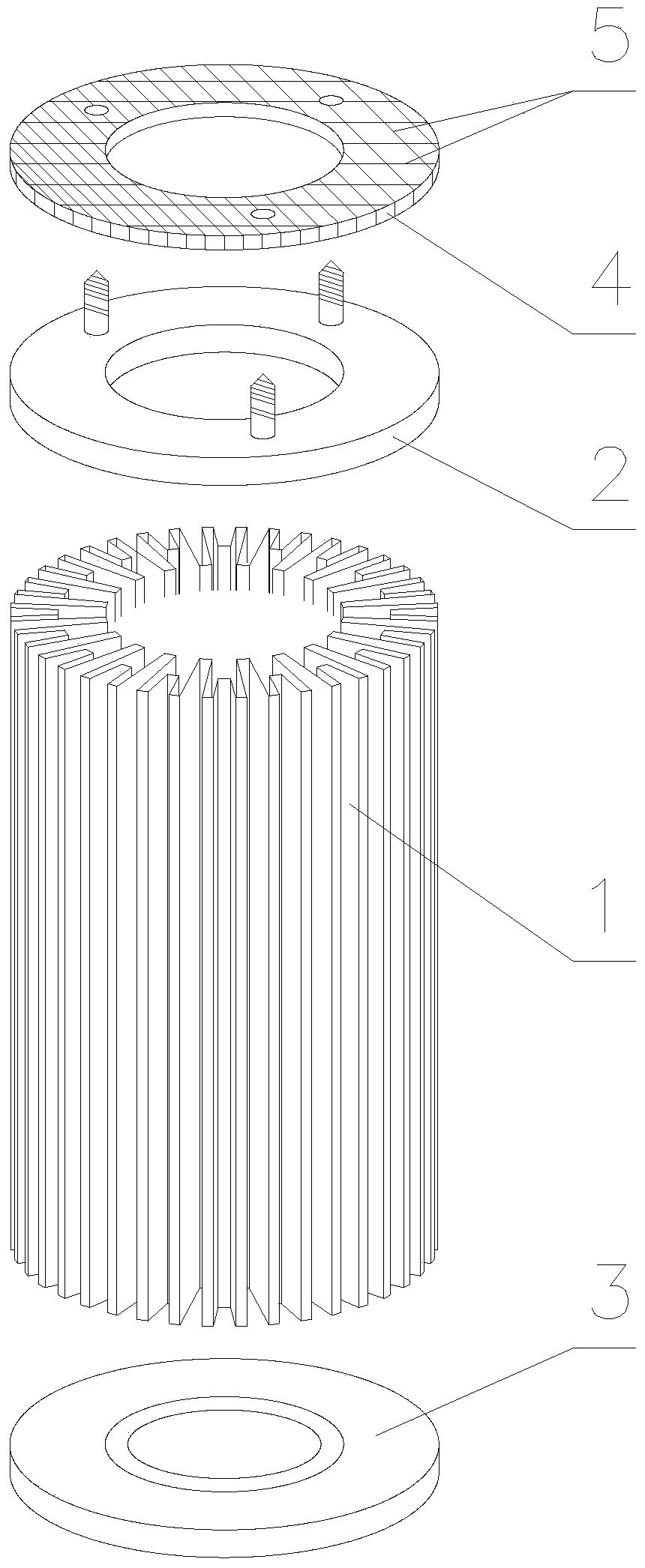

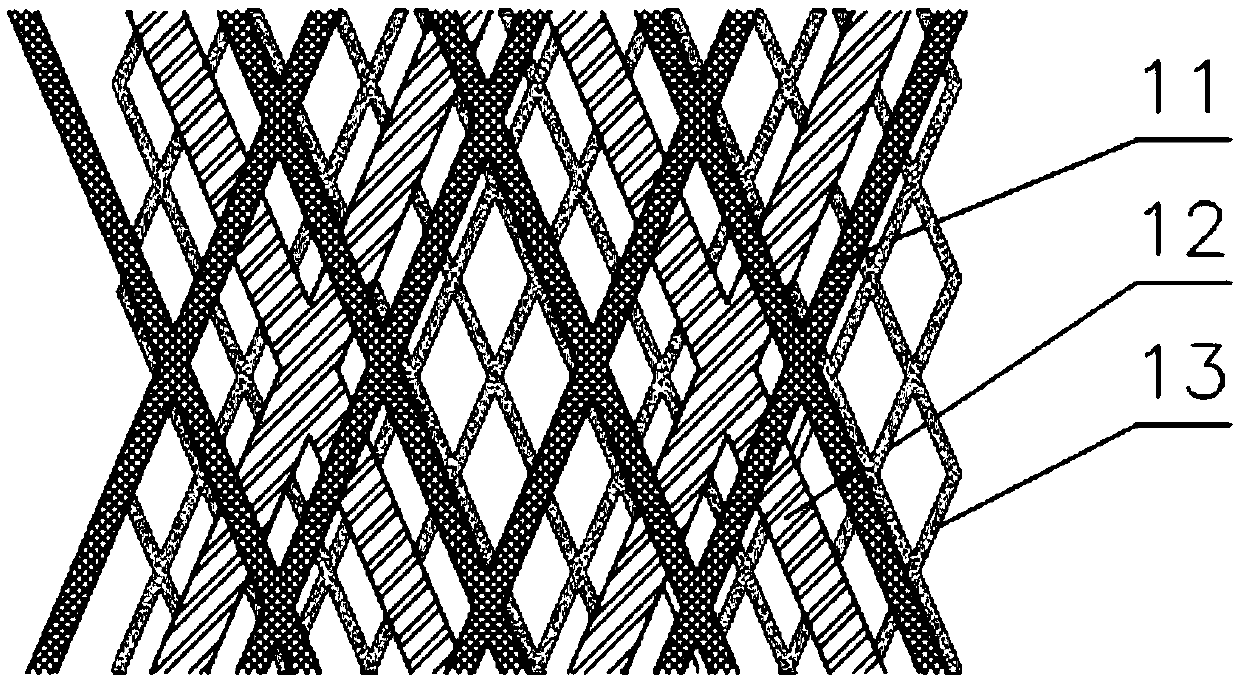

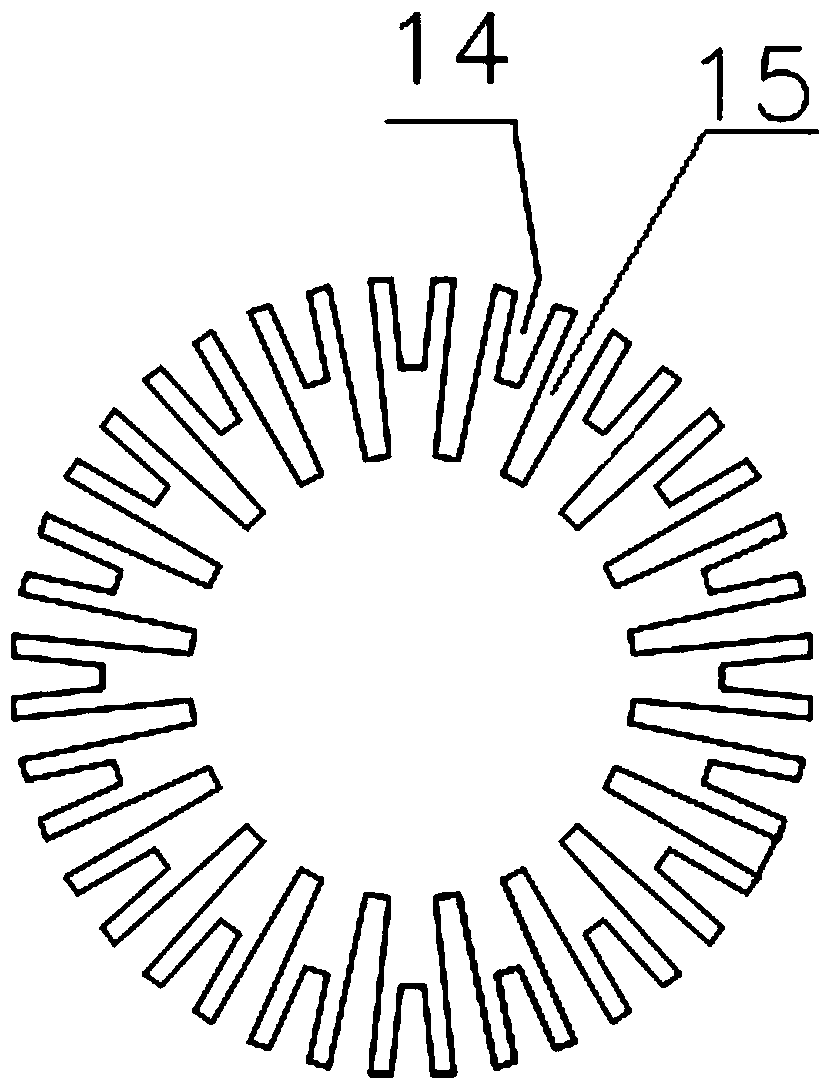

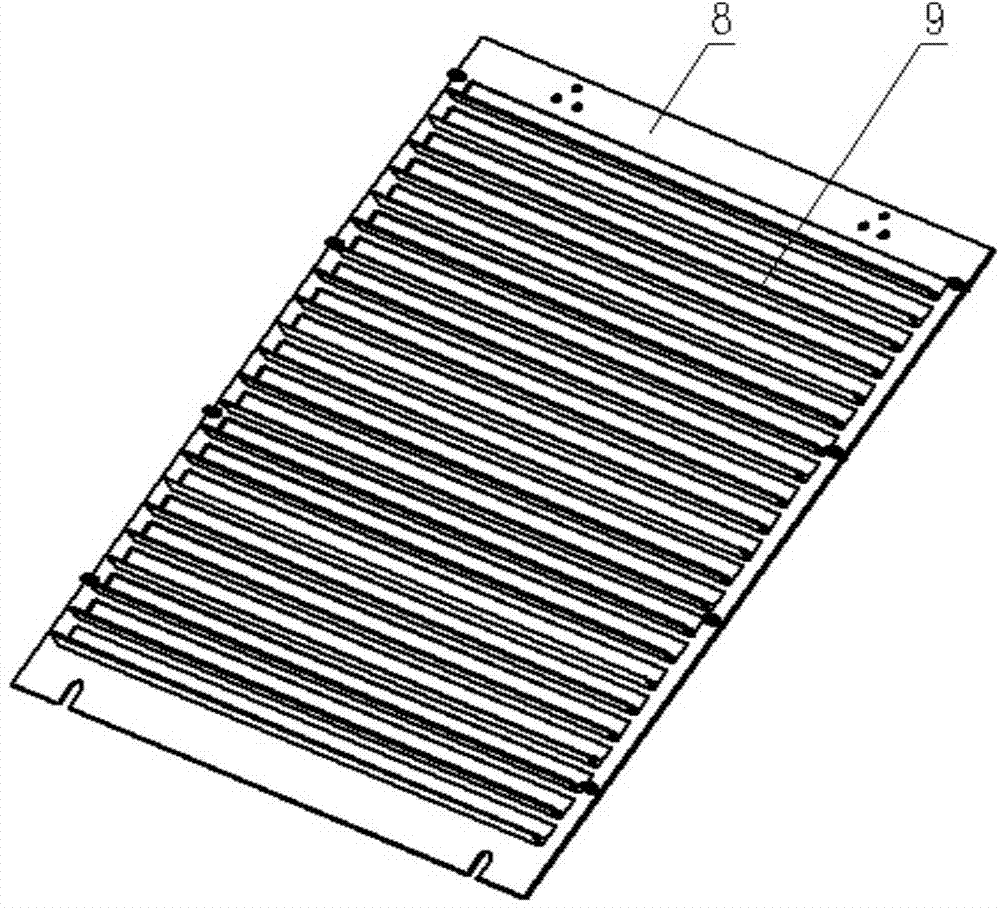

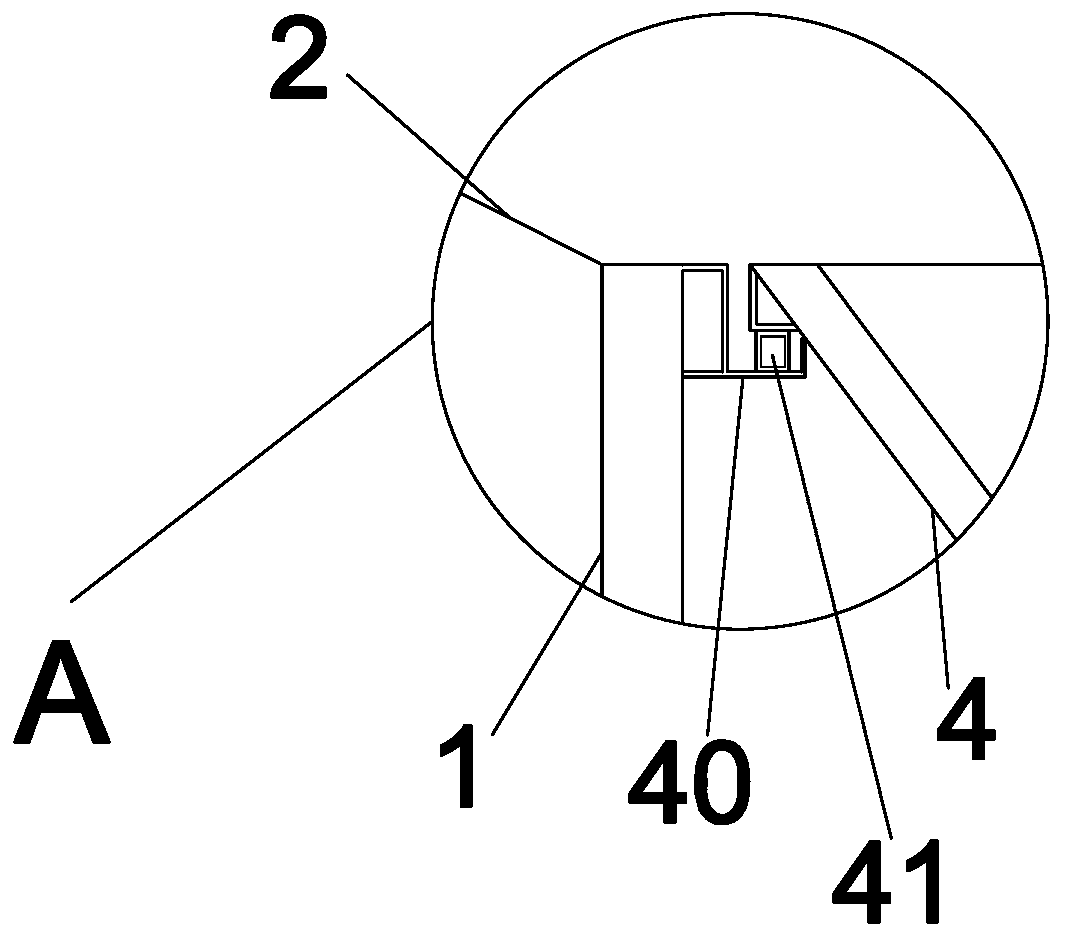

Mine-used pleat type metal screen filter cylinder

ActiveCN105498393AExcellent antistatic performance and explosion-proof performanceExcellent flame retardancy and wear resistanceDispersed particle filtrationMembrane filtersType metalComposite structure

The invention discloses a mine-used pleat type metal screen filter cylinder, which comprises a filter screen (1), a mounting cover (2) and a sealing cover (3), wherein the mounting cover (2) and the sealing cover (3) are respectively arranged at the top and the bottom of the filter screen (1), a sealing gasket (4) is arranged at the upper part of the mounting cover (2), and the filter screen (1) and the mounting cover (2) are made of metal with good electrical conductivity and good wear resistance; the filter screen (1) is in a three-layer metal screen composite structure of an outer-layer intermediate screen (11), a middle-layer thick screen (12) and an inner-layer thin screen (13); the filtering surface of the filter screen (1) is in a deep pleat (15)-and-shallow pleat (14) trapezoid pleat type structure; and the outer surface of the sealing gasket (4) is wrapped with a layer of electrical conduction screen (5). The mine-used pleat type metal screen filter cylinder has the characteristics that the service cycle is longer, the inflaming retarding property and the antistatic property are higher, the dedusting efficiency is high, the safety explosive-proof grade is higher, etc.

Owner:CHINA UNIV OF MINING & TECH

Wet-type dust removal device

The invention discloses a wet-type dust removal device consisting of a dust removal system and a sewage treatment system; the dust removal system is composed of an air deflector, a spray pipe, a smoke dust capture mechanism and a demister which are sequentially installed in a tower body from the bottom up; the air deflector is composed of a set of fin-shaped flow deflectors that are transversely arranged in a plane; the smoke dust capture mechanism is composed of a dust capture plate on which meshes are densely distributed and an inverse Y-shaped dust collection plate. The sewage treatment system is composed of a sewage box, a sewage pump, a filter paper tape, a pure water recycling mechanism, a sludge drying mechanism and a dust slag collecting mechanism. According to the wet-type dust removal device, dusty air has been subjected to dust removal for five times, thus being high in dust removal rate; number of the layers of the smoke dust capture mechanism, the dust removal rate of the air including particles of more than 5 microns is up to more than 98%; the dusty air is small in resistance and low in energy consumption; the wet-type dust removal device integrates the functions of dust removal and sewage treatment, and can reduce occupied area and investment of environmental protection equipment; the dust removal sewage can be recyclable after treatment, thus being saving in water resources.

Owner:辽宁银捷装备科技股份有限公司

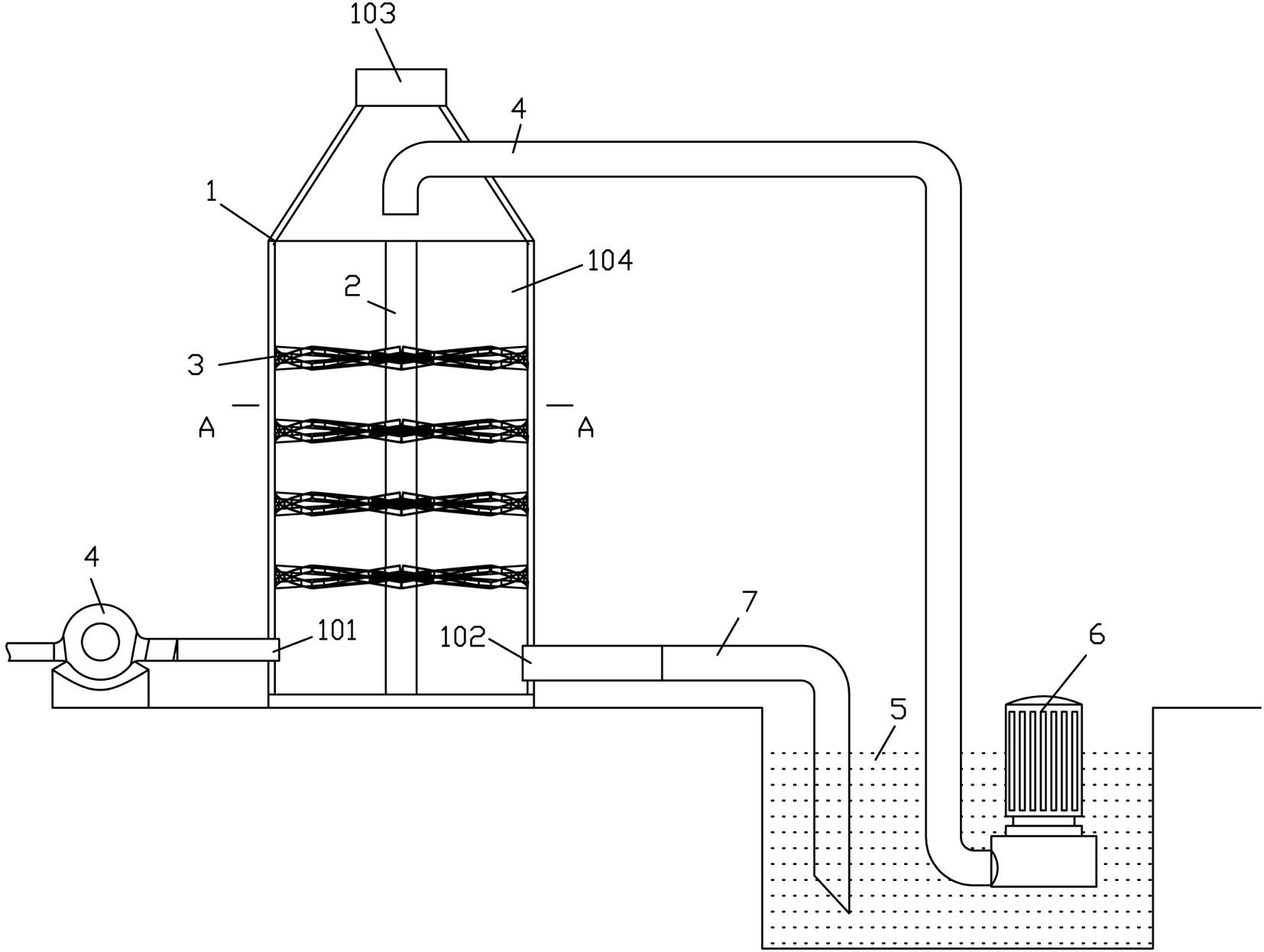

Mine dust removal system and dust removal method thereof

ActiveCN109908691ARealize the purpose of multi-stage joint dust removalImprove dust removal rateCombination devicesControllers with particular characteristicsEngineeringTurbofan

The invention discloses a mine dust removal system and a dust removal method thereof. The dust removal system comprises a primary dust removal device, a secondary dust removal device, a tertiary dustremoval device, a sedimentation filter pool and a water receiver, wherein the primary dust removal device comprises a primary dust removal outer cylinder, an air intake cylinder and a rotary dust removal mechanism; an air intake grid is disposed at an inlet of the air intake cylinder; the rotary dust removal mechanism comprises a primary dust removal inner cylinder, a turbofan, a water mist spraying mechanism and a rotary power transmission mechanism; the secondary dust removal device comprises a secondary dust removal outer cylinder, a secondary dust removal inner cylinder and a guide plate;the tertiary dust removal device comprises a tertiary dust removal cylinder, a corona electrode, a filter bag type dust collector and a rectifying power supply; the filter bag type dust collector comprises a dust removal framework and a dust removal filter bag; the dust removal framework is grounded; a back-blowing pipe is disposed inside the tertiary dust removal cylinder; and the back-blowing pipe is provided with a plurality of pulse back-blowing valves. The mine dust removal system disclosed by the invention is novel and reasonable in design, convenient to implement, capable of efficientlyremoving underground mine dust and reducing harm to human beings, strong in practicability, good in use effect and convenient to popularize and use.

Owner:XIAN UNIV OF SCI & TECH

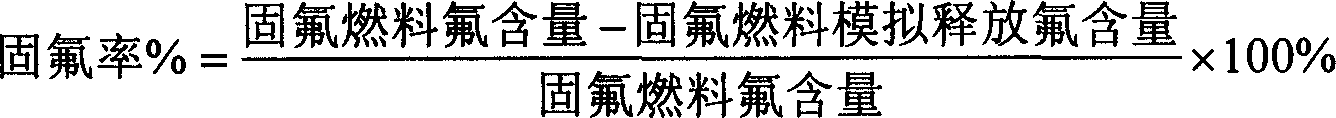

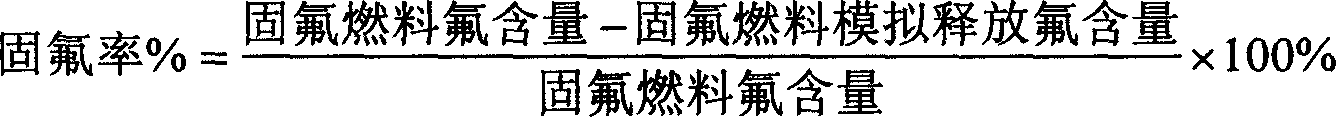

Fluorine capturing shaped coal fuel for stone coal and its production method

InactiveCN1546618AHigh sulfur removal rateImprove dust removal rateFuel additivesCoal dustAir pollution

The invention discloses a fluorine capturing shaped coal fuel for stone coal and its production method, wherein the fluorine capturing fuel comprises stone coal dust, anthracite duff, fluorine capturing addition agent and clay, wherein the fluorine capturing additive is burned dolomitite or burned limestone or lime, the preparation process includes mixing the cured fluorine capturing additive with anthracite duff, clay and stone coal dust based on proportion and grain diameter range, charging right amount of water, stirring homogeneously artificially or by machine. The invention realizes high fluorine capturing rate, sulfur capturing rate and dust depositing rate.

Owner:INST OF GEOGRAPHICAL SCI & NATURAL RESOURCE RES CAS

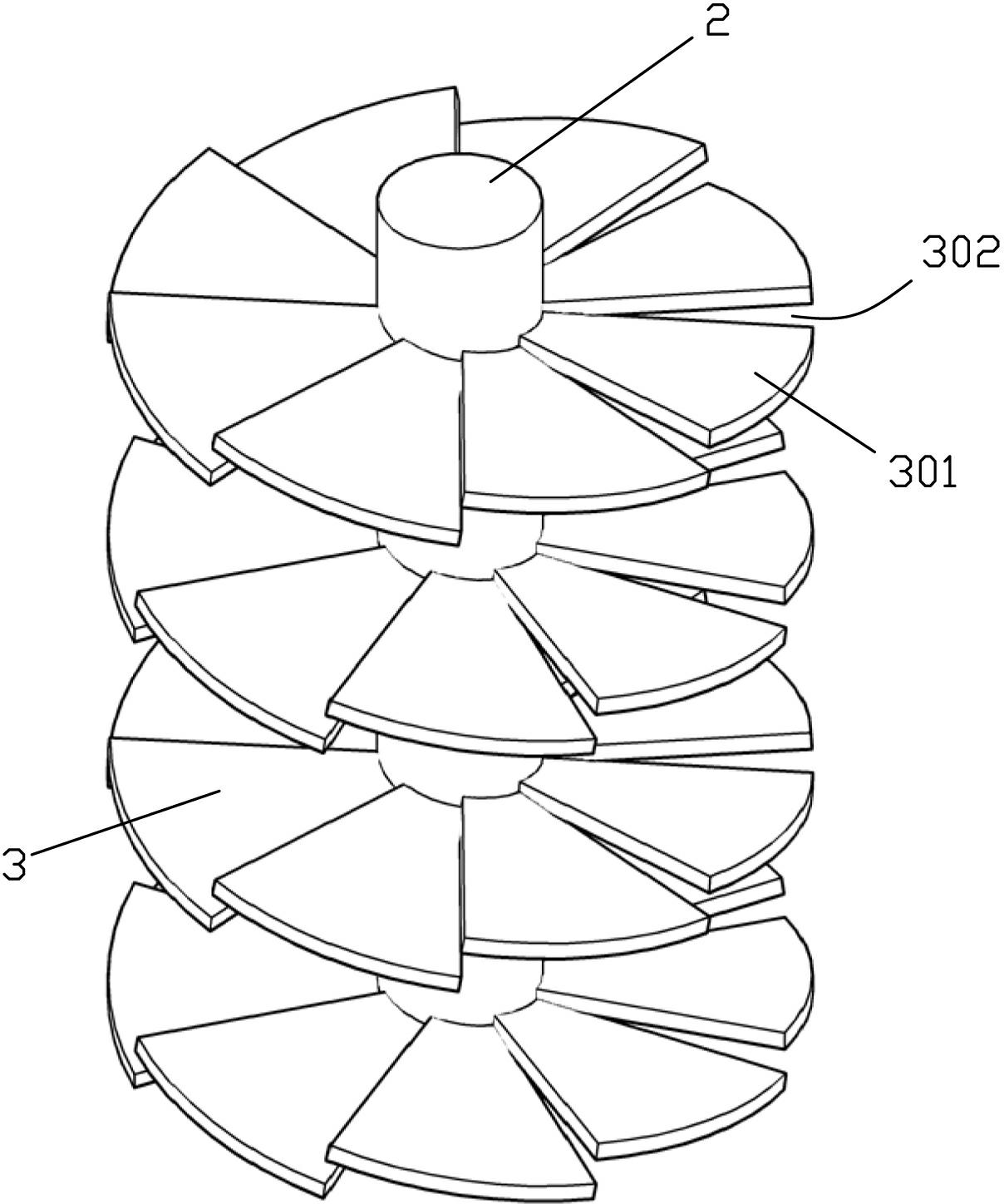

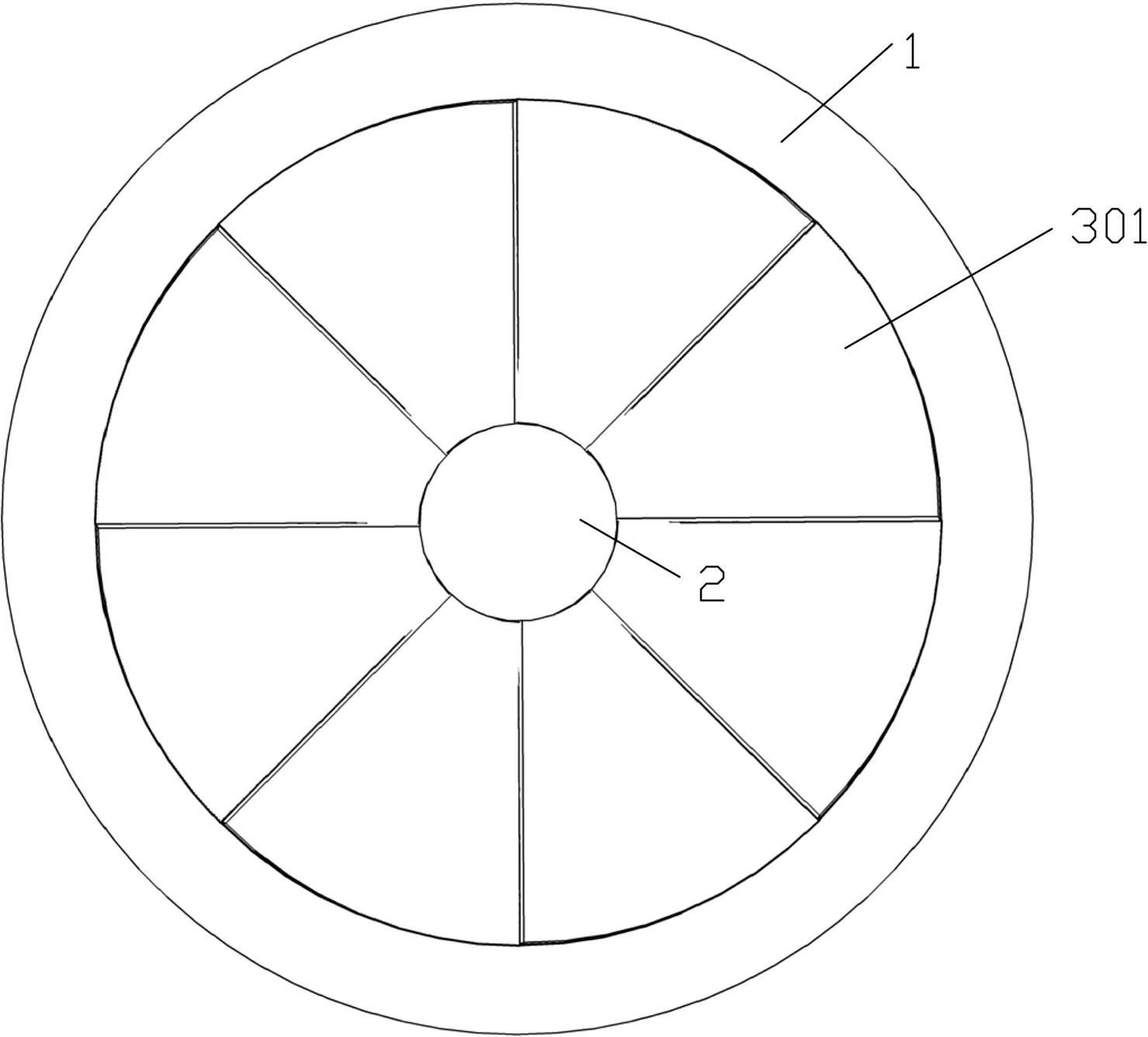

Deduster and method for treating haydite kiln tail gas therewith

ActiveCN102423589ASimple structureNo maintenanceUsing liquid separation agentIncreasing energy efficiencyFailure rateHeight difference

The invention discloses a deduster, which is composed of a deduster cylinder provided with an air inlet, a water outlet as well as an air outlet, and a shower pipe. The deduster cylinder is equipped with a chamber, inside which a fixed column is positioned. Multilayer baffles are fixed on the fixed column in a vertical direction. Each layer of baffle comprises multiple fan-shaped blades, and the blades of adjacent layers of baffles are in staggered arrangement mutually. Each blade and the horizontal plane form an inclined angel a, i.e. a height difference exists between two side faces of eachblade when they are lengthened and intersected. Also, gaps exist between two adjacent blades of the same layer. The method for treating haydite kiln tail gas with the deduster consists of the steps of: a) introducing the tail gas of a haydite kiln into a deduster for dedusting so as to form saturated steam; b) introducing the saturated steam obtained in step a) into a building block curing chamber so as to conduct curing to building blocks with the saturated steam. The deduster of the invention has the advantages of simple structure, high dedusting efficiency, long service life, and low failure rate.

Owner:ZHEJIANG DADONGWU GROUP CONSTR OF THE NEW MATERIAL

Dust removal device for stone processing

InactiveCN110064263ARealize the collectionExpand the scope of collectionUsing liquid separation agentTreatment involving filtrationSpray nozzleWorking environment

The invention relates to the technical field of dust removal auxiliary devices, in particular to a dust removal device for stone processing. The collecting range of a dust collecting cover on dust isenlarged, the dust in the working environment can be more sufficiently collected, and practicability is improved; the water consumption and sewage yield are reduced, and use reliability is improved; meanwhile, the dust removal rate and dust removal effect are increased. The dust removal device comprises a dust removal tower, a water tank, the dust collecting cover, an exhaust pipe, a base, a lifting plate, four supporting columns, a placement plate, two first motors, two reciprocating lead screws and a slider. The dust collecting cover is circular. A cavity is formed in the dust collecting cover. Dust inlets are formed in the four sides of the dust collecting cover respectively. The bottom end of the dust collecting box is communicated with a dust outlet pipe. The dust removal device further comprises a bladeless fan, a communication air pipe, a dust removal box, a high-tension transformer, a plurality of positive electrode plates, a plurality of negative electrode plates, an ash bucket, a round pipe, a second motor, a spraying pump, a T pipe, a spraying pipe, a water distributing pipe, a transmission shaft, a stirring blade and a spraying nozzle.

Owner:盐城国环睿保科技有限公司

Fluorine capturing fuel with enwrapped stone coal as main material and its production method

The invention discloses a fluorine capturing fuel with enwrapped stone coal as main material and its production method, wherein cured and burned dolomitite or burned limestone, anthracite duff and clay are mixed by a finite proportion and coated outside the stone coal, and the end product through further airing. The invention realizes high fluorine-fixing rate, sulfur-eliminating ratio and dust-depositing rate, the problem of air pollution of vast amount of fluoride and sulphide produced by stone coal combustion is solved substantially.

Owner:INST OF GEOGRAPHICAL SCI & NATURAL RESOURCE RES CAS

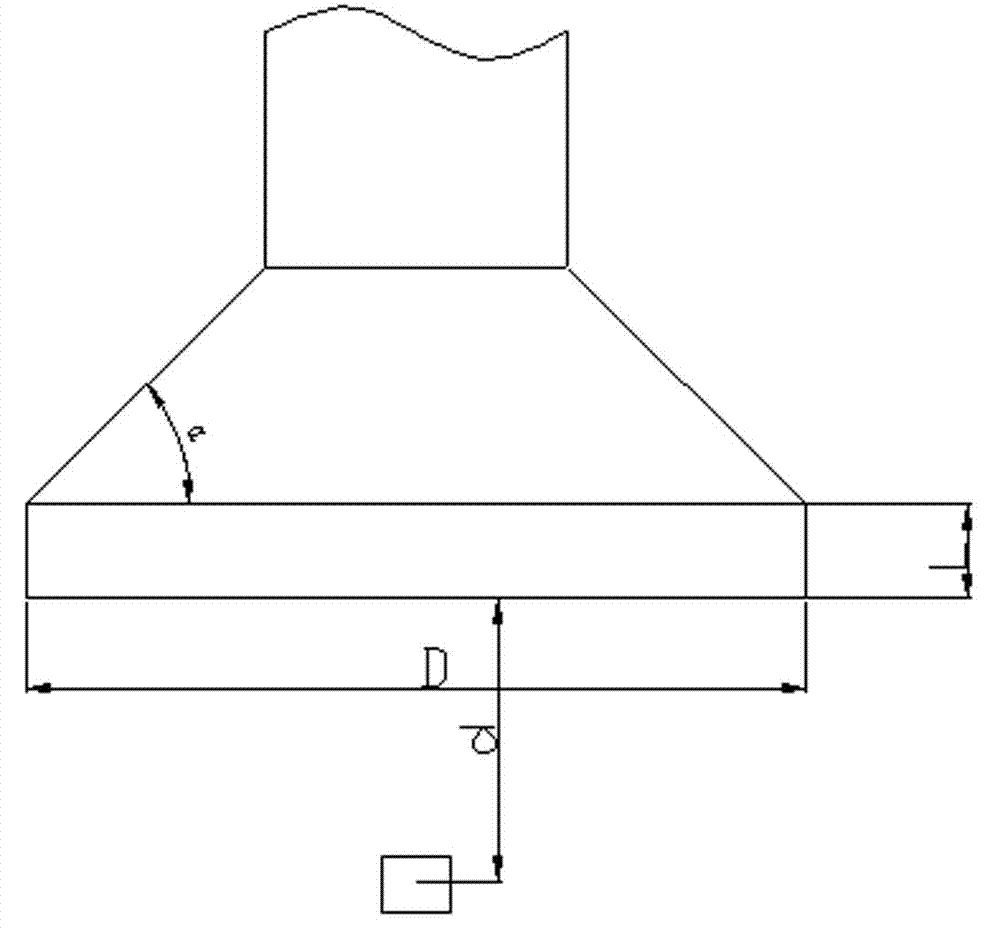

Purifying process and device for welding fume

ActiveCN102886184AImprove dust removal rateSimple processCombination devicesWelding/cutting auxillary devicesProcess engineeringSmall footprint

The invention belongs to the technical field of a welding accessory device, specifically a purifying process and a device for welding fume. The purifying process and the device solve a problem that the conventional dust removing method is not suitable for processing electric welding fume. The device comprises a plurality of parallel gas collecting hoods which are integrated with a welding gun, wherein the gas collecting hoods are connected with a rotary filler bed; the gas collecting hoods are of umbrella-shaped structures; an upper part, a lower part or a side part of the welding gun is provided with a connecting mechanism which is connected with the gas collecting hoods. According to the process, a gas speed inside the gas collecting hoods is 0.3-2.5m / s, the gas speed inside pipelines of the gas collecting hoods is 10-25 m / s, absorption liquid is water, and a gas liquid ratio of dust-containing gas and the adsorption liquid is 200-2000 m<3> / m<3>. The purifying process and the device have the beneficial effects of being simple in process flow, higher than 99% in dust removing rate, convenient to carry, small in floor area, low in operating cost, small in energy consumption, convenient to move and simple to operate.

Owner:ZHONGBEI UNIV

Machine for dust removal by filtration of water curtain

The invention provides a water-curtain filtering duster, comprising a shell and a fan. The shell is provided with an inlet valve, a drain valve, a cleaning mouth and a water gauge. The internal of the shell is a square cavity, in which the lower part is provided with a square water resisting board; the water resisting board is provided with via holes; the upper part of the cavity is provided with a round manger board, in which the middle is provided with the through holes; ventilating pipe of the fan inserts into the cavity through the round water resisting board; sidewall of one end of the ventilating pipe is opened with vents; an exhaust duct is arranged over the shell. The water-curtain filtering duster of the invention has simple structure, small volume. As the design of special structure is adopted, the balance between air pressure and water pressure, air flow and water flow can be solved during the dust removal to greatly improve the dust removal rate, thereby thoroughly avoiding blocking phenomenon.

Owner:陈美林

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com