Novel anaerobic reactor

An anaerobic reactor and a new type of technology, applied in the field of anaerobic reactors, can solve the problems of environmental hazards, easy to produce corrosion, reduce processing efficiency, etc., and achieve the effects of reducing time lag and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

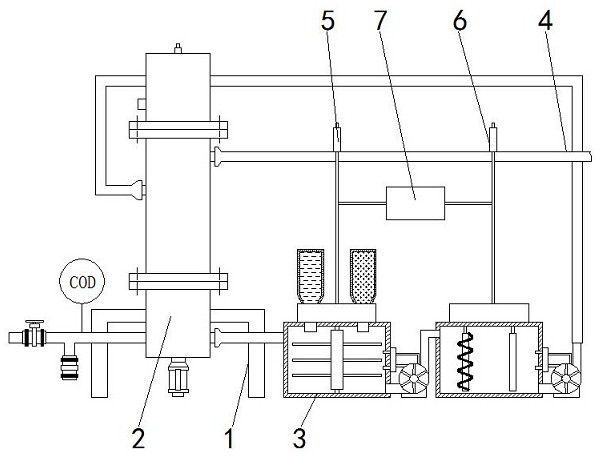

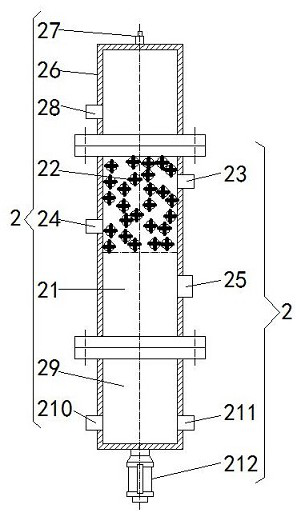

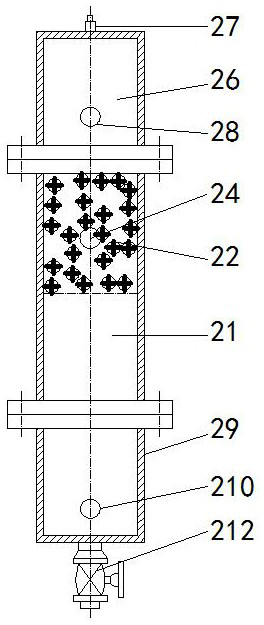

[0043] see Figure 1-5 , a novel anaerobic reactor disclosed by the present invention comprises a frame 1, a reaction mechanism 2 is installed on the top of the frame 1, the reaction mechanism 2 includes a reaction tank 21, and reaction pH sensors and The reaction temperature sensor, the left side is the reaction pH sensor and the right side is the reaction temperature sensor, the reaction tank 21 is fixedly connected to the top of the frame 1, and the inside of the reaction tank 21 begins to have a filler cavity 22, and the inside of the filler cavity 22 is uniformly stored with reaction fillers The packing material is made of PP and PE plastics, which have good corrosion resistance and will not be easily damaged. At the same time, the packing is not limited to the packing of moving bed biofilm reactor (MBBR). The material can be polyurethane sponge, polyethylene or polypropylene and other plastics, Or with activated carbon powder surface-treated polyurethane sponge, its dens...

Embodiment 2

[0045] see Figure 1-6 , a novel anaerobic reactor disclosed by the present invention includes a frame 1 and a control mechanism 3, the control mechanism 3 is fixedly connected to the right side of the frame 1, the control mechanism 3 includes a pH adjustment tank 31, and the pH adjustment tank 31 Fixedly connected to the right side of the frame 1, the top of the pH adjustment tank 31 is fixedly connected with a pH regulator 32, and the top of the pH regulator 32 is plugged with an acid tank 33 and an alkali tank 34, and the alkali tank 34 is located at the top of the acid tank 33. On the right side, the stirring shaft 35 is plugged into the inside of the pH regulating tank 31, the water pump 36 is plugged into the right side of the pH regulating tank 31, the back side of the water pump 36 is fixedly connected with a control circuit amplifier 37, and the right side of the water pump 36 is connected with a temperature Regulating tank 38, the top of the temperature regulating ta...

Embodiment 3

[0047] see Figure 1-6 , a novel anaerobic reactor disclosed by the present invention comprises a frame 1, a reaction mechanism 2 is installed on the top of the frame 1, the reaction mechanism 2 includes a reaction tank 21, and reaction pH sensors and The reaction temperature sensor, the left side is the reaction pH sensor and the right side is the reaction temperature sensor, the reaction tank 21 is fixedly connected to the top of the frame 1, and the inside of the reaction tank 21 begins to have a filler cavity 22, and the inside of the filler cavity 22 is uniformly stored with reaction fillers The packing material is made of PP and PE plastics, which have good corrosion resistance and will not be easily damaged. At the same time, the packing is not limited to the packing of moving bed biofilm reactor (MBBR). The material can be polyurethane sponge, polyethylene or polypropylene and other plastics, Or with activated carbon powder surface-treated polyurethane sponge, its dens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com