An anti-clogging conveying pipe structure and anti-clogging method for pneumatic conveying of viscous materials

A pneumatic conveying and conveying pipe technology, applied in the field of anti-blocking conveying pipe structure, can solve problems such as pipe blockage, straight pipe blockage, and bend pipe wear, so as to reduce impact force and corrosion, solve wear and blockage, and avoid wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

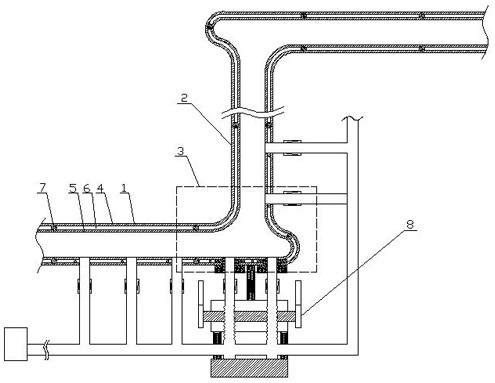

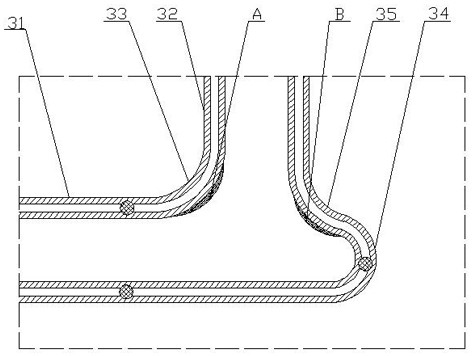

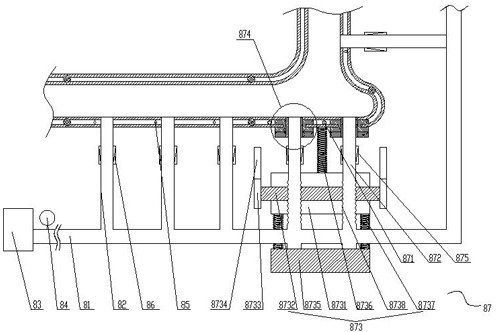

[0041] Such as figure 1 , figure 2 It shows an embodiment of an anti-clogging conveying pipe structure for viscous material pneumatic conveying according to the present invention, which includes horizontal pipes 1 and longitudinal pipes 2 arranged at intervals in sequence, and there is an elbow between the horizontal pipe 1 and the longitudinal pipe 2 3. The horizontal pipe 1, the longitudinal pipe 2, and the curved pipe 3 are integrated to form a conveying pipe. The horizontal pipe 1, the longitudinal pipe 2, and the curved pipe 3 all include an aluminum alloy outer pipe body 4 and a rubber inner pipe body 5. The aluminum alloy outer pipe body There is a gap 6 between the pipe body 4 and the rubber inner pipe body 5, and the connection between the aluminum alloy outer pipe body 4 and the rubber inner pipe body 5 is realized by a plurality of sealing rings 7 distributed at equal intervals. A controllable vibration blowing mechanism 8 set in the extension direction;

[0042]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com