Patents

Literature

59results about How to "Structural Strength Effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

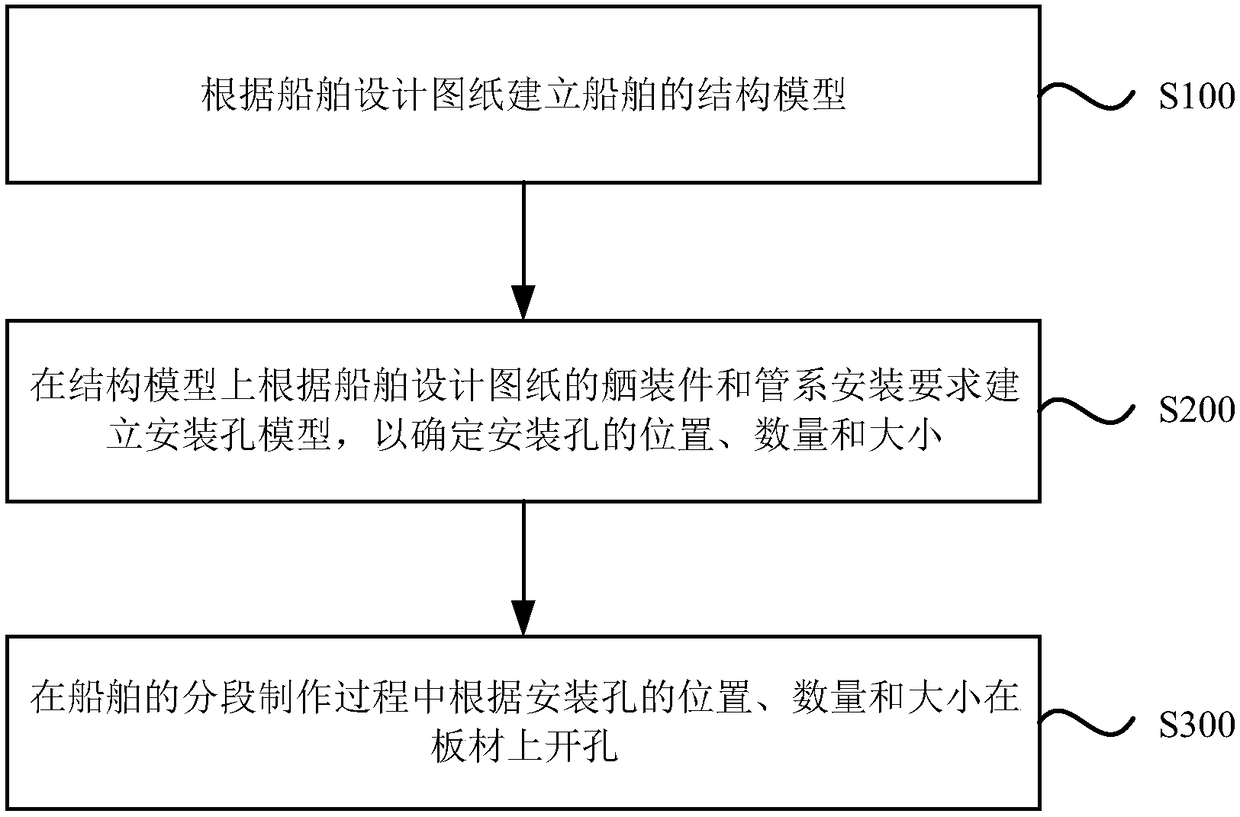

Pre-opening method for ship outfitting

InactiveCN109466691AAvoid modificationHigh precisionVessel designingNumerical controlMarine engineering

The invention discloses a pre-opening method for ship outfitting, which comprises the following steps of: S100, establishing a structural model of a ship according to a ship design drawing; step S200,establishing a mounting hole model on the structural model according to the outfitting piece and the pipe system mounting requirement of the ship design drawing so as to determine the position, the number and the size of the mounting holes; step S300, opening holes on a plate according to the position, the number and the size of the mounting holes in the sectional manufacturing process of the ship. Through the numerical control hole opening in the early stage of ship building, the number and the workload of manual hole opening in the later stage can be reduced, the hole opening precision andthe aesthetic sense can be ensured, meanwhile, the modification of the mounting holes in the later stage can be avoided, a large number of replenishing holes of the mounting holes can be avoided, andthe structural strength of the ship body can be ensured.

Owner:GUANGZHOU SHIPYARD INTERNATIONAL LTD

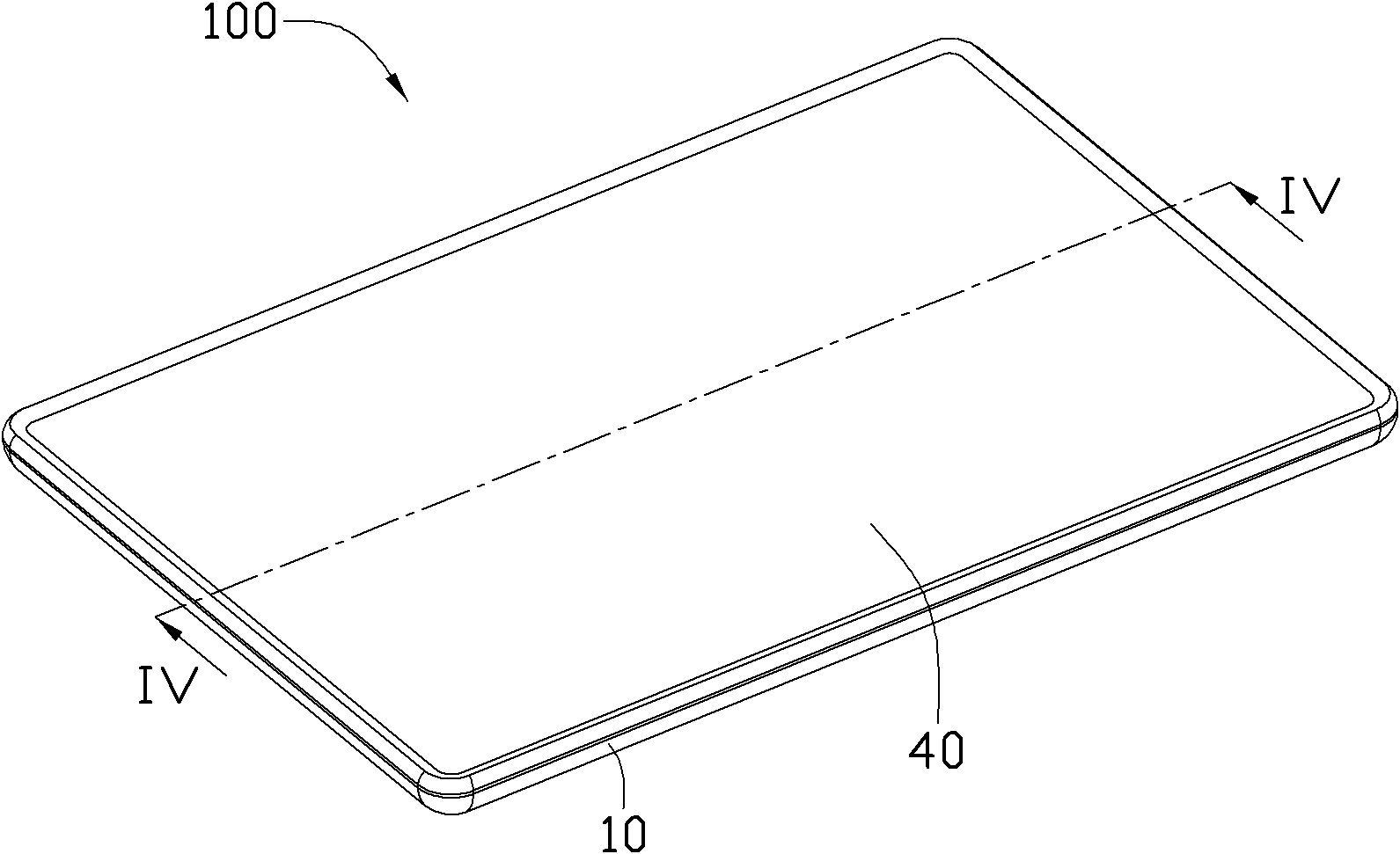

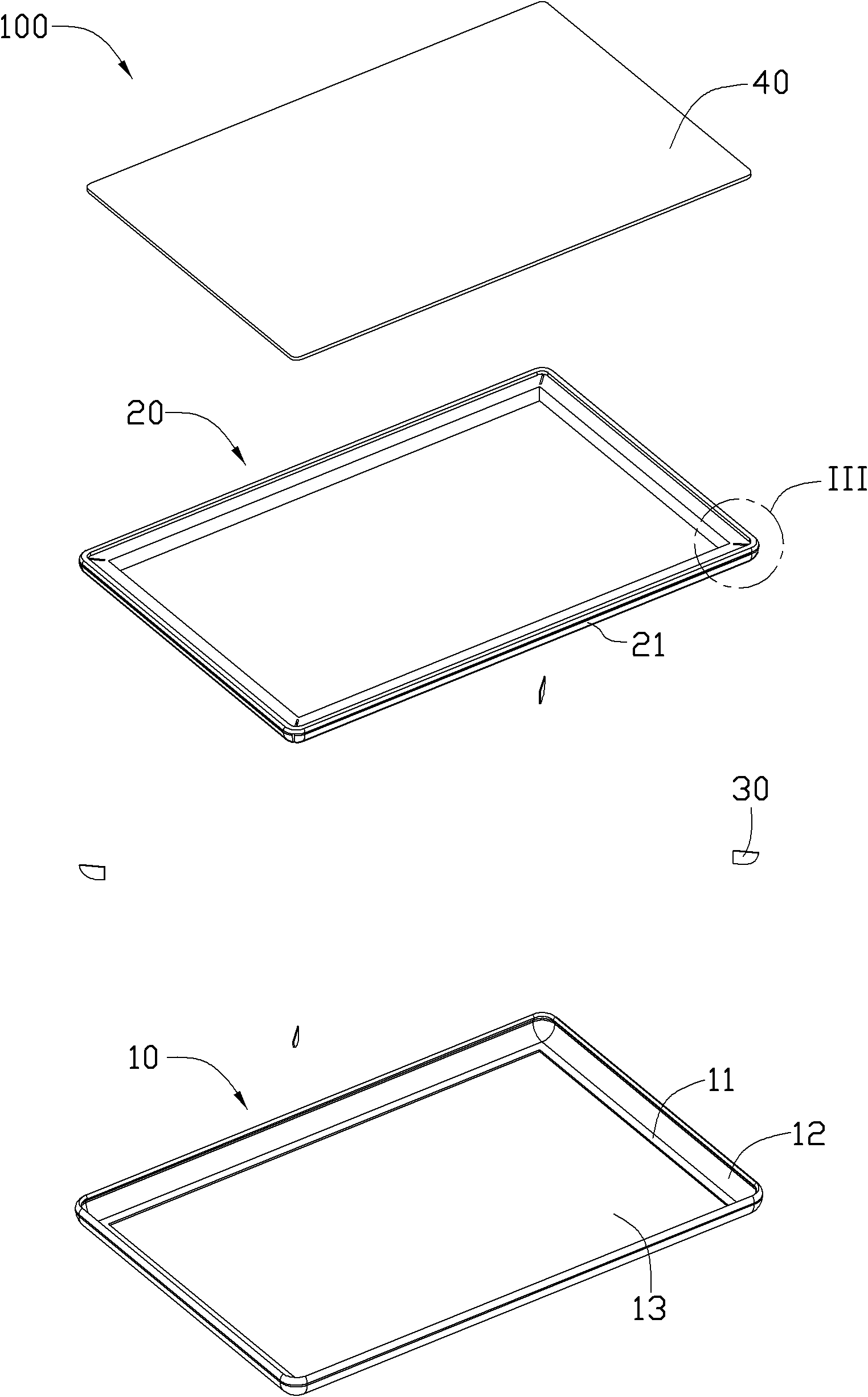

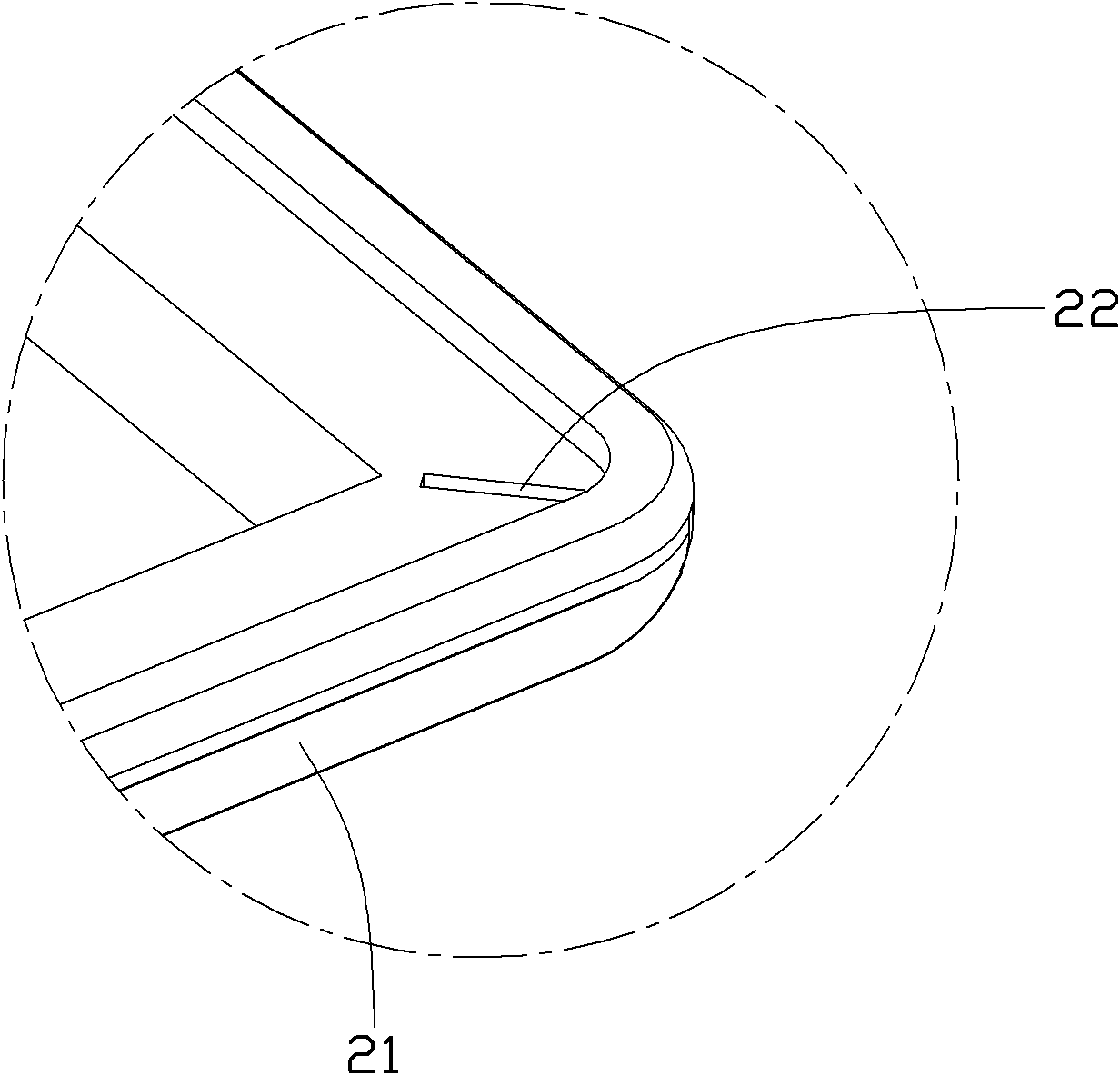

Electronic device and production method of metal casing of electronic device

InactiveCN102404959AStructural Strength EffectGuaranteed stabilityDigital data processing detailsCasings with display/control unitsEngineeringStructural engineering

Owner:FU TAI HUA IND SHENZHEN +1

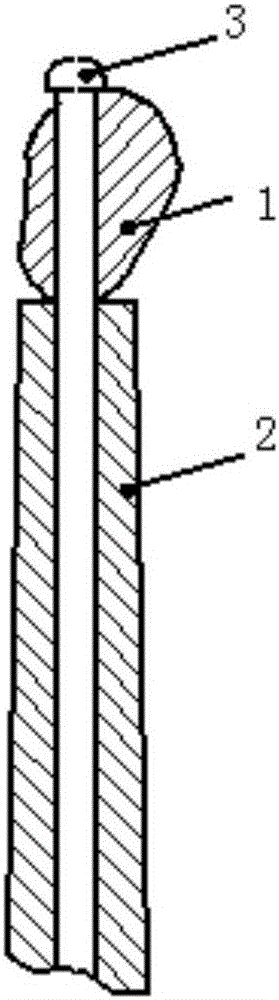

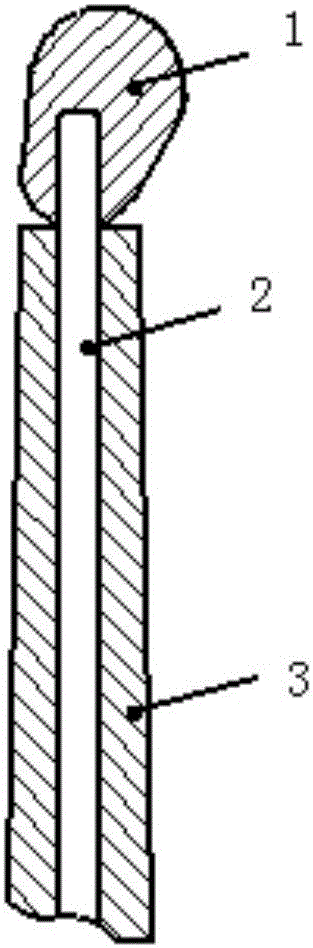

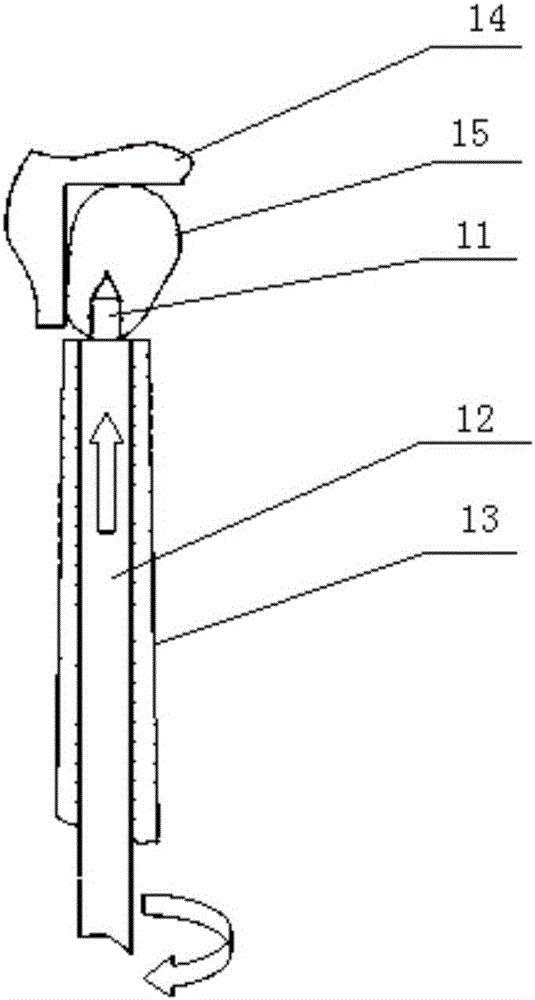

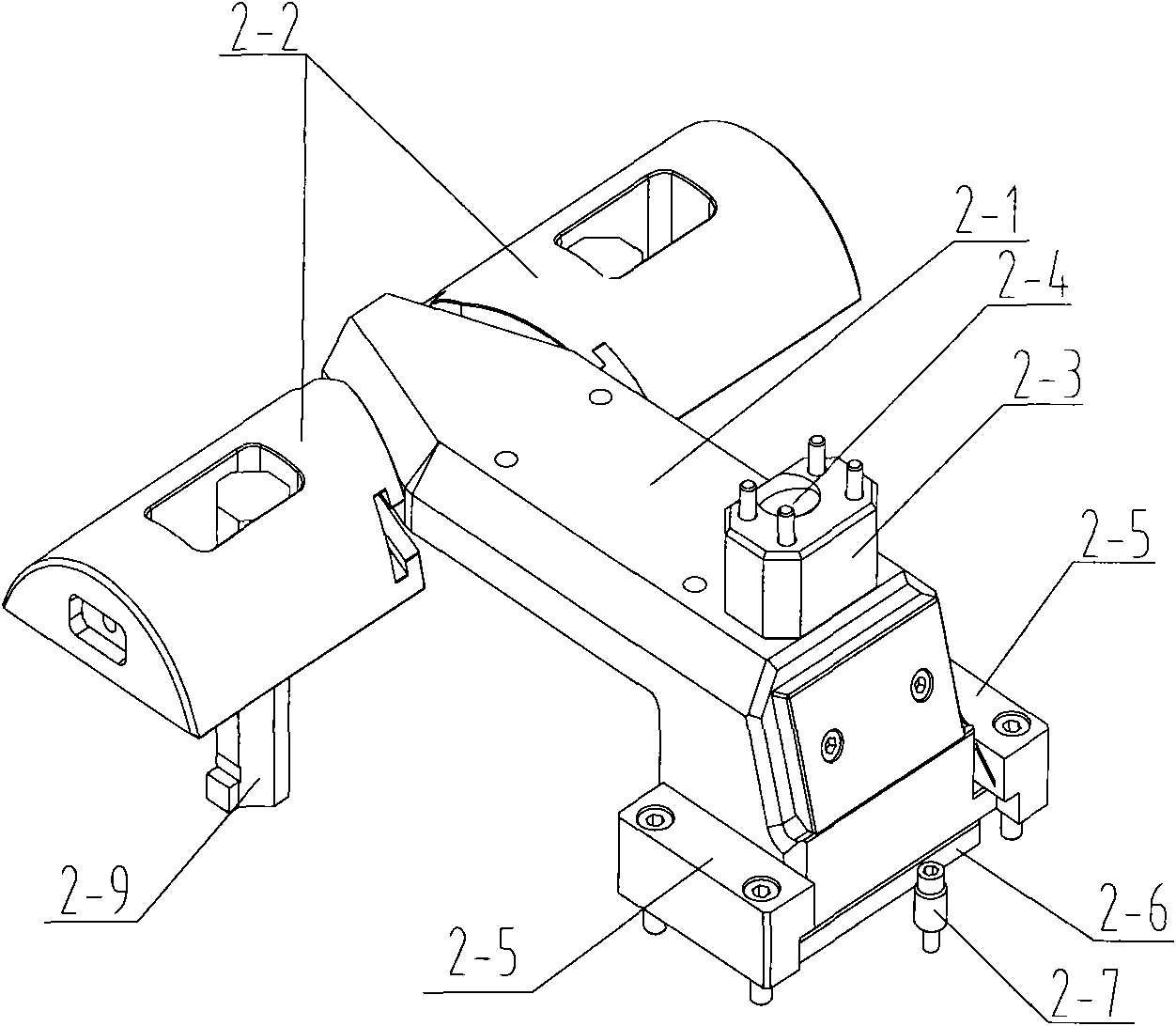

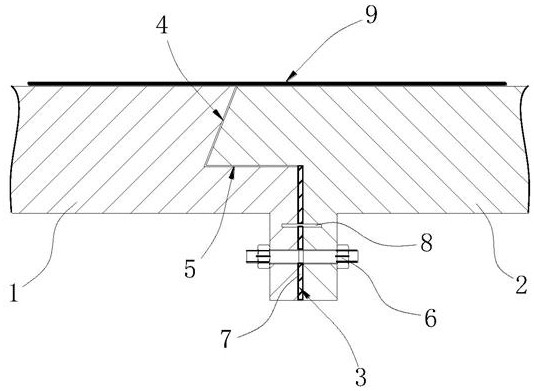

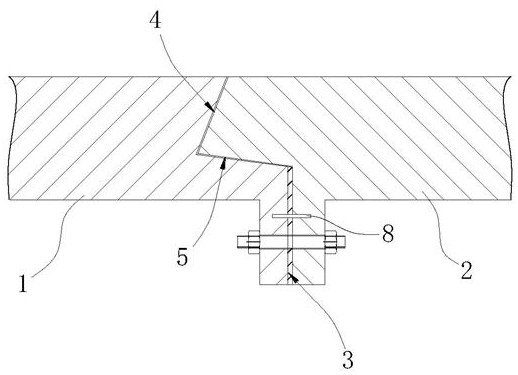

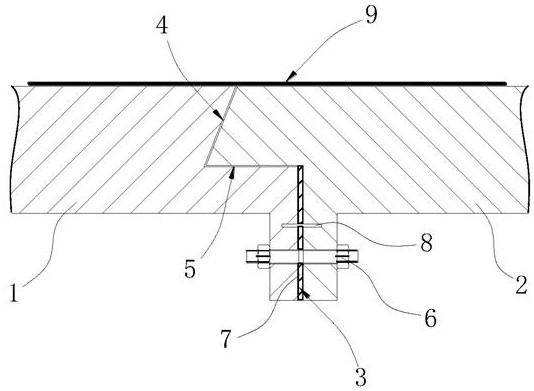

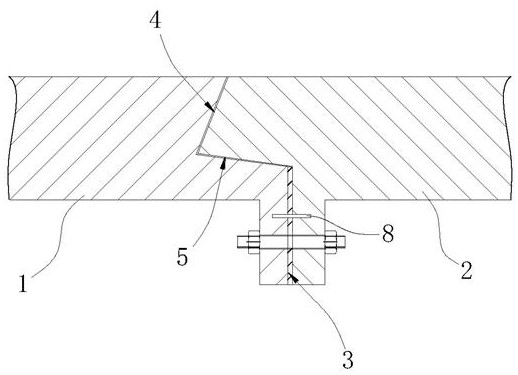

Method and device for fixing salt core for piston casting

InactiveCN105903908APrecise positioningStructural Strength EffectFoundry mouldsFoundry coresCasting moldEngineering

The invention discloses a method and device for fixing a salt core for piston casting. The method comprises the following steps: positioning a connecting nail which comprises a tip and a self-tapping thread at the top end in a positioning hole of a casting mold, and sleeving the connecting nail with a supporting rod, wherein the connecting nail can be rotated in the positioning hole; placing the sale core at the top end of the supporting rod and positioning the salt core; and rotating the connecting nail to screw the tip of the connecting nail into the salt core. According to the above arrangement scheme, the method provided by the invention can avoid the adverse impact of fixing of the salt core on the structure of a casting part based on the fact that the salt core can be quickly and conveniently mounted on the mold.

Owner:湖南江滨机器(集团)有限责任公司

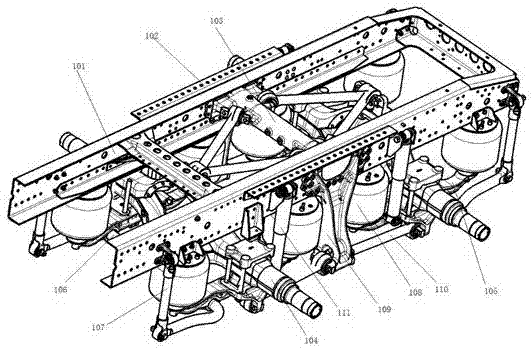

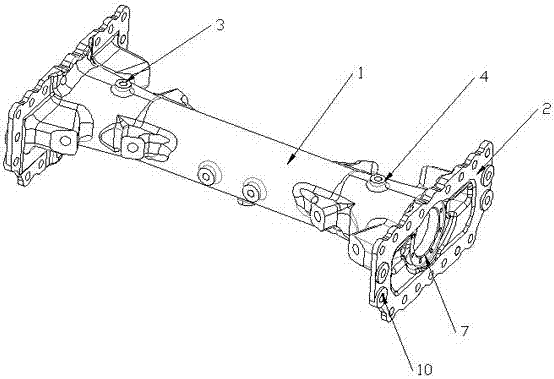

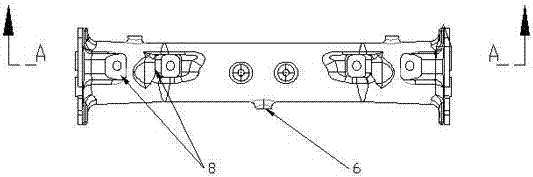

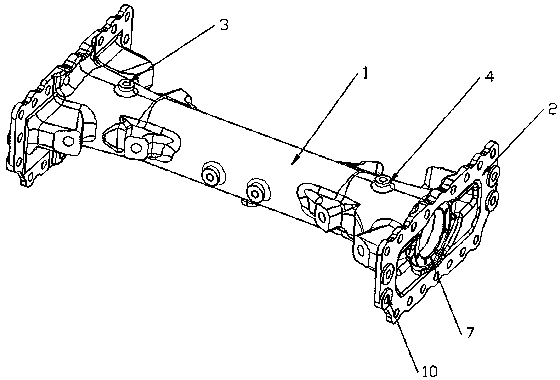

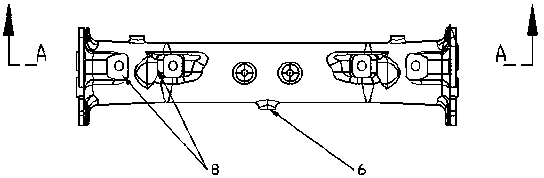

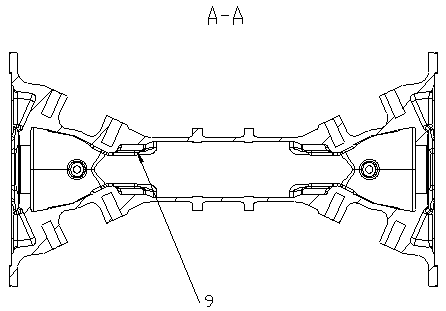

Improved type air suspension

ActiveCN107323528AReduce connection processingReduce assemblyUnderstructuresInterconnection systemsBeam tubeEngineering

The invention relates to an improved type air suspension. The improved type air suspension comprises a pair of longitudinal beams arranged symmetrically, a transversal beam, a pair of vehicle axles, four pairs of air bags, a pair of suspension supports, two pairs of shock absorbers and a pair of connecting lining plates, wherein a plurality of connecting holes are formed in the longitudinal beams; the transversal beam is installed between the two longitudinal beams and comprises a transversal beam main body, and the transversal beam main body is formed by one-piece casting for a transversal beam tube body and a pair of longitudinal beam connecting flanges, wherein the longitudinal beam connecting flanges are symmetrically arranged at the two ends of the transversal beam tube body; the pair of vehicle axles is installed at the lower ends of the longitudinal beams, and the two ends of the vehicle axles are fixed through supporting arms; the four pairs of air bags are correspondingly installed on airbag connection panels; the pair of suspension supports is arranged at the two outer side ends of the longitudinal beams; the two pairs of shock absorbers are correspondingly arranged at the two ends of the suspension supports; and the pair of connecting lining plates is arranged in the longitudinal beams. The improved type air suspension has the advantages that sealing performance of the transversal beam can be improved on the basis of the air supplying, and the structural strength of the transversal beam is ensured, meanwhile, manufacturing is more convenient, overall structure height can be reduced, so that the structure is more stable.

Owner:JIANGSU TANGCHEN AUTOMOBILE PARTS

Fabricated building component production mold

InactiveCN109079965AEvenly filledImprove structural strengthMouldsMould auxillary partsArchitectural engineeringElectric machinery

The invention discloses a fabricated building component production mold which comprises a mold body, a support mold plate, a support base, swinging lantern rings, driving motors and eccentric wheels.The mold body is installed on the top of the support mold plate in a fixedly-erected manner, the swinging lantern rings of runway type structures are fixedly installed on the outer walls of the two sides of the bottom of the support mold plate, rotating shafts are mounted in inner cavities in the both sides of the support base in a fixedly-erected manner, and an eccentric wheel is eccentrically mounted on each rotating shaft; and the swinging lantern rings are arranged on the eccentric wheels in a sliding and sleeving manner, driven sprockets are fixedly mounted on the outer walls of the lowerportions of the rotating shafts, and the driving motors for driving the rotating shafts to rotate are fixedly installed on the lower surfaces of the middle portions of a bottom plate of the support base. By means of the fabricated building component production mold, the whole mold can do reciprocated movement, the uniform filling of concrete in the mold is ensured, the structural strength of assembled building components is improved, and the condition that gaps exist between the formed fabricated building components, and consequently the structural strength of the building components is influenced is avoided.

Owner:任小青

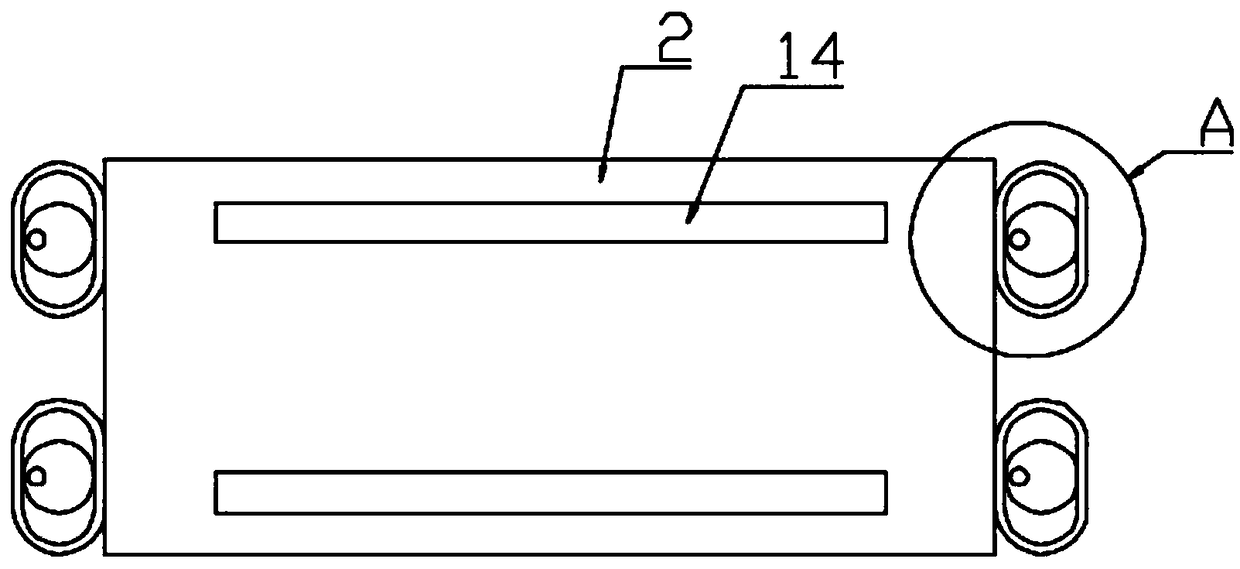

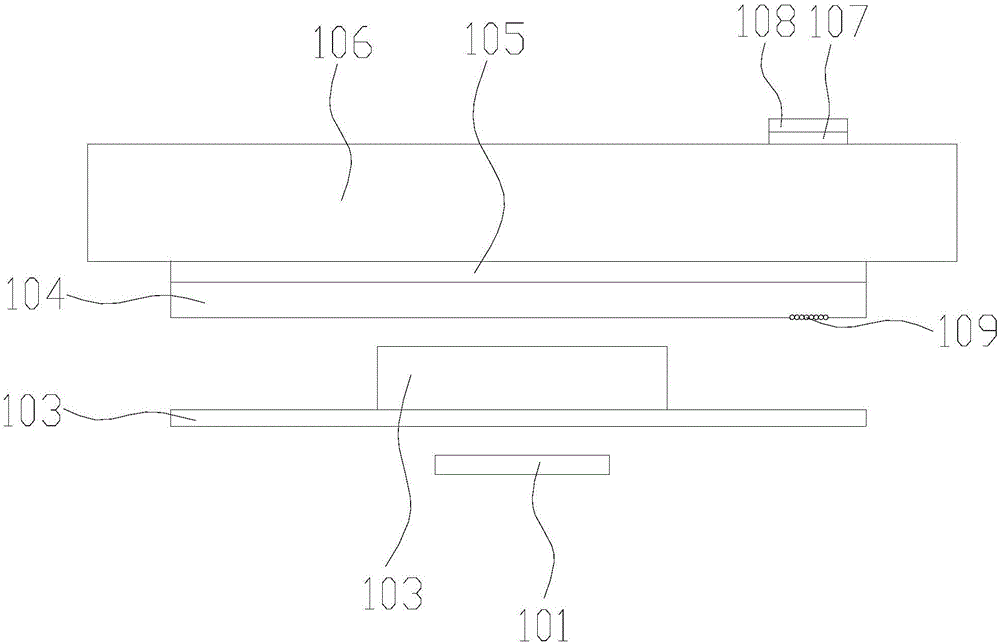

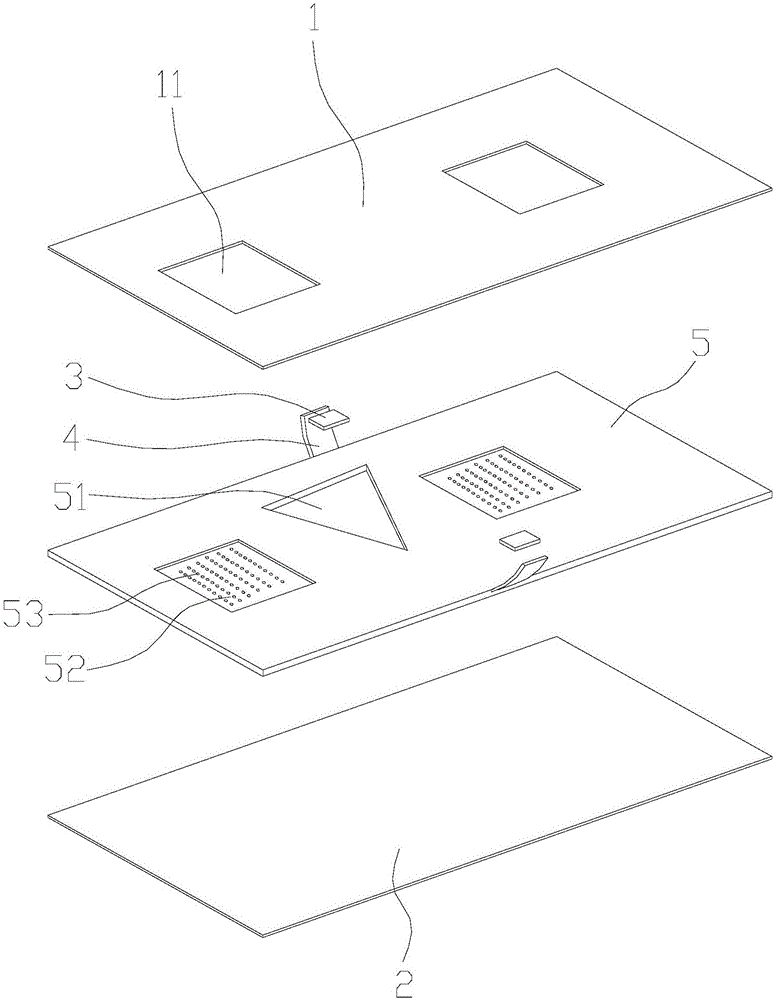

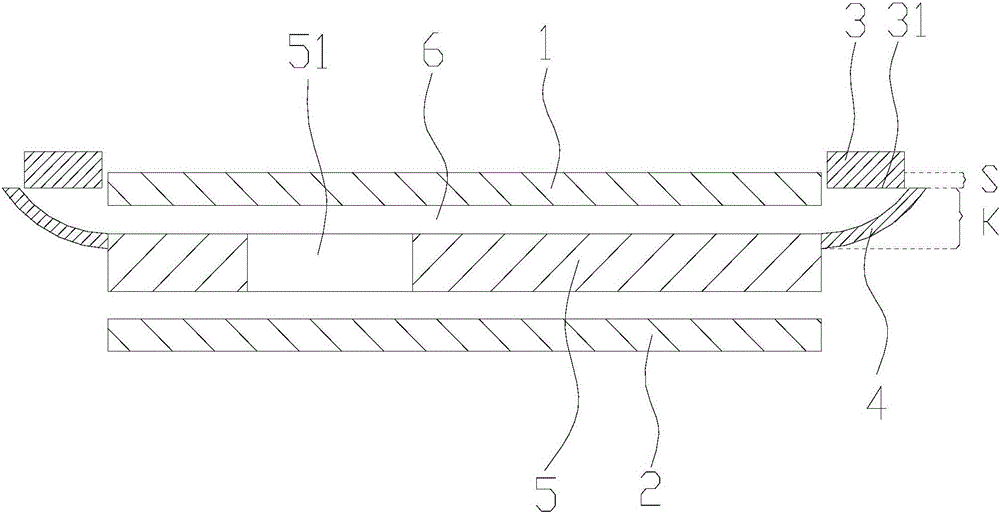

Light guide structure of touch key and mobile terminal

InactiveCN106405725ASimple installation structureGood optical performanceOptical light guidesInput/output processes for data processingLight guideComputer terminal

The embodiment of the invention provides a light guide structure of a touch key, which is applied to a mobile terminal with a touch screen. The touch screen is provided with a character region, and comprises an upper light reflecting piece, a lower light reflecting piece and a light source assembly, wherein the upper light reflecting piece is provided with a light outlet hole which is arranged corresponding to the character region of the touch screen, the upper light reflecting piece and the lower light reflecting piece are oppositely arranged so as to form a transmission cavity of light, the transmission cavity is internally provided with a light guide film used for transmitting the light to the light outlet hole, the light guide film is provided with al light guide column, and the light guide column is arranged on a light path of the light source assembly for emitting light to the light guide film. The invention further provides a mobile terminal which comprises the light guide structure of the touch key. In the light guide structure, the light guide column is arranged on the light guide film, thereby enabling the structure to be simpler, and being conducive to manufacturing; and a light guide column with the thickness being small can be adopted so as to reduce the thickness of the mobile terminal and be conducive to thinning of the mobile terminal. Meanwhile, installation of the light guide column does not require an installation hole on a shell, so that the structural strength of a product is high.

Owner:VIVO MOBILE COMM CO LTD

Integrally-cast crossbeam with air storage function of air suspension frame

PendingCN107757710AReduce connection processingReduce assemblyUnderstructuresStructural engineeringGas supply

The invention relates to an integrally-cast crossbeam with an air storage function of an air suspension frame. The crossbeam comprises a crossbeam main body and a pair of sealing end covers arranged at the two ends of the direction of the long axis of a crossbeam pipe body, wherein the crossbeam main body is formed by integrally casting the crossbeam pipe body and a pair of crossbeam connectors which are symmetrically arranged at the two ends of the crossbeam pipe body; meanwhile, a V-shaped seat pushing group is further integrally cast and formed on the outer wall of the crossbeam pipe body,and an air inlet and an air outlet are formed in the crossbeam pipe body; a reinforced convex rib group is further arranged on the inner wall of the crossbeam pipe body; and a seal ring set attached to the inner wall of the crossbeam pipe body is further mounted to the outer walls of one sections of the sealing end covers, wherein one sections of the sealing end covers extend into a cavity of thecrossbeam pipe body. The integrally-cast crossbeam has the advantages that the crossbeam is formed by integrally cast, on the basis of air supply storage, the sealing performance of the crossbeam canbe improved, the structural strength of the crossbeam is ensured, and meanwhile, manufacturing is more convenient.

Owner:JIANGSU TANGCHEN AUTOMOBILE PARTS

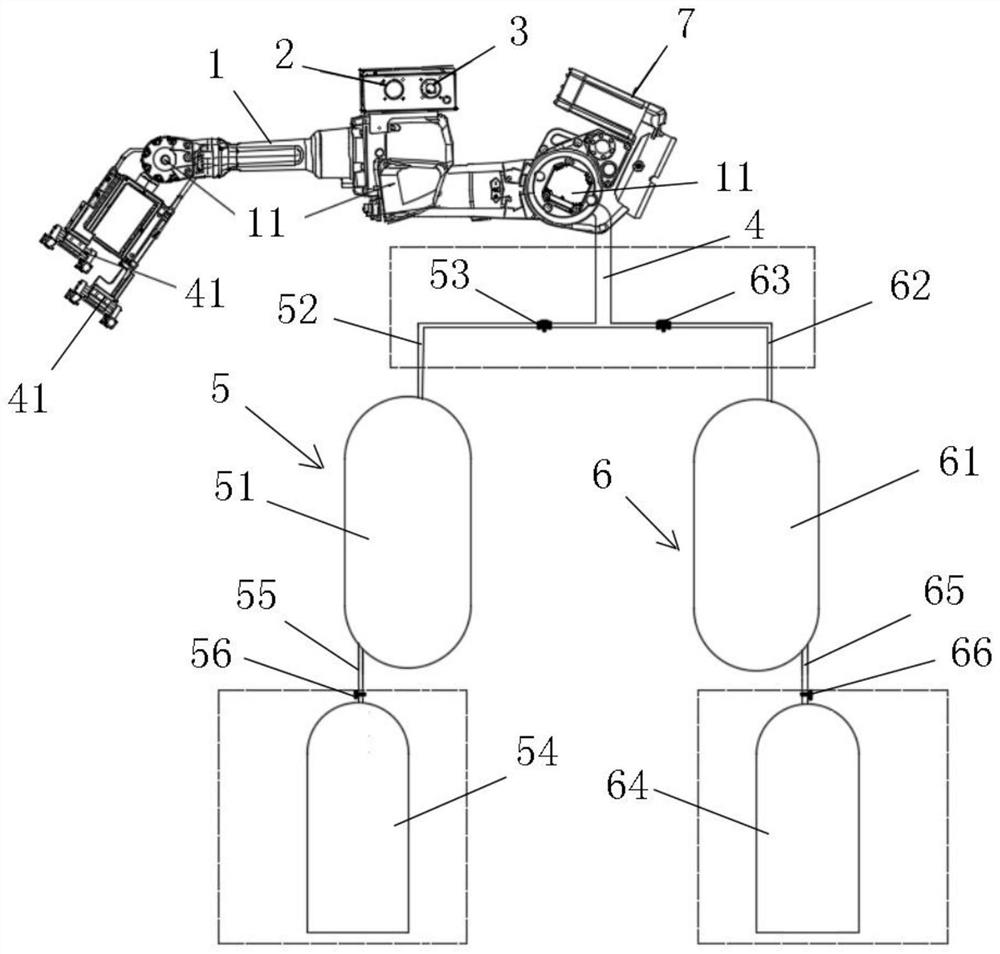

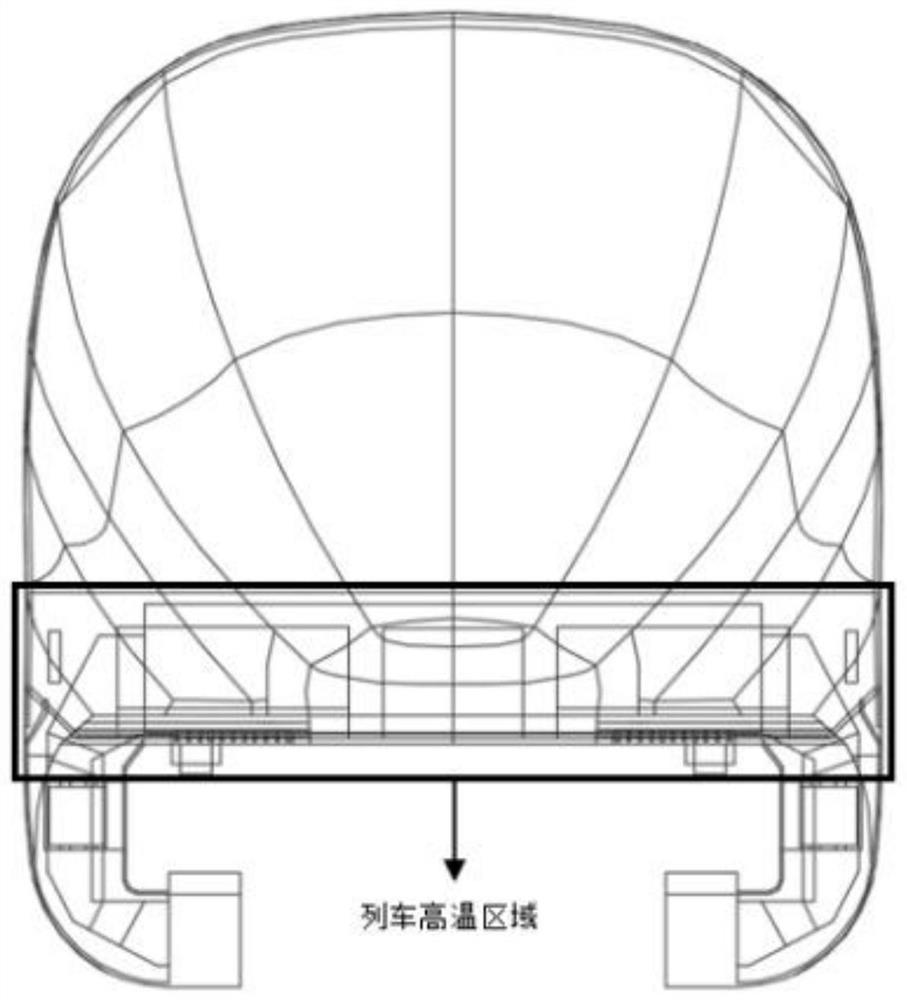

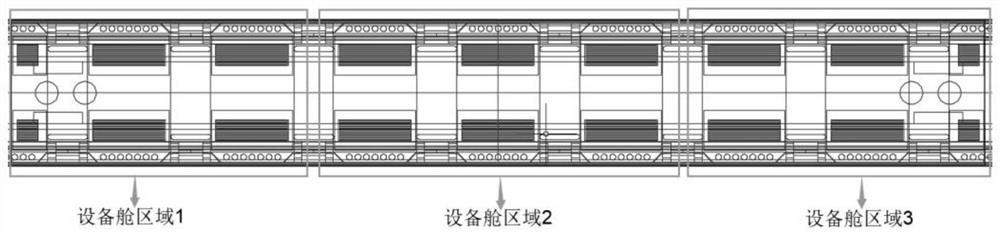

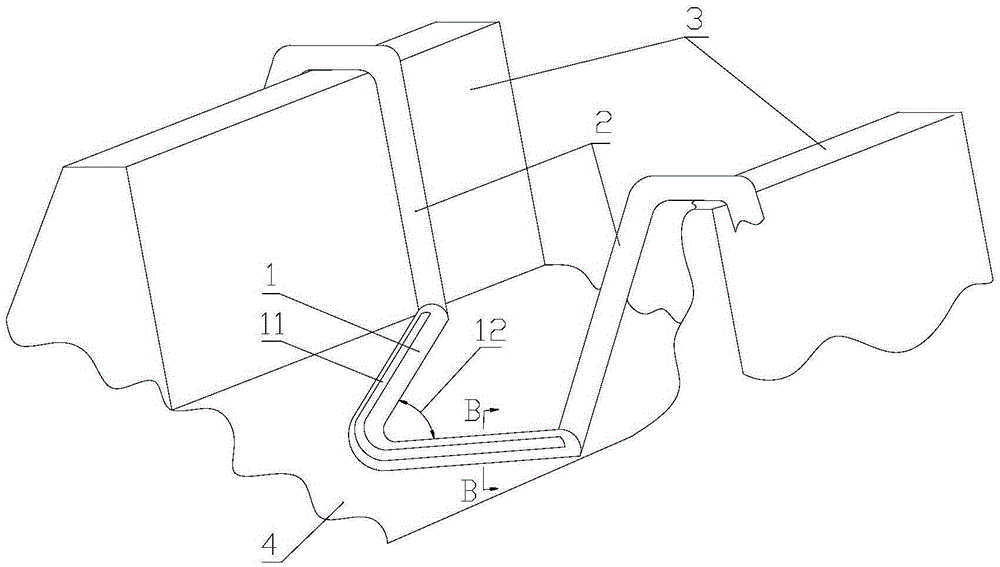

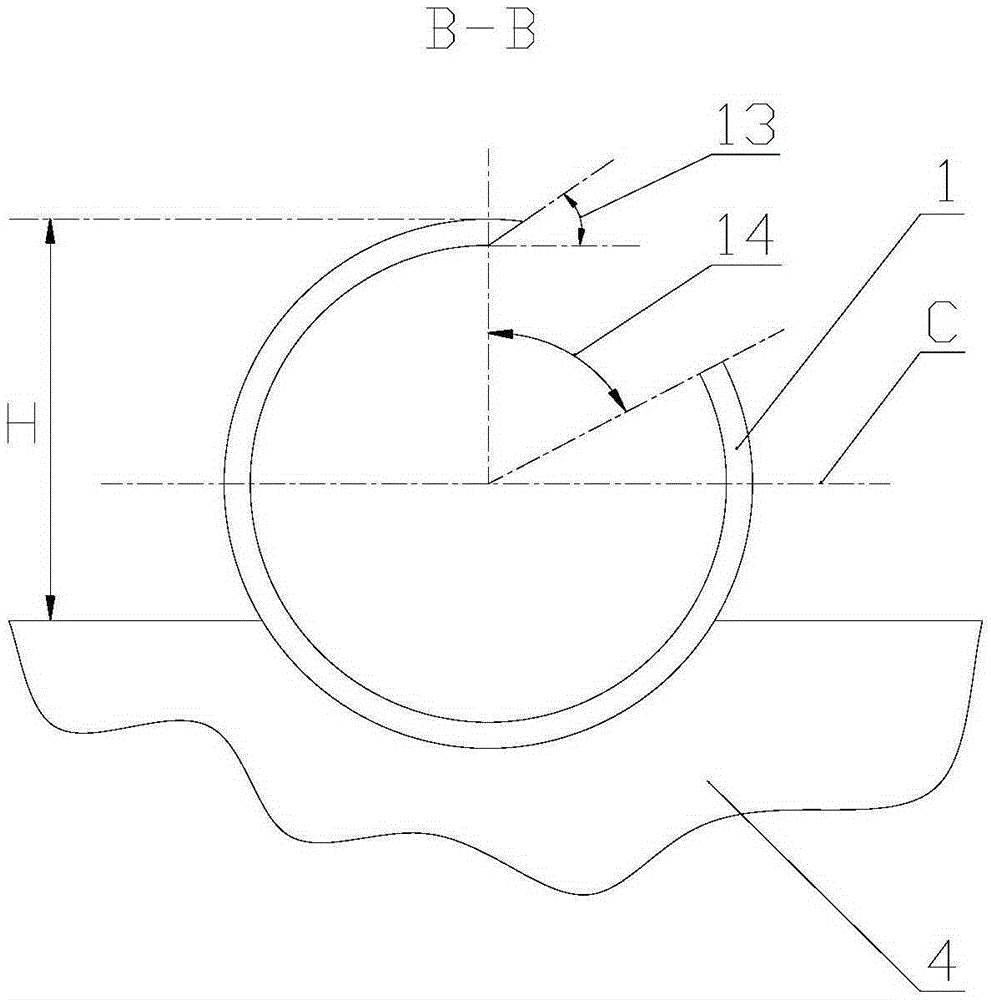

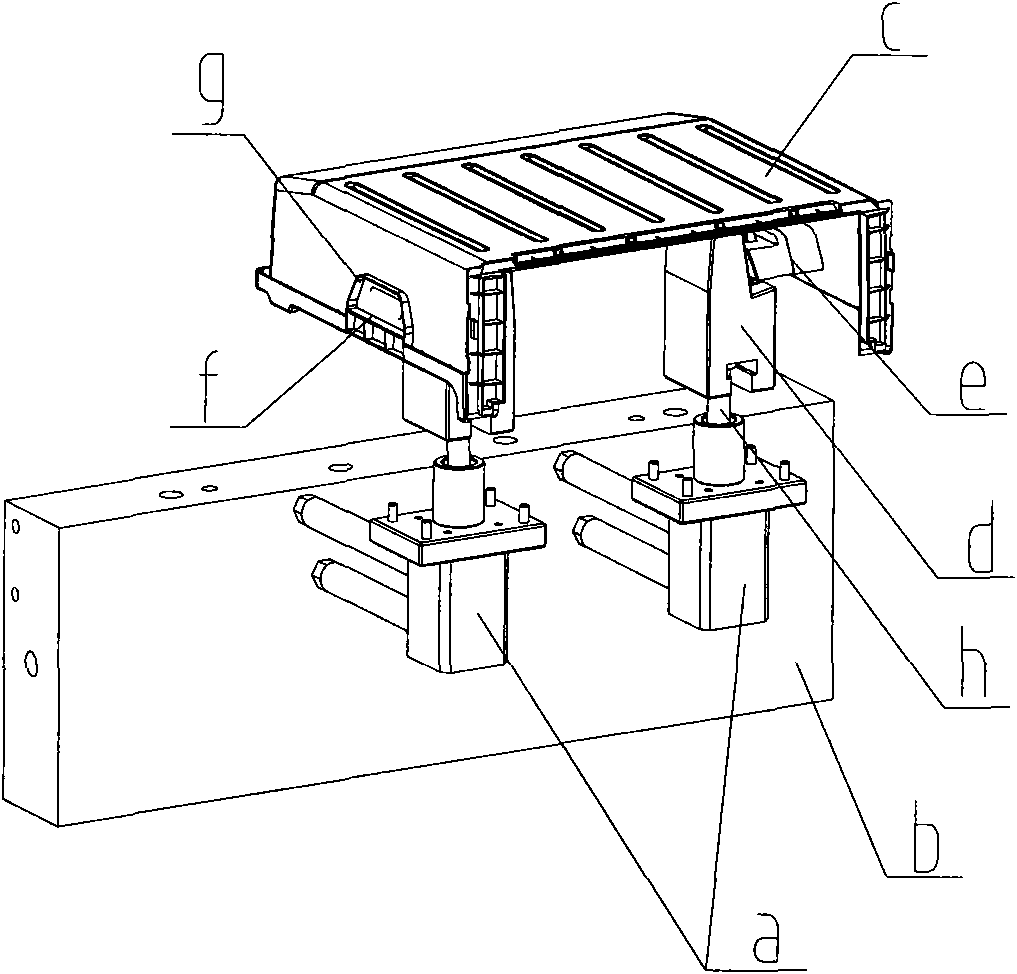

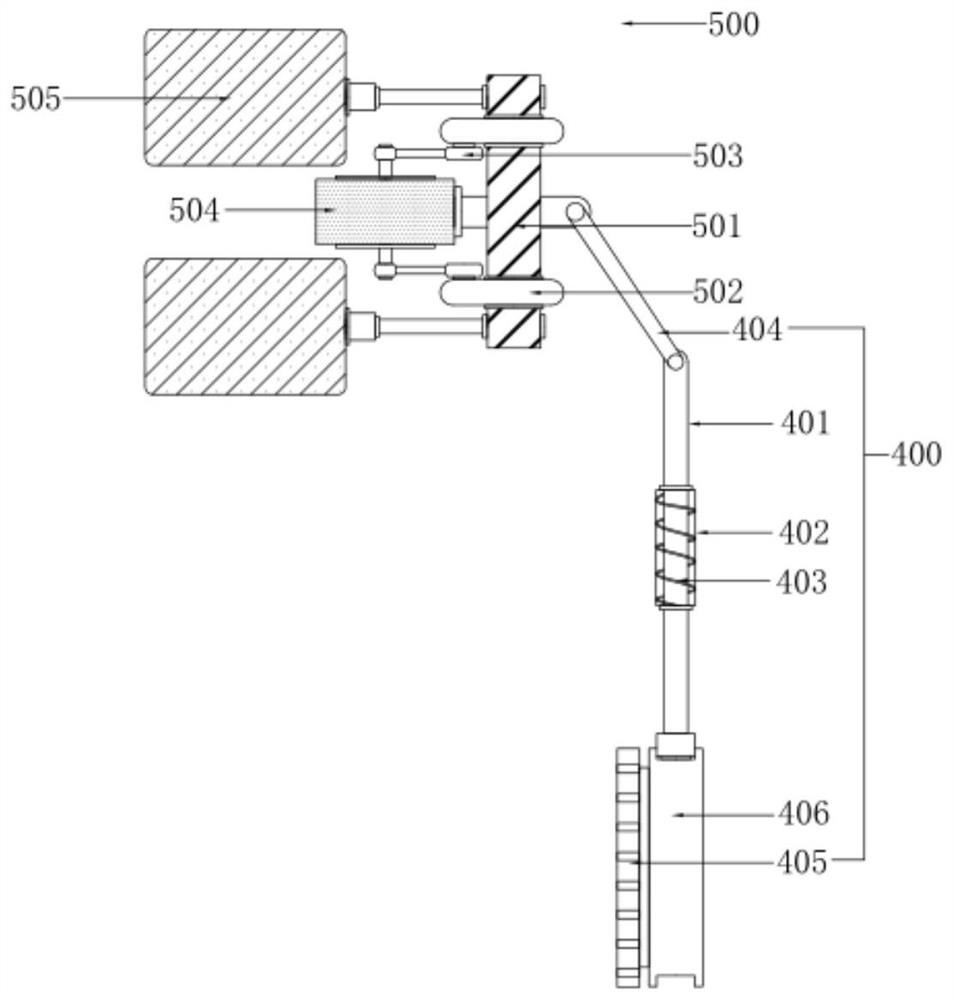

Inbound cooling system and method for vacuum pipeline maglev train

ActiveCN111891149AStructural Strength EffectReduce the temperatureRailway tunnelsLighting and heating apparatusCold airProcess engineering

The invention discloses an inbound cooling system and method for a vacuum pipeline maglev train. The inbound cooling system comprises a mechanical arm which is installed below a vacuum pipeline maglevtrain platform; a train body temperature measuring device which is used for detecting the train body temperature; a train body material detection device which is used for detecting train body materials; a cooling gas pipeline which is mounted on the mechanical arm, wherein a cooling gas spray head is arranged on the cooling gas pipeline; a high-pressure cold air supply system which is used for supplying high-pressure cold air to the cooling air pipeline; a high-pressure constant-temperature gas supply system which is used for supplying high-pressure constant-temperature gas to the cooling gaspipeline; the controller, the mechanical arm, the automobile body temperature measuring device, the automobile body material detecting device, the high-pressure cold air supply system and the high-pressure constant-temperature air supply system are all connected with the controller. According to the inbound cooling system and method, the temperature of the vacuum pipeline maglev train body can berapidly and effectively reduced, and adverse effects on the structural strength of the train body are avoided.

Owner:CENT SOUTH UNIV

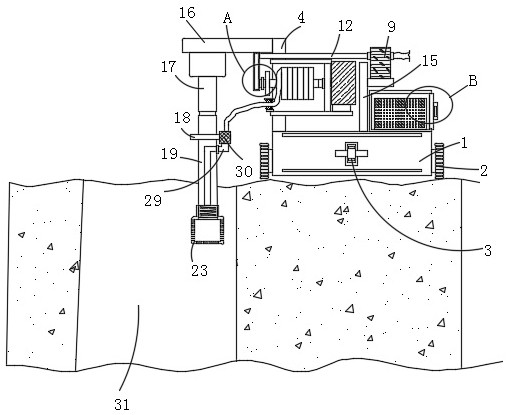

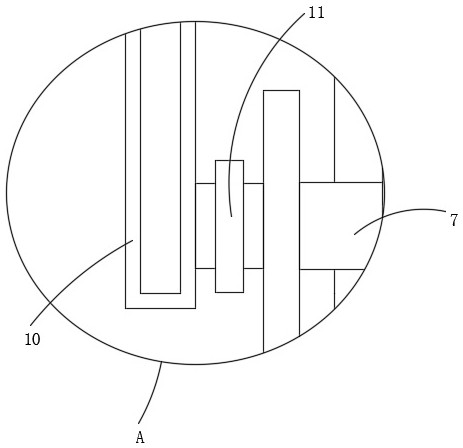

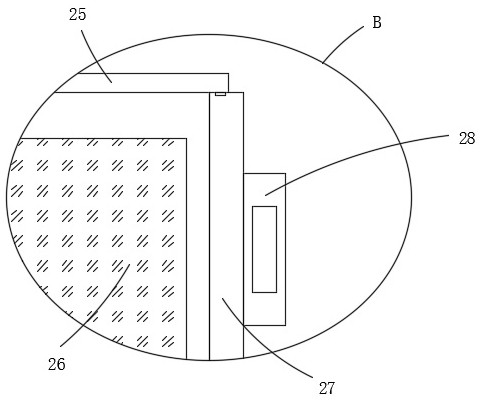

Sediment removal system and method for preventing sediment accumulation at canal bed of canal and

The invention provides a sediment removal system and a method for preventing sediment accumulation at a canal bed of a canal. The sediment removal system comprises a V-shaped vortex pipe and siphons, wherein the V-shaped vortex pipe is positioned at the canal bed of the canal, and is used to form spiral flows; a V-shaped sharp corner points to the direction opposite to the direction of a water flow; openings are formed in the water flow facing sides of the vortex pipe; the tail ends of the vortex pipe are close to the bottom of a canal bank of the canal; one end of one siphon is communicated with one tail end of the vortex pipe correspondingly; and the other ends of the siphons bypass the tops of the canal bank to extend to the outer sides of the canal. According to the sediment removal system and the method, the flow speeds of helical flows along the axial directions of the vortex pipe can be increased through the siphons, so that the sediment removal efficiency is improved, the sediment removal system is green and environmental-friendly; in addition, the siphons bypass the top of the canal bank to extend to the outer sides of the canal, so that the impact on the structural strength of the canal bank is avoided; moreover, the vortex pipe of the sediment removal system is V-shaped, so that the two helical flows flowing to the two tail ends of the vortex pipe respectively can be formed, the siphons can be arranged at the two tail ends of the vortex pipe, and the sediment removal efficiency is improved.

Owner:XIHUA UNIV

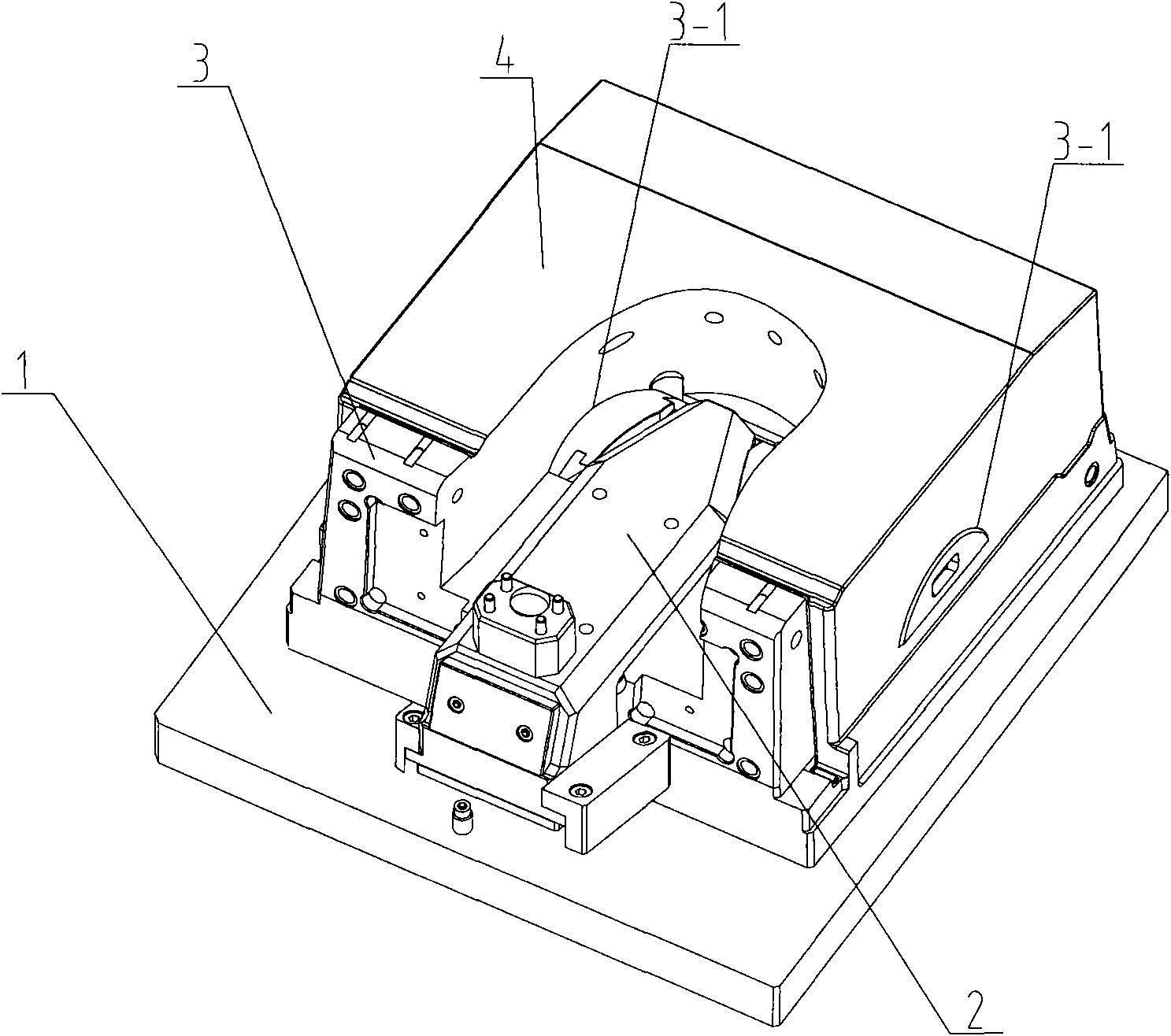

Injection mould provided wtih core-pulling mechanism driven by mould opening and closing actions

The invention provides an injection mould provided wtih a core-pulling mechanism driven by mould opening and closing actions, wherein, the injection mould can solve the problems that the core-pulling mechanism adopting a hydraulic cylinder to perform the core-pulling from the lower part of a product has the disadvantages of complicated structure, high cost and bad stability when the core-pulling is carried out in conventional core-pulling manners such as obliquely propping and the like so as to solve an internal inverted buckle existing in the product and so on. The injection mould adopts thetechnical scheme as follows: a driving slide block is connected with a mould movable template in a sliding manner, and the sliding direction is perpendicular to the mould opening direction of the mould; at least one side surface at the front end of the driving slide block takes the shape of a wedge; a driven slide block is inserted in an inserted block; in addition, the driven slide block is provided with a wedged end surface and matched with the driving slide block through an inclined slideway in a sliding manner. The core-pulling mechanism of the injection mould utilizes an inclined guide pillar to drive the slide block when the mould is opened and closed, the core-pulling action is completed in the direction perpendicular to the mould opening and closing direction, the problem of the internal inverted buckle can be solved, the strucutre is simple, the cost is low, the stability of the mould is good, and the injection moulding period is short.

Owner:QINGDAO HAIER MOLDS

Vehicle, vehicle control method and computer readable storage medium

ActiveCN109398041AStructural Strength EffectDoes not spoil aestheticsWindowsAir-treating devicesVisorVehicle control

The invention provides a vehicle, a vehicle control method and a computer readable storage medium. The vehicle comprises window visors and motors. The window visors are movably arranged on a vehicle body. The motors are connected with the window visors so as to drive the window visors to be switched between unfolding positions and folding positions. In the unfolding position, each window visor extends out of the vehicle body and shelters at least part of a vehicle window frame from the position above a vehicle window. By the application of the provided technical scheme, under the condition that the weather is clear and the window visors are not needed, each window visor is stored in a gap between a side wall outer board and a vehicle body framework and cannot protrude out of the surface ofthe vehicle body so that the wind drag cannot be increased, and the overall beauty of the vehicle body cannot be damaged either. When the window visors need to work, the motors are controlled througha controller to drive the window visors to extend out from the side wall outer boards, when the vehicle windows are opened for ventilation, the window visors can stop rainwater from entering the vehicle, and the problem that the vehicle windows on the two sides of the vehicle directly communicate with the outside world, so that the wind drag is too large is solved.

Owner:BEIJING CHEHEJIA AUTOMOBILE TECH CO LTD

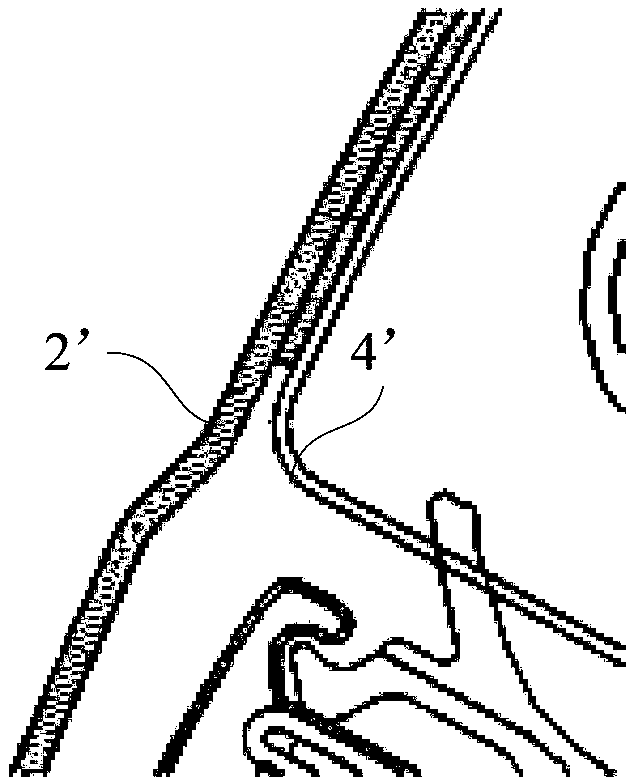

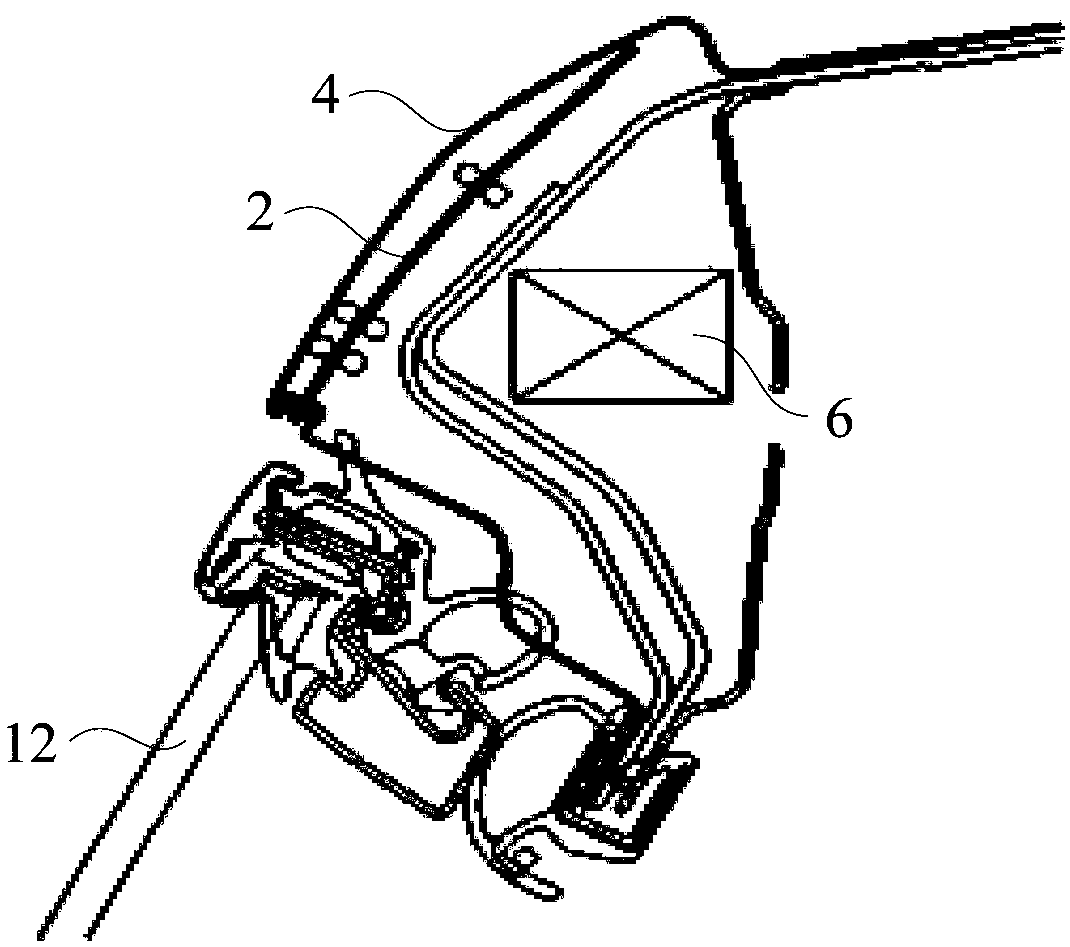

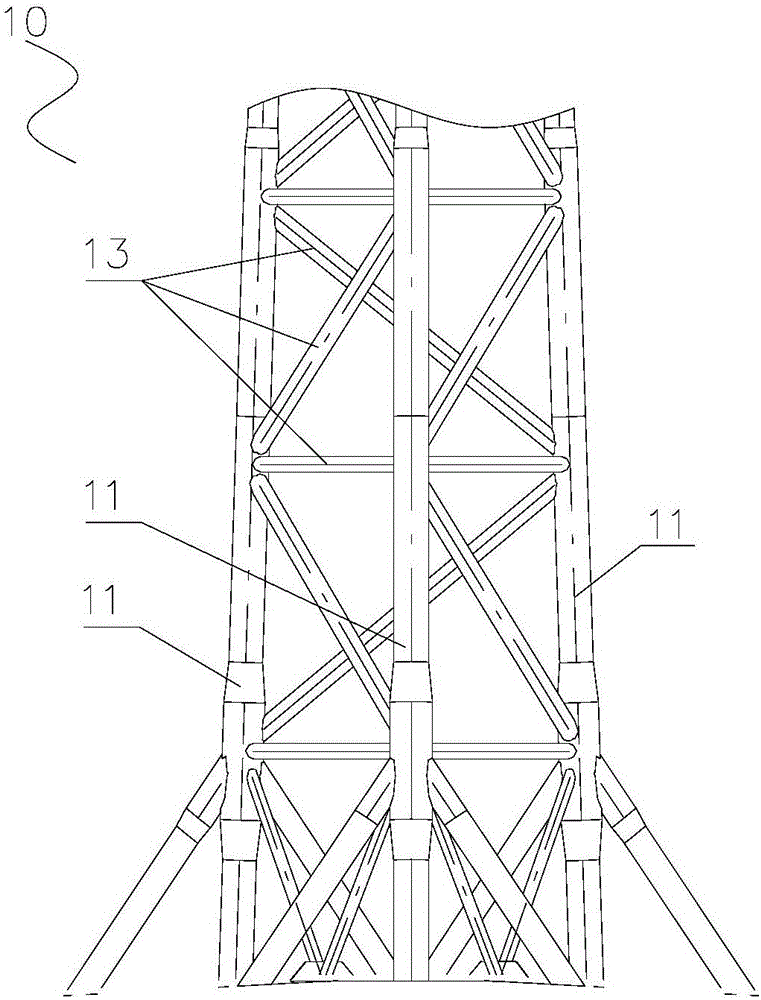

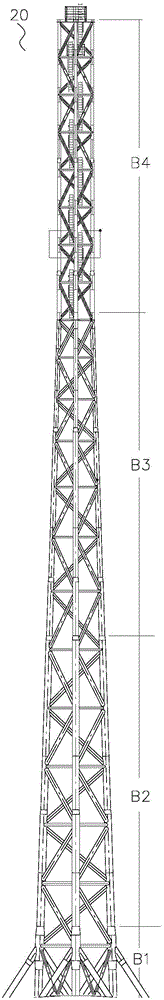

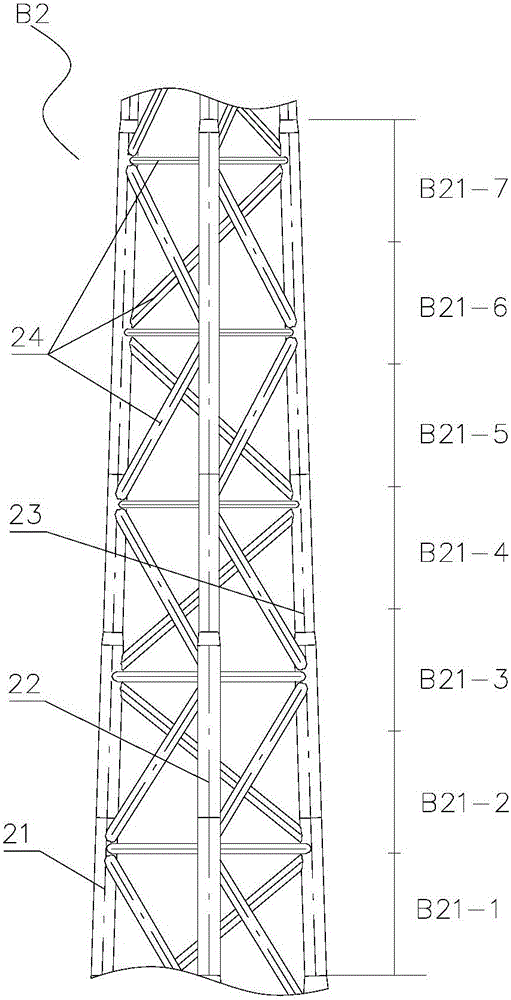

FPSO large flare tower building technology

InactiveCN105781214AImprove structural strengthGuaranteed structural strengthTowersButt jointEngineering

The invention discloses an FPSO large flare tower building technology. The technology comprises the following steps that 1, four main sections are built; 2, the four main sections are in butt joint to form a flare tower. In the first step, the method for building each main section comprises the following steps that 11, three groups of connection sections are built, wherein each group of the connection sections comprises seven connection sections; 12, the connection sections of each group are spliced into a stand column, wherein the abutted seam welding areas of every two adjacent connection sections are not in the same straight line; 13, multiple inclined struts are built and assembled with the first stand column, the second stand column and the third stand column to form the main section. According to the FPSO large flare tower building technology, ground construction is only needed, the construction cost is low, the construction period is short, and potential safety hazards caused by working at heights are avoided; the abutted seam welding areas of the adjacent connection sections are staggered by a certain angle, and the weak structure caused due to the fact that the abutted seam welding areas are in the same straight line is avoided; all the stand columns and inclined struts are assembly gradually from bottom to top, and the cutting accuracy of the inclined struts is easy to control.

Owner:CSSC GUANGZHOU WENCHONG DOCKYARD CO LTD

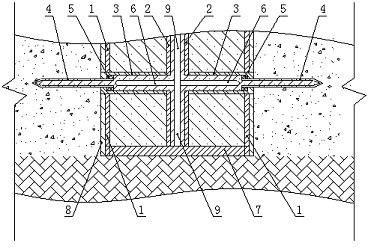

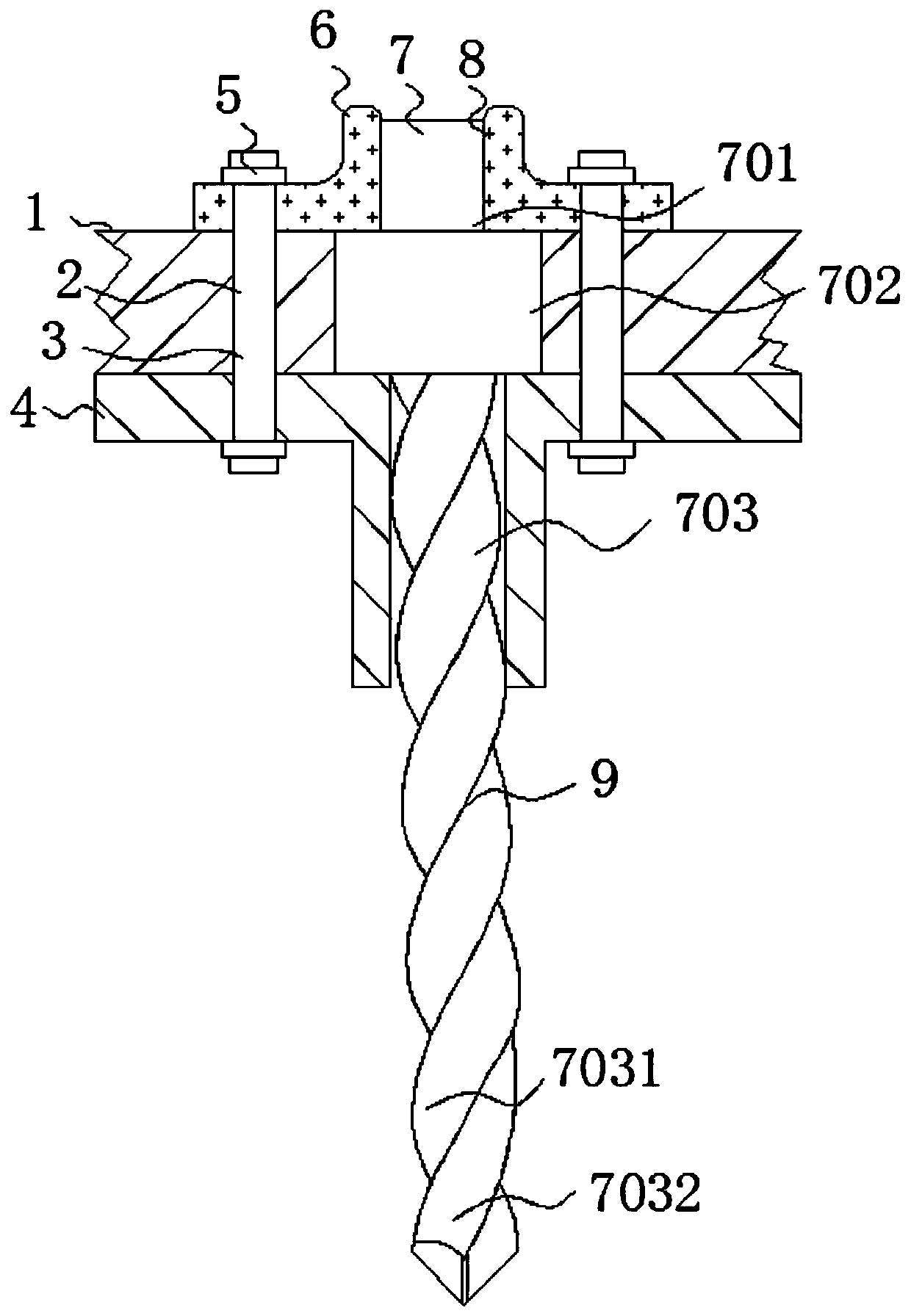

Soft foundation building foundation structure and construction method

PendingCN113699984AIncrease frictionReduce sinkageBulkheads/pilesSoil preservationPiston ringArchitectural engineering

The invention relates to the technical field of constructional engineering, in particular to a soft foundation building foundation structure. According to the technical scheme, the structure comprises a plurality of pipe piles, rigid grouting pipes are arranged in the middles of the pipe piles, and the rigid grouting pipes are circumferentially connected with a plurality of sleeves; one end of the sleeve communicates with the interior of the rigid grouting pipe, the other end of the sleeve is fixedly connected with the side wall of the pipe pile, and a soil inserting rod is inserted into the sleeve; a piston ring is fixed outside the inner end of the soil inserting rod, the soil inserting rod and the piston ring can move in the sleeve in the direction away from the grouting pipe, and a plurality of grouting holes are formed in the side wall of the soil inserting rod. A slidable guide rod is arranged in the soil inserting rod in a matched mode, the inner end of the guide rod is fixedly connected with the rigid grouting pipe, and the length of the portion, inserted into the soil inserting rod, of the guide rod is smaller than the movable stroke of the soil inserting rod in the sleeve. The structural strength of the soft foundation and the bearing capacity of the foundation can be improved, the pipe piles and the foundation are connected to form soil piles, and therefore the sinking amount of the foundation piles and a building structure is reduced, and the safety of the building structure is ensured.

Owner:张坤

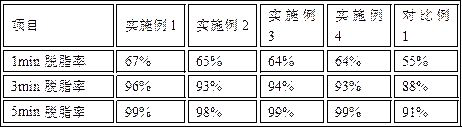

Aluminum alloy surface treatment method before injection molding

The invention relates to the technical field of aluminum alloys, in particular to an aluminum alloy surface treatment method before injection molding. The aluminum alloy surface treatment method comprises the following steps that (1) a to-be-treated aluminum alloy workpiece is degreased, and the degreased aluminum alloy workpiece is washed with water; (2) the aluminum alloy workpiece is placed inabsolute ethyl alcohol, and washing is conducted with water; (3) the aluminum alloy workpiece is polished with a chemical polishing solution, acid pickling is conducted after polishing, and then washing is conducted with water; (4) anodic oxidation treatment is conducted on the aluminum alloy workpiece; and (5) the aluminum alloy workpiece is put into an etching solution for etching. The aluminumalloy surface treatment method is adopted for treating the aluminum alloy workpiece before injection molding, the treated aluminum alloy workpiece is good in appearance effect, the surface aluminum oxide film layer is provided with combination holes with excellent performance, the combination strength of aluminum alloy and resin after injection molding can be improved, the product yield and the product reliability can be improved, and the aluminum alloy surface treatment method is easy and convenient to operate, easy to control, high in production efficiency, stable in product quality and capable of reducing environmental pollution.

Owner:广东东明新材科技有限公司

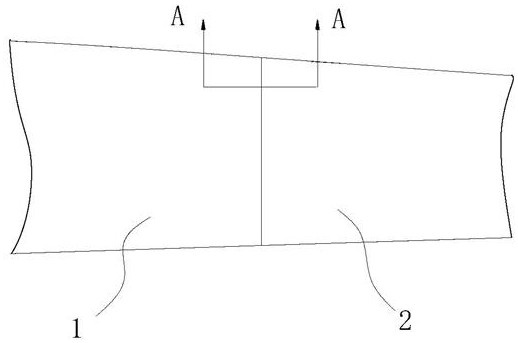

High-strength connecting structure and sectional type wind power blade

ActiveCN113339190AAvoid punchingStructural strength does not affectMachines/enginesWind energy generationMarine engineeringWind power

The invention relates to the technical field of wind power blades, in particular to a high-strength connecting structure and a sectional type wind power blade. The high-strength connecting structure comprises a first section and a second section which are arranged in the length direction of the wind power blade, and the first section and the second section comprise first matching faces, second matching faces, connecting faces and connecting bolts; the first matching faces extend towards the interior of the wind power blade, and the first matching faces are perpendicular to the length direction of the wind power blade; the second matching faces and the first matching faces are staggered, and the second matching faces are staggered in the direction close to the first section relative to the first matching faces; the connecting faces are connected with the first matching faces and the second matching faces; the connecting bolts are located in the wind power blade and penetrate through the two first matching faces to fix the first section and the second section, and the connecting bolts are parallel to the length direction of the wind power blade; and an anti-flanging structure is arranged between the first section and the second section, and the anti-flanging structure limits the second section from being flanged towards the outer side of the wind power blade. According to the high-strength connecting structure and the sectional type wind power blade, the connecting strength and the sealing performance are guaranteed, and the service life of the wind power blade is prolonged.

Owner:CHANGZHOU HONGFA ZONGHENG ADVANCED MATERIAL TECH

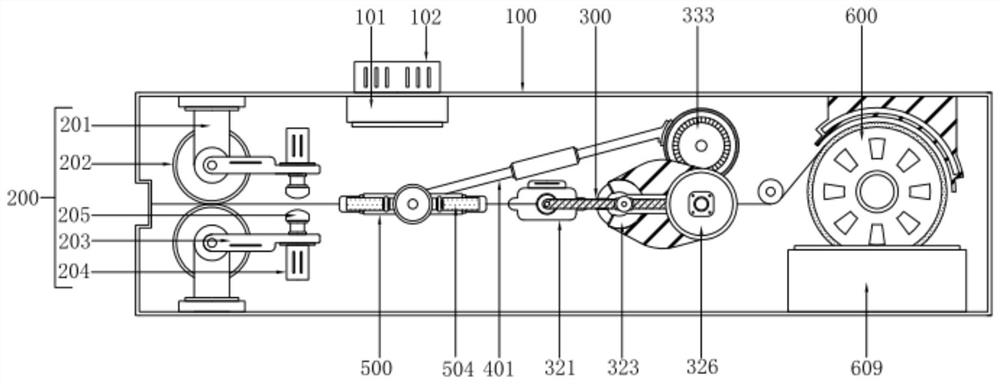

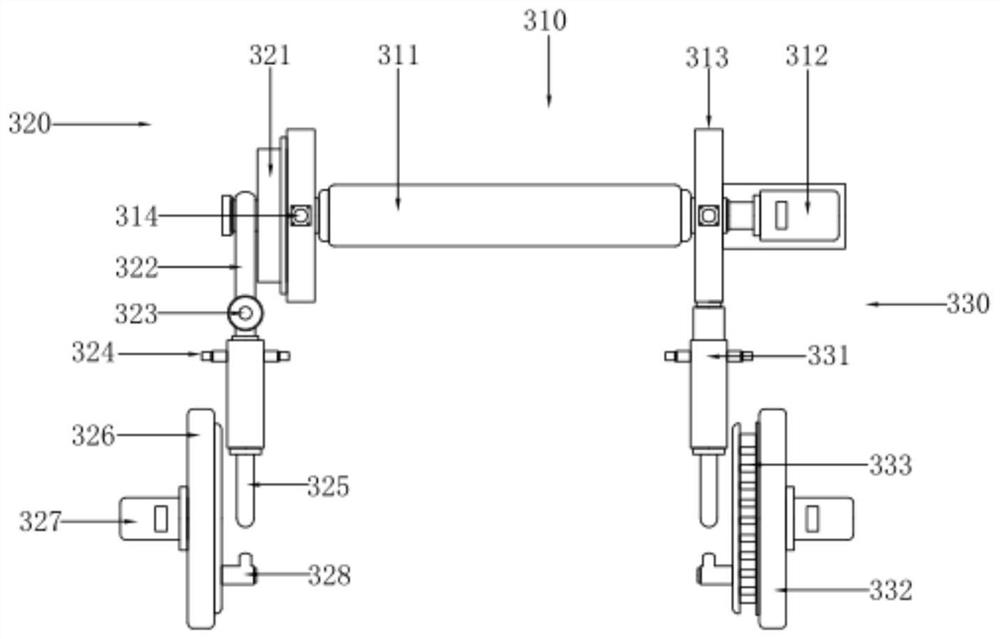

Textile fabric cleaning equipment and method used for textile equipment

InactiveCN111778699AImprove cleaning qualityPlay a supporting roleMechanical cleaningPressure cleaningManufacturing engineeringTextile

The invention discloses textile fabric cleaning equipment and method used for textile equipment, which belongs to the technical field of textile fabric processing. The inner cavity of a box body is provided with a dust collecting cover; the dust collecting cover is connected to a dust collector through a pipeline; the rear side of a guide wheel assembly is provided with a fabric flapping assembly;the fabric flapping assembly is connected to a fabric shaking assembly through a linkage assembly; and the rear side of the fabric shaking assembly is provided with a fabric cleaning assembly. The pressed textile fabric is driven to shake in a wavy mode through a shaking power assembly, so that dust on the fabric is shaken off, and structural strength of the textile fabric is not affected; the fabric flapping assembly is used, so that a flapping plate performs continuous flapping action at the two sides of the textile fabric; the flapping assembly is matched with a shaking power assembly to improve cleaning quality on the textile fabric; and the shaking power assembly is linked with the fabric flapping assembly through the linkage assembly, so that the shaking power assembly and the fabric flapping assembly synchronously work and use co-drive force, and therefore, use of energy is saved.

Owner:湖州中裕布业股份有限公司

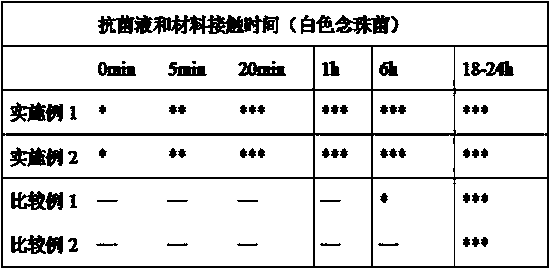

Bacteriostatic building concrete manufacturing process

The invention relates to a bacteriostatic building concrete manufacturing process, which is characterized by comprising the steps of mixing the following materials uniformly in parts by weight: 6-10 parts of cement, 0.2-0.5 part of silicon ash, 10-15 parts of sand, 15-20 parts of gravel, 1-2 parts of water, 0.02-0.05 part of antibacterial liquid and 0.01-0.02 part of copper-plated steel fibers, then adding 0.01-0.05 part of a water reducing agent, and stirring the materials uniformly again.

Owner:耿云花

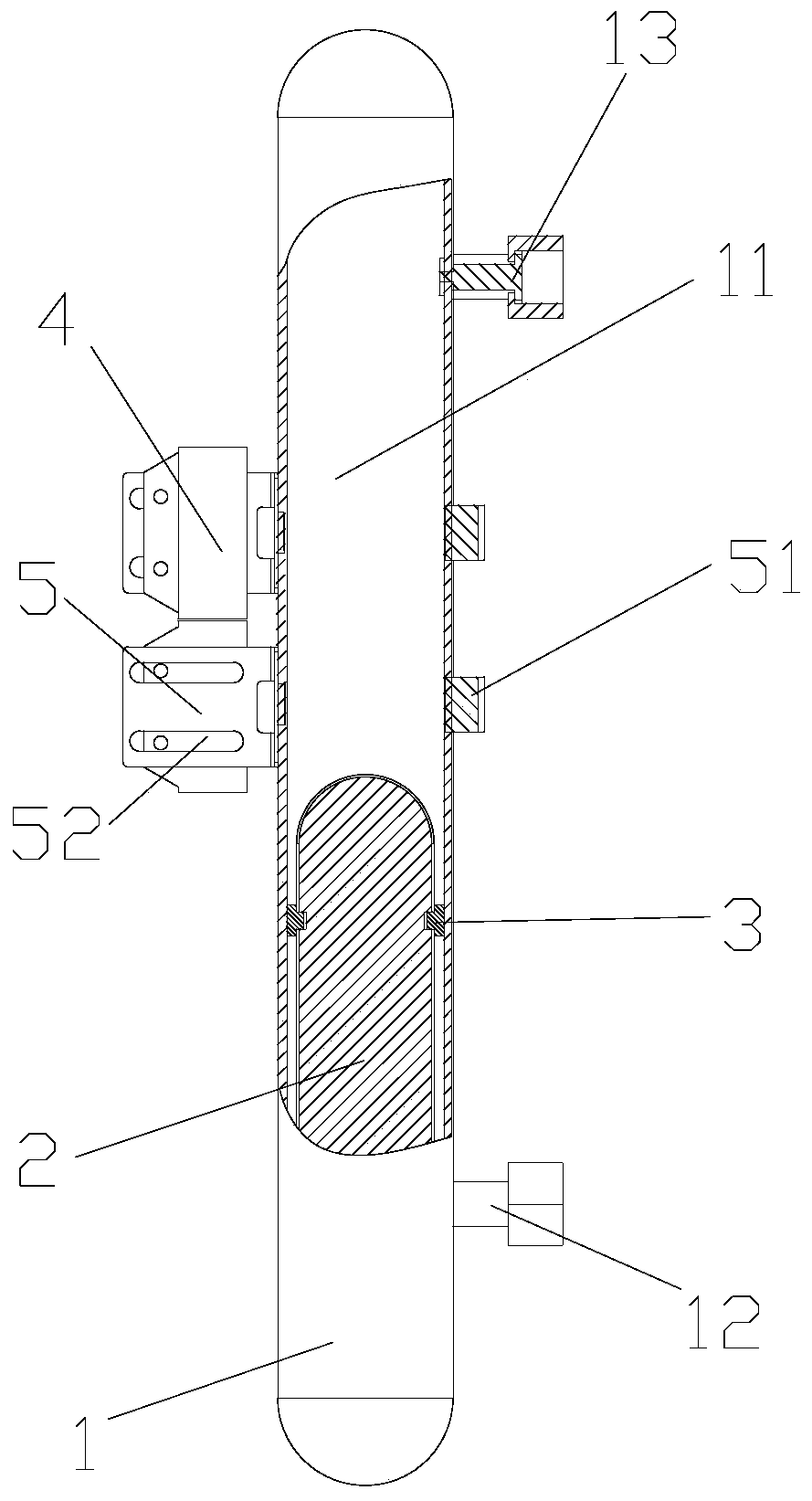

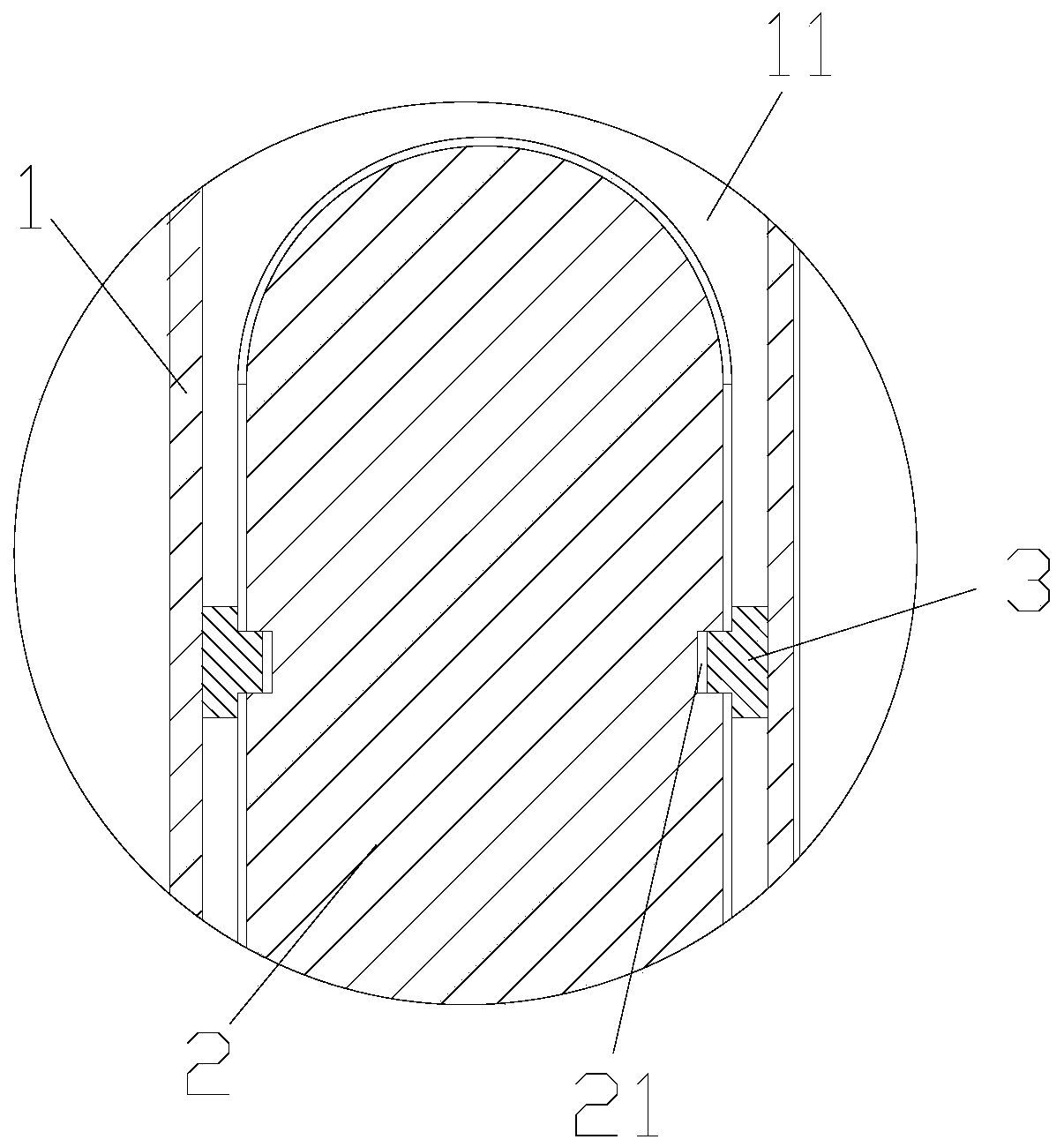

Liquid level detection device and steam car washing machine

InactiveCN110595580AStructural Strength EffectHigh strengthVehicle cleaning apparatusLevel indicators by floatsEngineeringElectrical and Electronics engineering

The invention provides a liquid level detection device and a steam car washing machine, and the liquid level detection device is used to detect the liquid level in a container and comprises the following parts of a casing having a cavity therein and provided with a first communication port, wherein the first communication port communicates with the cavity and is used to connect with the container;a float disposed in the cavity movably, wherein the float is driven through the liquid to float in the cavity when the liquid flows into the cavity through the first communication port; a magnetic part connected to the float to drive the magnetic part to float through the float; and a detection component provided on the outer side of the casing and used to detect the magnetic part to determine that the liquid level in the container reaches a predetermined height when the magnetic part floats to the detection range of the detection component. The liquid level detection device of the inventionsolves the problem of poor safety of the liquid level detection device in the prior art.

Owner:ZHUHAI GREE INTELLIGENT EQUIP CO LTD +1

Multicolor oxidation process for aluminum die casting

ActiveCN112030209AImprove surface smoothnessImprove surface qualitySurface reaction electrolytic coatingCasting cleaning apparatusSand blastingDie casting

The invention relates to a multicolor oxidation process for aluminum die castings. The multicolor oxidation process comprises the following steps of S1, preheating a smelting furnace; S2, melting themolten materials; S3, spraying a granular aluminum alloy flux; S4, filtering the molten aluminum; S5, carrying out vacuum die-casting formation; S6, carrying out highlight soaking treatment; S7, drilling; S8, sand blasting; S9, wire drawing; S10, milling a C angle; S11, carrying out one-color oxidation; S12, milling a highlight surface; and S13, carrying out dichroic oxidation. The process has thefollowing advantages that the mechanical property and the structural strength of the manufactured aluminum die castings are guaranteed.

Owner:NANTONG WOTELI MASCH MFG CO LTD

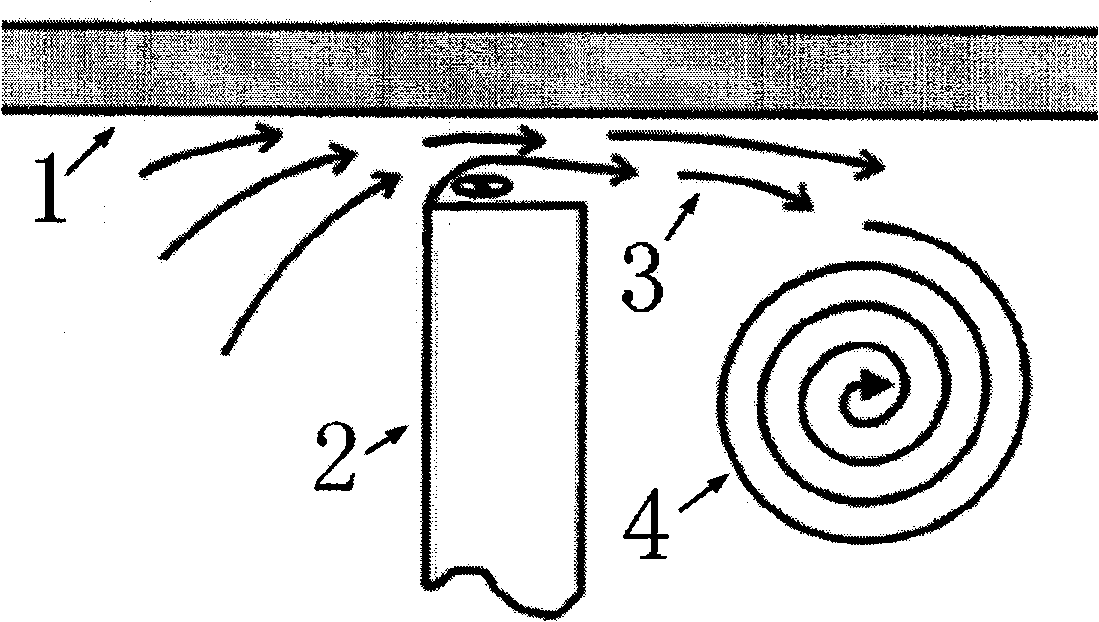

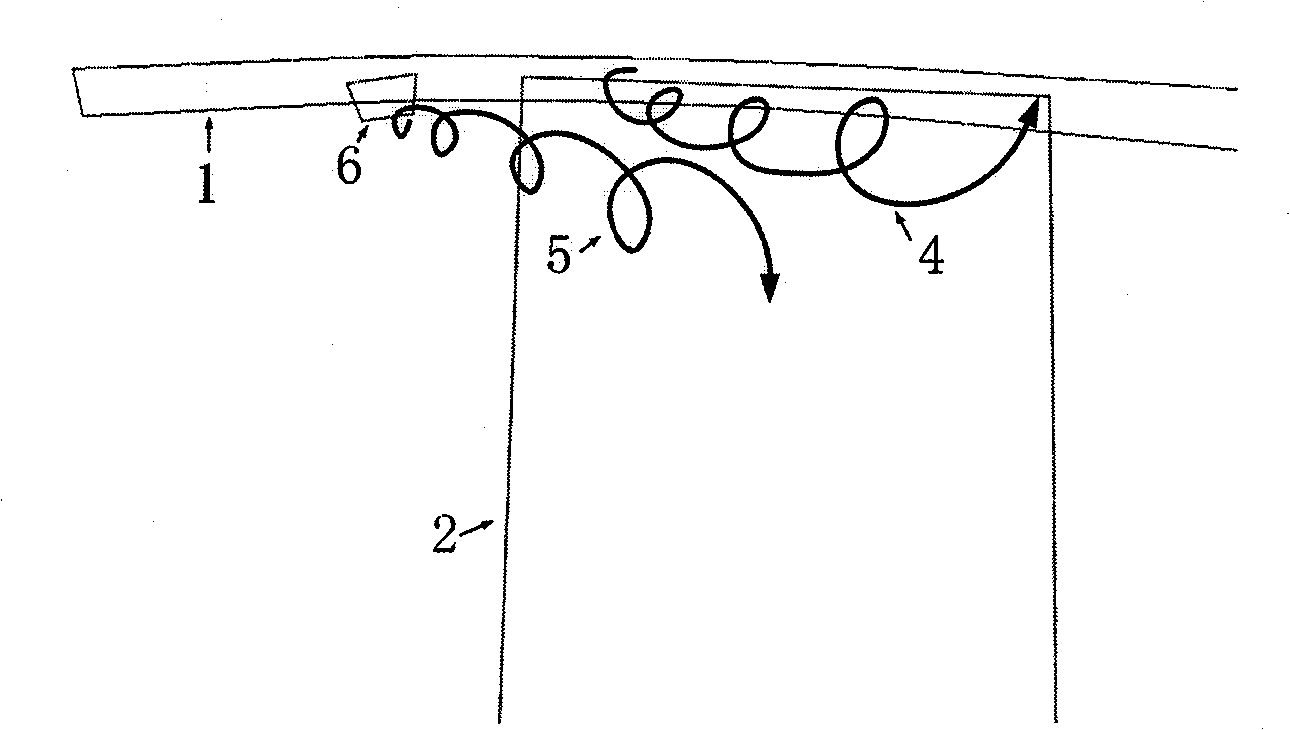

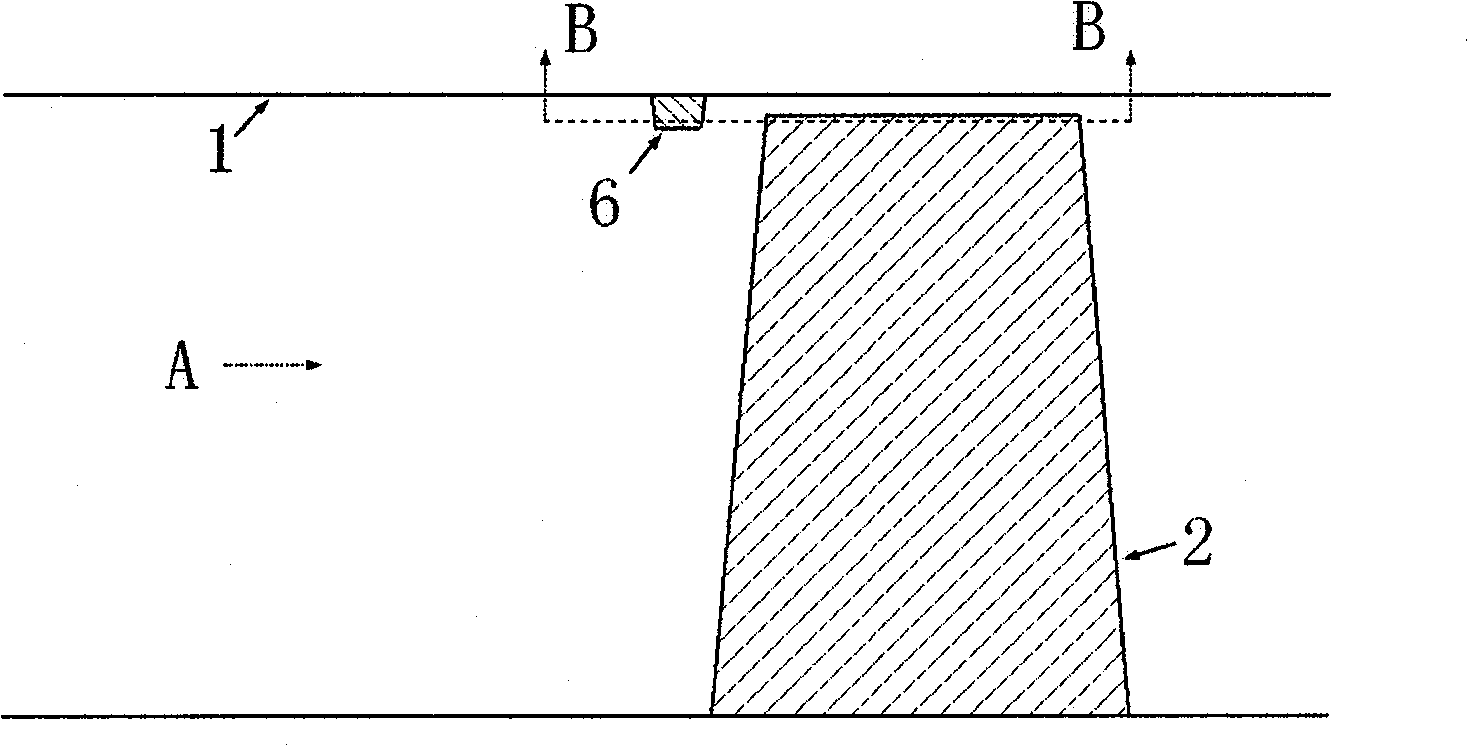

Method for controlling radial clearance leakage loss of turbomachine

ActiveCN101922312BInhibition formationImprove efficiencyLeakage preventionMachines/enginesImpellerEngineering

The invention relates to a method for controlling radial clearance leakage loss of a turbomachine. The invention remodels the end wall near the radial clearance of the turbomachine, thereby changing the flow behavior near the clearance and achieving the goal of reducing flow loss. The remodeling method is mainly realized by arranging a triangular or rectangular or trapezoidal spoiler on the end wall, wherein the spoiler can be welded on the end wall or integrated with the end wall, the height of the spoiler is 2-15% of that of the rotating blade, the axial length of the spoiler is 5-30% of axial chord length of the rotating blade, and the placement direction of the spoiler and the air flow form a certain included angle, thereby generating vortexes which are reverse to the leakage vortexes. The invention effectively controls the flow loss caused by leakage flow and obviously enhances the efficiency of the turbomachine.

Owner:BEIHANG UNIV

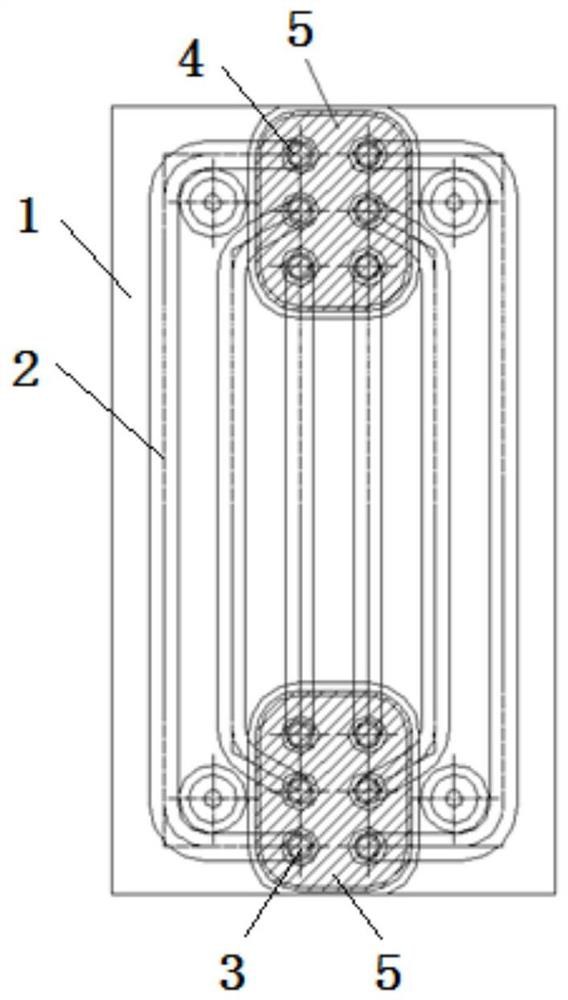

Cooling wall structure of blast furnace

PendingCN111647700ASpeed up the flowReduce power consumptionCooling devicesThermodynamicsBlast furnace smelting

The present invention relates to a cooling wall structure of a blast furnace, belonging to the technical field of blast furnace smelting devices. The structure comprises multiple sections of cooling walls; multiple cooling pipes are provided in a wall body of each section of cooling wall; the lower end of each section of cooling pipe is a water inlet, and the upper end is a water outlet; the waterinlet and the water outlet penetrate outside a furnace shell of the blast furnace located on the outer sides of the cooling walls; the cooling pipes on the upper and lower adjacent sections of cooling walls are connected in sequence by means of contact pipes to form multiple cooling channels from bottom to top; multiple cooling pipes in the wall body of each section of cooling wall are verticallyarranged in parallel; the water inlets and the water outlets of the adjacent cooling pipes are staggered high and low, respectively; and open holes are correspondingly provided on the furnace shell and the water inlets and the water outlets staggered on the cooling pipes high and low one to one. The cooling pipes straightly enter and exit to solve the problems of destruction of the structural strength of the furnace shell caused by larger open holes due to one-to-many arrangement of the open holes on an existing furnace shell and the water inlets and the water outlets and difficult mounting of the contact pipes and valves caused by stop of the flowing of cooling water due to more bends of the cooling pipes and the contact pipes.

Owner:CISDI ENG CO LTD

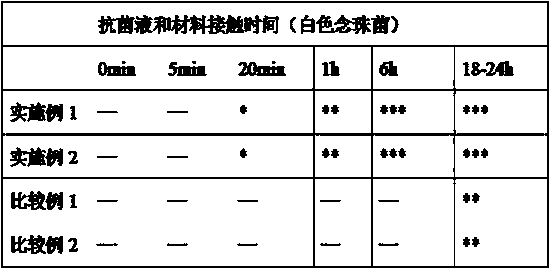

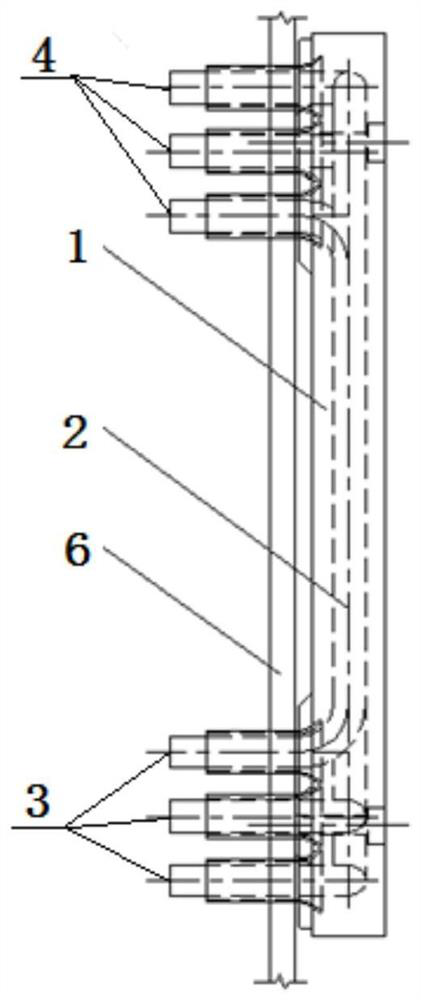

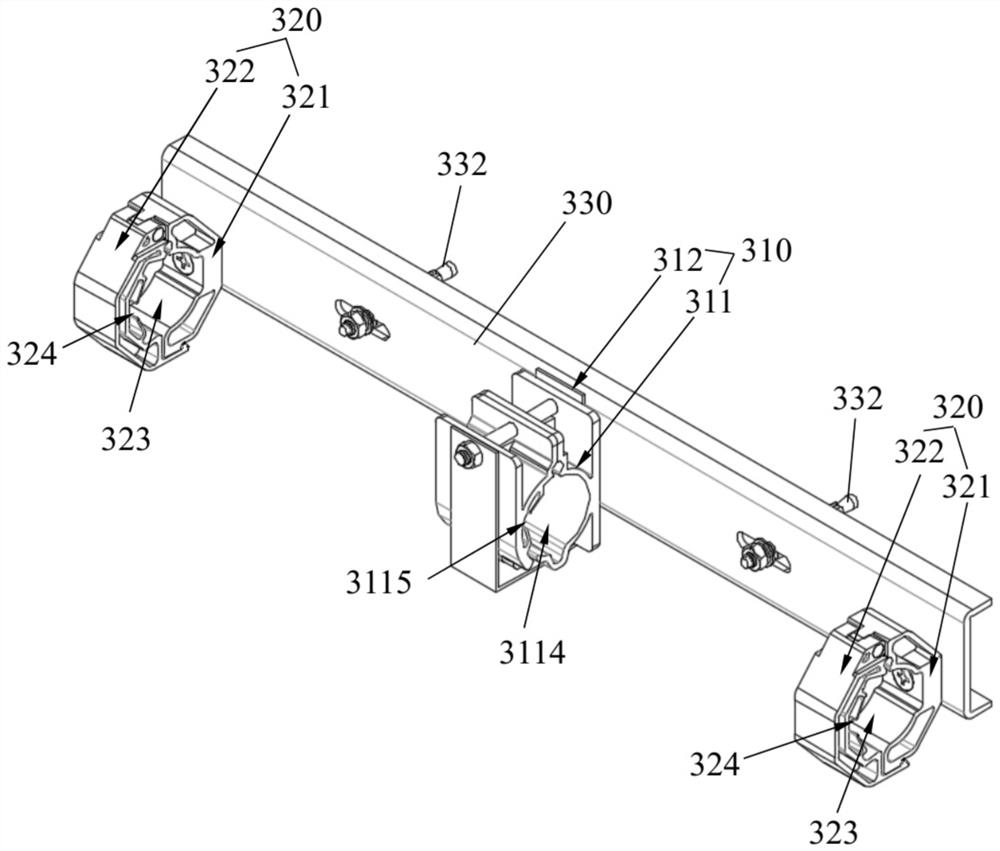

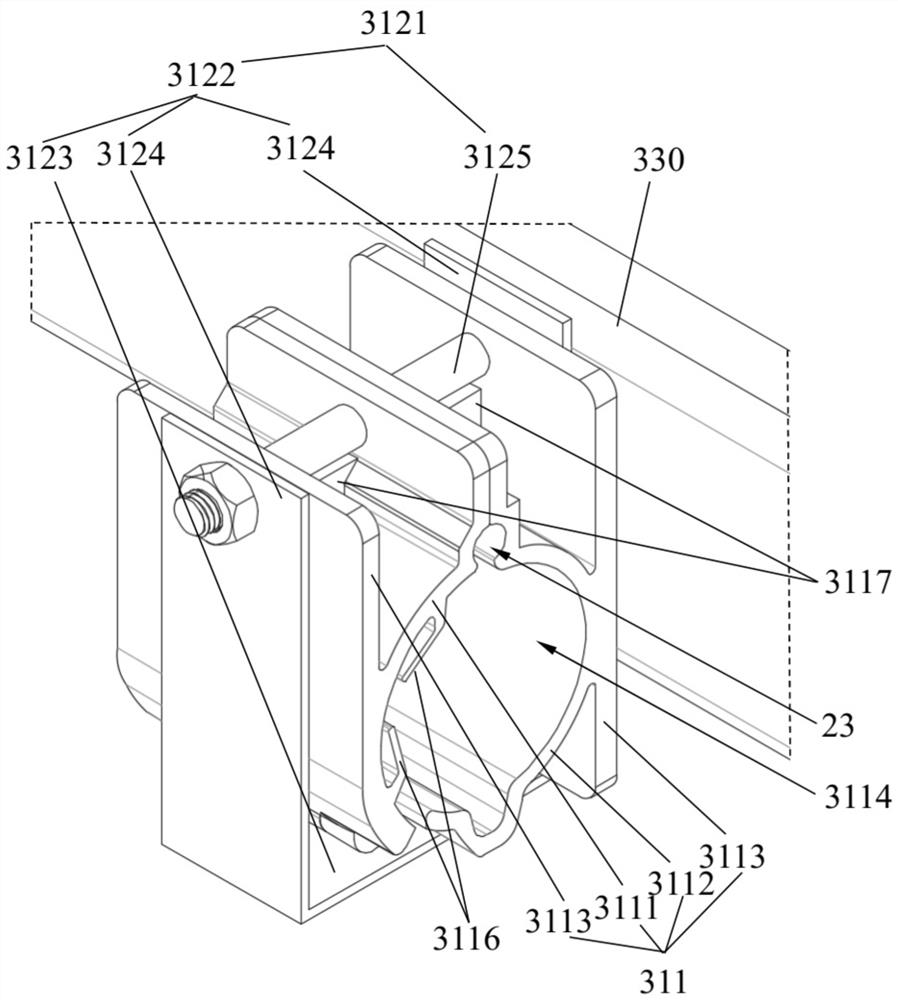

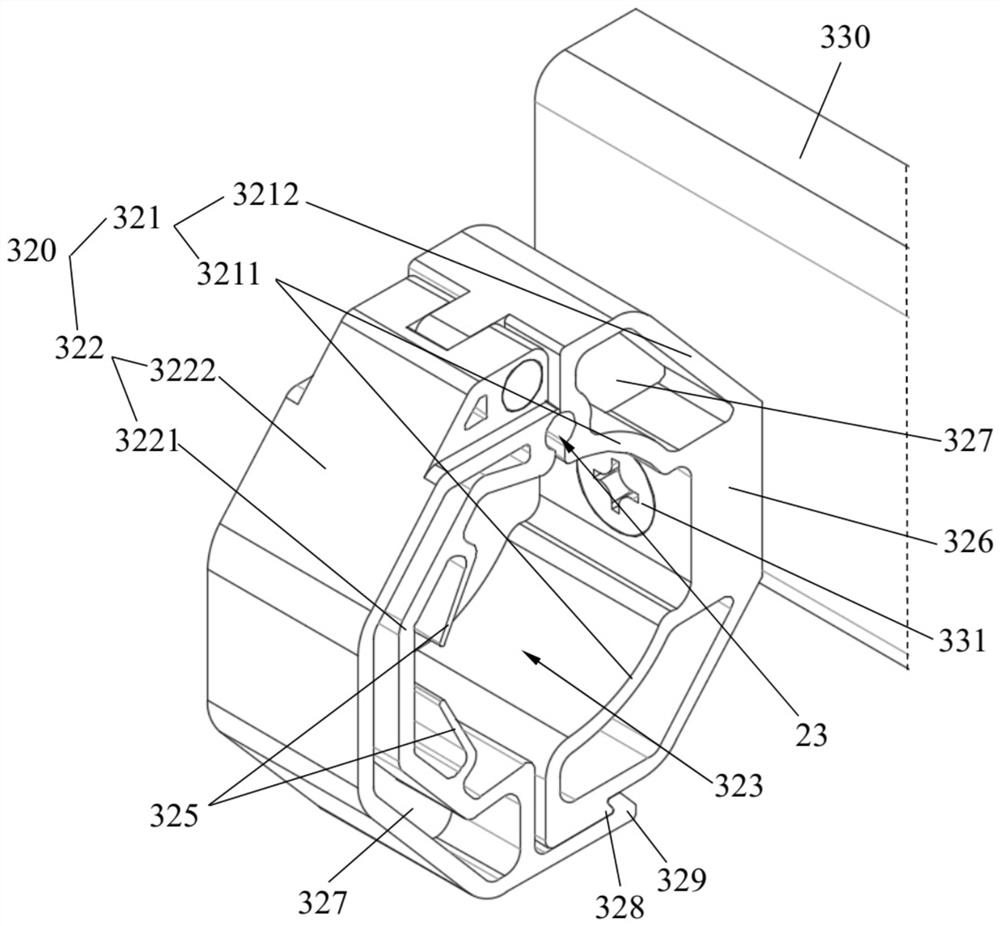

Leaky coaxial cable clamp mechanism and leaky coaxial cable bearing system

ActiveCN114696271AReduce axial displacementReduce or eliminate axial displacementNon-rotating vibration suppressionCable installations in tunnelsAxial displacementCoaxial cable

The invention discloses a leaky coaxial cable clamp mechanism and a leaky coaxial cable bearing system.The leaky coaxial cable clamp mechanism comprises a bearing support, a main clamp and at least two auxiliary clamps, the bearing support is fixed to an installation wall body, the main clamp and the at least two auxiliary clamps are all fixed to the bearing support, the at least two auxiliary clamps are arranged on the two sides of the main clamp at intervals, and the main clamp and the at least two auxiliary clamps are fixed to the bearing support. The auxiliary clamp can generate elastic deformation in the vibration state of the leaky coaxial cable so as to have a damping and buffering effect, and the main clamp is fixed relative to the bearing support in the vibration state of the leaky coaxial cable. According to the leaky coaxial cable clamp, the bearing requirement of the leaky coaxial cable can be met, the installation number of the leaky coaxial cable clamp mechanisms is effectively reduced, the situation that the bearing support is loosened due to the fact that the stress between the bearing support and the installation wall body is influenced by vibration can be avoided, the influence of the vibration on the stress between the main clamp and the leaky coaxial cable can be relieved or eliminated, larger clamping force can be applied to the leaky coaxial cable, and the leaky coaxial cable is prevented from being damaged. Therefore, the leaky coaxial cable is prevented from loosening, the safety performance is effectively improved, and axial displacement of the leaky coaxial cable under the action force of the tunnel wind tunnel effect is reduced or eliminated.

Owner:ZHONGTIAN RADIO FREQUENCY CABLE CO LTD +1

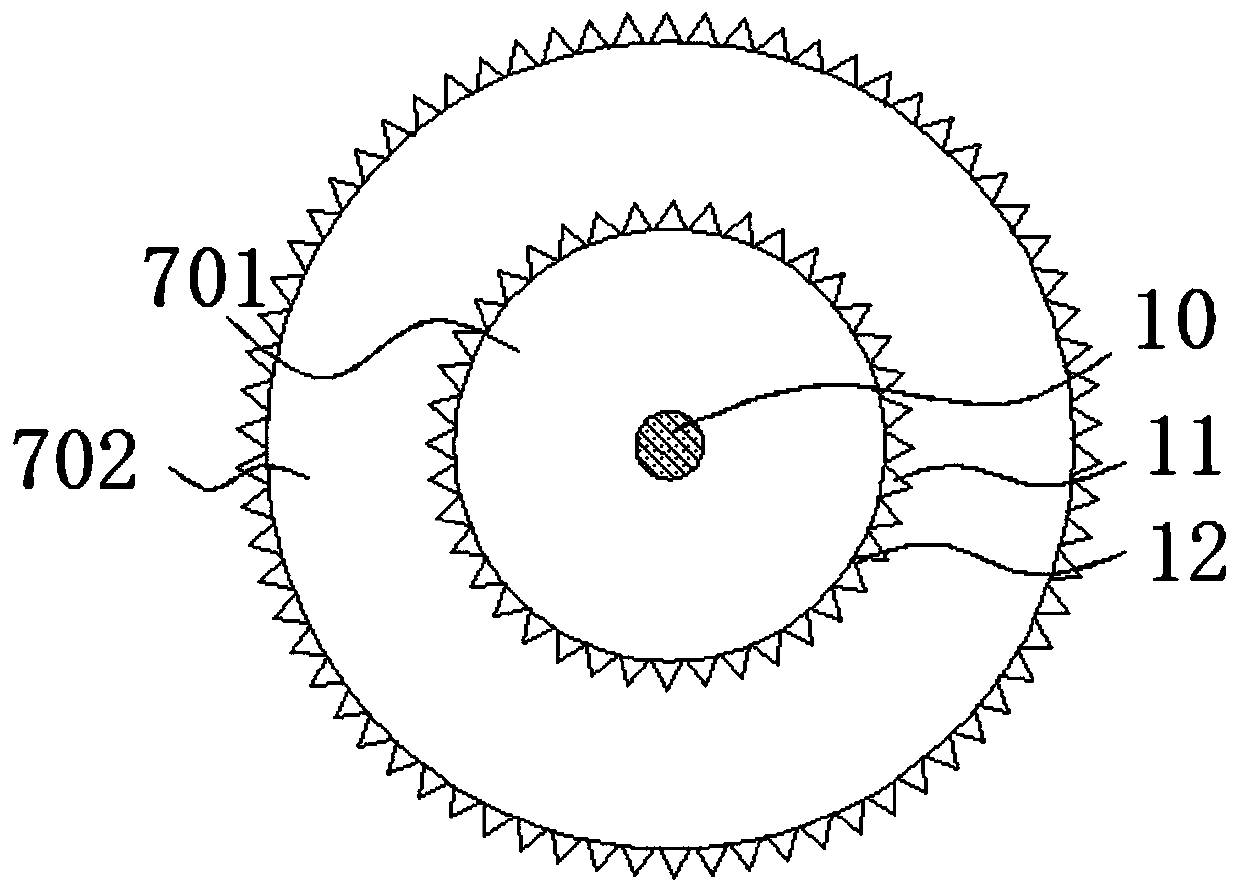

Crankshaft for compressor

ActiveCN111043145AImprove structural strengthSolve bending and twisting deformationCrankshaftsRotary/oscillating piston pump componentsControl theoryMechanical engineering

The invention discloses a crankshaft for a compressor and belongs to the technical field of crankshafts. The crankshaft comprises a short shaft, an eccentric part and a long shaft; the top of the eccentric part is fixedly connected with the short shaft; the bottom of the eccentric part is fixedly connected with the long shaft; the long shaft is formed by hinging a twisting strip A and a twisting strip B; the structural strength of the twisted long shaft is relatively high, large torsional stress can be borne, and the long shaft is not easy to bend, twist, deform or break when a surface generates torsional stress during long-time high-speed rotation; the long shaft is prevented from being bent, twisted, deformed or twisted off due to the long-time high-speed rotation; triangular sawteeth are fixedly connected to outer side walls of the short shaft and the eccentric part; an inverted-triangle-shaped oil groove B are formed between the triangular sawteeth, meanwhile, the integrated oil groove is formed in a surface of the long shaft, the triangular structure strength is high, crankshaft breakage caused by the fact that the oil groove are formed in the surface of the crankshaft to affect the crankshaft structure strength is prevented, the internal part of the crankshaft is connected to a steel wire, and the structure strength is further improved.

Owner:黄石正达工贸有限公司

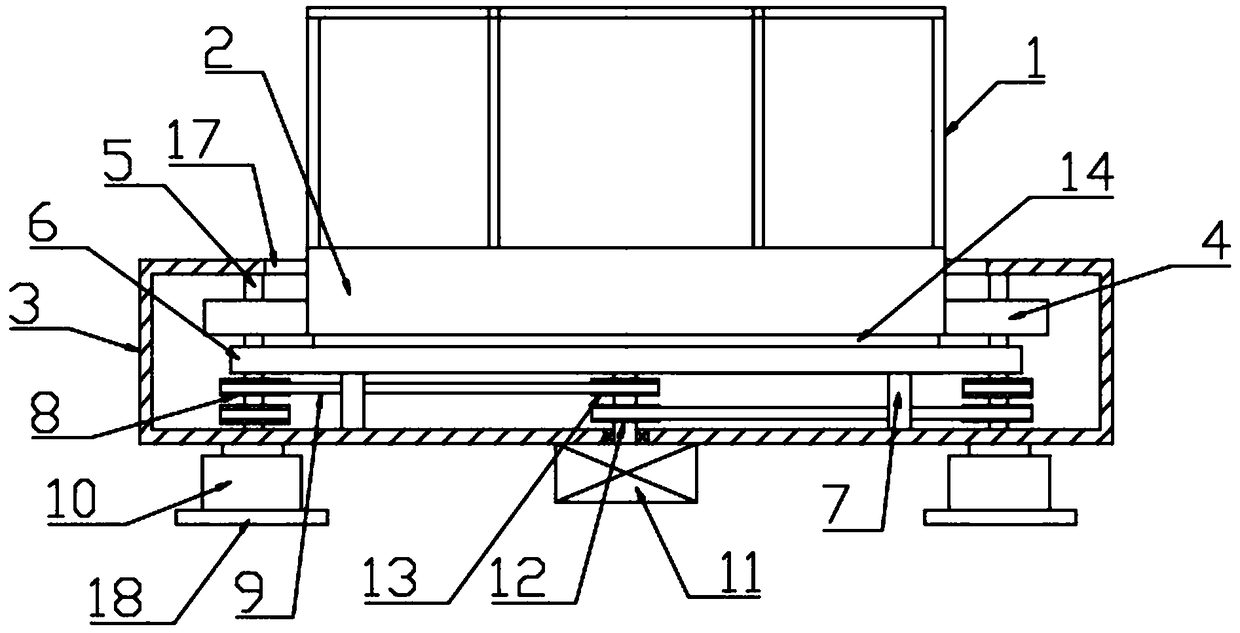

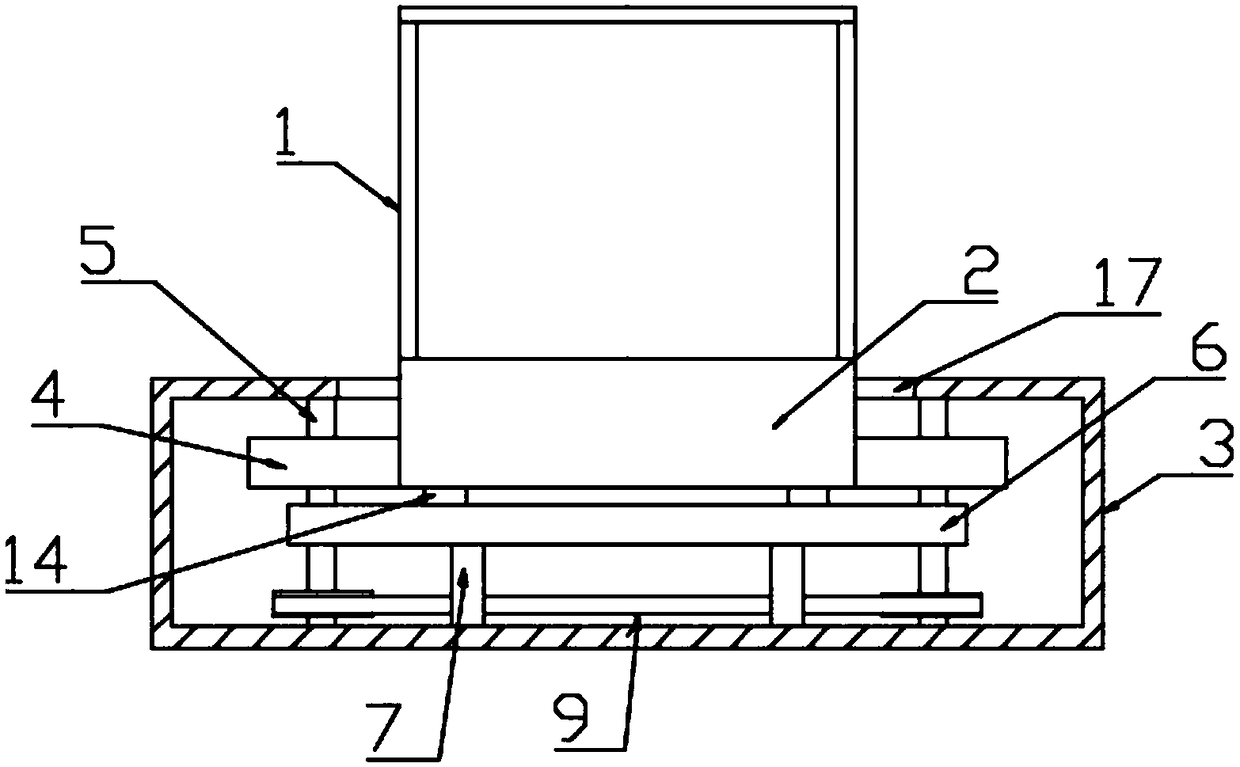

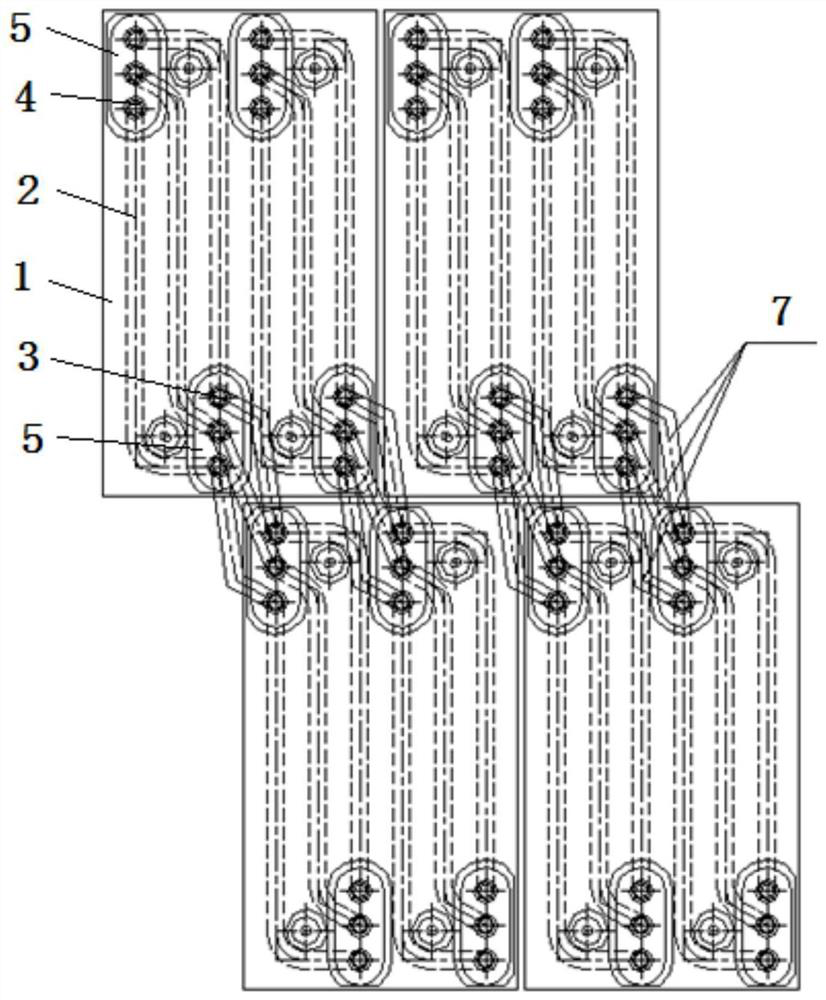

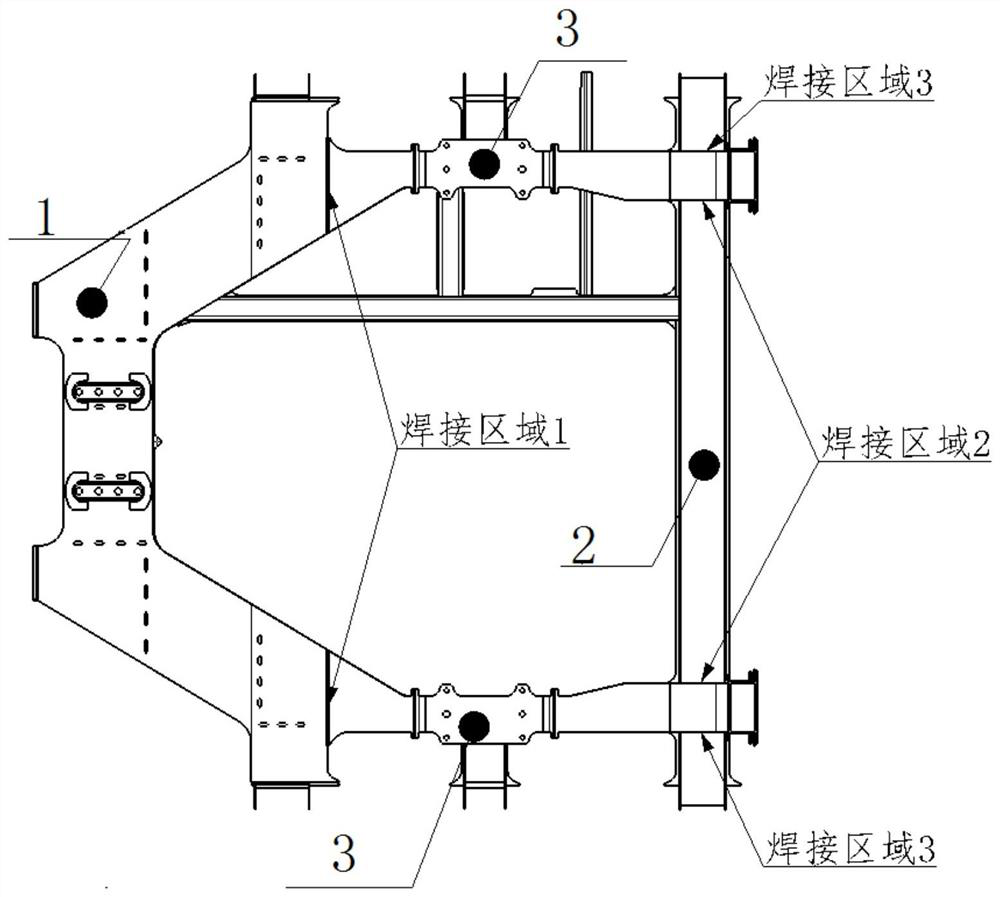

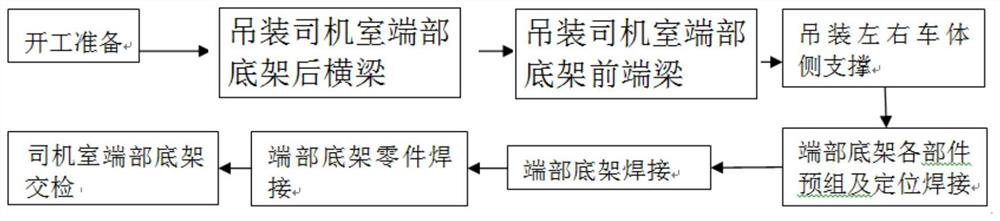

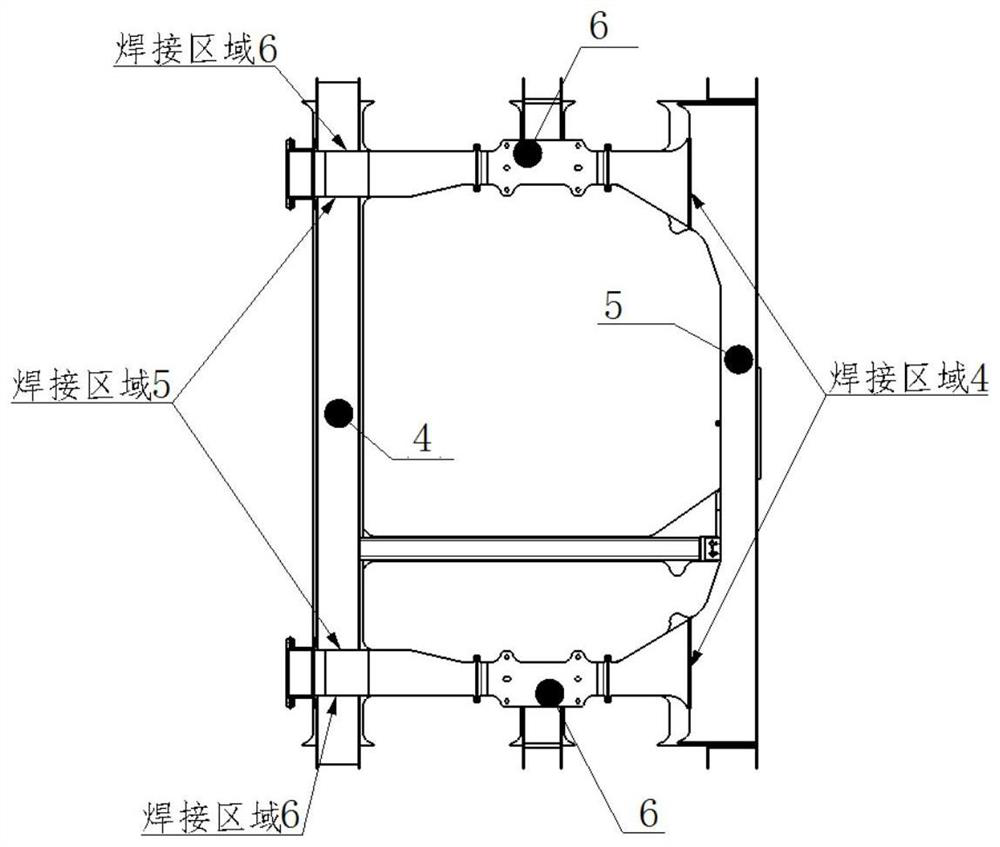

Car body underframe assembly and its welding process

ActiveCN110860770BStructural strength has no effectStructural Strength EffectArc welding apparatusUnderframesWelding processAutomotive engineering

The invention discloses a car body underframe assembly and its welding process. The process adopts a modularized production method to complete the assembly and welding of the driver's cab end underframe and the two-position end underframe respectively, and then hoist the above two The end chassis and the side beams of the chassis on both sides are attached to the base plate to complete the pre-assembly and positioning of the chassis frame; finally, parts are added on the basis of the chassis frame, and the front welding and reverse welding are completed successively to form the vehicle. Body underframe assembly; the welding is all using CMT pulse cold transition process. The present invention adopts a modular process, divides the bottom frame into three large modules, and each large module has different small modules, and carries out blanking, processing and distribution of materials according to the modules. The site is clean and the process is clear, effectively avoiding The phenomenon of wrong installation and missing installation. The invention also discloses a vehicle body underframe assembly.

Owner:安徽雷尔伟交通装备有限公司

A deep and shallow well foundation pit dewatering system for large foundation pits and its dewatering method

ActiveCN111779009BPrevent extractionReduce water flowFoundation engineeringTowing devicesFiltrationPrecipitation

The invention discloses a deep and shallow well foundation pit dewatering system for a large foundation pit and a dewatering method thereof. One end is fixedly connected with a drawbar, and the top of the chassis of the vehicle body close to the building foundation pit is fixedly connected with a first fixed side plate. The present invention can use machinery instead of manual to transport the pumping equipment to the construction site. At the same time, with the help of the expansion and contraction of the jacking cylinder, the pumping depth of the pump can be determined according to the actual depth and water level of the foundation pit, and the filter box provided And the water filter port can effectively prevent the sediment and water in the foundation pit from being pumped out together, reduce the flow of sediment in the foundation pit, and ensure that the structural strength inside the foundation pit is not affected. The whole system is ingeniously designed, simple to operate and easy to use. It is worth promoting and using later.

Owner:襄阳地质工程勘察院有限责任公司

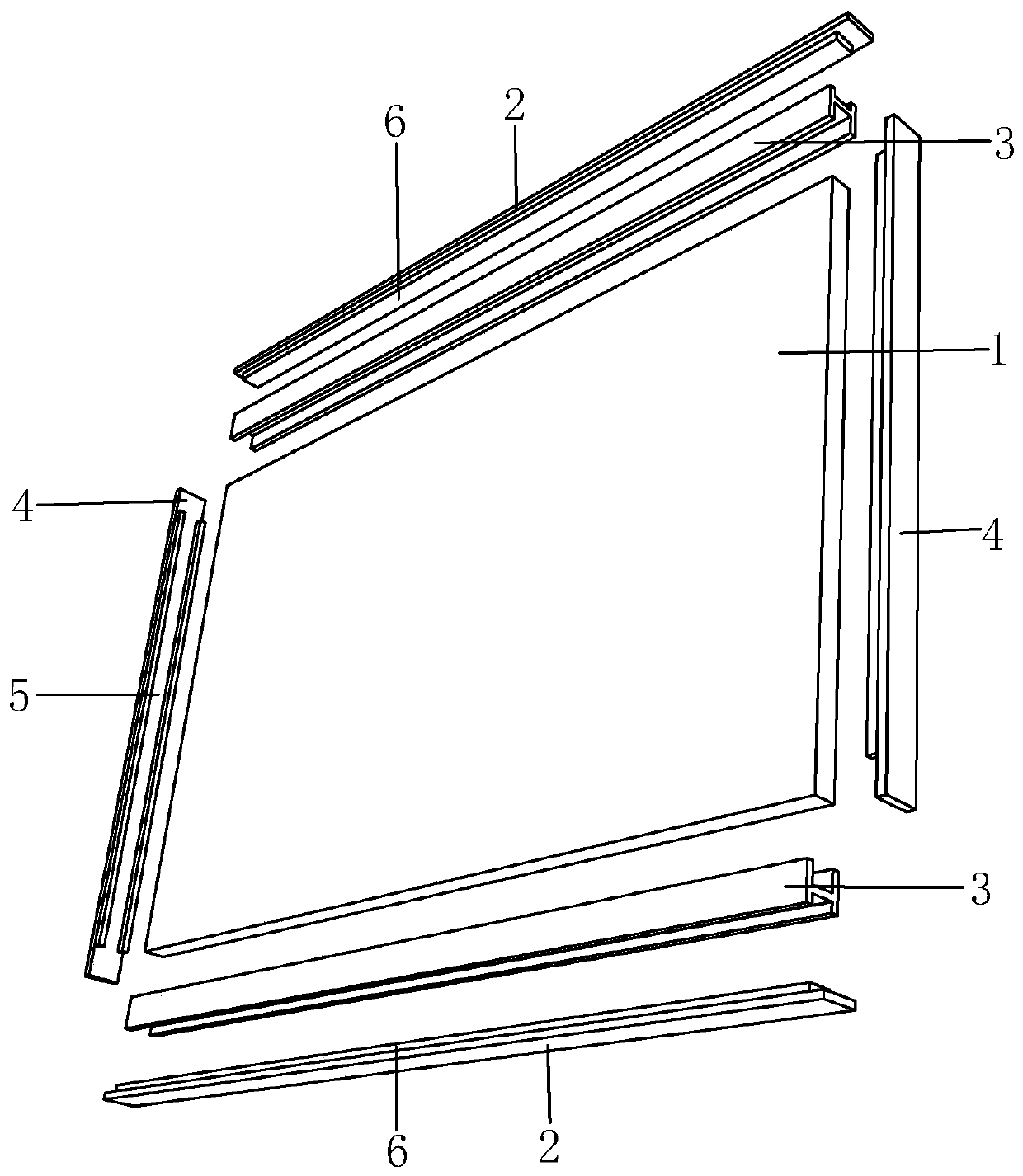

Sound-insulation wooden door and manufacturing method thereof

ActiveCN110374474AGuaranteed connection strengthImprove connection strengthMaterial gluingNoise insulation doors/windowsAdhesiveManufacturing engineering

The invention discloses a sound-insulation wooden door and a manufacturing method thereof. The wooden door comprises a core veneer, wherein edge covering structures are arranged on the four peripheraledges of the core veneer; and adhesives are coated on the connecting parts of the edge covering structures and the core veneer. The manufacturing method comprises the following steps of (a) assembling the core veneer; (b) adjusting; (c) covering the edges; and (d) installing a decoration panel. According to the sound-insulation wooden door and the manufacturing method thereof provided by the invention, the wooden door is novel in structure, high in attractiveness, reliable in connection, practical and safe; and the manufacturing method is simple in process from large to small step by step inorder, convenient for site operation, low in difficulty, low in labor intensity, flexible to adjust, and capable of effectively ensuring the product quality.

Owner:浙江图森定制家居股份有限公司

A method for preparing an alloy part of a bending machine arm

The invention provides a bending machine arm alloy component and a preparation method thereof. The bending machine arm alloy component is prepared from, by weight, 2.3-2.6% of C, 0.4-0.7% of Si, 1.1-1.7% of Mn, 0.9-1.2% of Ni, 2.2-2.7% of Cr, 0.5-0.7% of Mu, 1.1-1.7% of Ti, 0.2-0.4% of Be, 0.4-0.7% of rare earth, 0.8-1.1% of Al, 0.6-0.9% of Nb and the balance Fe and impurities which cannot be removed. By means of the various elements such as Ni, Cr and Ti added into the raw materials, the structural strength of a mechanical arm can be increased, and the wear resistance of the mechanical arm can also be enhanced. In addition, in the preparation method, the effect that structural strength is not broken or damaged can be effectively achieved, and the method is applicable to industrial production and machining and can be further applied and popularized.

Owner:HEXIAN LONGSHENG PRECISION MACHINERY CO LTD

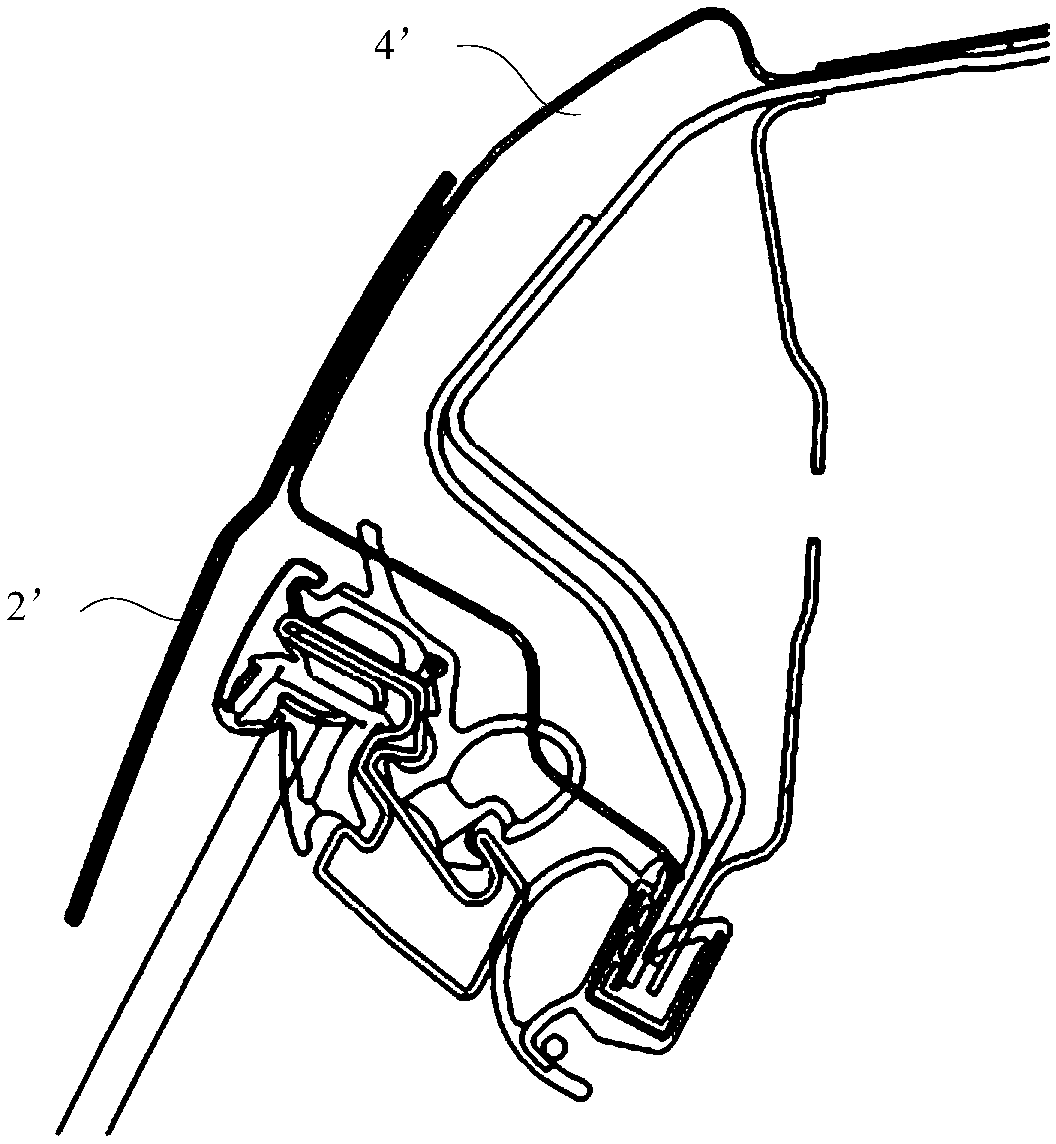

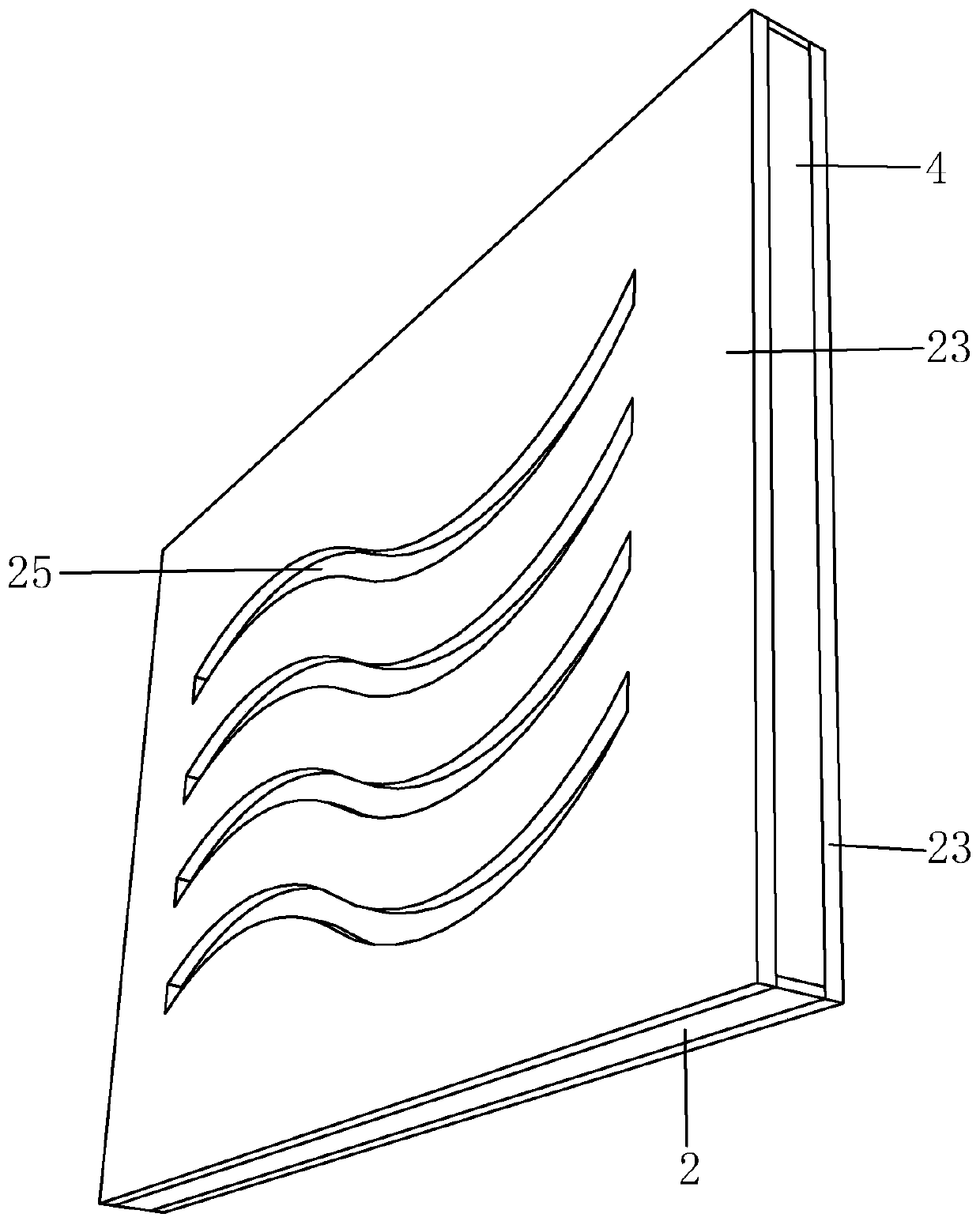

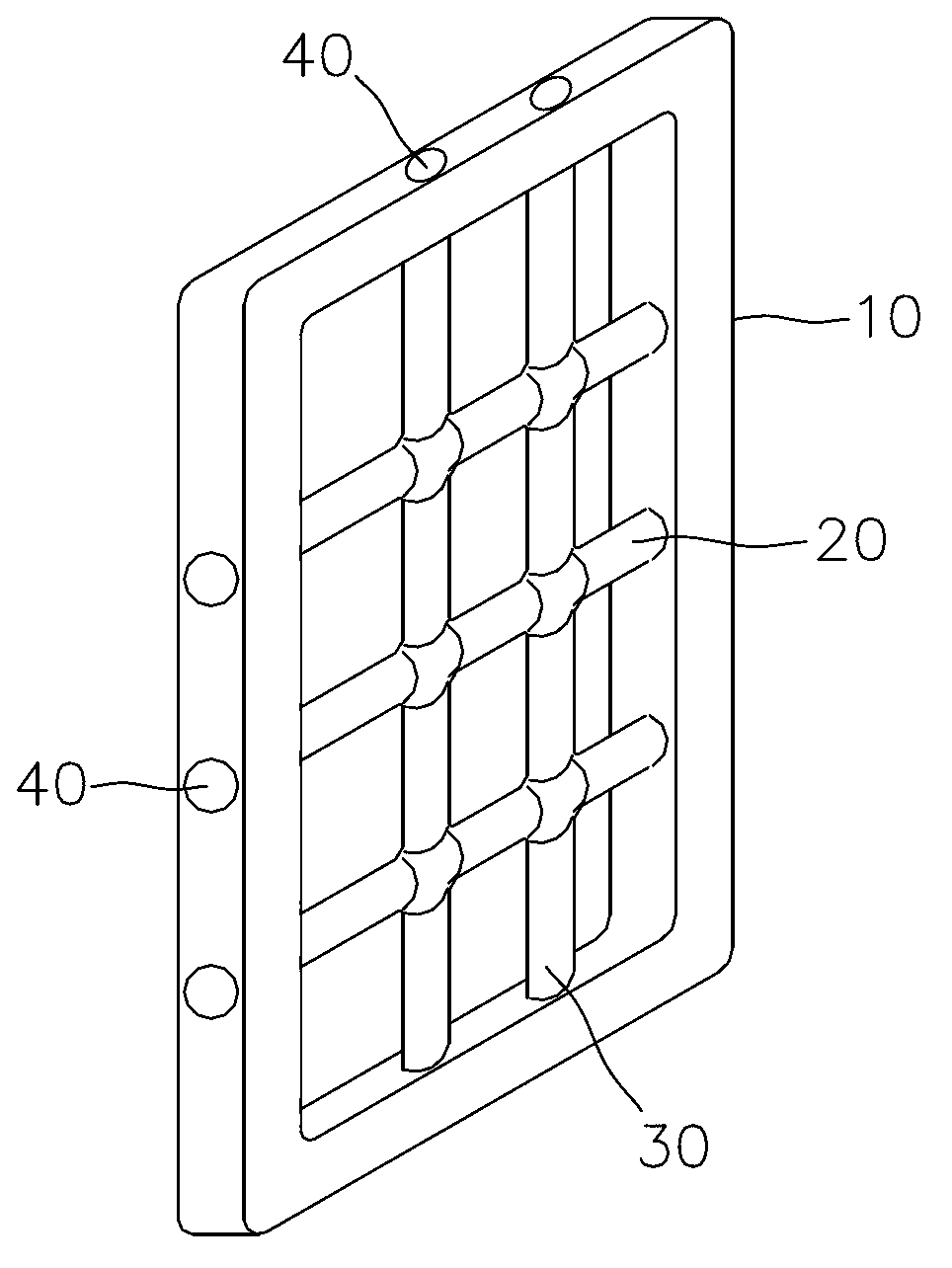

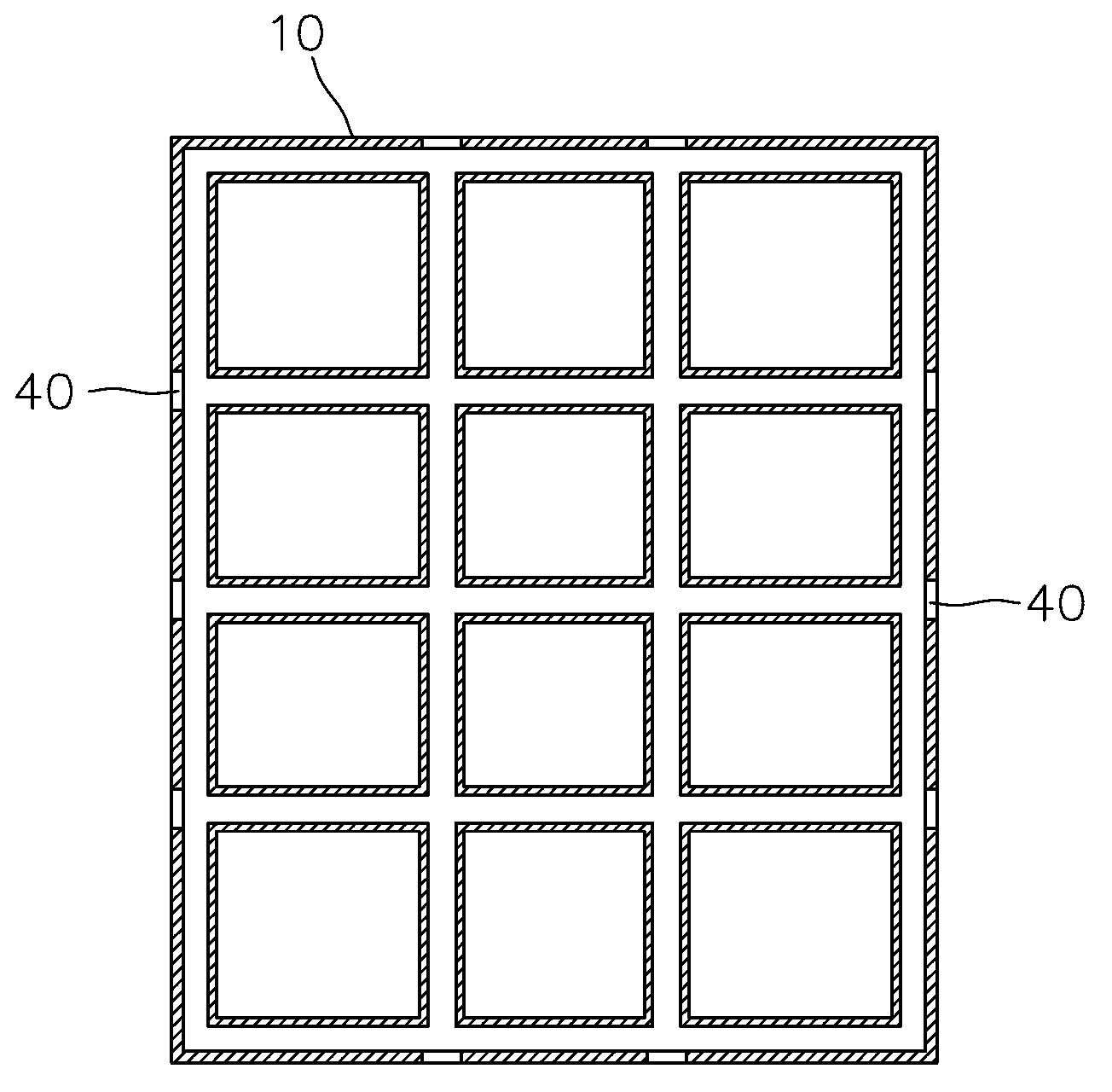

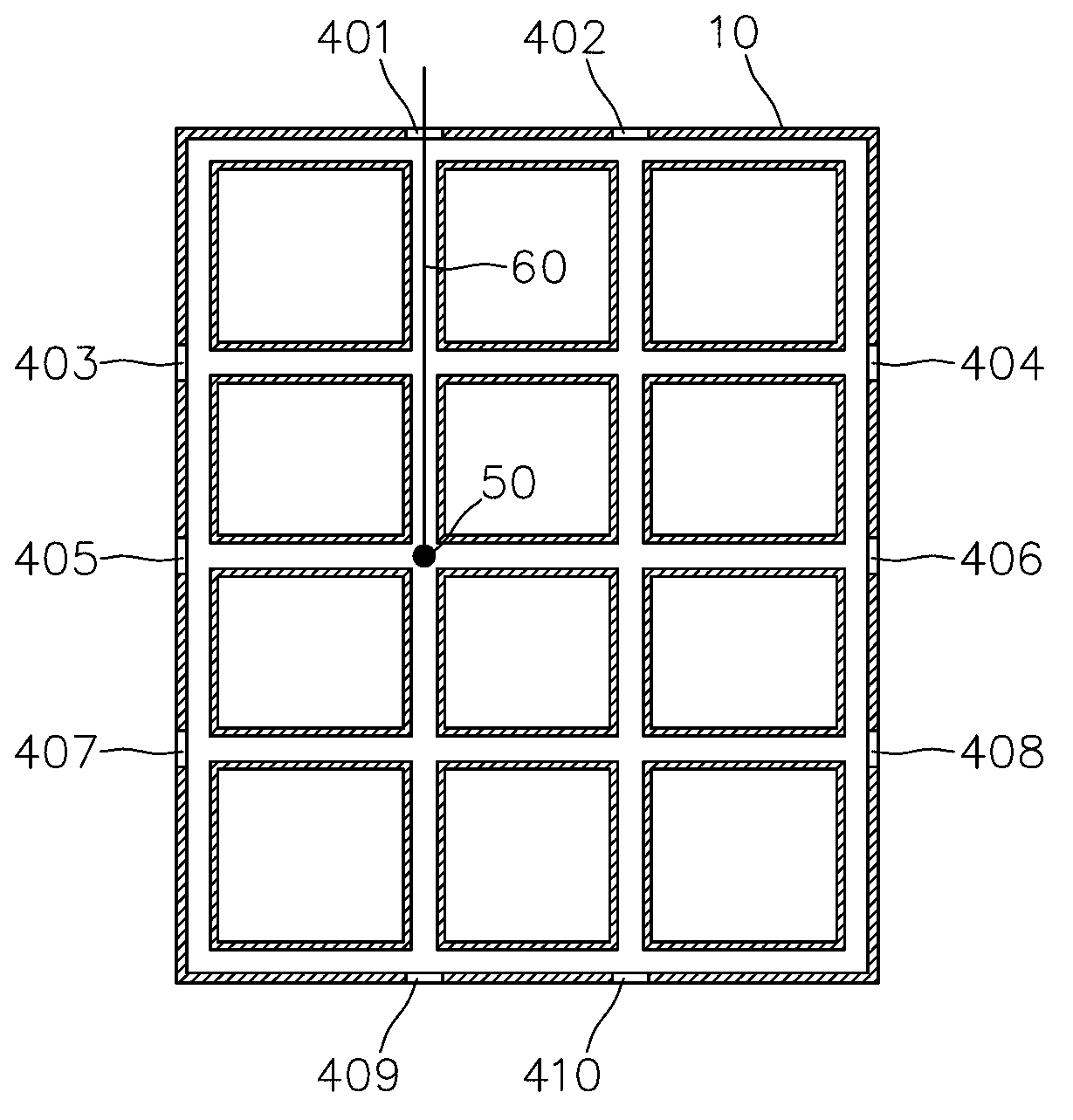

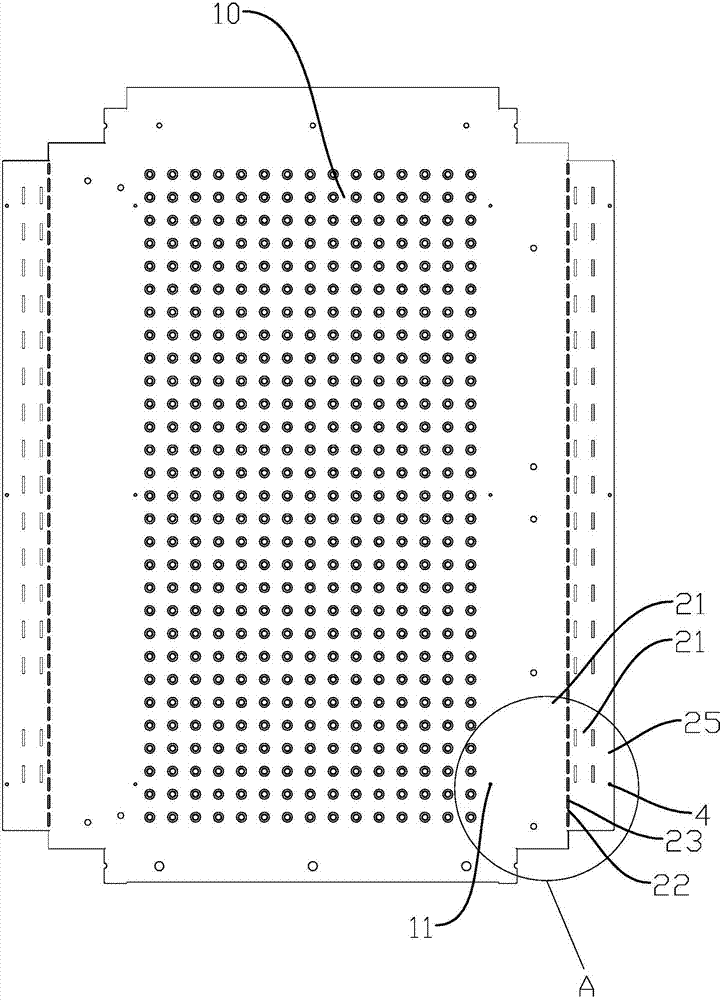

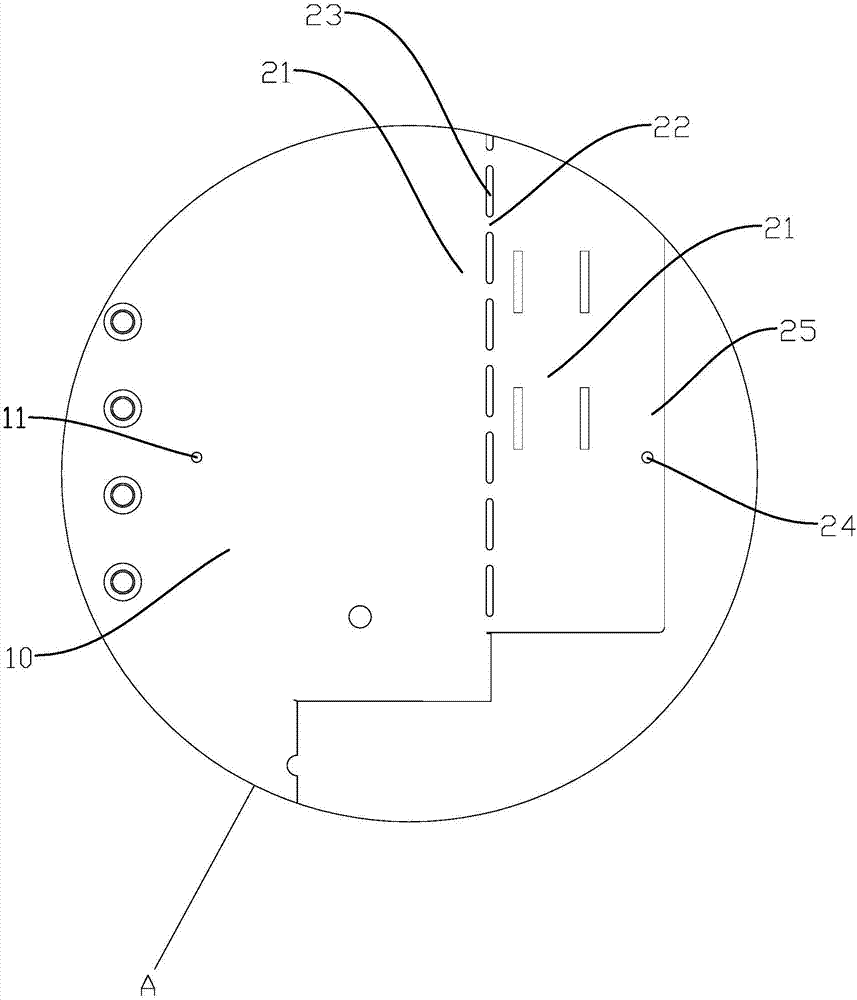

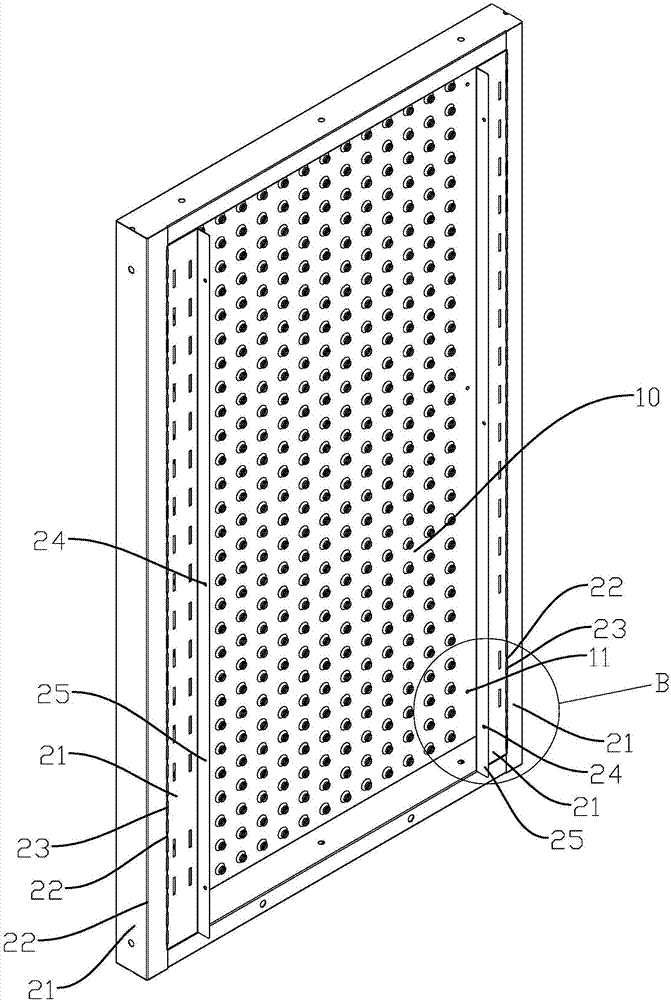

Threading method for distributed resistance network anti-theft window

ActiveCN102839902AGuaranteed WiringQuick installationFixed grillesBurglar alarm by disturbance/breaking stretched cords/wiresElectrical resistance and conductanceVertical bar

The invention relates to the field of family security protection, in particular to a threading method for a distributed resistance network anti-theft window. The method comprises the following steps of firstly, arranging openings at the intersecting part of a window frame and a horizontal bar as well as the intersecting part of the window frame and a vertical bar; the openings are communicated with an inner cavity of the anti-theft window; then, taking any one opening on the window frame as an entrance, falling a guide object connected with a line into the inner cavity of the anti-theft window from the entrance; overturning and inclining the anti-theft window for enabling the guide object to move in the inner cavity of the anti-theft window, so that the line is distributed in the inner cavity of the anti-theft window according to pre-set requirement; and finally, taking any one opening as the exit, so that the guide object guides the line to extend to the outer side of the anti-theft window from the exit, thereby finishing the threading process. The threading method is rapid in assembling, guarantees the inner cavity of the anti-theft window to be distributed according to a set requirement and greatly reduces the assembling difficulty; and meanwhile, the threading method has no damage to the integral structure of the anti-theft window and prevents the structure intensity of the anti-theft window from being affected.

Owner:安徽科蓝智能技术有限公司

Method for manufacturing closed flanged metal plate

InactiveCN107008779AReduce structural strengthStructural Strength EffectEngineeringUltimate tensile strength

The invention discloses a method for manufacturing a closed flanged metal plate. The method is used for bending the part to be bent on the metal plate into a closed tubular bending part. The bending part comprises a plurality of flanged plates which are formed by bending the plate along a plurality of fold lines, and the section of the bending part is a polygon. The method comprises the steps: step I, drilling a plurality of through holes along at least one fold line on the part to be bent on the metal plate; step II, bending the part to be bent by bending equipment, and thus the flanged plates on the two sides of the fold line without through holes are bent to a preset angle along the fold line between the two flanged plates; step III, bending the part to be bent by hand, and thus the flanged plates on the two sides of the fold line with the through holes are bent to the preset angle along the fold line between the two flanged plates. The method can be effective and convenient to process and manufacture, cannot have much impact on the structural strength of the closed flanged metal plate, and can effectively ensure the product quality and the neat appearance.

Owner:TRANTEX PROD CO LTD

A high-strength connection structure and segmented wind turbine blades

ActiveCN113339190BAvoid punchingStructural strength does not affectMachines/enginesWind energy generationTurbine bladeClassical mechanics

The present invention relates to the technical field of wind power blades, in particular to a high-strength connection structure and segmented wind power blades, including: a first segment and a second segment arranged along the length direction of the wind power blade, the first segment and the second segment The segment includes: a first mating surface extending to the inside of the wind turbine blade, the first mating surface is perpendicular to the length direction of the wind turbine blade; a second mating surface is offset from the first mating surface, and the second mating surface is closer to the first mating surface relative to the first mating surface. The direction of the segment is misaligned; the connection surface, the connection surface connects the first mating surface and the second mating surface; the connecting bolt, the connecting bolt is located in the wind turbine blade, and passes through the two first mating surfaces, and the first segment and the second segment The section is fixed, and the connecting bolts are parallel to the length direction of the wind turbine blade; wherein, an anti-flange structure is provided between the first segment and the second segment, and the anti-flange structure restricts the second segment from flanging to the outside of the wind turbine blade. In the present invention, the connection strength and sealing performance are ensured, and the service life of the wind power blades is increased.

Owner:CHANGZHOU HONGFA ZONGHENG ADVANCED MATERIAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com