Patents

Literature

50results about How to "Guaranteed thinner" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

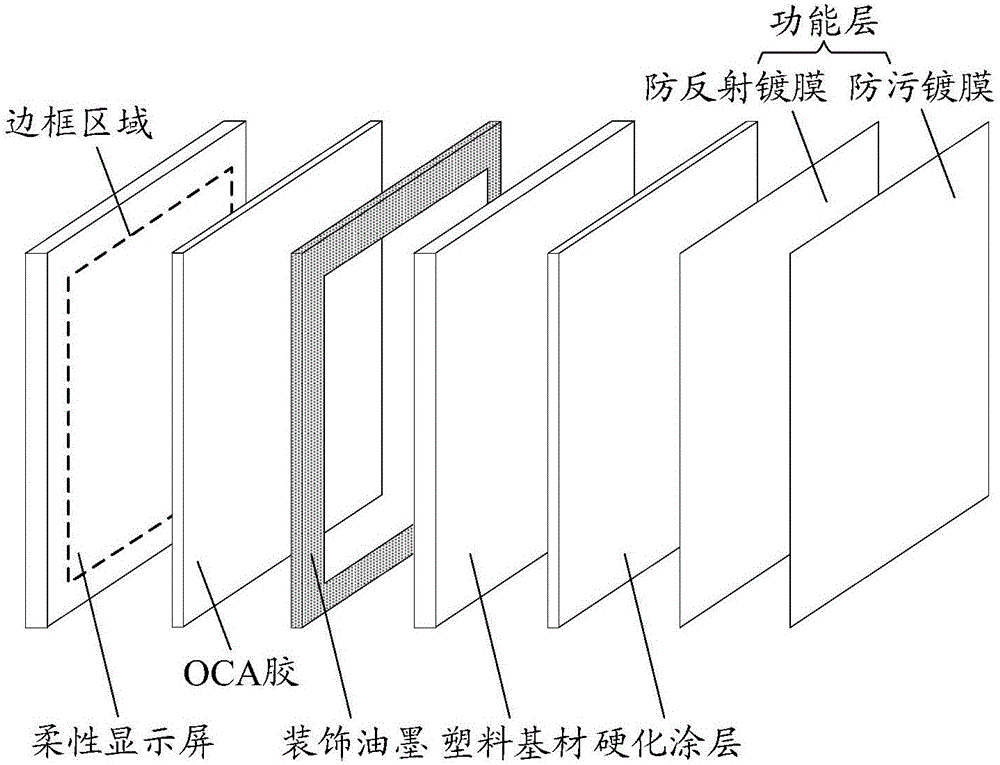

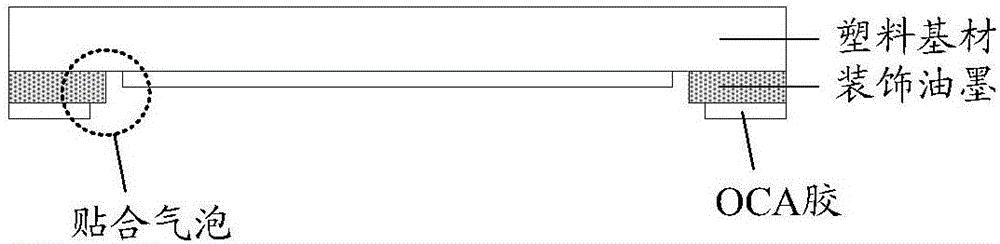

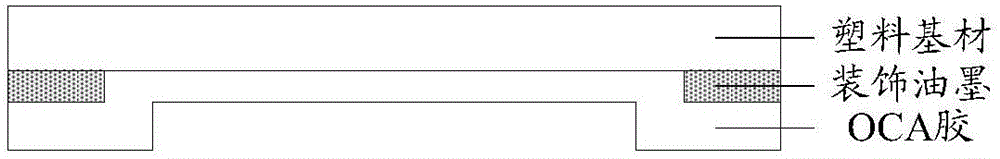

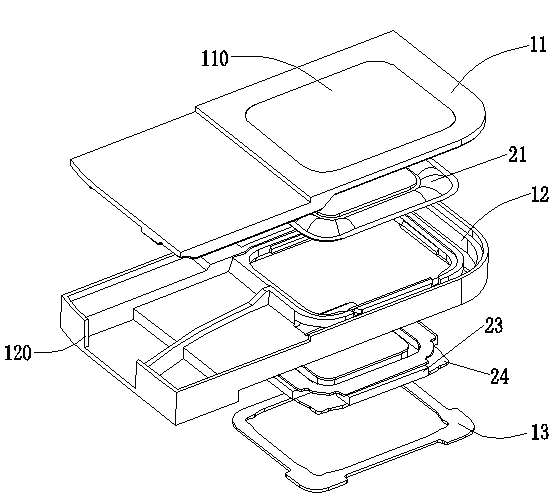

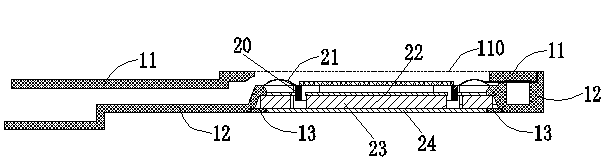

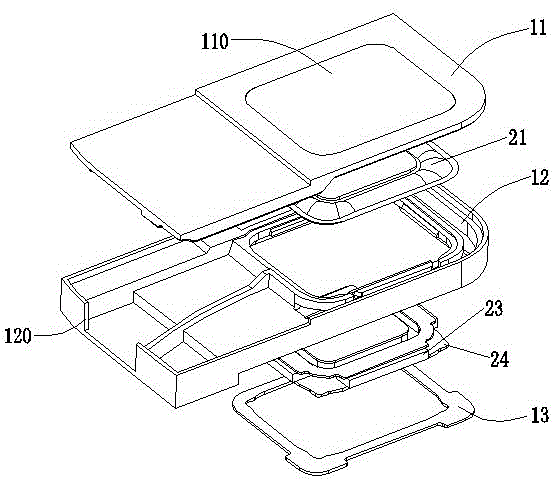

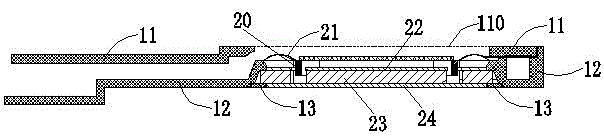

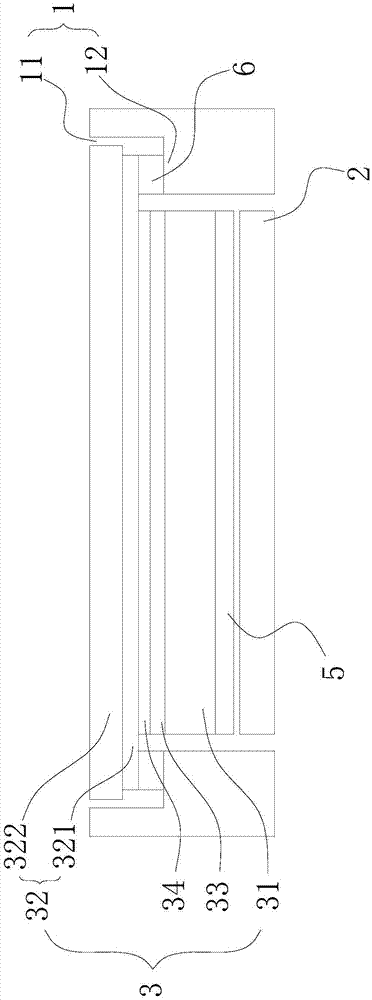

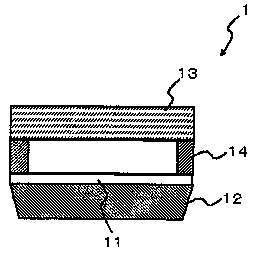

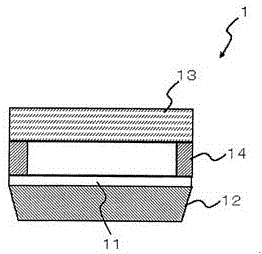

Mother board and its production method, cover board and its production method, and display device

InactiveCN106782094AGuaranteed thinnerNon-linear opticsIdentification meansDisplay deviceEngineering

An embodiment of the invention provides a mother board and its production method, a cover board and its production method, and a display device, relates to the technical field of displaying, and solves the problem that bubbles occur to a glue layer in the upper surface of the cover board due to gaps in the decorative ink edge. The cover board may be attached to a display panel through a thin glue layer so that total thickness of a display module is increased. The production method of the mother board comprises: forming an ink pattern layer on a substrate baseplate, wherein the ink pattern layer includes a plurality of hollowed-out areas; forming hardening liquid covering the ink pattern layer on the substrate base plate by means of coating; curing the hardening liquid to form a hardened layer covering the ink pattern layer. The production method is used for producing a mother board comprising the cover board.

Owner:BOE TECH GRP CO LTD

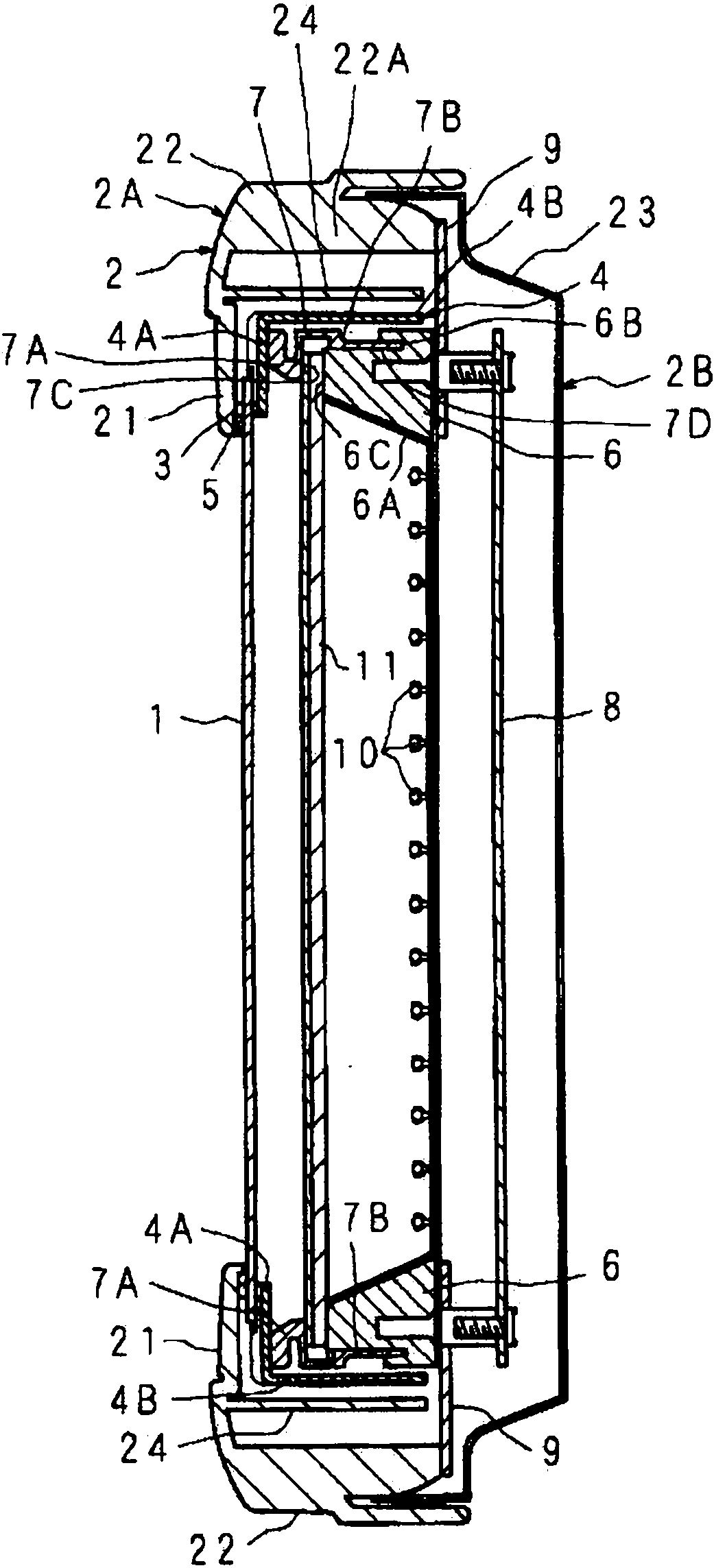

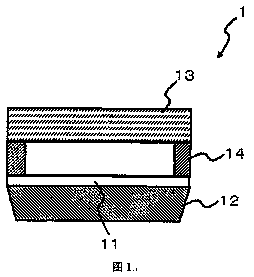

Display device

InactiveCN101842826AImprove rigidityImprove retentionNon-linear opticsIdentification meansDisplay deviceMechanical engineering

Owner:SHARP KK

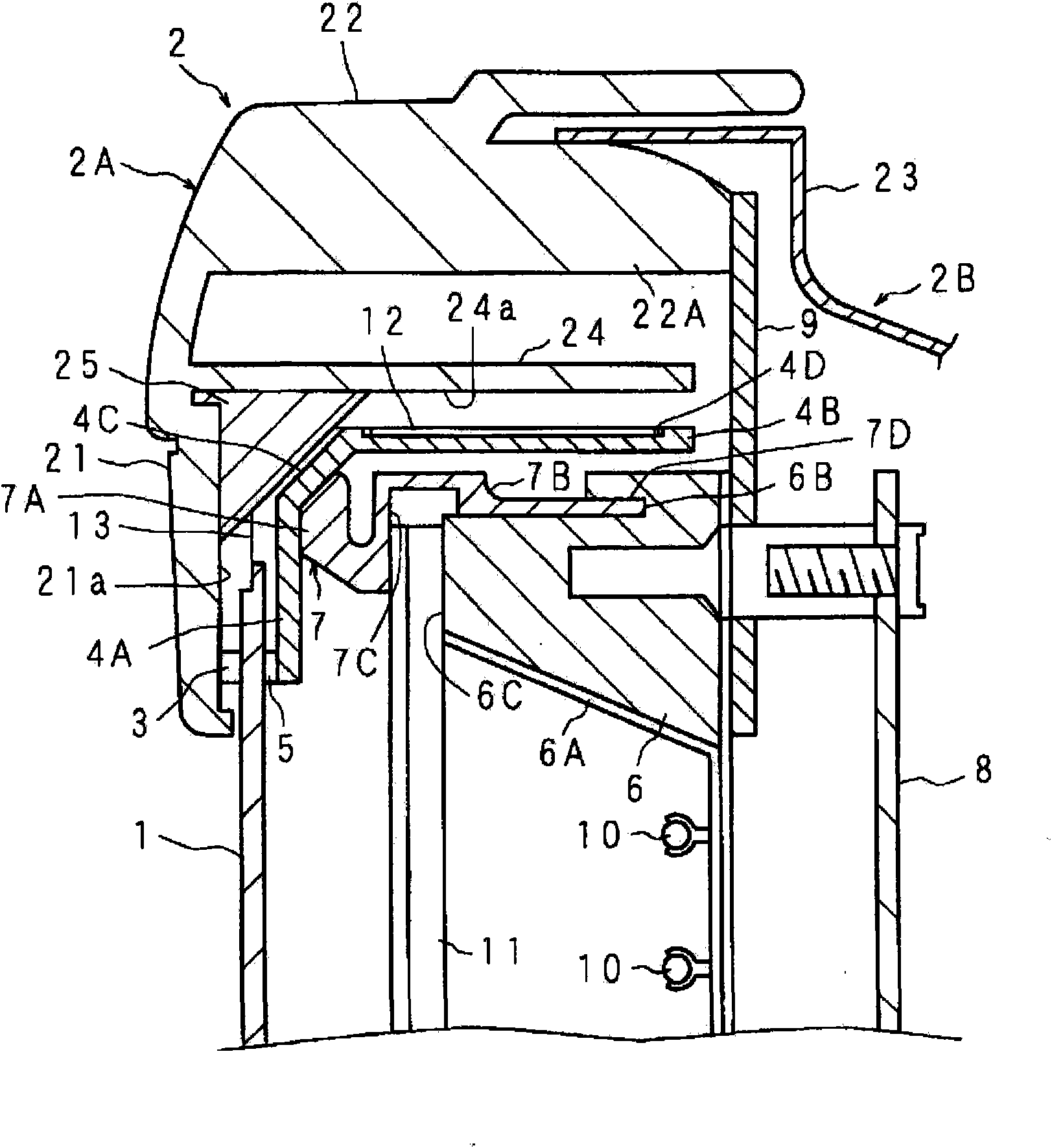

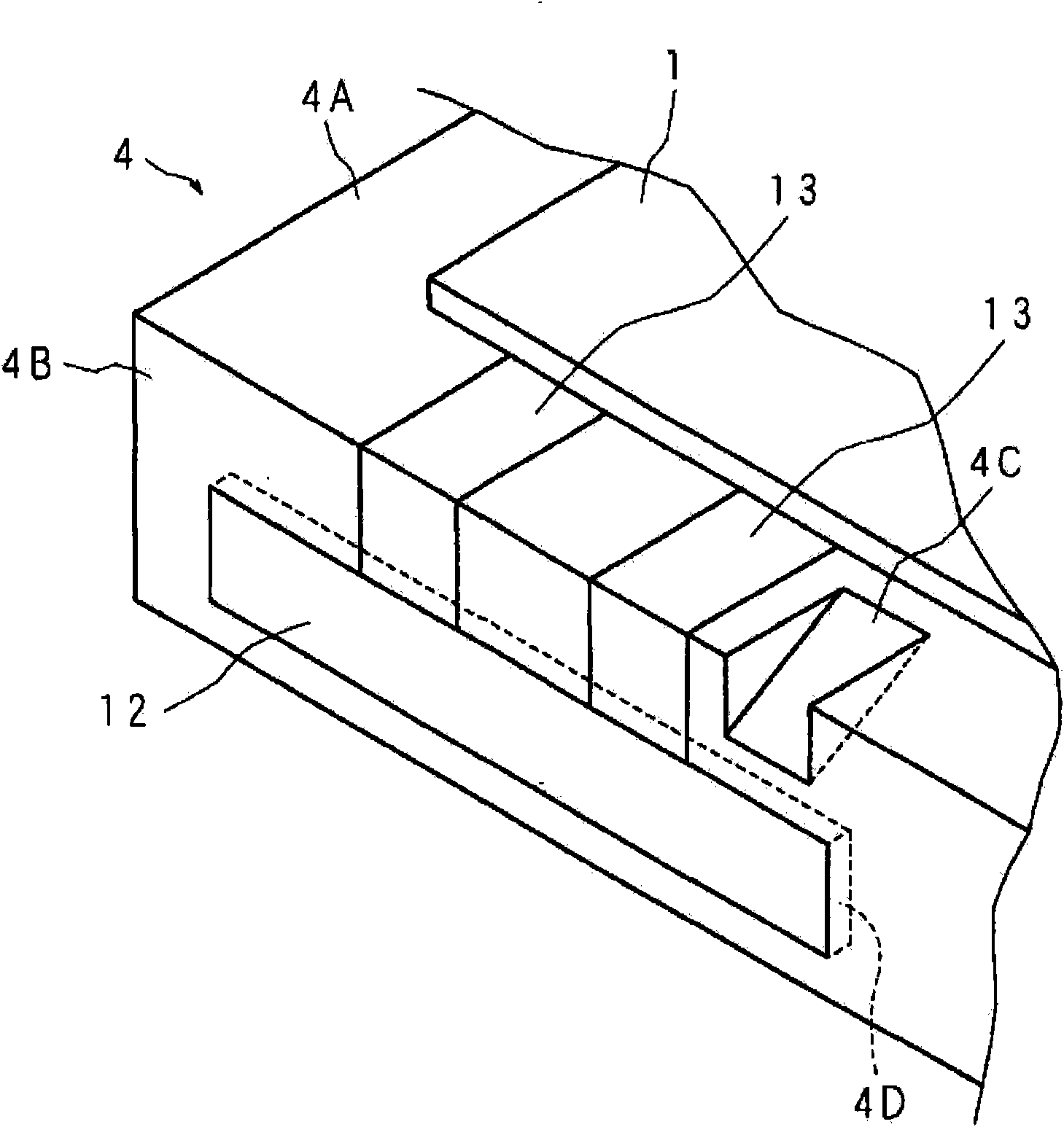

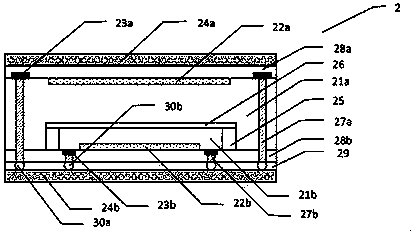

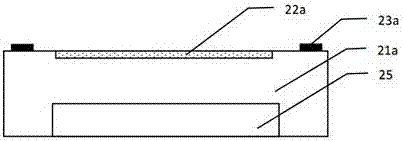

Speaker module and electronic device using the same

ActiveCN103108269AGuaranteed thinnerGuaranteed acoustic performanceFrequency/directions obtaining arrangementsEngineeringLoudspeaker

Owner:GOERTEK INC

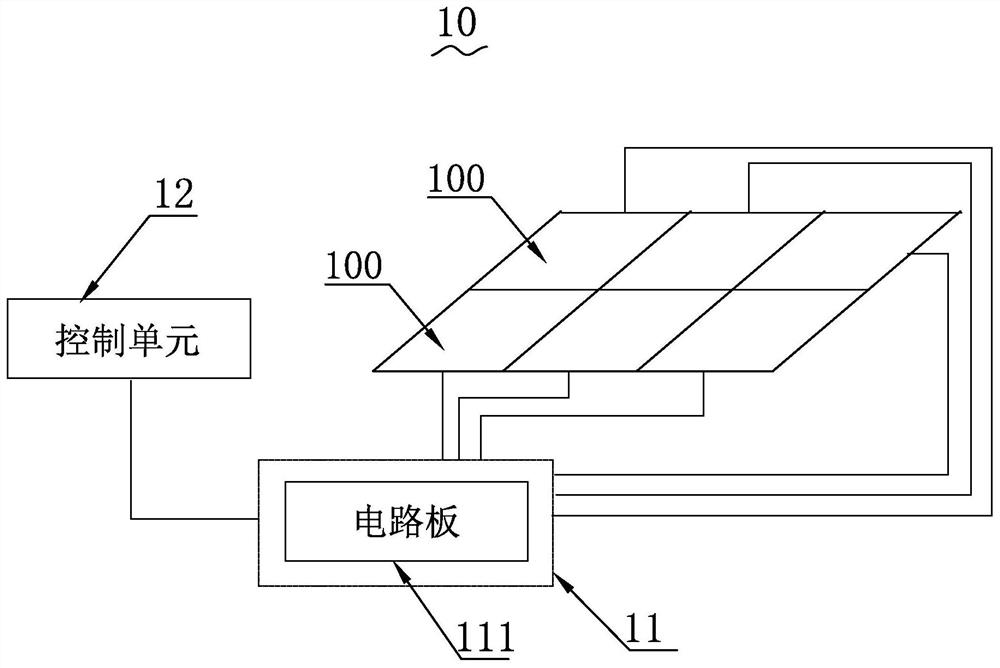

Backlight source, display panel and display device

InactiveCN105093684AImprove antistatic performanceReduce thicknessNon-linear opticsAdhesiveDisplay device

The invention provides a backlight source, a display panel and a display device. A ground lead is arranged on a flexible printed circuit board (FPC) of the backlight source, a reflective sheet is arranged to be a conductive reflective sheet, static electricity of the conductive reflective sheet is conducted to the ground lead through conductive adhesives, the static electricity is conducted out through the ground lead, therefore, the anti-static electricity capacity of the backlight source is improved, failure is prevented from being caused due to the fact that the backlight source is damaged by the static electricity, and the static electricity is prevented from damaging the display panel. In addition, a metal backboard is omitted, therefore, the thickness of the backlight source is reduced, and lightening and thinning of the backlight source can be guaranteed. The display panel and the display device manufactured by the backlight source also can have the good anti-static electricity capacity while lightening and thinning are guaranteed.

Owner:BOE TECH GRP CO LTD +1

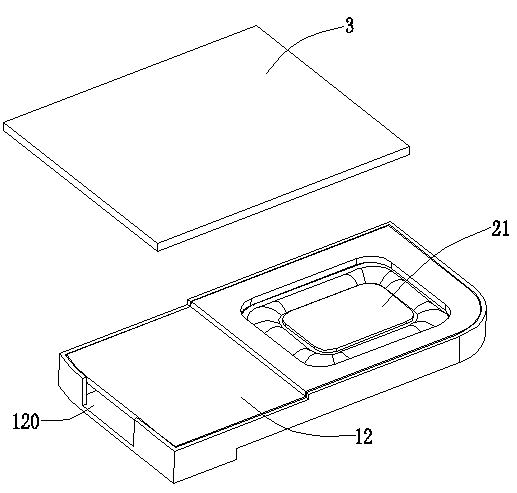

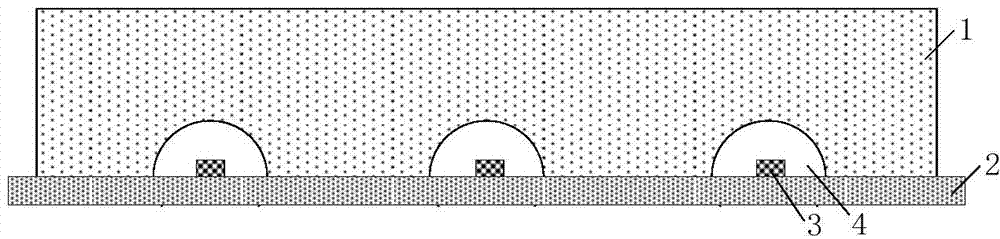

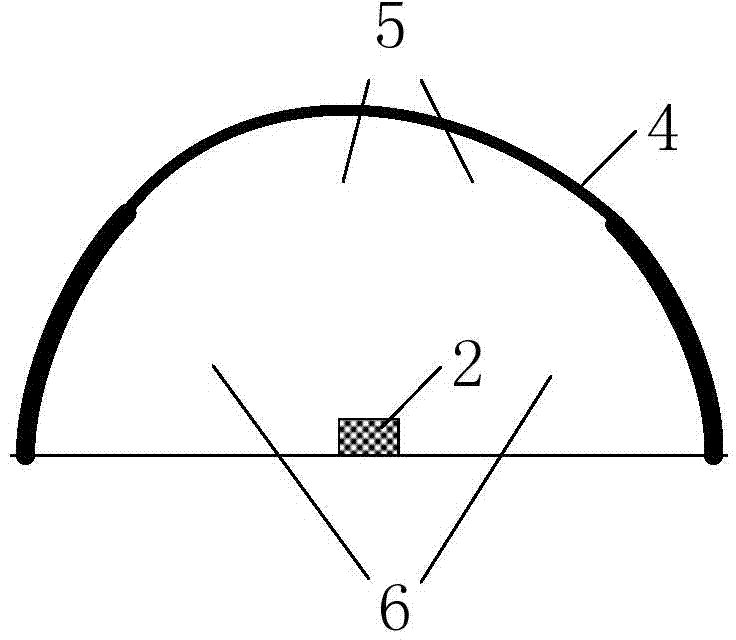

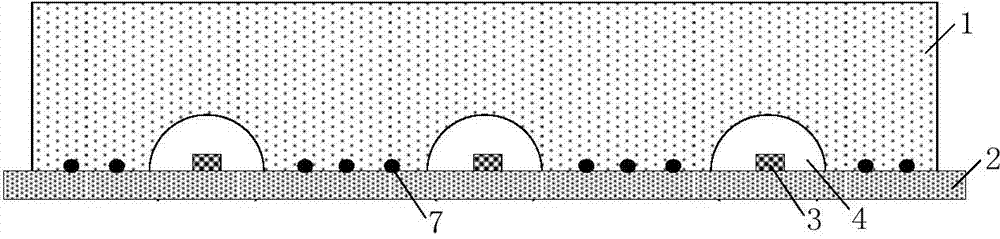

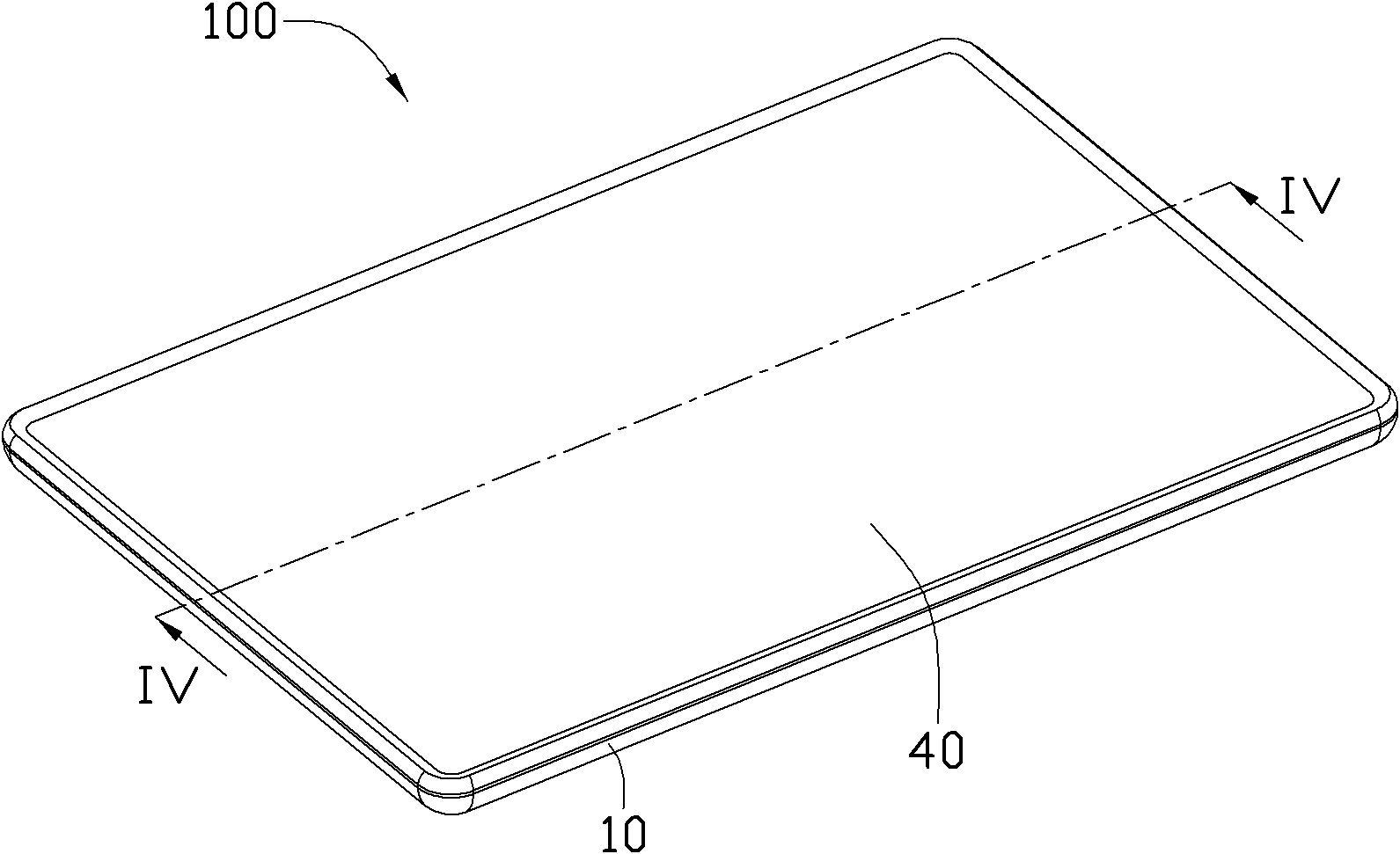

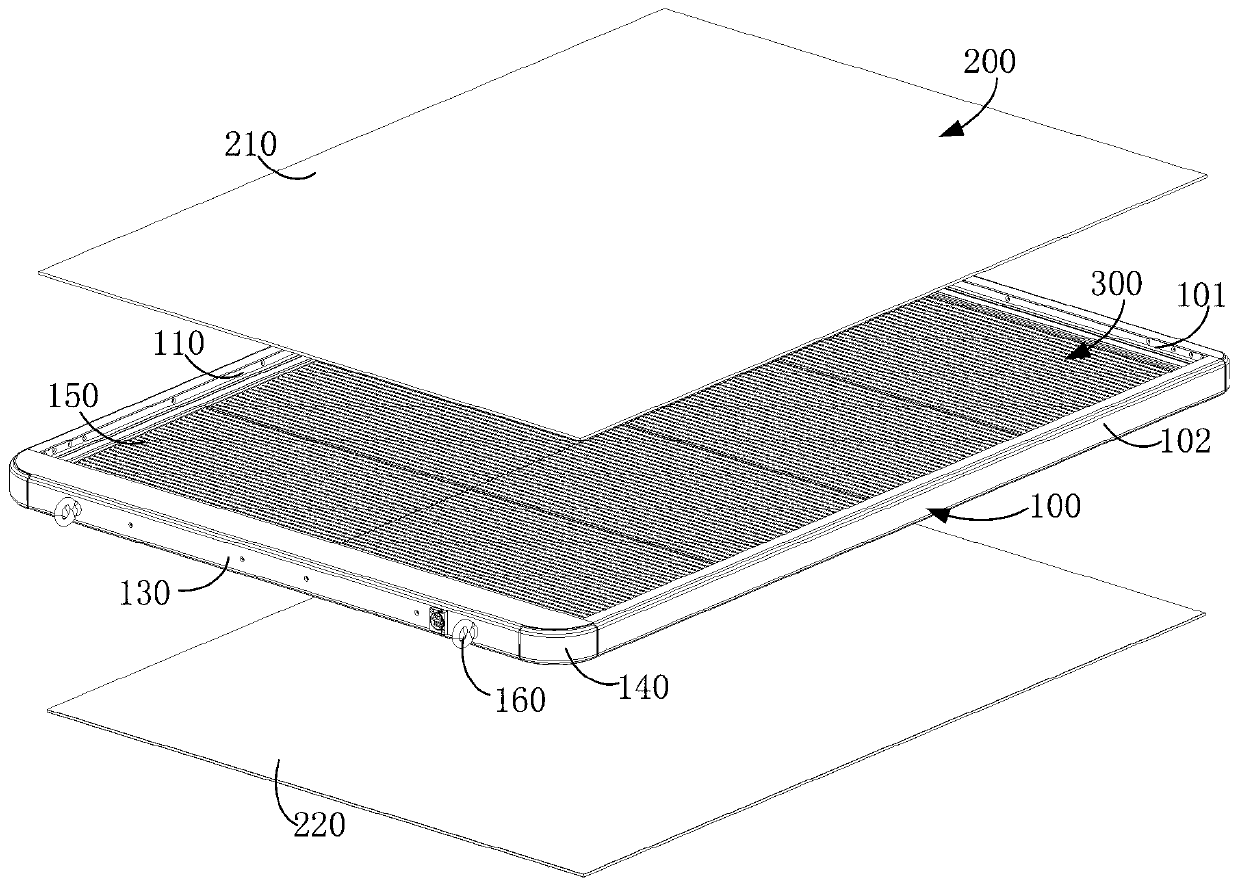

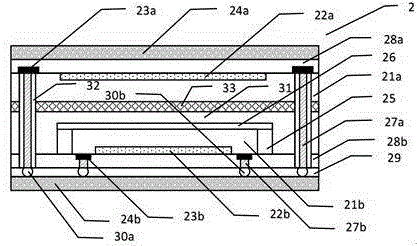

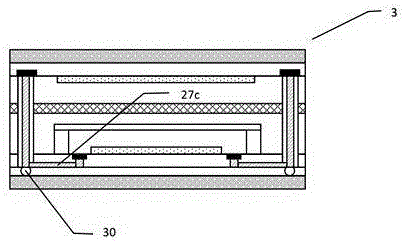

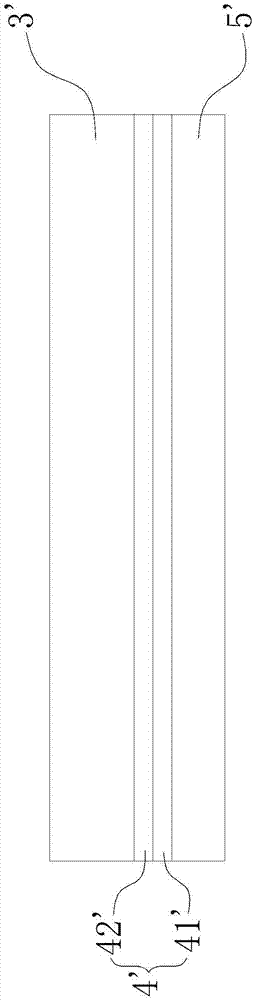

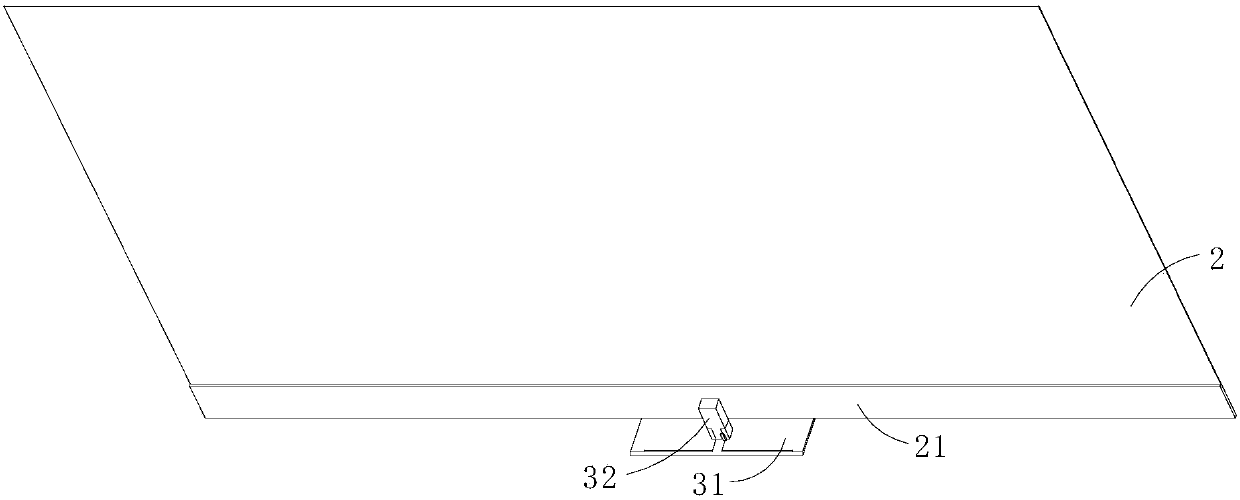

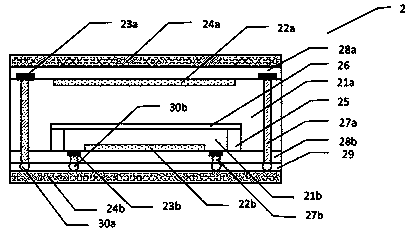

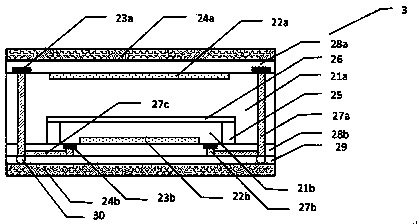

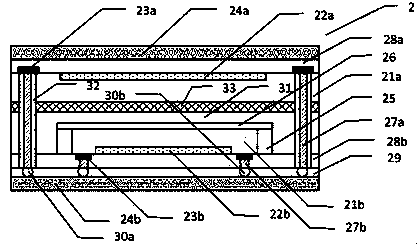

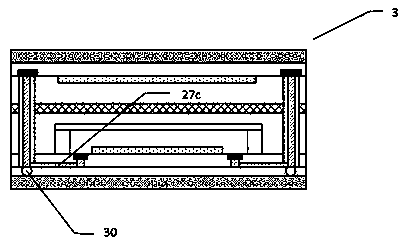

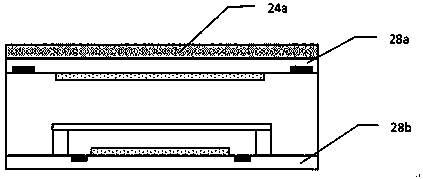

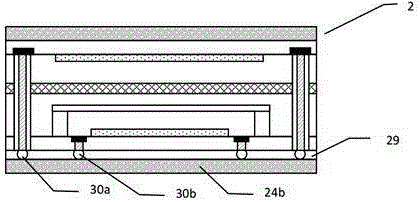

Backlight module and display device including same

InactiveCN104295997AGuaranteed thinnerMechanical apparatusLight guides for lighting systemsLight guideDisplay device

The invention provides a backlight module and a display device. The backlight module comprises a light guide plate, a back plate and at least one light-emitting element. A plurality of grooves are formed in the face, attached to the back plate, of the light guide plate, fluorescent powder is arranged on the surfaces of the grooves, and the fluorescent powder can generate white light after being excited by the light-emitting elements. The light-emitting elements are arranged on the back plate and are placed in the grooves of the light guide plate. According to the backlight module and the display device, the light guide plate is introduced in the downright light-emitting element arrangement mode, the light-emitting elements are arranged in the grooves of the light guide plate, the backlight module can guarantee the thinness of the display device and is also suitable for the narrow bezel design, and high application value is achieved.

Owner:BEIJING BOE VISION ELECTRONICS TECH +1

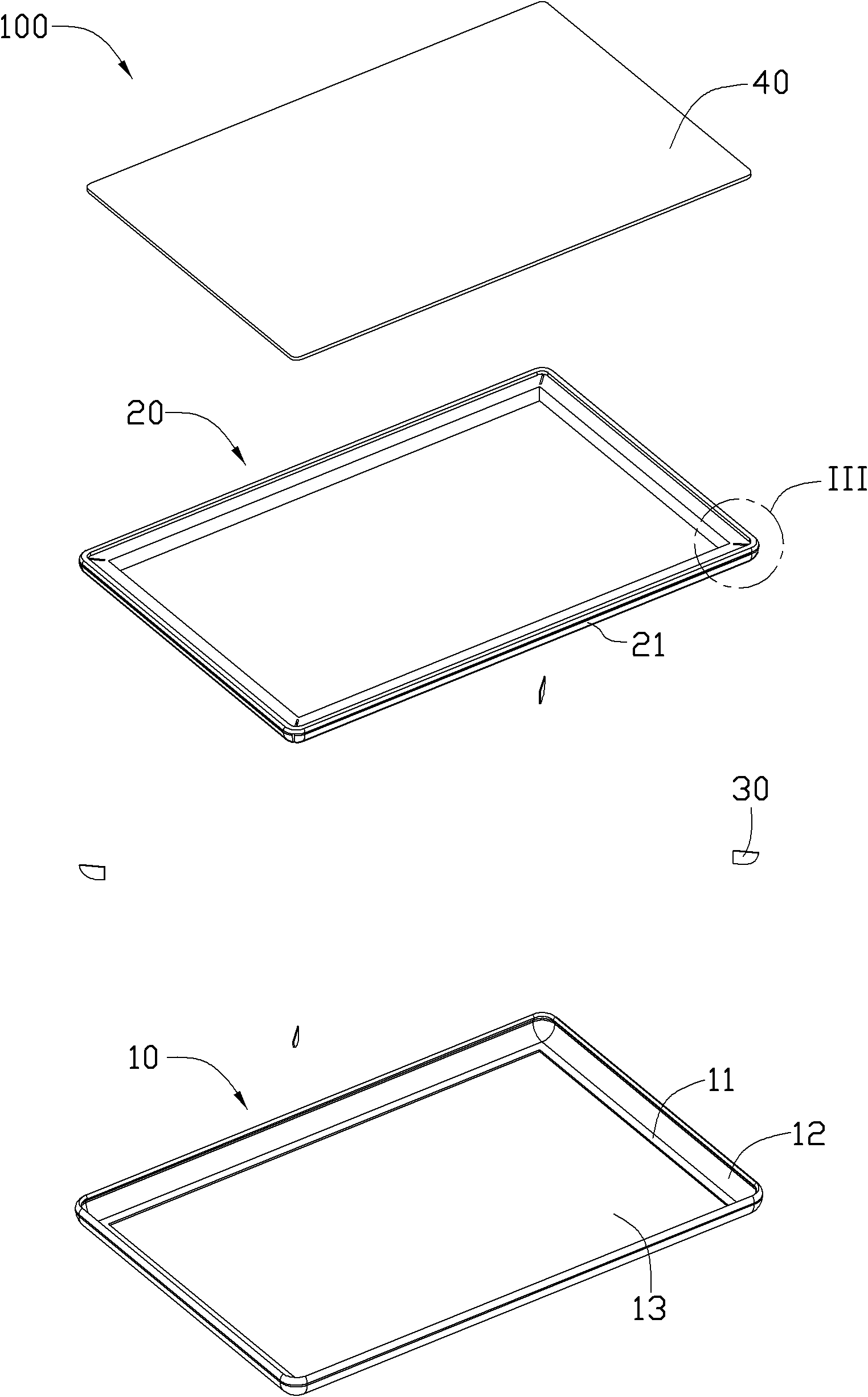

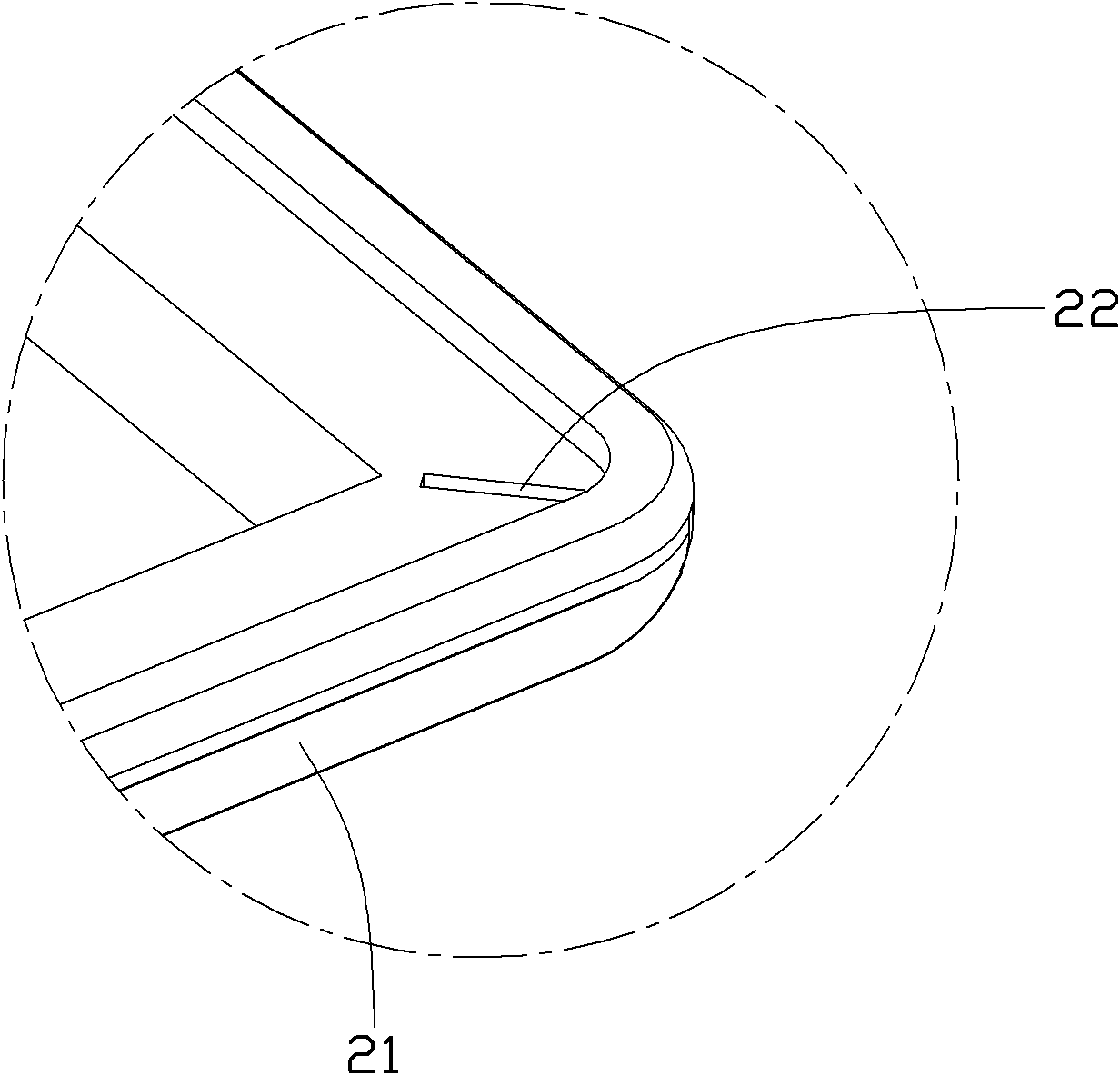

Electronic device and production method of metal casing of electronic device

InactiveCN102404959AStructural Strength EffectGuaranteed stabilityDigital data processing detailsCasings with display/control unitsEngineeringStructural engineering

Owner:FU TAI HUA IND SHENZHEN +1

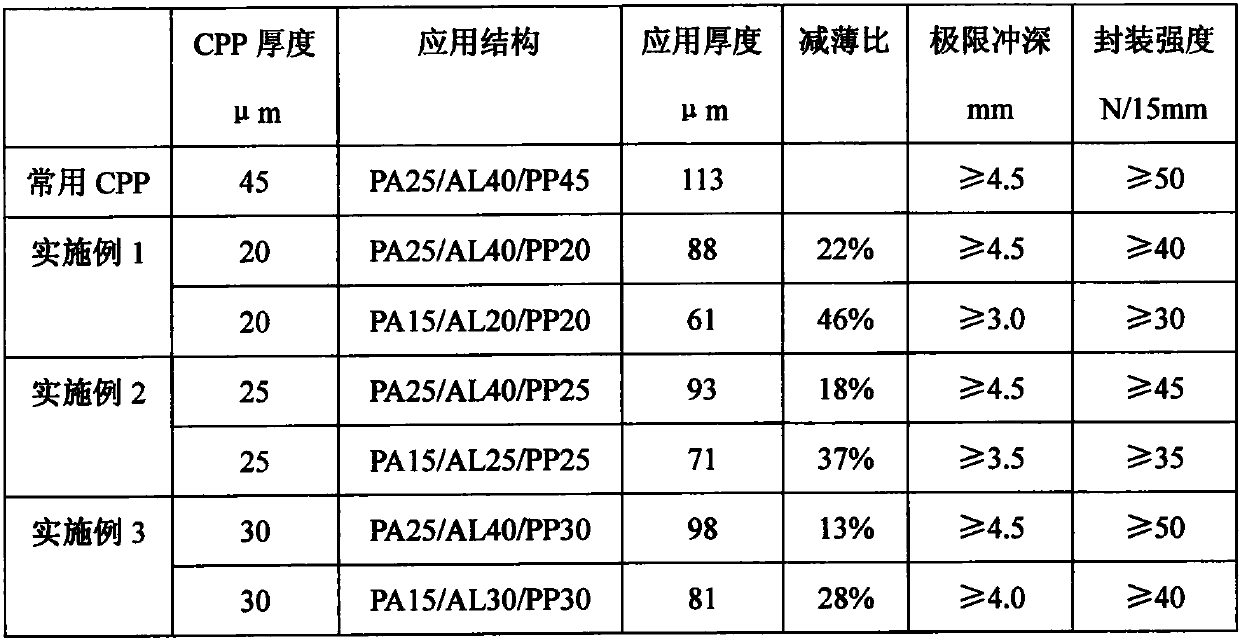

Polypropylene film used for ultra-thin type aluminum-plastic film and preparation method thereof

PendingCN107757032AImprove temperature resistanceLess crystal pointSynthetic resin layered productsElectrical equipmentPolymer scienceFiltration

The invention provides a polypropylene film used for an ultra-thin type aluminum-plastic film. The polypropylene film comprises a polypropylene outer layer, a polypropylene core layer and a polypropylene heat-seal layer, wherein the polypropylene core layer is arranged between the polypropylene outer layer and the polypropylene heat-seal layer, and the polypropylene outer layer, the polypropylenecore layer and the polypropylene heat-seal layer are sequentially compounded together. The invention also provides a preparation method of the polypropylene film used for the ultra-thin type aluminum-plastic film. According to the preparation method, polypropylene resin of different melting points are combined, so that polypropylene has better temperature resistance; and a charging device with a vacuumizing or nitrogen sealing function and a secondary filtration technology are used, and one or more combinations of other raw materials is added, so that the produced casting polypropylene film has fewer crystal points. The casting polypropylene film is applicable to the ultra-thin type aluminum-plastic film, thinning is guaranteed, and packaging and depth scouring performances are also guaranteed at the same time.

Owner:SHANGHAI ZIJIANG NEW MATERIAL TECH CO LTD

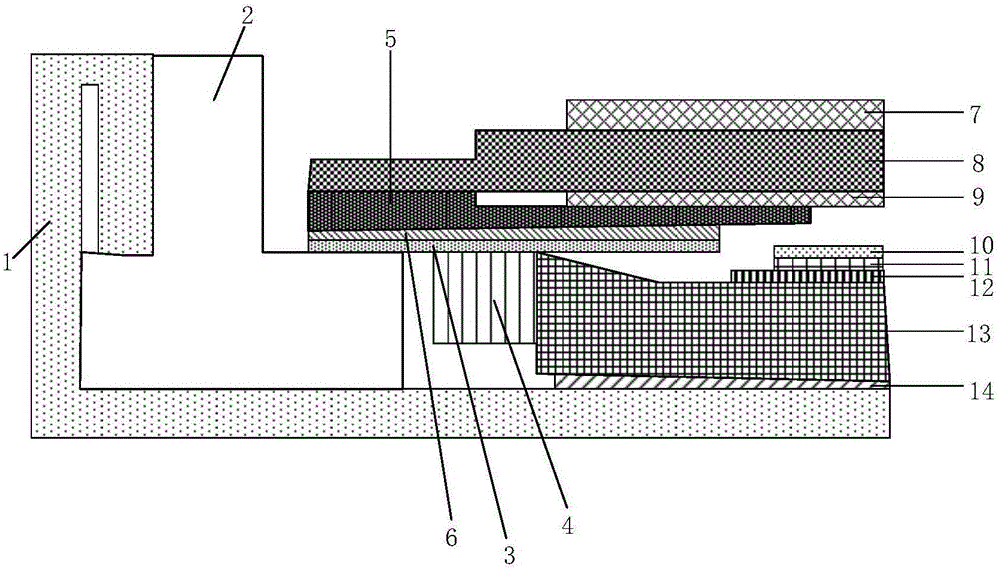

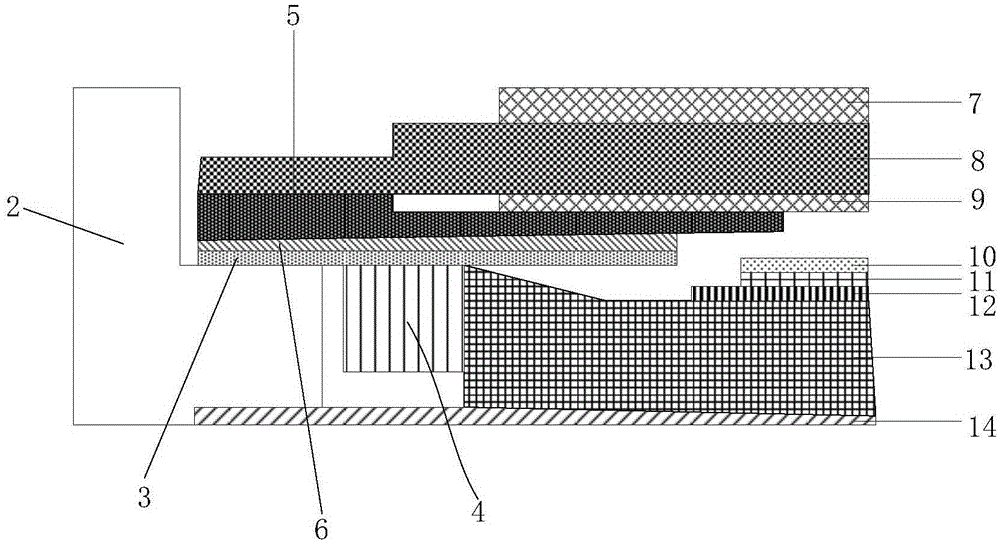

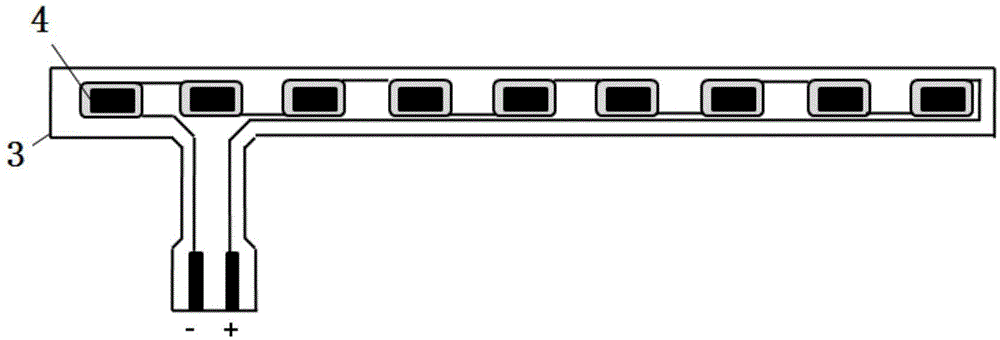

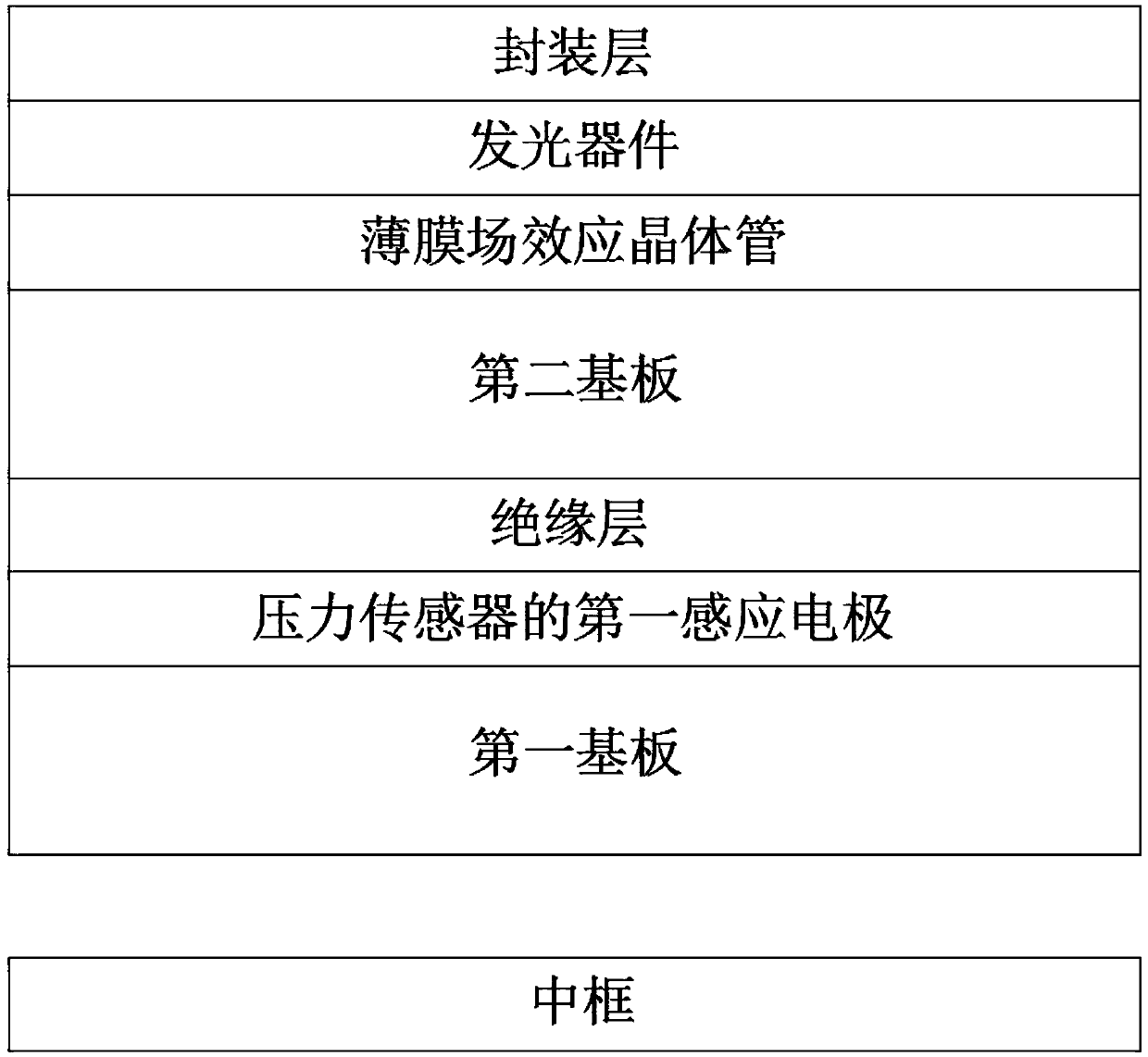

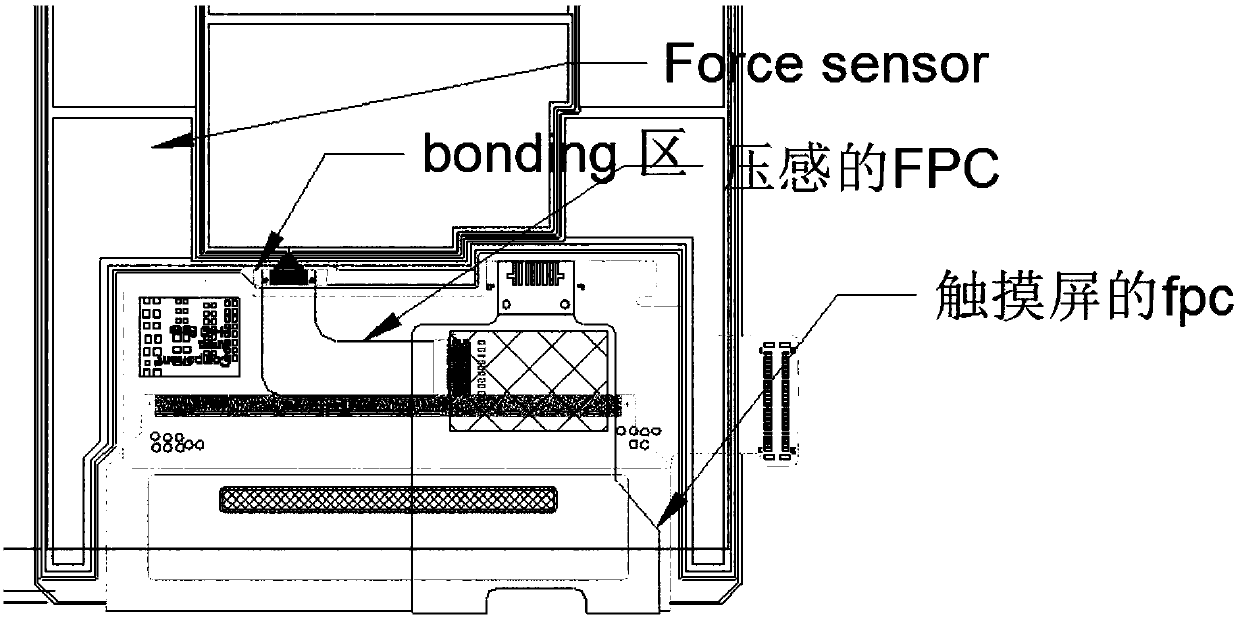

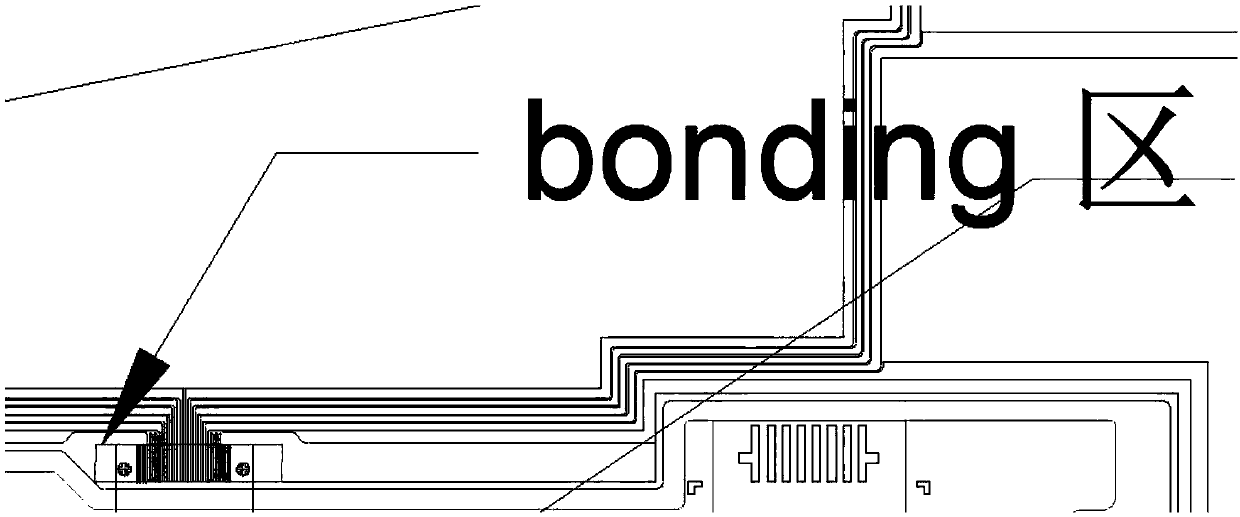

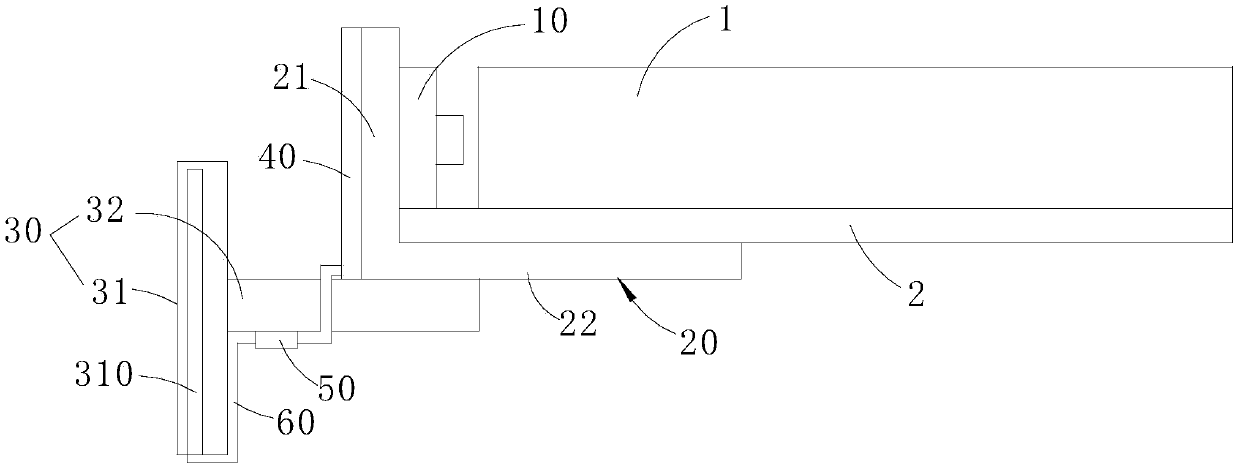

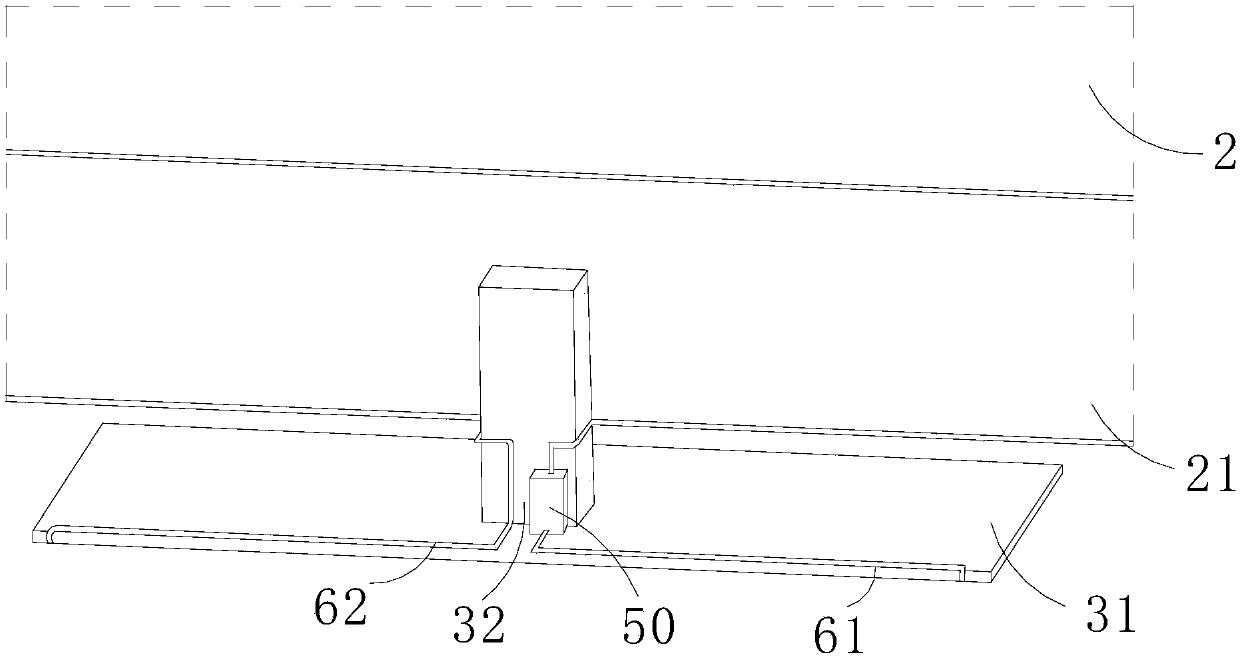

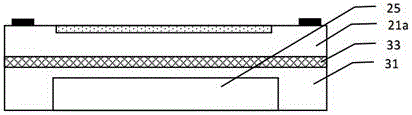

Force touch module, preparation method thereof, touch screen panel and display device

ActiveCN107589871AIncreasing the thicknessGuaranteed thinnerInput/output processes for data processingFlexible circuitsDisplay device

The invention discloses a force touch module, a preparation method thereof, a touch control panel and a display device, and belongs to the related technical field of touch control display. The force touch module comprises a first substrate, a second substrate and a first sensing electrode of a pressure sensor; an insulating layer is arranged between the first substrate and the second substrate; the first sensing electrode is arranged between the insulating layer and the first substrate; a via hole is formed in the second substrate and is located at the position corresponding to the first sensing electrode; a force sensing signal line is arranged at the second substrate and one end of the force sensing signal line penetrates the via hole to be connected with the first sensing electrode; theother end of the force sensing signal line is connected with a corresponding flexible circuit of the device. A second sensing electrode of the pressure sensor is a device middle frame. According to the force touch module, the preparation method thereof, the touch screen panel and the display device, the thickness of the display screen cannot be added excessively while a touch control function isadded, the technology and the structure can be simplified, and the yield is increased.

Owner:BOE TECH GRP CO LTD +1

Display screen

InactiveCN111583822ATranslucentGood light transmissionIdentification meansEngineeringToughened glass

The invention relates to a display screen, which comprises a frame assembly, which is used to form a mounting space; a surface shell assembly, which is arranged in the mounting space and comprises first transparent tempered glass and second transparent tempered glass which are arranged at intervals, an interval gap being formed between the first transparent tempered glass and the second transparent tempered glass; and a light-emitting assembly, which is located in the interval gap, and comprises a transparent circuit board and lamp beads, wherein the transparent circuit board is fixed to the second transparent tempered glass, the transparent circuit board is provided with an installation face facing the first transparent tempered glass, and the lamp beads are arranged on the installation face. Due to the fact that the first transparent tempered glass, the second transparent tempered glass and the transparent circuit board all have light transmission performance, the whole display screen has good light transmission performance. When the display screen stops working, it is ensured that the display screen with light transmission does not block light.

Owner:深圳市德豪显示照明科技有限公司

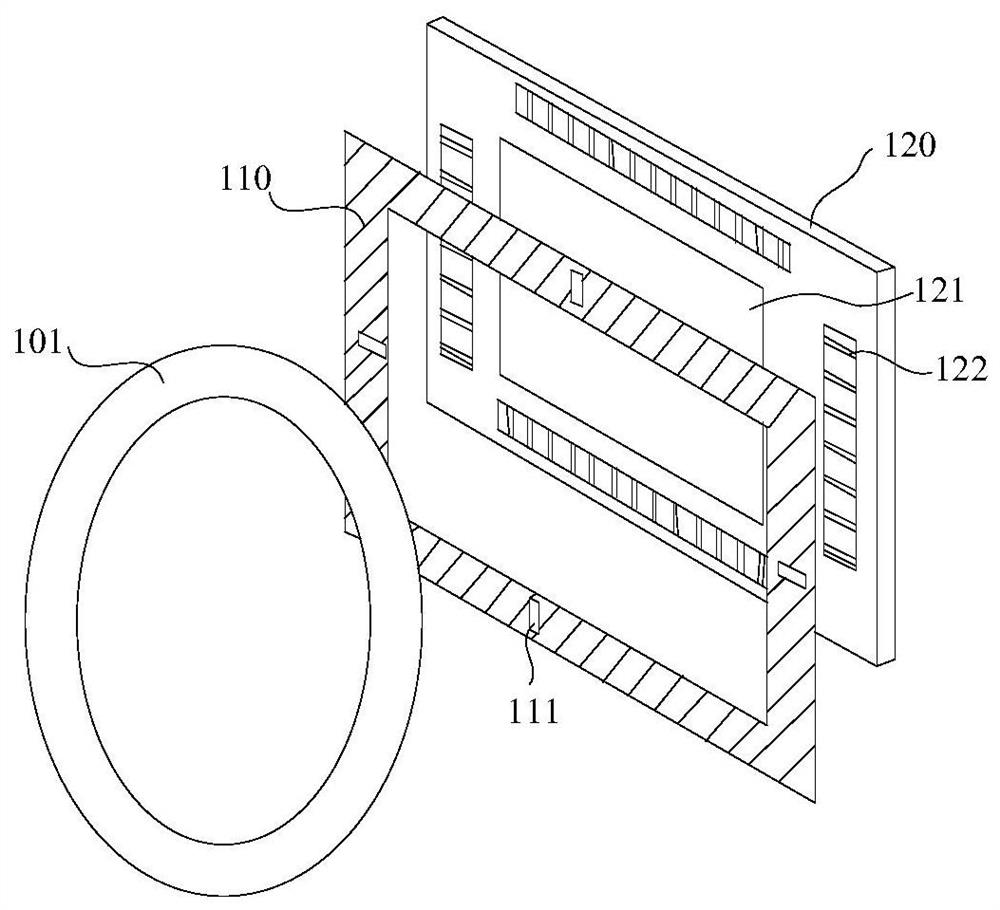

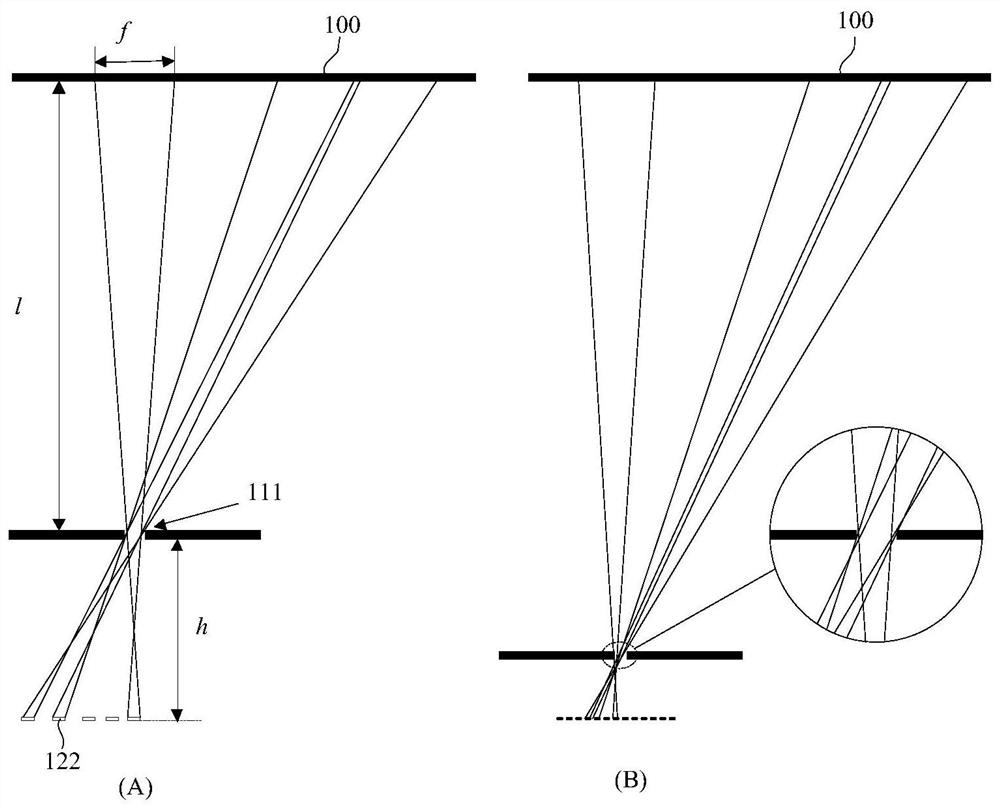

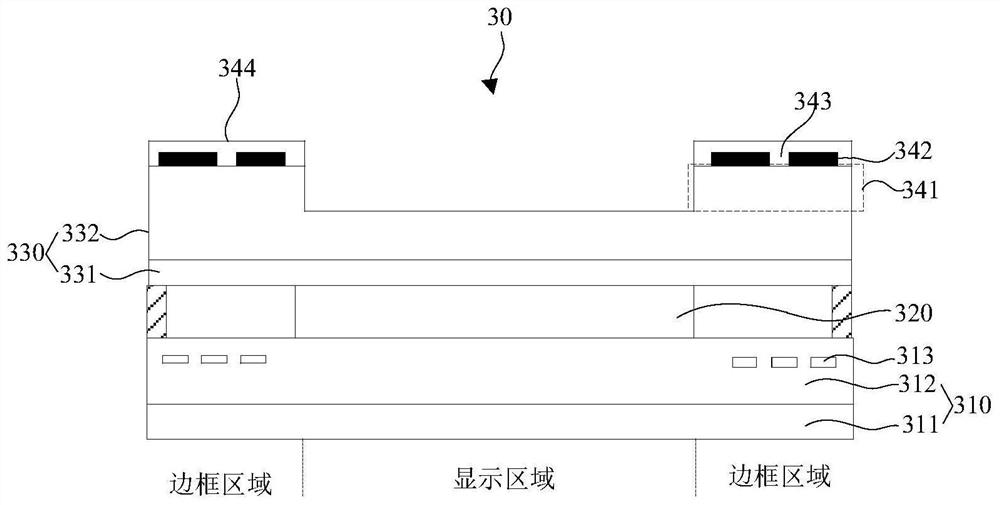

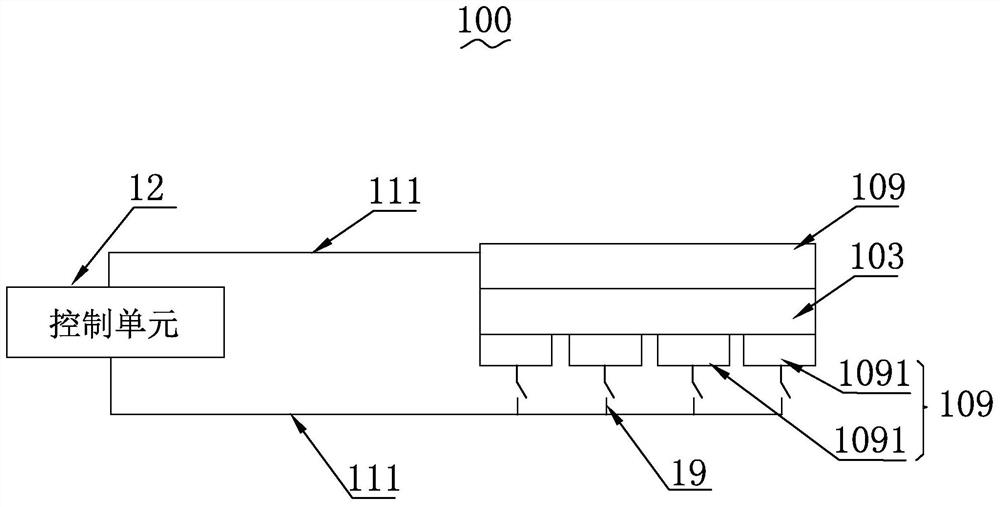

Display module and manufacturing method thereof and head-mounted display device

The invention discloses a display module and a manufacturing method thereof and a head-mounted display device. A photosensitive unit is integrated in an array substrate in a frame area of a display panel, and an optical tracking structure comprising a bump and a light passing port corresponding to the photosensitive unit is arranged in the frame area; the distance between the first surface of the bump and the array substrate is greater than the distance between the surface of a cover plate in a display area and the array substrate, so that reflected light of different positions of eyes is transmitted to the photosensitive unit by virtue of the optical tracking structure to realize an eyeball tracking function, the display area is ensured to be light and thin favourably, and the eyeball tracking function is realized.

Owner:BOE TECH GRP CO LTD

Anti-interference image sensor

ActiveCN106373973AGuaranteed ability to receive lightAvoid occlusionSolid-state devicesRadiation controlled devicesImage sensorAlloy

The invention provides an anti-interference image sensor. The sensor comprises a first substrate, a silicon substrate and a second substrate; the first substrate comprises a front side with a first light reception area and a back side opposite to the front side; the silicon substrate includes a front side with a groove and a back side opposite to the front side; the second substrate is arranged in the bottom of the groove, the second substrate comprises a front side including a second light reception area and a back side opposite to the front side, and the front side of the second substrate and the back side of the silicon substrate are coplanar; and the back side of the first substrate is bonded to the front side of the silicon substrate via a Fe-Co alloy layer.

Owner:JIANGSU JUNLONG ELECTRIC TECH

Method for preparing bipolar plate made from carbon/carbon composite of fuel cell of proton exchange membrane

Based on materials of carbon granules in intermediate phase and carbon fiber as reinforcing material, bipolar plates are manufactured through gel injection mold at one time procedure. Manufacturing procedure includes following steps: adding carbon granules in intermediate phase and carbon fiber according to certain ratio into monomer solution and mixing the solution so as to obtain pulp; molding the pulp into metal mold having a reversed gas flow channel, heat preserving till completed reacting between monomer and crosslinking agent so as to obtain biscuit of bipolar plates; drying and sintering the biscuit; carrying out procedure of hole sealing by using thermosetting resin; charring solidified resin so as to obtain bipolar plates made from carbon / carbon composite. Features of the invention are high mechanical strength, good conductivity, no poison and pollution.

Owner:SHANGHAI JIAO TONG UNIV

Loudspeaker module and electronic device using the loudspeaker module

ActiveCN103108269BGuaranteed thinnerGuaranteed acoustic performanceFrequency/directions obtaining arrangementsEngineeringLoudspeaker

Owner:GOERTEK INC

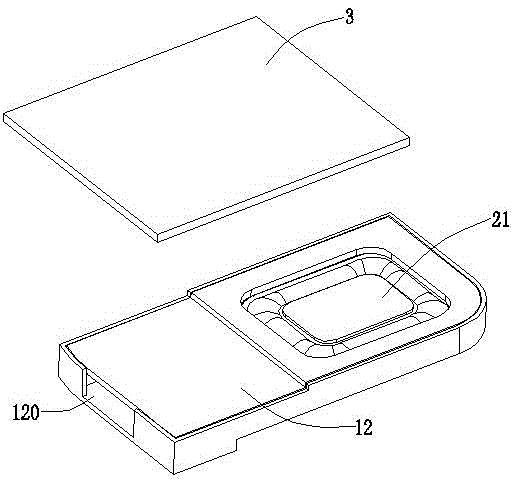

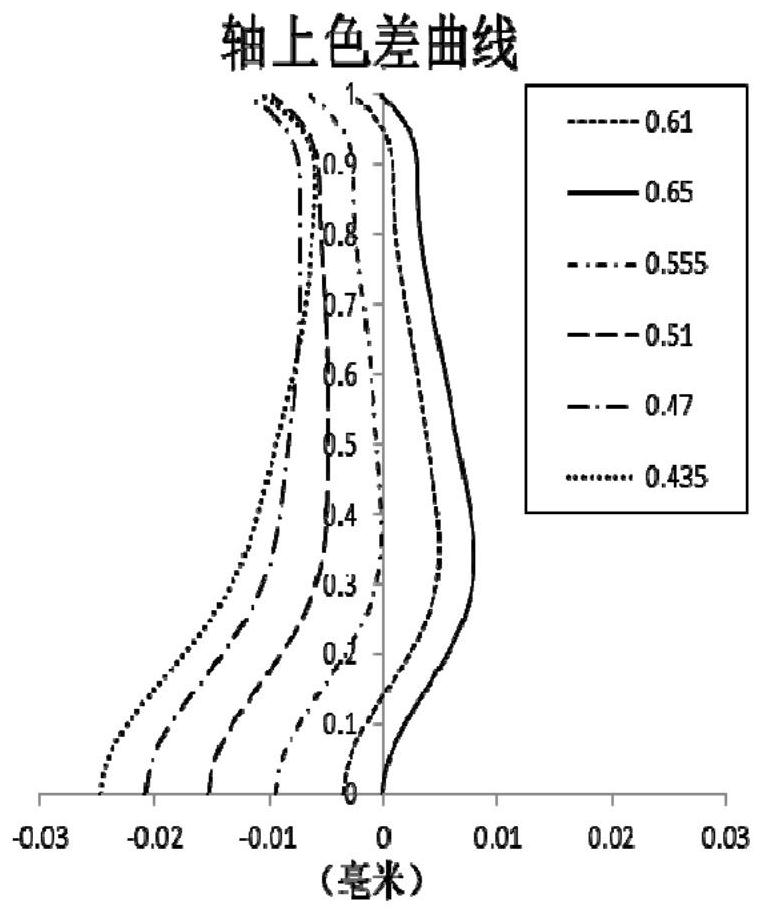

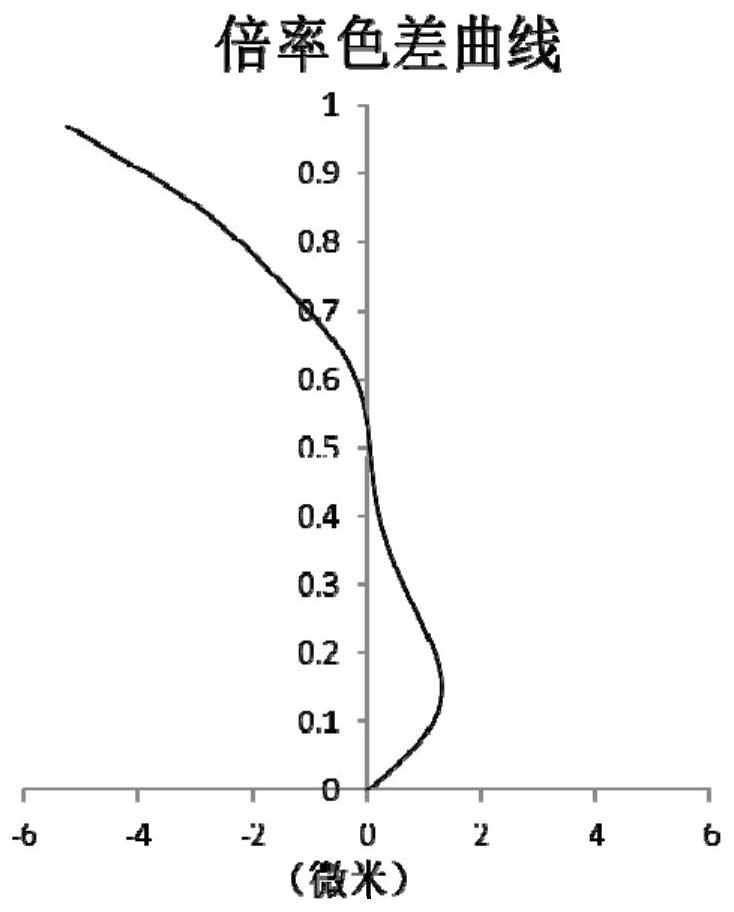

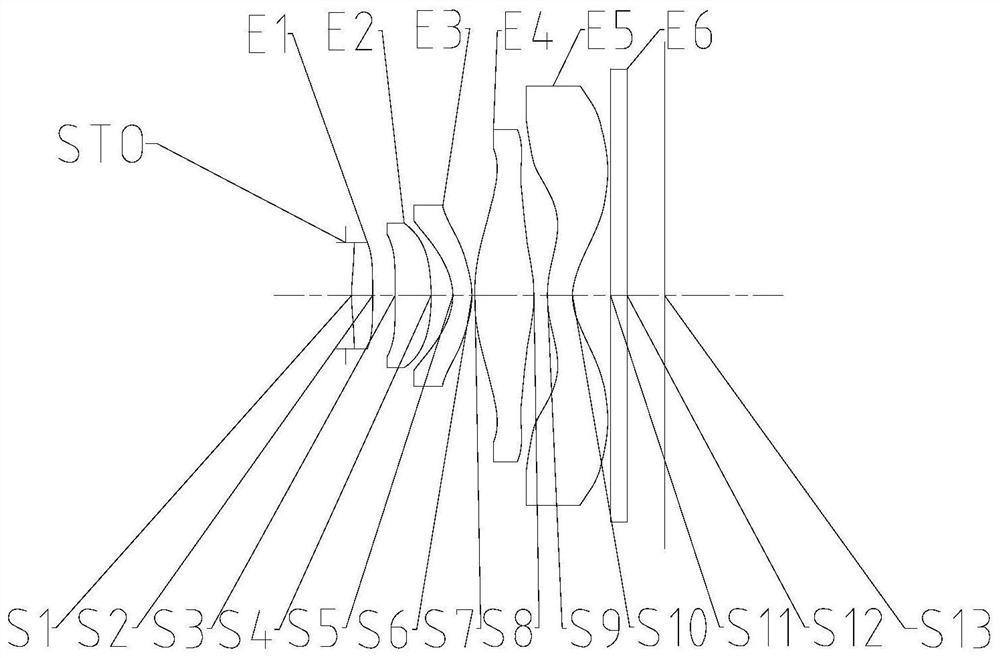

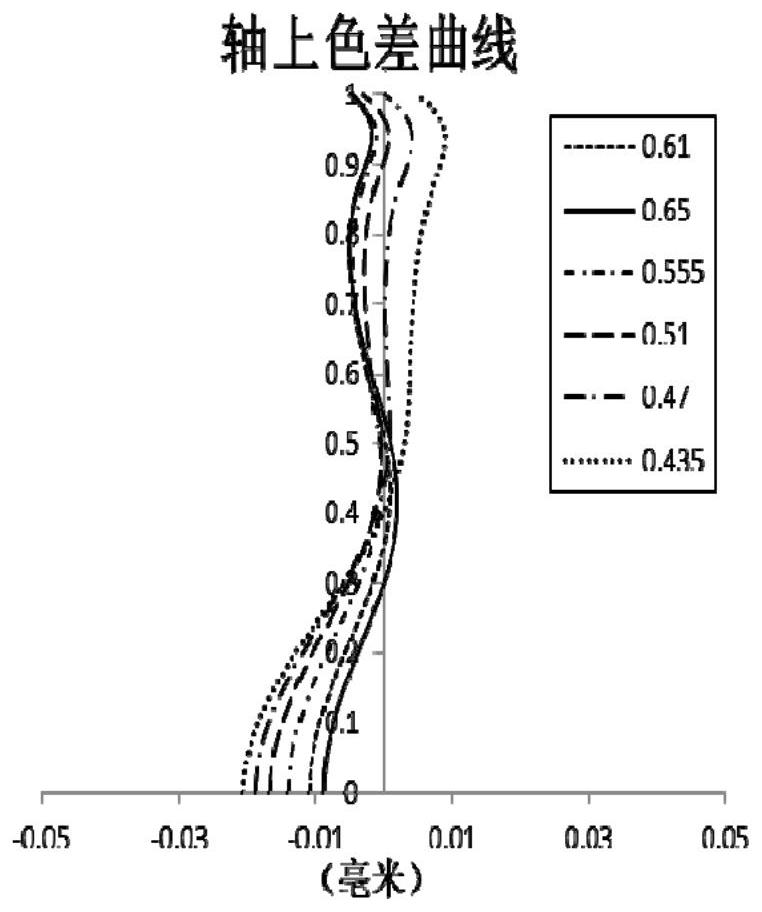

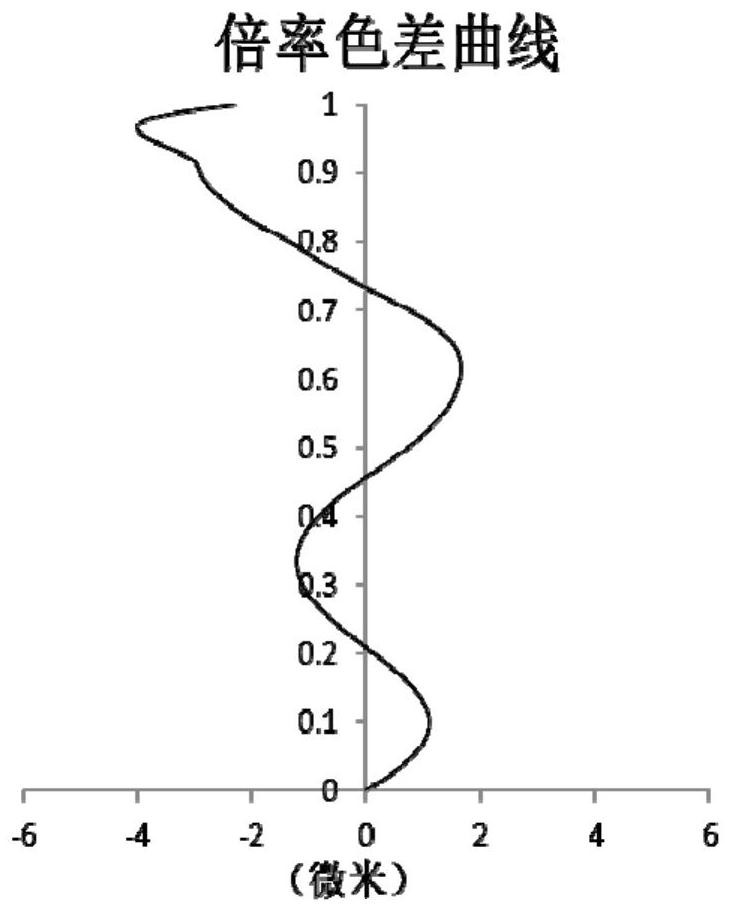

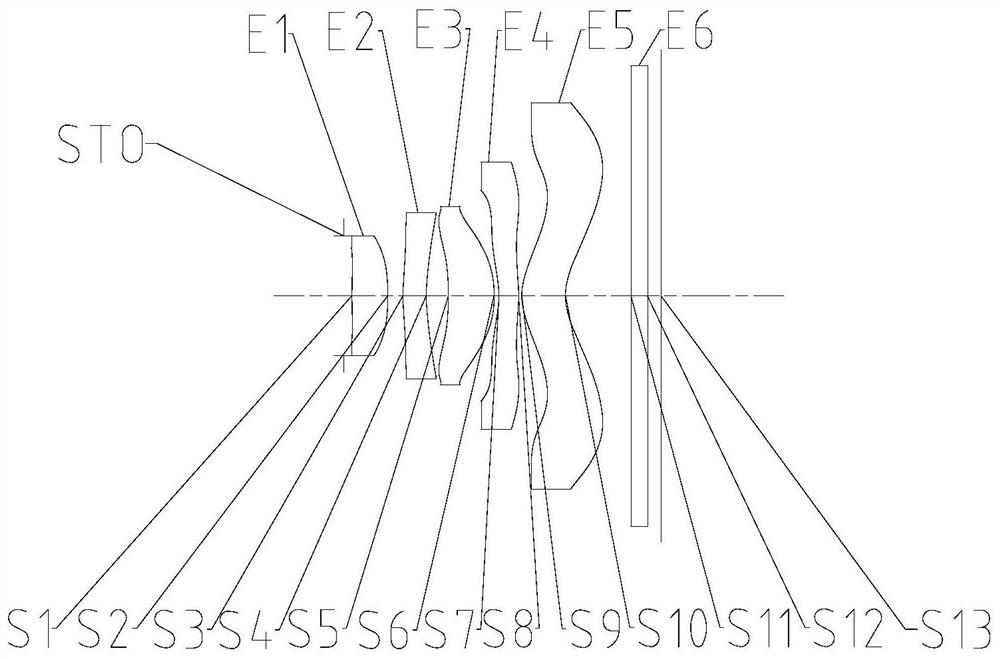

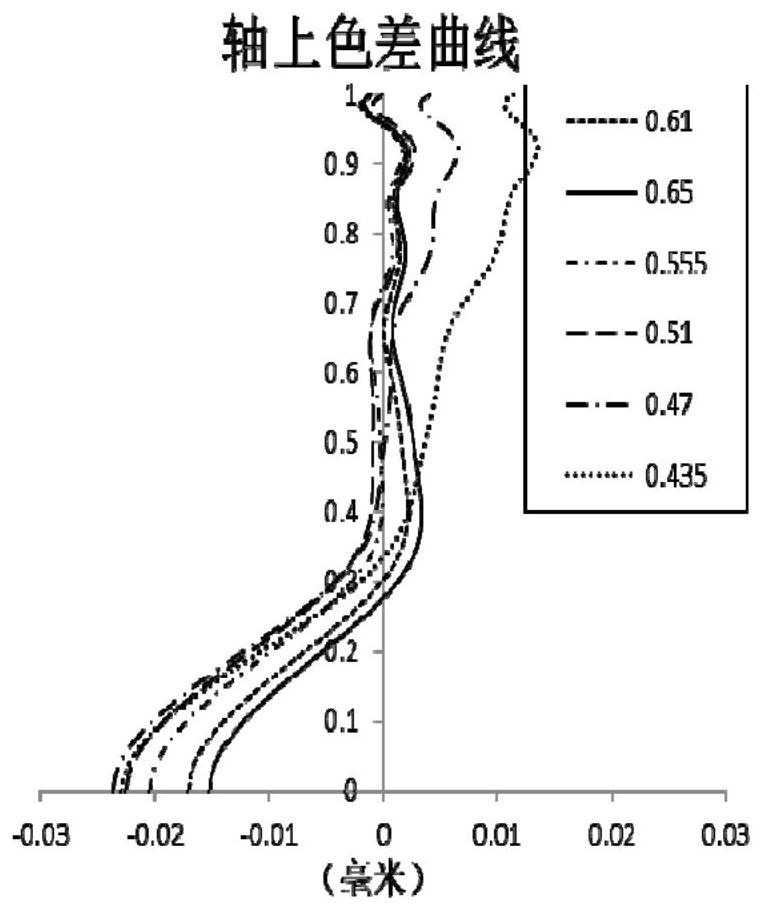

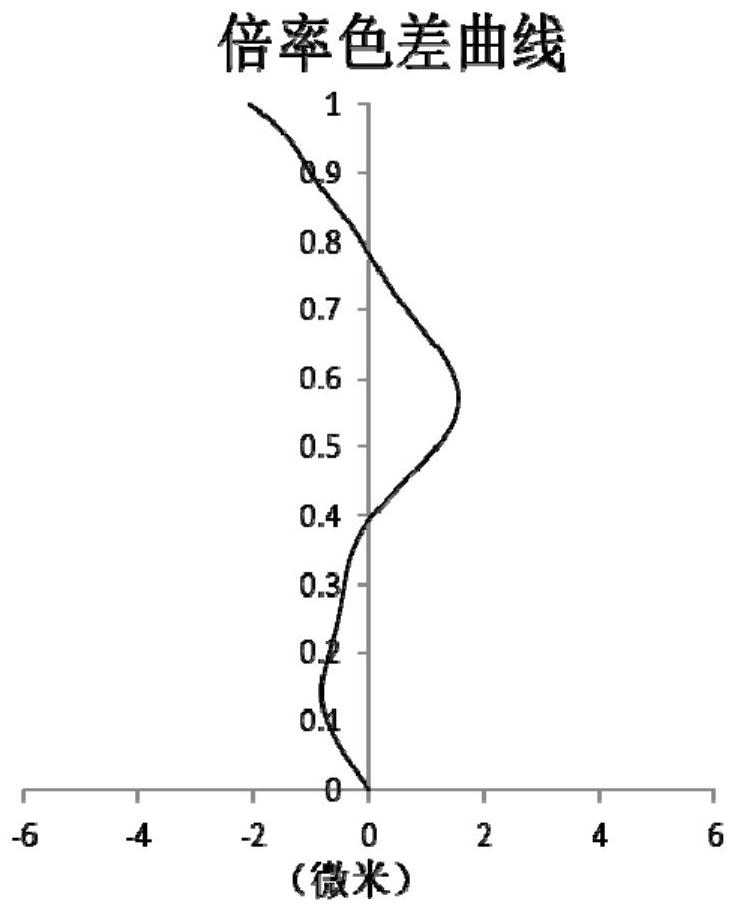

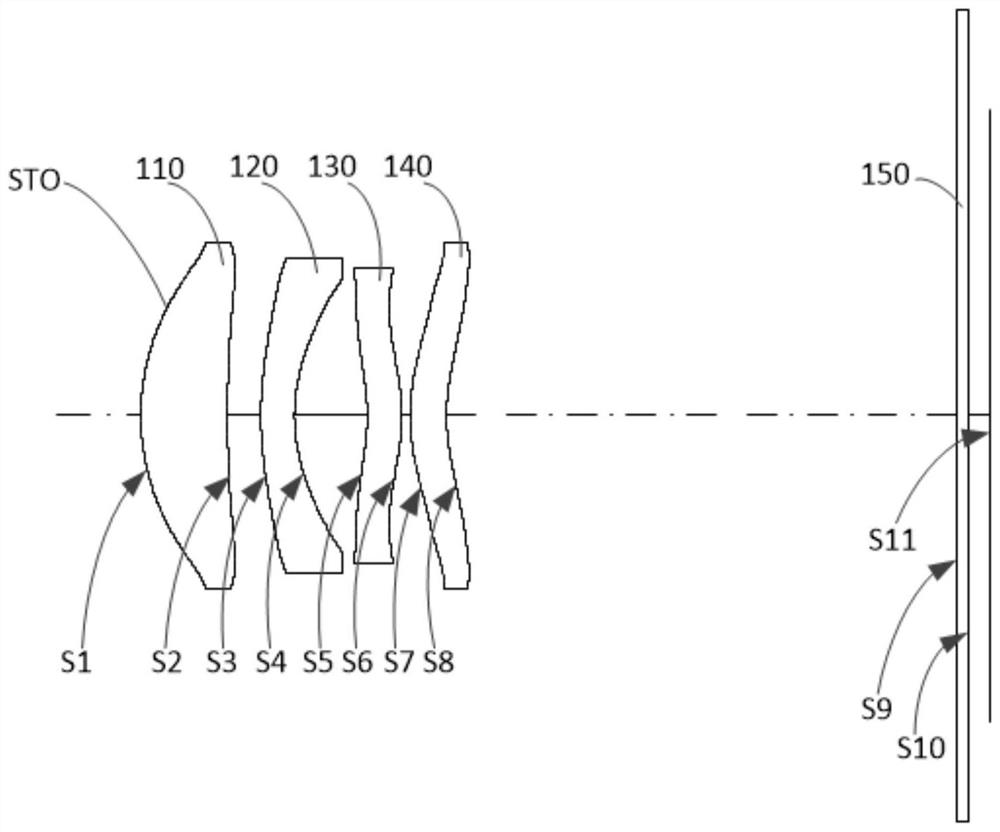

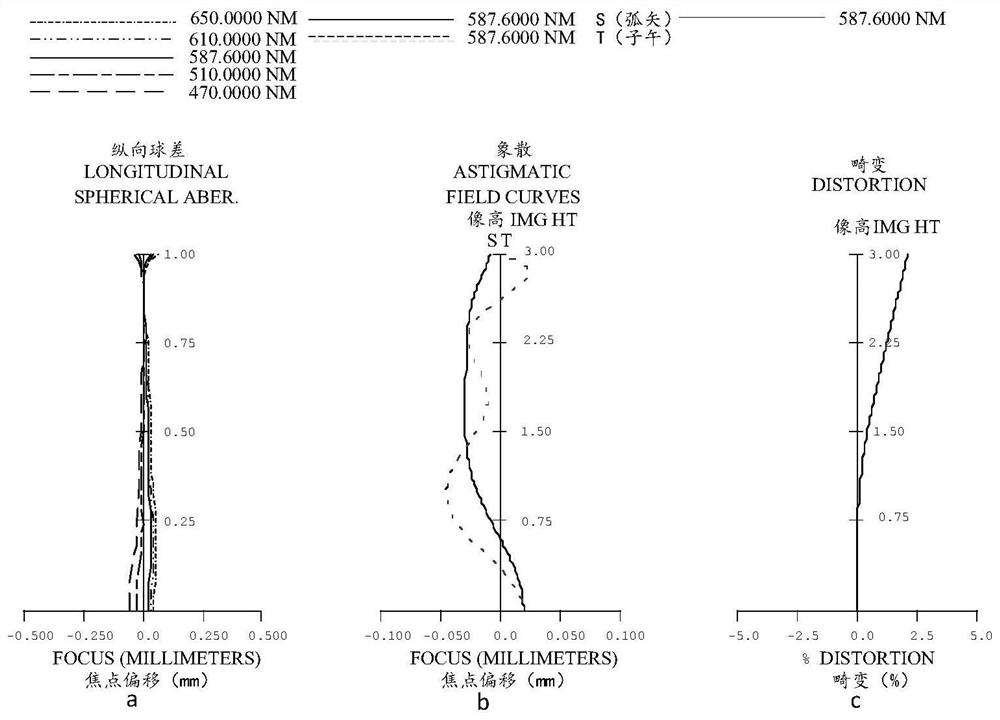

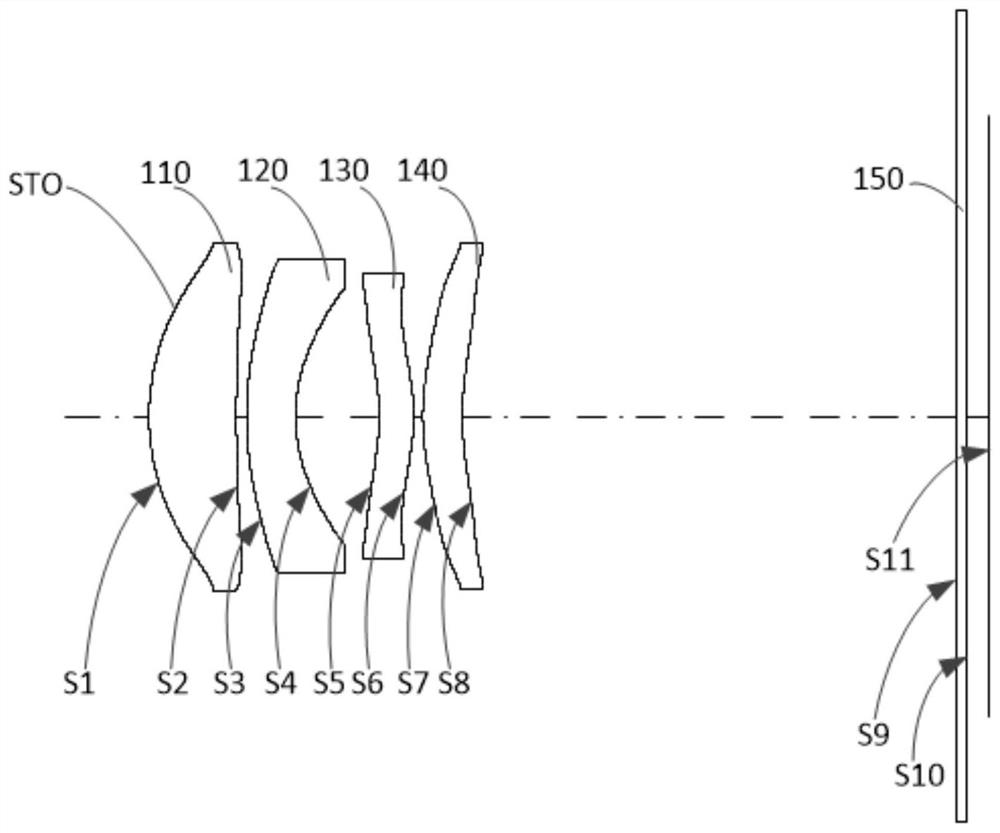

Optical imaging lens

The invention provides an optical imaging lens. From the object side of the optical imaging lens to the image side of the optical imaging lens, the optical imaging lens comprises a diaphragm, a first lens with positive focal power, a second lens with positive focal power, a third lens, a fourth lens of which the object side surface is a convex surface, and of which the image side surface is a convex surface, and a fifth lens element; the on-axis distance TTL from the object side surface of the first lens to the imaging surface of the optical imaging lens and half ImgH of the diagonal line length of an effective pixel area on the imaging surface of the optical imaging lens meet the relational expression that 1.2 < TTL / ImgH < 1.5; and the maximum half field angle Semi-FOV of the optical imaging lens is greater than 45 degrees and less than 60 degrees. With the optical imaging lens adopted, the problem that a mobile phone lens is small in selfie view field in the prior art can be solved.

Owner:ZHEJIANG SUNNY OPTICAL CO LTD

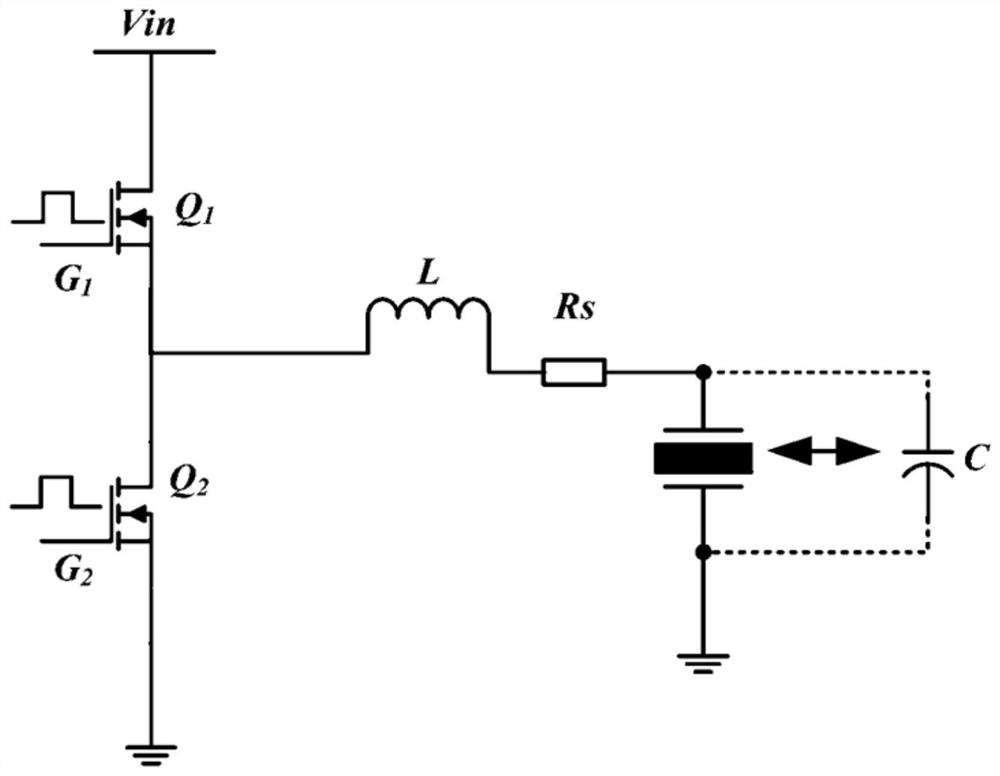

Fingerprint touch control identification module, fingerprint touch control identification method and electronic equipment

ActiveCN113343800AStable voltageImprove emission efficiencyCharacter and pattern recognitionPattern recognitionMiniaturization

The invention relates to the technical field of ultrasonic fingerprint identification, and comprises a fingerprint touch control identification module and a fingerprint touch control identification method; the fingerprint touch control identification module can start a corresponding fingerprint touch control identification area based on a finger touch position to carry out fingerprint detection and obtain data after the finger touch position is detected, thus further processing based on the obtained data to obtain a corresponding fingerprint image. On the basis of the plurality of fingerprint touch control identification areas which are arranged in a partitioned manner, large-area fingerprint identification signals can be realized without additionally configuring other detection modules, and the capacitance value accessed into a circuit each time can be in a resonance range, so that the voltage stability in fingerprint identification is ensured, and the emission efficiency is improved. The invention further provides electronic equipment which can meet the requirements of miniaturization and large-area ultrasonic fingerprint identification.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

Optical imaging lens

The invention provides an optical imaging lens. From the object side of the optical imaging lens to the image side of the optical imaging lens, the optical imaging lens sequentially comprises: a first lens, wherein the first lens has positive focal power, and the image side surface of the first lens is a convex surface; a second lens, wherein the second lens has positive focal power; a third lens; a fourth lens; and a fifth lens element. The on-axis distance TTL from the object side surface of the first lens to the imaging surface of the optical imaging lens and half of the diagonal line length ImgH of an effective pixel area on the imaging surface of the optical imaging lens meet the condition that 0.9<TTL / ImgH<1.4; and the maximum half field angle Semi-FOV of the optical imaging lens meets the condition that 50 degrees <Semi-FOV<60 degrees. The optical imaging lens solves the problem that an optical imaging lens in the prior art cannot give consideration to both a large field angle and miniaturization.

Owner:ZHEJIANG SUNNY OPTICAL CO LTD

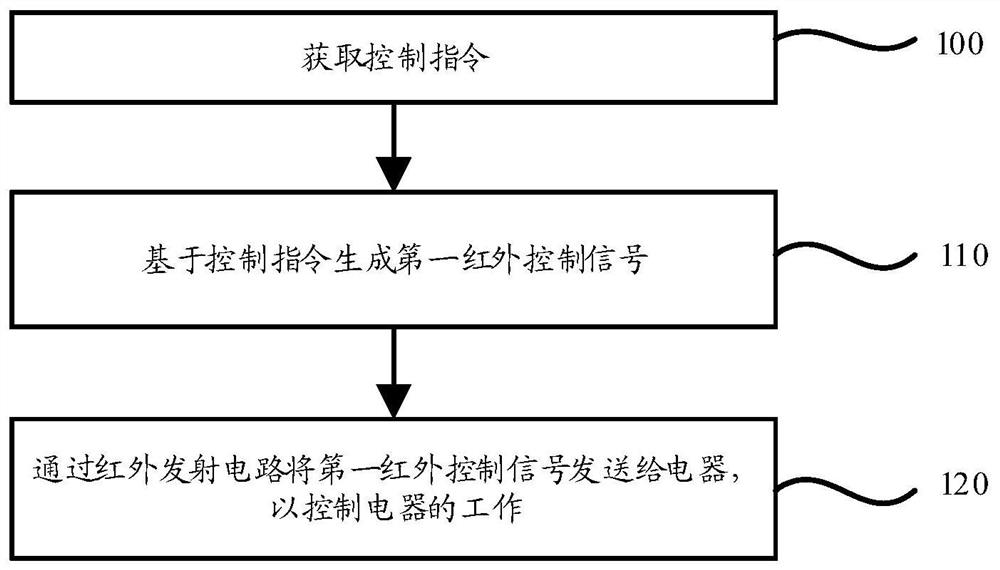

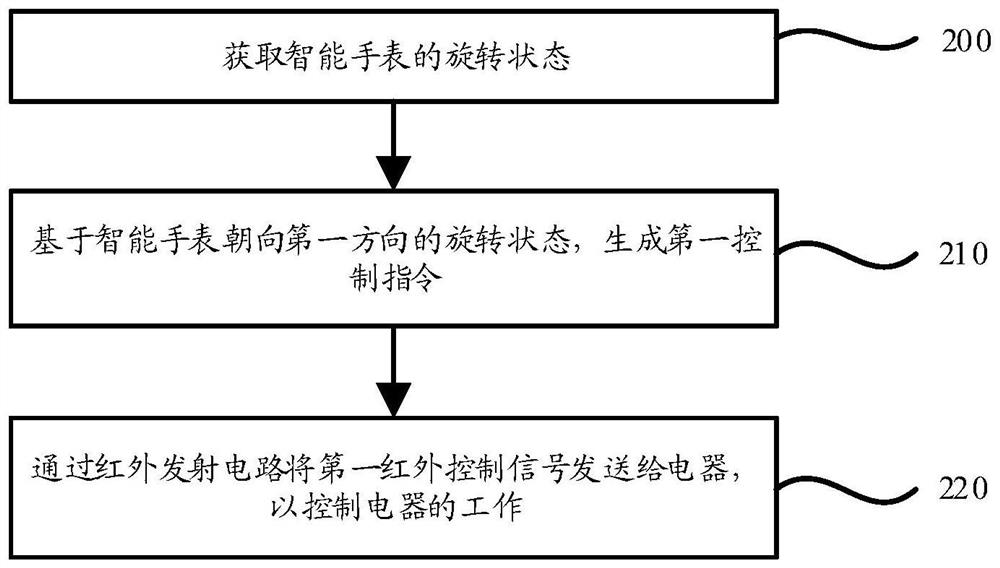

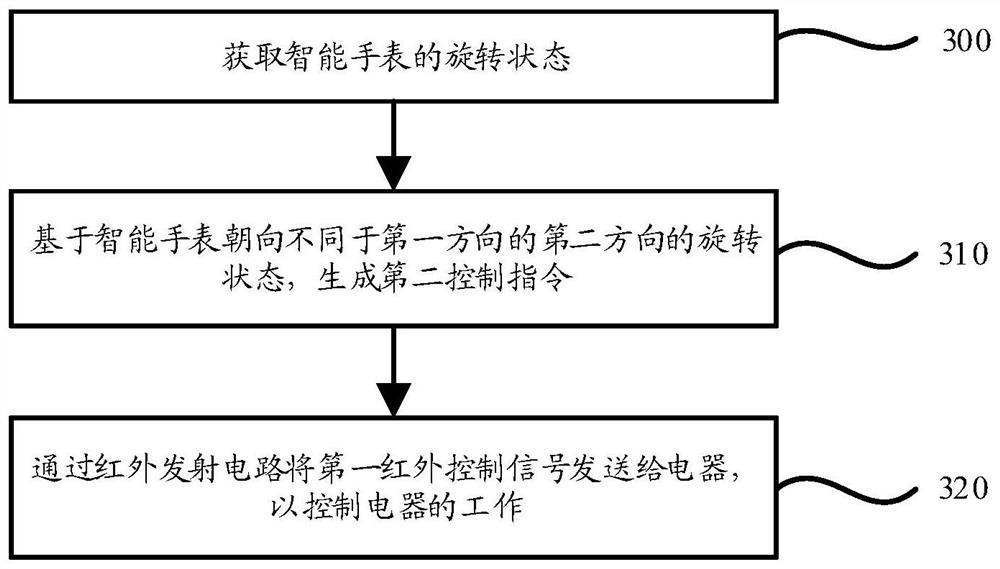

Electric appliance control method based on wearable device and mobile terminal and storage medium

InactiveCN111726269AKeep the full screen designGuaranteed thinnerNon-electrical signal transmission systemsHome automation networksControl signalEmbedded system

The invention discloses an electric appliance control method based on a wearable device and a mobile terminal and a storage medium. The wearable device comprises an infrared emission circuit. The control method comprises the steps: a control instruction is acquired; a first infrared control signal is generated based on the control instruction; the first infrared control signal is sent to the electric appliance through the infrared emission circuit so as to control the work of the electric appliance. By adopting the method, the operation of the electric appliance can be controlled through the infrared control signal transmitted by the infrared transmitting circuit on the wearable device. In addition, the mobile terminal can control the operation condition of the electric appliance through the first infrared control signal under the condition that an infrared emission circuit does not need to be installed, and therefore the mobile terminal can keep the characteristics of full-screen design, lightness and thinness while the functions are achieved.

Owner:QIKU INTERNET TECH SHENZHEN CO LTD

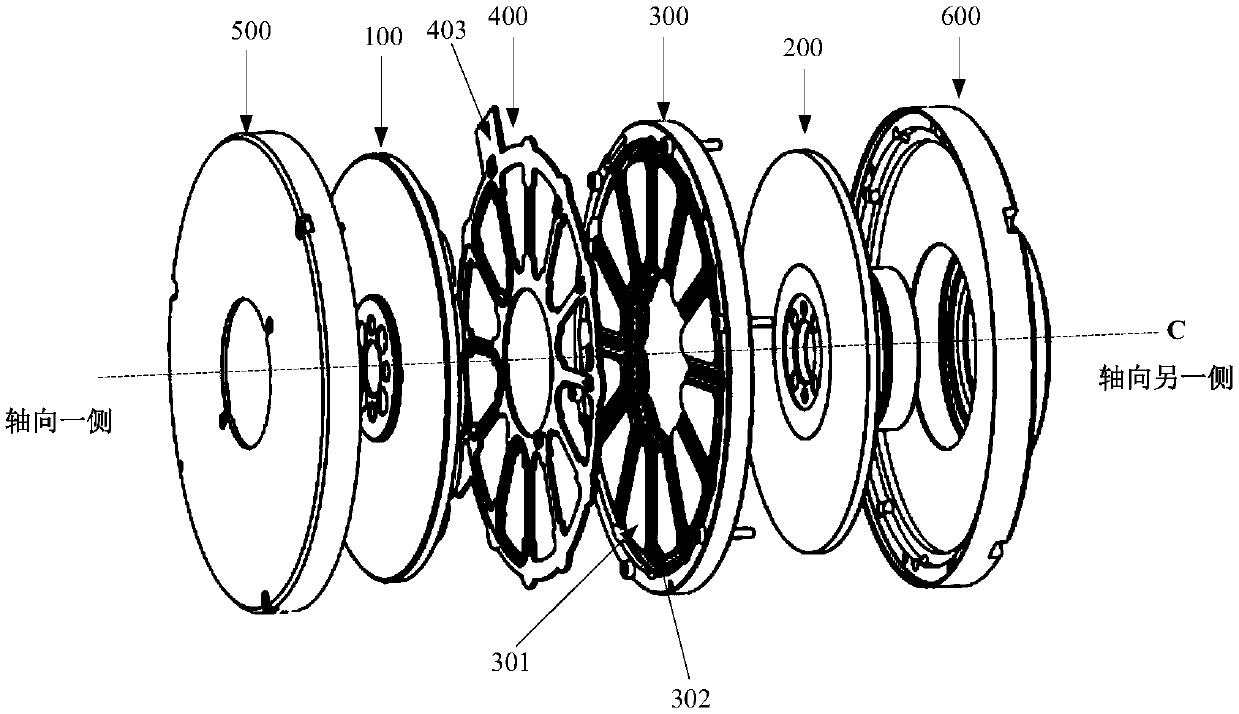

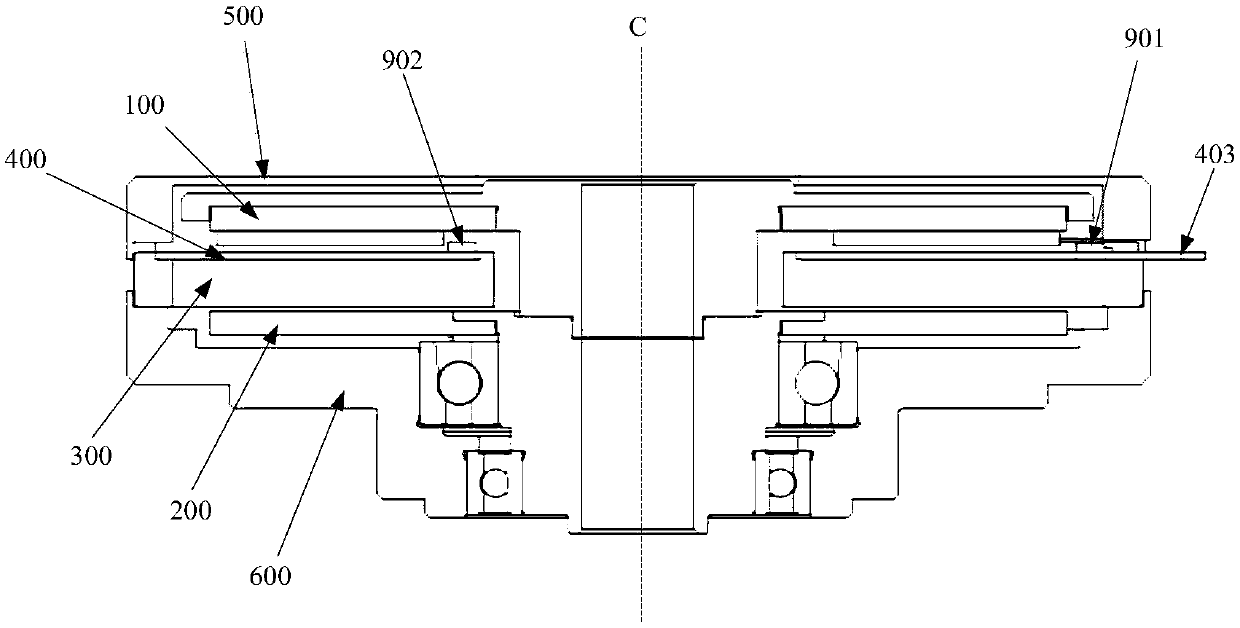

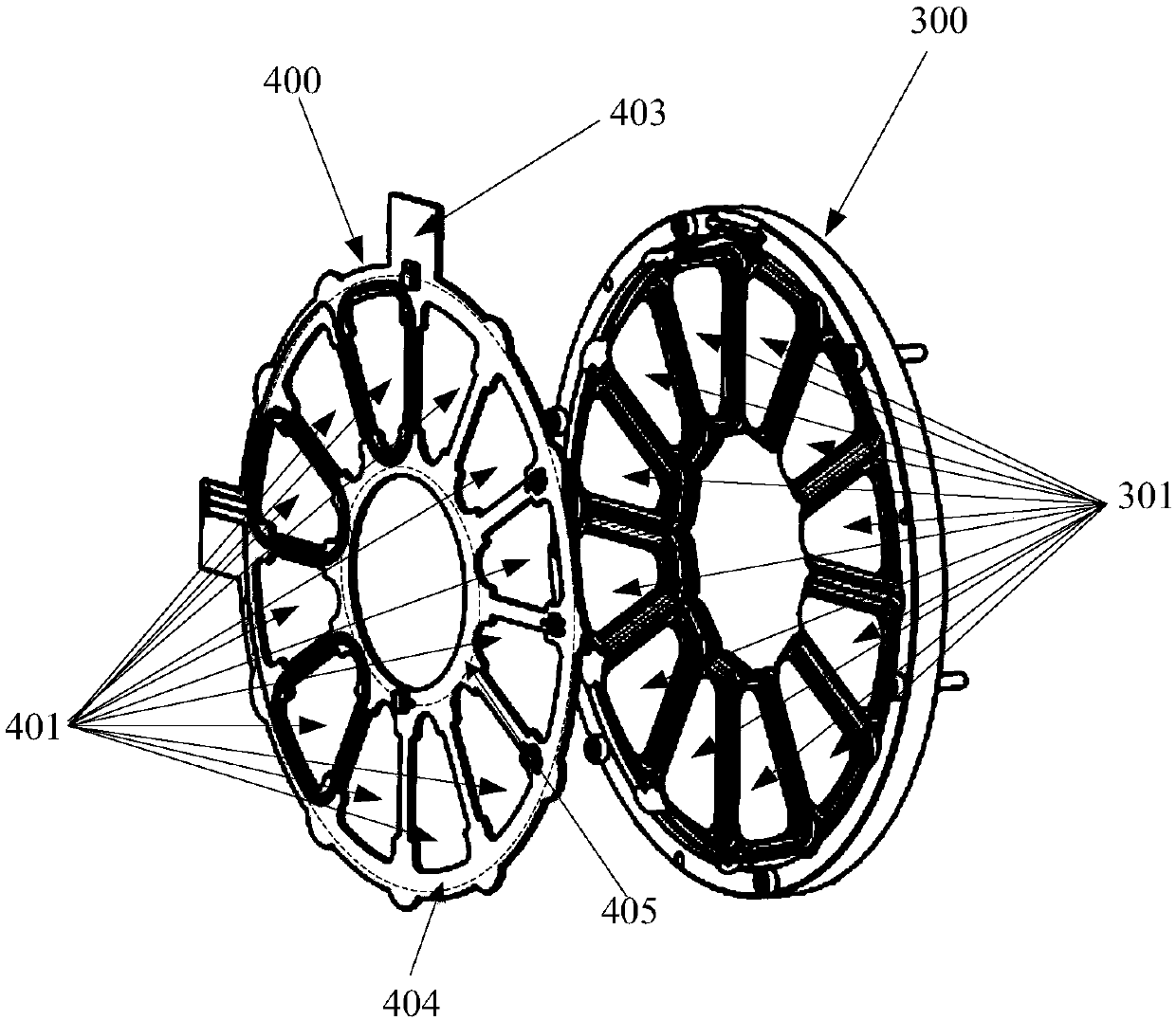

Motor and electrical equipment comprising same

InactiveCN109861461ASave height spaceReduce axial sizeStructural associationSynchronous machines with stationary armatures and rotating magnetsMagnetStator

The invention relates to a motor and electrical equipment comprising the same. The motor is provided with a shaft, two rotors, a stator and a circuit board, wherein the shaft is configured to rotate by taking the central axis as a center, the two rotors are configured in the axial direction in a mode of reserving a specified interval, at least one of the rotors is provided with a magnet, the stator is configured between the two rotors and provided with a plurality of stator cores configured in the circumferential direction and a coil wound around the plurality of stator cores, and the circuitboard is arranged between the stator and the rotor with the magnet. The motor is characterized in that the circuit board is provided with a plurality of slot holes configured in the circumferential direction, the plurality of slot holes run through the circuit board in the axial direction, and the plurality of stator cores are respectively embedded in the plurality of slot holes. The structure ofthe circuit board of the motor can assist the assembly and positioning of the stator cores so as to simplify the complexity of the construction and assembly.

Owner:NIDEC CORP

Smart watch

InactiveCN107132756AProcess OptimizationLower assembly costsMechanical clocksTime-pieces with integrated devicesEmbedded systemElectricity

The invention discloses a smart watch. The smart watch comprises a casing, a circuit module arranged in the casing, a touch display panel accommodated in the casing and located above the circuit module, and a near-field communication device arranged between the touch display panel and the circuit module and connected with the circuit module, wherein the near-field communication device comprises at least one shading part. Additionally equipped with a near-field communication (NFC) function, the smart watch is still thin.

Owner:EVERDISPLAY OPTRONICS (SHANGHAI) CO LTD

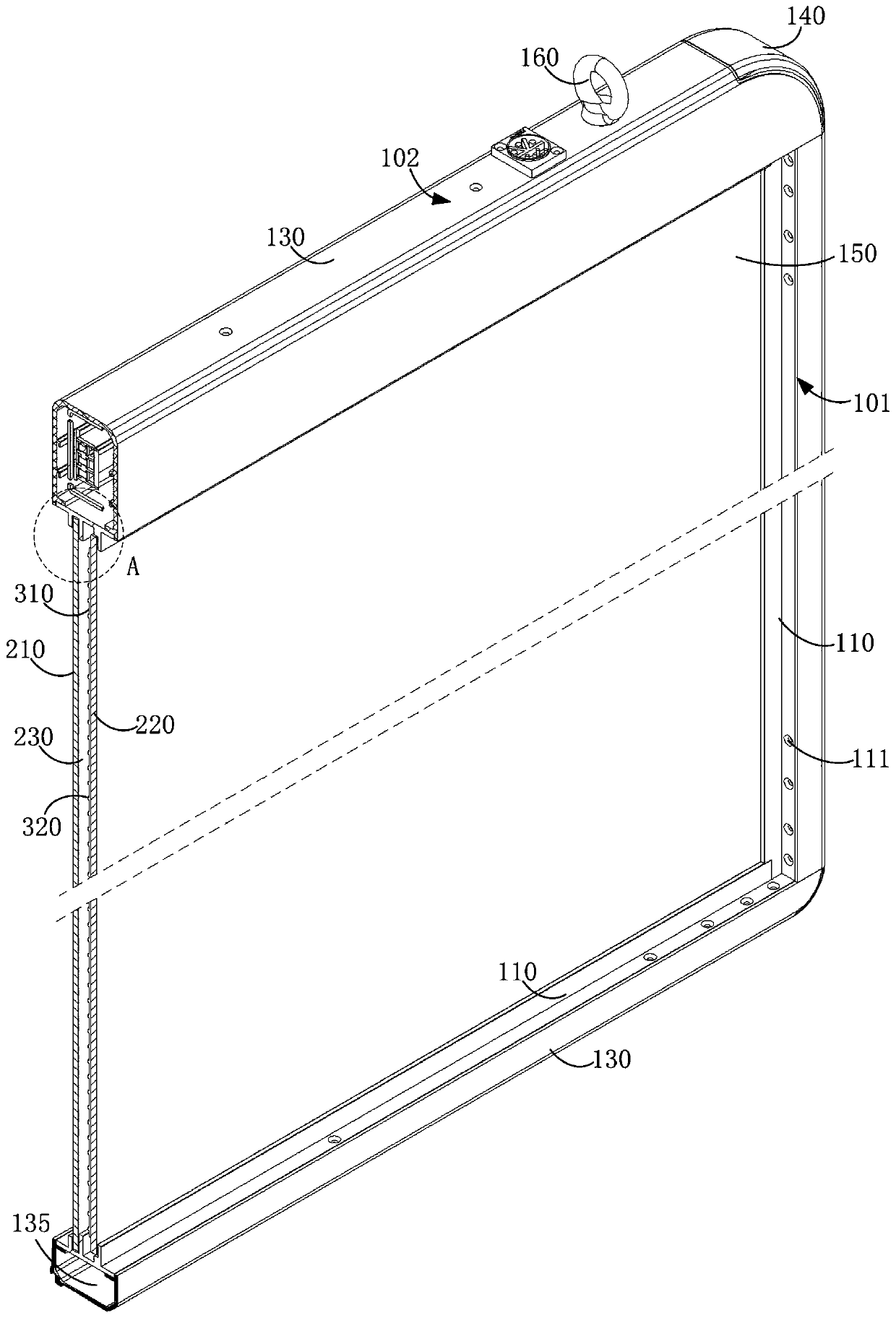

Thinner and lighter display device

ActiveCN107894673AGuaranteed thinnerImprove cooling effectNon-linear opticsHeat conductingLight guide

The invention discloses a thinner and lighter display device. The thinner and lighter display device comprises a light guiding plate, an LED light bar, a heat dissipating plate, a base and a water cooling tube, wherein the light guiding plate is used for conducting light rays; the LED light bar is arranged at a light incident end of the light guiding plate and is used for emitting light rays toward the light guiding plate; the heat dissipating plate is arranged beside the LED light bar, and the LED light bar fits to the inner side of the heat dissipating plate; the base is connected with the outer side of the heat dissipating plate and used for supporting the display device; and the water cooling tube comprises an inlet end, an outlet end and multiple buckling sections which are connectedbetween the inlet end and the outlet end, the buckling sections fit to the heat dissipating plate and are used for enabling a cooling liquid to be circulated, and the cooling liquid enters from the inlet end and then flows out from the outlet end and takes away heat on the heat dissipating plate. The invention provides a new heat dissipation structure of the display device, area of the heat dissipating plate is reduced and use of a heat dissipating fin is avoided by fully utilizing heat dissipating capabilities of the heat dissipating plate and a heat conducting base, so that the display device has good heat dissipation effect while guaranteeing that the display device is thinner and lighter, and cost of a heat dissipation structure is reduced.

Owner:HUIZHOU CHINA STAR OPTOELECTRONICS TECHNOLOGY CO LTD

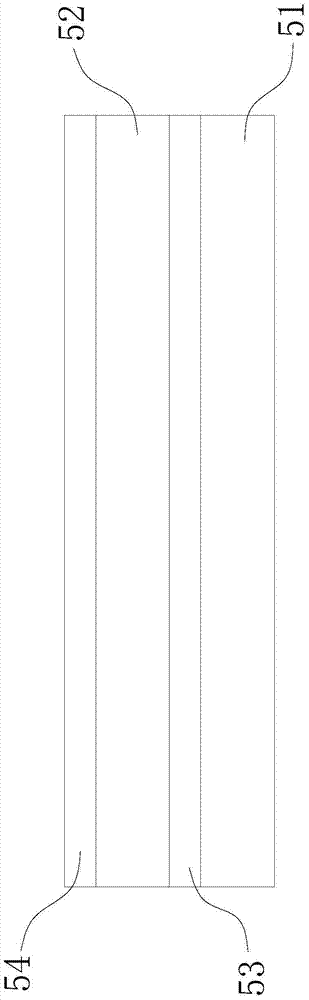

A double-sided image sensor

InactiveCN106409855BGuaranteed thinnerGuaranteed ability to receive lightSolid-state devicesRadiation controlled devicesOptoelectronicsImage sensor

The invention provides a double-sided image sensor. The double-sided image sensor includes a first substrate which includes a front side having a first light receiving area and a reverse side opposite to the front side; a groove in the reverse side of the first substrate, the depth of the groove being smaller than or equal to half of the thickness of the first substrate; and a second substrate fixed in the groove, the second substrate including a front side having a second light receiving area and a reverse side opposite to the front side, and the front side of the second substrate and the reverse side of the first substrate being coplanar.

Owner:山东华芯电子有限公司

An anti-jamming image sensor

ActiveCN106373973BGuaranteed ability to receive lightAvoid occlusionSolid-state devicesRadiation controlled devicesAlloySilicon

The invention provides an anti-interference image sensor. The sensor comprises a first substrate, a silicon substrate and a second substrate; the first substrate comprises a front side with a first light reception area and a back side opposite to the front side; the silicon substrate includes a front side with a groove and a back side opposite to the front side; the second substrate is arranged in the bottom of the groove, the second substrate comprises a front side including a second light reception area and a back side opposite to the front side, and the front side of the second substrate and the back side of the silicon substrate are coplanar; and the back side of the first substrate is bonded to the front side of the silicon substrate via a Fe-Co alloy layer.

Owner:JIANGSU JUNLONG ELECTRIC TECH

A method of manufacturing a sensor with a reference capacitance

ActiveCN106409856BGuaranteed thinnerReduce thicknessRadiation controlled devicesCapacitanceBiochemical engineering

The invention provides a method for manufacturing a sensor with a reference capacitor, which comprises the steps of (1) providing a substrate, wherein the first substrate comprises an obverse side provided with a first light receiving area and a reverse side opposite to the obverse side; (2) manufacturing a groove at the reverse side of the first substrate, wherein the depth of the groove is less than or equal to half of the thickness of the first substrate; (3) providing a second substrate, and fixing the second substrate in the groove, wherein the second substrate comprises an obverse side provided with a second light receiving area and a reverse side opposite to the obverse side, and the obverse side of the second substrate and the reverse side of the first substrate are in the same plane; and (4) manufacturing a vertical capacitor, wherein the capacitor is parallel to the side surface of the first substrate, and the capacitor is coated by an insulating material.

Owner:JIANGSU TIWIN OPTO ELECTRONICS TECH

Optical imaging lens

The invention provides an optical imaging lens. The optical imaging lens comprises: a first lens with positive focal power, wherein the image side surface of the first lens is a convex surface; a second lens, wherein the object side surface of the second lens is a convex surface, and the image side surface of the second lens is a concave surface; a third lens; a fourth lens, wherein the fourth lens has negative focal power; and a fifth lens, wherein the on-axis distance TTL from the object side surface of the first lens to the imaging surface of the optical imaging lens and the half ImgH of the diagonal length of an effective pixel area on the imaging surface meet the following condition: TTL / ImgH is less than 1.2, and the maximum half field angle Semi-FOV of the optical imaging lens is greater than 45 degrees and less than 60 degrees. The problem that an optical imaging lens in the prior art is large in size is solved.

Owner:ZHEJIANG SUNNY OPTICAL CO LTD

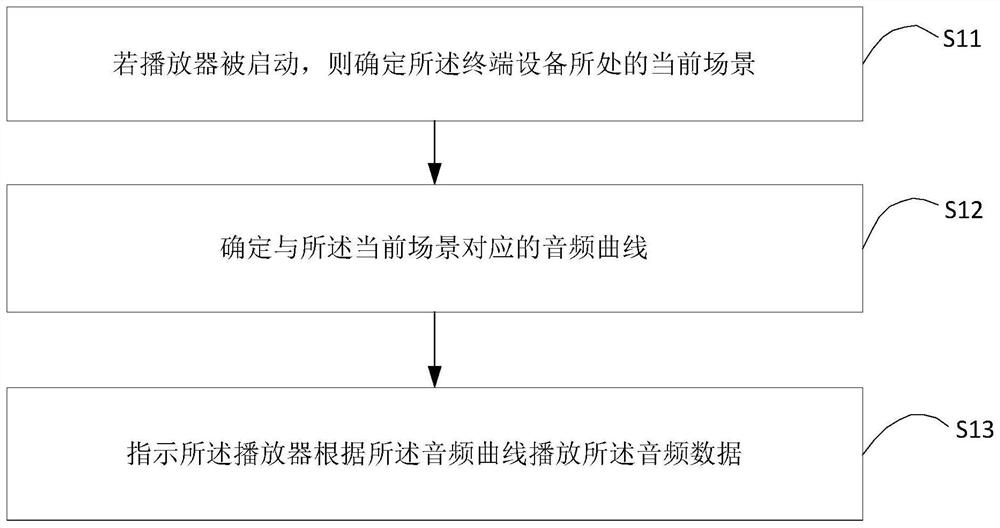

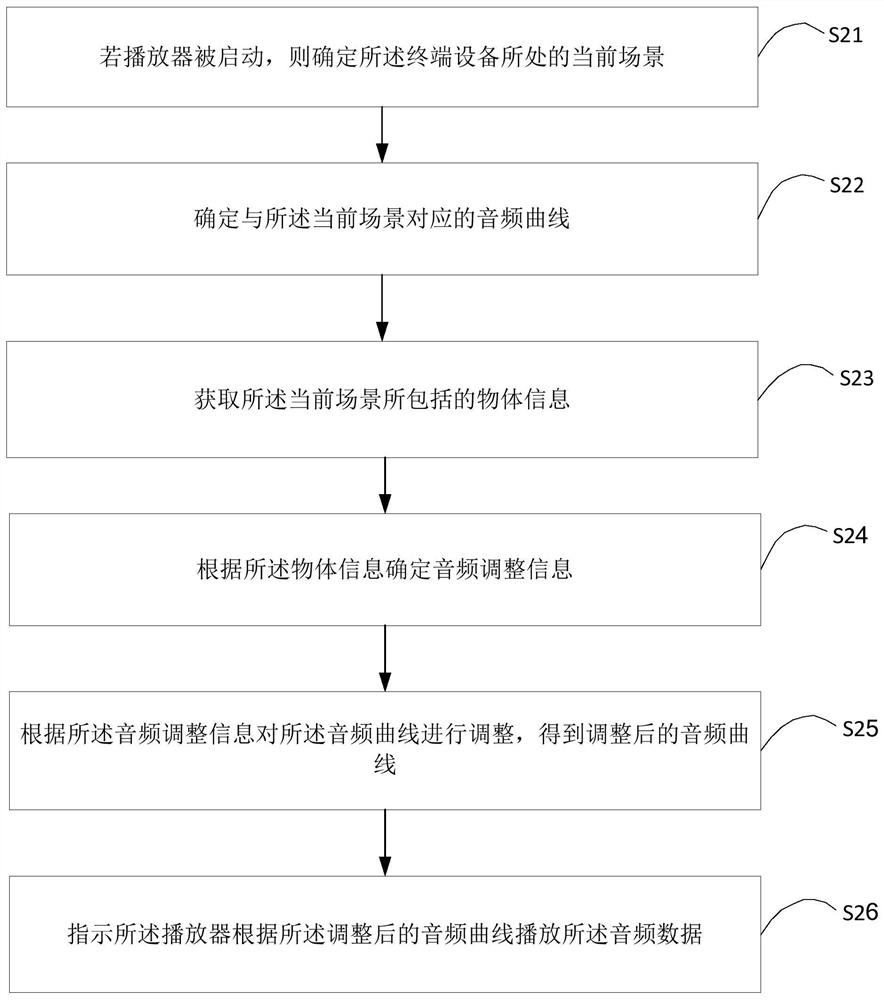

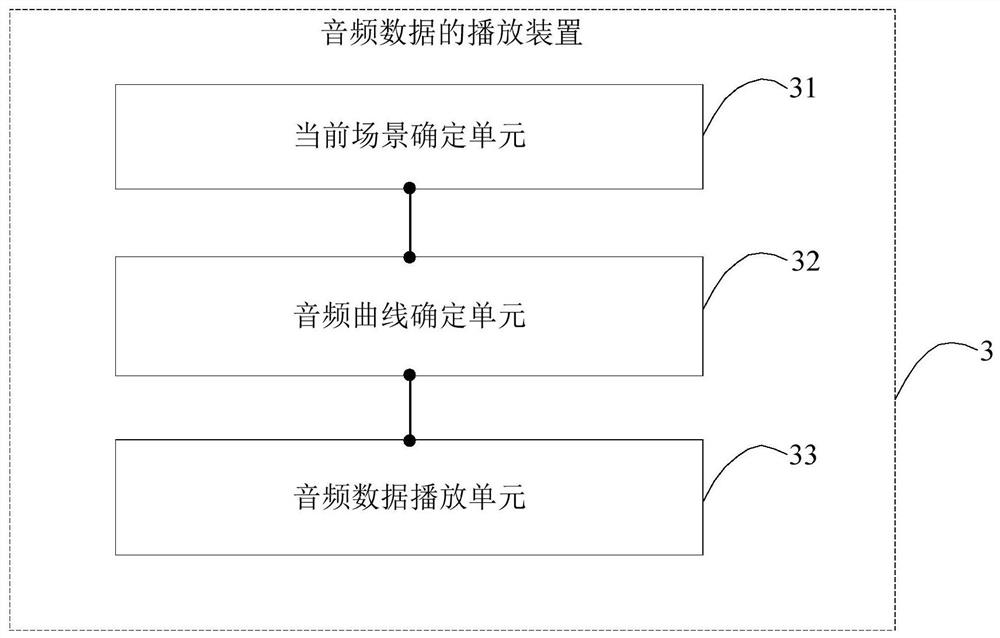

Audio data processing method, device and terminal equipment

ActiveCN111179984BGuaranteed thinnerImprove soundTelevision system detailsColor television detailsTerminal equipmentHuman–computer interaction

This application is applicable to the technical field of audio data processing, and provides an audio data processing method, device, and terminal equipment, including: if the player is activated, then determine the current scene where the terminal equipment is located; determine the current scene corresponding to the current scene; Audio curve: instruct the player to play the audio data according to the audio curve. Through the above method, the sound effect can be effectively improved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

A method of manufacturing a sensor

ActiveCN106430075BGuaranteed thinnerGuaranteed ability to receive lightDecorative surface effectsChemical vapor deposition coatingEngineering

The invention provides a manufacturing method of a sensor. The manufacturing method comprises the following steps: (1) providing a first substrate, wherein the first substrate comprises a front side provided with a first light receiving area and a back side opposite to the front side; (2) forming a groove in a back side of the first substrate, wherein the depth of the groove is smaller than or equal to a half of the thickness of the first substrate; and (3) providing a second substrate, and fixing the second substrate in the groove, wherein the second substrate comprises a front side provided with a second light receiving area and a back side opposite to the front side, and the front side of the second substrate and the back side of the first substrate are coplanar.

Owner:山东鸿荣电子有限公司

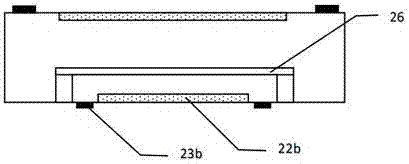

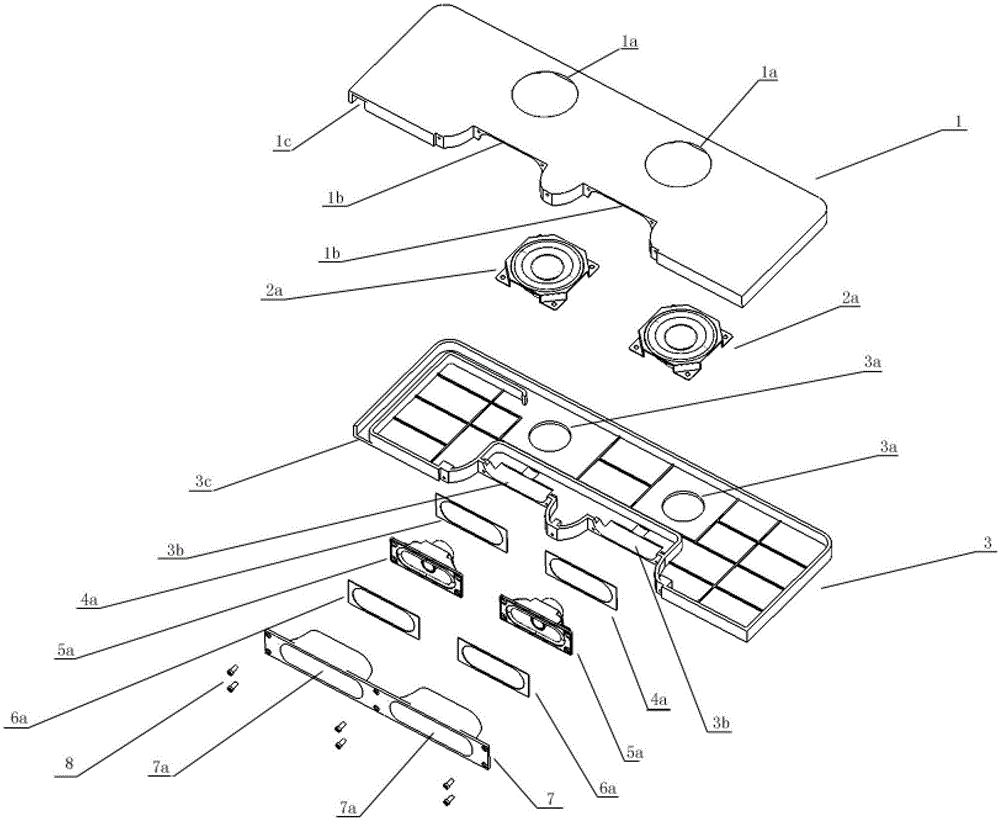

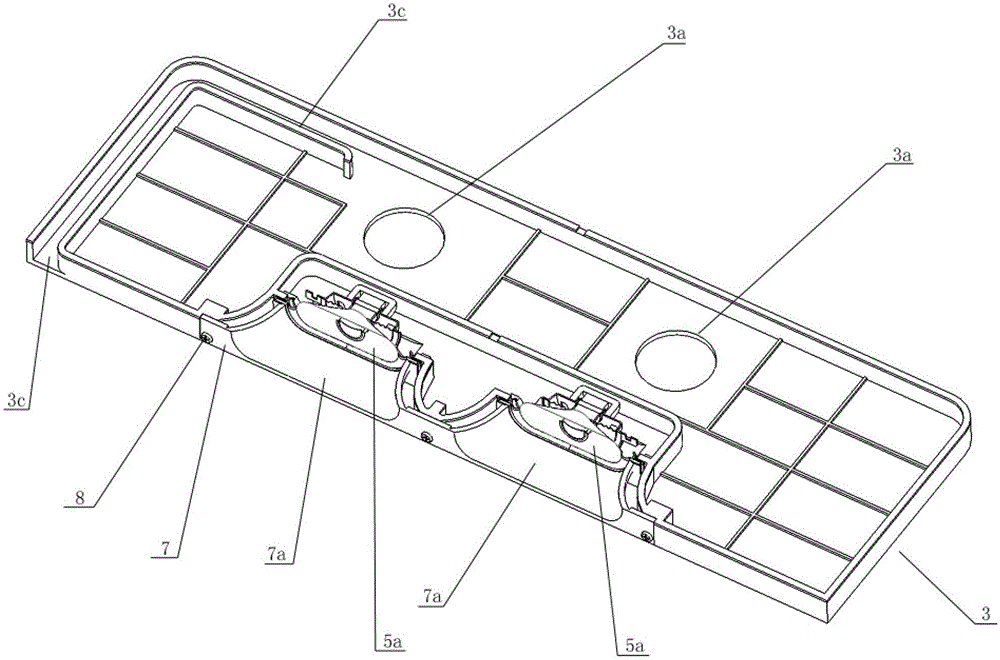

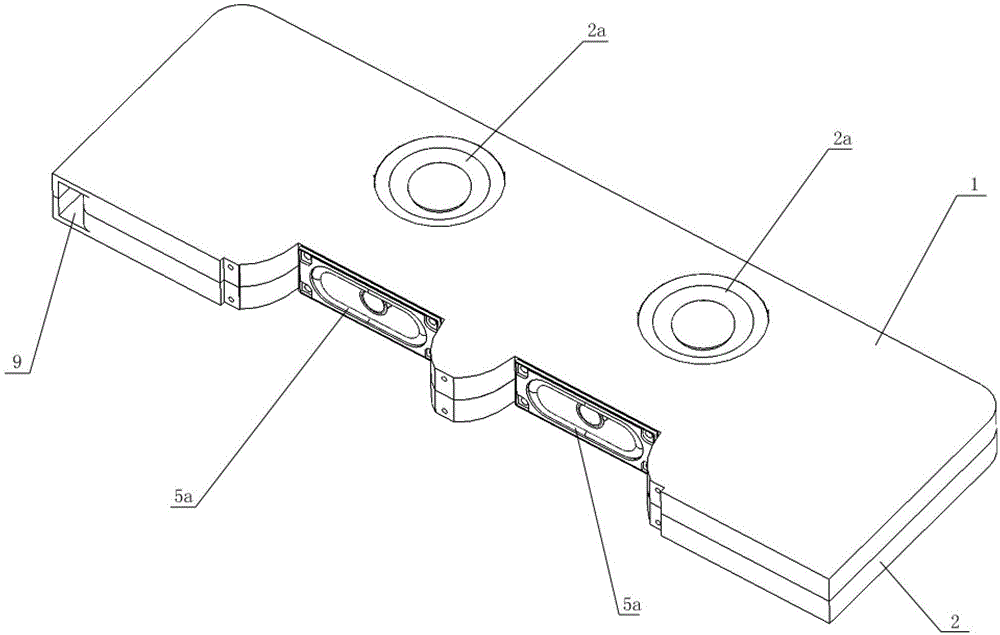

Horn type multi-point excitation speaker box

ActiveCN103269468BExcellent Acoustic IndexIngenious and reasonable structureLoudspeaker transducer fixingFrequency/directions obtaining arrangementsEngineeringSound quality

A horn type multi-point excitation loudspeaker enclosure comprises an enclosure body, bass loudspeaker units (2) and high pitch loudspeaker units (5), and is characterized in that: there are at least two bass loudspeaker units (2) and the number of the high pitch loudspeaker units (5) is the same as that of the bass loudspeaker units (2); the enclosure body is flat and elongated and is provided with lower mounting holes (3a) and upper mounting holes (1a), the number of the lower mounting holes (3a) and the upper mounting holes (1a) is the same as that of the bass loudspeaker units (2), the bass loudspeaker units (2) are mounted in the upper mounting holes (1a) and the lower mounting holes (3a); a plurality of side holes (1b, 3b) distributed along a long shaft of the enclosure body are arranged on the long side of the enclosure body, the number of the side holes (1b, 3b) is the same as that of the high pitch loudspeaker units (5), and the high pitch loudspeaker units (5) are mounted in the side holes (1b, 3b); a horn (7) is arranged in front of the high pitch loudspeaker units (5), and the horn (7) is provided with bugles (7a) in one-to-one correspondence with the high pitch loudspeaker units (5).

Owner:WUXI JIEFU ELECTROACOUSTIC

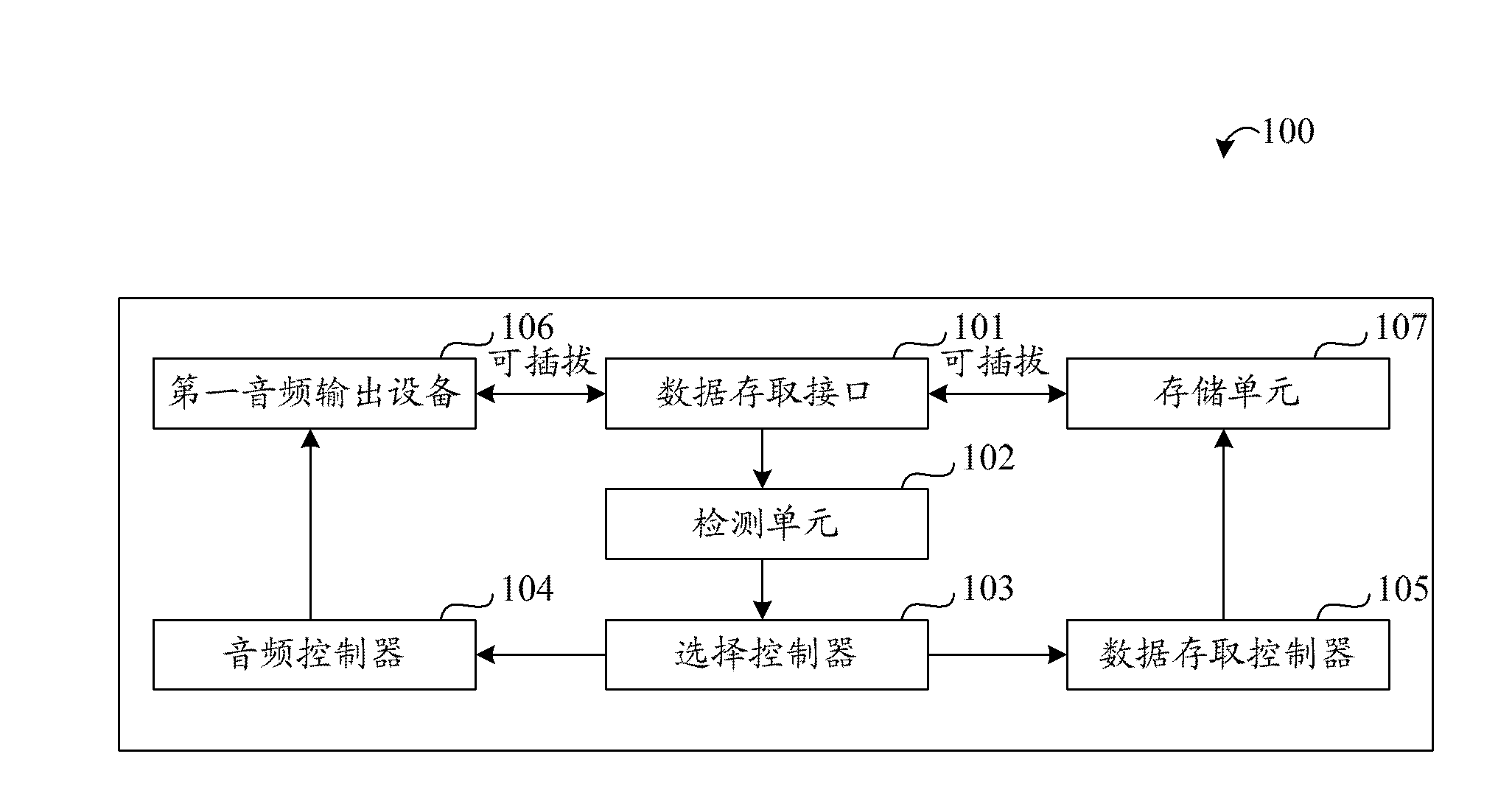

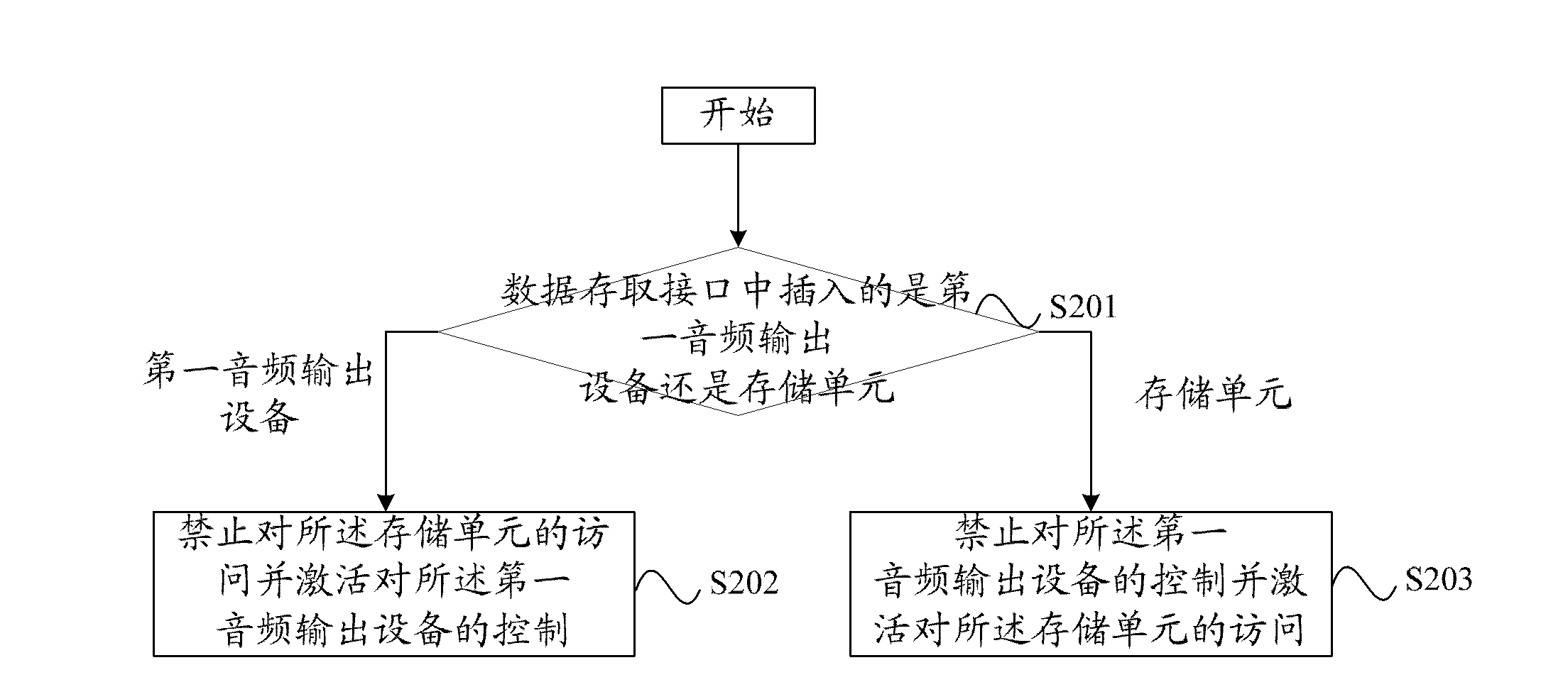

Information processing equipment and method

ActiveCN103164378AEnhances and complements audio performanceDoes not affect functionElectric digital data processingInformation processingData access

The invention discloses information processing equipment and a method. The information processing equipment comprises a data access port, a first voice frequency output device or a storage unit, a detection unit, a voice frequency controller, a data access controller and a selection controller, wherein the first voice frequency output device or the storage unit can be respectively inserted into the data access port according to design, the detection unit is used for detecting whether the first voice frequency output device or the storage unit is inserted into the data access port and outputting detected result information, the selection controller is used for receiving the detected result. When the detected result information shows that the first voice frequency output device is inserted into the data access port, the selection controller forbids access of the data access controller to the storage unit and activates the voice frequency controller to control the first voice frequency output device. When the detected result information shows that the storage unit is inserted into the data access port, the selection controller forbids control of the voice frequency controller to the first voice frequency output device and activates access of the data access controller to the storage unit.

Owner:LENOVO (BEIJING) LTD

Manufacturing method of image sensor

InactiveCN106505074AGuaranteed ability to receive lightAvoid occlusionSemiconductor/solid-state device detailsSolid-state devicesSiliconPhysics

The invention provides a manufacturing method of an image sensor. The method comprises the steps that (1) a first substrate is provided, wherein the first substrate comprises a front surface with a first light receiving area and a back surface opposite to the front surface; (2) a silicon substrate is provided, wherein the silicon substrate comprises a front surface with a groove and a back surface opposite to the front surface; (3) the back surface of the first substrate and the front surface of the silicon substrate are bonded through an iron-cobalt alloy layer; and (4) a second substrate is provided, the second substrate is arranged at the bottom of the groove and comprises a front surface with a second light receiving area and a back surface opposite to the front surface, and the front surface of the second substrate and the back surface of the silicon substrate are coplanar.

Owner:南通沃特光电科技有限公司

Imaging system, lens module and electronic equipment

ActiveCN113281880AGuaranteed miniaturizationGuaranteed thinnerOptical elementsConditional expressionEngineering

The embodiment of the invention discloses an imaging system, a lens module and electronic equipment. The imaging system sequentially comprises, from an object side to an image side along an optical axis, a first lens which has positive refractive power, and has an object-side surface being convex in a paraxial region; a second lens which has negative refractive power, and has an image-side surface being concave in a paraxial region; a third lens which has positive refractive power or negative refractive power, and has an object-side surface being concave in a paraxial region and an an image-side surface being convex in a paraxial region; and a fourth lens which has positive refractive power or negative refractive power, and has an object-side surface being convex in a paraxial region and an an image-side surface being concave in a paraxial region. The imaging system meets the following conditional expression: fno-f / TTL is less than 1.55. On the premise of ensuring miniaturization and thinning, the imaging quality can be improved.

Owner:JIANGXI JINGCHAO OPTICAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com