Patents

Literature

33results about How to "Solve the jam situation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

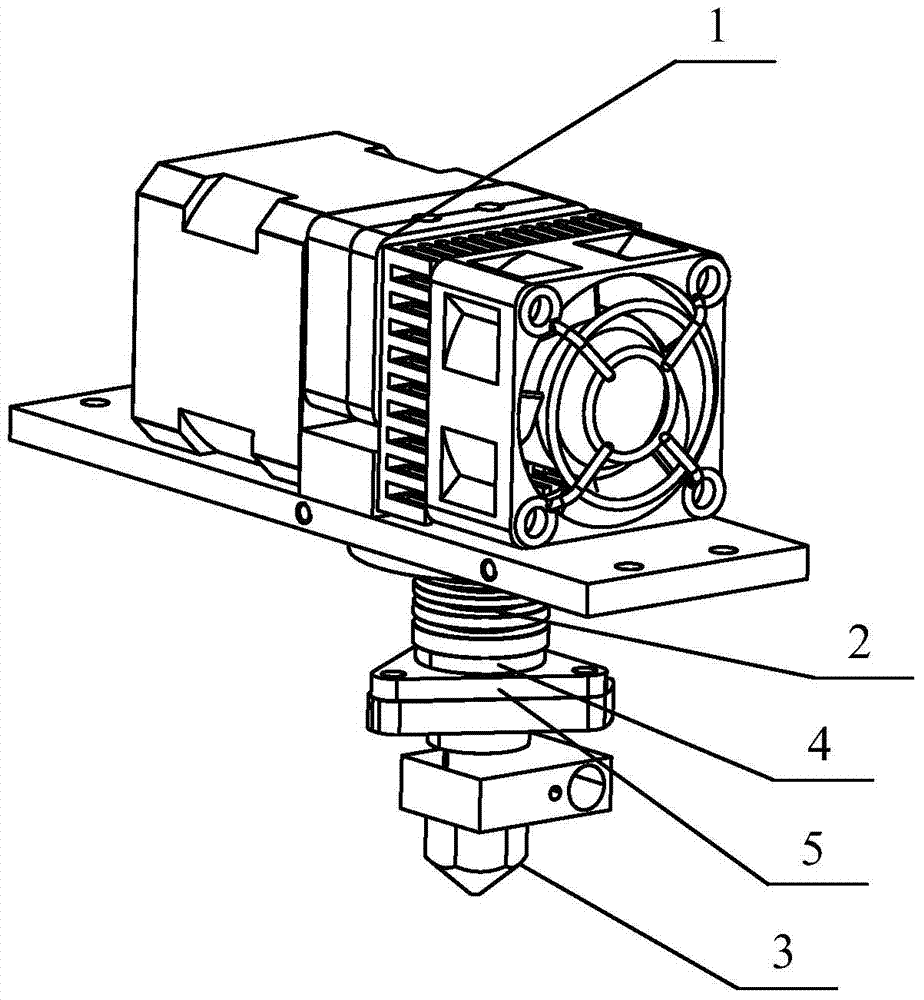

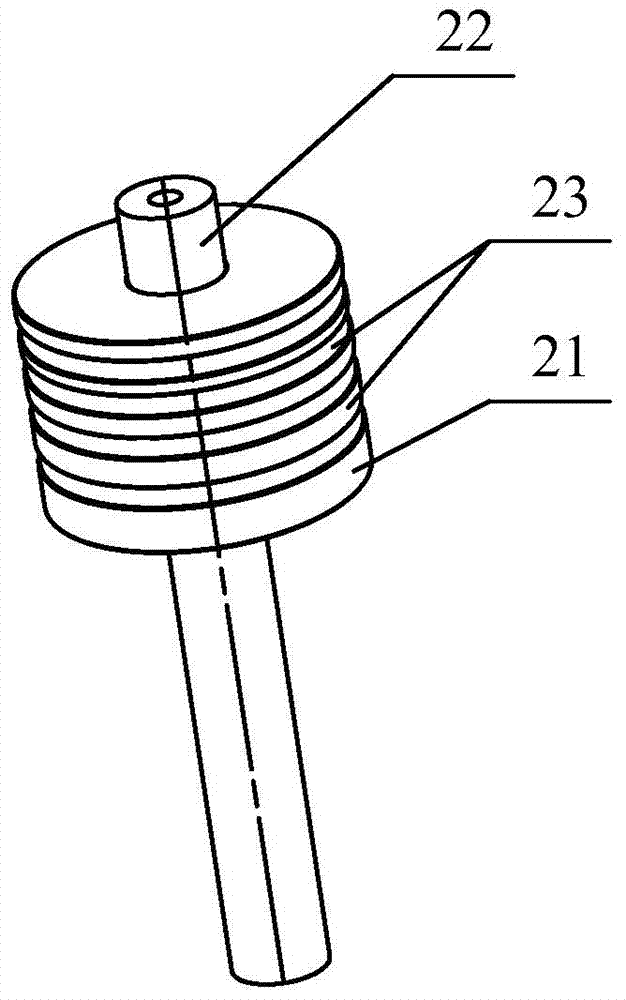

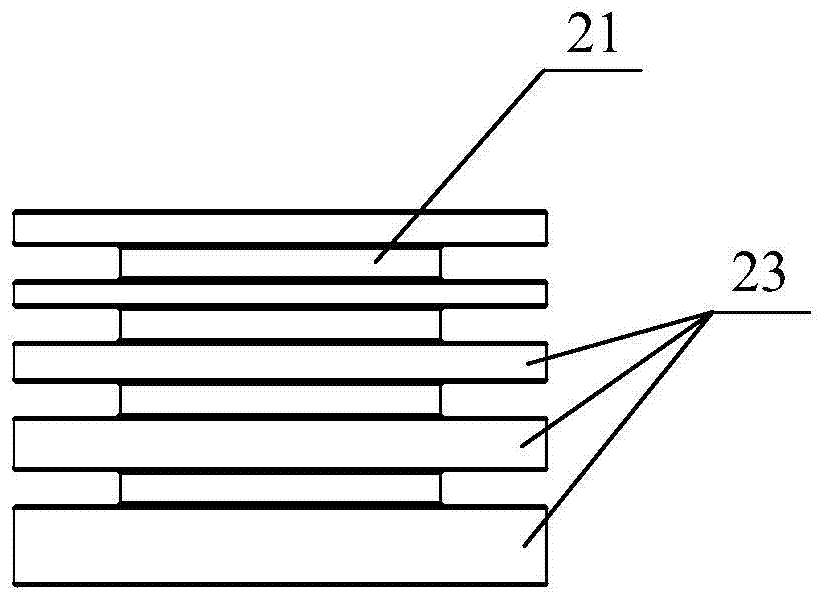

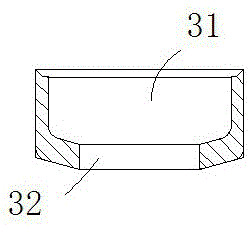

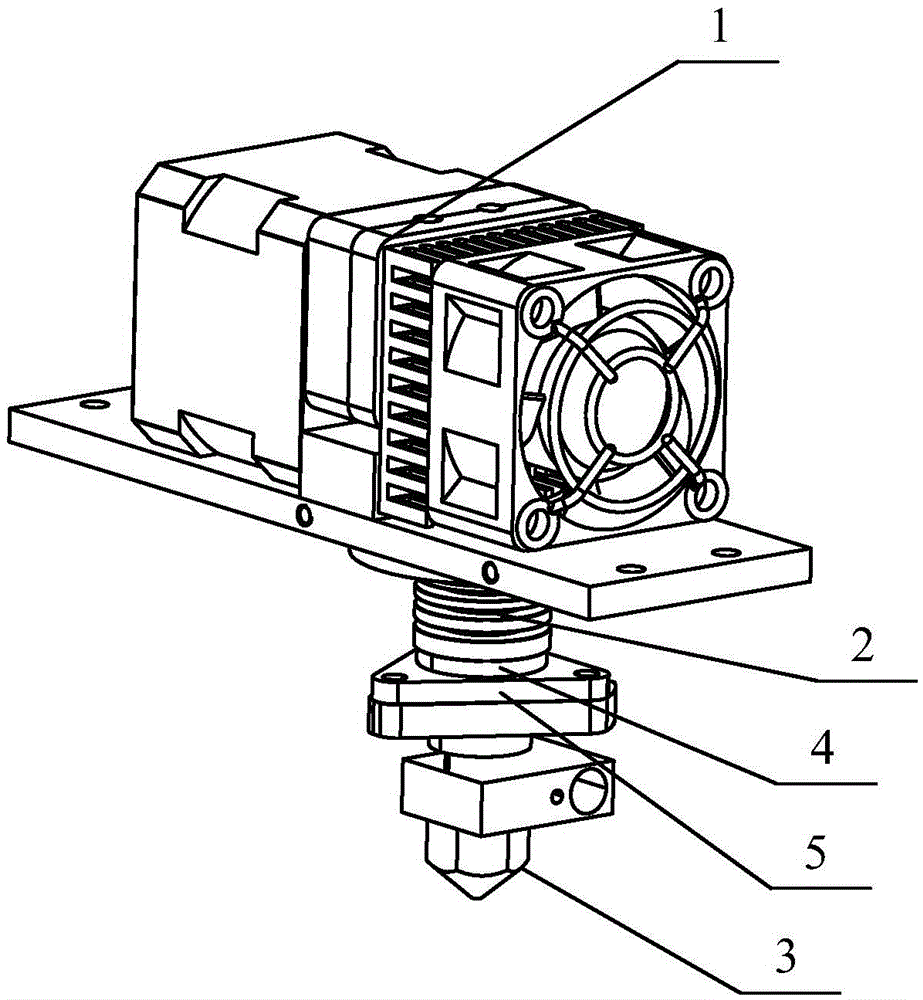

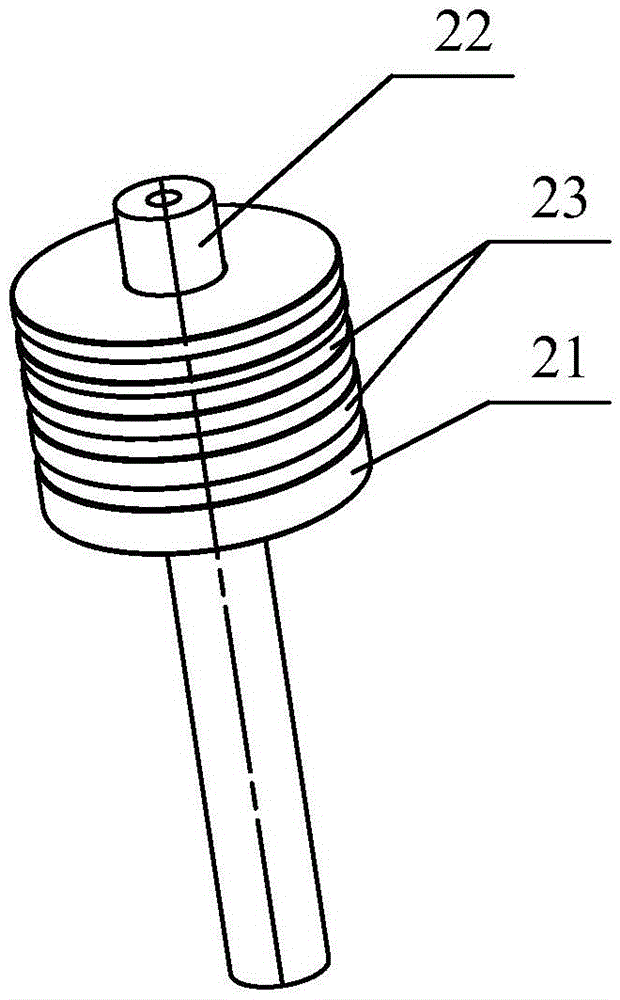

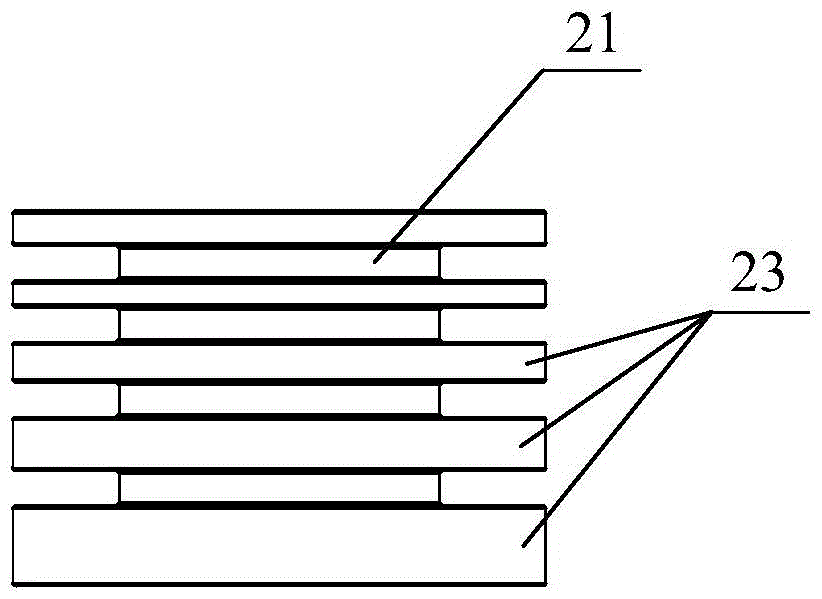

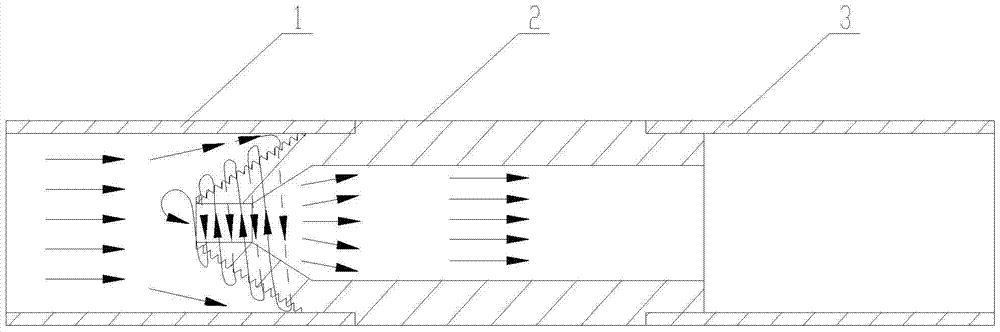

Feeding venturi and feeding structure for 3D printer

The invention provides a feeding venturi for a 3D (three-dimensional) printer. The feeding venturi comprises a radiating outer tube and a polytetrafluoroethylene inner tube embedded in the radiating outer tube; a feeding passage for enabling a printing material to pass through is formed in the polytetrafluoroethylene inner tube. According to the feeding venturi, by the polytetrafluoroethylene inner tube, the condition that the PLA (Poly Lactic Acid) printing material is blocked in the venturi is prevented and stability and smoothness of wire output of a heating printing head, so that surface quality of a printed model is improved; a feeding structure is simple and reliable, is low in cost and is suitable for popularization and application.

Owner:SHANGHAI MEDDO MEDICAL DEVICE

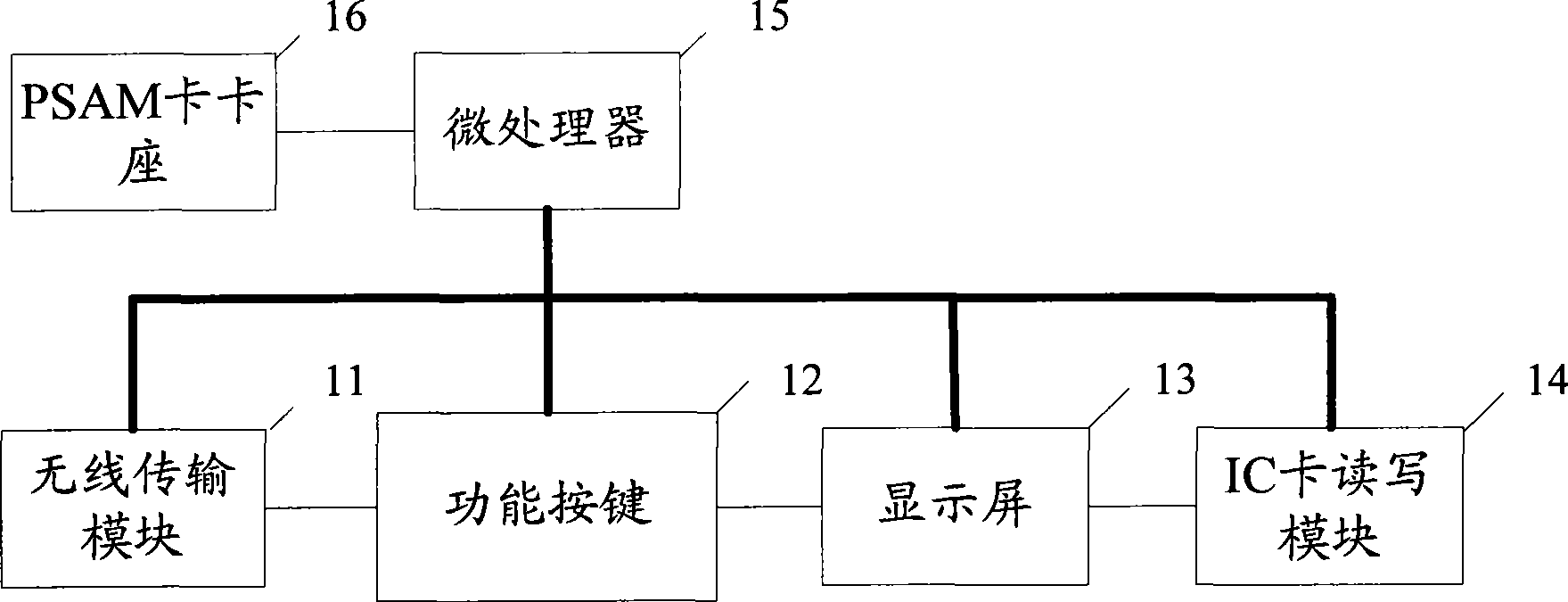

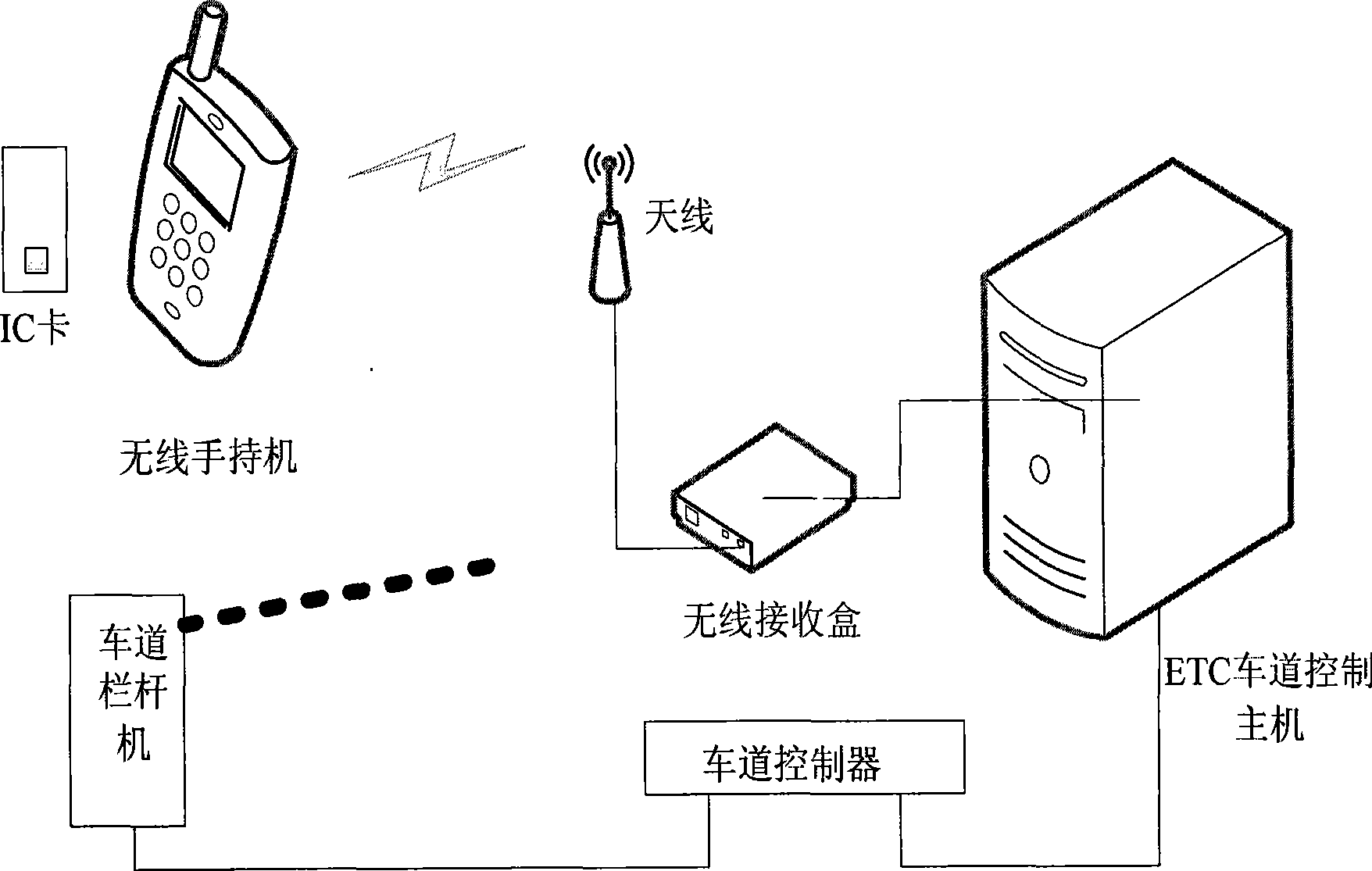

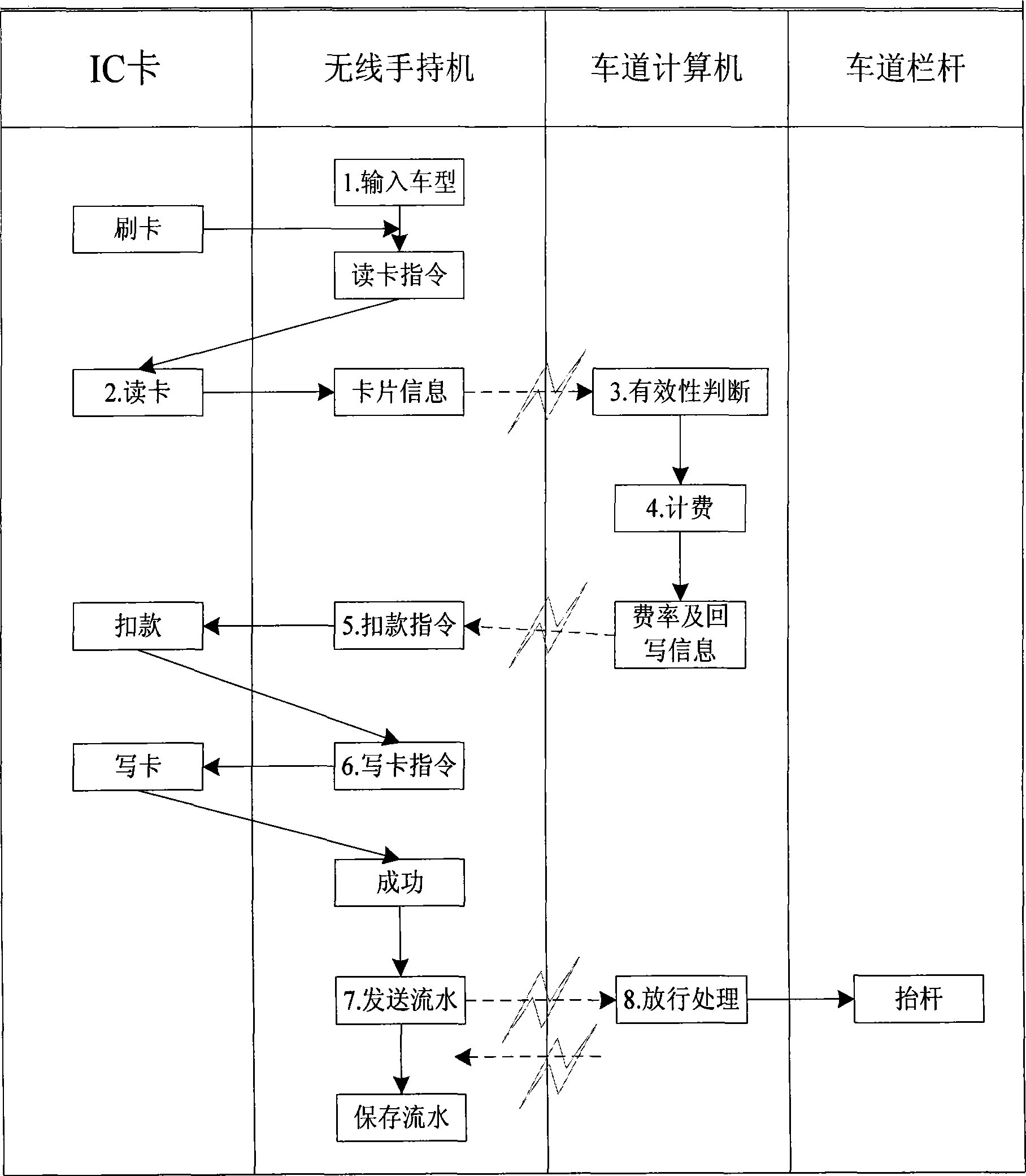

Wireless handset and system used for ETC lane and its implementing method

InactiveCN101482982ASolve the jam situationImprove self-healing abilityTicket-issuing apparatusCo-operative working arrangementsKey pressingWireless transmission

The inventive embodiment discloses a wireless handset and system applied to ETC lane and realizing method therefore, wherein the wireless handset comprises a wireless transmission module for exchanging information with ETC lane control host antenna by wireless transmission network; functional keys for inputting relative vehicle information; a display screen for displaying information about functional keys input result and IC card read-write result; an IC card read-write module for reading information in an IC card and transmitting the information to the ETC lane control host by the wireless transmission module, and executing operation of fee deducting and data writing according to the returning control information from the ETC lane control host; and a microprocessor for intensively controlling operation and interaction of each module unit. The adoption of the invention enables the wireless hardest to quickly finish judgment for the validity of vehicle IC card and operation of fee deducting and car passing when the ETC can not work well, thereby the traffic of lane is assured.

Owner:广东利通科技投资有限公司

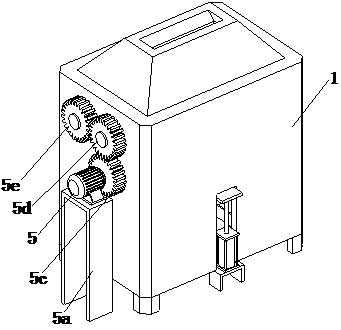

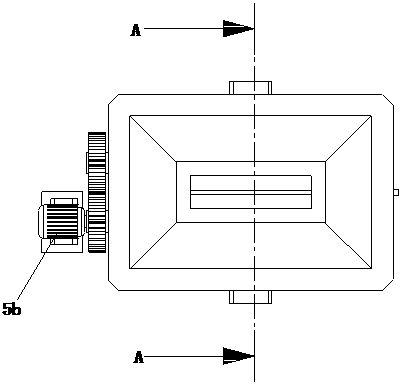

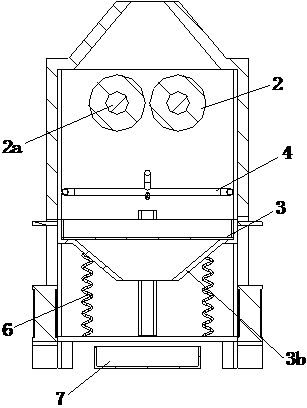

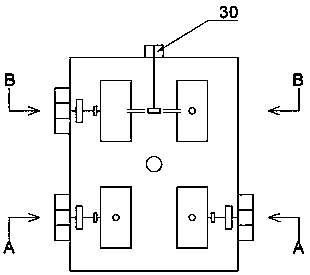

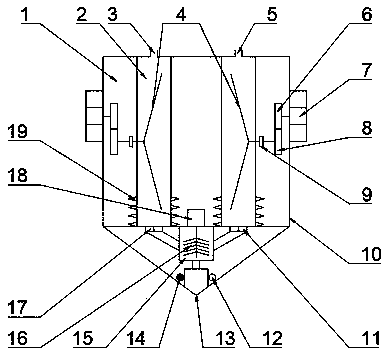

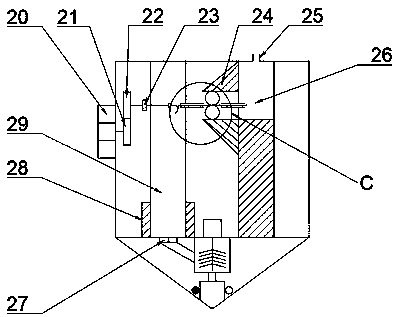

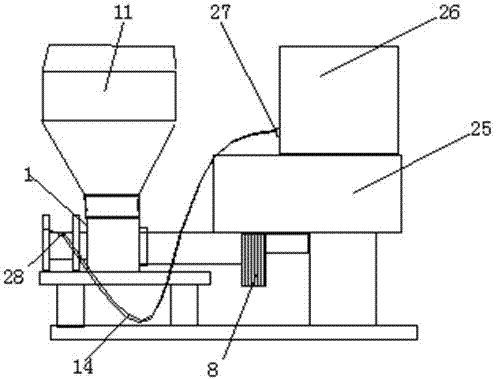

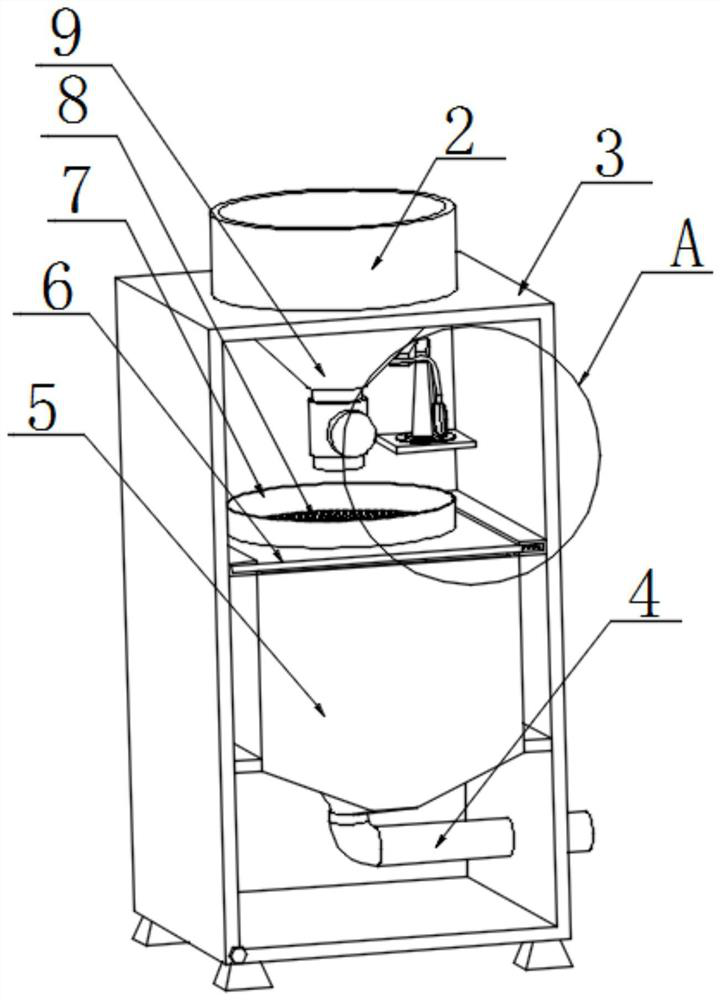

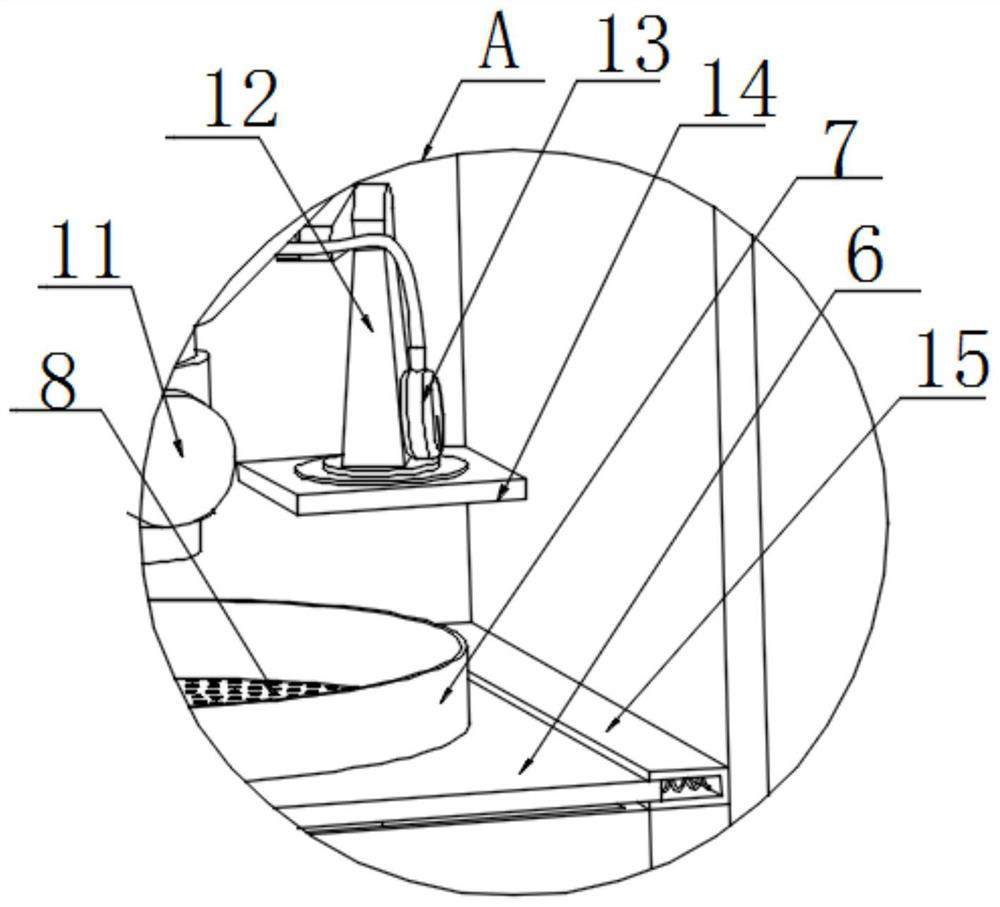

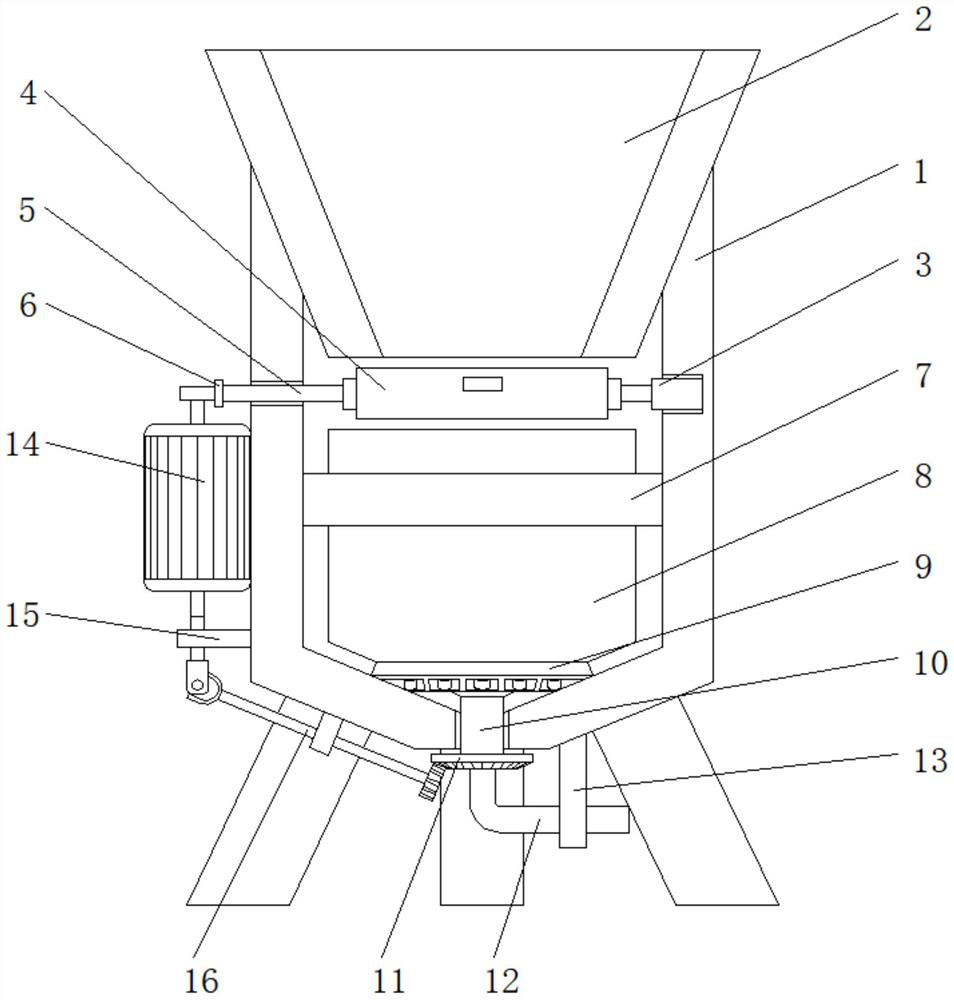

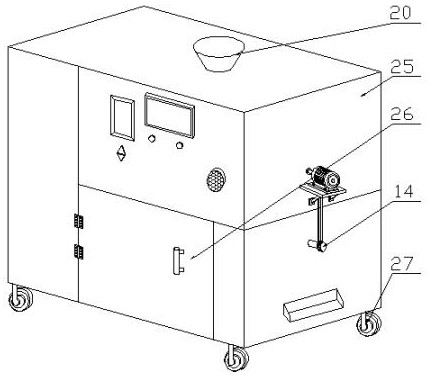

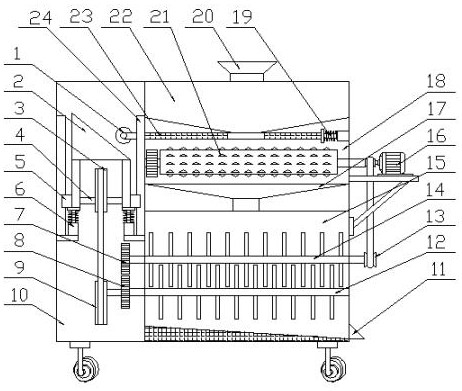

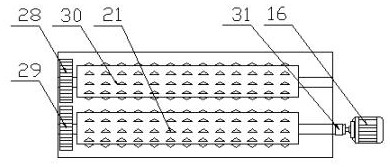

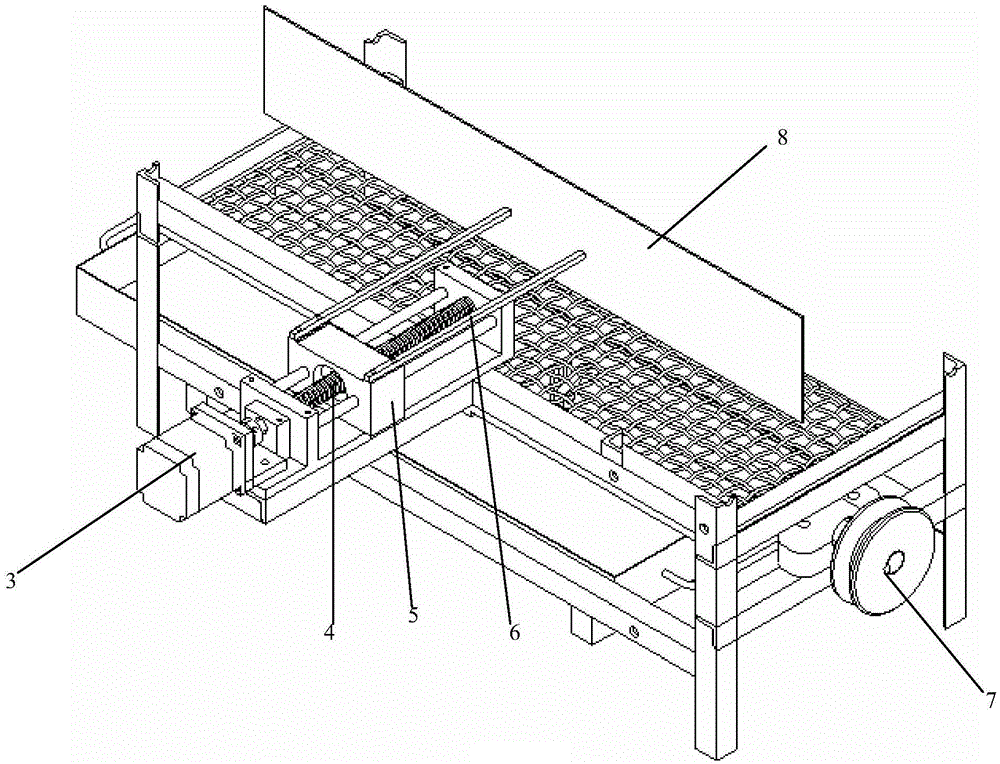

Sand leaking device for building road bridge construction

InactiveCN108654733AAvoid wastingSolve the jam situationSievingScreeningEngineeringBuilding construction

The invention relates to the technical field of building equipment, in particular to a sand leaking device for building road bridge construction. The sand leaking device comprises a cabinet body, a block removing assembly, a vibrating sand screening assembly and a blocking preventing assembly. The block removing assembly, the vibrating sand screening assembly and the blocking preventing assembly are arranged in the cabinet body. The block removing assembly comprises a drive part and two rotating roller shafts. Each rotating roller shaft is provided with an extruding roller cylinder in a sleeved manner. A gap is formed between the two extruding roller cylinders. A plurality of extruding plates are arranged on the outer side wall of each extruding roller cylinder. The vibrating sand screening assembly comprises a screening box and a vibrating part. A filter screen is arranged in the screening box. The sand leaking device has the beneficial effects that by means of the block removing assembly, crushing operation can be carried out on caked sandstone, the situation that due to the fact that the caked sandstone cannot pass the filter screen, waste of sand is caused is avoided, moreover,the situation of blocking of the filter screen can be solved by means of the blocking preventing assembly, the problem of blocking does not need to be solved manually, and great convenience is brought to workers.

Owner:石梦成

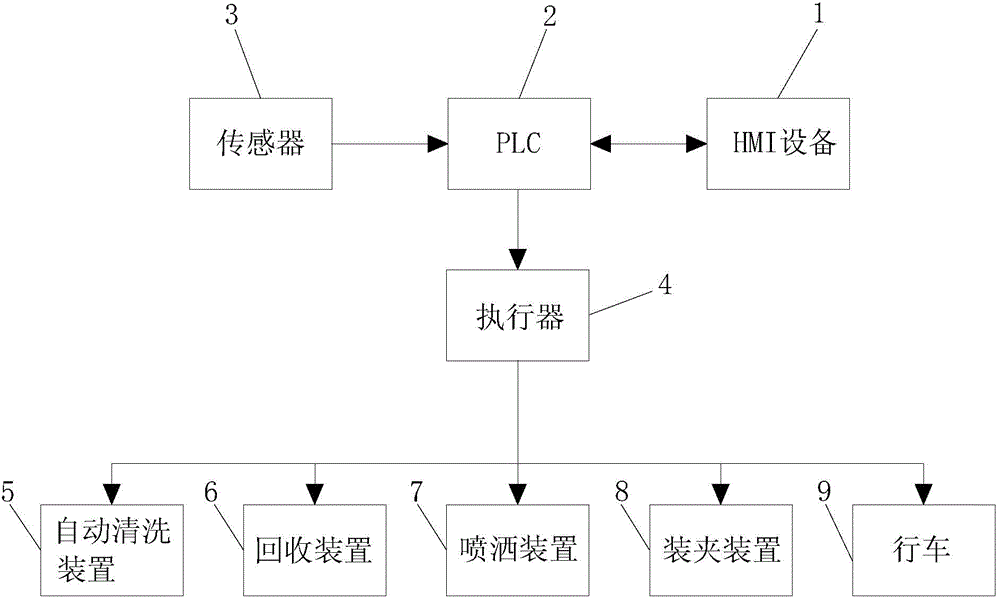

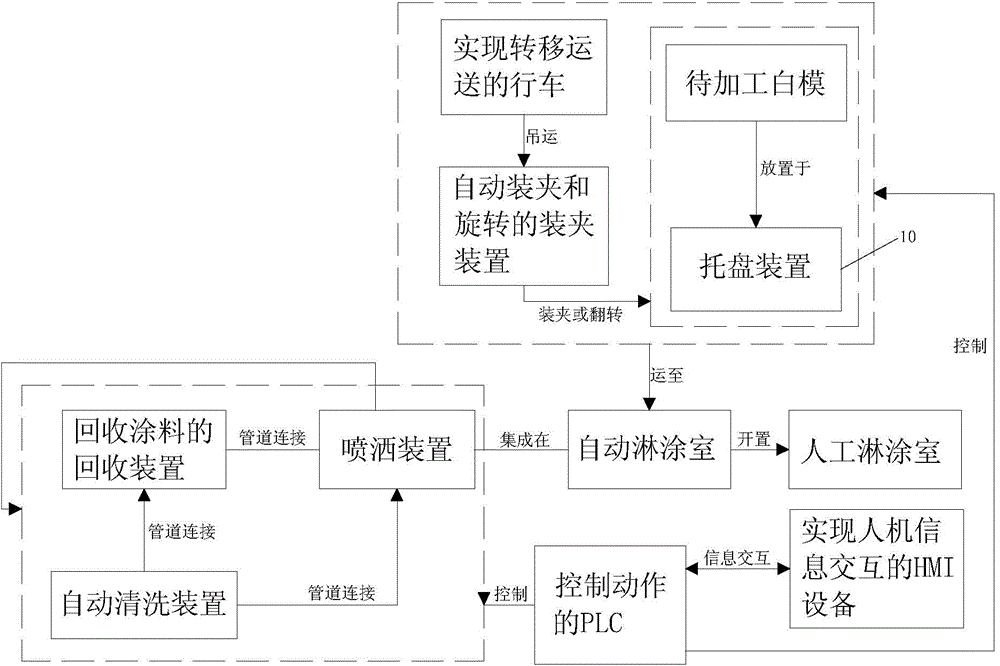

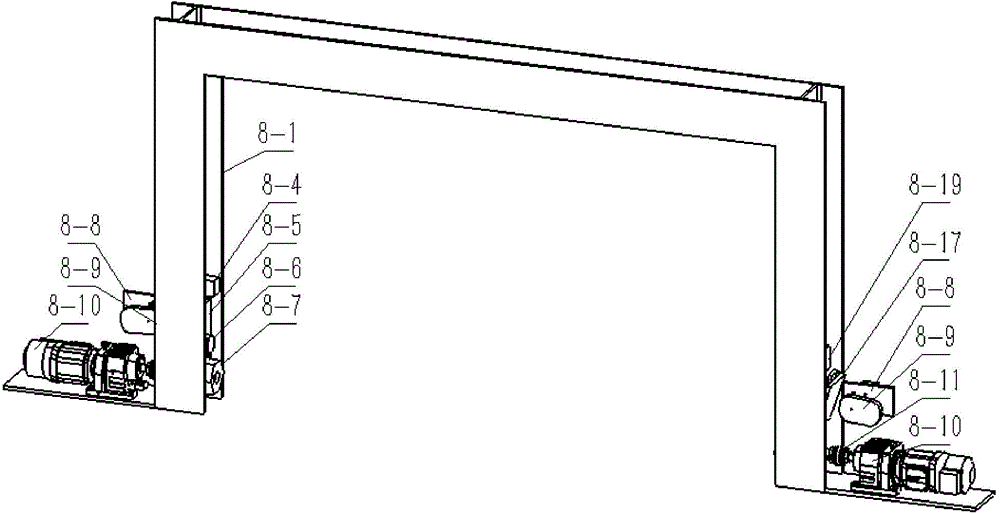

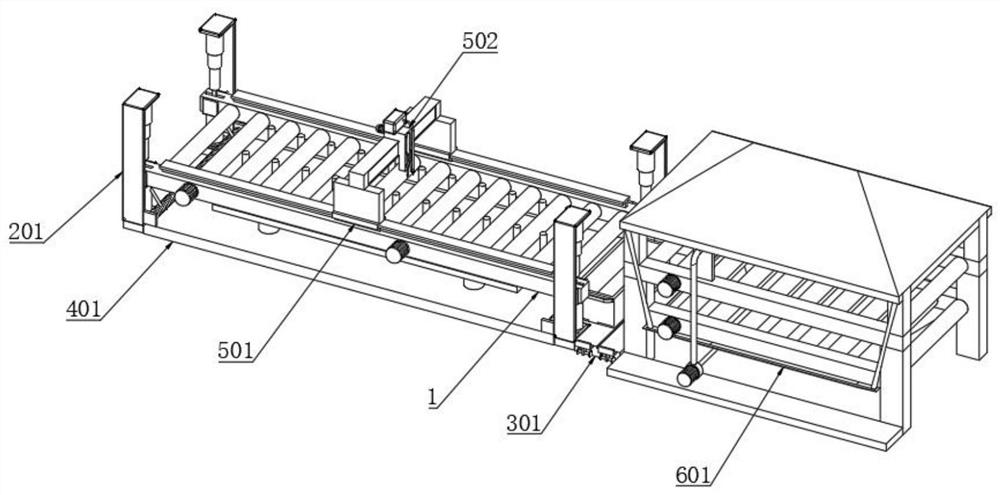

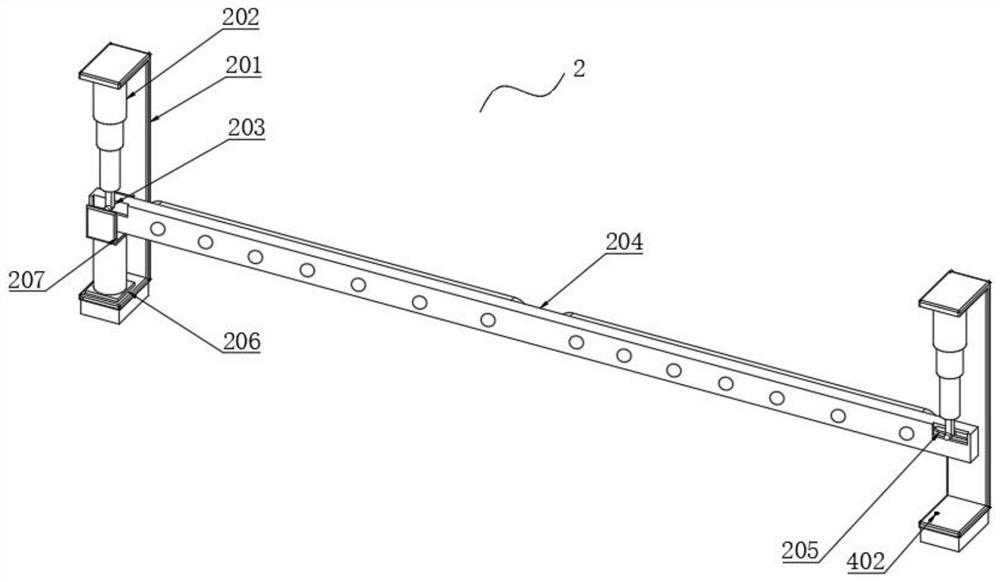

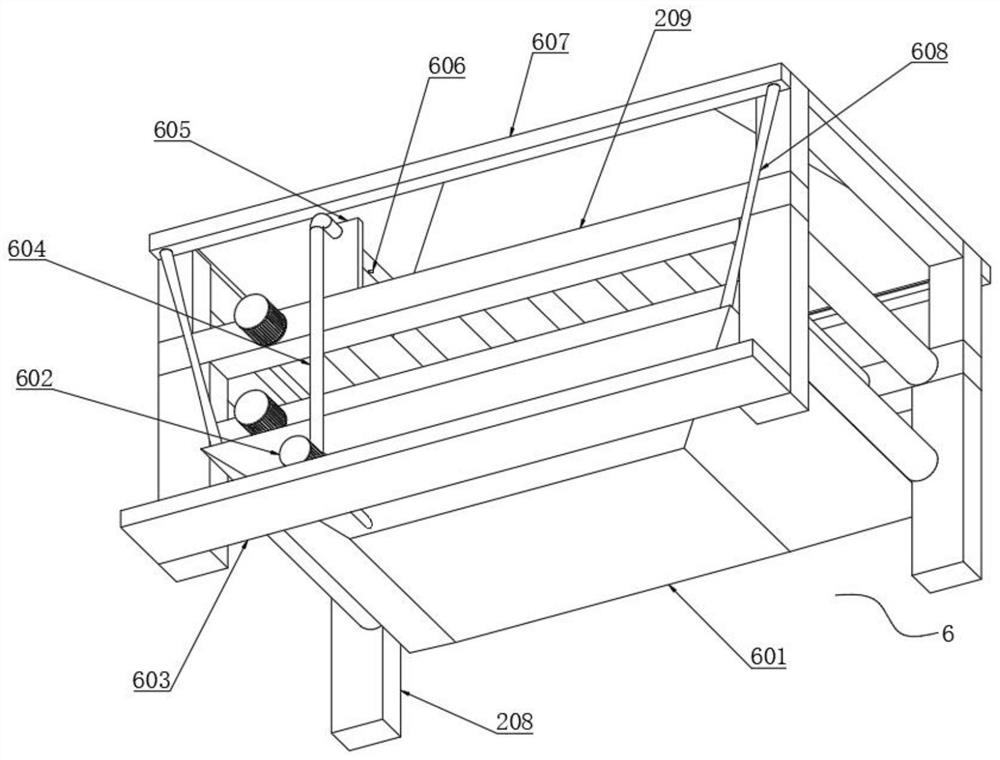

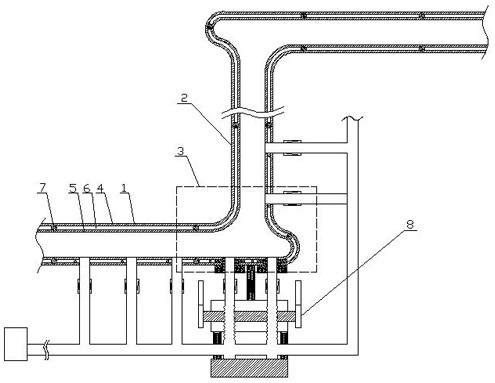

Automatic curtain-coating system for lost foam casting

ActiveCN104588250AHigh degree of automationImprove efficiencyLiquid surface applicatorsLiquid spraying apparatusDevice formControl system

The invention relates to an automatic curtain-coating system for lost foam casting. The system comprises a control system, a curtain-coating-recovery-cleaning system, a clamping device, a pallet device and a traveling crane, wherein the curtain-coating-recovery-cleaning system is formed by integrating an automatic cleaning device, a recovery device and a spraying device through a pipeline and a reversing valve; the automatic cleaning device, the recovery device, the spraying device, the clamping device and the traveling crane are connected with the control system through cables; the curtain-coating-recovery-cleaning system is distributed in the conveying direction of the traveling crane; the clamping device is connected to the traveling crane through a steel cable; the pallet device is connected with the clamping device; the recovery device and the spraying device form curtain-coating equipment. The system has the advantages of high automation degree, high efficiency, low production cost and the like, safety in a production process can be improved, curtain-coating quality can be ensured, manpower is saved, and working efficiency is improved.

Owner:WUHU ANPU ROBOT IND TECH RES INST

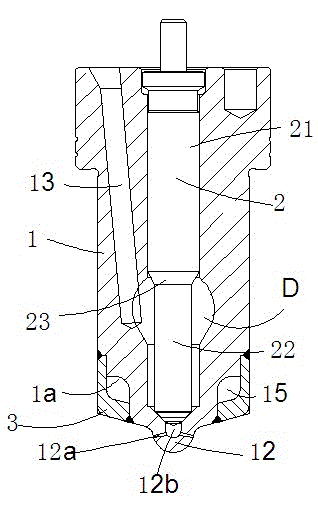

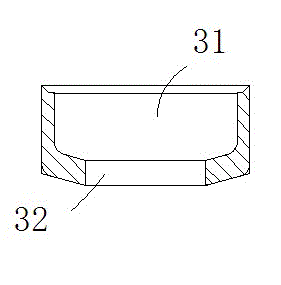

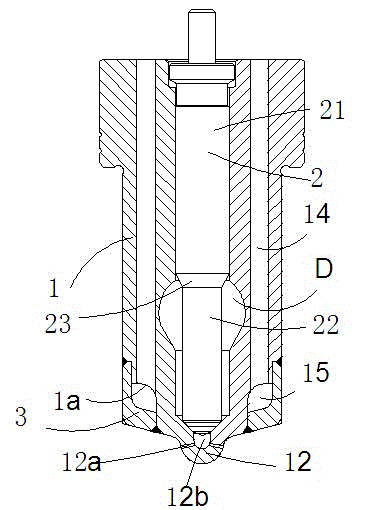

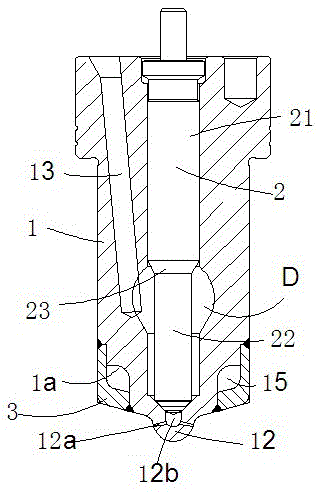

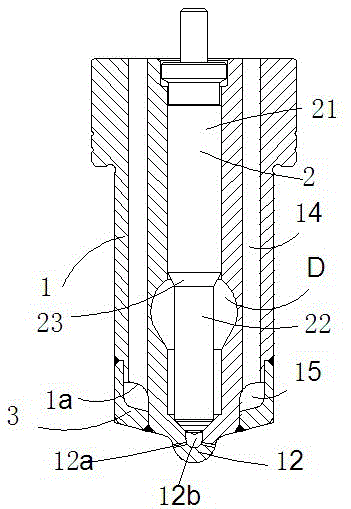

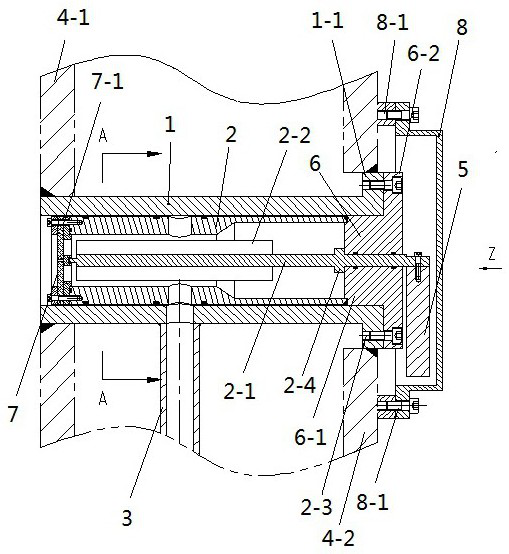

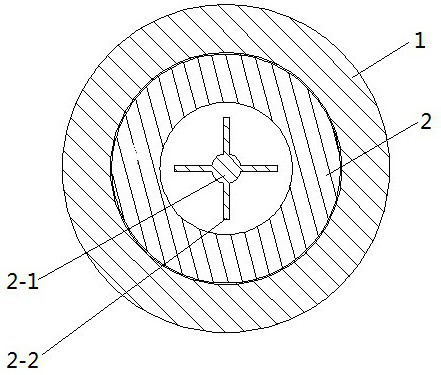

Cooling-type needle valve coupling with carbon deposition prevention effect

ActiveCN102979654ASlow coolingImprove cooling effectFuel injection apparatusMachines/enginesCouplingCooling chamber

The invention discloses a cooling-type needle valve coupling with a carbon deposition prevention effect. The cooling-type needle valve coupling comprises a needle valve body and a needle valve, which are assembled with each other. The needle valve is assembled in a valve chamber which is machined in the needle valve body; an annular clearance passage, through which a high pressure fuel passes, is formed between the outer circumference of the lower rod body of the needle valve and the inner wall of the valve chamber; and the annular clearance passage is communicated with an oil inlet passage. The cooling-type needle valve is characterized in that a cooling water jacket is fixedly mounted to the lower part of the needle valve body, a cooling chamber is formed between the cooling water jacket and the needle valve body, the needle valve body is provided with at least one group of cooling annular passages, the cooling annular passages are communicated with the cooling chamber, the opening at the two ends of each cooling annular passage are formed in the upper surface of the needle valve body; at least two jet holes are formed in the front end of the needle valve body and are communicated with the annular clearance passage. The cooling-type needle valve coupling has the advantages of smart structure, good performance, low oil consumption, less carbon deposition in the nozzle and long service life and can meet the needs for oil-fuel injector needle-valve couplings in marine diesel engines.

Owner:YUYAO SHUCHUN MACHINERY

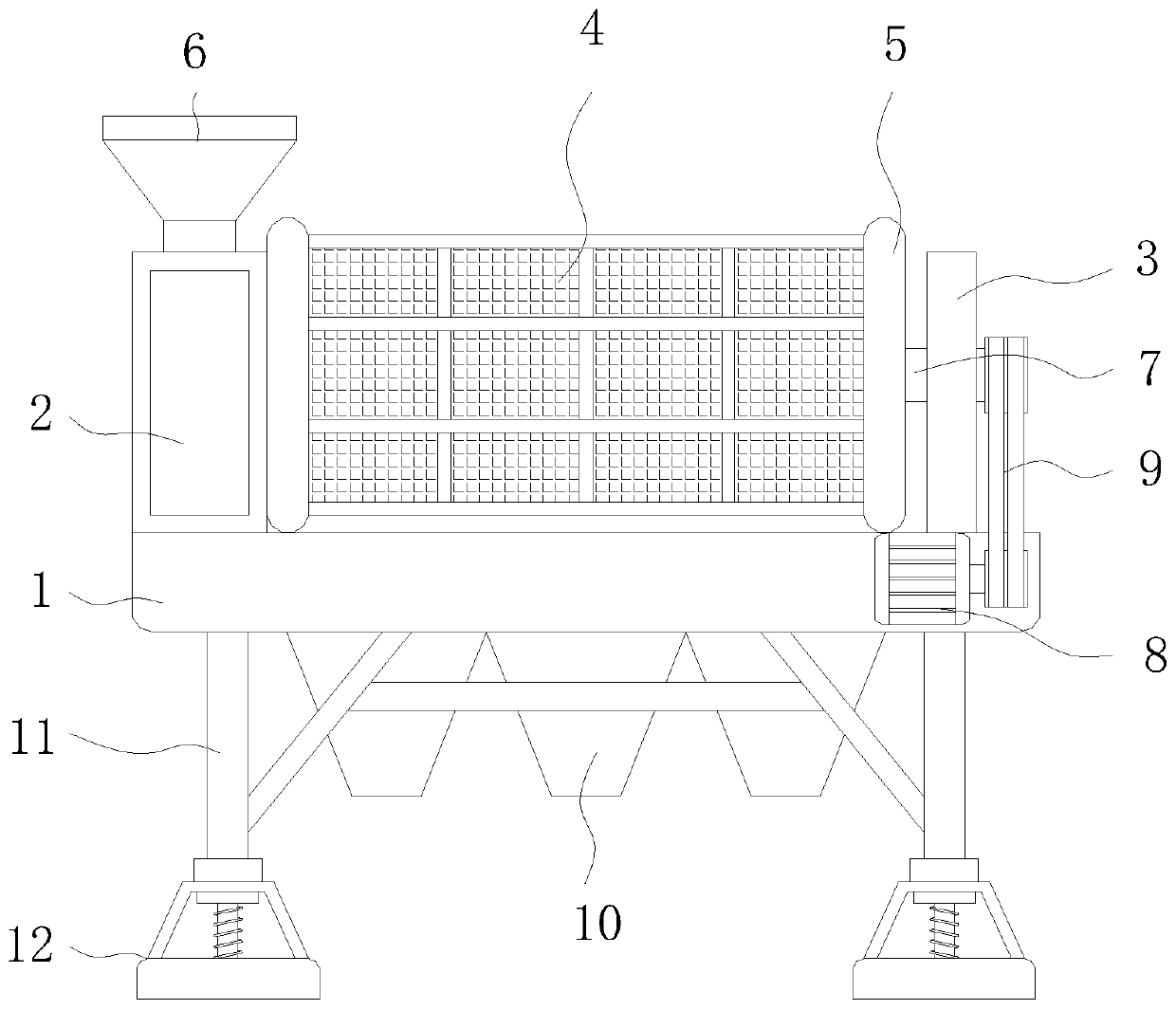

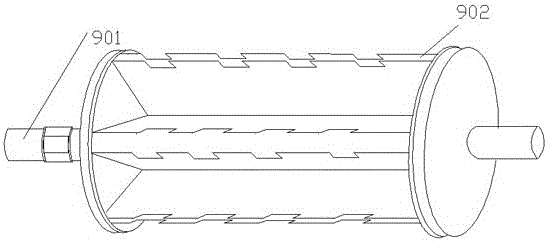

Drum-type screening equipment for household garbage

The invention relates to the technical field of garbage treatment. The invention further discloses drum-type screening equipment for the household garbage. The equipment comprises a workbench, a shell, a side plate and a roller, the bottom of the shell is fixedly connected with the left side of the top of the workbench, the bottom of the side plate is fixedly connected with the right side of the top of the workbench, the left side and the right side of the roller are movably connected with the opposite sides of the shell and the side plate respectively, and a transmission shaft is arranged inthe roller. According to the invention, the roller is driven to rotate through the motor, in the rotating process of the roller, the rubber ball is driven to move back and forth in the equipment, andone side of the rubber ball repeatedly impacts the inner wall of the roller, so that some garbage left in the roller falls off due to vibration generated by impact between the rubber ball and the inner wall of the roller, blockage caused by the fact that some garbage is left on the inner wall of the roller in the using process of the equipment is prevented, and then the blockage probability of theequipment is reduced.

Owner:山东中宝环境服务集团有限公司

3D (three-dimensional) printer spray head for printing monomer materials and composite materials

InactiveCN110435146AWell mixedSolve the jam situation3D object support structuresApplying layer meansOrganic solventDrive motor

The invention relates to a 3D (three-dimensional) printer spray head for printing monomers material and composite materials. The 3D printer nozzle comprises a reinforced phase feeding mechanism, a monomer material feeding mechanism, a discharging mechanism, a stirring device, a heat sink, an electromagnetic valve control device and a nozzle, wherein the reinforced phase feeding mechanism comprisesa reinforced phase cavity, an organic solvent cavity, a feed roller, a drive motor, blades and a heater; the monomer material feeding mechanism comprises a stirring drive motor, a monomer material cavity and stirring rods; and the discharging mechanism comprises a rotating motor, a mixing and stirring chamber, a heater and a temperature sensor. When the monomer material is printed, the monomer material is uniformly stirred in the cavity and then reaches the nozzle by way of the mixing and stirring chamber to be sprayed out; and when the composite material is printed, a reinforced phase and the monomer material enter the mixing and stirring chamber together for secondary uniform stirring, and the mixed material is sprayed out by the same nozzle. The 3D printer spray head can not only printdifferent kinds of monomer materials, but also can print the composite materials; and the materials can be uniformly mixed by stirring, and thus, the spray head can be effectively prevented from being blocked.

Owner:NANCHANG HANGKONG UNIVERSITY

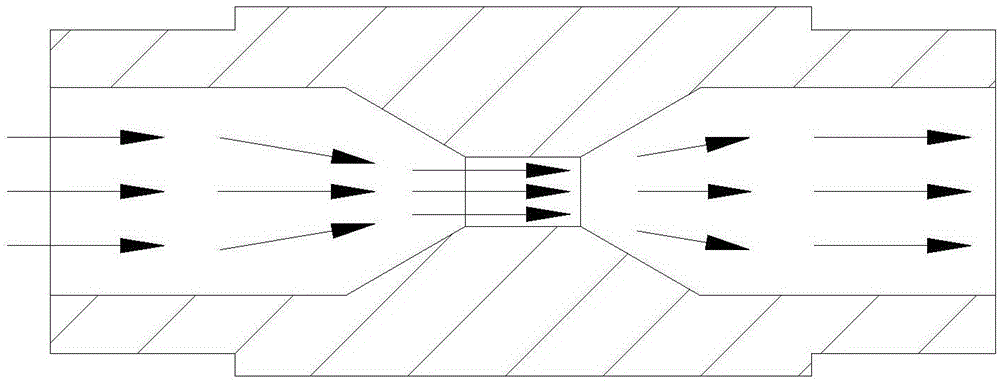

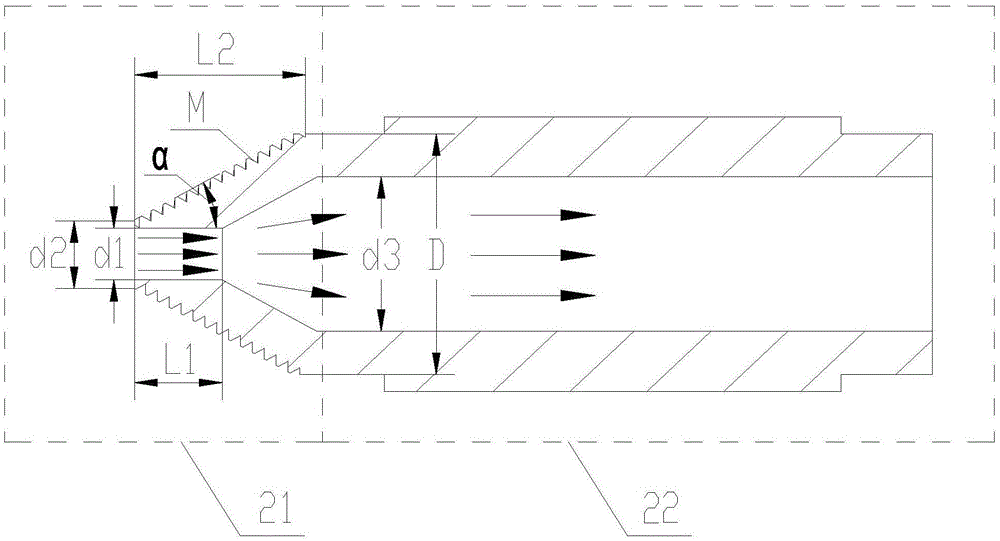

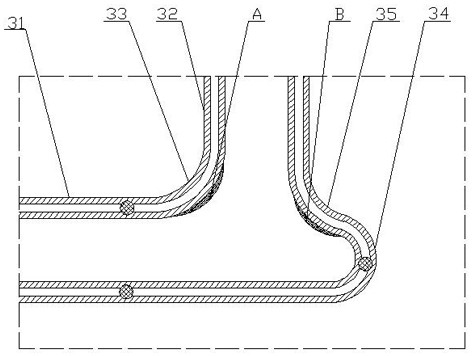

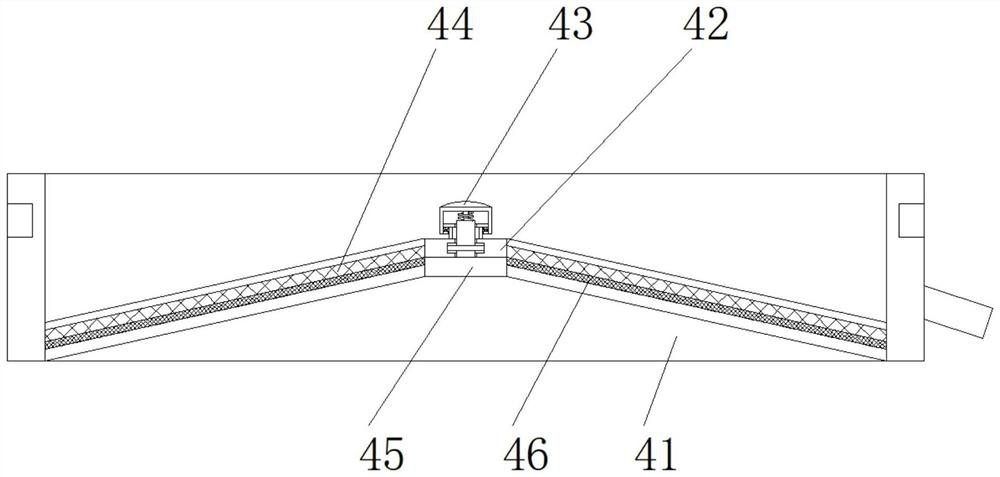

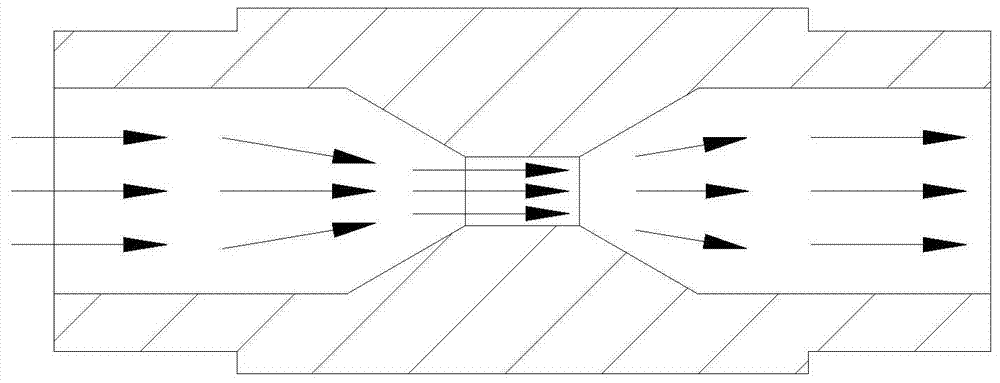

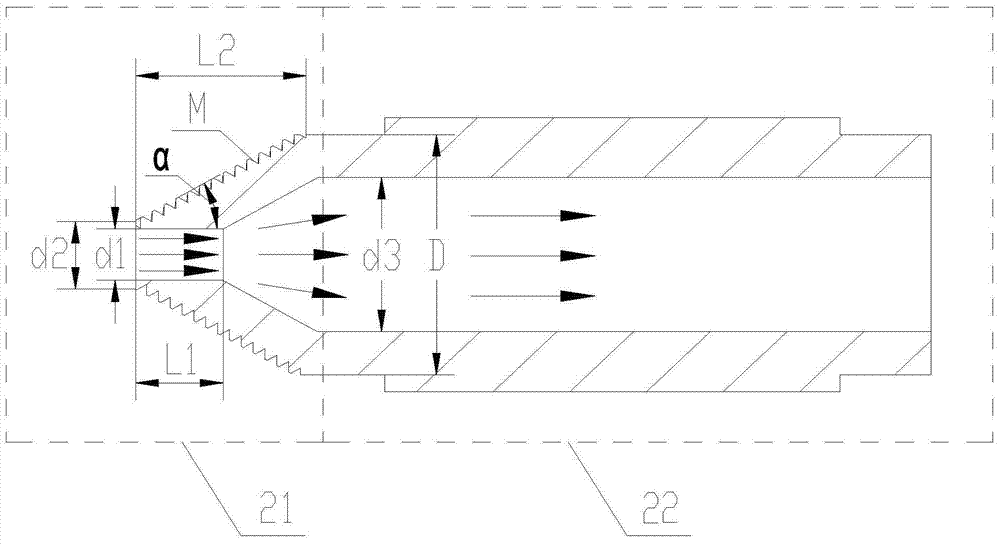

Refrigerating unit and throttle device

InactiveCN105042954ASolve the jam situationReduce welding leaksMechanical apparatusFluid circulation arrangementRefrigerationThrottle

The invention discloses a throttle device possessing refrigerating throttling effect and an anti-blocking function. The throttle device comprises a front end throttling section and a back end pipeline connection section, wherein the front end throttling section has a throttling and anti-blocking function and is equipped with a throttling hole; outside the throttling hole is provided an inclined wall surface and thread grooves formed on the inclined wall surface; and the back end pipeline connection section has two sections of steps for pipeline connection. Blocking slag can be flushed by spiral impact of fluid in the pipeline, so a self anti-blocking function can be achieved; and the throttle device is simply structured with safety and reliability. The invention further discloses a refrigeration unit having the above throttle device.

Owner:GREE ELECTRIC APPLIANCES INC

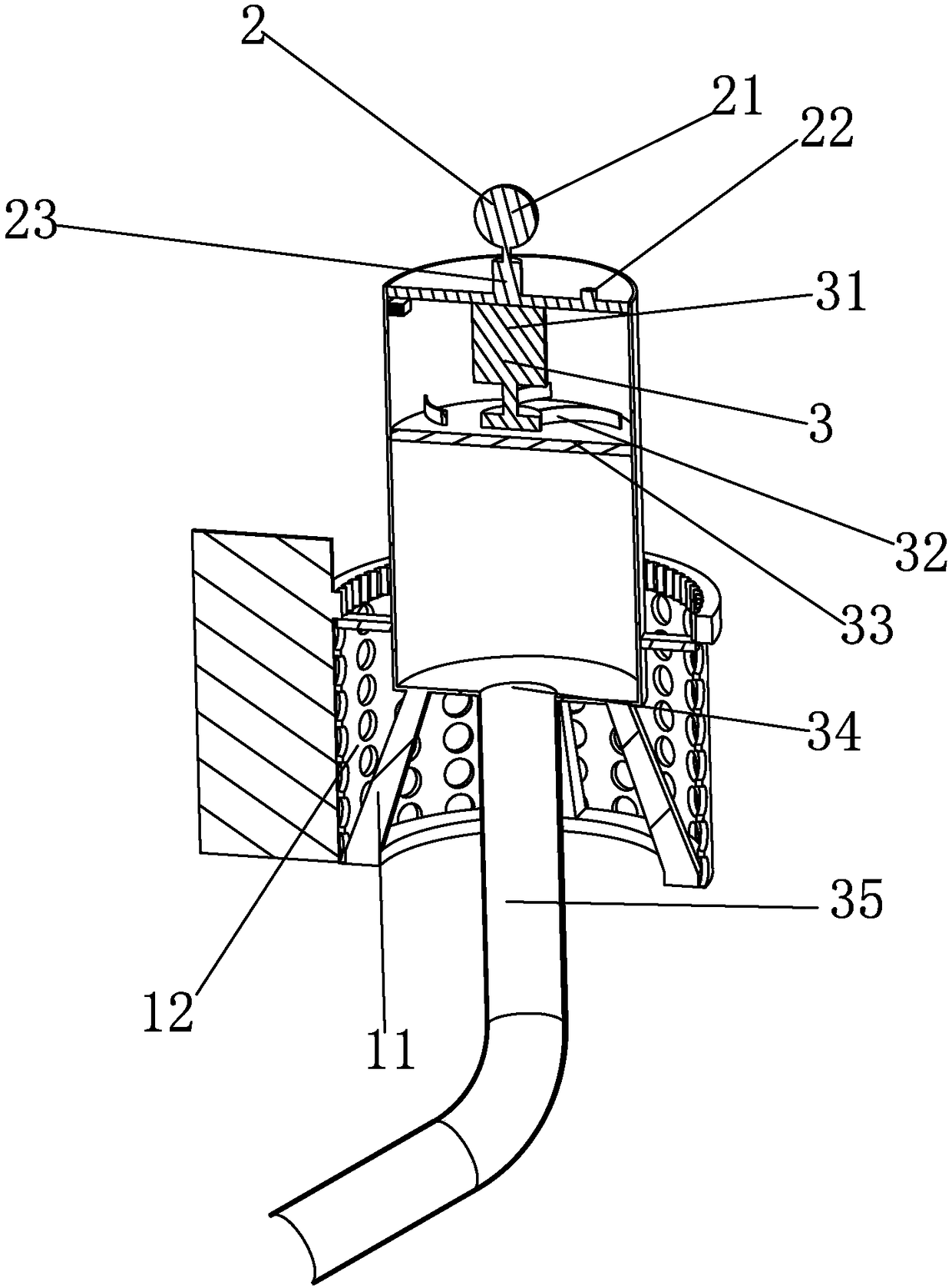

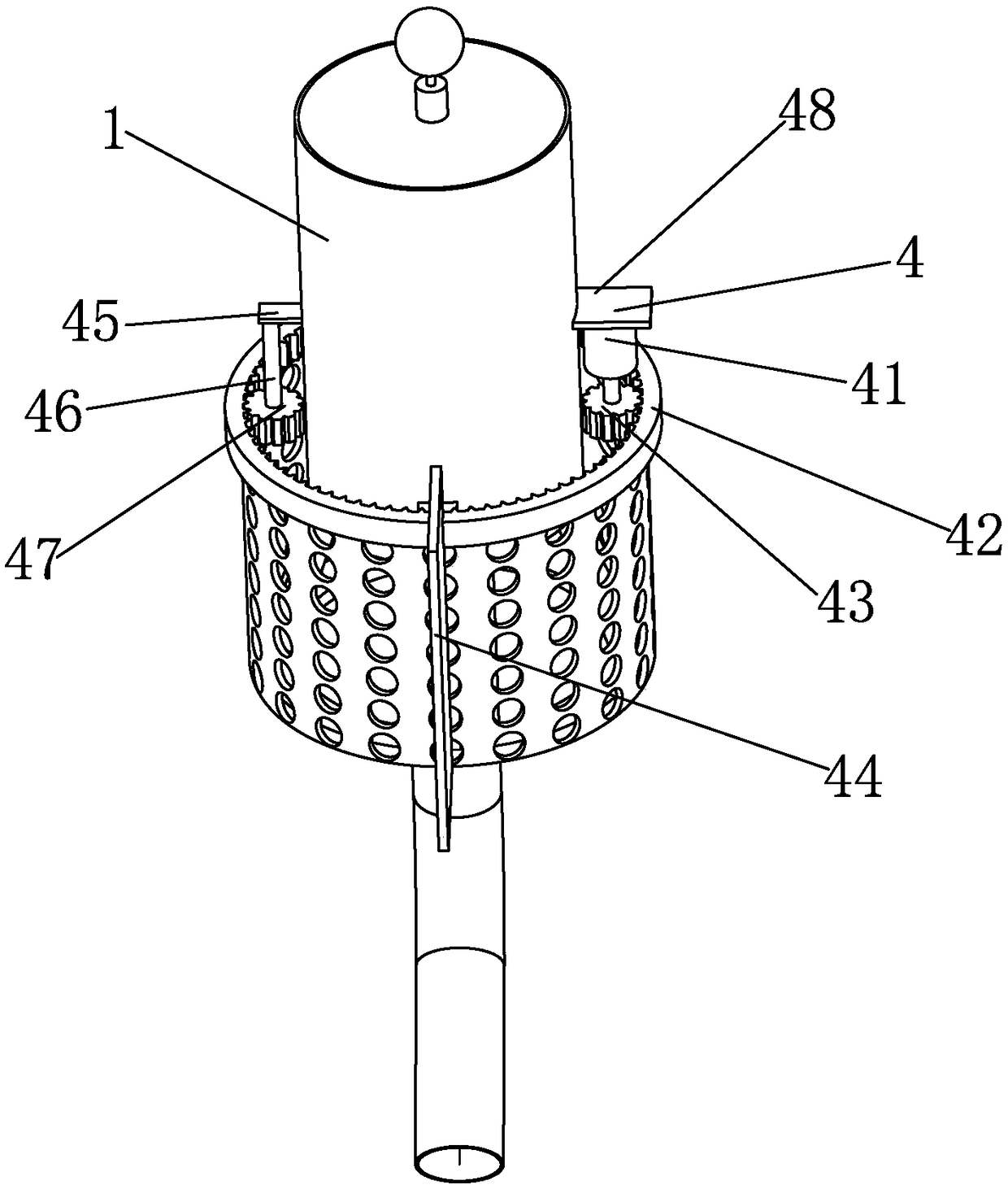

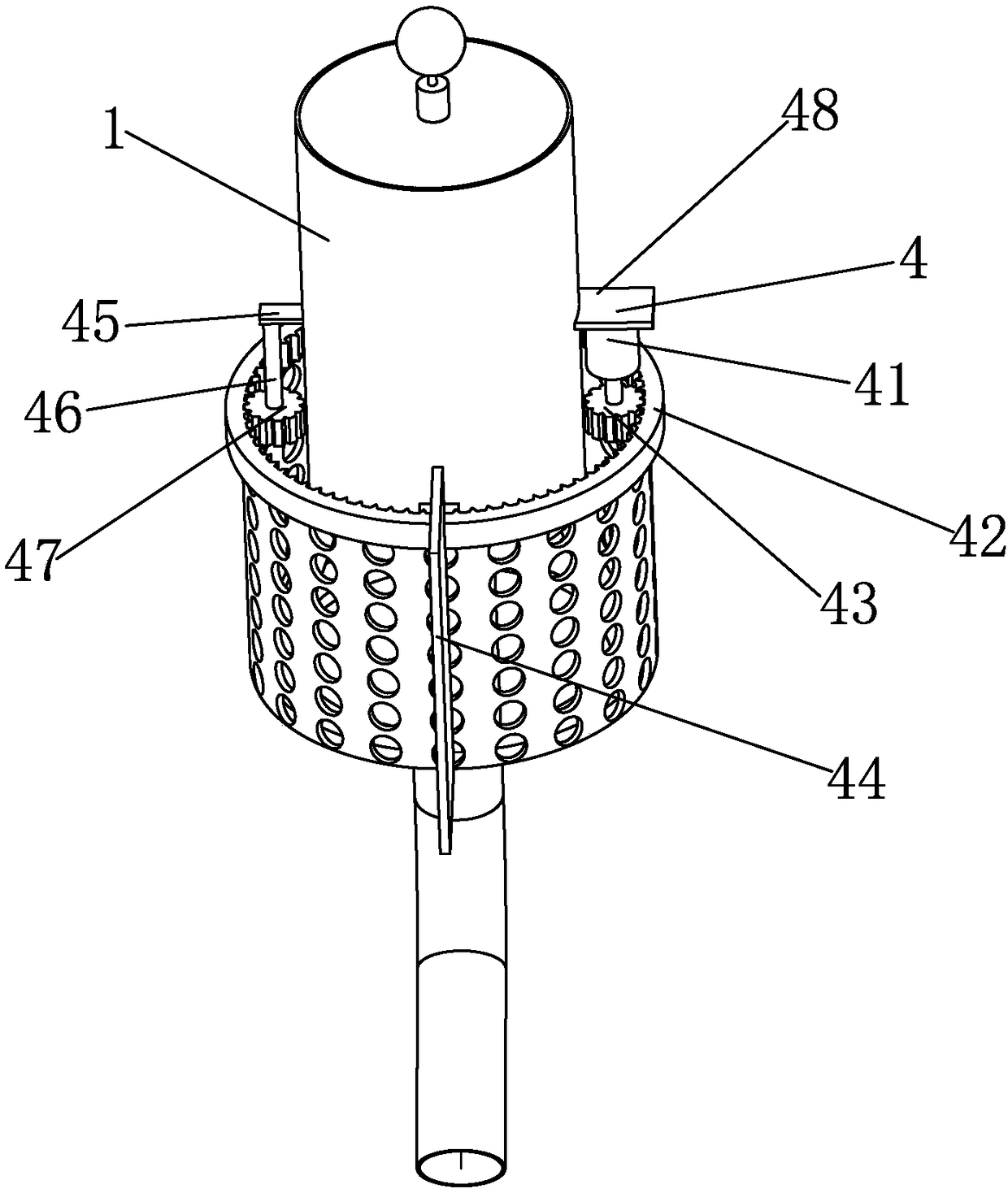

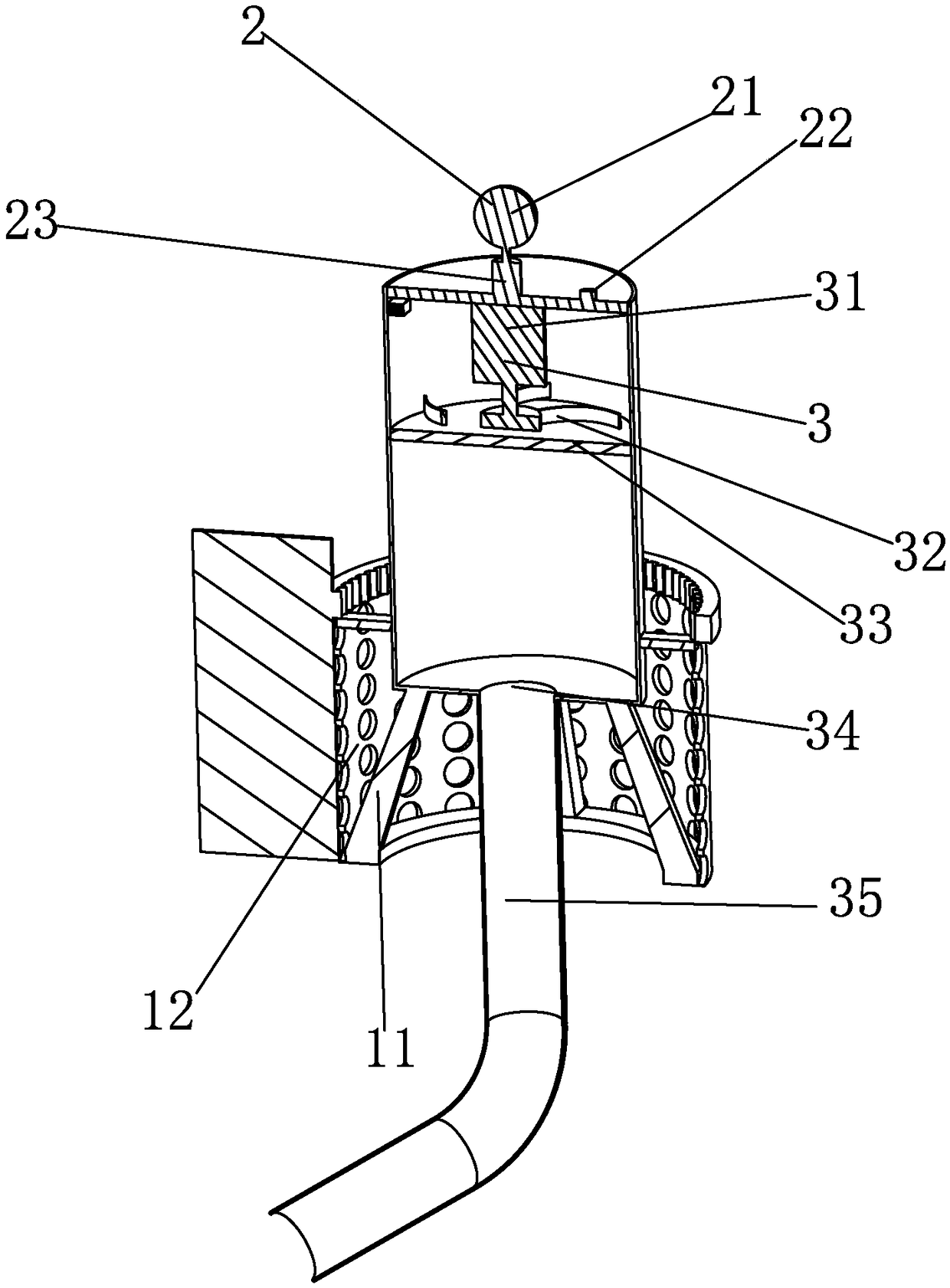

Drainage mechanism

InactiveCN108412021APrevent from rushingAvoid cloggingFatty/oily/floating substances removal devicesSewerage structuresEngineering

The invention discloses a drainage mechanism. The drainage mechanism includes a fixing barrel, a fixing rack is arranged at the lower end of the fixing barrel, and an annular filtering net is arrangedon the outer side of the fixing rack. The drainage mechanism is characterized in that a warning device is arranged at the upper end of the fixing barrel, a drawable device for drawing out garbage isarranged in the fixing barrel, and a scraping device capable of conducting scraping around the outer wall of the annular filtering net to avoid garbage blockage is arranged on the outer side of the annular filtering net; an external filtering net is arranged on the outer side of the fixing barrel, a connecting ring is arranged between the lower end of the external filtering net and the lower end of the annular filtering net, and the scraping device is disposed between the external filtering net and the annular filtering net. The structure is simple, and more convenience is provided for use; through arrangement of the warning device, people can be reminded to stay away from the drainage mechanism; through arrangement of the scraping device, garbage and water can be prevented from flushing into a drainage well, and therefore the interior of the drainage well is prevented from being blocked; through arrangement of the drawable device, components can be drawn out, and the blockage situation is avoided. The drainage mechanism is simple in structure, high in practicability and capable of meeting use demands of people.

Owner:GUANGDONG KNOWLEDGE CITY OPERATION SERVICES CO LTD

Manhole safety device used on rainy days

The invention discloses a manhole safety device used on rainy days. The safety device comprises a fixed barrel, and a fixing frame is arranged at the lower end of the fixed barrel; an annular filter screen is arranged on the outer side of the fixing frame. The device is characterized in that a warning device is arranged at the upper end of the fixed barrel, and an extracting device capable of extracting garbage is arranged in the fixed barrel; the outer side of the annular filter screen is provided with a scraping device capable of scraping the outer wall of the annular filter screen to prevent garbage blocking. The safety device is simple in structure and convenient to use; people can be reminded through the warning device, and people can be prevented from being close to the device; the garbage and water can be prevented from being flushed into a manhole through the scraping device, and the manhole is prevented from being blocked; parts can be extracted through the extracting device,the problem of blockage is solved, and the safety device is simple in structure, high in practicality and capable of meeting use requirements of people.

Owner:中山市盛凌食品设备有限公司

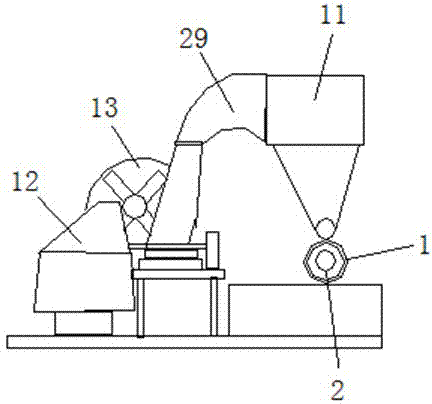

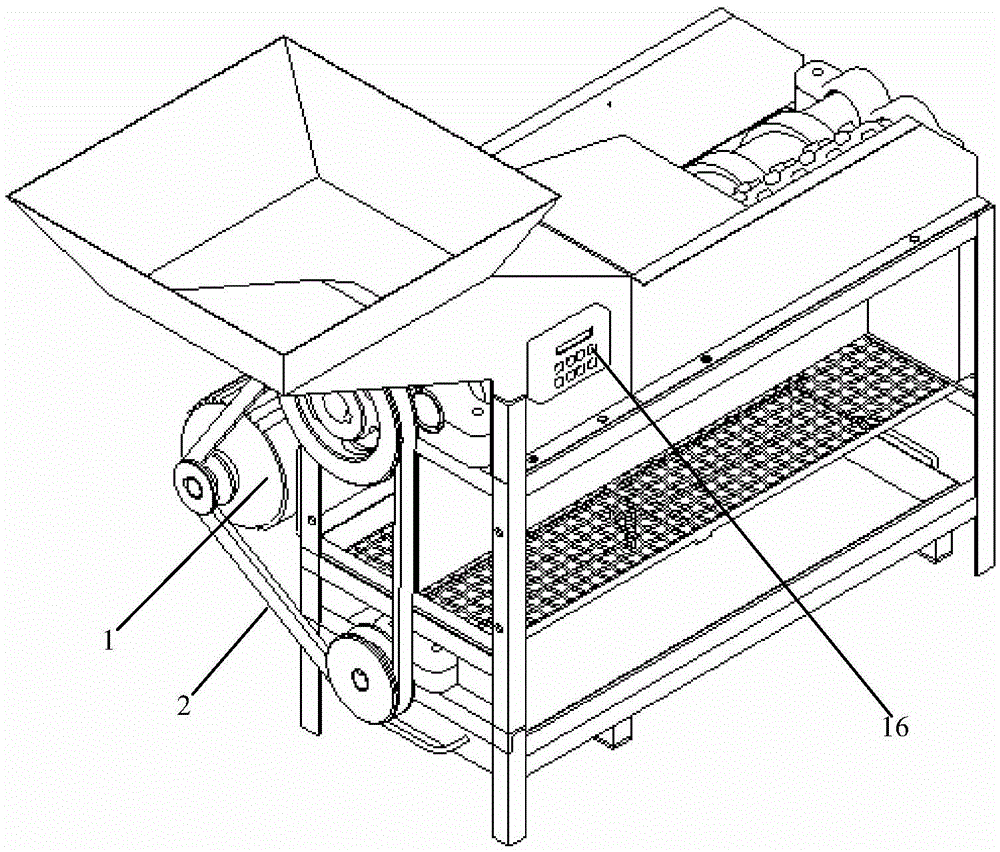

Straw puffing equipment

InactiveCN103934873AMeet the requirementsSmooth feeding and dischargingReed/straw treatmentElectric machineryProcess engineering

The invention relates to straw puffing equipment. The straw puffing equipment comprises a straw smashing and feeding device, a smashed straw puffing device, a power control device and a water cooling device, wherein the smashed straw puffing device comprises a cylinder body; the straw extruding equipment is characterized in that the straw smashing and feeding device comprises a conical-opening feeding bin, a straw smashing bin connecting the conical-opening feeding bin and a transverse preliminary-cutting tool arranged between the conical-opening feeding bin and the straw smashing bin, and the straw smashing bin comprises a reaming tray knife driven by a motor. The straw puffing equipment has the beneficial effects that by adopting the straw smashing and feeding device with a new structure, the straw extruding equipment can realize smooth feeding and discharging, prevents a phenomenon that treatment material extruded from the extruding device is carbonized and blocked due to material supplying interruption between the feeding device and the extruding device, and ensures that the extruded straws meet the using requirement.

Owner:安徽鲁班集团神牛机械有限公司

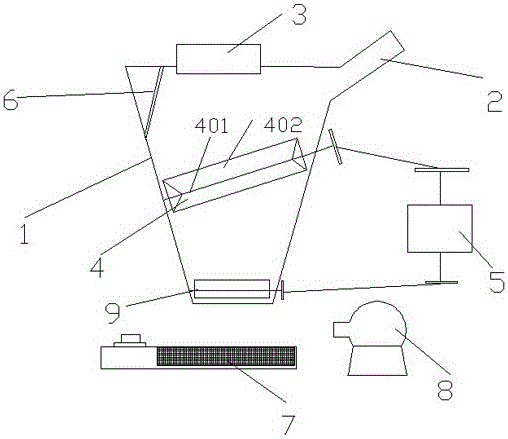

Wheat processing device

InactiveCN106492915AEasy to separateIncrease the number of collisionsGrain huskingGrain polishingMaterial resourcesEngineering

The invention discloses a wheat processing device. The wheat processing device comprises a processing barrel body and a discharging opening. A feeding pipe which extends upwards in an inclined manner and an induced draft fan are arranged at the top of the processing barrel body. A dehusking mechanism which extends downwards in an inclined manner is arranged inside the processing barrel body. The dehusking mechanism is driven by a motor, so that after falling onto the dehusking mechanism, wheat is collided and impacted upwards and further impacted onto a collision plate arranged inside the processing barrel body. The dehusking mechanism comprises a rotating shaft and multiple overturning plates which are arranged around the rotating shaft. The overturning plates are densely provided with protrusions and dents. A material shifting mechanism is arranged at the discharging opening of the processing barrel body. The material shifting mechanism comprises a material shifting shaft and multiple material shifting pieces which are uniformly arranged around the material shifting shaft. A vibrating screen is arranged below the discharging opening. An air blower is arranged between the discharging opening and the vibrating screen. According to the wheat processing device, husk on the wheat is removed through collision; impurity removal efficiency is improved; the wheat is prevented from being blocked in the processing process; and manpower or materials resources are not wasted.

Owner:平顶山鸿顺源工贸有限公司

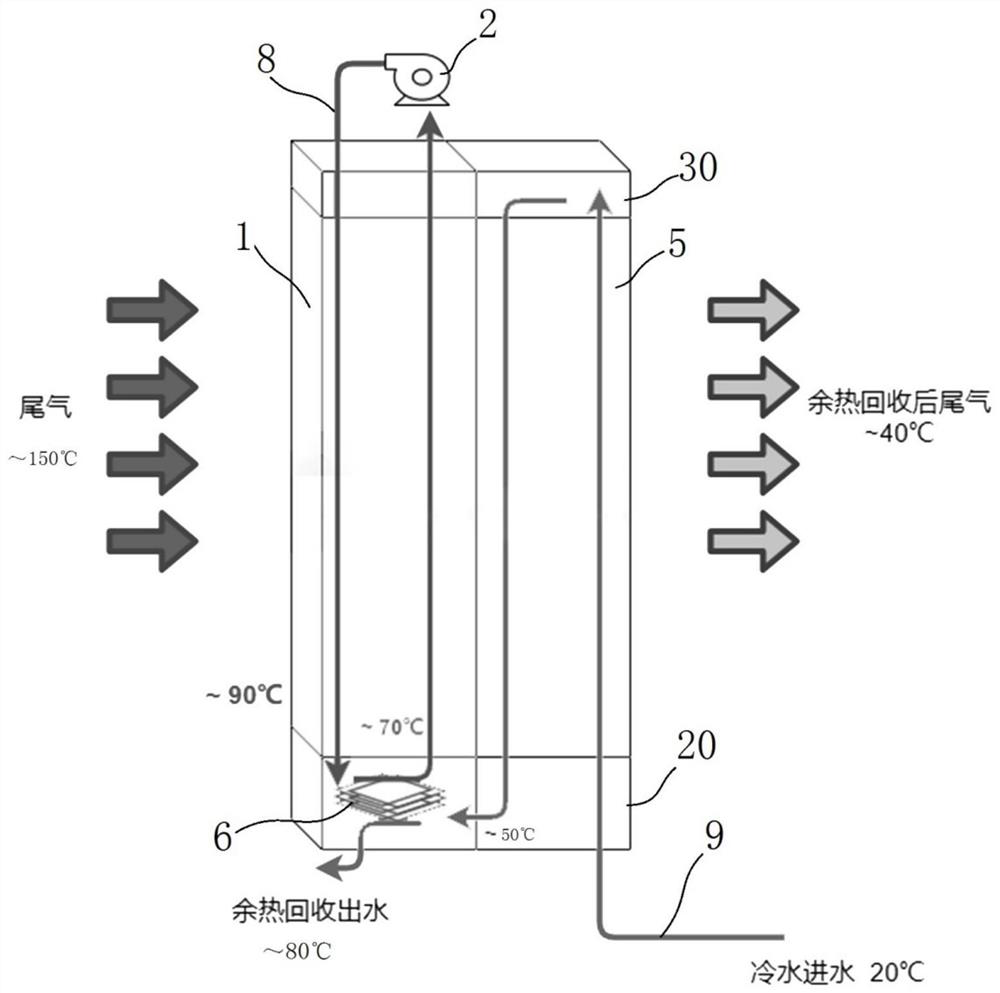

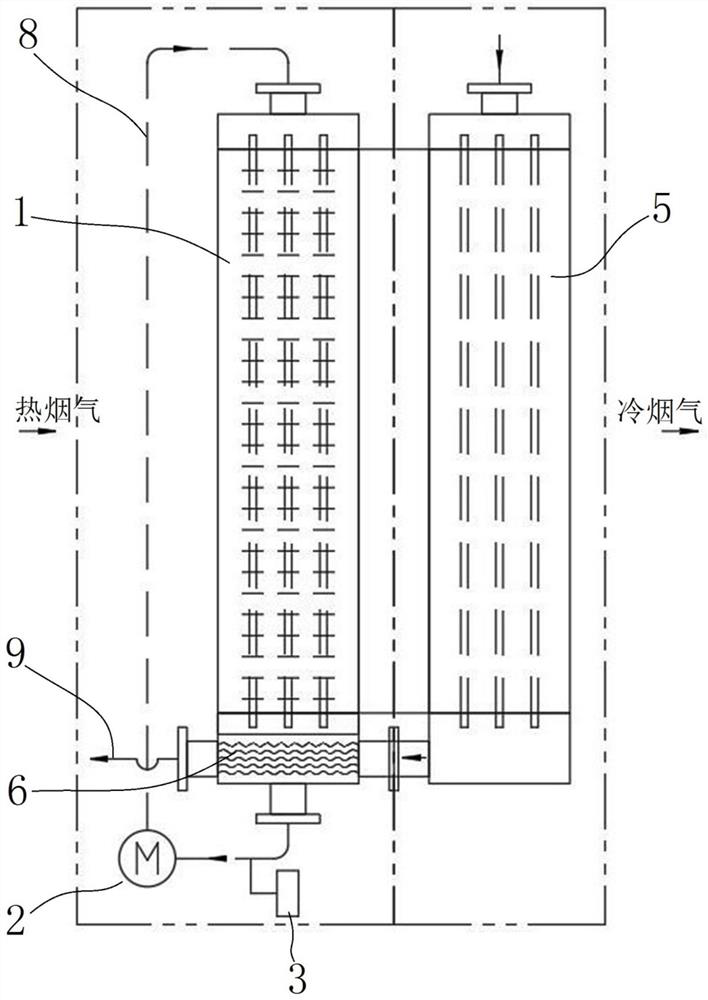

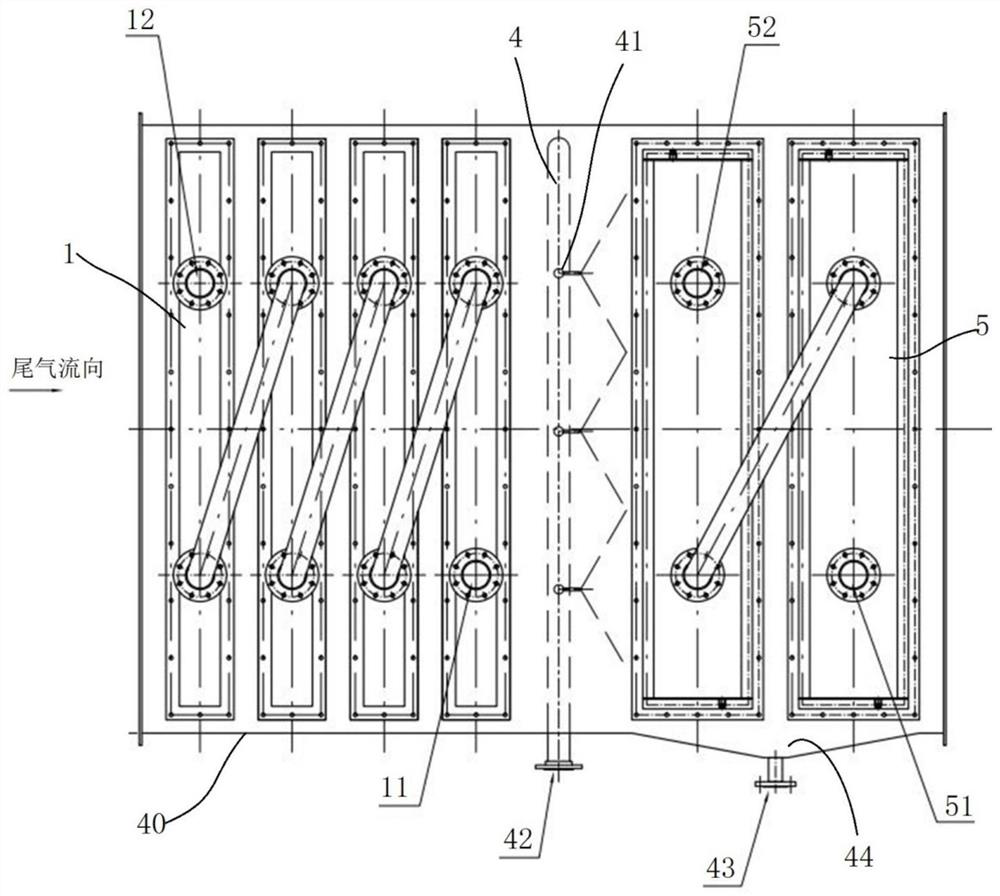

Waste heat recovery system, waste heat recovery method and boiler system

PendingCN112879893ATo achieve anti-corrosion purposesNo rustingCorrosion preventionWaste gas energyWater vaporFlue gas

The invention relates to a waste heat recovery system, a waste heat recovery method and a boiler system, and solves the technical problem that smoke exhaust of an air duct is blocked due to the fact that a heat exchanger is prone to corrosion, rusting and dust blockage during traditional waste heat recovery on the premise that cost is not increased too much. The waste heat recovery system comprises a tubular shell connected to a flue in series, and a first heat exchanger and a second heat exchanger which are arranged in the shell, wherein the temperature of a first heat exchange medium is higher than the dew point temperature of water vapor condensed on the outer surface of the first heat exchanger in the flue gas; the first heat exchanger is a finned tube heat exchanger made of common carbon steel; the second heat exchanger is located on the downstream of the first heat exchanger in the flue gas flowing direction, a second internal pipeline is arranged in the second heat exchanger and provided with a cooling water inlet and a cooling water outlet, the cooling water inlet is connected to a water supply system for supplying a second heat exchange medium, the second heat exchange medium exchanges heat with the flue gas for the second time in the second internal pipeline, a large amount of water vapor in the flue gas is condensed on the outer surface of the second heat exchanger; and the second heat exchanger is a tube heat exchanger made of a high-corrosion-resistance material.

Owner:SHANGHAI DONGRUN HEAT EXCHANGE EQUIP MFG

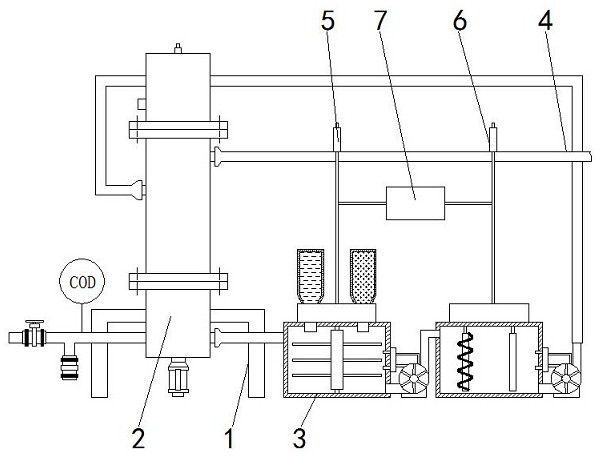

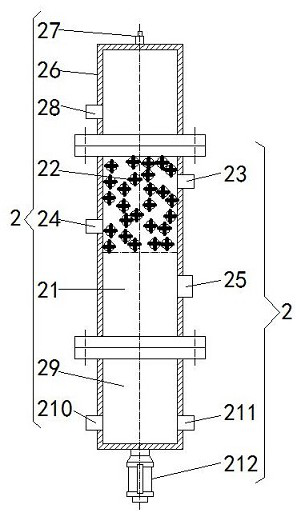

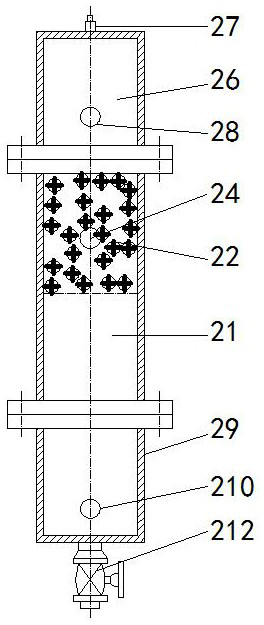

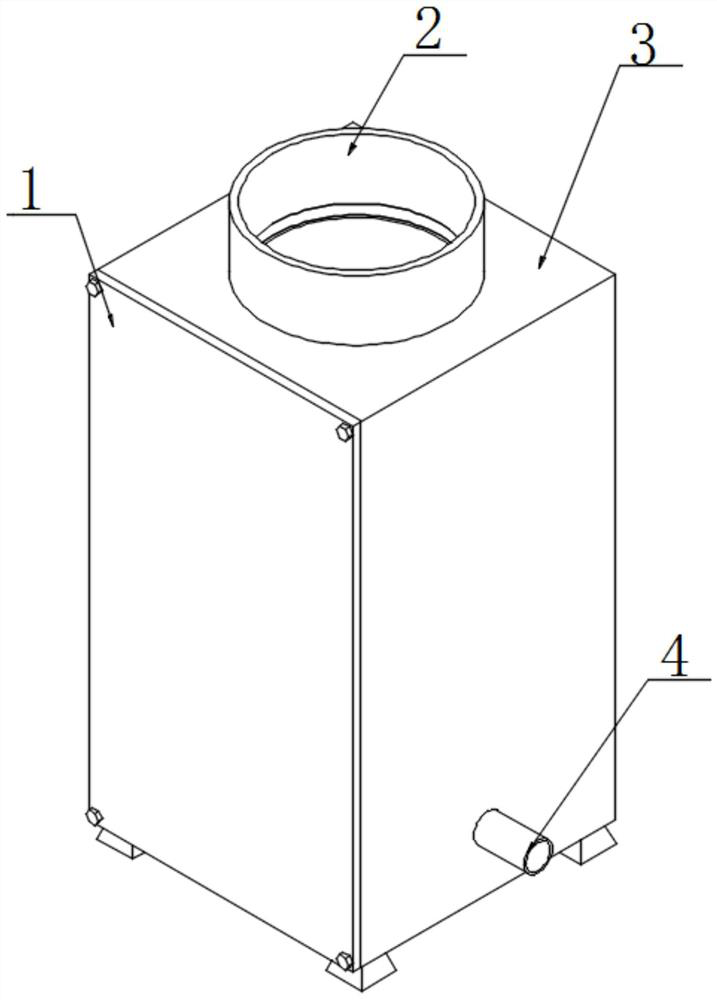

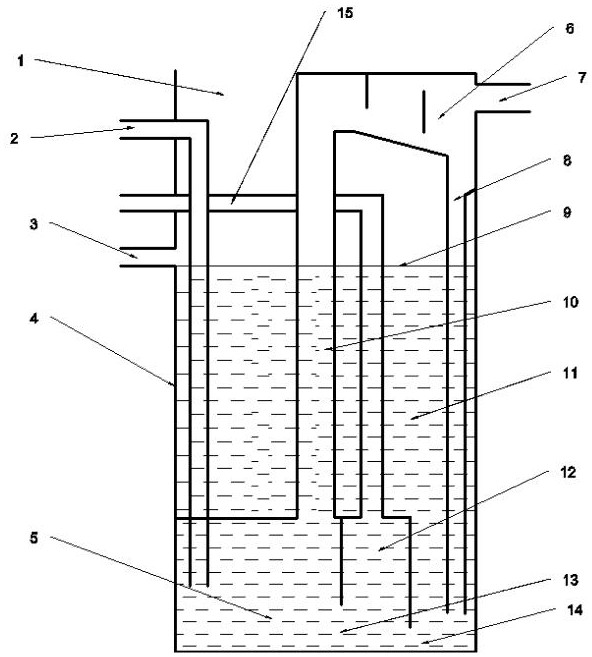

Novel anaerobic reactor

InactiveCN113788538ASolve the jam situationLow costWater treatment parameter controlBiological treatment regulationPH meterFrequency conversion

The invention provides a novel anaerobic reactor which comprises a rack, a reaction mechanism is mounted at the top of the rack, the reaction mechanism comprises a reaction tank, a bottom tank is riveted to the bottom of the reaction tank, and an emptying valve is inserted into the bottom of the bottom tank. According to the invention, an intelligent pH meter with modbus communication, a COD online detector and a temperature sensor are used, and a regulating valve with an adjustable opening degree and a related water pump with frequency conversion control are combined to communicate with a self-developed intelligent water affair cloud platform, so that data are uniformly transmitted to a database; real-time changes of pH, temperature, COD and other signals in the anaerobic reactor are predicted and analyzed through an artificial intelligence optimization control model, the production efficiency is improved, and the power consumption is reduced; and through data prediction, the probability of failure of the anaerobic process section is greatly reduced, and an intelligent production mode of unattended operation or few-person operation of the anaerobic process section is realized.

Owner:南京水滴智能环保装备研究院有限公司 +1

Automatic powder screening machine

InactiveCN113441390ASolve the situation of moisture stickingSolve the problem of screening efficiencySievingScreeningStructural engineeringMechanical engineering

The invention discloses an automatic powder screening machine which comprises a shell, a collecting box body for collecting powder is arranged at the bottom in the shell, a screening mechanism is arranged at the top of the collecting box body, the screening mechanism comprises two sliding rails fixed to the two sides of the interior of the shell, a moving plate is arranged between the two sliding rails in a sliding mode, moving assemblies are arranged between the moving plate and the sliding rails, an annular plate is fixedly connected to the top of the moving plate, and filtering holes are formed in the portion, on the inner side of the annular plate, of the moving plate. Powder is fed and discharged by controlling a switch valve on a discharging pipe at the bottom of a funnel, so that the powder falls into the annular plate, meanwhile, the powder is screened through filtering holes, an electric push rod is used for driving the moving plate to move between the two sliding rails, meanwhile, the annular plate is driven to move, the moving plate can be driven by the electric push rod to move horizontally, and the powder is dispersed under the action of inertia and then enters the collecting box body through the filtering holes.

Owner:安徽中科春谷激光产业技术研究院有限公司

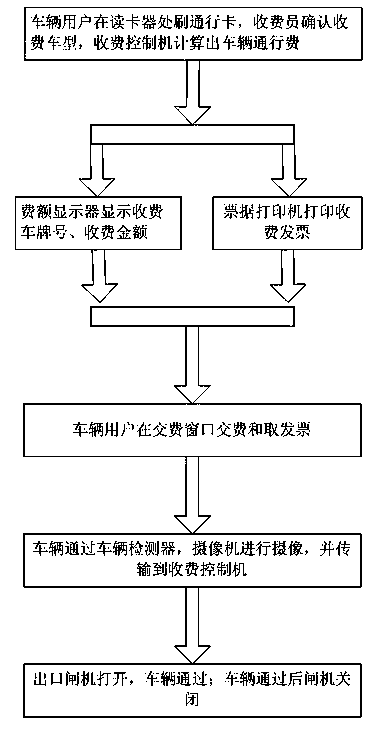

Highway exit station rapid-charging system and implementation method thereof

InactiveCN104063907ALess toll travel timeSolve the blockageTicket-issuing apparatusEngineeringCard reader

The invention discloses a highway exit station rapid-charging system and an implementation method thereof. The highway exit station rapid-charging system and the implementation method thereof solve the problem that an existing charging exit is congested. The highway exit station rapid-charging system comprises a charging control machine installed in a charging control room and is characterized by further comprising a card reader, a printer, a vehicle detector, a camera, a fee displayer and an exit gate, wherein the card reader is installed on the front portion of a safety island, the printer is installed in the charging control room, the fee displayer is installed on the rear portion of the safety island, and the exit gate is installed behind the safety island; the card reader, the printer, the vehicle detector, the camera, the fee displayer and the exit gate are all connected with the charging control machine. The card reader is installed on the front portion of the safety island, the situation that all operation behaviors of charging are carried out in a charging window in a concentrated mode is changed, and meanwhile charging and invoice printing are synchronously carried out, so that time is saved by occupying more space, charging passing time of a vehicle is shortened greatly, and the problem that the exist is congested is solved effectively.

Owner:CHENGDU UNIV OF INFORMATION TECH

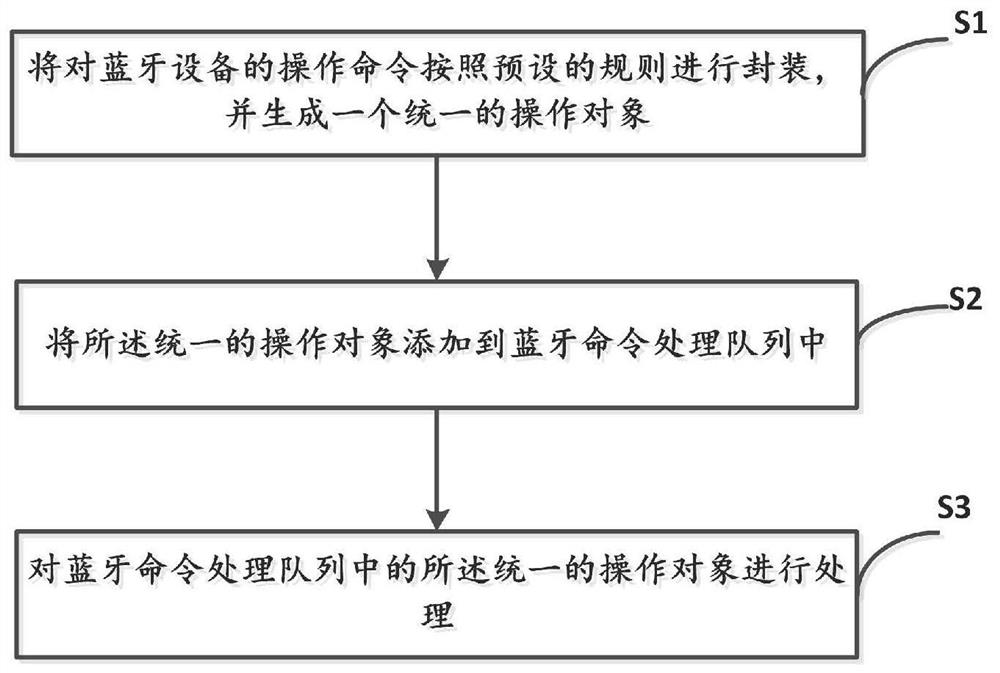

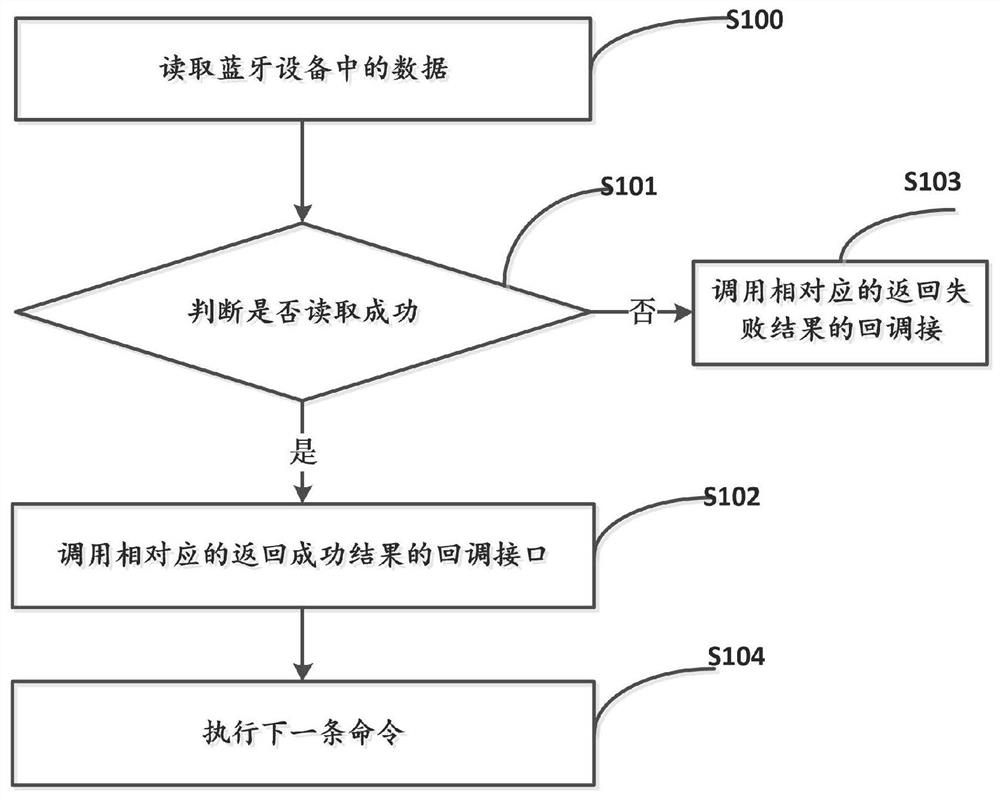

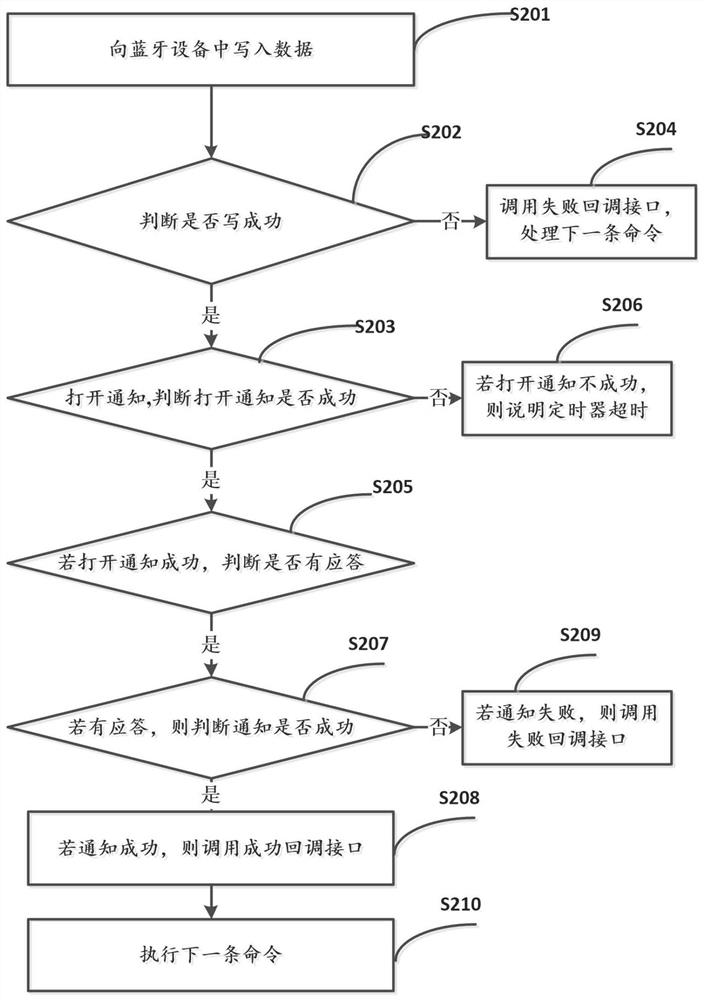

Bluetooth equipment operation command processing method and system and readable storage medium

PendingCN112445548ASimplify processing logicSimplified logic and code sizeTransmission systemsExecution paradigmsEmbedded systemComputer hardware

The invention provides a Bluetooth equipment operation command processing method and system and a readable storage medium. The method comprises the following steps: packaging an operation command of Bluetooth equipment according to a preset rule, and generating a unified operation object; adding the unified operation object into a Bluetooth command processing queue; processing the unified operation object in the Bluetooth command processing queue; the system comprises a packaging generation module for packaging an operation command of Bluetooth equipment according to a preset rule and generating a unified operation object; an adding module used for adding the unified operation object into a Bluetooth command processing queue; and a processor module used for processing the unified operationobjects in the Bluetooth command processing queue. According to the invention, the logic and the code amount of the operation command of the Bluetooth equipment can be simplified, and the problem that the Bluetooth equipment is blocked when multiple command operations are performed on the Bluetooth equipment can be solved at the same time.

Owner:GUANGZHOU STARS PULSE CO LTD

Automatic air pressure control safety device

PendingCN112812805AEasy to add liquidFor automatic dischargeLiquid hydrocarbon mixture productionHydrocarbon oils treatmentCombustion chamberAutomatic control

The invention discloses an automatic air pressure control safety device, and belongs to the field of waste tire pyrolysis. The device comprises a box body. An air inlet pipe and a liquid level pipe are arranged on the left side face of the box body, and a liquid injection opening is formed in the upper left portion of the box body. An air collecting box is arranged in the box body, one end of the air inlet pipe penetrates through the left side of the box body to enter the air collecting box, the air collecting box and a liquid-air separation box are communicated through a rising air channel in the middle of the interior of the box body, an air outlet pipe is arranged on the upper portion of the liquid-air separation box, a back-flow pipe is arranged on the lower portion of the liquid-air separation box, the lower end of the back-flow pipe is arranged at the bottom of the box body, and a combustion chamber conveying pipe is arranged on the left side of the box body to prevent harmful waste gas from being discharged into the atmosphere to pollute the atmosphere. By means of the relation between the liquid level and the pressure intensity, the air pressure in the air inlet pipeline is controlled according to the liquid level in the box body, and the problems that pressure control of a manual valve is not accurate and not timely, and the valve is prone to gas leakage and blockage due to abrasion are solved. When the air pressure in the system is too high, the manual valve cannot react in time, and major potential safety hazards of pipeline breakage, air leakage, fire explosion, reaction kettle explosion and waste gas collection device explosion are caused.

Owner:黄慧

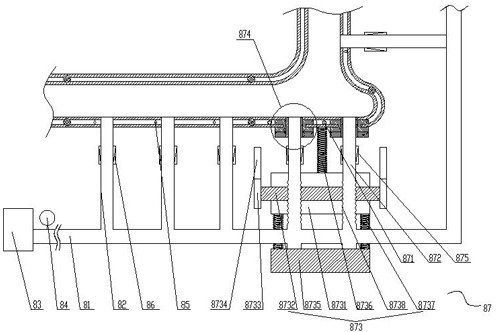

A production optimization scheduling device based on steelmaking and continuous casting

ActiveCN112091192BSolve the process of sorting and handlingHeight adjustableSortingHydraulic cylinderTransmission belt

The invention discloses a production optimization scheduling device based on steelmaking and continuous casting. The bottom end is provided with a detection mechanism, the middle part of the top of the conveyor belt is provided with a dividing mechanism, and the inside of the adjustment mechanism is provided with a cooling mechanism. The adjustment mechanism includes a fixed frame, a hydraulic cylinder, a rotating rod, a fixed rod, a sliding groove, and a support , rubber pad, fixed frame and transmission belt. Through the cooperation between the adjusting mechanism and the dividing mechanism, the present invention is convenient for the staff to separate the waste steel from the steel, thereby solving the problem that the continuous casting equipment is difficult to separate the waste steel from the steel during use. The phenomenon of steel separation, through the cooperation between the adjustment mechanism and the receiving mechanism, solves the problem that the staff cannot collect the waste steel during the use of the continuous casting equipment.

Owner:SHENYANG JIANZHU UNIVERSITY

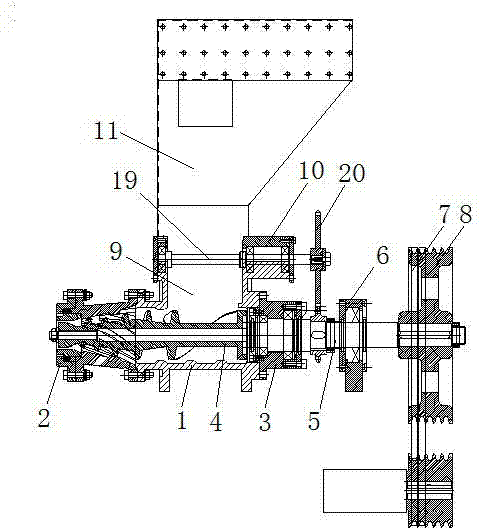

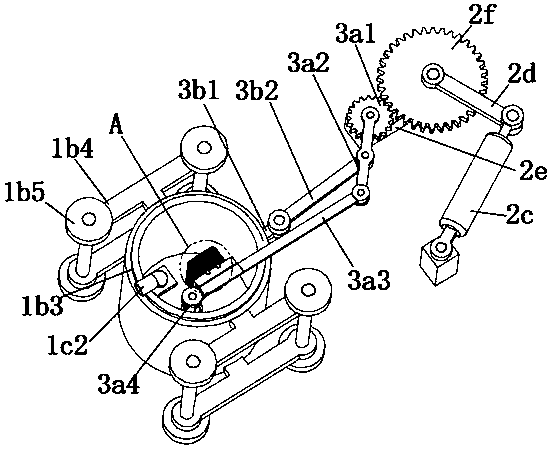

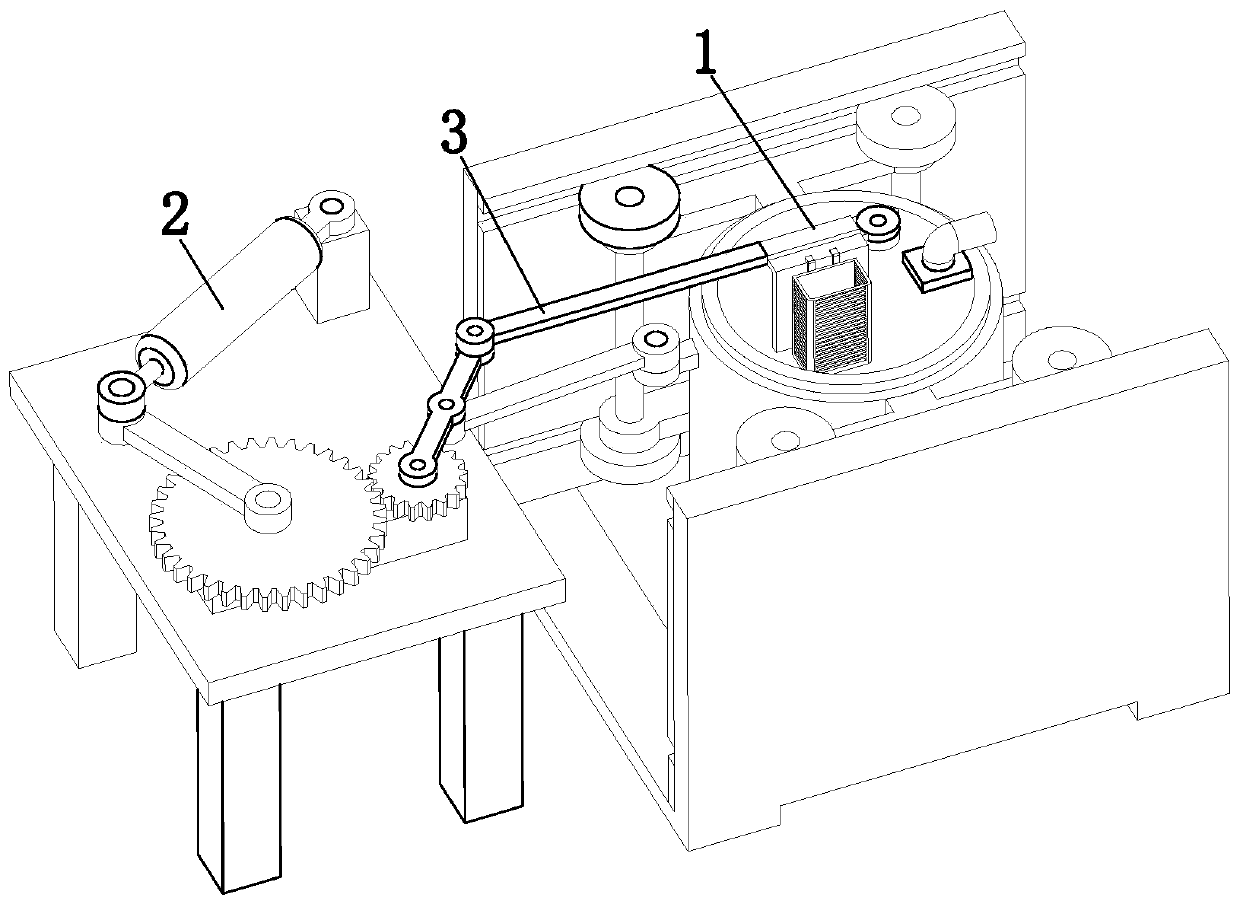

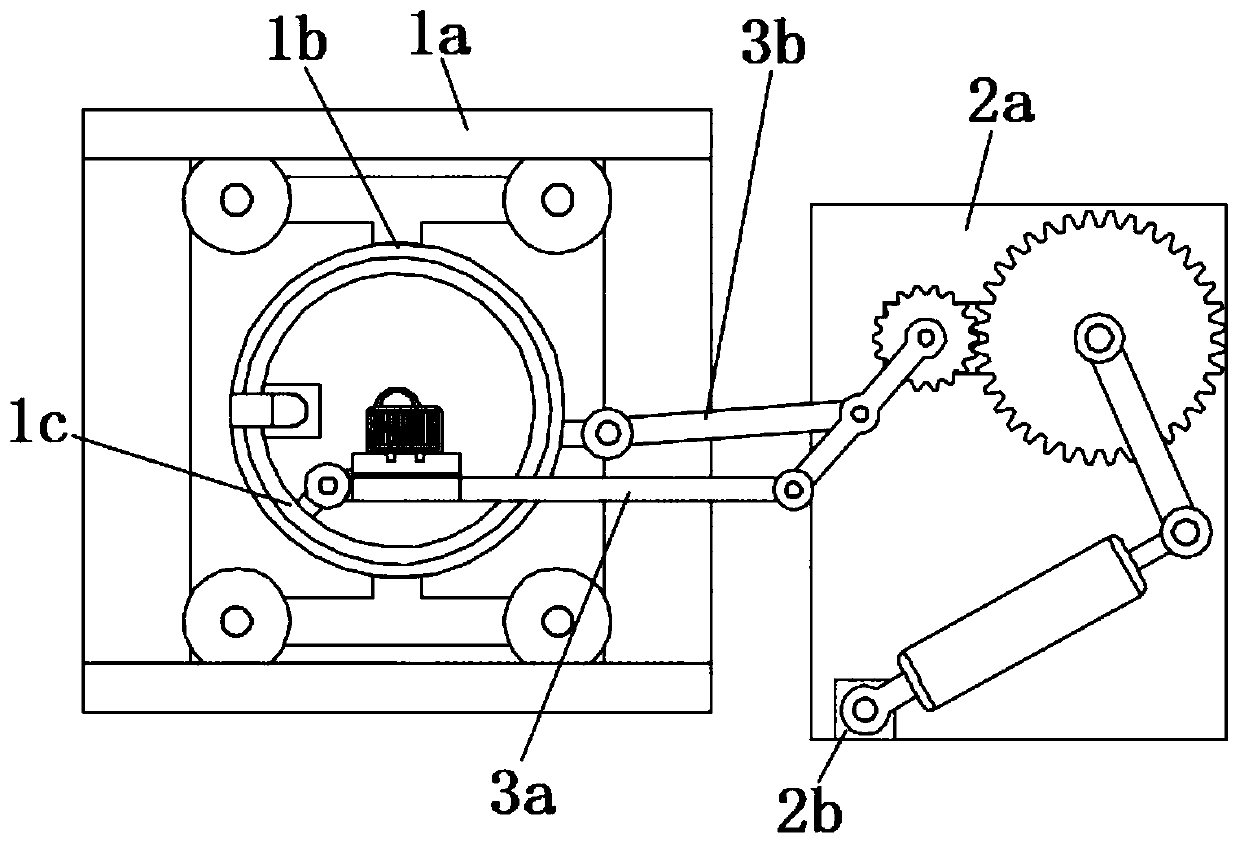

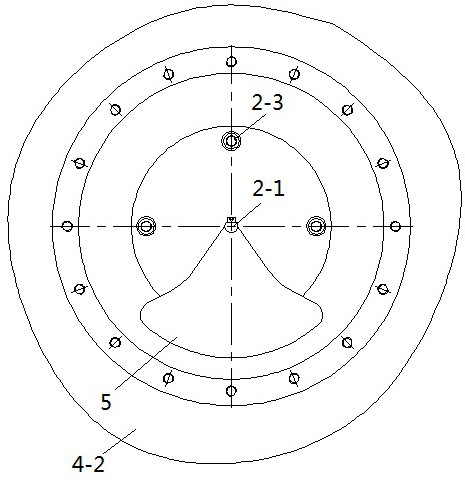

Device for cleaning sprayer of 3D printing equipment

PendingCN109760318AImprove cleaning efficiencySolve the jam situation3D object support structuresApplying layer meansEngineeringSprayer

The invention relates to the technical field of 3D printing equipment, in particular to a device for cleaning the sprayer of 3D printing equipment. The device comprises a positioning cleaning component, a bearing driving component and a linkage component rotatably connected with the bearing driving component, wherein the positioning cleaning component comprises a bearing mounting component, an auxiliary rotating component in the bearing mounting component, and a positioning cleaning subassembly for cleaning a to-be-cleaned sprayer; the linkage component comprises a first linkage subassembly and a second linkage subassembly; the first linkage subassembly and the second linkage subassembly are in transmission connection with the bearing driving component; the output end of the first linkagesubassembly is connected with the auxiliary rotating component; and the output end of the second linkage subassembly is in transmission connection with the positioning cleaning subassembly. The devicecan improve the sprayer cleaning efficiency and can solve the situation that the sprayer is plugged during the cleaning process to improve the sprayer cleanliness during the cleaning process.

Owner:ANHUI SCI & TECH UNIV

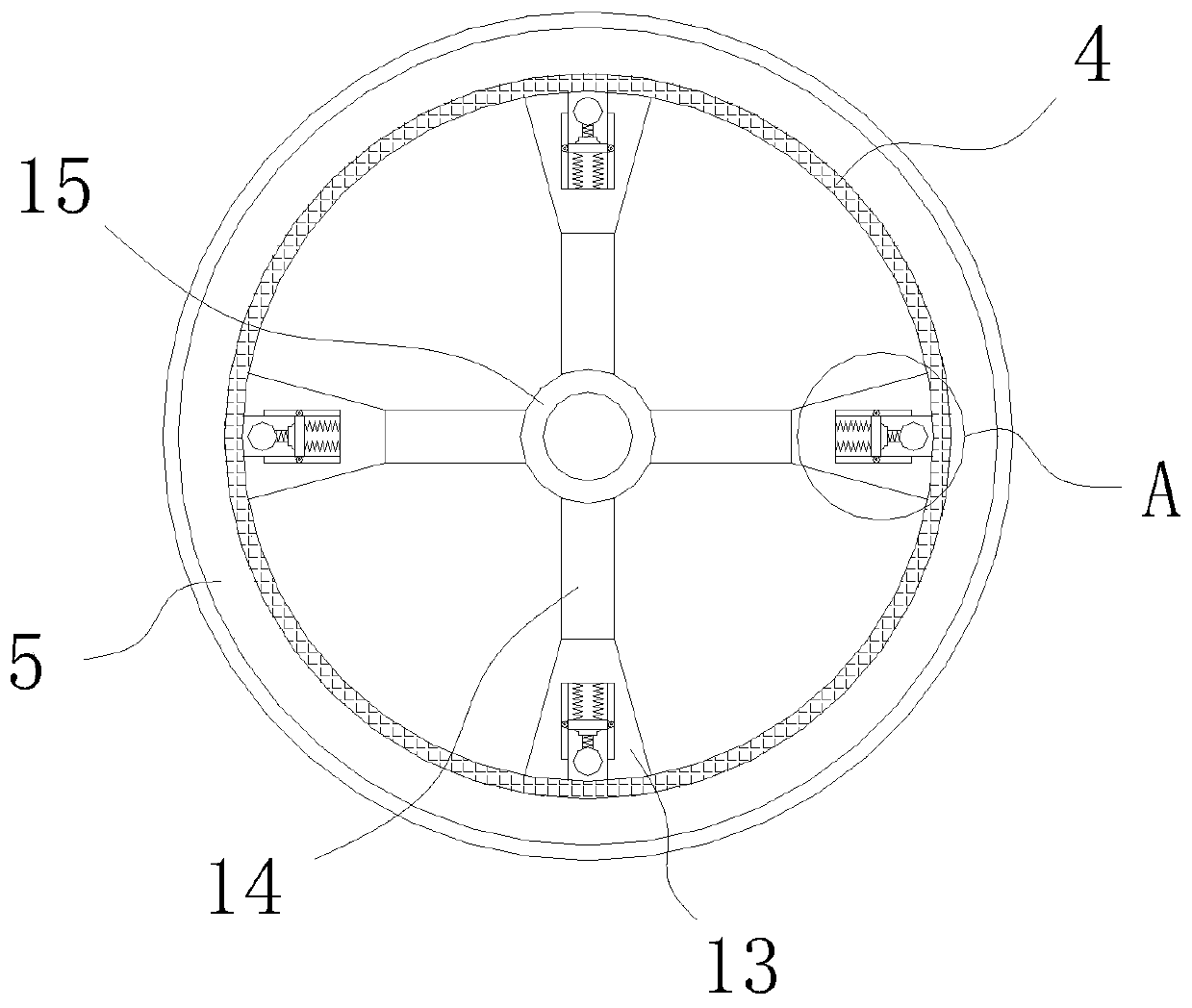

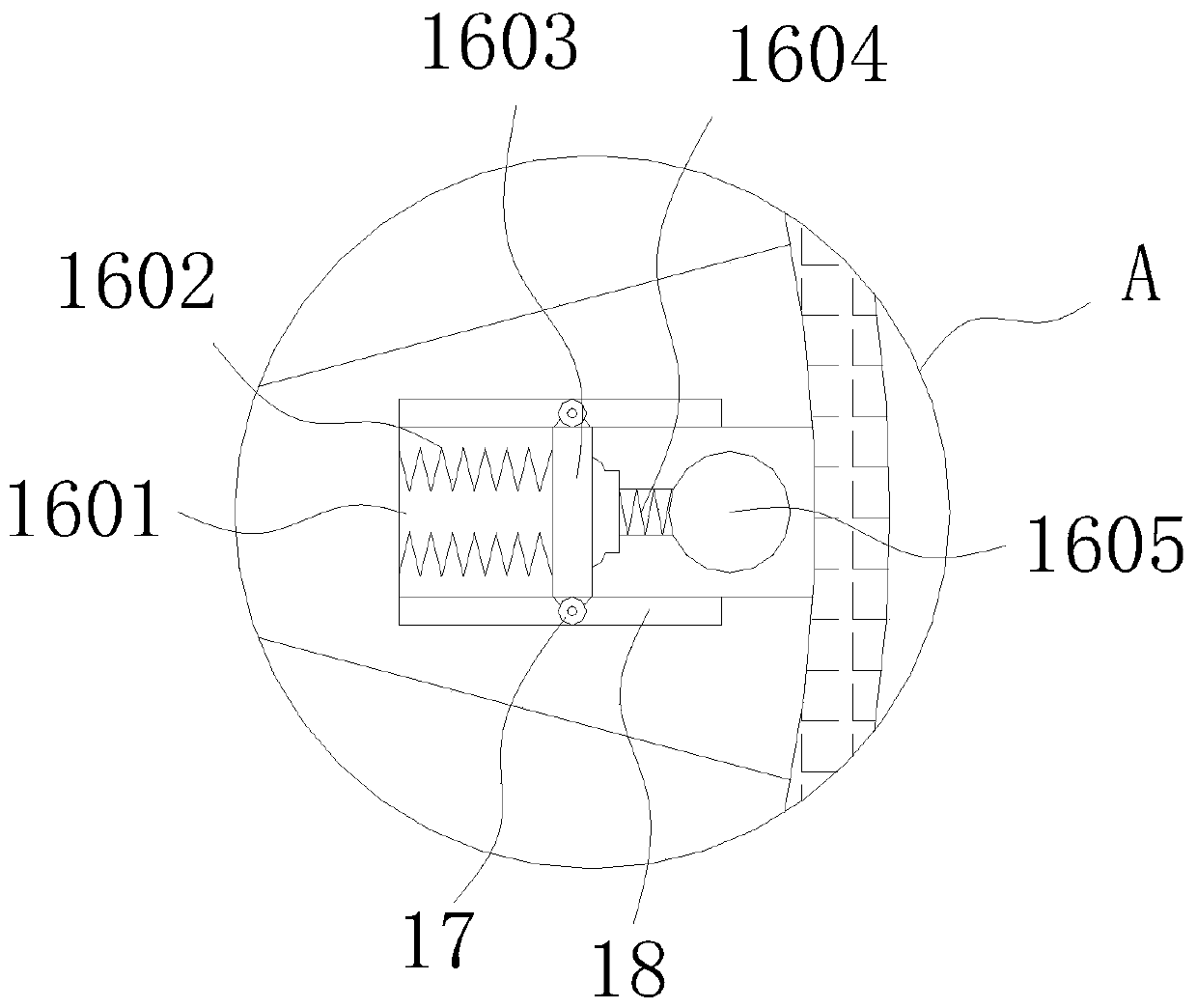

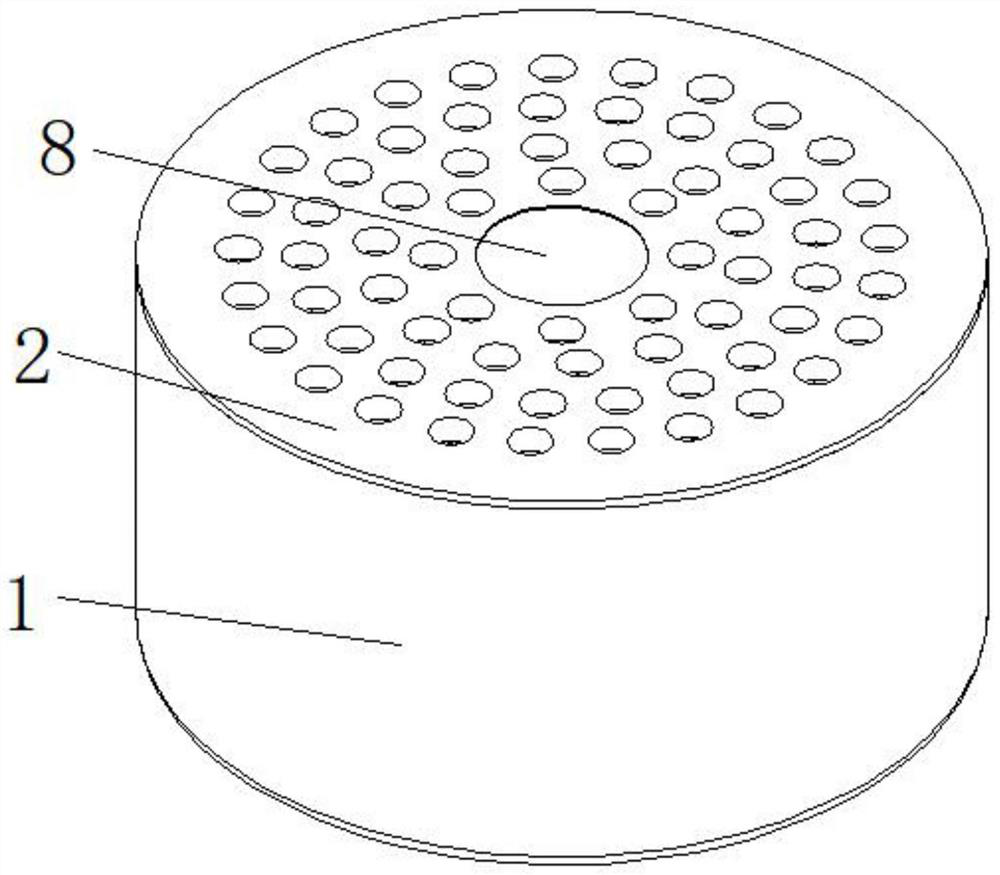

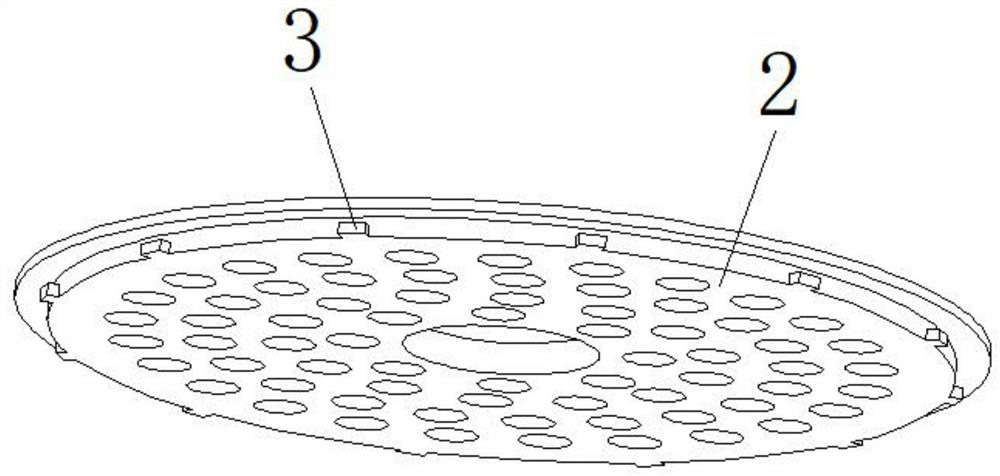

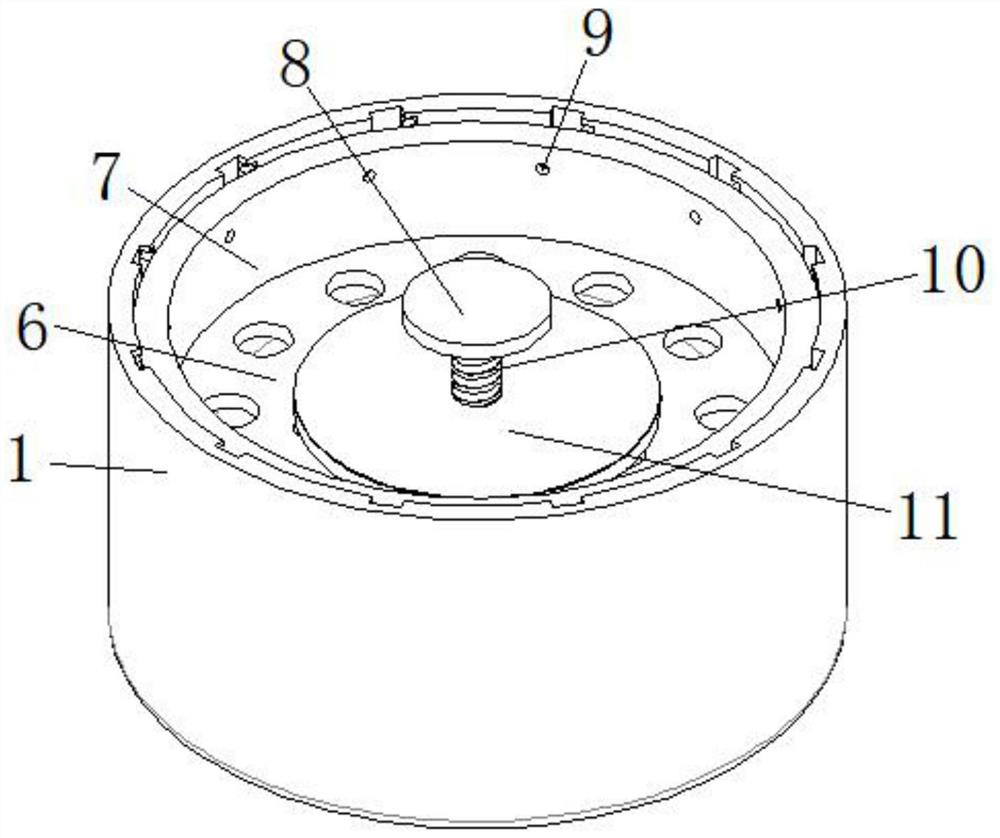

Floor drain for pet dog bathing room

PendingCN113309208ASolve the jam situationNormal movementFatty/oily/floating substances removal devicesSewerage structuresEngineeringStructural engineering

The invention belongs to the technical field of floor drains, and particularly relates to a floor drain for a pet dog bathing room. The floor drain for the pet dog bathing room comprises a protective shell, a floor drain shell is arranged in the protective shell, a buckle top plate is arranged at the top of the floor drain shell, a fixed drain plate is arranged in the floor drain shell, and a one-way flywheel is arranged at the bottom of the fixed drain plate. When pet hair blocks the floor drain, water in the floor drain can drive a floating block to float upwards, so that the floating block drives a floating pedal to float upwards through a threaded rod, the floating pedal is made to float out of the top of a buckle top plate, then the floating pedal is treaded manually, the floating pedal drives a one-way flywheel to rotate through the threaded rod, and the pet is driven by the one-way flywheel to rotate, therefore, the one-way flywheel drives a rotating sleeve to rotate through a connecting top plate, the rotating sleeve drives first blades and the first blades on the surface of the sleeve to rotate in a crossed mode, the first blades are matched to smash the hair, and the hair blocking condition is solved.

Owner:陈霞

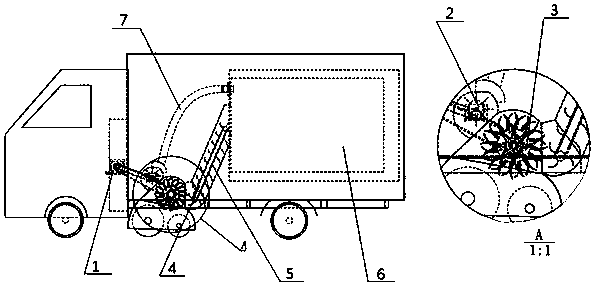

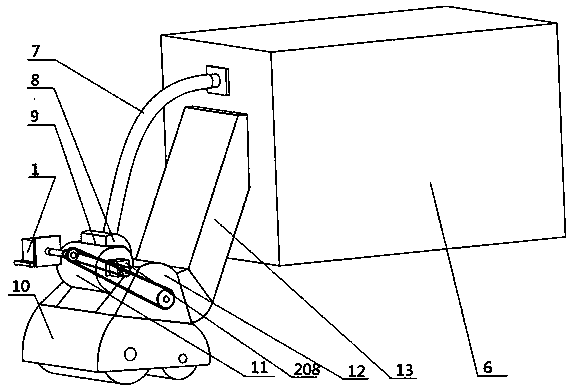

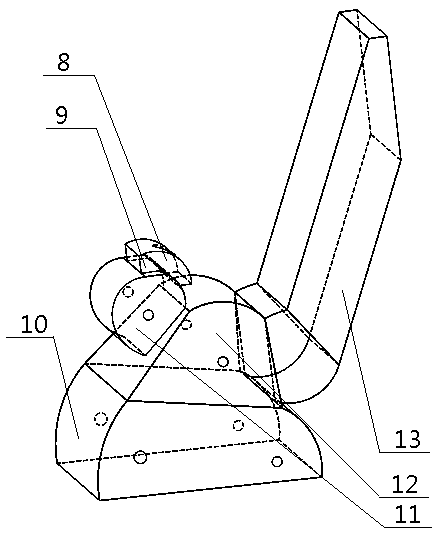

A main and auxiliary cavity type garbage jam prevention device for electric sweeper

The invention relates to a main-auxiliary cavity type garbage jamming prevention device of an electric sweeper truck. The main-auxiliary cavity type garbage jamming prevention device comprises cavities formed in a frame, wherein the cavities include a main cavity, a jamming prevention guide wheel is installed in a main cavity body and comprises a left impeller, a middle impeller and a right impeller, the impellers are installed on impeller shafts, the impeller shaft of the left impeller and the impeller shaft of the right impeller are respectively installed on the main cavity body, and conveying blades are installed on the impellers. The left end and the right end of the main cavity are opened and are also communicated with two auxiliary cavities, a screen guiding wheel is installed in the left-side auxiliary cavity and is installed on a screen guiding wheel impeller shaft, two ends of the screen guiding wheel impeller shaft are installed on the auxiliary cavity on the left side, and screen blades are installed on the screen guiding wheel. The main-auxiliary cavity type garbage jamming prevention device utilizes the jamming prevention guide wheel installed in the main cavity to cut, transport and guide garbage and meanwhile utilizes the screen guiding wheel in the left-side auxiliary cavity to convey the garbage and filter dust. The problem that strip-shaped flexible garbage blocks a garbage channel in the garbage sweeping process can be solved.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

An Anti-Carbon Deposition Cooling Type Needle Valve Coupler

ActiveCN102979654BSlow coolingImprove cooling effectFuel injection apparatusMachines/enginesCouplingCooling chamber

The invention discloses a cooling-type needle valve coupling with a carbon deposition prevention effect. The cooling-type needle valve coupling comprises a needle valve body and a needle valve, which are assembled with each other. The needle valve is assembled in a valve chamber which is machined in the needle valve body; an annular clearance passage, through which a high pressure fuel passes, is formed between the outer circumference of the lower rod body of the needle valve and the inner wall of the valve chamber; and the annular clearance passage is communicated with an oil inlet passage. The cooling-type needle valve is characterized in that a cooling water jacket is fixedly mounted to the lower part of the needle valve body, a cooling chamber is formed between the cooling water jacket and the needle valve body, the needle valve body is provided with at least one group of cooling annular passages, the cooling annular passages are communicated with the cooling chamber, the opening at the two ends of each cooling annular passage are formed in the upper surface of the needle valve body; at least two jet holes are formed in the front end of the needle valve body and are communicated with the annular clearance passage. The cooling-type needle valve coupling has the advantages of smart structure, good performance, low oil consumption, less carbon deposition in the nozzle and long service life and can meet the needs for oil-fuel injector needle-valve couplings in marine diesel engines.

Owner:YUYAO SHUCHUN MACHINERY

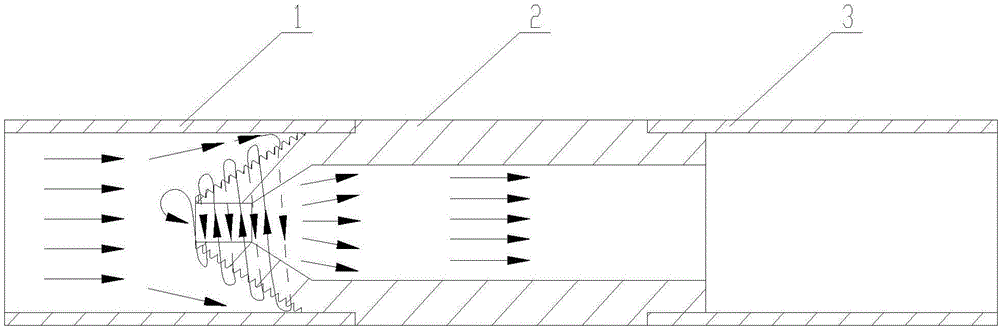

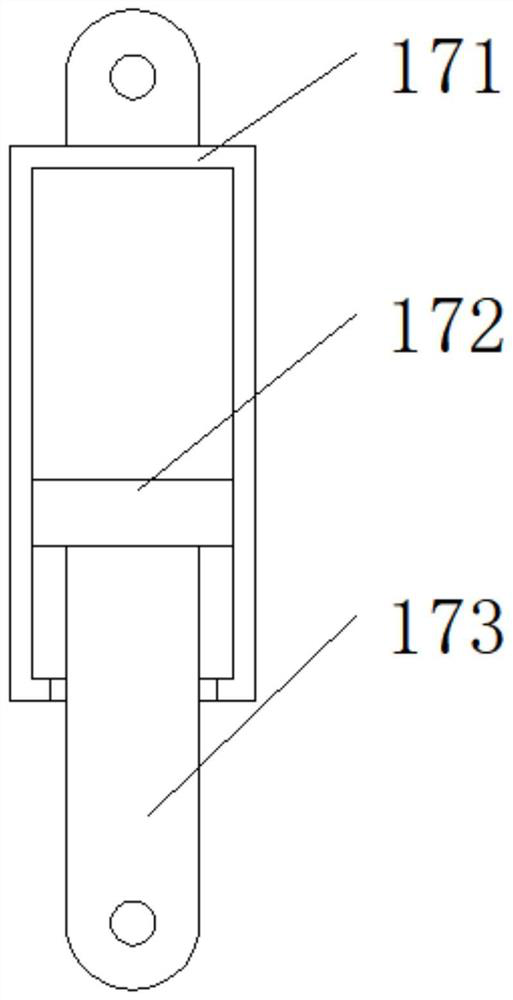

An anti-clogging conveying pipe structure and anti-clogging method for pneumatic conveying of viscous materials

The invention relates to an anti-clogging conveying pipe structure and an anti-clogging method for viscous material pneumatic conveying, comprising horizontal pipes and longitudinal pipes arranged at intervals in sequence, there is an elbow between the horizontal pipes and the longitudinal pipes, the horizontal pipes, the longitudinal pipes The delivery pipe is formed integrally with the bent pipe, the horizontal pipe, the longitudinal pipe and the bent pipe all include an aluminum alloy outer pipe body and a rubber inner pipe body, there is a gap between the aluminum alloy outer pipe body and the rubber inner pipe body, and the aluminum alloy The connection between the outer tube body and the rubber inner tube body is realized through a plurality of sealing rings distributed at equal intervals, and also includes a controllable vibration blowing mechanism arranged along the extending direction of the delivery tube. The invention has the following advantages: effectively solving the wear and blockage of the inner wall of the straight pipe part and the bent pipe part, and ensuring the structural strength of the conveying pipe.

Owner:常州逸盛机电技术有限公司

A construction sand screening device

ActiveCN110369272BAvoid uneven sievingReduce resistanceSievingScreeningClassical mechanicsStructural engineering

The invention discloses a sand screening device for construction, which relates to the technical field of construction machinery, specifically a sand screening device for construction, including a fixed bin, a hopper, a reset rod, a screening device, a pressing rod, a guide plate, The first bearing, the roller, the second bearing, the transmission pipe, the bevel gear, the drainage pipe, the fixed rod, the electric motor, the connecting rod, the transmission rod and the stabilizer. The sand screening device for construction can lock the first fixed frame and the second fixed frame through the locking device, which can effectively prevent the second fixed frame from shifting during screening and cause uneven screening. The locking device can The misalignment adjustment of the first screen and the second screen allows the sand screening device to filter sand of various specifications, which can effectively enhance the scope of application of the sand screening device and solve the problem of existing sand screening devices. The ability to sieve sand with a fixed size makes the application range of the sand sieving device small.

Owner:滁州市嘉冠建设工程有限公司

Feed crushing and mixing device for animal husbandry

ActiveCN110122904BImprove stirring efficiencySolve the jam situationFeeding-stuffTransportation and packagingCrop livestockGear wheel

Owner:GUANGZHOU TIANDI IND CO LTD

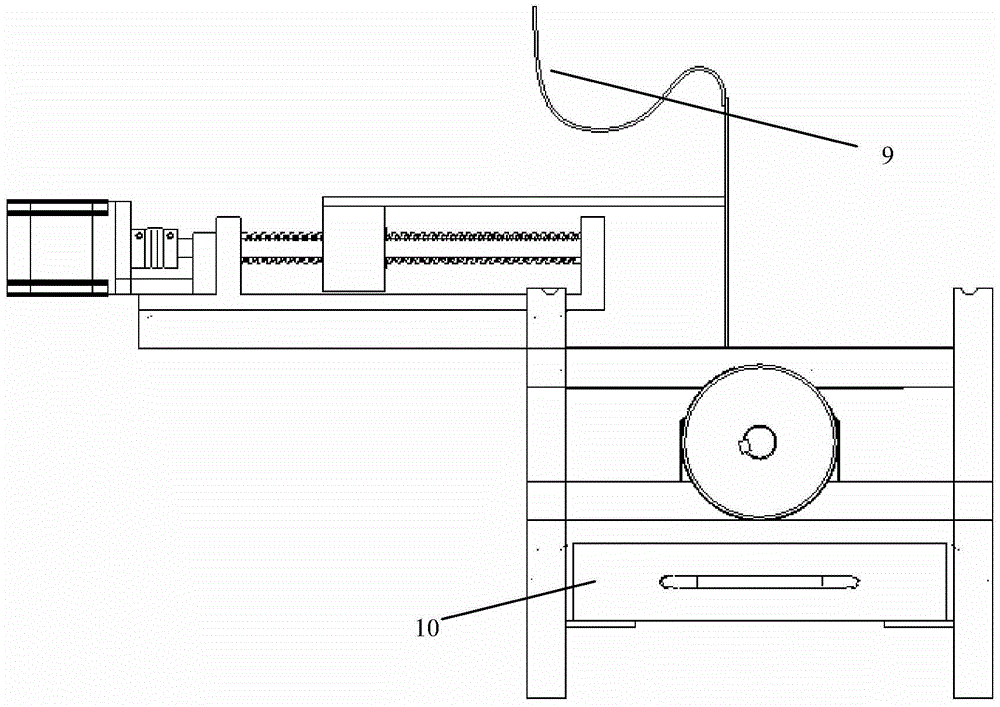

A device for discharging bract leaves and recovering corn kernels from a corn peeling machine

The invention discloses a bract-discharging and corn-recycling device of a corn husker. The bract-discharging and corn-recycling device comprises a screening device, a pushing device and a control device, wherein the screening device comprises a vibration pulley, a recycling bin, a steel wire net and a vibration shaft; a motor drives the vibration pulley; the vibration shaft drives a cam; a cylindrical shifting shaft is arranged on the cam; the shifting shaft shifts a guide groove, so that the steel wire net connected with the guide groove is driven to vibrate; the pushing device comprises a stepping motor and a pushing rod; the stepping motor is connected with a screw rod and drives the screw rod to rotate, so that a nut slide block is pushed, and then the pushing rod pushes a pushing plate to move forward; a machine body and the pushing plate are connected by S-shaped rubber skin. Bracts husked by the bract-discharging and corn-recycling device fall onto the steel wire net under the action of gravity, corns kernels falling in a husking process fall in the recycling bin, and the stepping motor drives the screw rod to rotate to push the bracts out, so that the phenomenon that the bracts block at a discharging opening is reduced, contact between people and equipment is reduced, the bract-discharging and corn-recycling device is simple in structure and high in safety factor, and personal safety can be fully protected.

Owner:QINGDAO UNIV OF SCI & TECH

An anti-clogging cutter head nozzle

The invention discloses an anti-clogging cutterhead nozzle, which solves the technical problem that the cutterhead nozzle is prone to blockage. The invention comprises a cylinder communicated with the injection port on the front panel of the cutter head, the cylinder communicates with the liquid supply pipe, a shaft is arranged in the inner cavity of the cylinder, and a weight is arranged at the rear end of the shaft. The shaft rod is connected to the non-center of gravity of the weight, and a sealing structure is provided between the weight and the inner cavity of the barrel, and the outer cover of the weight is covered with a protective shell whose inner cavity is larger than the rotation space of the weight. The invention can realize the self-rotation of the cutter head with the relative rotation of the shaft rod, so as to achieve the effect of the shaft rod and the blade stirring the clogged muck inside the nozzle, effectively solve the situation that the cutter head nozzle is blocked during the excavation process, and ensure the safety of the cutter head of the roadheader. Normal excavation, thereby reducing the phenomenon of mud cake and gushing on the cutter head, and reducing tool wear.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

3D printer feed pipe and feed structure

The invention provides a feeding venturi for a 3D (three-dimensional) printer. The feeding venturi comprises a radiating outer tube and a polytetrafluoroethylene inner tube embedded in the radiating outer tube; a feeding passage for enabling a printing material to pass through is formed in the polytetrafluoroethylene inner tube. According to the feeding venturi, by the polytetrafluoroethylene inner tube, the condition that the PLA (Poly Lactic Acid) printing material is blocked in the venturi is prevented and stability and smoothness of wire output of a heating printing head, so that surface quality of a printed model is improved; a feeding structure is simple and reliable, is low in cost and is suitable for popularization and application.

Owner:SHANGHAI MEDDO MEDICAL DEVICE

A refrigeration unit and throttling device thereof

InactiveCN105042954BSolve the jam situationReduce welding leaksMechanical apparatusFluid circulation arrangementEngineeringRefrigeration

The invention discloses a throttling device, which simultaneously has the cooling throttling effect and the function of self-blocking prevention. The throttling device includes a front-end throttling section and a rear-end pipeline connection section; wherein, the front-end throttling section plays a major throttling and anti-blocking role, and it includes a throttling orifice, an inclined wall surface outside the orifice, and an inclined wall The threaded groove on the wall; the rear end pipeline connection section, which includes two steps, is mainly used for pipeline connection. This scheme uses the spiral flow of fluid inside the pipeline to wash away the clogged slag, which has the function of preventing clogging itself, and has a simple structure, safety and reliability. The invention also discloses a refrigerating unit using the throttling device.

Owner:GREE ELECTRIC APPLIANCES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com