3D (three-dimensional) printer spray head for printing monomer materials and composite materials

A technology of 3D printers and composite materials, applied in 3D object support structures, additive processing, coating devices, etc., can solve problems such as uneven mixing of composite materials and low efficiency of nozzle operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

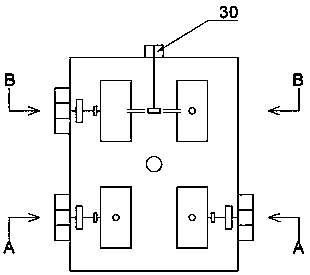

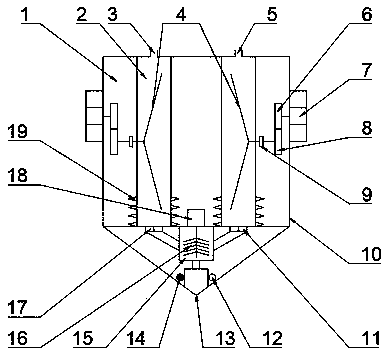

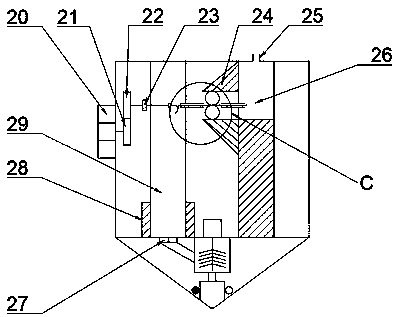

[0014] A 3D printer nozzle for printing monomer materials and composite materials, characterized in that it includes a reinforcement phase feeding mechanism, a monomer material feeding mechanism, a discharging mechanism, a stirring device, a cooling device, a solenoid valve control device and a nozzle 13 , the monomer material feeding mechanism includes an outer shell 1, a monomer material chamber 2, a feed port, a stirring drive device, a stirring rod 4 and a pressurizing device, the outer shell 1 is a rectangular parallelepiped with a square bottom, and the The monomer material cavity 2 is located in the housing and there are two monomer material cavities 2, the two monomer material cavities are symmetrically distributed in the housing, there is a stirring rod 4 in the monomer material cavity, and the feed port is a monomer material cavity. There is a hole in the center of the top surface of the material chamber, and the stirring drive device includes a stirring drive motor 7...

Embodiment 1

[0016] Embodiment 1: print a single material, the drive motor 20, the roller drive motor 30 is not powered; the stirring drive motor 7 and the rotating motor 18 are powered on, and the single material is fed from the first feed port 3 or The second feed port 5 enters into a single material cavity 2, the stirring drive motor 7 is connected with the stirring driving gear 6 through the shaft, the stirring driving gear 6 is geared with the stirring driven gear 8, and the stirring rod 4 passes through the stirring coupling 9 and the shaft are connected with the stirring driven gear 8, the stirring driving motor 7 works to drive the stirring driving gear 6 to rotate, and the stirring driving gear 6 rotates the stirring driven gear 8 through gear meshing, thereby driving the stirring rod 4 to rotate, and the single material Perform one stirring and mix evenly, the first solenoid valve 11 or the second solenoid valve 17 is energized, and the material enters the mixing and stirring cham...

Embodiment 2

[0017]Embodiment 2: printing composite materials, the feeding process of the matrix material is the feeding process of the monomer material, and the reinforced phase wire material enters the organic solvent chamber 26 through the third feeding port 25 from the external feeding system, and the organic solvent chamber 26 has an auxiliary The flux for strengthening phase melting, the reinforcing phase wire material is infiltrated with the flux in the organic solvent cavity, and the flux attached to the surface of the reinforcing phase helps to mix the reinforcing phase and the matrix material better; in the organic solvent cavity 26 and the reinforcing Respective openings on the phase cavity 29 allow the reinforced phase to pass through, and the roller drive motor 30 works to drive the feeding roller 35 to rotate; The stepper motor is energized to work, the driving motor 20 is connected with the driving gear 21 through the shaft, the driving gear 21 and the driven gear 22 are gear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com