Wheat processing device

A wheat and cutting technology, applied in grain processing, application, grain pod removal, etc., can solve the problems of wheat mixed with impurities and low cutting efficiency, and achieve the improvement of impurity removal efficiency, thorough impurity removal, and increase the number of collisions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with accompanying drawing and specific embodiment, and present embodiment is based on the premise of technical scheme of the present invention, has provided detailed implementation and specific operation process, but protection scope of the present invention is not limited to following implementation example.

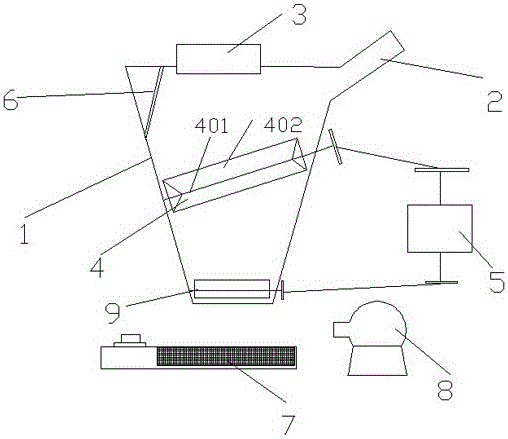

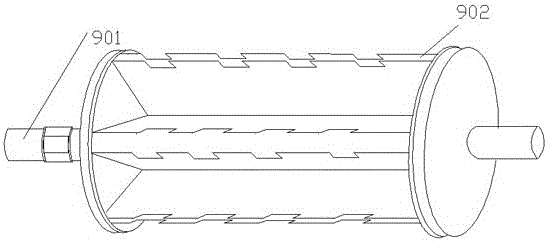

[0018] As shown in the figure, a wheat feeding device according to the present invention includes a feeding cylinder 1 and a discharge port arranged at the bottom of the feeding cylinder 1. One side of the top of the feeding cylinder 1 is provided with an inclined Upward feeding pipe 2, the other side of the top of the feeding cylinder 1 is provided with an induced draft fan 3 to extract impurities inside the feeding cylinder 1, and a peeling mechanism 4 inclined downward is provided inside the discharging cylinder 1 , The peeling mechanism 4 is driven by the motor 5 to rotate, so that the whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com