Patents

Literature

37 results about "Mineral dust" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mineral dust is atmospheric aerosols originated from the suspension of minerals constituting the soil. It is composed of various oxides and carbonates. Human activities lead to 30% of the dust load in the atmosphere. The Sahara Desert is the major source of mineral dust, which subsequently spreads across the Mediterranean (where it is the origin of rain dust) and Caribbean seas into northern South America, Central America, and eastern North America, and Europe. Additionally, it plays a significant role in the nutrient inflow to the Amazon rainforest. The Gobi Desert is another source of dust in the atmosphere, which affects eastern Asia and western North America.

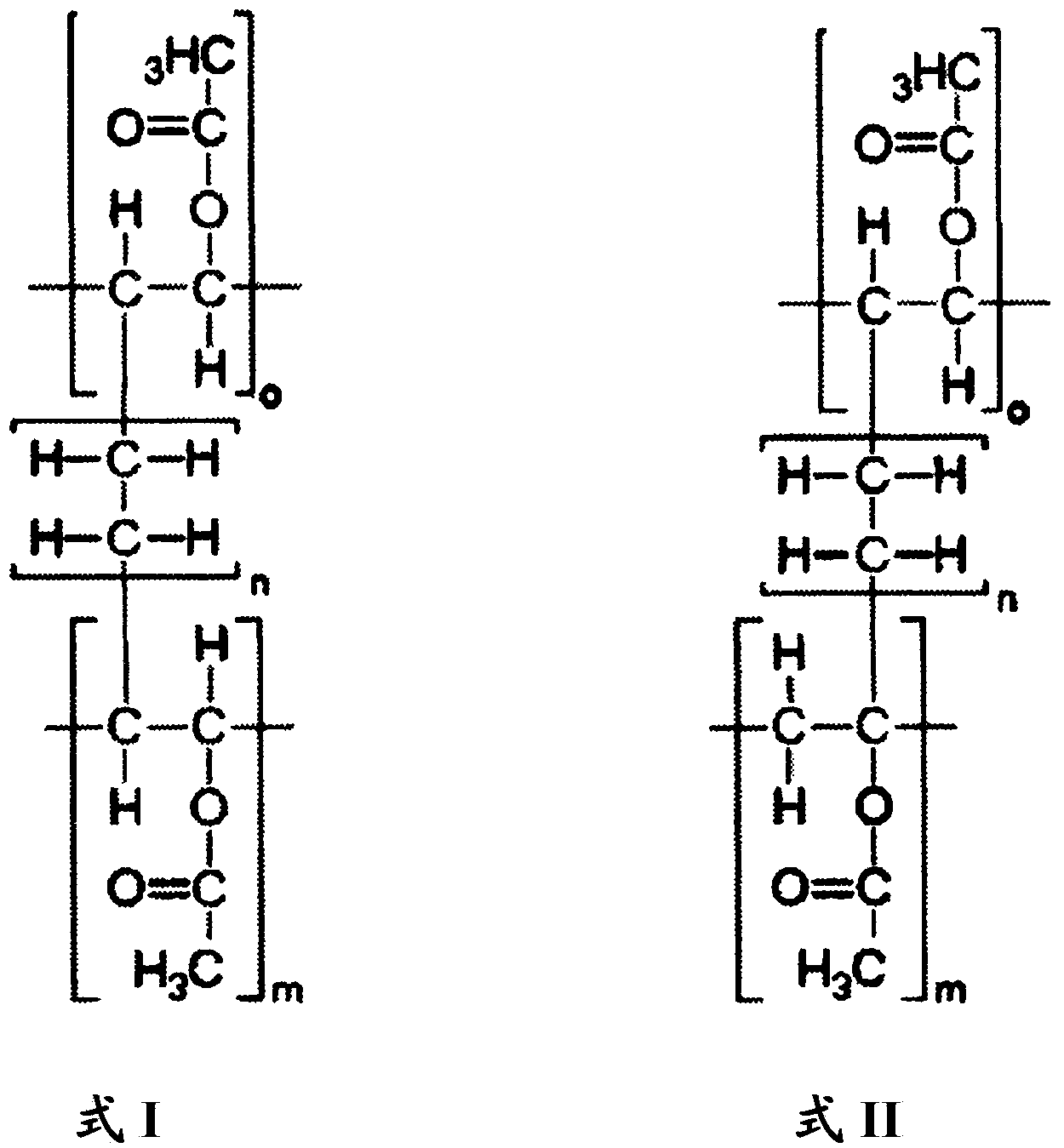

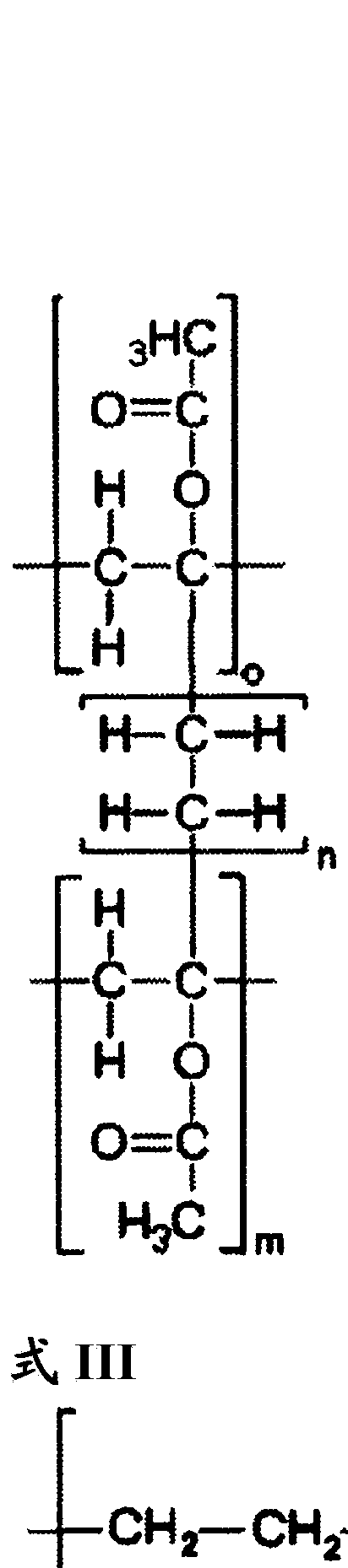

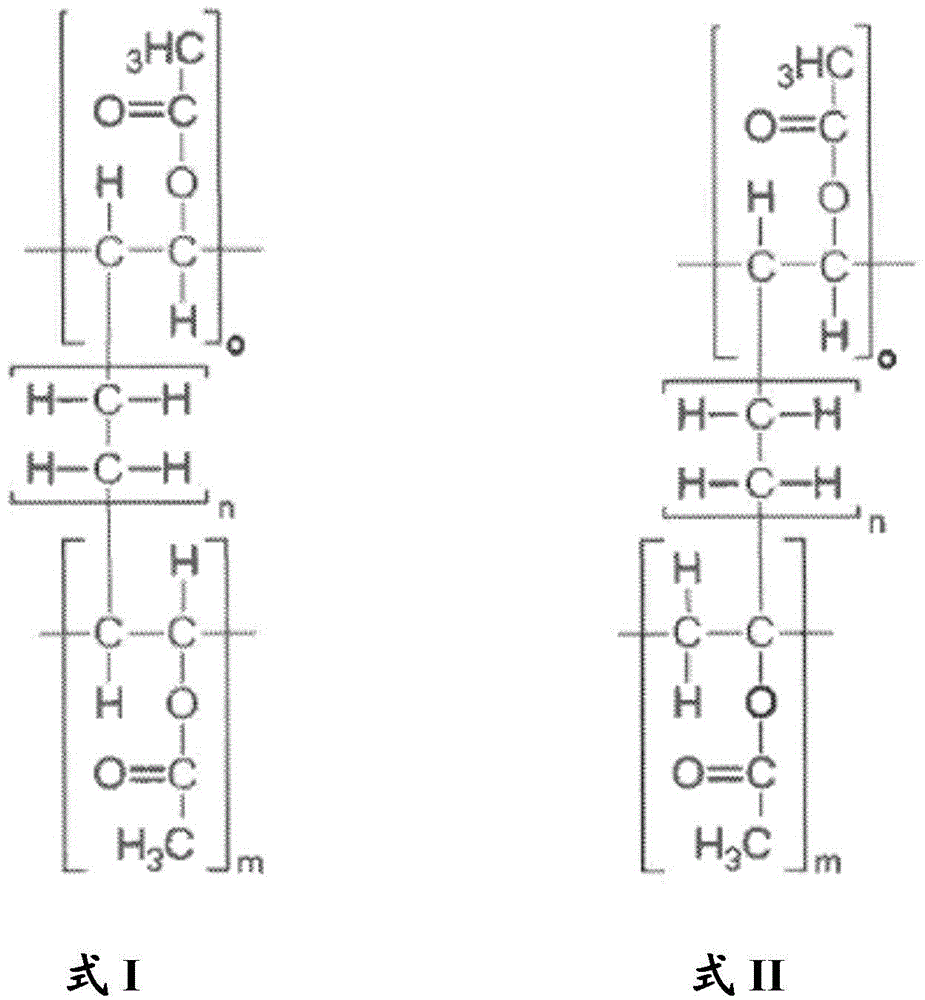

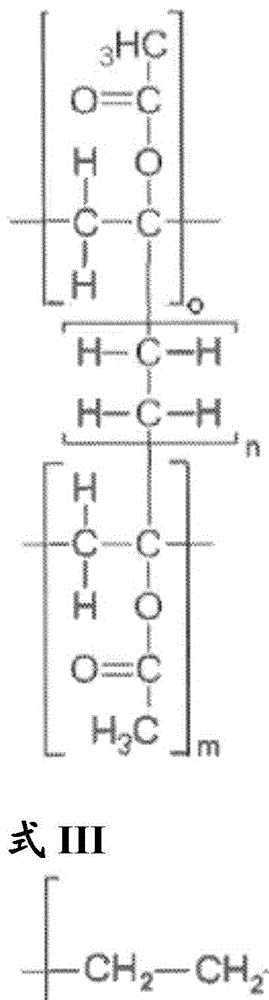

Coated compound fertilizer and preparation thereof

ActiveCN101462907AExcellent nutrient resistance control functionExcellent S-type nutrient dissolution modeFertilizer mixturesLow-density polyethyleneMineral dust

The invention discloses an S type coated compound fertilizer and a preparation method thereof. The S type coated compound fertilizer comprises compound fertilizer granules and a coating wrapped on the surface of the granulated fertilizer; wherein, the material for preparing the coating comprises the substances based on the mass portion ratio: 15-27 portions of polystyrene foam, 24-30 portions of recovered Polypropylene polymers, 7-20 portions of low density polyethylene, 10-45 portions of inorganic mineral dust and 2-9 portions of starch or modified starch. The S type coated compound fertilizer has an excellent S type nutrient dissolving mode, can control the release time and amount of nitrogen, phosphorus and potassium nutrient in an intelligentized way, and meets different needs of agricultural production such as culture of seedling, contact fertilizer application and one-off application.

Owner:BEIJING ACADEMY OF AGRICULTURE & FORESTRY SCIENCES

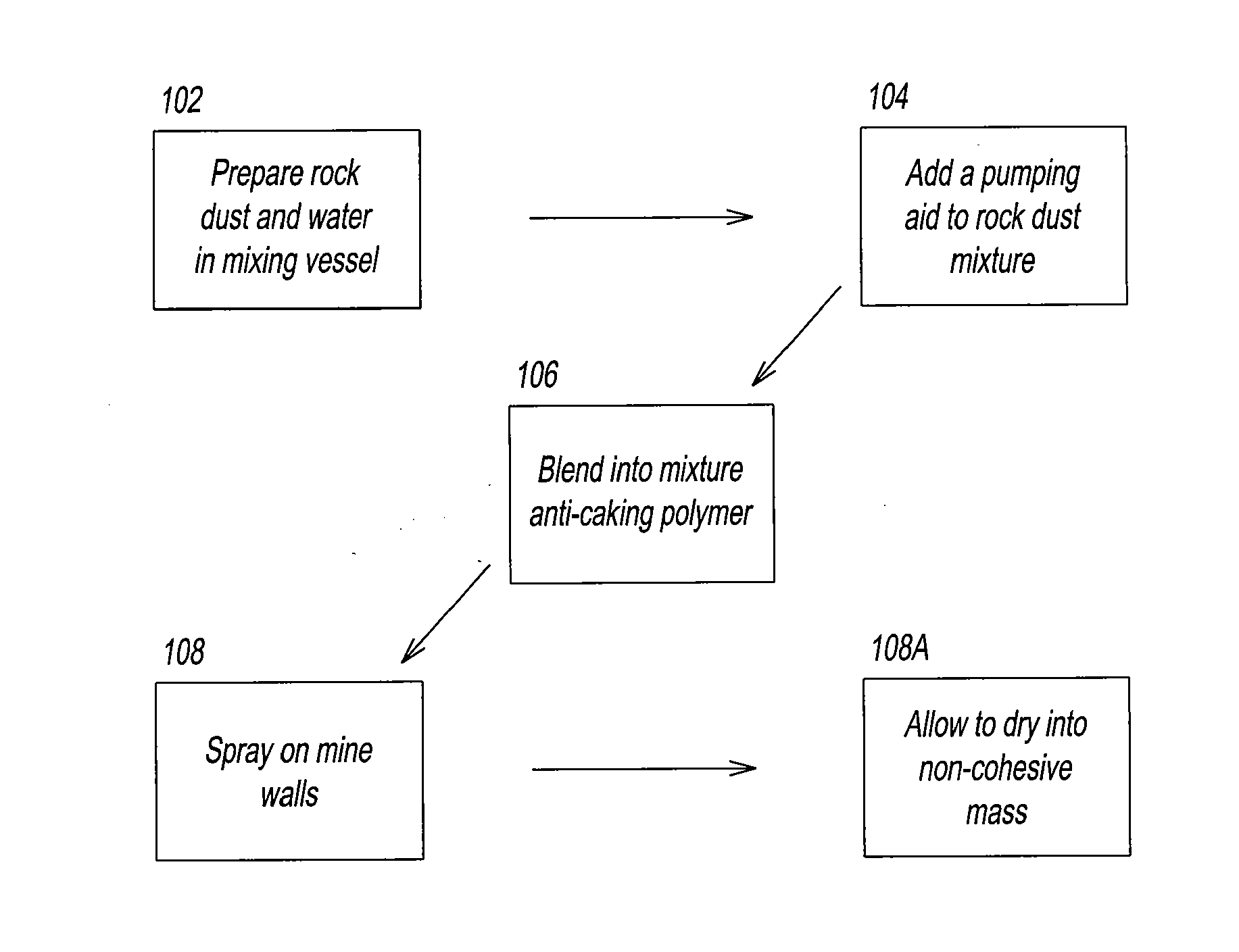

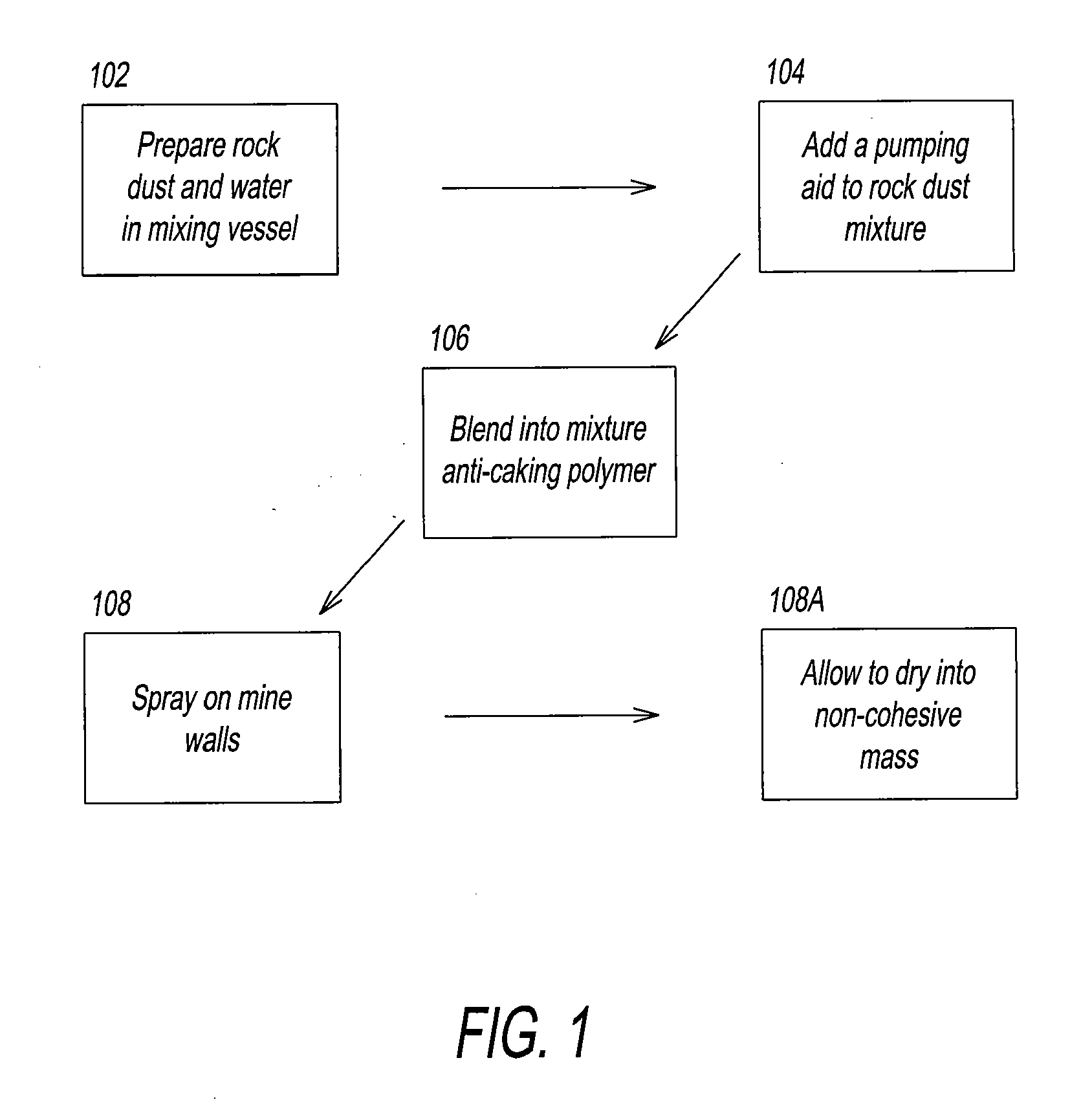

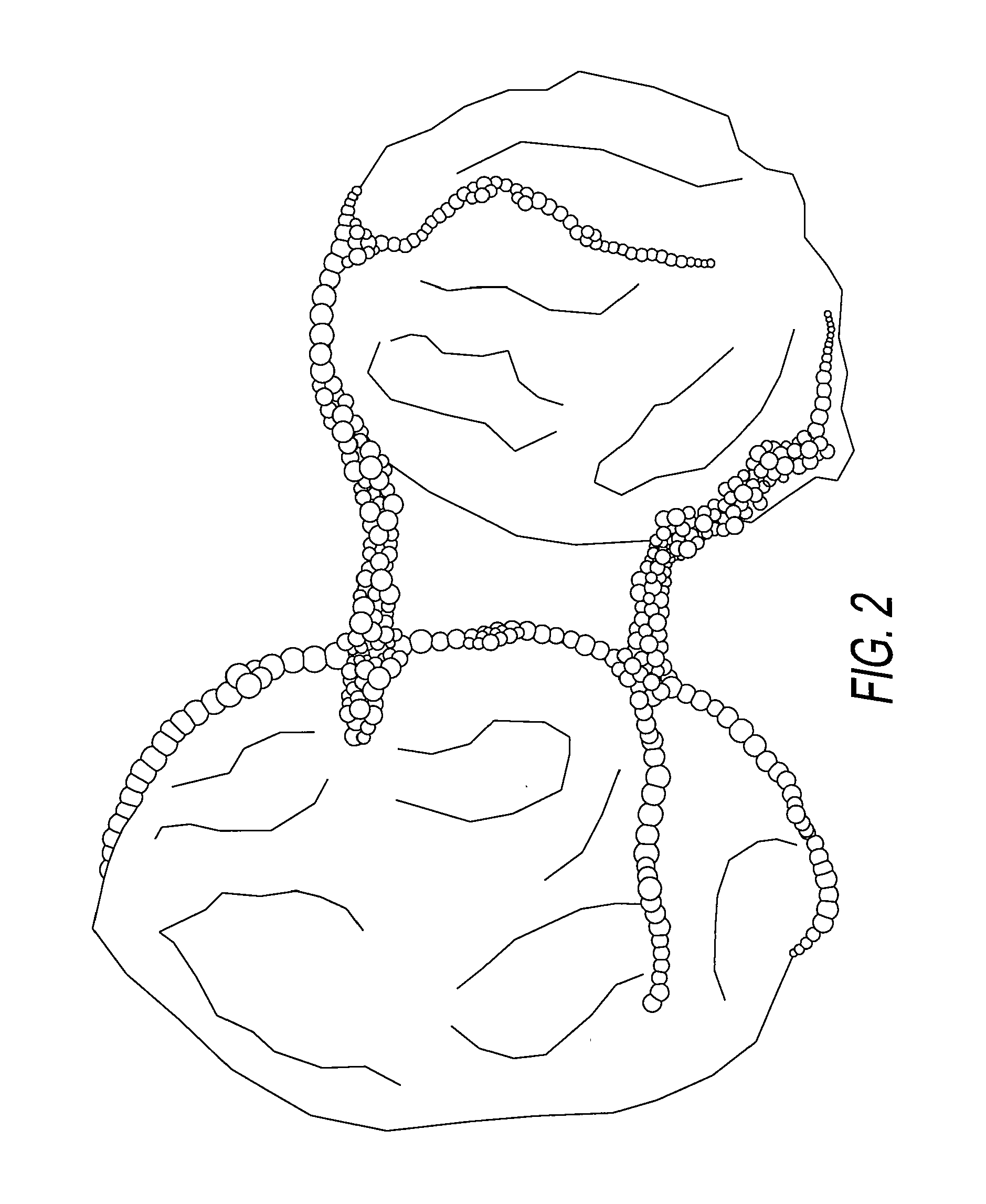

Rock dusting compositions and methods of use thereof

ActiveUS20120181051A1Prevent the spread of flamesSolve the lack of adhesionPretreated surfacesFire rescueMineral dustMining engineering

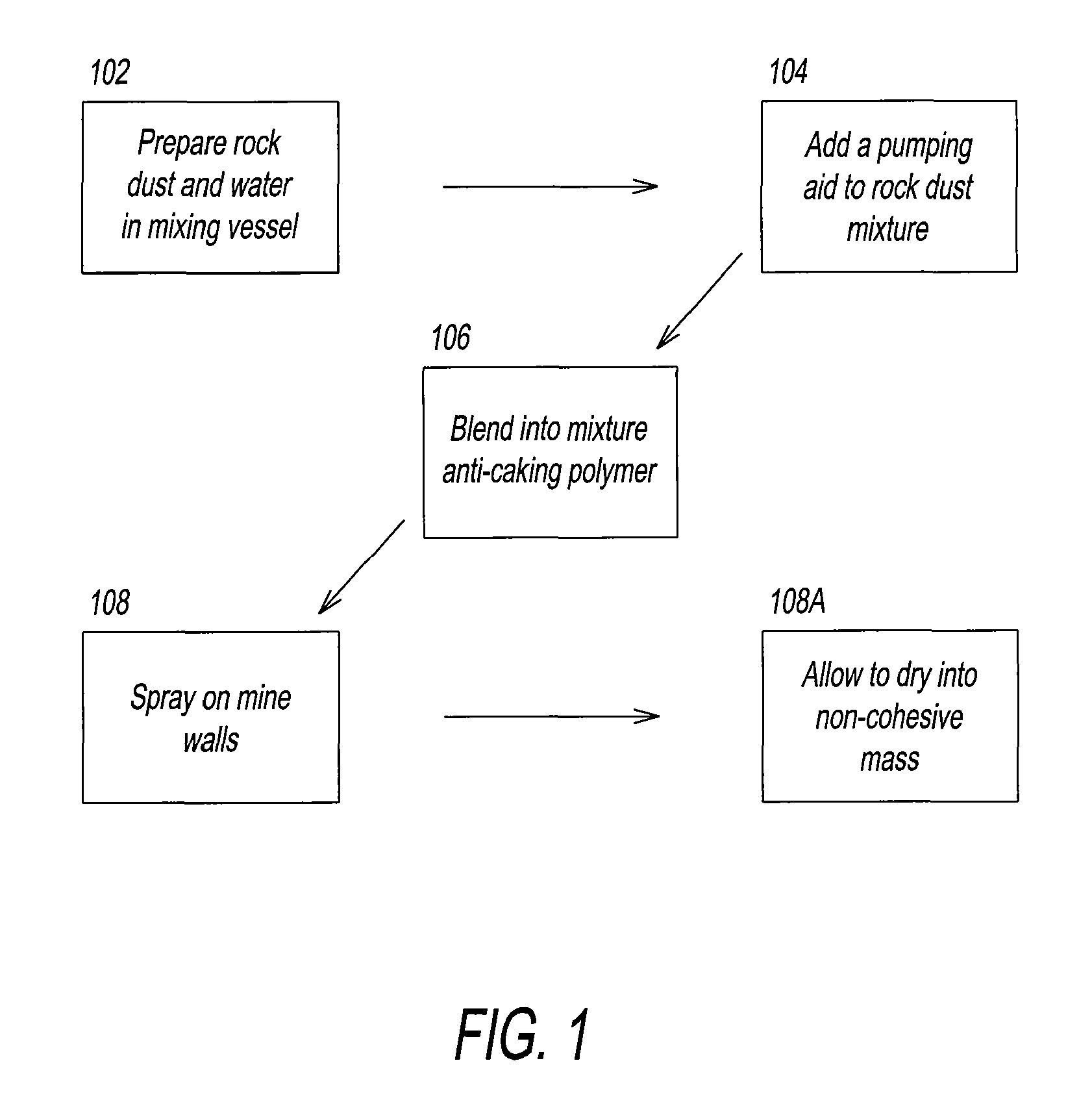

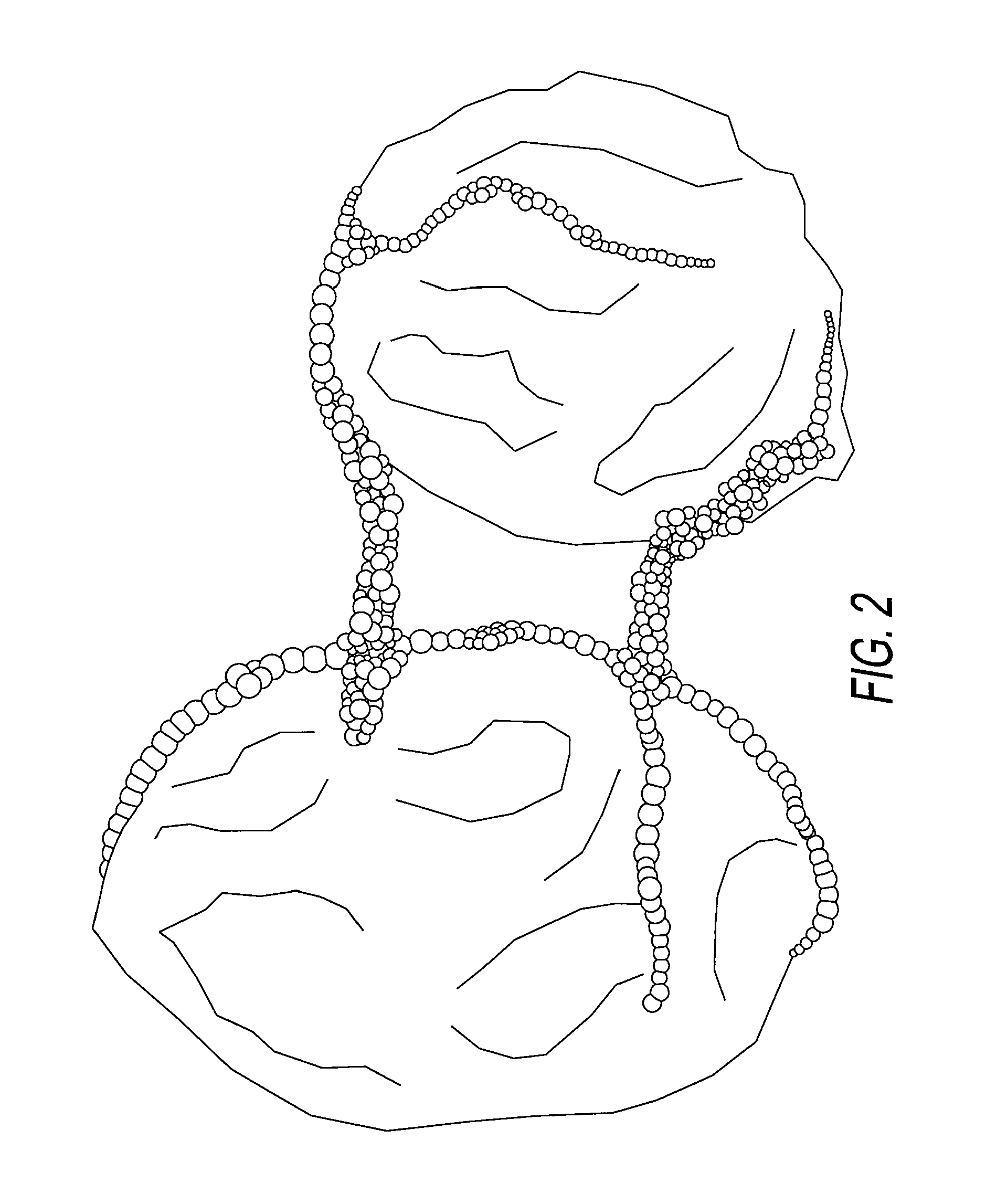

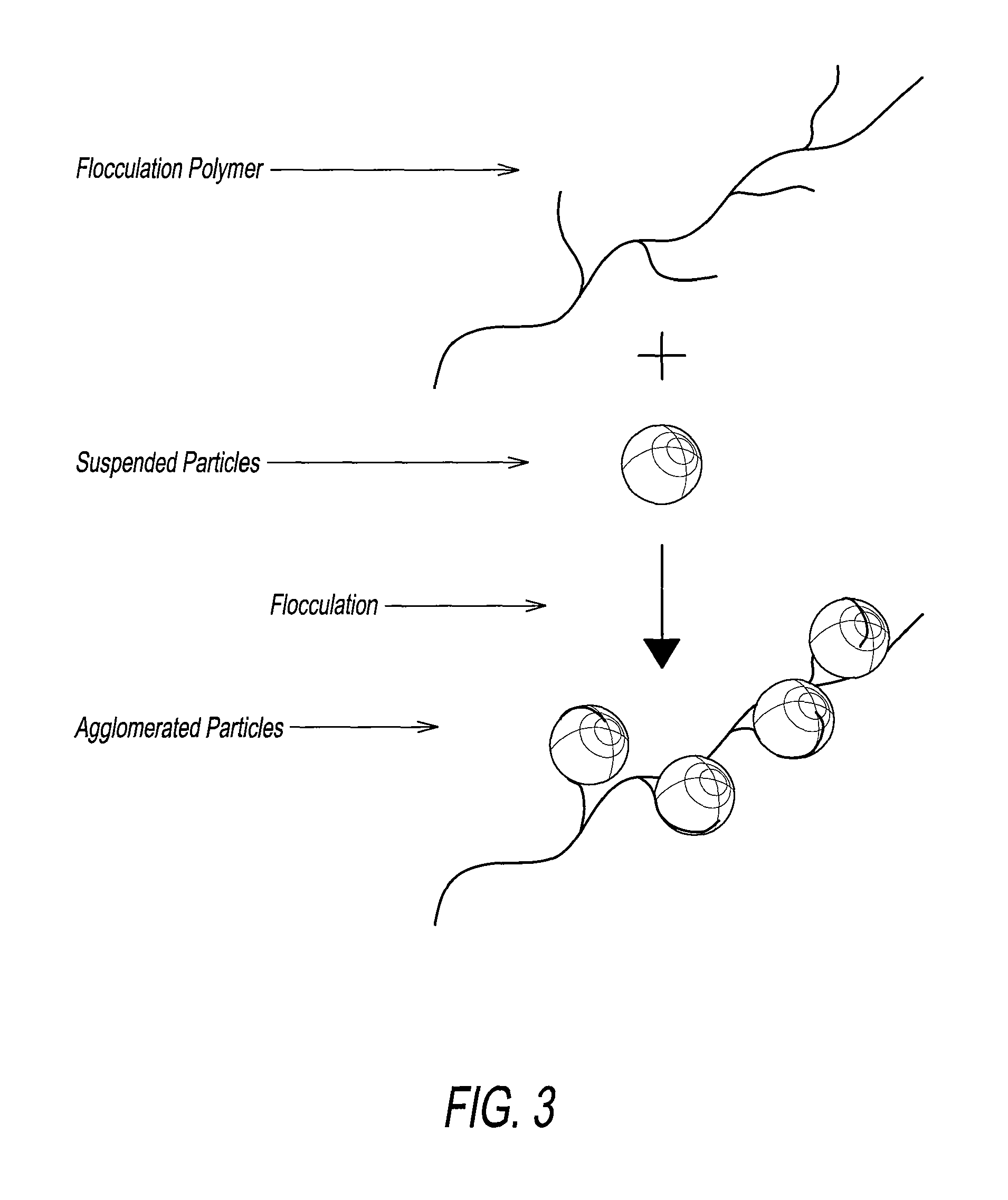

A rock dusting composition composed of rock dust, e.g., limestone or other mineral dust, water, pumping aid, and polymer, e.g., acrylamide homopolymers, acrylamide copolymers, and combinations thereof, and a method for applying the composition to the surface of a mine. The composition has a water content and a polymer content sufficient to allow the polymer to (i) disperse water molecules within the composition and, upon drying of the composition, (ii) dissipate forming void spaces in the dried composition. The composition is useful for suppressing propagation of a flame and / or fire caused by ignition of coal dust and / or gas within a coal mine.

Owner:DSI UNDERGROUND IP HLDG LUXEMBOURG S A R L

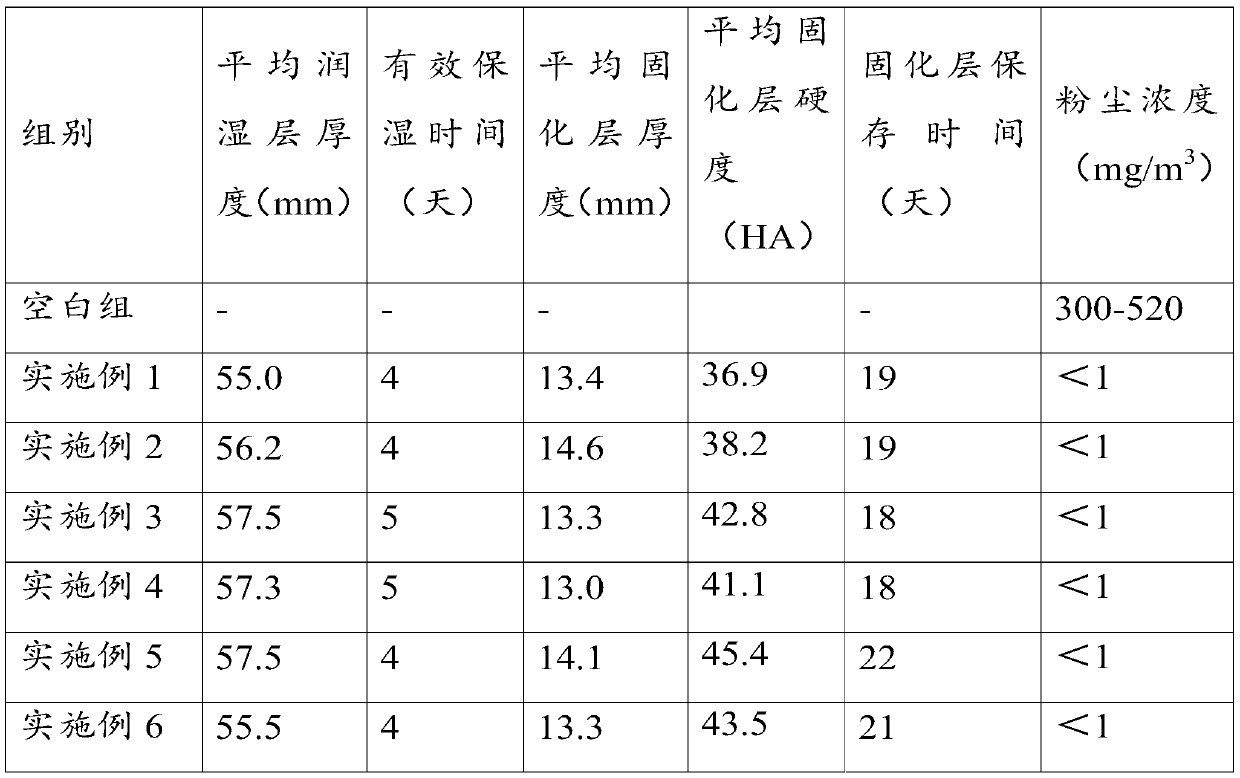

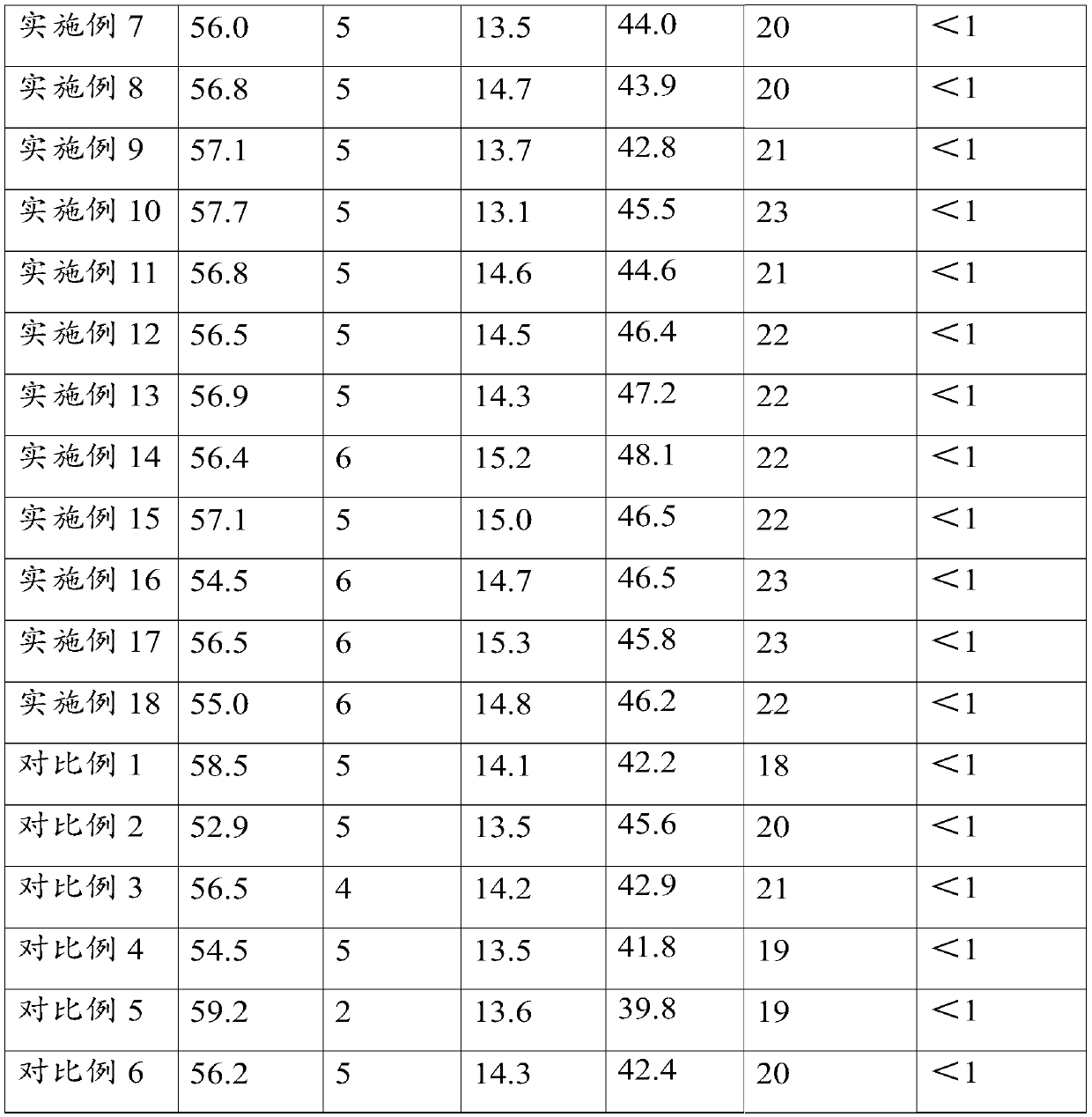

Dust suppressant and preparation method and application thereof

InactiveCN111349422AImprove adhesionImprove wettabilityOther chemical processesDust removalMineral dustPlant Gums

The invention relates to the field of mineral dust treatment, and particularly provides a dust suppressant and a preparation method and application thereof. The dust suppressant is composed of the following components in parts by mass: 60 to 62 parts of vegetable gum, 24 to 28 parts of a humectant, 8 to 12.5 parts of a wetting agent and 2.5 to 3 parts of a thickening agent. The dust suppressant has the advantages of good dust suppression effect, high dust suppression efficiency, good environmental protection property, easily-degradable raw materials, small secondary pollution, low cost, long moisturizing time and long cured layer preservation time, has the characteristics of multiple dust suppressants, and has good adaptability to the environment of mine tailings ponds.

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD

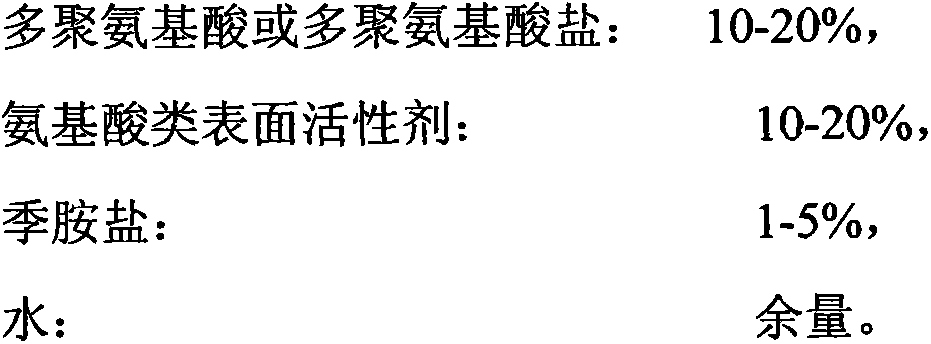

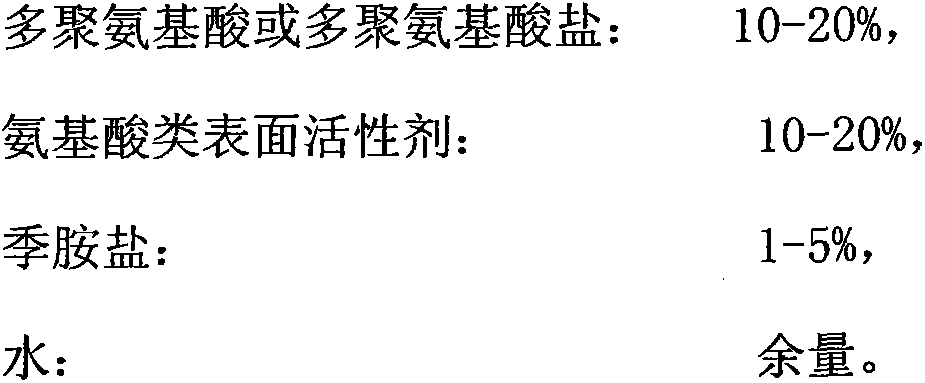

Environment-friendly type dust capturing agent

InactiveCN104017542ASafe and rapid degradationGood biocompatibilityOther chemical processesDust removalMineral dustRespirable dust

The invention discloses an environment-friendly type dust capturing agent and a preparation method thereof. The capturing agent is composed of the following compositions in percent by mass: 10-20% of poly(amino acid) or poly(amino acid salt), 10-20% of an amino acid surfactant, 1-5% of an quaternary ammonium salt, and the balance water. The advantages comprise that the dust capturing agent is nontoxic in composition and completely degradable by nature microbes, and does not cause pollution to soil and underground water after being directly discharged. The agent is easy to dissolve in water, and can be directly sprayed for usage by utilizing an original water spraying system of a mine. The dust capturing agent has the dust removing rate on total coal dust up to 95% or more, and has the dust removing rate on respirable dust up to 90% or more. The agent has corrosion-resistant and sterilization effects, and is capable of improving the environment in mine tunnels. The agent has certain gathering and cladding effects on dust, enables mineral dust to form relatively large particles, and is insusceptible to cause secondary dust rising after drying is performed. The agent is capable of improving the downhole operation environment, reducing dust damage and promoting safe production.

Owner:LANZHOU XUZHAO BIOTECH

Method for selenium-enriching cultivation by using selenium powdered ore

InactiveCN101113111AIncrease dosageIncrease selenium contentClimate change adaptationFertilising methodsMineral dustMineral Sources

The invention provides a selenium-rich growing method employing selenium dust, which is characterized in that: (1) the particle size of selenium is as fine as below 2mm; (2) the selenium dust is treated with the above particle size to pH8.5-9.0; (3) the treated selenium dust is used as base fertilizer according the dosage of 50-100kg / 667m2. The invention has the beneficial effects that: the contend of water soluble selenium in the mineral dust can be enhanced to be absorbed by crops with the dosage of only 50-100kg / 667m2 to generally increase the selenium contend of crop above the standard of 0.1mg / kg, which greatly improves the utilization ratio of low contend and low quality selenium mineral source.

Owner:YANGTZE UNIVERSITY

Rock dusting compositions and methods of use thereof

ActiveUS8883868B2Prevent the spread of flamesSolve the lack of adhesionPretreated surfacesFire rescueMineral dustMining engineering

A rock dusting composition composed of rock dust, e.g., limestone or other mineral dust, water, pumping aid, and polymer, e.g., acrylamide homopolymers, acrylamide copolymers, and combinations thereof, and a method for applying the composition to the surface of a mine. The composition has a water content and a polymer content sufficient to allow the polymer to (i) disperse water molecules within the composition and, upon drying of the composition, (ii) dissipate forming void spaces in the dried composition. The composition is useful for suppressing propagation of a flame and / or fire caused by ignition of coal dust and / or gas within a coal mine.

Owner:DSI UNDERGROUND IP HLDG LUXEMBOURG S A R L

Enhancing type polyolefin/clay nanocomposite and preparing method thereof

The invention relates to an enhancing type polyolefin / clay nanocomposite which is prepared from polyolefin and modified clay in a melt blending and aggregation mode. The modified clay is prepared through reaction and pretreatment through a coupling agent containing double bonds; the clay comprises SiO2 and Al2O3, and the clay is aluminosilicate mineral dust with the granularity smaller than 200 meshes and a layered or fibroid structure. According to the enhancing type polyolefin / clay nanocomposite, a reaction with quaternary ammonium salt is not needed, the clay is dispersed in a solvent first and then reacts with the coupling agent containing double bonds, and the modified clay is obtained. The double bonds of the coupling agent are opened in the melt blending process through a reaction blending method and react with polyolefin and derivatives of polyolefin, and strong interaction of chemical bonds between the clay and polyolefin and between the clay and the derivatives of the polyolefin is established. The clay is evenly dispersed in the polymer through the shearing force of a screw, and the thus the mechanical property and the performance on other aspects of the materials are greatly improved.

Owner:殷明

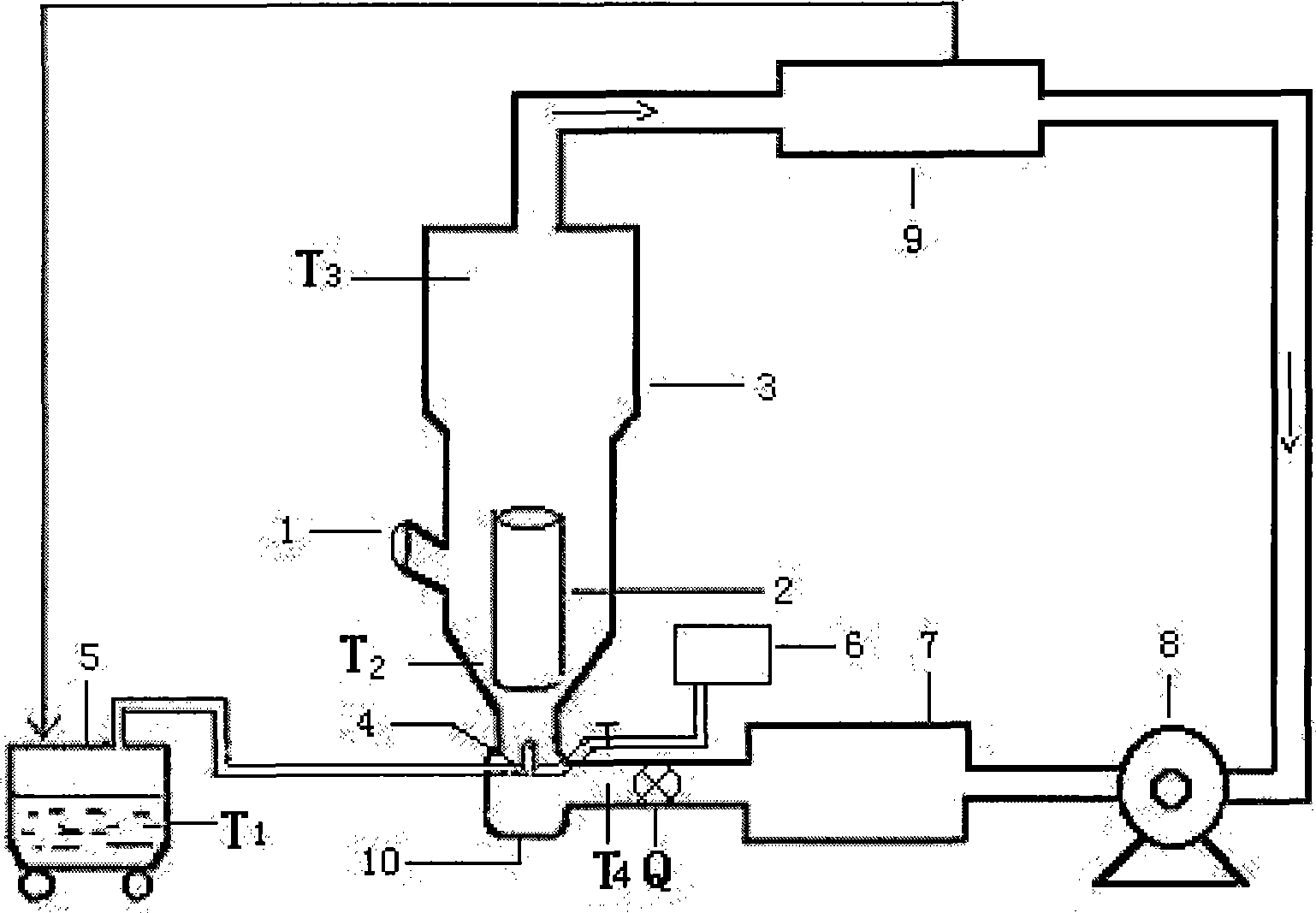

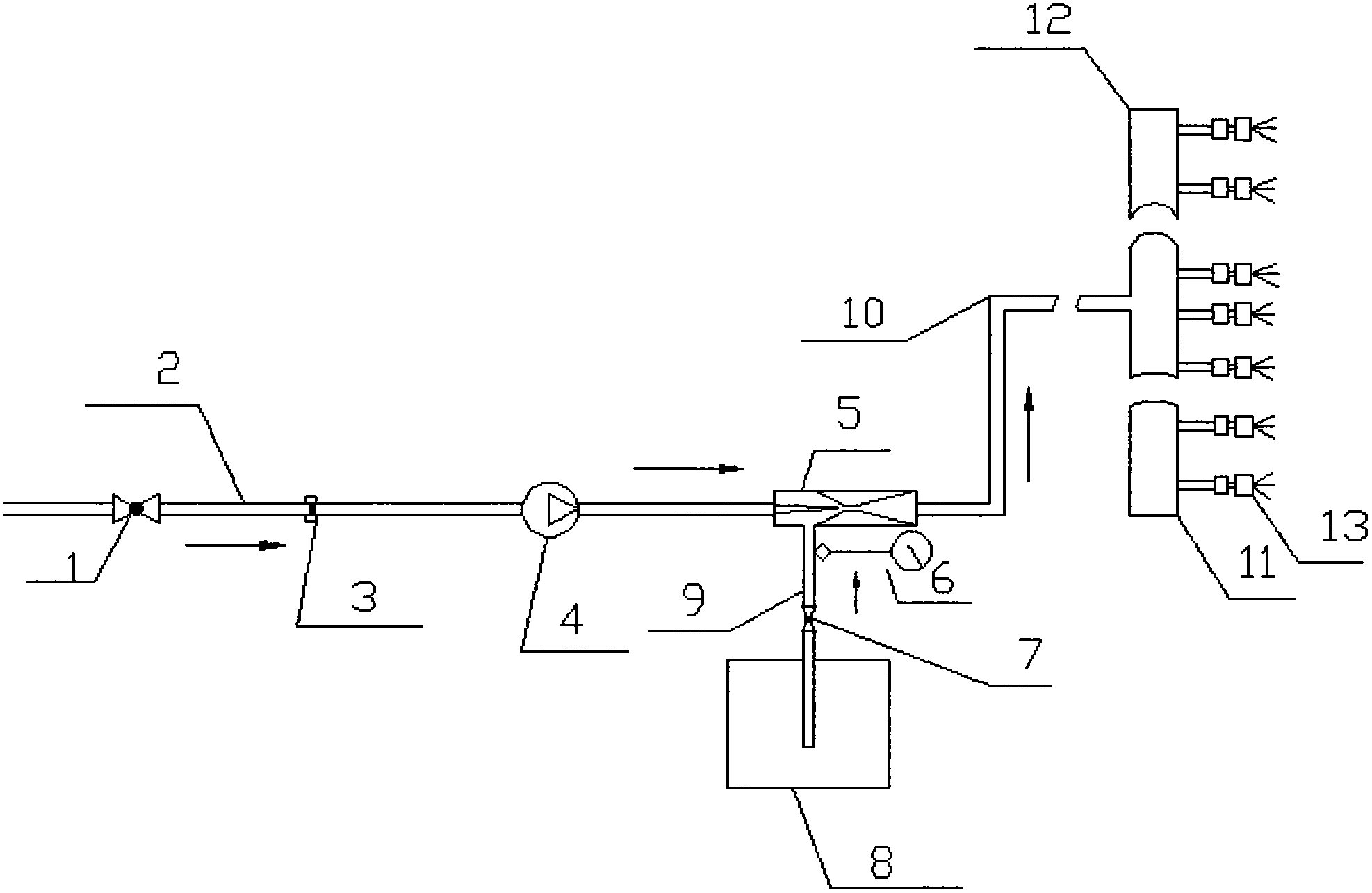

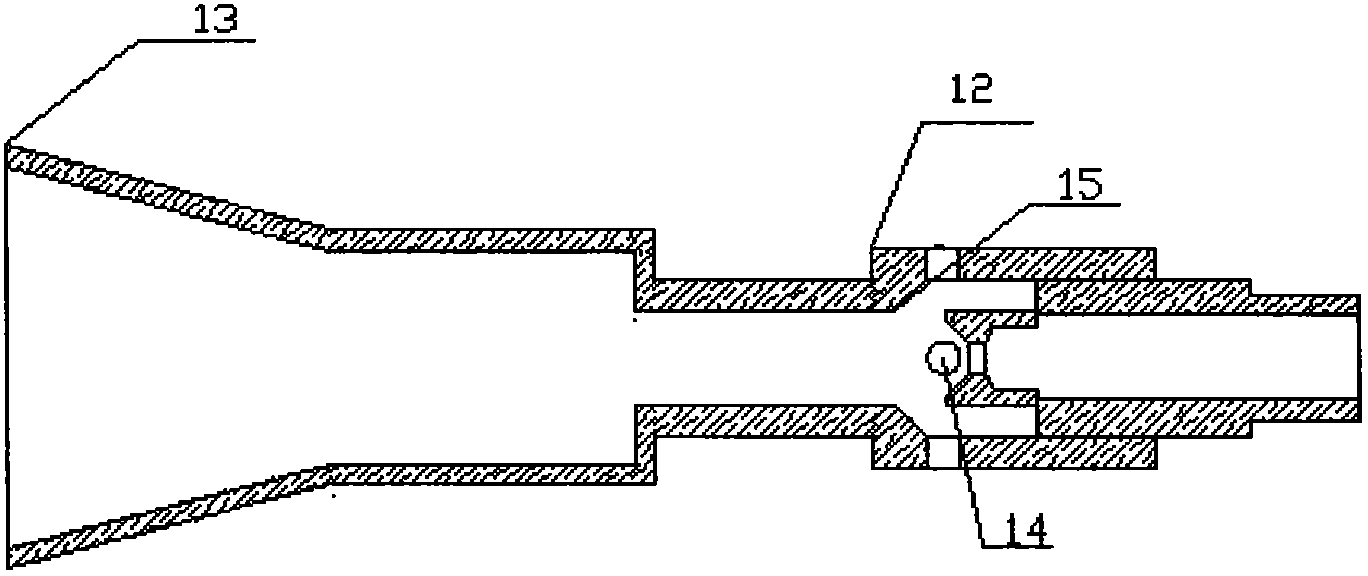

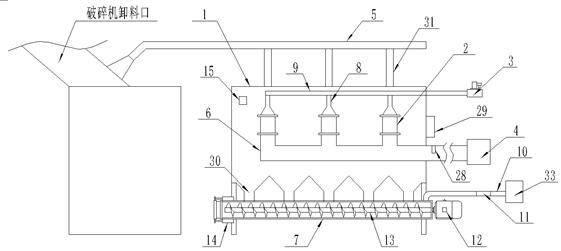

No-air-source foam plug dust removing system applied to underground coal mine

InactiveCN103388484ASolve bulkyOvercoming System ComplexityDust removalFire preventionMineral dustFoaming agent

The invention relates to a no-air-source foam plug dust removing system applied to underground coal mine. The no-air-source foam plug dust removing system mainly consists of components such as a clear water pipeline, a mineral flameproof pressure pump, a proportioning mixer, a foaming agent liquid storage tank, a foaming agent pipeline, a foaming liquid pipeline, a foaming liquid distribution device, a foam maker and a foam nozzle. A current water source in a dust removal site is conveyed to the mineral flameproof pressure pump through a filtering device, clear water is pressured and then enters the proportioning mixer, the proportioning mixer generates negative pressure inside and sucks a foaming agent into the foaming agent pipeline, the clear water fully and uniformly mixed with the foaming agent and then enters the foam maker through the foaming liquid distribution device, the foam maker sucks surrounding air by utilizing the Venturi effect to mix with foaming liquid to form high-quality foam, and the foam is sprayed out through the foam nozzle to form a foam plug with the certain thickness so as to block the propagation of mineral dust; and when the system is in use, the number of the foam nozzles and the thickness of the foam plug are selected according to the requirements of the dust removal site. The no-air-source foam plug dust removing system disclosed by the invention does not need a special compressed air conveyance pipeline and has the advantages of simple structure and convenience in use.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

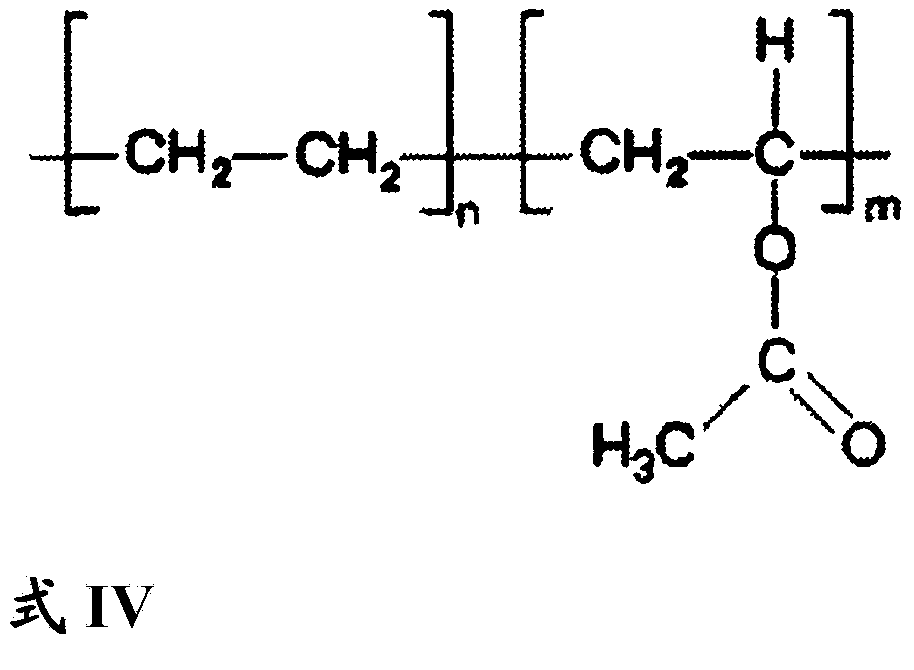

Chemical binder for coating payload in open top hopper cars, trucks, piles and similar storage/shipping containers

ActiveCN103429683AMonocarboxylic acid ester polymer adhesivesLiquid surface applicatorsMineral dustParticulates

The invention is directed towards methods and compositions for treating piles of particulate materials to inhibit and prevent the loss of valuable fuel or mineral dust from being released from storage piles or open containers. The method involves applying to the pile a binder coating containing VAE and crude glycerin. The binder coating cures and hardens slowly so it is able to remain flexible while the pile or payload is still settling, jostling, being bumped, and otherwise moving around. This coating is especially effective for coal piles and also for piles within and for being moved by open topped railroad cars. The coating's flexibility prevents the coating from becoming brittle and shattering. The coating has better performance than its ingredients do alone. The coating is effective both when it is flexible and after it cures. As a result the invention can both prevent unwanted dust pollution as well as save its users money by avoiding loss of blown away material.

Owner:NALCO CO

Building paint coating for absorbing formaldehyde

InactiveCN108003765AExtended service lifeEffective absorptionFireproof paintsAnti-corrosive paintsMineral dustHazardous substance

The invention belongs to the technical field of new building materials, and particularly discloses a building paint coating for absorbing formaldehyde. The building paint coating for absorbing the formaldehyde is prepared from 2-3 parts of nanometer titanium dioxide, 2-3 parts of powder quartz, 1-2 parts of dye, 3-4 parts of dispersing agent, 0.8-1.2 parts of antifoaming agent, 70-80 parts of emulsion, 2-3 parts of formaldehyde absorbent, 2-4 parts of diatom ooze powder, 15-20 parts of filler, 0-0.3 part of flatting agent and 1-1.5 parts of mineral dust. By means of the building paint coatingfor absorbing the formaldehyde, aldehyde, benzene, ammonia and other harmful chemicals in indoor air and on building materials can be effectively absorbed and decomposed; under the condition of photocatalysis, the building paint coating has the functions of effectively decomposing other harmful substances in the air and absorbing peculiar smell in the air; the building paint coating is energy-saving, environmentally friendly, resistant to heat and corrosion, and long in service life.

Owner:陈益德

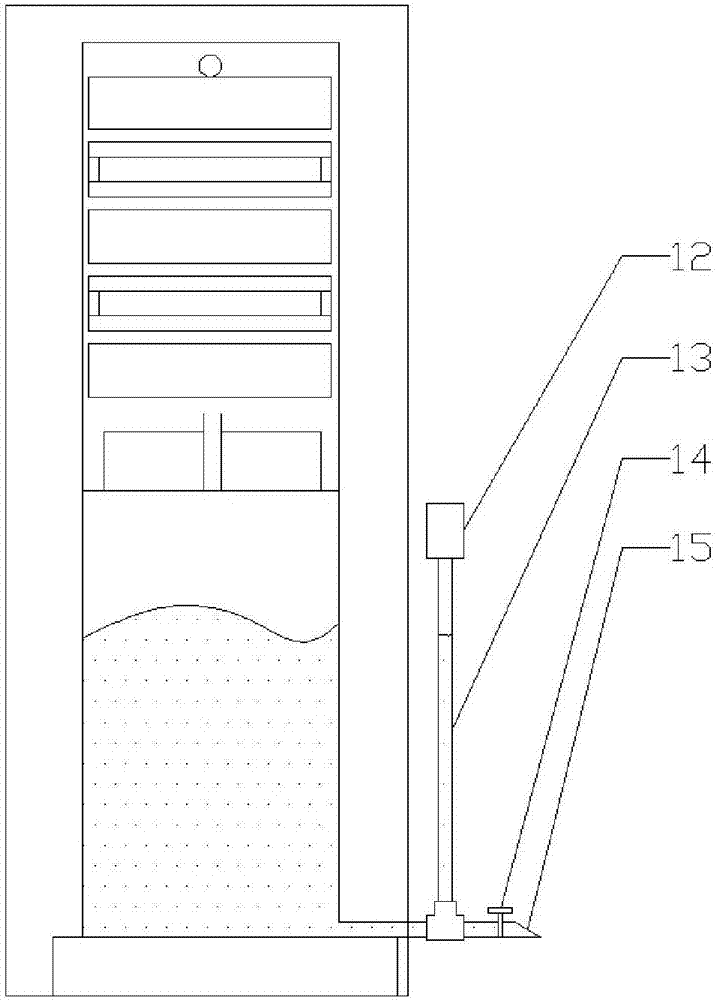

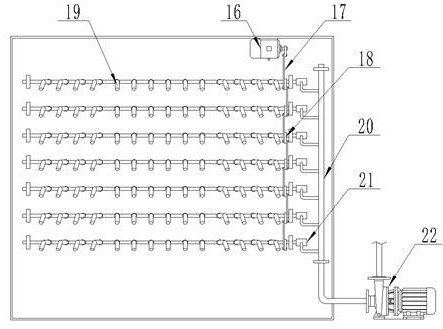

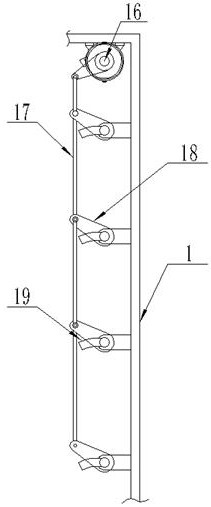

Mineral mist spray dust removal device

PendingCN109464873AImprove dust removal effectAchieve cleanupCombination devicesUsing liquid separation agentMineral dustMixed flow

The invention belongs to the technical field of mineral dust removal equipment, and specifically discloses a mineral mist spray dust removal device. The mineral mist spray dust removal device comprises a dust removal machine shell, wherein an atomizing cavity is formed in the interior of the dust removal machine shell; the top of the atomizing cavity is provided with a connecting pipe used for connection; atomizing machines used for adjustment are arranged at two ends of the inner cavity of the atomizing cavity respectively, and a movable plate is arranged at the bottom of the atomizing cavity; two air bags are arranged on two sides of the buffer spring; a fixed plate is arranged below the movable plate, and a rubber plate is arranged below the fixed plate; a mixed flow cavity is formed inthe space between the rubber plate and the fixed plate; two hoses are arranged between the mixed flow cavity and the atomizing cavity; an air outlet plate is installed at the lower end of the rubberplate, and a dust collection net used for dust collection is arranged in the inner cavity of the air outlet plate; and an electric push rod is arranged at the bottom of the fixed plate. According to the mineral mist spray dust removal device, the rubber plate is pushed by the electric push plate, so that water mist inside the mixed flow cavity is compressed and sprayed, and then the dust removal effect of water mist in mineral holes is improved.

Owner:ANHUI WANBEI COAL REFCO GRP LTD HANSHAN HENGTAI NONMETALLIC MATERIALS BRANCH

Dust humectant performance measuring method

InactiveCN101191764AHigh degree of automationSurface/boundary effectParticle size analysisMineral dustUltrasonic dispersion

The invention discloses a determination method for dust moistening agent performance. The dust is sieved, the mineral dust with the particle diameter less than 180 mesh is obtained; the sieved dust sample is distributed in the moistening agent solution, is made ultrasonic dispersion and still placement; the particle diameter of the dust in the moistening agent suspension is tested, the performance of the dust moistening agent is determined by particle diameter parameters. The invention is suitable for determining the performance of various fine dust moistening agent, the dust characteristics can be referred during the determination, the determination result can more directly reflect the moistening process of the moistening agent to the dust, the different moistening performances of the same moistening agent to the dust with different particle diameters can be synchronously analyzed, the action effect of the moistening agent to the dust with different particle grades can be quantitatively analyzed; the invention has high determination automation degree and broad application range.

Owner:CENT SOUTH UNIV

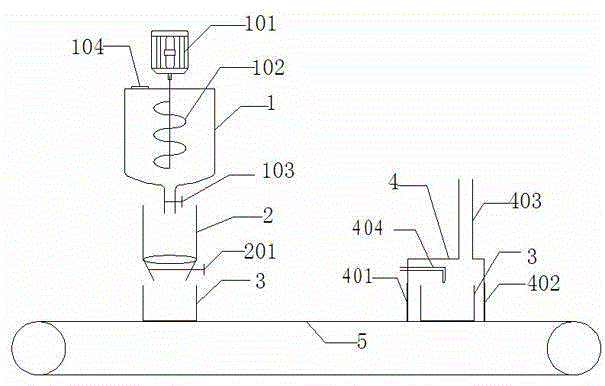

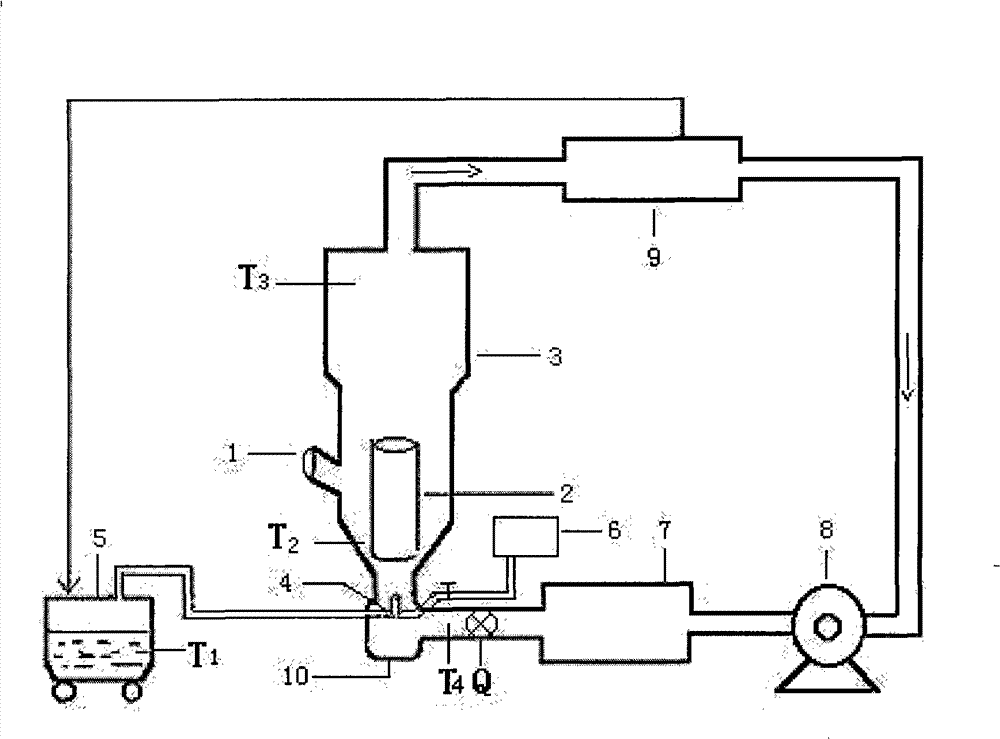

Box-type automatic sintering device

The invention provides a box-type automatic sintering device which is characterized by comprising a dosing kettle, a mixture storage tank, a sintering box, a sintering chamber and a conveyer belt. According to the device provided by the invention, a great number of particle mineral powder and mineral dust caused by production of silicomanganese alloy enterprises can be automatically handled, sintered into large blocks and smashed to have granularity which meets the smelting requirements for smelting raw materials of silicomanganese alloy. The device provided by the invention is simple in structure, low in equipment investment and good in sintering quality, and can be used for producing continuously and automatically.

Owner:广西敏诚矿业股份有限公司

Environment-friendly treating device for flue gas from sulfuric acid production

ActiveCN110038363ASolve the situation that is easy to block the filter holeSolve the jam situationDispersed particle filtrationTransportation and packagingMineral dustFlue gas

The invention relates to an environment-friendly treating device for flue gas from sulfuric acid production. The environment-friendly treating device comprises a ventilating frame, a connecting pipe,a detachable device and anti-blocking sieving holes, wherein the left end of the ventilating frame is communicated with the ventilating frame; the detachable device is arranged at the upper end of theinterior of the ventilating frame; the anti-blocking sieving holes are arranged at the right end of the detachable device. The environment-friendly treating device has the beneficial effects that thedifficulties that filtering holes are easily blocked when mineral dust is removed and the quantity of normal filtering holes is reduced to cause reduction of the filtering efficiency, and after a period of time of working, partial mineral dust is easy to deposit on the surface of a filtering device to cause the increase of bear load on the device and the like can be solved; by expansion of hole diameter and auxiliary downward pushing of a pushing plate, the blocked mineral dust can be dredged and fall down; a filtering net can be detached at any time, so that convenience is brought for timedcleaning and replacement of the filtering net; the anti-blocking sieving holes can be wholly taken by the detachable device at any time, so that cleaning is convenient, the possibility of deposition of a large amount of mineral dust on the detachable device is reduced, and the increase of the bear load on the device can be avoided.

Owner:阜阳知麓信息科技有限公司

Mineral dust treatment device

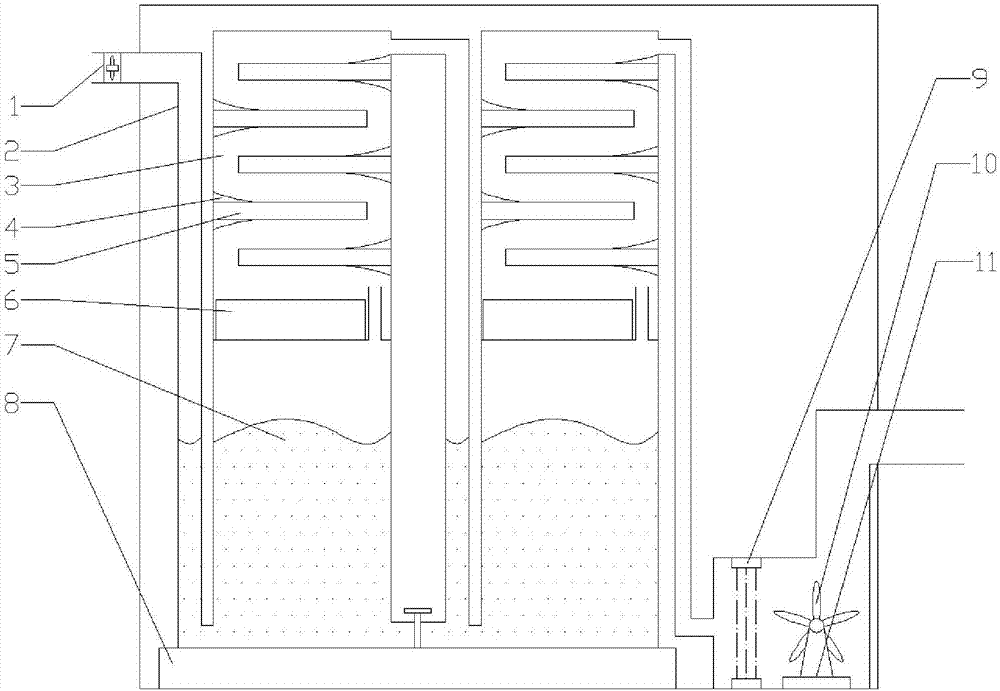

InactiveCN107158871AReduce noiseNo noise pollutionCombination devicesGas treatmentLow noiseMineral dust

The invention discloses mineral dust treatment, including an air intake fan, an air intake pipe, a gas scrubbing tower, a dust removal board slot, an electrostatic dust removal board, a dust collecting box, a gas scrubbing solution, a tower base, a dust detector, an exhaust fan, The fan bracket, the top cover of the liquid injection port, the liquid injection pipe, the liquid discharge valve and the liquid discharge port, the intake fan is located at the top of the intake pipe, and the bottom end of the intake pipe is connected to the bottom of the gas scrubbing tower. The plate is divided into upper and lower parts, the lower part contains the scrubbing solution, and the upper half of the scrubber tower is equipped with electrostatic dust removal equipment, which includes dust removal board slot, electrostatic dust removal board and dust collection box. The utility model adopts the combination of solution filtration and electrostatic dust removal to treat mineral dust, the noise generated during the treatment is low, and no noise pollution will be caused. The exhaust terminal is provided with a dust detector, which can quantify the treatment effect and prompt the operation. The personnel should replace the scrubbing solution to clean the dust box in time.

Owner:成都尚智恒达科技有限公司

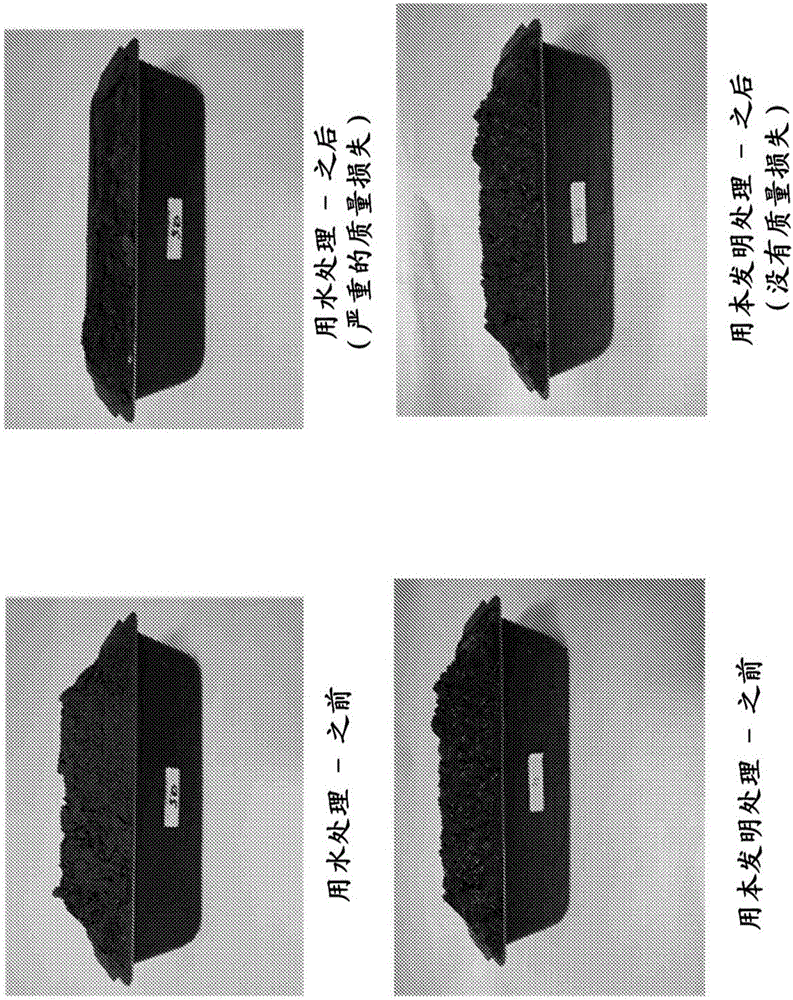

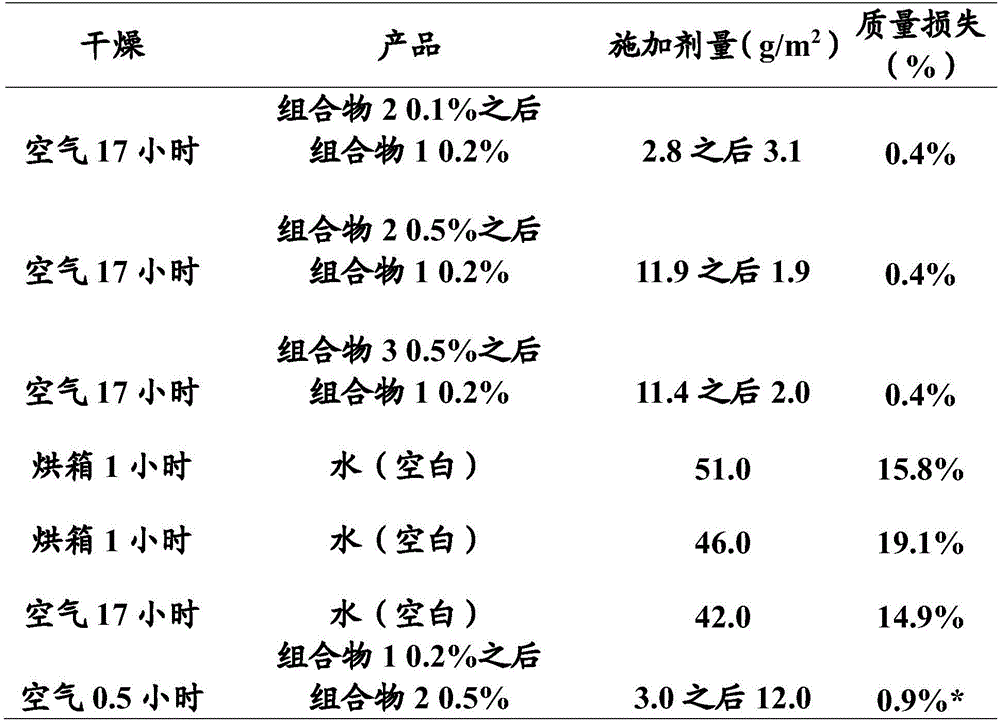

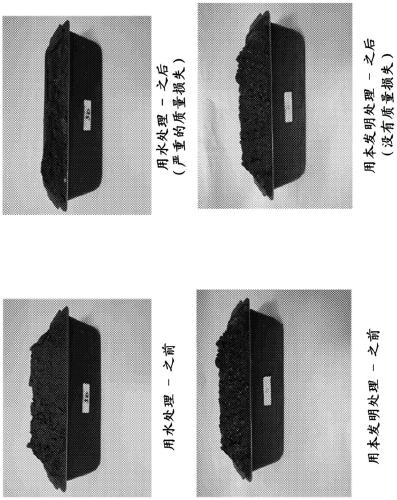

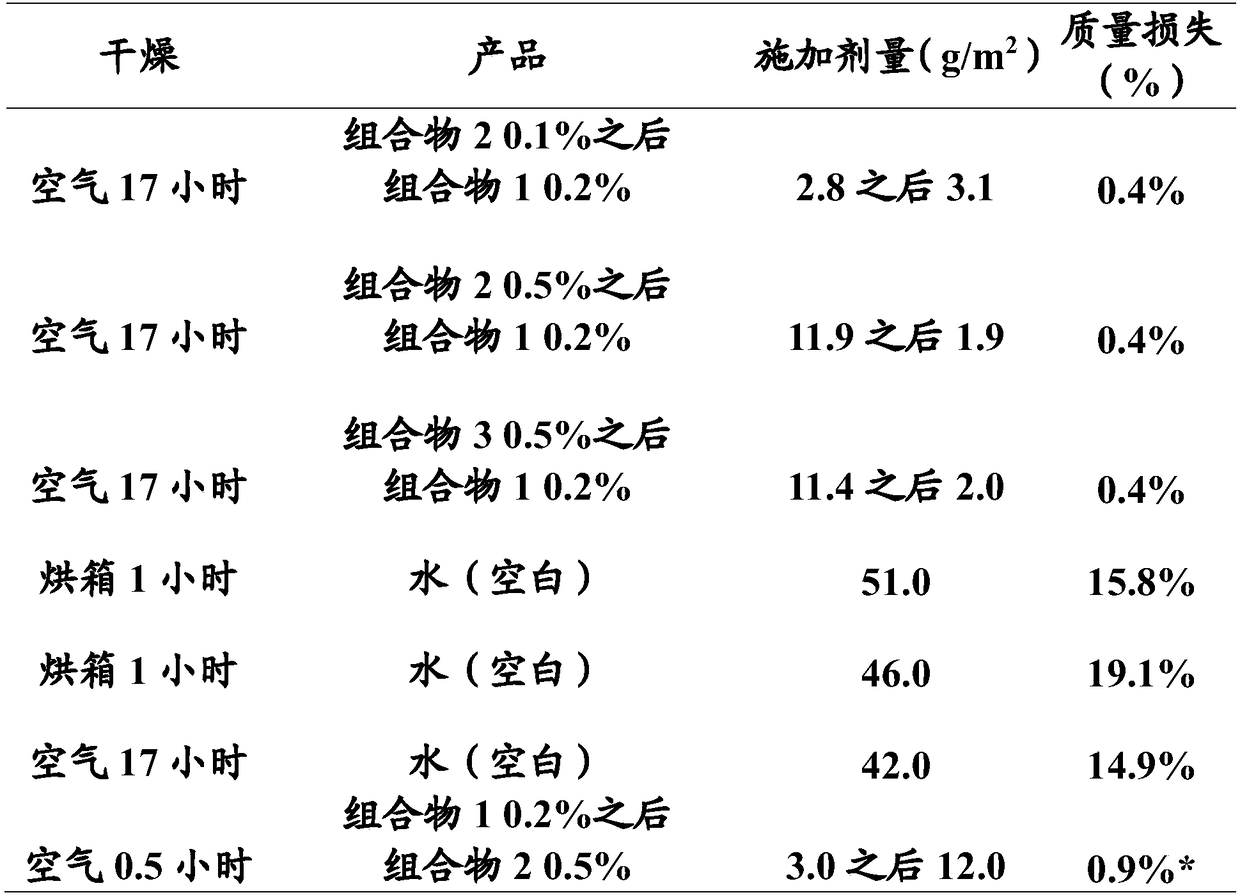

Method and composition for dust control

The invention is directed towards methods and compositions for treating piles of particulate materials to inhibit and prevent the loss of valuable fuel or mineral dust from being released from storage piles or open containers. The method involves applying separately to the pile two different compositions. When separate the two compositions are low viscosity and easy to spray. When combined the two form a gel coating that is resistant to erosion but is flexible while the pile or payload is still settling, jostling, being bumped, and otherwise moving around.

Owner:ECOLAB USA INC

Use of aqueous solution of organic ammonium carboxylate in preventing dusting of fine material and combination of an aqueous solution of organic ammonium carboxylate and fine material

InactiveUS20190194513A1Reduce the amount requiredOrganic chemistryOther chemical processesMineral dustCrushed stone

A method to control dusting of sand, crushed stone, mineral dust, metal powder and the like by using an aqueous solution of organic of ammonium carboxylate is disclosed.

Owner:GRANULA

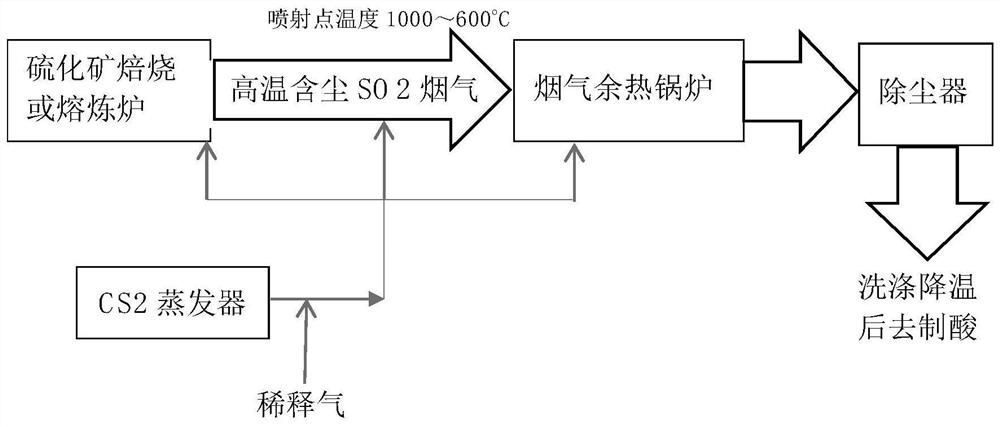

A method for suppressing the production of sulfur trioxide in flue gas from heavy non-ferrous metal smelting acid production

The invention relates to a method for suppressing the generation of sulfur trioxide in the flue gas of acid-making smelting of heavy nonferrous metals. Carbon disulfide is used as a reducing agent to suppress the generation of sulfur trioxide. Add a certain concentration of CS 2 gas for this purpose. Its principle of action is to use the injected CS 2 Gas pairs with catalytic SO 2 form SO 3 The effect of the dust surface to compete with the reaction, thereby inhibiting the SO 2 Catalytic oxidation to produce SO 3 ; additional CS 2 It is also possible to directly put the SO 3 Revert to SO 2 . Eliminate SO through the above effects 3 the goal of. Compared with the prior art, the present invention has the advantages of simple operation, low cost and high efficiency, and does not consume SO in the flue gas during the elimination process 2 The production of sulfuric acid is reduced, and there will be no secondary pollution such as waste water and residue.

Owner:SHANGHAI JIAO TONG UNIV

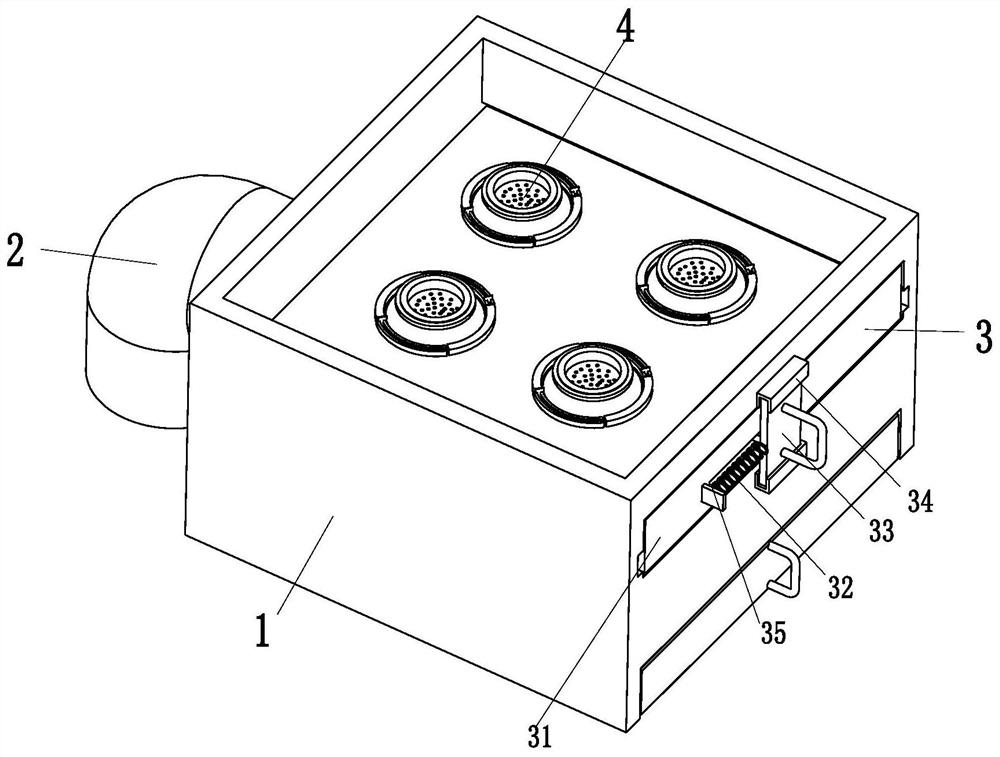

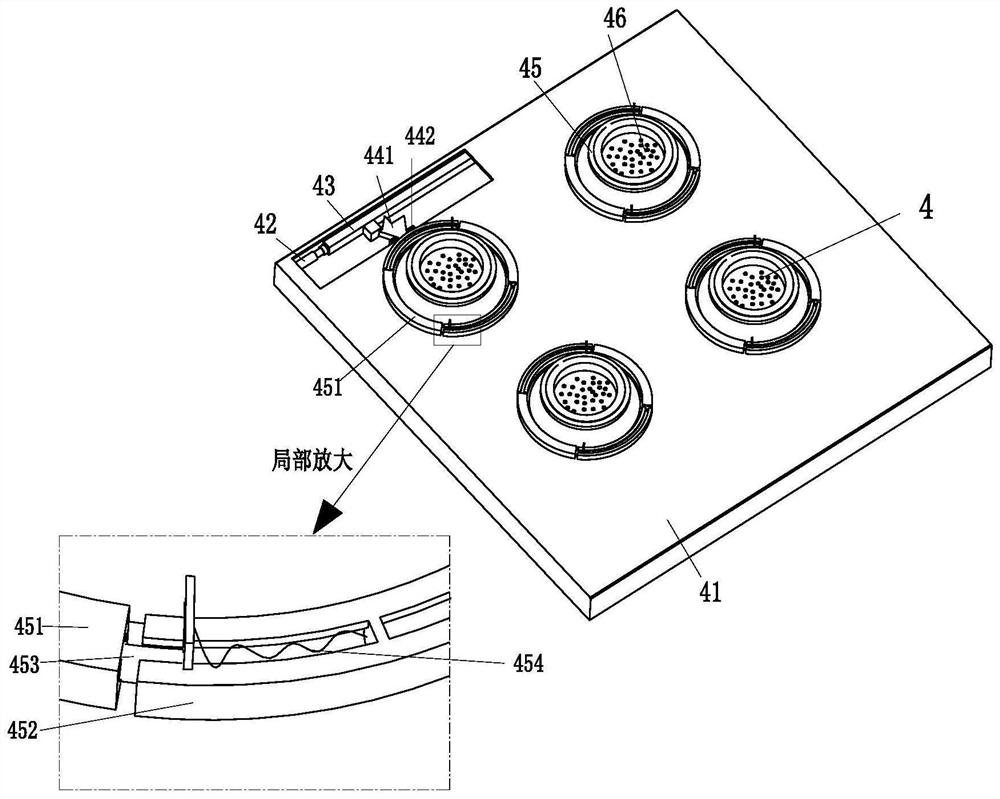

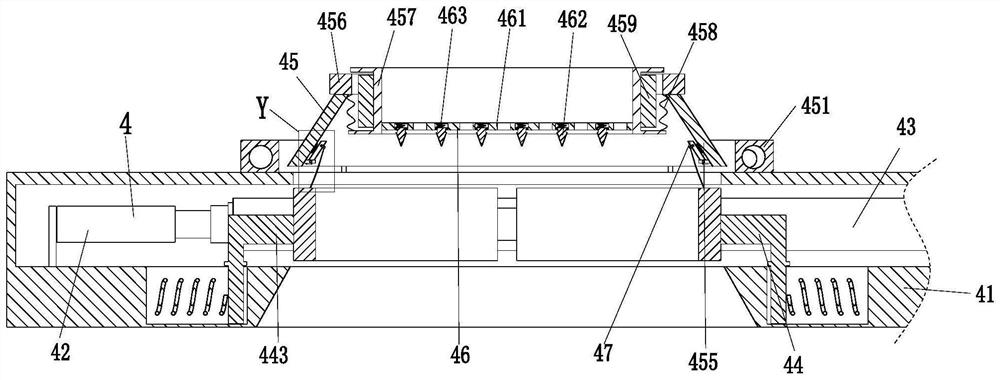

An environment-friendly sulfuric acid production flue gas treatment device

ActiveCN110038363BEasy to cleanEasy to replaceDispersed particle filtrationTransportation and packagingMineral dustFlue gas

The invention relates to an environment-friendly sulfuric acid production flue gas treatment device, which includes a ventilation frame, a connecting pipe, a detachable device, and an anti-blocking screening hole assembly. The left end of the ventilation frame communicates with the connecting pipe, and the upper end of the ventilation frame is provided Block the screening hole assembly, and a detachable device is installed at the right end of the anti-blocking screening hole assembly. The invention can solve the problem that the filter holes are easily blocked when the mineral dust is removed, and the number of normally filtered holes is reduced to reduce the filtration efficiency. After working for a period of time, part of the mineral dust is easy to accumulate on the surface of the filter device, resulting in the failure of the device. For problems such as increased load, through the enlarged aperture and the auxiliary push down of the push plate, the clogged mine dust can be dredged and dropped, and the filter can be detached at any time, which facilitates regular cleaning and replacement of the filter. The detachable device can be removed at any time The anti-blocking screening hole is taken as a whole, which is convenient for cleaning, reduces the possibility of a large amount of mine dust accumulating on the detachable device, and avoids the increase of the load of the device.

Owner:阜阳知麓信息科技有限公司

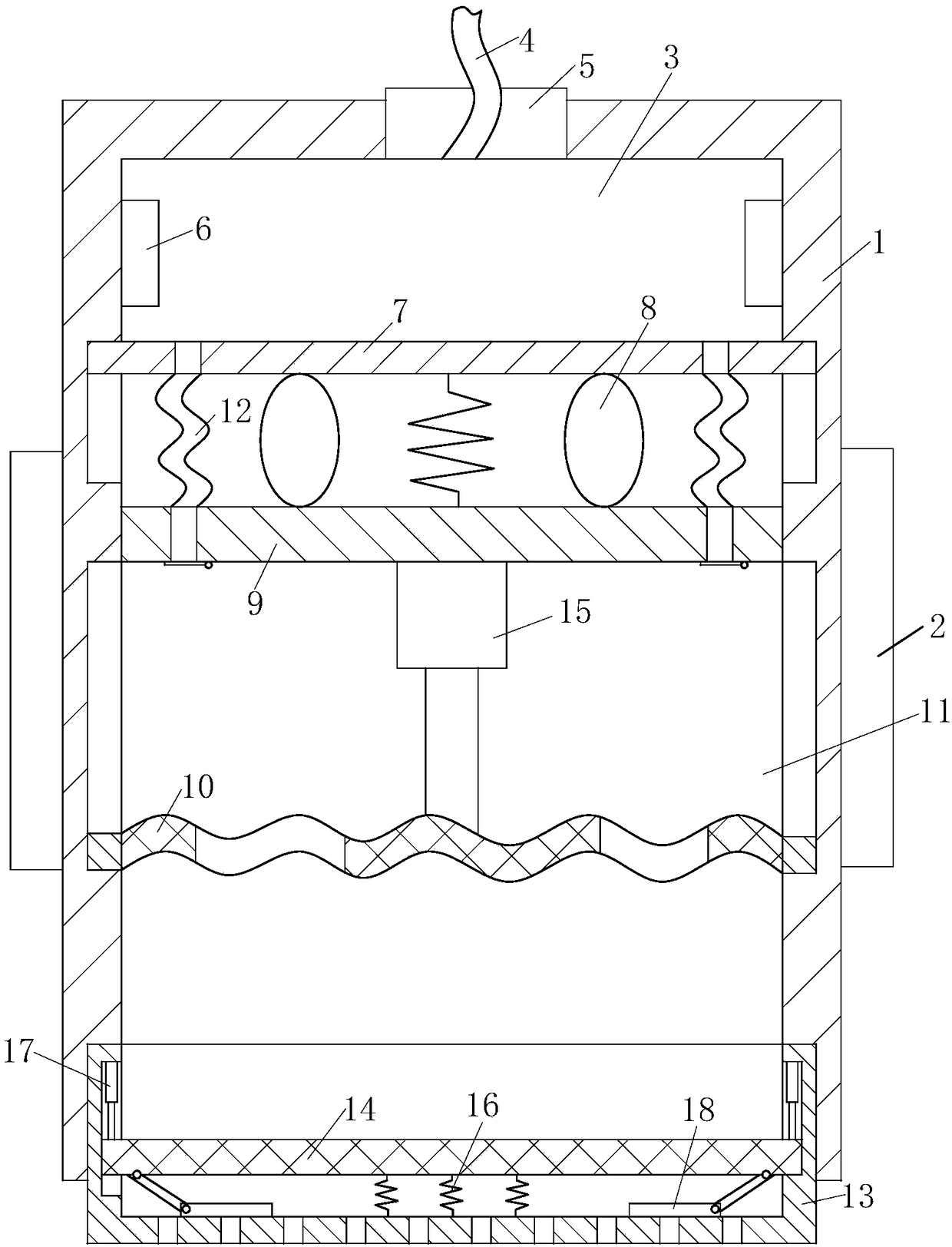

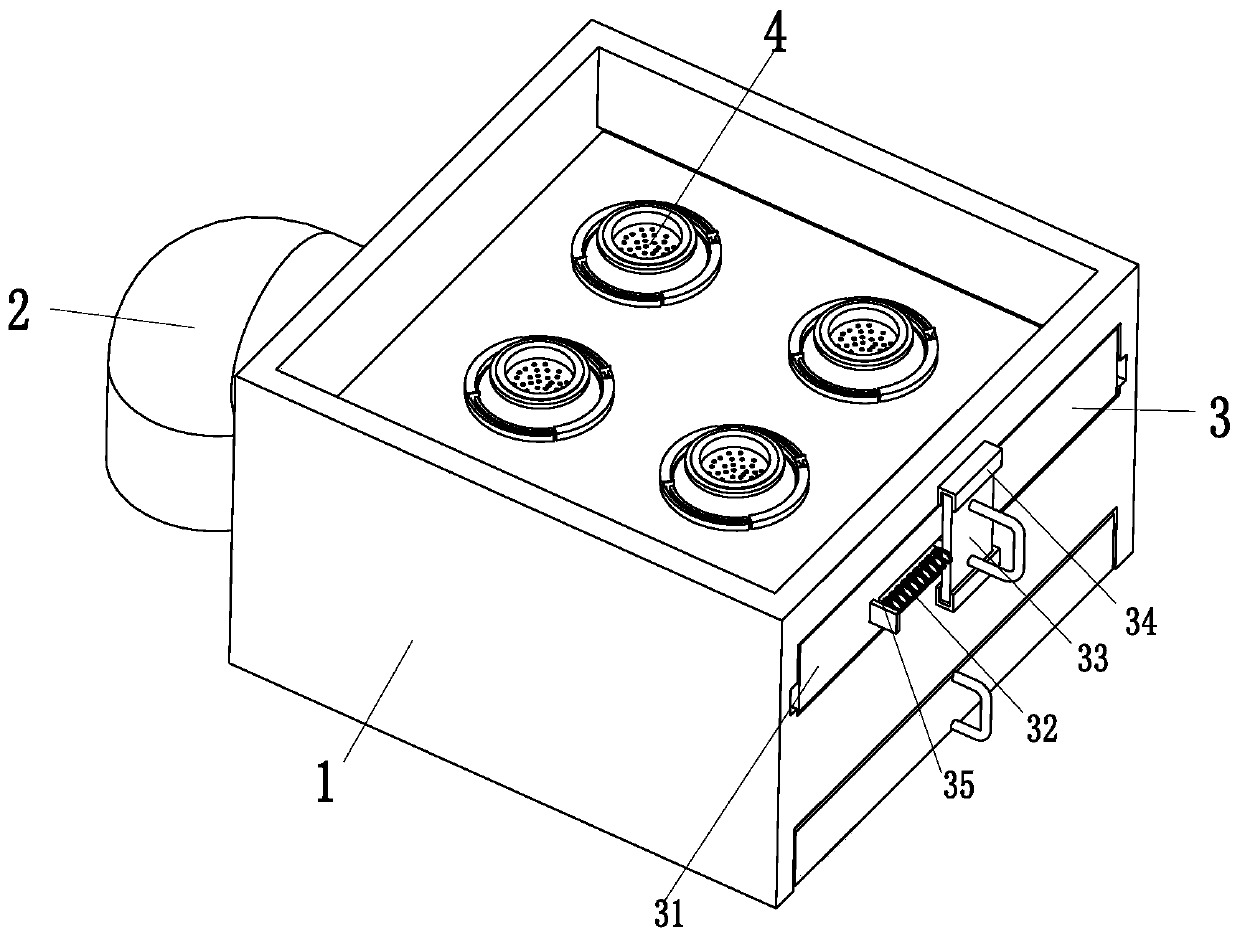

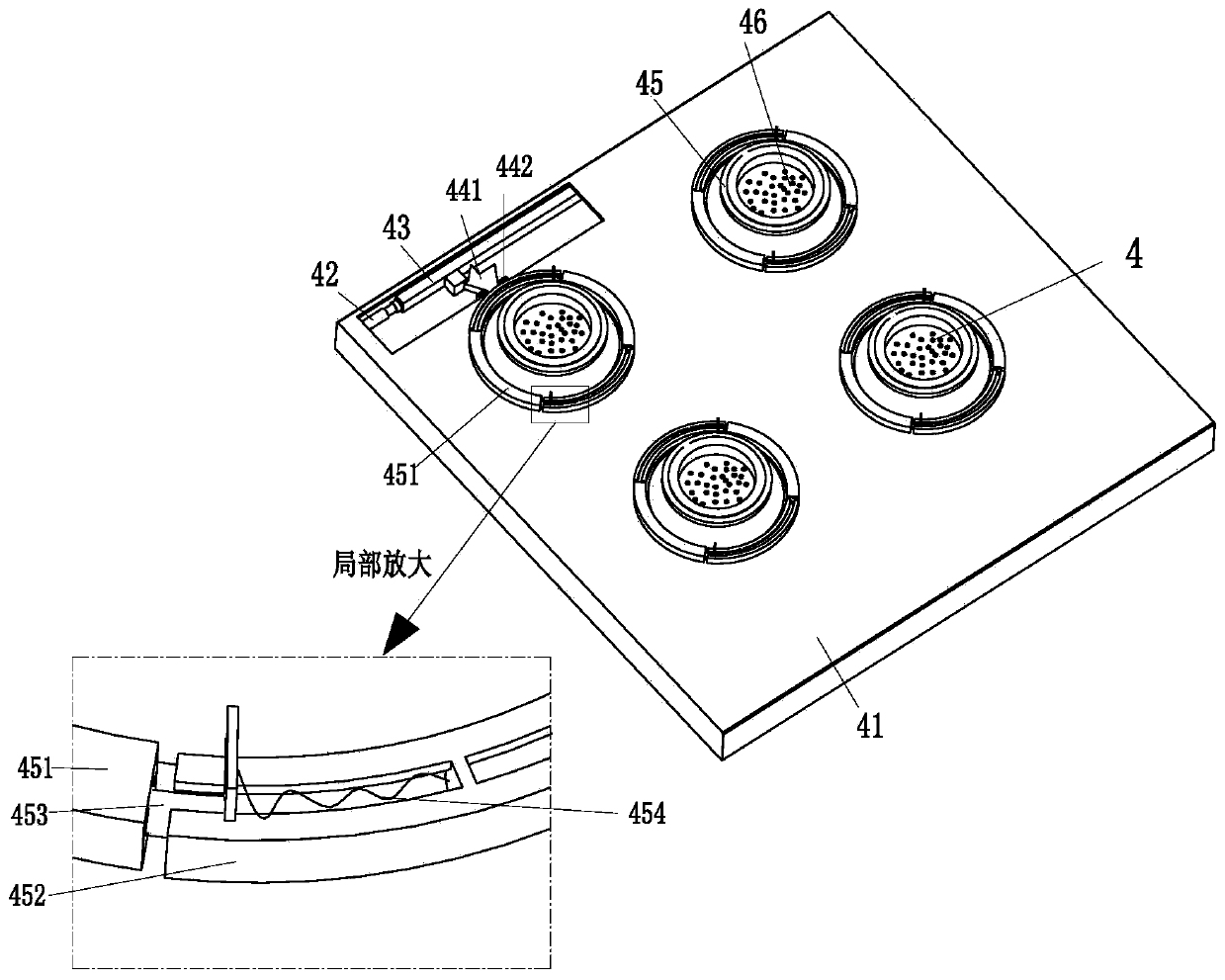

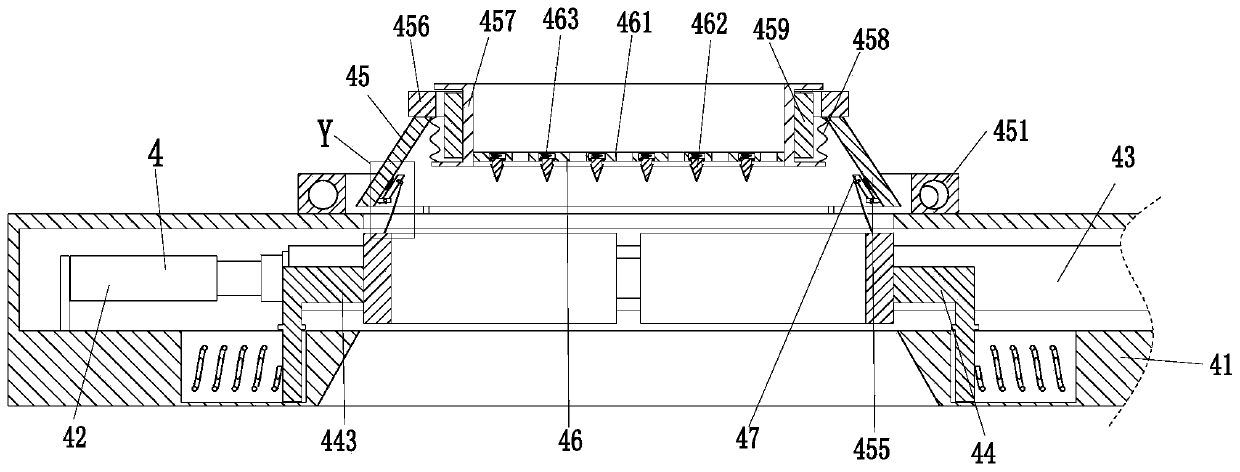

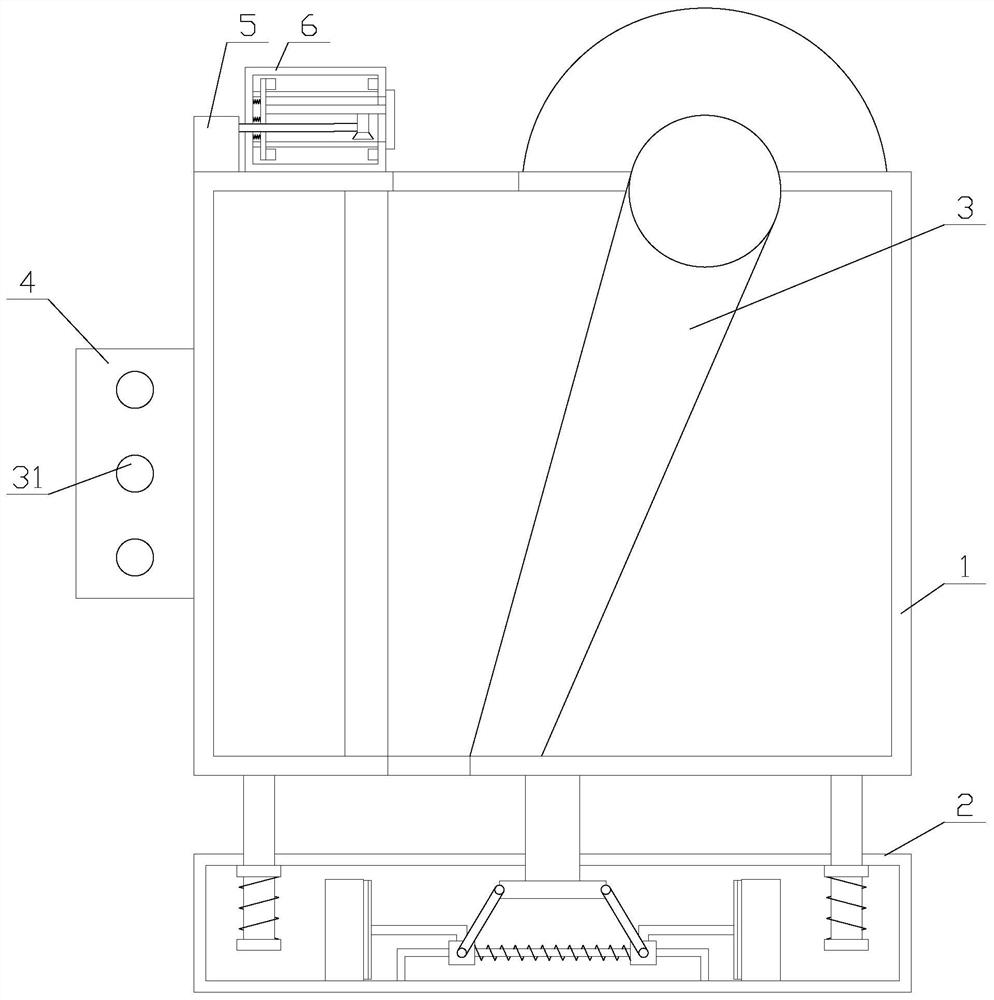

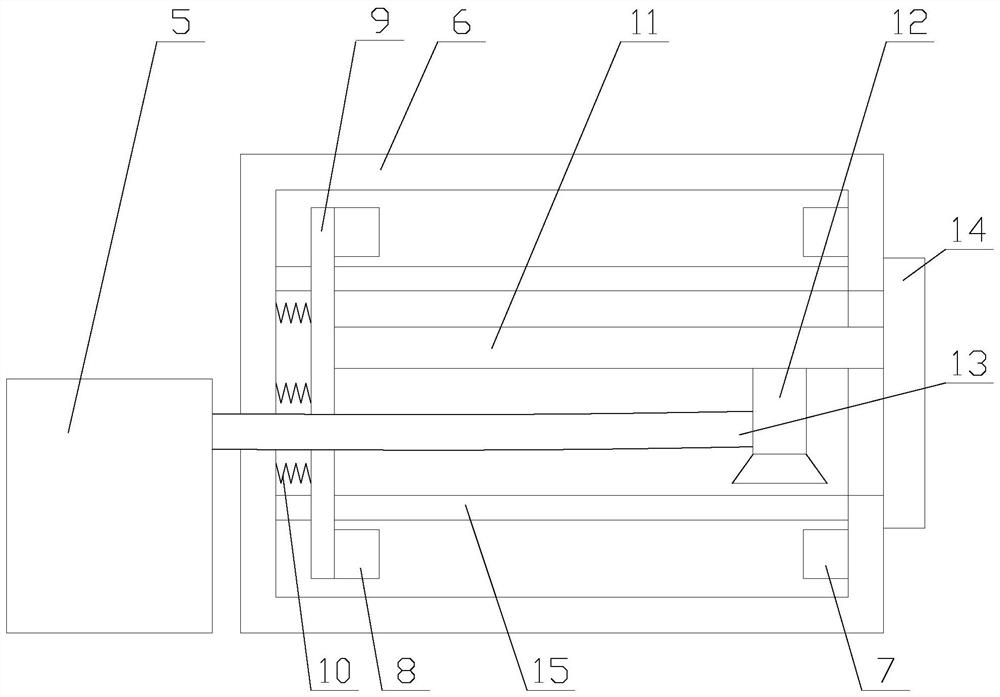

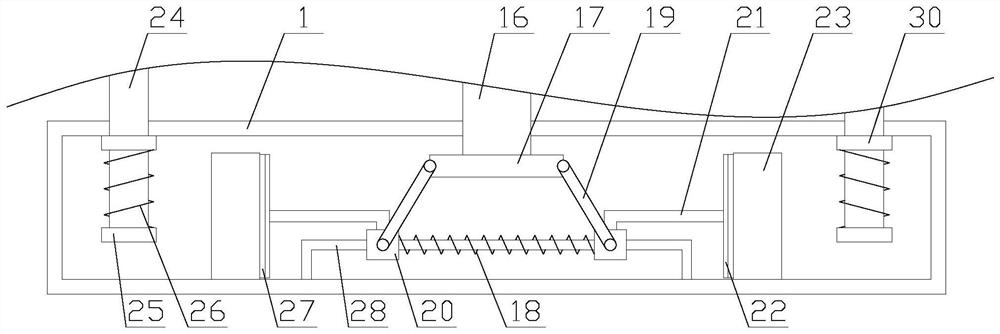

A Vibration-absorbing Jaw Crusher with Dust-proof Function for Mineral Processing

ActiveCN110152767BGood vibration reduction effectImprove practicalitySpringsUsing liquid separation agentMineral dustMining engineering

The invention relates to a vibration-damping jaw crusher with dust-proof function for mineral processing, which includes a main body, a base and a crushing device, and also includes a dust-proof mechanism and a vibration-damping mechanism. The dust-proof mechanism includes a water pump and a fixed box, the fixed box is provided with a dust-proof assembly, the dust-proof assembly includes a connecting rod, a nozzle, a cover plate, a support plate, a hose, two drive units and a number of first springs, and the vibration-damping mechanism includes Vibration assembly and two auxiliary assemblies, the vibration damping assembly includes a support rod, a support plate, a second spring and two vibration damping units, the vibration damping unit includes a slider, a moving rod, a pressure plate, an air bag and an adjustment rod, the The vibration-damping jaw crusher with dust-proof function used for mineral processing sprays water into the main body when the equipment is working through the dust-proof mechanism to avoid dust scattering and affect the surrounding air environment. The vibration-damping mechanism realizes vibration reduction of the main body. functions to reduce the chance of equipment damage.

Owner:宜昌鹰燕矿业有限责任公司

Chemical adhesives for coating loads in open top hopper cars, trucks, buildings, similar storage units/containers

ActiveCN103429683BMonocarboxylic acid ester polymer adhesivesLiquid surface applicatorsMineral dustGlycerol

The present invention relates to methods and compositions for treating piles of particulate material which inhibit and prevent the spread of valuable fuel or mineral dust from storage piles or open containers. The method includes applying a binder coating comprising VAE and crude glycerin to the heap. The adhesive coating slowly cures and hardens while the pile or load is still settling, jostling, bumping and moving around. The adhesive coating is capable of remaining flexible. The coating is particularly effective on coal piles, and also on piles in and / or moving through open railroad cars. The coating flexibility prevents the coating from becoming brittle and crumbling. The coatings have better properties than those shown by the components alone. The coating is effective when the coating is flexible or after it has cured; thus, the present invention can both prevent unwanted dust contamination and save the user money by avoiding blow-off material.

Owner:NALCO CO

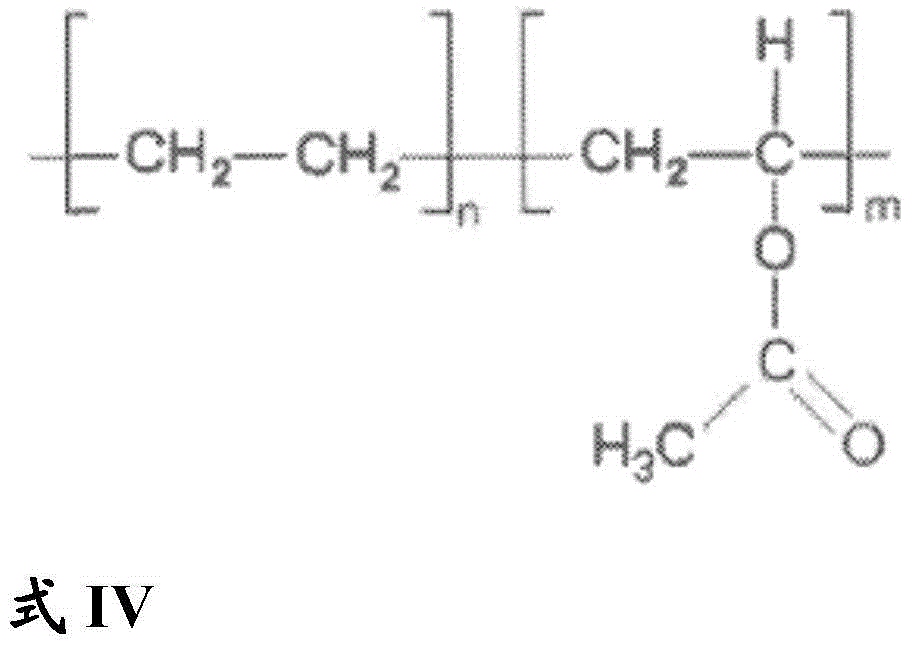

Preparation method of spherical lead oxide atmospheric mineral dust

The invention discloses a preparation method of spherical lead oxide atmospheric mineral dust. The preparation method comprises the following steps: 1, respectively preparing a lead acetate solution,a hexamethylenetetramine solution and a trisodium citrate solution, and 2, mixing the prepared lead acetate solution, hexamethylenetetramine solution and trisodium citrate solution according to a molar ratio of 1: 1: (0.4-0.2), carrying out water bath heating and filtering to obtain spherical lead oxide. Because the mineral dust is an important component of atmospheric dust, and lead oxide in themineral dust has great influence on the atmospheric environment and human health. The spherical lead oxide atmospheric mineral dust prepared by the method disclosed by the invention can well simulatelead oxide mineral dust in real atmosphere, and has great significance for researching the fields of atmospheric environment, human health and the like of the atmospheric mineral dust.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

Method for selenium-enriching cultivation by using selenium powdered ore

InactiveCN100574602CIncrease dosageIncrease selenium contentClimate change adaptationFertilising methodsMineral dustMineral Sources

Owner:YANGTZE UNIVERSITY

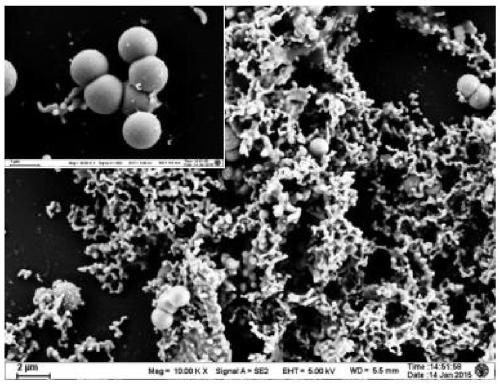

Base used for installation of mineral dust sampler

InactiveCN107588792AEasy to adjustSave adjustment timeMeasurement apparatus componentsWithdrawing sample devicesMineral dustArchitectural engineering

The invention discloses a base used for installation of a mineral dust sampler. The base comprises at least three support rods, a bearing plate and a rotating shaft, wherein one ends of the support rods are movably chained with the lower surface of the bearing plate through a connecting piece, the angles between the adjacent support rods are the same, the length of each support rod is adjustable,the rotating shaft is arranged on the upper surface of the bearing plate and positioned on the axis of the bearing plate, and one end, far away from the bearing plate, of the rotating shaft is provided with a clip. Under the condition of changing acquisition points, a worker can rapidly adjust the vertical direction and the horizontal direction of the mineral dust sampler, the adjustment time is saved, the labor cost is saved, and the work efficiency is increased.

Owner:重庆美高科技有限公司

A kind of mineral dust filter device

ActiveCN112791833BAvoid wastingImprove the construction environmentDispersed particle filtrationTransportation and packagingMineral dustMineral Sources

The invention relates to a mineral dust filter device, which belongs to the technical field of mineral dust collecting equipment; There is a wind device for inhaling dust inside the dust box, and a cleaning device for cleaning the inside of the dust box, and a water filter device for discharging wastewater is installed on the discharge device, and the cleaned slag is dried The invention can suck the dust generated by the crusher and the slag with smaller particles into the dust collecting box to concentrate and discharge the materials for collection, so as to prevent the waste of mineral resources. The slag and dust adhering to the dust collecting box are cleaned, and the waste water is discharged through the water filter device and dried by the drying device, which also solves the phenomenon that more dust is formed at the discharge port of the original crusher, and ensures the on-site workers good construction environment.

Owner:XINBARHU YOU BANNER RONG DA MINING LLC

Coated compound fertilizer and preparation thereof

ActiveCN101462907BExcellent nutrient resistance control functionExcellent S-type nutrient dissolution modeFertilizer mixturesLow-density polyethyleneMineral dust

The invention discloses an S type coated compound fertilizer and a preparation method thereof. The S type coated compound fertilizer comprises compound fertilizer granules and a coating wrapped on the surface of the granulated fertilizer; wherein, the material for preparing the coating comprises the substances based on the mass portion ratio: 15-27 portions of polystyrene foam, 24-30 portions of recovered Polypropylene polymers, 7-20 portions of low density polyethylene, 10-45 portions of inorganic mineral dust and 2-9 portions of starch or modified starch. The S type coated compound fertilizer has an excellent S type nutrient dissolving mode, can control the release time and amount of nitrogen, phosphorus and potassium nutrient in an intelligentized way, and meets different needs of agricultural production such as culture of seedling, contact fertilizer application and one-off application.

Owner:BEIJING ACADEMY OF AGRICULTURE & FORESTRY SCIENCES

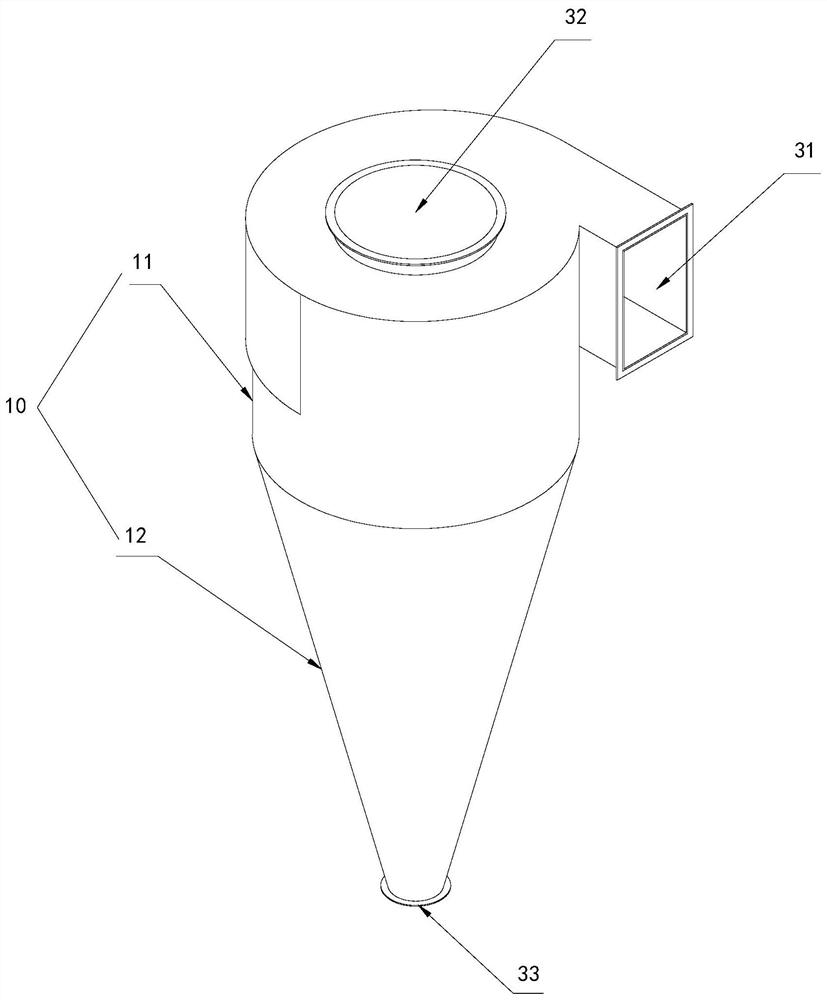

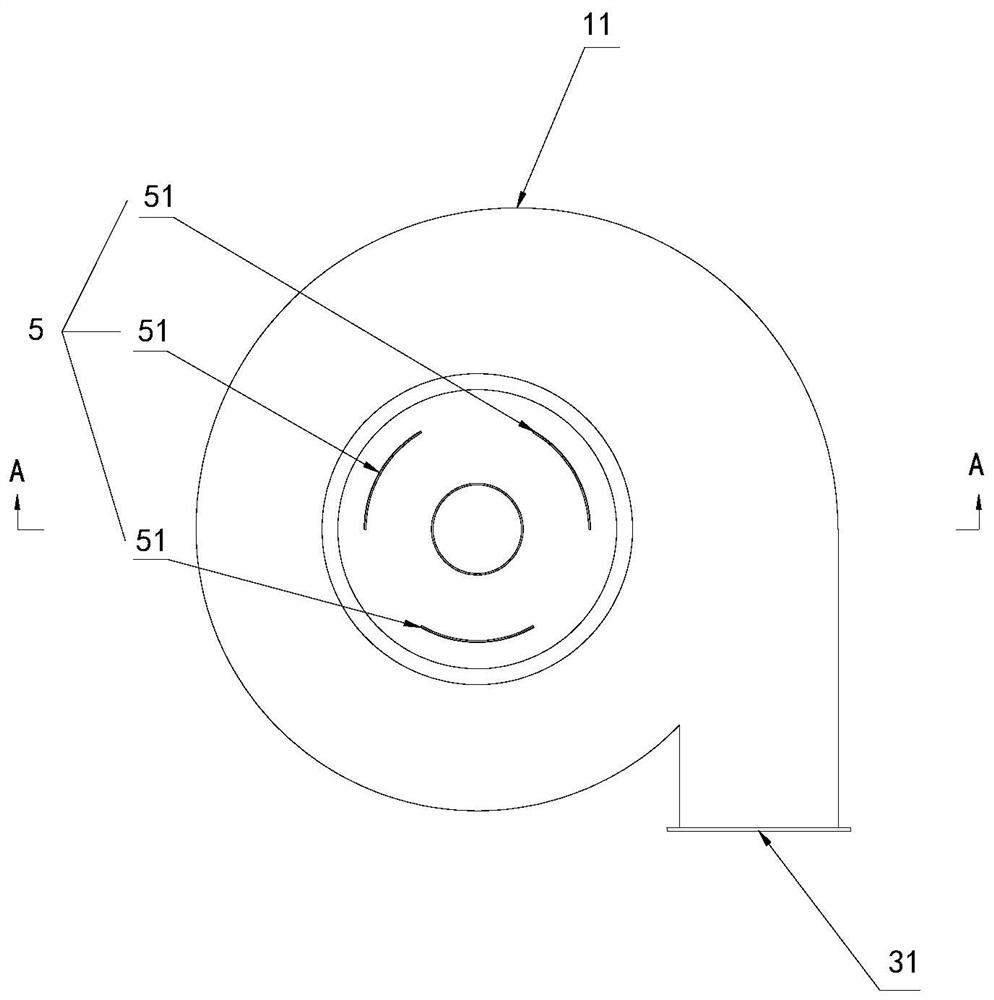

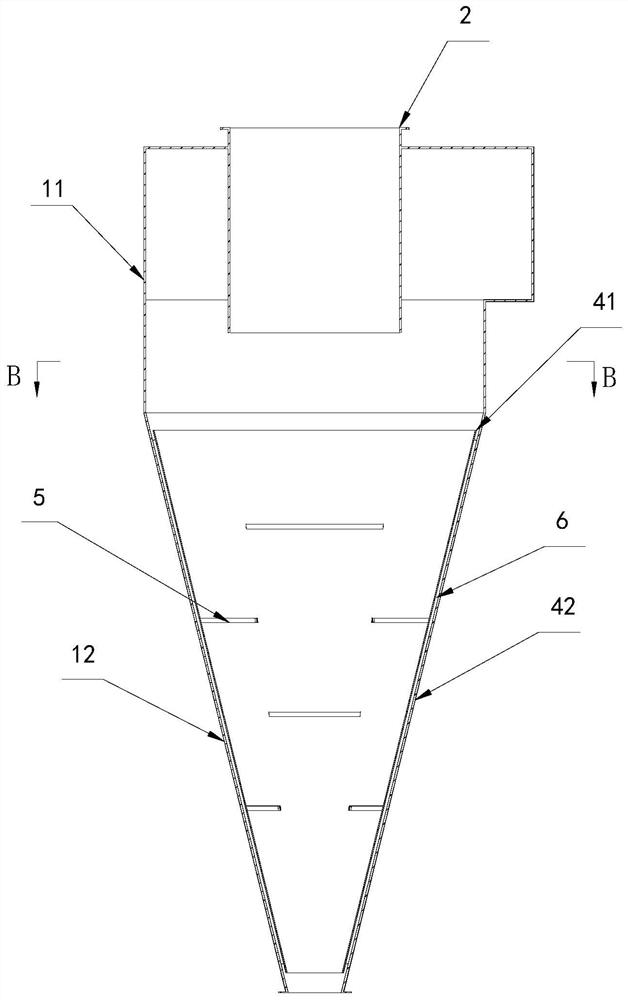

Efficient cyclone dust collector with double-layer side wall

PendingCN113289777ASolve recurring issuesSmall pressure lossReversed direction vortexMineral dustEngineering

The invention relates to the technical field of mineral dust particle collecting devices, provides an efficient cyclone dust collector with a double-layer side wall, and aims to solve the problems that in the particle collecting process of a cyclone dust collector in the prior art, particles are repeatedly driven by an outer vortex to rotate when sliding down along the inner wall of a cone, so that the energy consumption is increased and the dust collecting efficiency is reduced. The efficient cyclone dust collector which comprises a cone, wherein the cone comprises an inner side wall and an outer side wall; an interlayer between the inner side wall and the outer side wall communicates with an ash bucket; and a circular seam is formed in the inner side wall. The efficient cyclone dust collector has the beneficial effects that particles gathering on the inner side wall can quickly enter the interlayer between the inner side wall and the outer side wall through the circular seam, directly slide down to the bottom of the cone along the outer side wall, and then fall into the ash bucket for dust collection; the particles which enter the interlayer are no longer mixed with vortex airflow; and consequently, the problem that the particles are repeatedly raised by the vortex airflow when sliding down along the side wall of the cone can be well solved, the pressure loss can be reduced, the energy consumption can be reduced, and the dust collecting efficiency can be improved.

Owner:成都建筑材料工业设计研究院有限公司

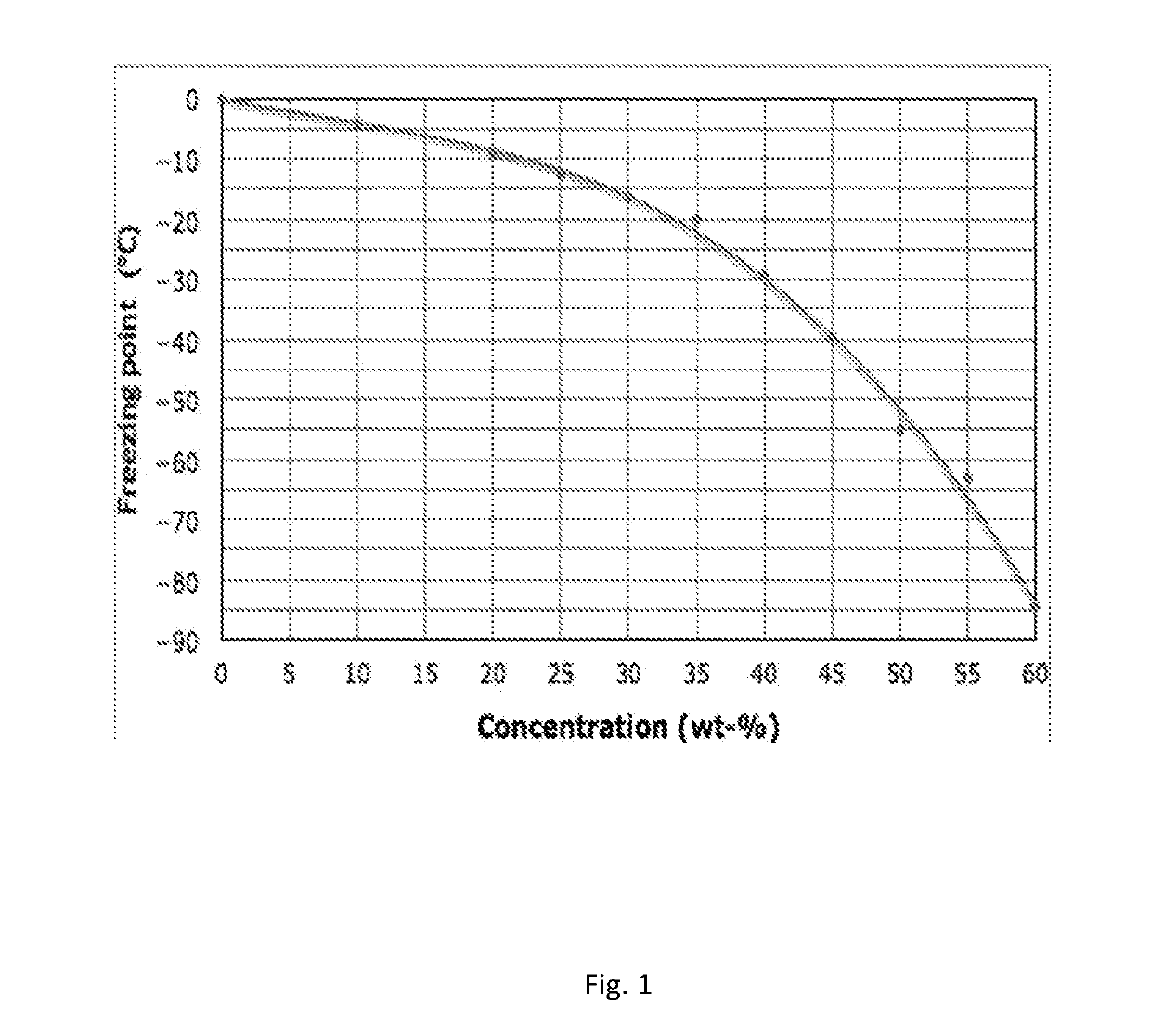

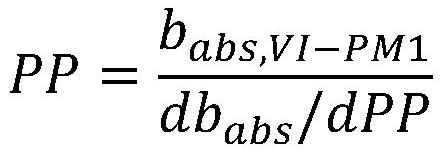

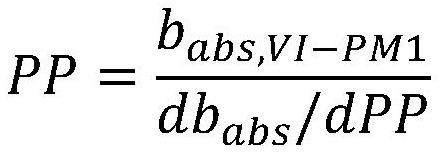

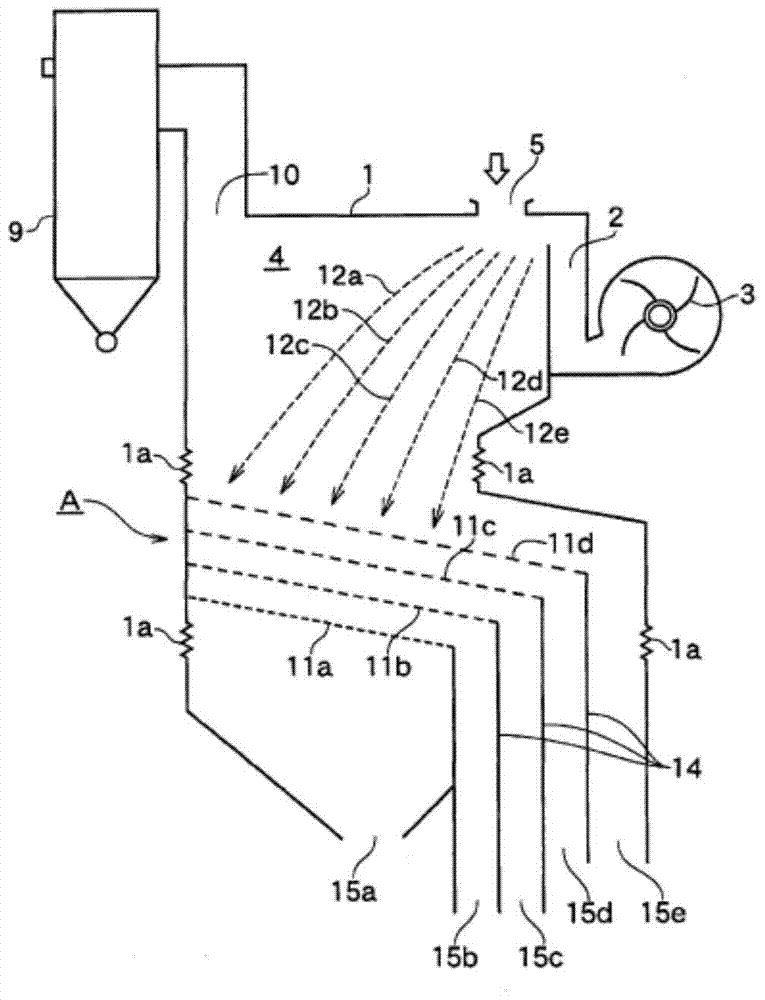

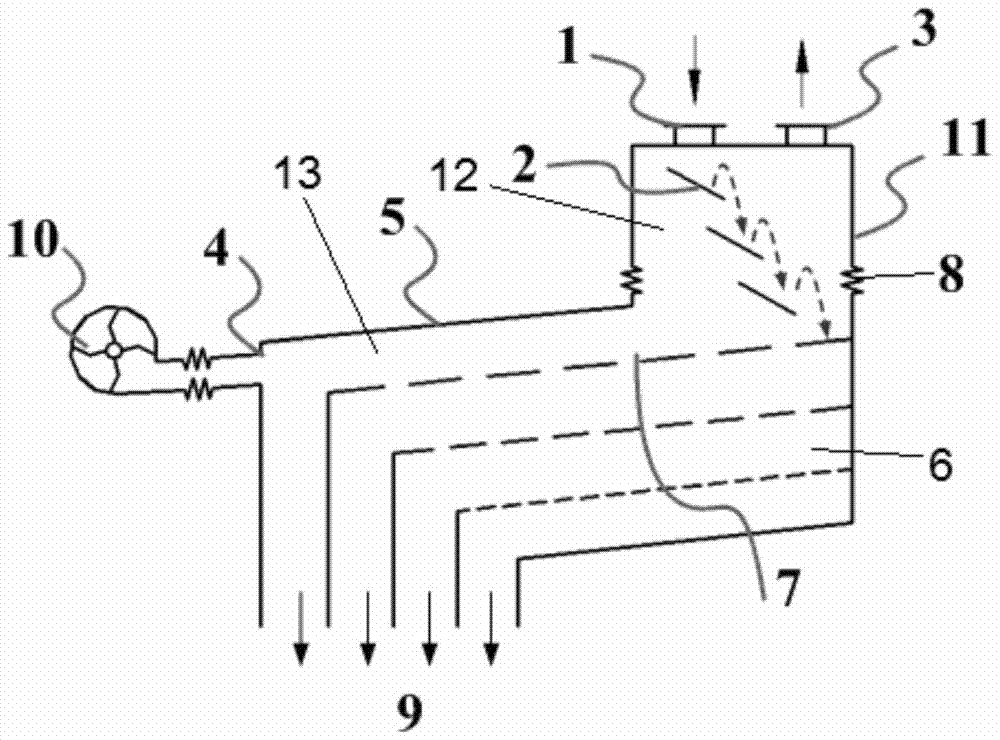

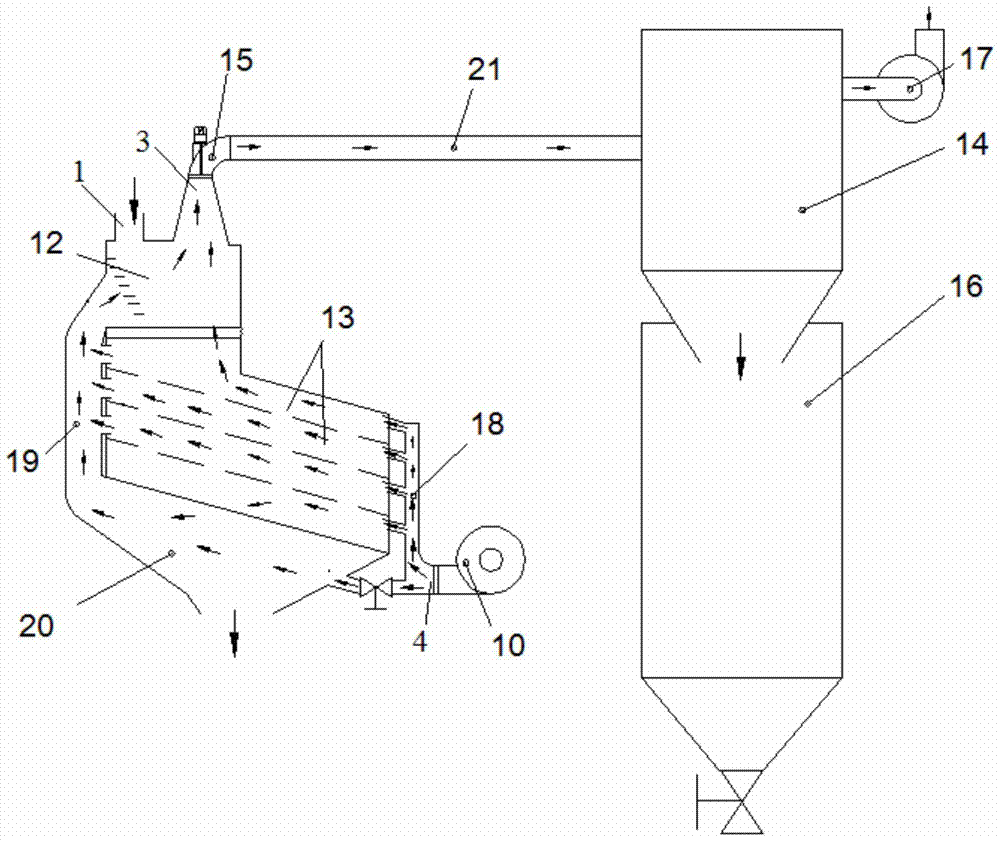

A method for quantification of mineral dust in air based on optical absorption of particles concentrated by a virtual impactor and a device performing the said method

PendingCN112414904APromote absorptionHigh quality absorbent cross sectionAnalysing gaseous mixturesPreparing sample for investigationMineral dustAir sample

The present invention belongs to the field of devices and methods for measurement of particle concentration, more precisely to the field of devices and methods for quantification of particles based ontheir physical characteristics, especially with the use of optical means. The invention relates to a method for determination of ambient mineral dust concentration based on optical absorption of particles concentrated by a virtual impactor as well as a device performing the said method. The method comprises the following steps: sampling air samples with particle size smaller than 1 mum (PM1) andsampling air samples with particle size up to 10 mum; concentrating the samples with particle sizes up to 10 mum with a virtual impactor; measuring optical absorption of collected samples at least onewavelength from UV to IR spectre, preferably from 370 to 950 nm, most preferably at 370 nm; subtracting the absorption of the samples with particle size smaller than 1 mum from the absorption of thesample concentrated by the virtual impactor.

Owner:阿尔沃索公司

Mineral sorting device and mineral processing system

The invention discloses a mineral processing system and a mineral sorting device thereof. The dust removal ventilation passage of the mineral sorting device includes a first dust removal ventilation branch (13), and at least one layer of screen cloth is included in the screen cloth (7) Correspondingly equipped with a first dust-removing ventilation branch (13), the first dust-removing ventilation branch (13) extends along the inclined direction of the corresponding screen, and the lower side of the first ventilation and dust-removing branch (13) is The upper screen surface of the corresponding screen (7), so that in the ventilation state, the dust removal ventilation air flow on the first dust removal ventilation branch (13) is inclined upward along at least part of the corresponding upper screen surface of the screen flow. In the present invention, a part of the dust removal ventilation passage is arranged along the upper screen surface of the screen, so that the dust raising effect of the vibration of the screen on the minerals can be used during the working process, so that the dust can be fully raised, and then the dust removal airflow can flow against the minerals. The movement direction on the sieve surface flows upwards, so as to achieve good results.

Owner:ZOOMLION HEAVY IND CO LTD

Methods and compositions for dust control

The present invention relates to methods and compositions for treating piles of particulate material to inhibit and prevent the loss of valuable fuel or mineral dust from release from storage piles or top-opening containers. The method involves separate application of two different compositions to the stack. When separated, the two compositions were low viscosity and easy to spray. When combined, the two compositions form a gel coat that is resistant to erosion but flexible while the pile or load is still settling, pushing, bumping, and otherwise moving around.

Owner:ECOLAB USA INC

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com