Mine-used pleat type metal screen filter cylinder

A metal mesh and pleated technology, which is applied in the field of mine pleated metal mesh filter cartridges, can solve the problems that the filter cloth cannot achieve the flame retardant effect, the flame retardant and antistatic properties are attenuated, and the dust removal efficiency of the dust collector is low, and achieves excellent performance. Antistatic performance and explosion-proof performance, prolonging service life, and preventing the effect of reducing the filter area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

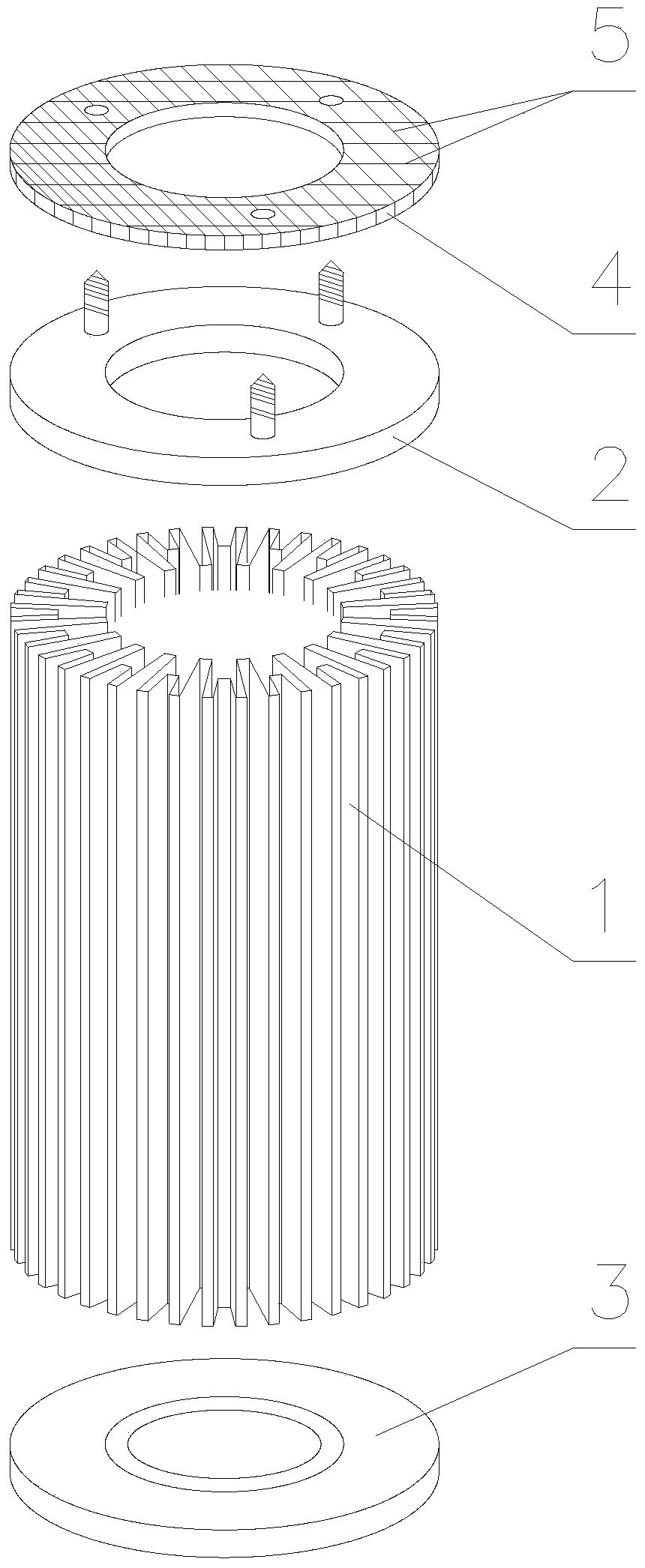

[0020] like Figure 1 to Figure 3 As shown, a mining pleated metal mesh filter cartridge includes a filter screen 1, an installation cover 2, and a sealing cover 3, and the installation cover 2 and the sealing cover 3 are respectively installed on the top and bottom of the filter screen 1, and the installation A gasket 4 is installed on the top of the cover 2,

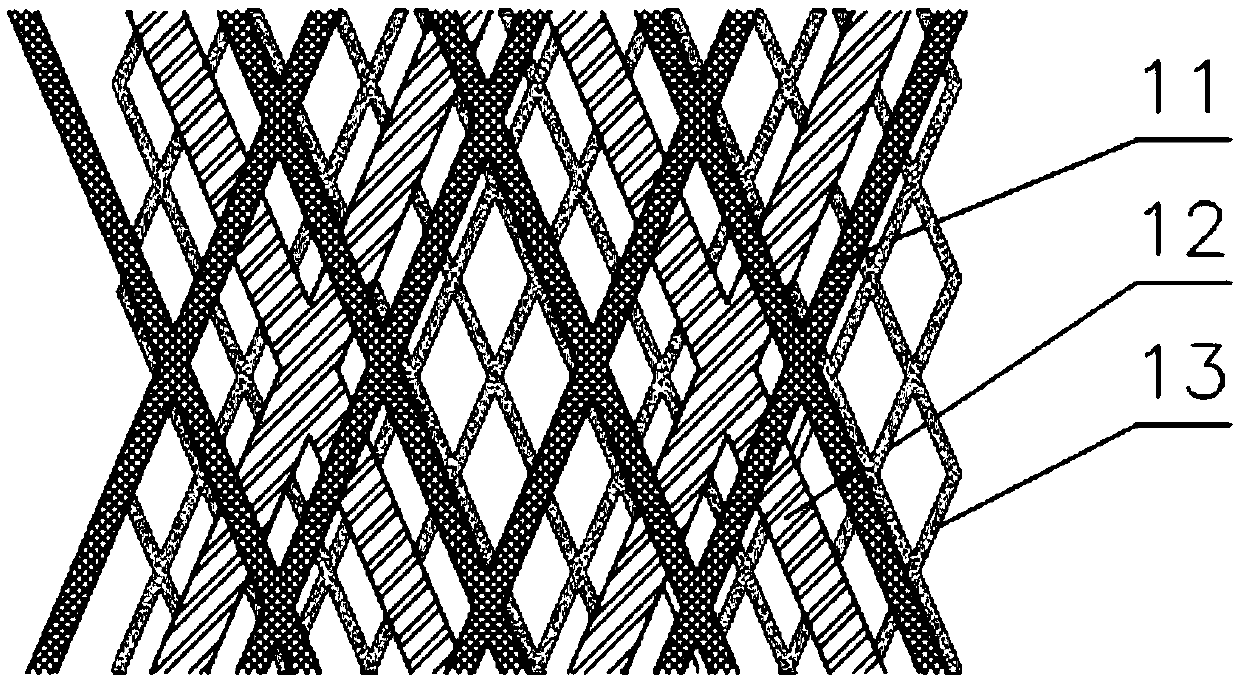

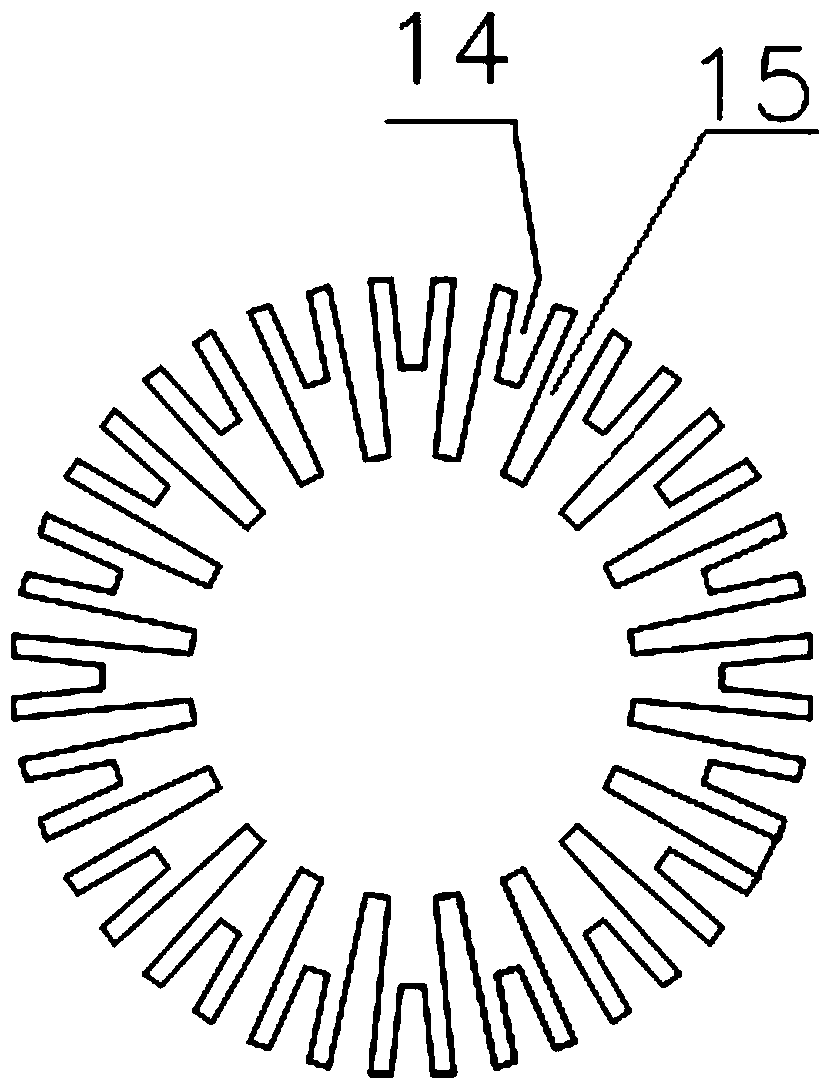

[0021] The material of the filter screen 1 and the installation cover 2 is a metal with good conductivity and wear resistance; the filter screen 1 is a three-layer metal mesh composite of the outer layer middle mesh 11, the middle layer coarse mesh 12 and the inner layer fine mesh 13. structure; the filter surface of the filter screen 1 is a trapezoidal pleated structure with deep pleats 15 and shallow pleats 14; the outer surface of the sealing gasket 4 is wrapped with a layer of conductive mesh 5. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com