Enhancing type polyolefin/clay nanocomposite and preparing method thereof

A nano-composite material and polyolefin technology, applied in the field of nano-composite materials, can solve the problems of material failure, limited application, fracture, etc., and achieve the effect of improving the mechanical properties of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

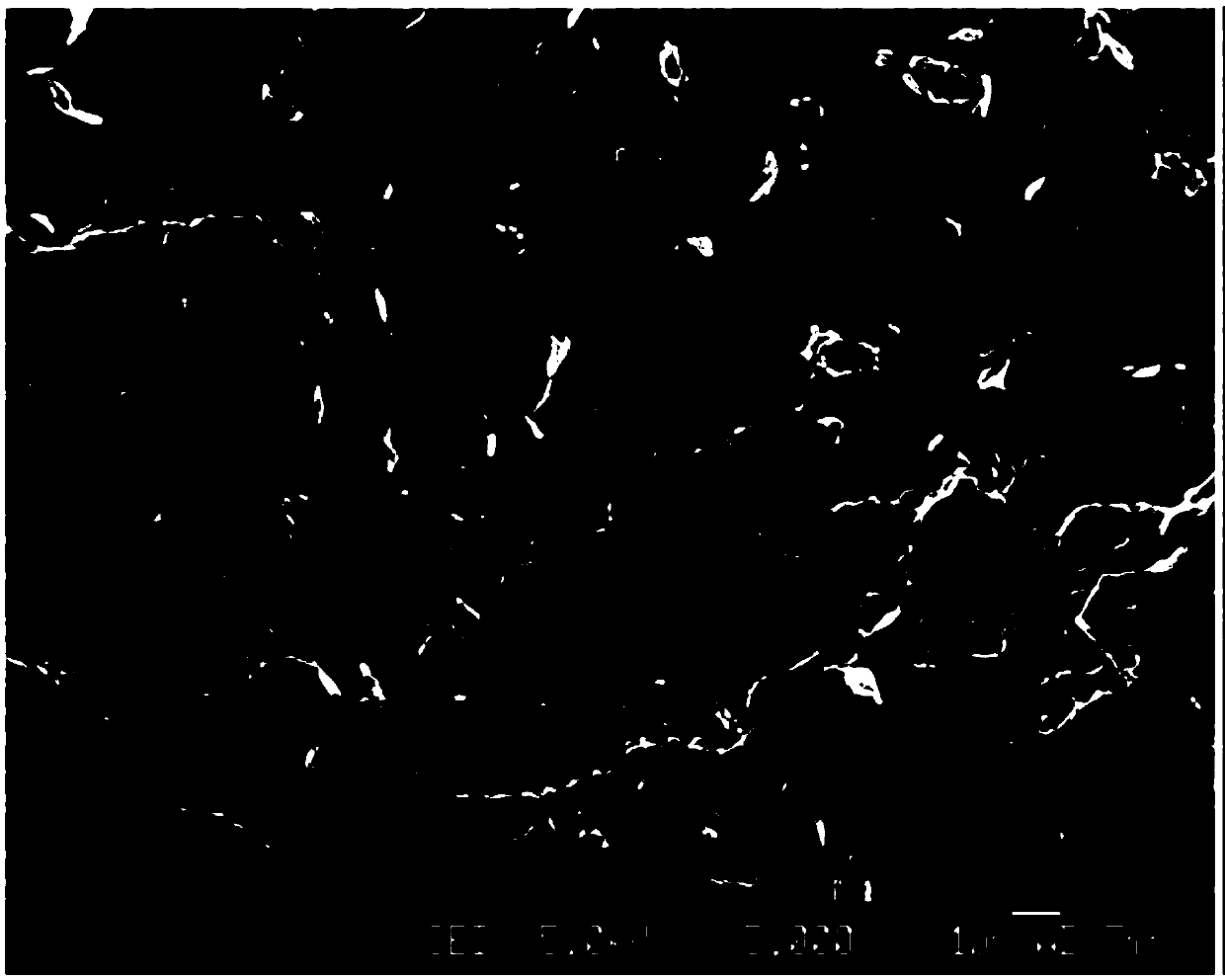

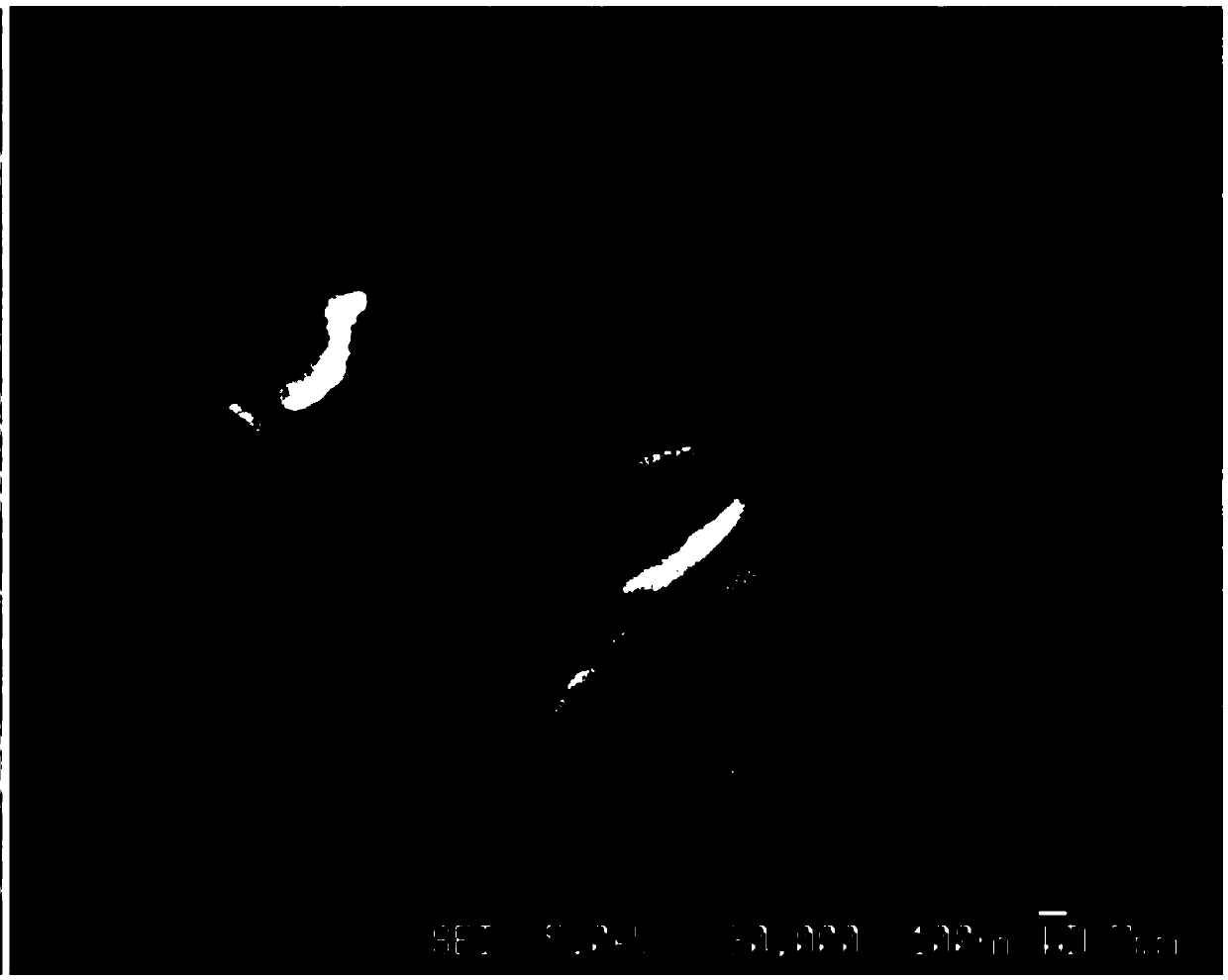

Image

Examples

Embodiment 1

[0028] 1 g of montmorillonite (MMT) was dispersed in 50 g of water, 0.5 g of coupling agent Vinyltrichlorosilane was added, the pH was adjusted to 4, and the reaction was carried out at 50° C. for 4 hours. The product was centrifuged and washed 3 times, and vacuum-dried at 80°C to constant weight to obtain product A.

Embodiment 2

[0030] Disperse 3 grams of mica in 100 grams of water-alcohol mixed solution (water / ethanol=9 / 1, w / w), add 0.03 grams of coupling agent Vinyltris (β-methoxyethoxy) silane, adjust the pH to 4.8, and react at room temperature for 1 hour . The product was centrifuged and washed 3 times, and vacuum-dried at 80°C to constant weight to obtain product B.

Embodiment 3

[0032] 5 grams of kaolinite were dispersed in 15 grams of water, 50 grams of the coupling agent Vinyltriethoxysilane was added, the pH was adjusted to 3, and the reaction was carried out at 80° C. for 0.5 hours. The product was centrifuged and washed 3 times, and vacuum-dried at 80°C to constant weight to obtain product C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com