Cooling-type needle valve coupling with carbon deposition prevention effect

A cooling type, anti-carbon technology, applied in the direction of engine components, machines/engines, charging systems, etc., can solve problems such as insufficient force, poor oil dripping and atomization, black smoke from diesel oil, etc., to improve service life, Good cooling effect, prevent serious carbon deposition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

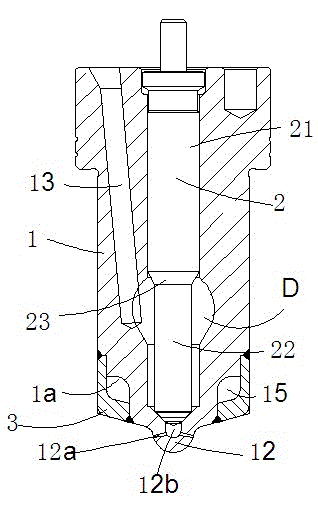

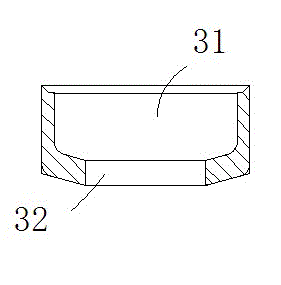

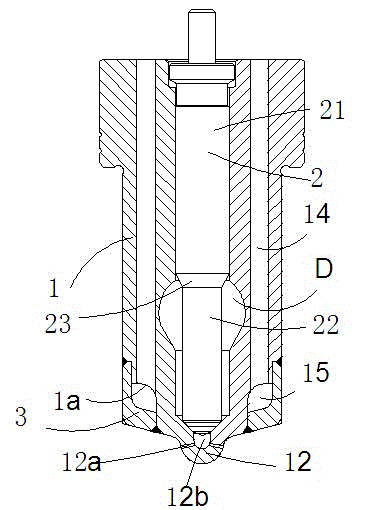

[0023] Figures 1 to 4 It is a schematic cross-sectional structure diagram of the present invention.

[0024] The reference signs are: needle valve body 1, annular surface 1a, valve cavity 11, nozzle body 12, nozzle hole 12a, nozzle cavity 12b, oil inlet passage 13, cooling ring 14, cooling chamber 15, needle valve 2 , Upper rod body 21, lower rod body 22, tapered transition section 23, cooling water jacket 3, cavity 31, shaft hole 32, annular gap channel D.

[0025] An anti-carbon deposition cooling needle valve coupler of the present invention comprises a matching needle valve body 1 and a needle valve 2, the needle valve 2 is assembled in the valve cavity 11 made of the needle valve body 1, and the needle valve Between the outer peripheral surface of the lower rod body 22 of 2 and the inner wall of the valve cavity 11, an annular gap chann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com