Patents

Literature

208results about How to "Translucent" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

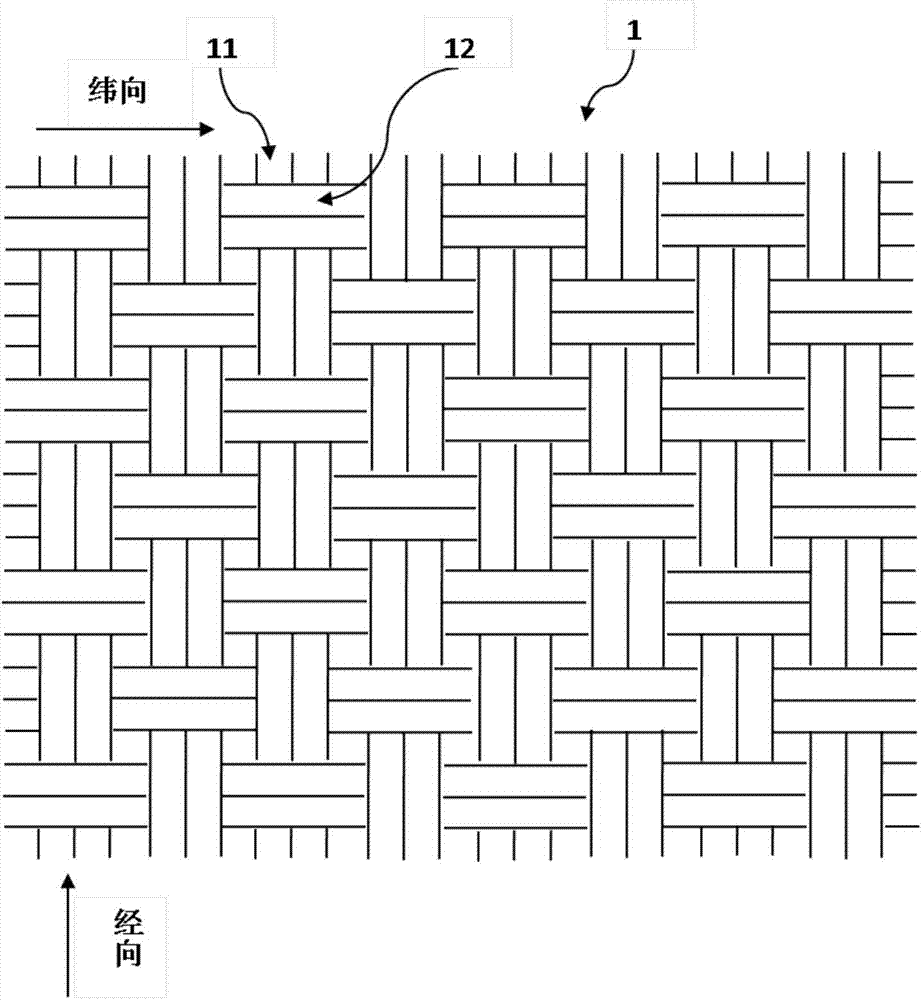

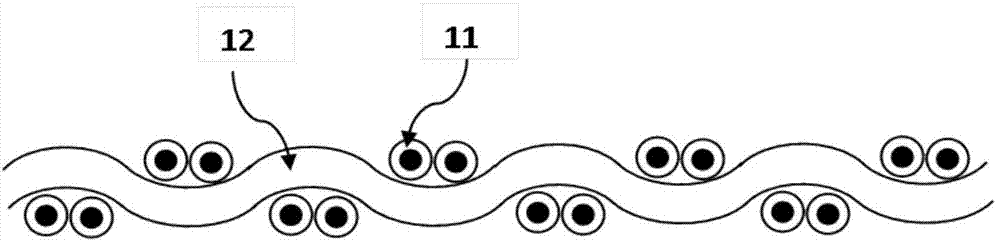

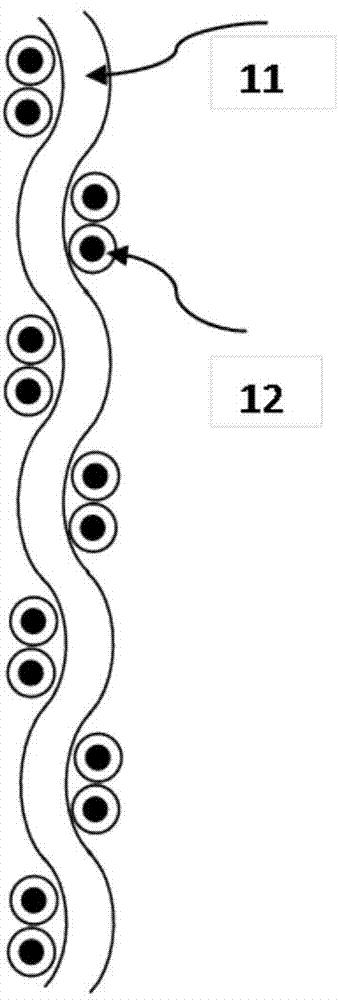

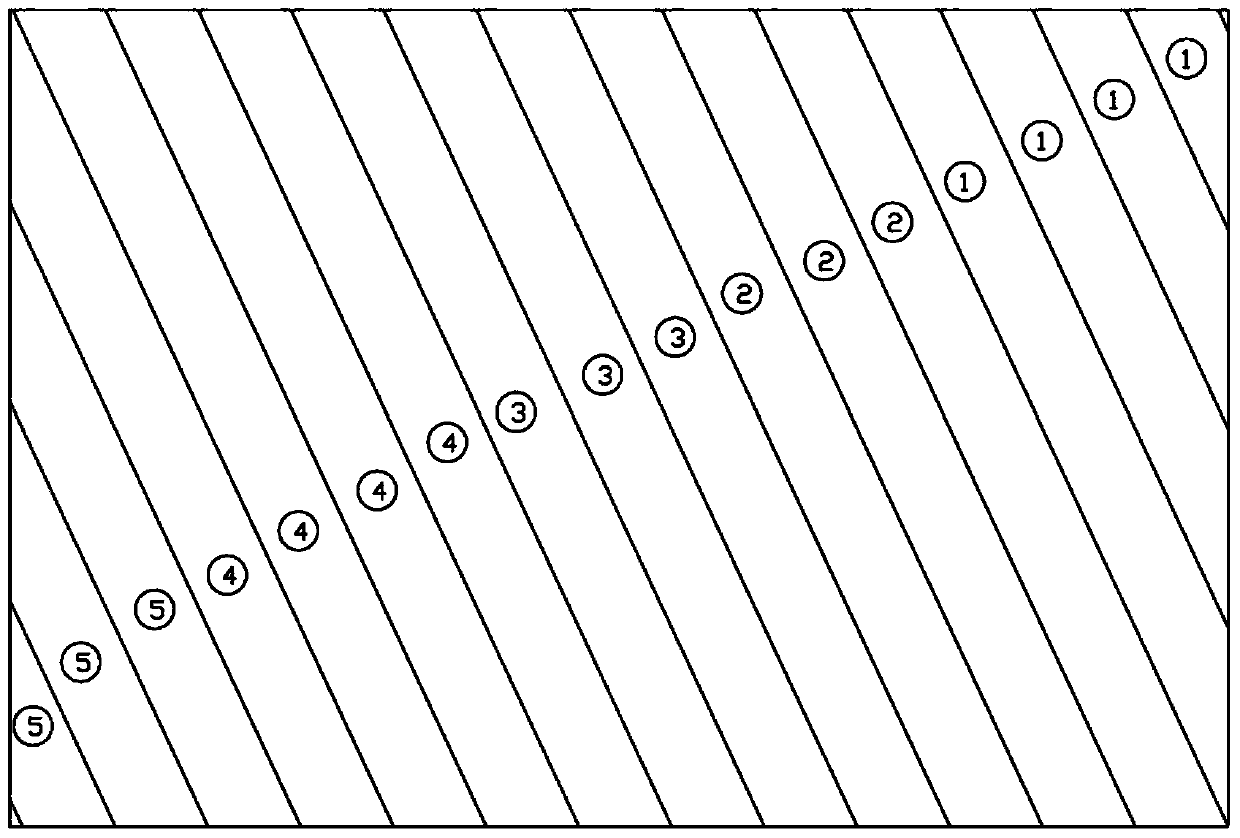

Sun-shading composite material with extinction and high flame-retardant effects

The invention discloses a sun-shading composite material with extinction and high flame-retardant effects. The composite material is a fabric comprising warps and wefts, wherein the fabric is woven by covering threads, rectangular or square gaps are left among the wefts, and the porosity of the composite material is 2-5%; the covering threads are made of a polyvinyl chloride composite material coating the surfaces of polyester fibers, the polyvinyl chloride composite material has the extinction and high flame-retardant effects and the covering threads are 0.3-0.5mm in diameter. The invention also provides a preparation method of the composite material. The sun-shading composite material has the characteristics of sunshading, ultraviolet ray resistance, inflaming retarding, high color fastness and the like of similar sun-shading composite materials, and also has the advantages of low glossiness, glare control, softness, comfort for eyes, fine and smooth handfeel and good breathability, and therefore, the sun-shading composite material can be well applied to the fields of leisure, fashion and individuation.

Owner:NINGBO XIANFENG NEW MATERIAL

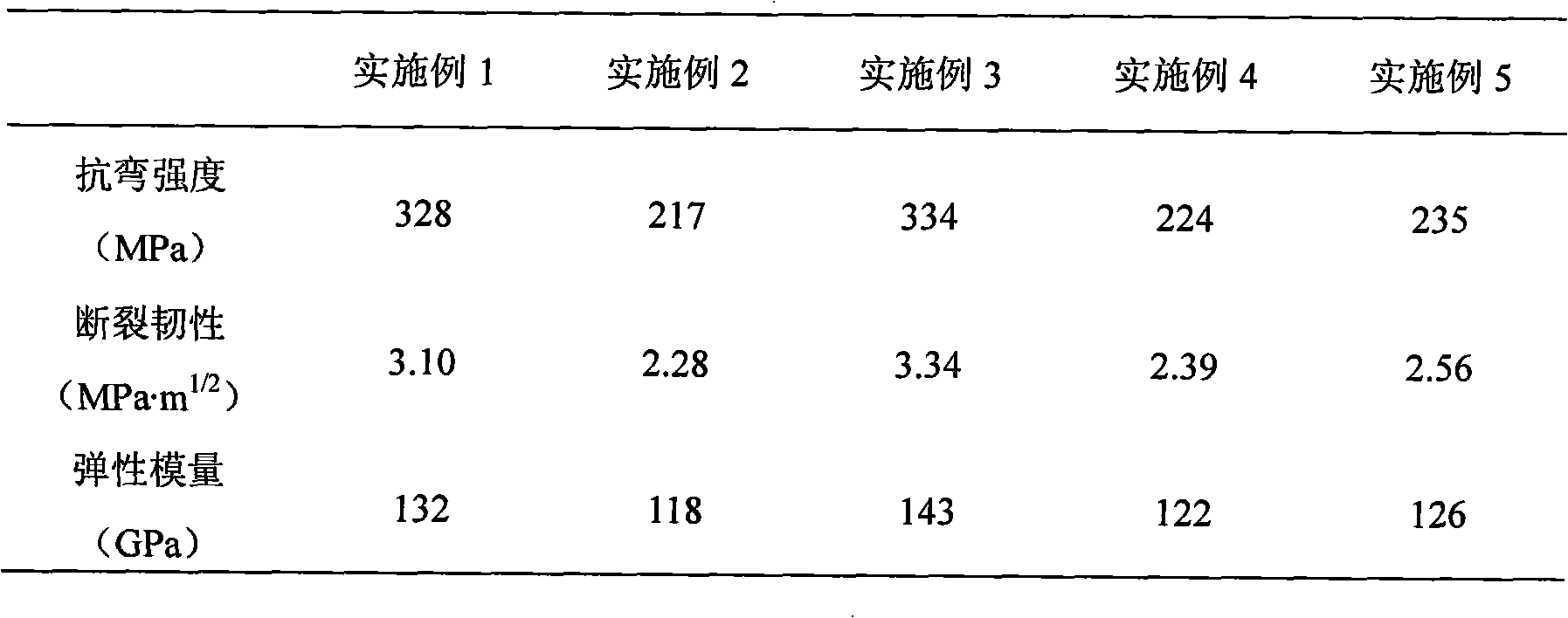

Rare earth-mixing high strength lithium bisilicate sitall material and preparation method thereof

The invention relates to a rare earth-mixing high strength lithium bisilicate sitall material and a preparation method thereof. Parent glass of the invention includes the following components according to molar percentage: 61.2 to 66.0 percent of SiO2, 0 to 2.5 percent of B2O3, 0 to 1.6 percent of Al2O3, 1.0 to 3.7 percent of P2O5, 0 to 2.3 percent of ZrO2, 1.0 to 1.8 percent of K2O, 24.2 to 31.8 percent of Li2O, 0 to 2.0 percent of MgO, 0 to 2.0 percent of CaO, and 0.5 to 4.2 percent of La2O3+Y2O3. A corresponding raw material prepared from the oxidates is processed by the steps of ball milling, 80 mesh sieve sieving and uniform mixing to obtain a batch; the batch is led into a copple to be melted after the temperature from 1480 to 1520 DEG C is maintained for 2 to 3 hours, and the melted batch is cast into a stainless steel mould to be molded and then is annealed at 500 DEG C for 0.5 hour; and the step of coring is carried out in a resistance furnace at the temperature from 500 to 550 DEG C for 1 hour, and the step of crystallization is carried out at the temperature from 600 to 850 DEG C for 2 hours. The crystallization degree of the sitall is as high as 60 to 70 percent, the flexural strength is 100 MPa or more higher than the sitall to which the rare earth oxides are not added, the highest flexural strength reaches 334 MPa, the maximum elastic modulus reaches 143 GPa, and the highest fracture toughness reaches 3.34 MPa-m. The sitall of the invention has favorable stability, and the heat treatment temperature is lower and is easy to control.

Owner:CENT SOUTH UNIV

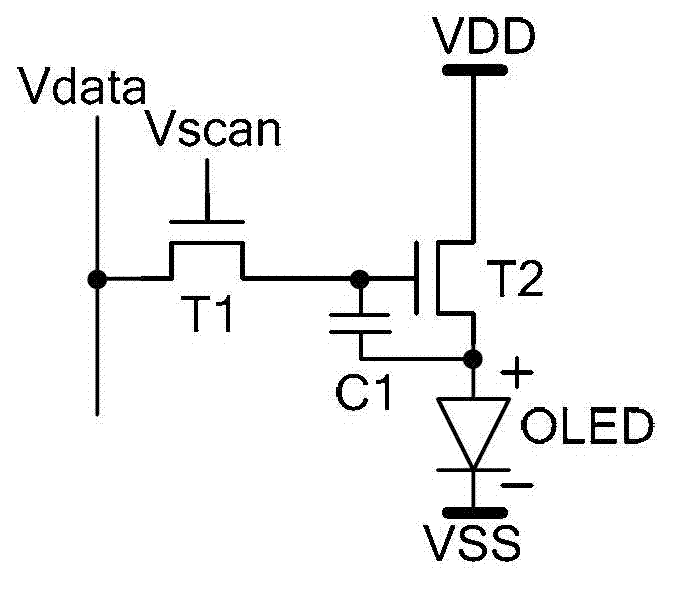

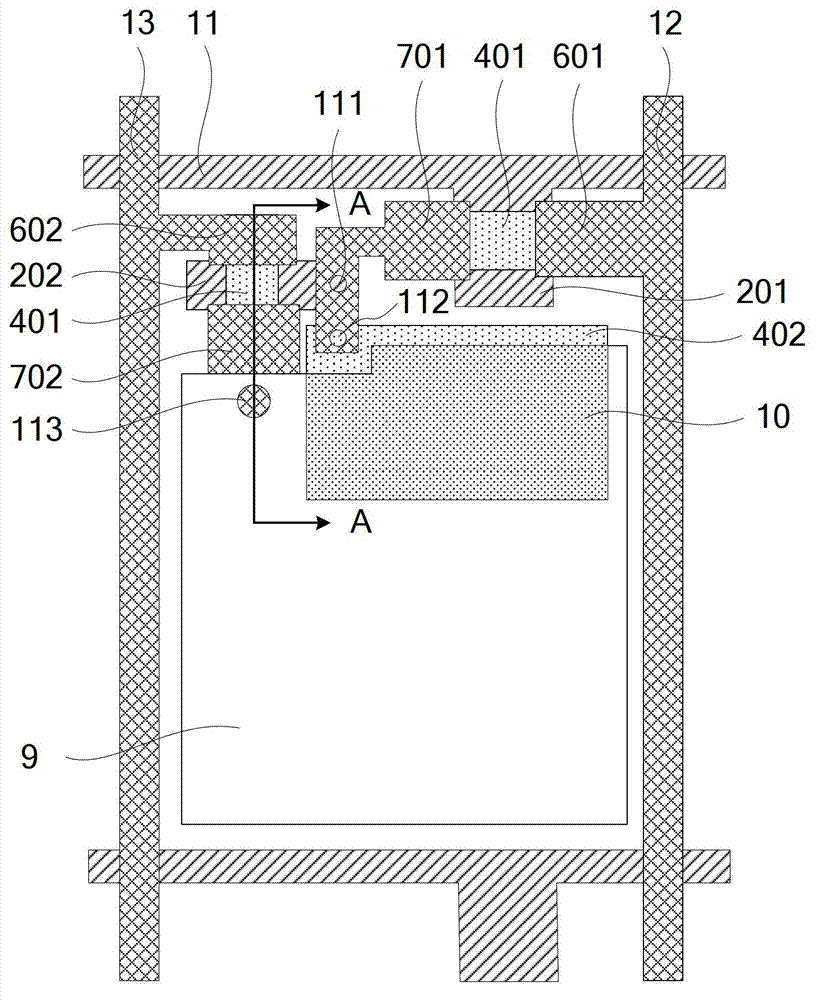

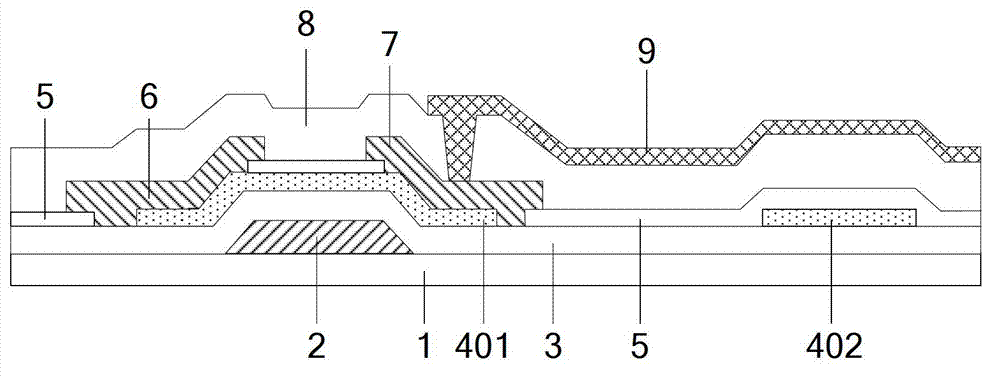

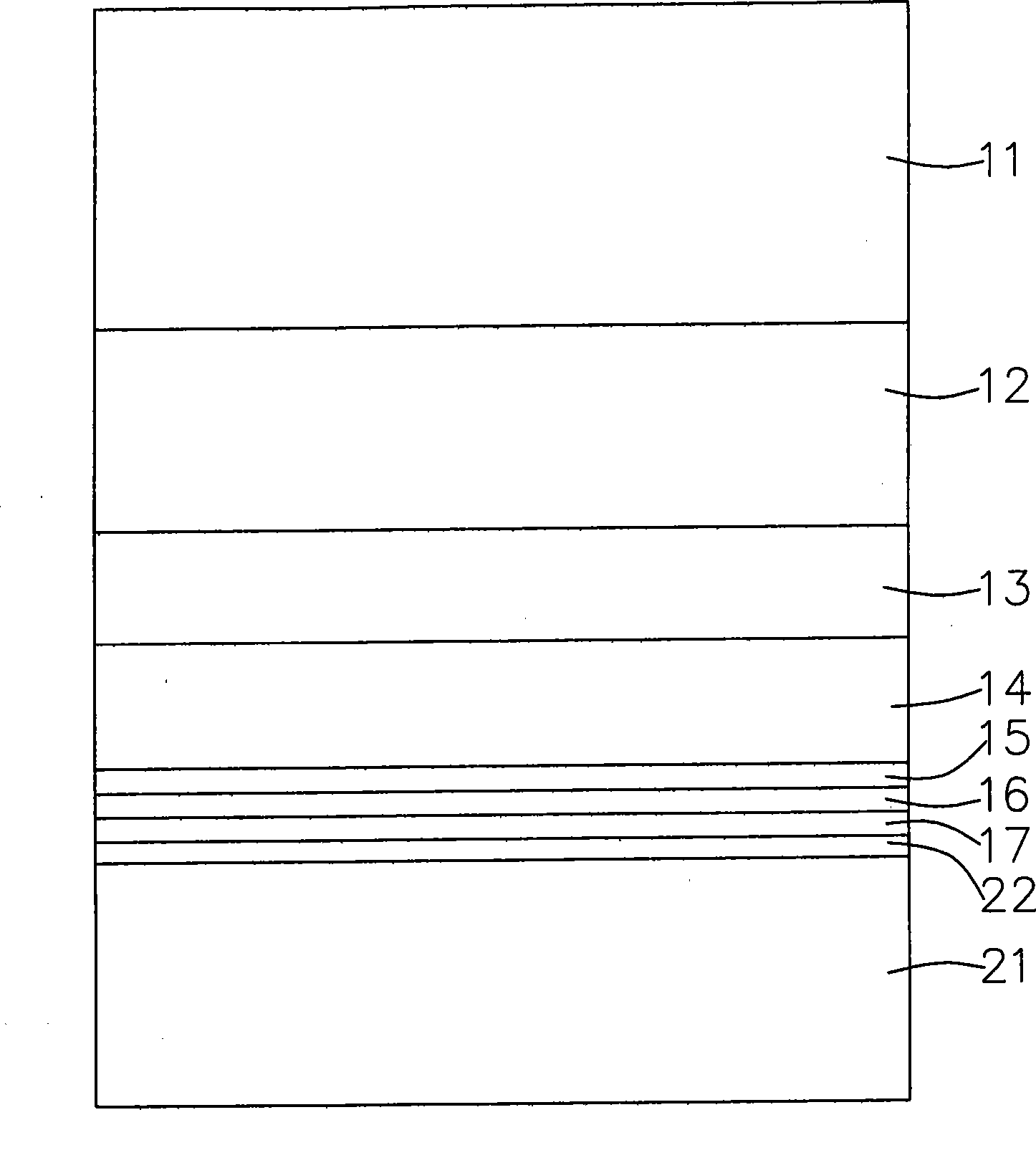

Array substrate, display device and manufacturing method

InactiveCN103208506AIncrease opening ratioReduce current intensitySolid-state devicesSemiconductor/solid-state device manufacturingCapacitanceDisplay device

The embodiment of the invention discloses an array substrate, a display device and a manufacturing method, and relates to the technical field of display devices. A second area of a transparent oxide active layer is used for forming a first electrode plate of a storage capacitor, so that the aperture ratio of the array substrate is increased. The array substrate comprises the oxide active layer and a pixel electrode, wherein the oxide active layer comprises patterns of first and second areas of the oxide active layer; the pixel electrode and the corresponding part of the second area of the oxide active layer form the storage capacitor; the second area of the oxide active layer forms the first electrode plate of the storage capacitor; the pixel electrode opposite to the second area of the oxide active layer forms a second electrode plate of the storage capacitor; and a film layer between the first and second electrode plates form a dielectric substance of the storage capacitor.

Owner:BOE TECH GRP CO LTD

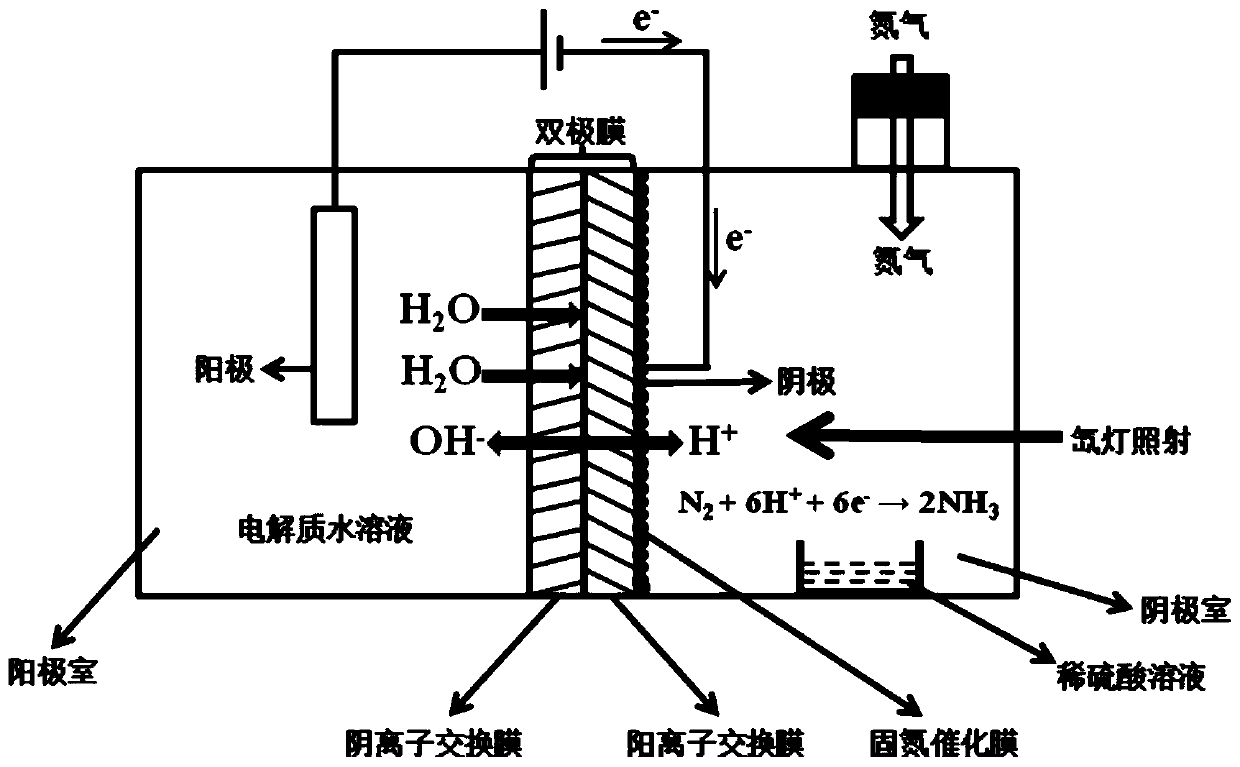

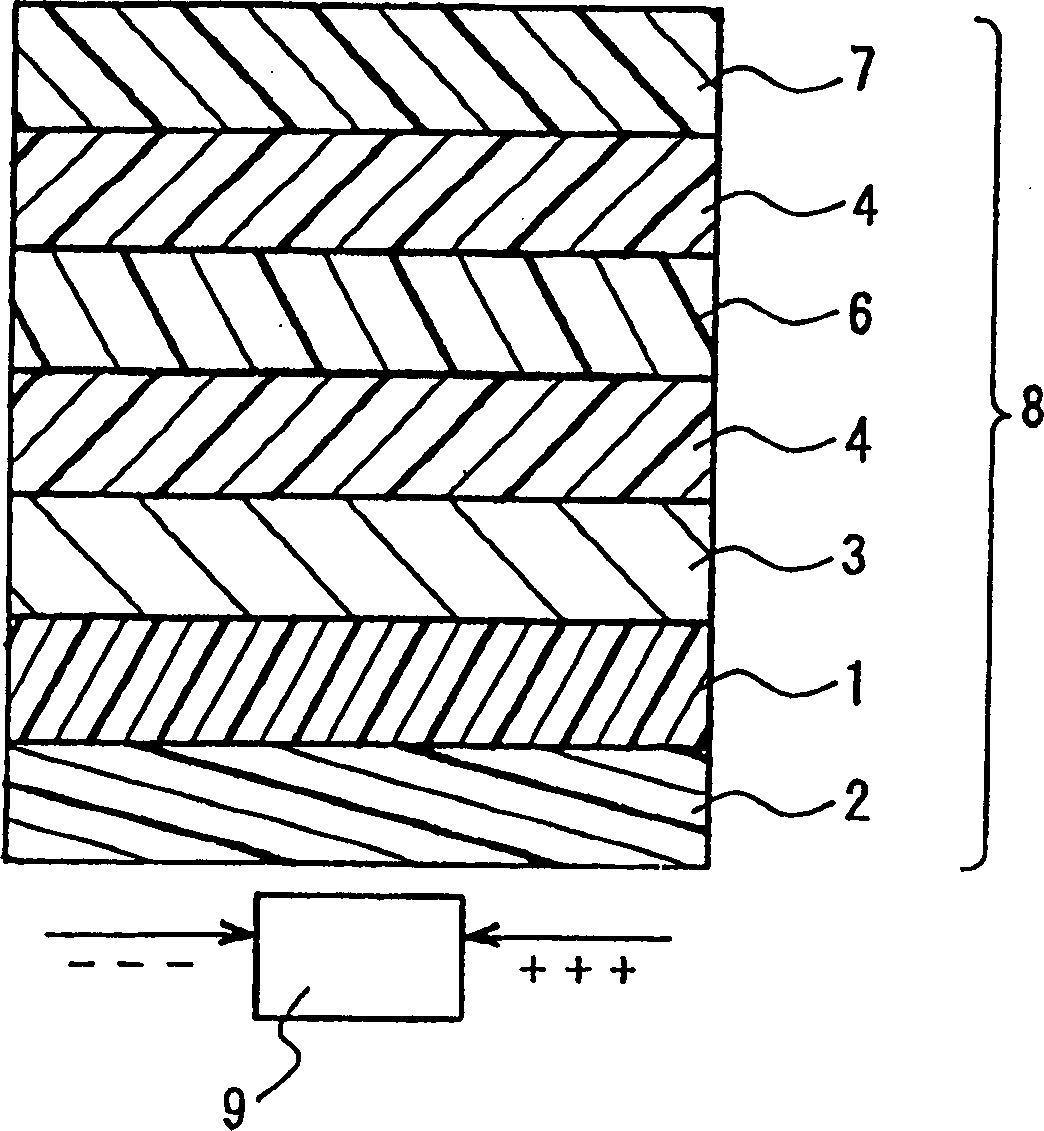

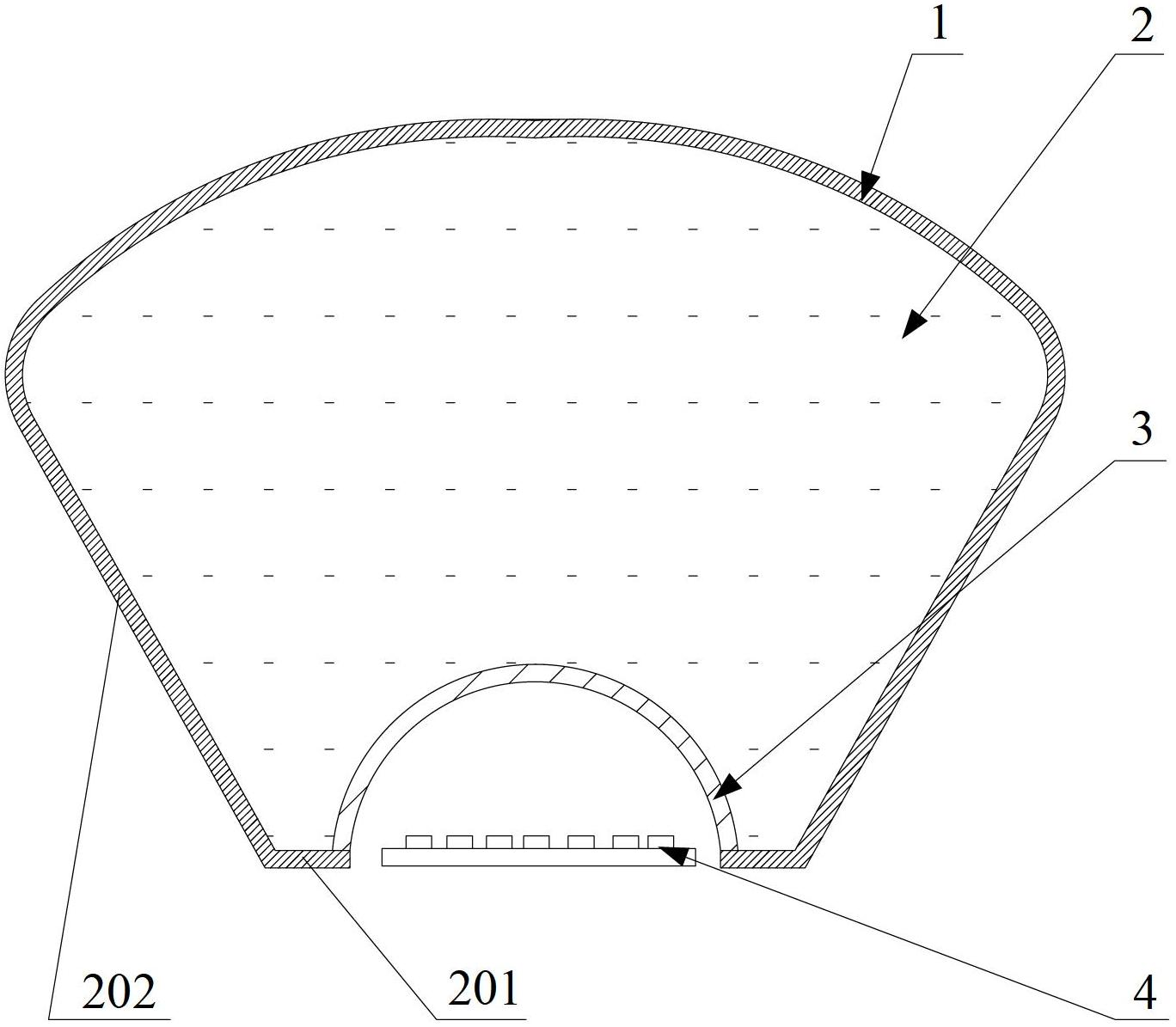

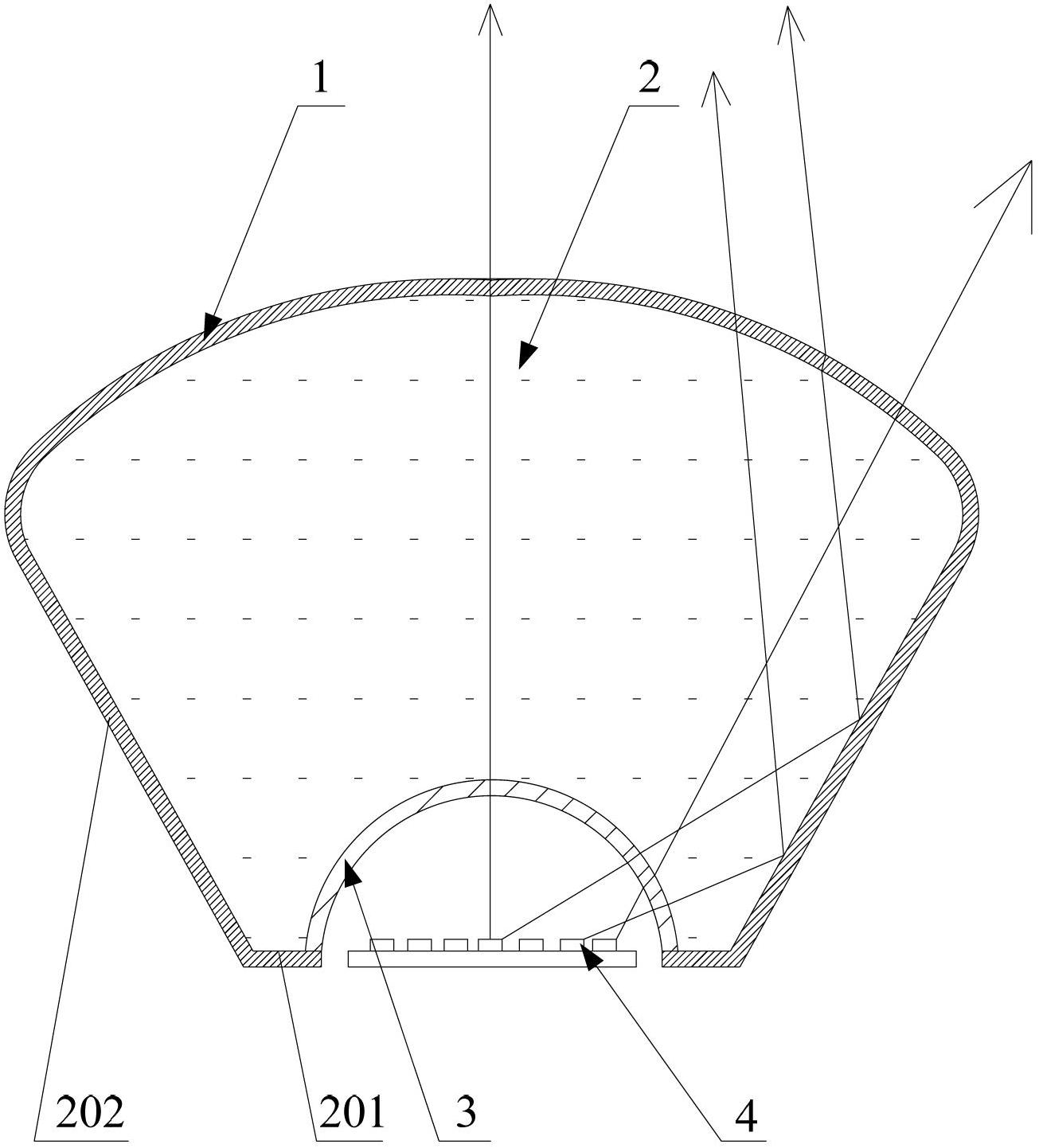

Device and method for synthesizing ammonia through photoelectrocatalysis nitrogen fixation

ActiveCN110079816AInhibition of hydrogen evolution side reactionAvoid hydrogen evolution reactionCellsMetal/metal-oxides/metal-hydroxide catalystsElectrolysisNitrogen gas

The invention provides a device and a method for synthesizing ammonia through photoelectrocatalysis nitrogen fixation and relates to the technical field of electro-catalysis electrolysis. The device for synthesizing ammonia through photoelectrocatalysis nitrogen fixation comprises a photoelectric composite membrane, wherein the photoelectric composite membrane consists of a bipolar membrane and anano nitrogen fixation catalysis membrane and is used for dividing an anode chamber and a cathode chamber into a double-chamber electrolytic bath; the bipolar membrane comprises an anion exchange membrane and a cation exchange membrane; the nano nitrogen fixation catalysis membrane is carried on the surface of the cation exchange membrane; an electrolyte solution is put into the anode chamber; thecathode chamber is filled with nitrogen; a BiVO4 or Pt electrode is adopted as an anode; a nitrogen fixation catalyst membrane is used as a cathode; a container filled with dilute sulfuric acid is arranged in the cathode chamber and is used for absorbing generated ammonia gas; a xenon lamp is adopted as a light source; an external direct-current power supply is adopted to provide electric field force; a positive pole and a negative pole of the external direct-current power supply are respectively connected with the anode and the cathode. The device is adopted for photoelectrocatalysis nitrogen fixation in a non-water solution, and has benefits that hydrogen evolution side reactions can be effectively inhibited, and the photoelectrocatalysis nitrogen fixation efficiency can be improved.

Owner:TAIYUAN NORMAL UNIV

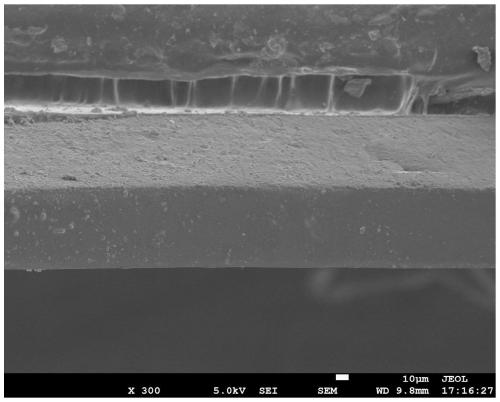

Workmanship of indoor microscopic oil displacement model

The invention relates to workmanship of a microscopic oil displacement model used in oilfield chemistry and acid fracturing laboratories to simulate a medium-low permeable oil deposit so as to study the oil displacement process. The invention adopts the technical scheme that the workmanship includes the steps: polishing, washing and blow-drying a glass substrate and then roasting the glass substrate on a glue baking plate; spin coating a layer of tackifier on the glass substrate and then baking on the glue baking plate, so as to form a nano-film; spin coating a layer of photoresist, and baking on the glue baking plate; converting an oil deposit picture into a black and white picture, importing the picture into photoetching software, exposing the glass substrate and then developing in developing liquid, washing, blow-drying, and baking on the glue baking plate; sealing the unexposed part of the glass substrate through paraffin wax, rusting in corrosive liquid, washing, then boiling in sulfuric acid and hydrogen peroxide, washing and blow-drying; tightly pressing the glass substrate to a mica sheet ,and sintering in a muffle furnace; and finally, grinding an access passageway, and putting capillary tubes into the access passageway to make a microscopic oil displacement model for studying the oil displacement process.

Owner:SOUTHWEST PETROLEUM UNIV

Silicone resin composite material containing nano-ZnO quantum dots and preparation method and application thereof

InactiveCN101649114APhotoluminescenceTranslucentPoint-like light sourceProtective devices for lightingQuantum dotTransmittance

The invention relates to a silicone resin composite material containing nano-ZnO quantum dots, which is a nanometer composite material consisting of colorless and transparent silicone resin in a visible light area and nano-ZnO quantum dot granules dispersed in the silicone resin evenly. The ratio in weight portion of the silicon resin to the nano-ZnO quantum dot granules is 0.1-10:99.9-90. The preparation method comprises the following steps: firstly preparing the nano-ZnO quantum dot granules, and dispersing the nano-ZnO quantum dot granules into acetone so as to prepare acetone solution of the nano-ZnO quantum dot granules; and secondly, adding corresponding acetone solution of the nano-ZnO quantum dot granules according to the ZnO content in the composite material into the silicone resin, after evenly mixing the mixture, extracting solvent, and injecting the solvent into a mould so as to prepare the silicone resin composite material containing the nano-ZnO quantum dots through curing and forming. The composite material has the excellent light transmittance and luminous performance, and is suitable for the surface encapsulation of photoelectric devices, LED solid lighting devicesor outdoor neon lamps.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Gel type ice and snow material with adjustable solidification temperature and transmittance and preparation method thereof

InactiveCN111154033AExtended life cycleBroaden application scenariosOther chemical processesPlasticizerPolymer chemistry

The invention relates to a gel type ice and snow material with adjustable solidification temperature and transmittance and a preparation method thereof, wherein the preparation method comprises the specific steps: firstly, taking an acrylamide polymerization monomer, a cross-linking agent, an initiator, a catalyst, a solidification temperature and transmittance regulator as raw materials to prepare an acrylamide ice and snow material; secondly, taking sodium alginate, a solubilizer, soluble divalent / trivalent metal ion salt, a crosslinking speed regulator, a plasticizer, a gelatinizing agent,a solidification temperature and a light transmittance regulator as raw materials, and carrying out ionic crosslinking to obtain the sodium alginate gel type ice and snow material. By blending the rawmaterial components, the solidification temperature of the gel type ice and snow material can be regulated and controlled within a wide range, and the synthesized material has the characteristics ofgood formability and easiness in processing.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Degradable bio-based air filter membrane and preparation method thereof

ActiveCN105597575ATranslucentMeet the requirements of light transmissionSemi-permeable membranesMembranesFiberPorosity

The invention belongs to the technical field of air purification and particularly provides a bio-based degradable efficient air-filtering fiber membrane material. This air-filtering fiber membrane is made by means of static spinning from bio-based polymer soy protein and polyvinyl alcohol as main materials and one or more of water-soluble natural polymer derivatives such as methylcellulose, chitosan and hydroxyethyl cellulose, as auxiliary materials, wherein the diameter of nano fiber is 100-1000 nm, the thickness of the fiber membrane is 20-1000 micrometers, and the fiber membrane is up to higher than 65% in porosity, 10-100 nanometers in pore size and up to higher than 90% in filtering efficiency. The bio-based degradable air filter membrane can be processed to serve for various purposes such as masks, screen windows and air purifiers, is safe and reliable and is low in cost; meanwhile, the preparation method is simple, the requirements on equipment is low, the production cost is low, the obtained air filter membrane has good filtering effect and high absorbing capacity, is degradable and recyclable and has promising market prospect.

Owner:BEIJING UNIV OF CHEM TECH

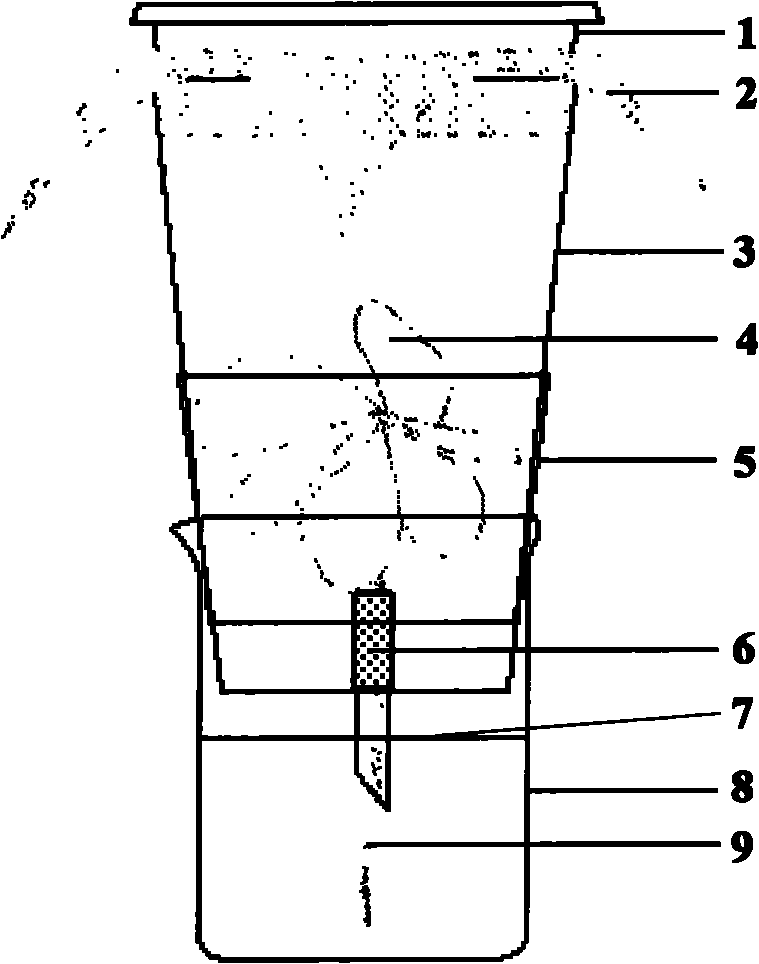

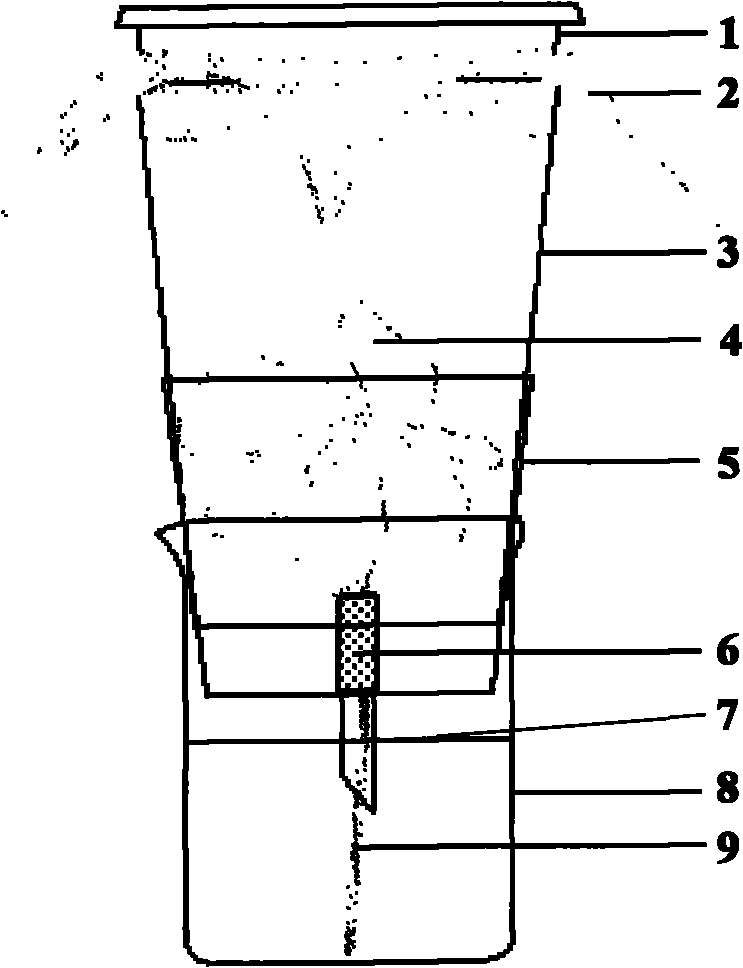

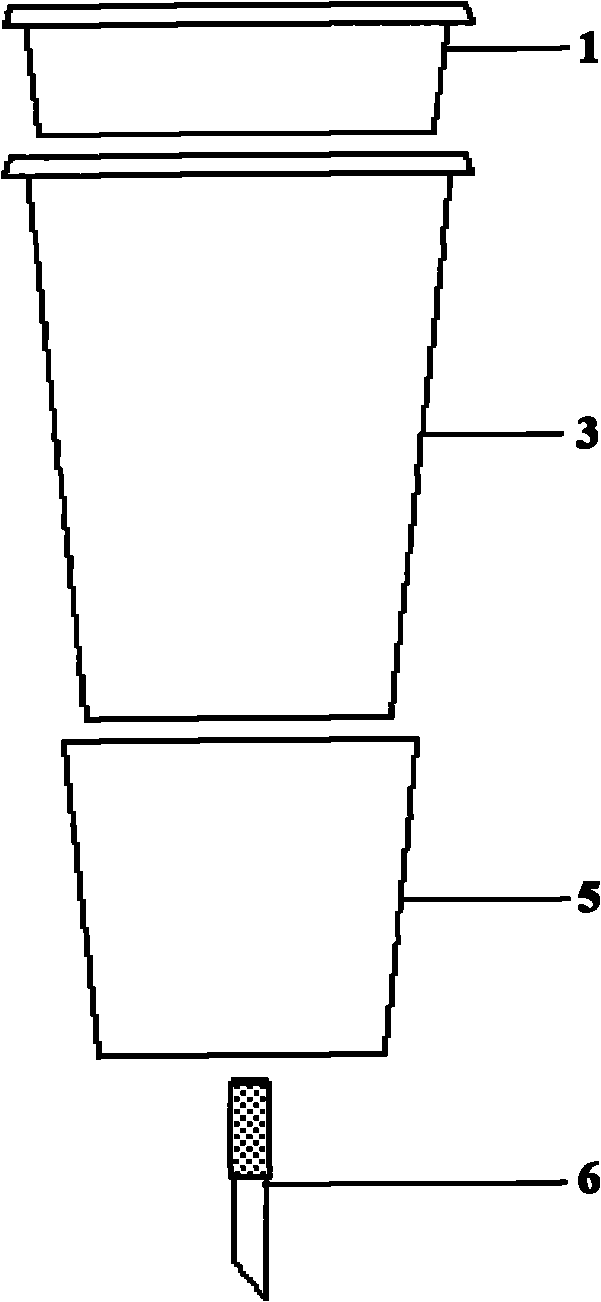

Tetranychina harti feeder

InactiveCN101810155AAvoid deathPrevent escape from disappearanceAnimal husbandryMicroscopic observationEngineering

The invention relates to a Tetranychina harti feeder, which belongs to the technical field of entomology experiment. The feeder consists of an upper feeding chamber and a lower water pool. Safflower oxalis leaf isolated leaf with petiole is vertically planted into the feeder. The blade in which the mite is cultivated is hung in the feeding chamber. The petiole enters under the water level of the water pool through a petiole inserting pipe at the bottom of the feeding chamber. When the Tetranychina harti is fed by the feeder, the blade part of the safflower oxalis leaf is free from the preserving liquid, therefore the blade is difficult to yellow and mildew, the blade surface is dry, and the mite can freely move on the blade, and has natural living state. The feeding chamber is manufactured by a disposable plastic cup, a gauge and the like, and has the advantages of sealing property, permeability and light transmission; and the microenvironment in which the mite is cultivated is consistent with the set feeding condition. Each component of the feeder is easy to disassemble and assemble, therefore the microscopic observation and replacement of the blade are convenient.

Owner:NANJING AGRICULTURAL UNIVERSITY +1

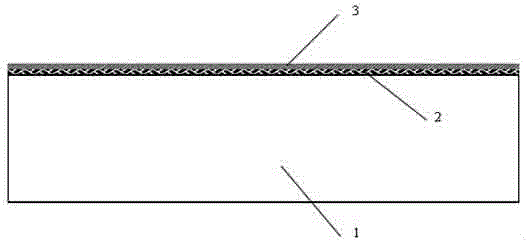

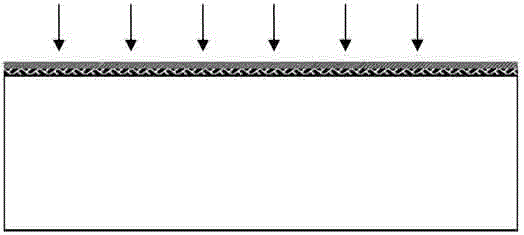

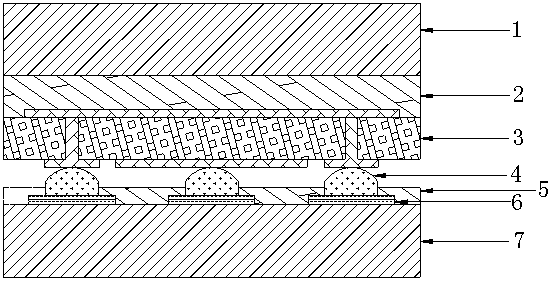

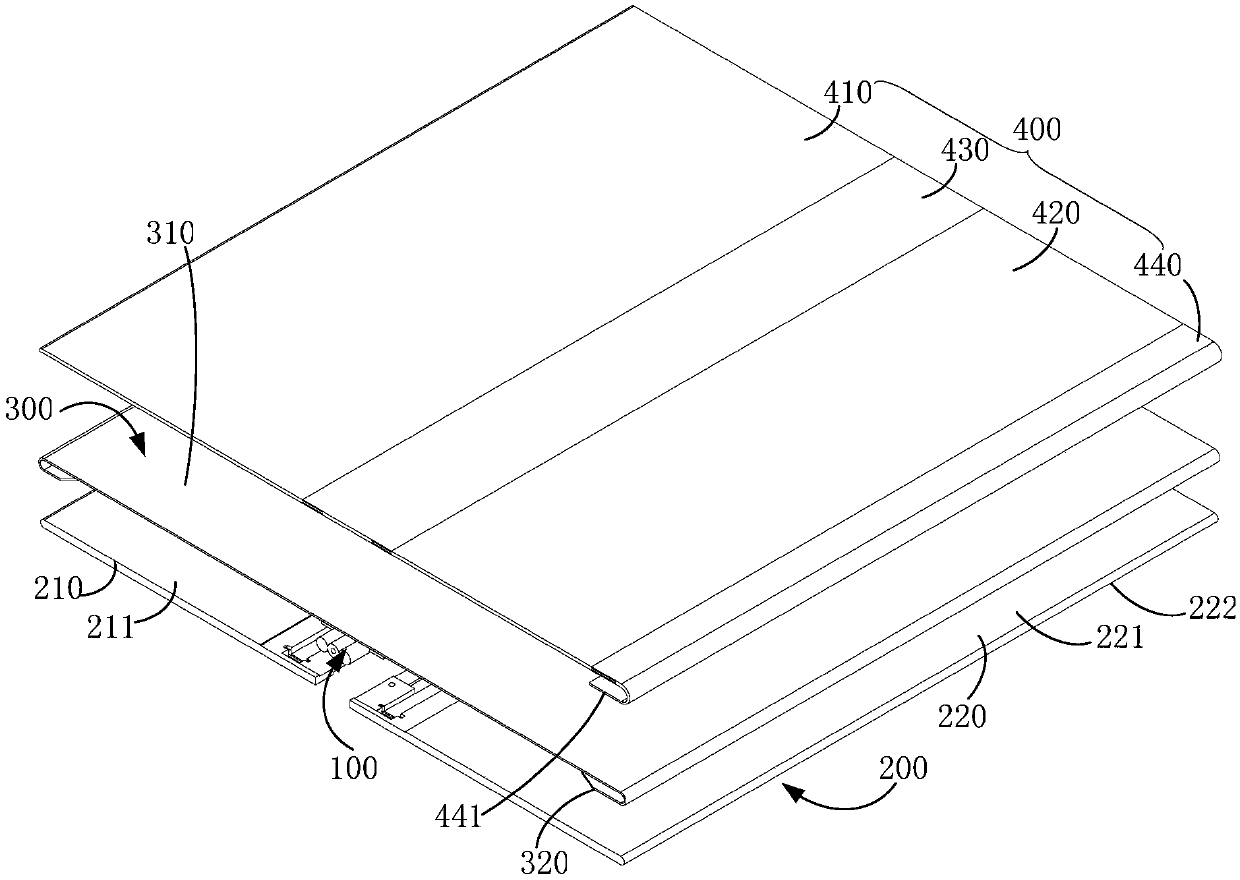

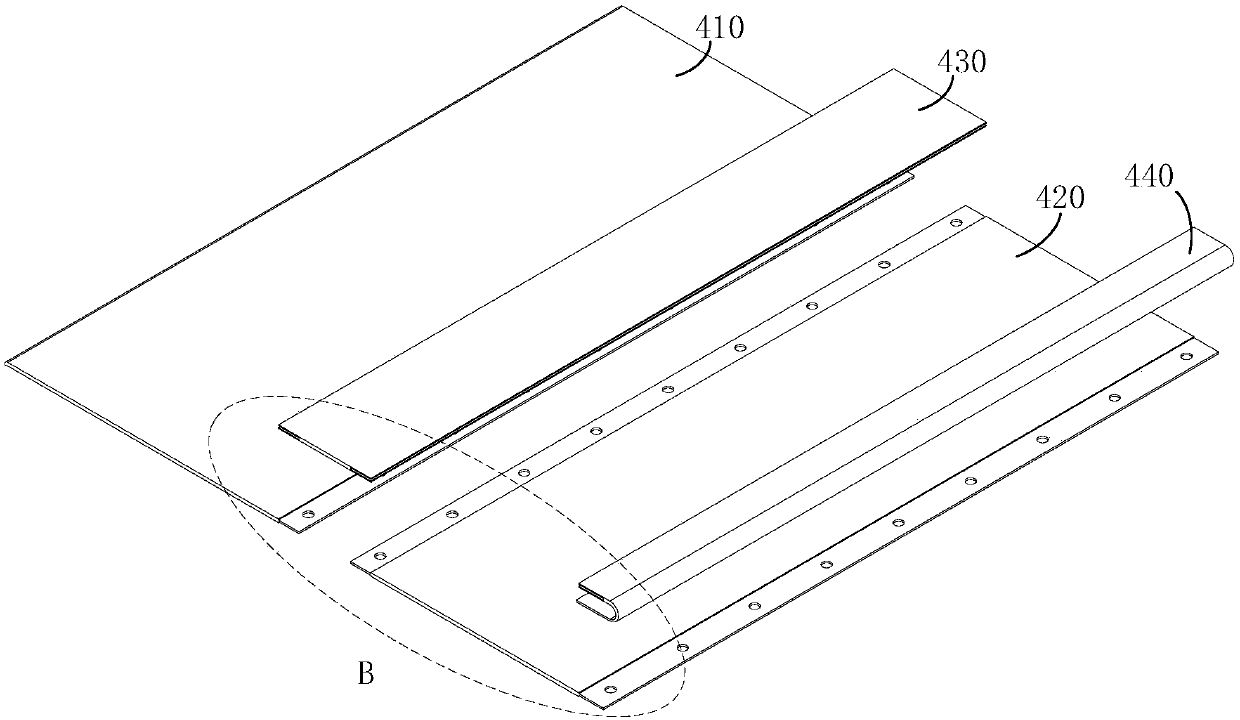

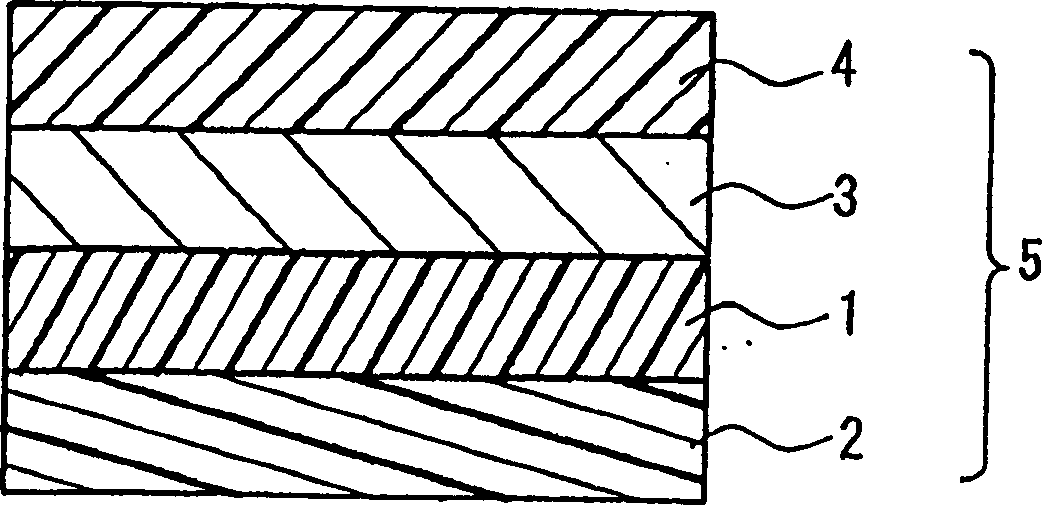

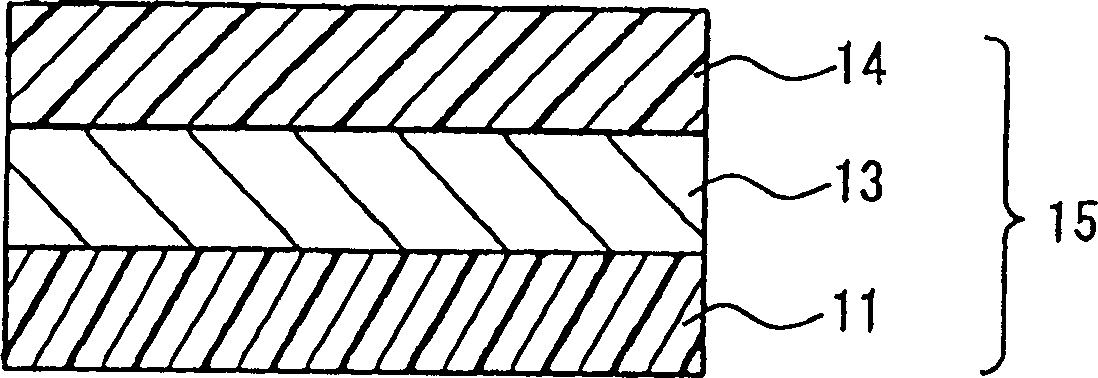

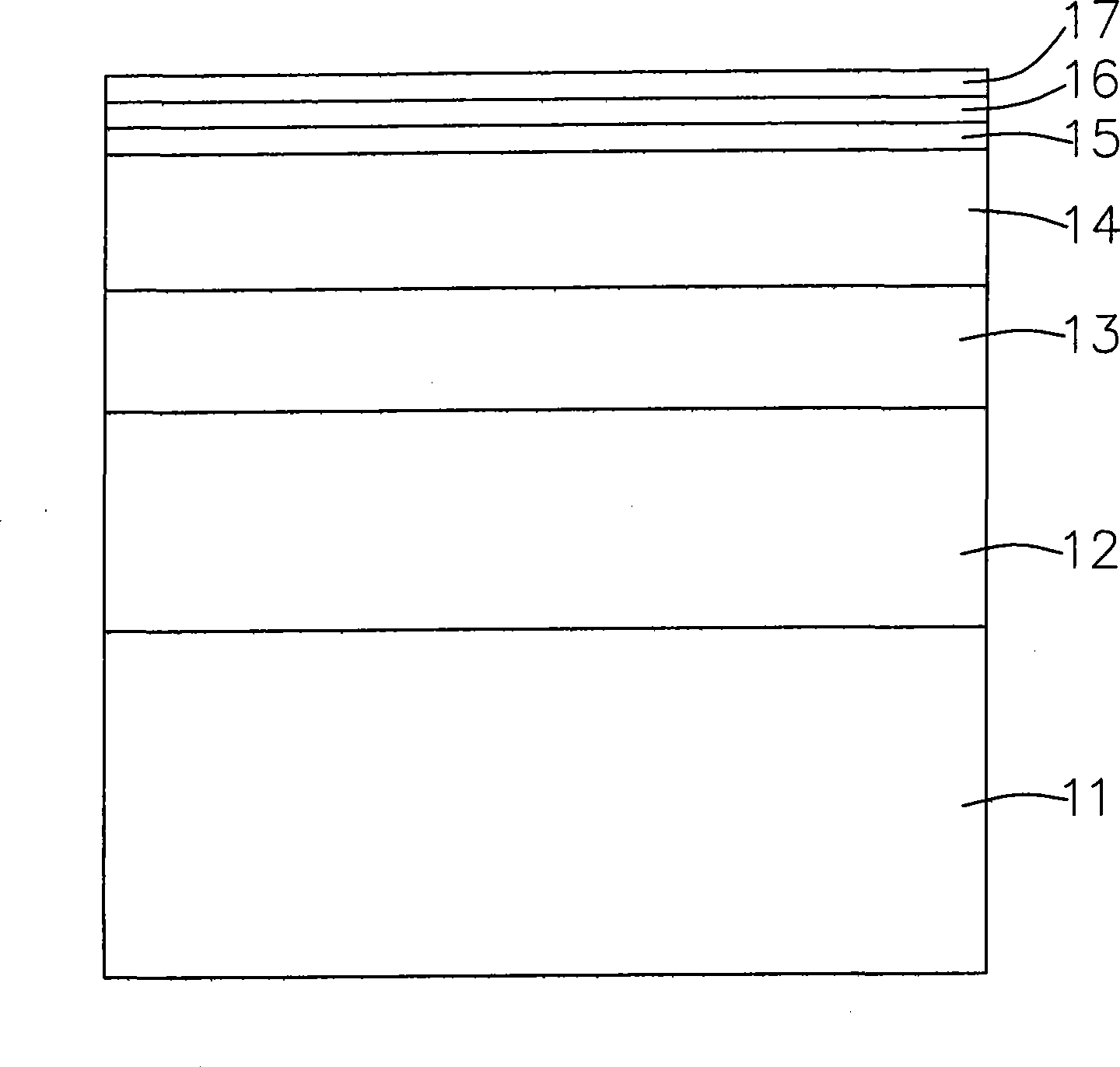

WMT solar cell module and preparation method thereof

InactiveCN103258888AImprove moisture resistanceAging resistantFinal product manufacturePhotovoltaic energy generationEngineeringSolar battery

The invention discloses a WMT solar cell module. The WMT solar cell module is formed by upper layer glass, a first hot melt adhesive film layer, a MWT solar cell string, a conductive adhesive layer, a second hot melt adhesive film layer, a conductive foil layer and lower layer glass in a sealing mode, wherein the upper layer glass, the first hot melt adhesive film layer, the MWT solar cell string, the conductive adhesive layer, the second hot melt adhesive film layer, the conductive foil layer and the lower layer glass are sequentially stacked. The pattern of the conductive foil layer is matched with the pattern of the electrode at the back side of the MWT solar cell string. A hole is formed in the position, corresponding to the conductive foil layer, of the second hot melt adhesive film layer, and the conductive foil layer is enabled to be capable of being contacted with the electrode at the back side of the MWT solar cell string. The conductive adhesive layer is arranged between the conductive foil layer and the electrode at the back side of the MWT solar cell string. The invention further discloses a preparation method of the MWT solar cell module. A two-layer-glass structure is adopted, and the glass has good functions of being moisture-resisting, ageing-resisting, ultraviolet-resisting, and not prone to be ageing. Compared with a rear panel of conventional molecular materials, the WMT solar cell module is very good in weather resistance, and therefore the service life of the module can be prolonged.

Owner:CECEP SOLAR ENERGY TECH (ZHENJIANG) CO LTD

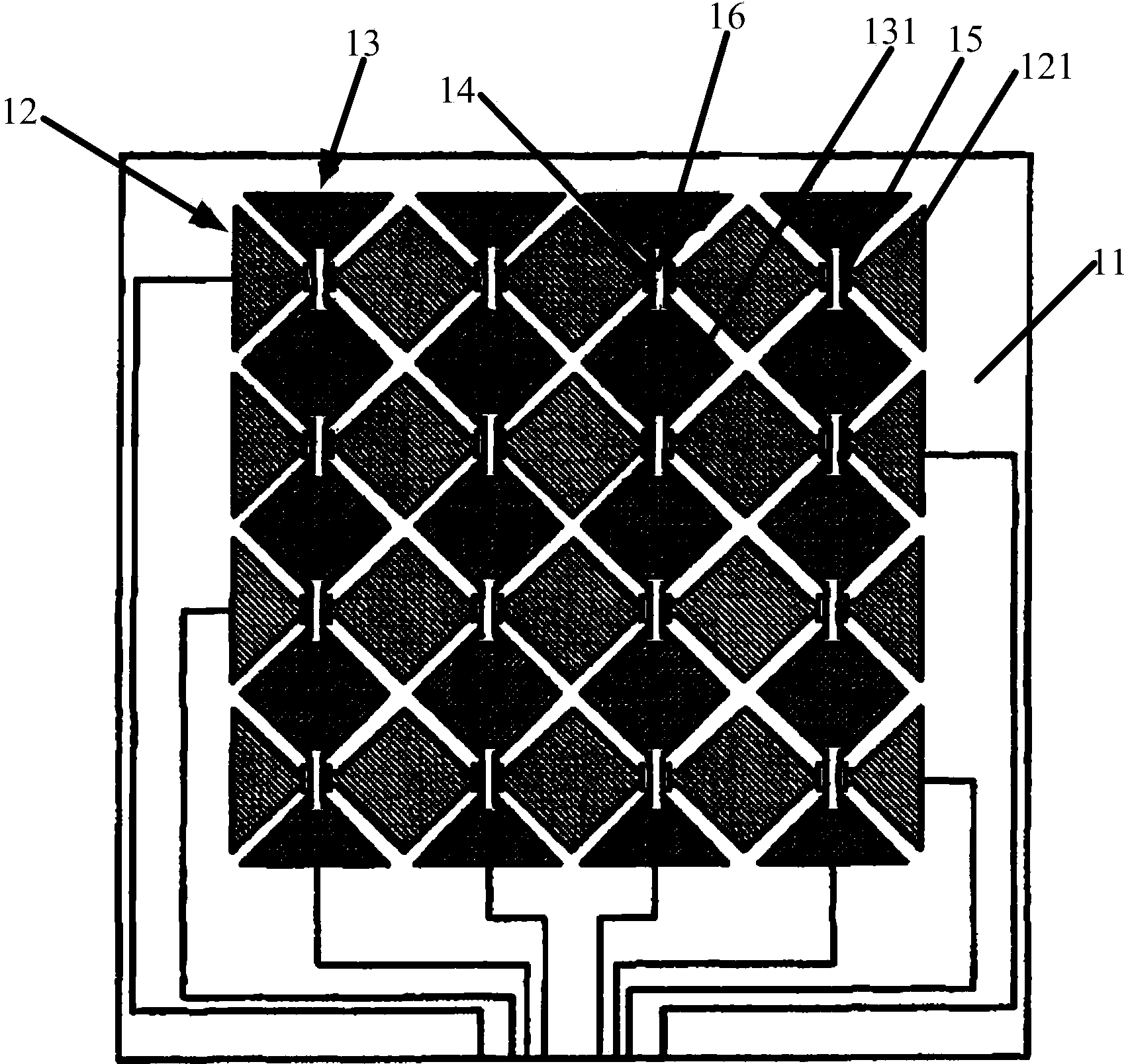

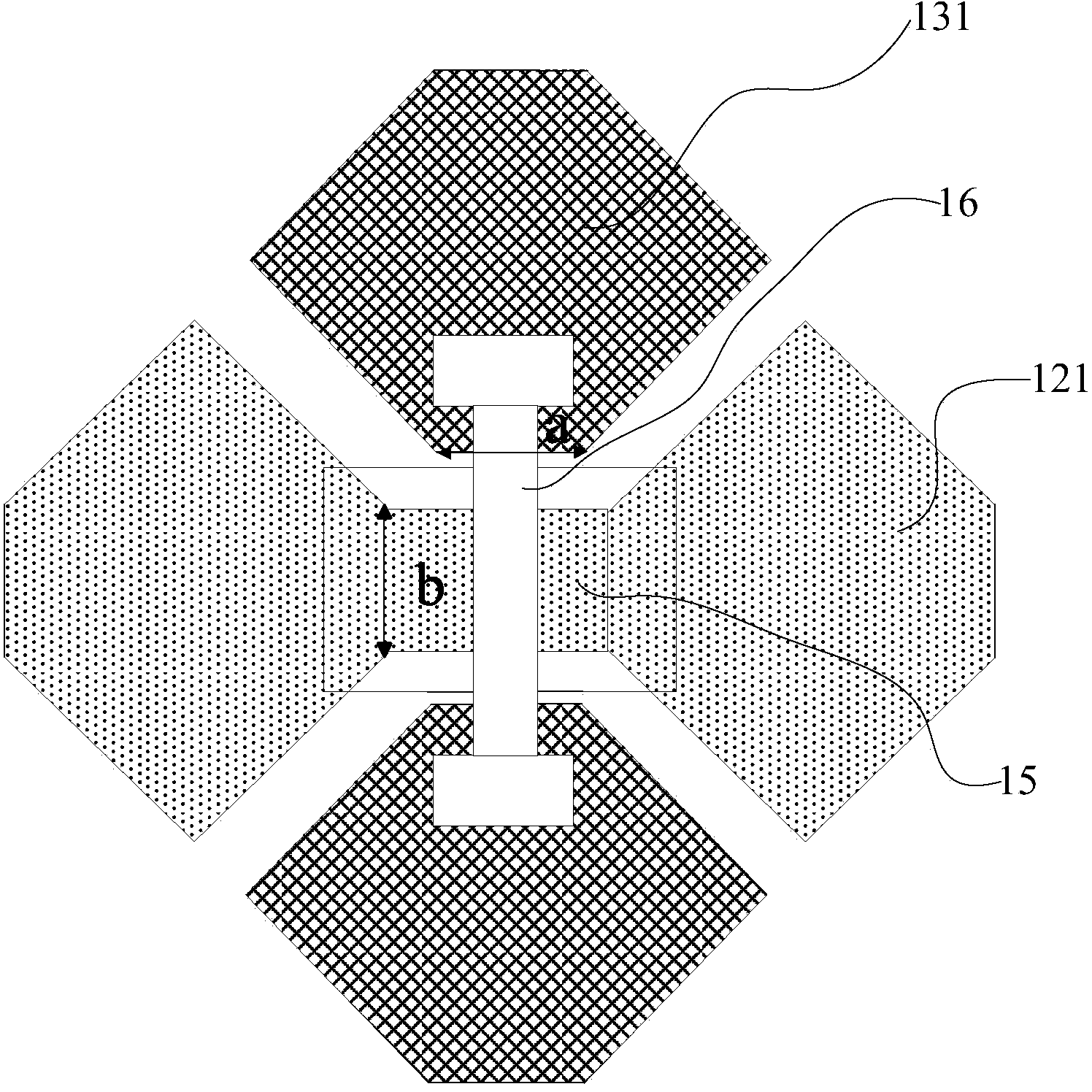

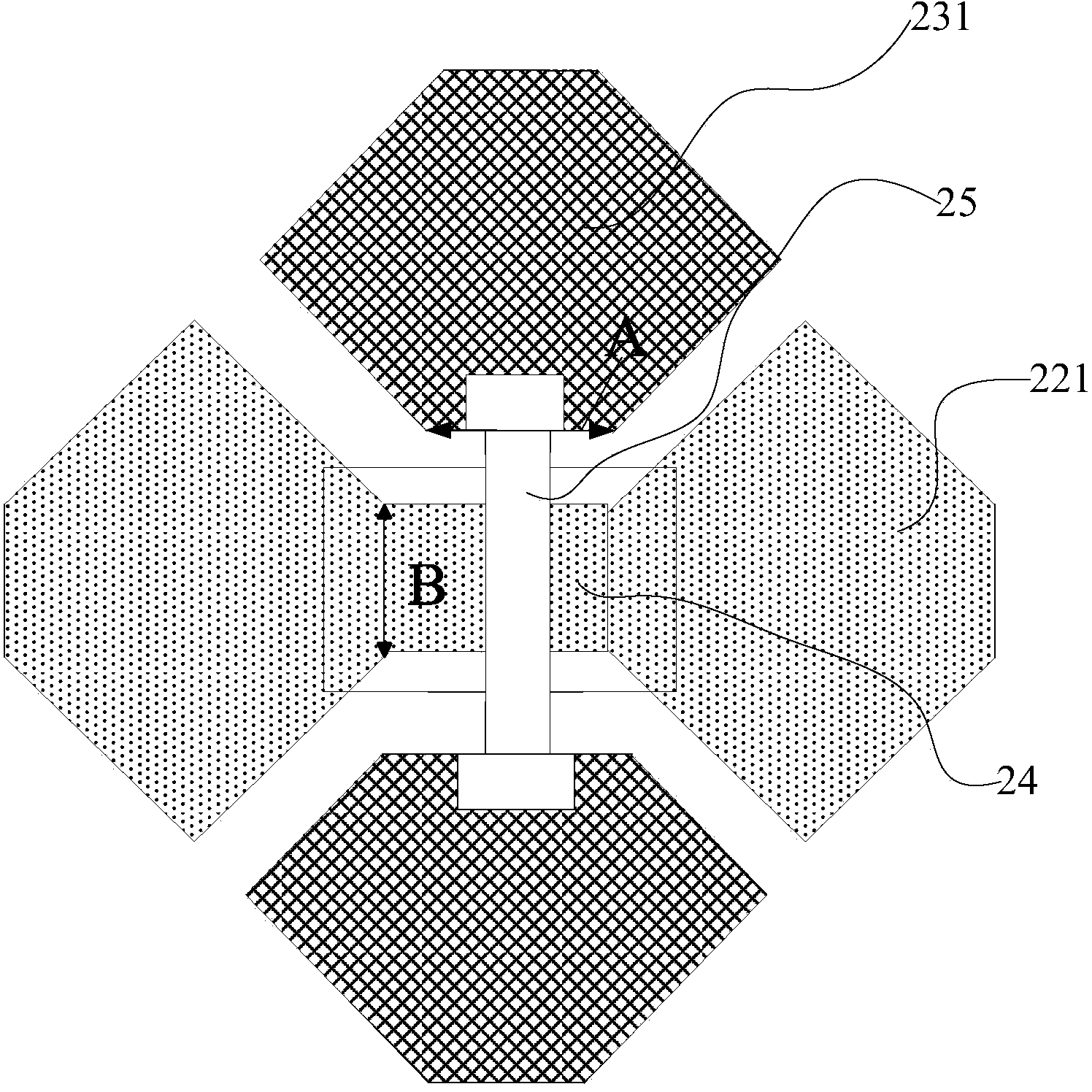

Touch electrode structure and touch screen

InactiveCN103677418ALower resistanceWidth does not affectInput/output processes for data processingInsulation layerTouchscreen

The invention provides a touch screen and a touch electrode structure thereof, and relates to the technical field of touch. In order to solve the problems that the touch screen is poor in static tolerance, and static breakdown easily happens, the touch electrode structure comprises a substrate with the light-permeable performance. A plurality of first electrodes and a plurality of second electrodes are arranged on one face of the substrate. Each first electrode comprises a plurality of first electrode units. Each second electrode comprises a plurality of second electrode units. Every two adjacent first electrode units are connected with each other through a strip-shaped connection portion. Every two adjacent second electrode units are connected with each other through a strip-shaped bridge connection portion. All the connection portions have electrical conductivity, and the connection portions are the same as the first electrodes in material. The connection portions intersect with the bridge connection portions. Insulation layers with the light-permeable performance are arranged at the intersections and located between the connection portions and the bridge connection portions, and the connection portions are covered with the insulation layers. The width of the intersections between the connection portions and the first electrode units is larger than that of the intersections between the second electrode units and the bridge connection portions located on the second electrode units.

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD

Method for collecting spore powder of ganoderma lucidum

This invention discloses a novel method for collecting Ganderoma lucium spore powder. The method is cost saving and environmentally friendly, and can improve the productivity and quality of Ganderoma lucium spore powder. The method comprises: (1) constructing a sealed space by using thin film material, observation device and aerator to tightly surround the culture frame, and horizontally setting a single-layered or multi-layered bed board; (2) placing one layer or multiple layers of Ganderoma lucium bags on the bed board in the sealed space when the edge of Ganderoma lucium pileus turns yellow brown from yellow white; (3) observing the ejection condition of Ganderoma lucium spores, aeration condition, temperature and humidity in the sealed space through the observation device; (4) adjusting the aeration condition, temperature and humidity in the sealed space accordingly; (5) collecting the Ganderoma lucium spore powder on the bed board in the sealed space when the spores are not ejected any more.

Owner:东莞市农业种子研究所 +1

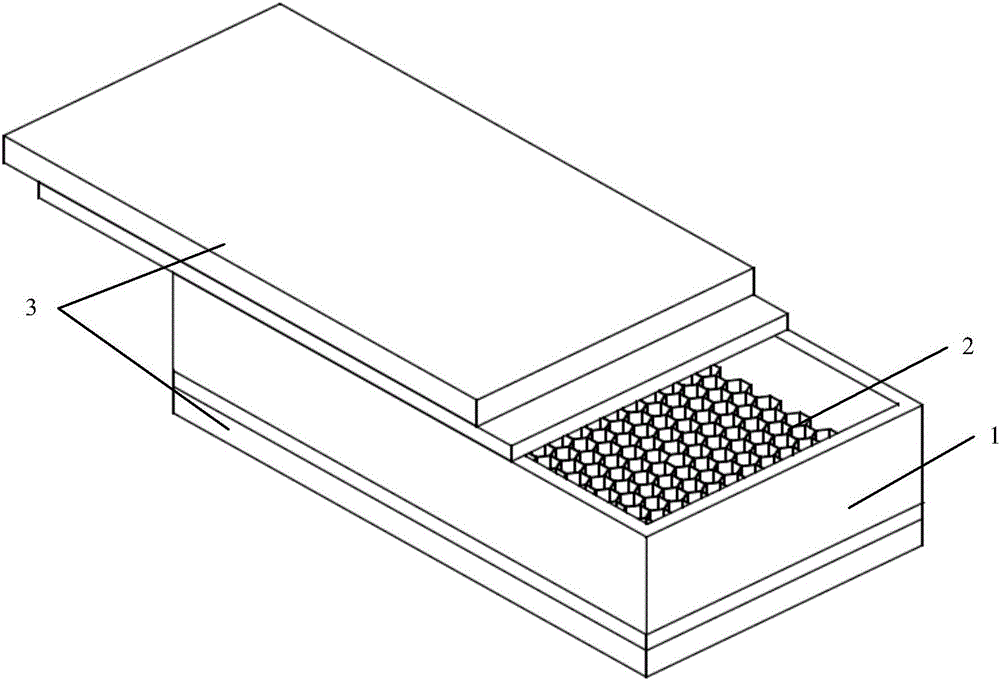

Aerogel honeycomb sandwich board

InactiveCN106499150AGood chemical stabilitySolution to short lifeCovering/liningsSynthetic resin layered productsSandwich boardThermal insulation

The invention relates to an aerogel honeycomb sandwich board. The aerogel honeycomb sandwich board is composed of an upper-layer panel (3), a lower-layer panel (3) and a middle aerogel honeycomb core body. The aerogel honeycomb sandwich board is resistant to fire and flames, achieves heat insulation, and is good in sound insulation performance, high in strength and resistant to compression; the aerogel honeycomb sandwich board is good in anti-impact performance, low in mass and environmentally friendly, and has good application prospects.

Owner:SUZHOU ZIAN METAL PROD

High-strength magnesia porcelain ultrathin plate and preparation method thereof

The invention relates to a high-strength magnesia porcelain ultrathin plate with thickness of 0.5-1.5mm and strength of 160MPa-200MPa. The high-strength magnesia porcelain ultrathin plate is prepared from the following mineral raw materials in percentage by mass through an aqueous tape casting technology: 70wt%-75wt% of talcum, 10wt%-15wt% of kaolin, 6wt%-10wt% of potassium feldspar, 2wt%-5wt% of barium carbonate, 1wt%-3wt% of zinc oxide, and 4wt%-6wt% of other alkaline earth metallic minerals. The slurry mixing process mainly comprises four stages including high-speed ball milling, dispersing by means of rapid milling and slow milling, plastifying and tackifying by means of slow milling, and stirring for removing bubbles under a vacuum condition; and then, the high-strength porcelain ultrathin plate is obtained through a tape casting firing step. The high-strength magnesia porcelain ultrathin plate has the characteristics of light weight, excellent light transmission, exquisite texture, high whiteness, and on the like; moreover, the high-strength magnesia porcelain ultrathin plate is easy to implement in industrialization, and has stability and high uniform performance in large-scale preparation.

Owner:JINGDEZHEN CERAMIC INSTITUTE

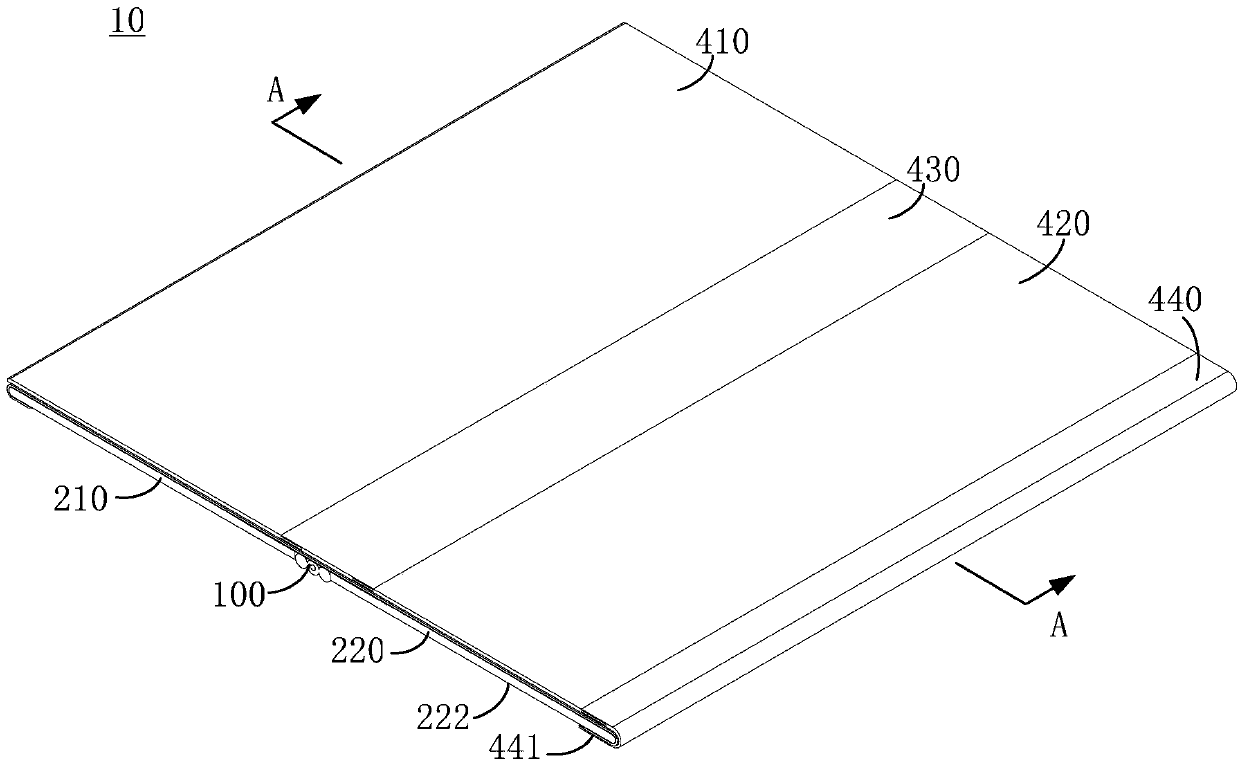

Foldable screen and electronic device

ActiveCN110491285AAvoid dentsPlay the role of ballastTelephone set constructionsIdentification meansEngineeringFlexible display

The invention relates to a foldable screen and an electronic device. The electronic device has a folding state and an unfolding state, and comprises a rotating shaft assembly, a supporting assembly, aflexible display screen and a cover plate, wherein the supporting assembly comprises a first supporting plate and a second supporting plate which are connected to the rotating shaft assembly, and thefirst supporting plate and the second supporting plate can rotate relative to the rotating shaft assembly to be switched between the folding state and the unfolding state; the flexible display screenis laid on the rotating shaft assembly and the first and second supporting plates, and the two ends of the flexible display screen are connected with the first supporting plate and the second supporting plate respectively; the cover plate has a light transmission property and is attached to one surface, back to the supporting assembly, of the flexible display screen; and the cover plate can be bent or unfolded along with the flexible display screen. The flexible display screen is clamped among the cover plate and the rotating shaft assembly, the first supporting plate and the second supporting plate to prevent the flexible display screen from being wrinkled so as to ensure the flatness of the flexible display screen. The cover plate can absorb external impact energy to prevent the flexible display screen from being damaged.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

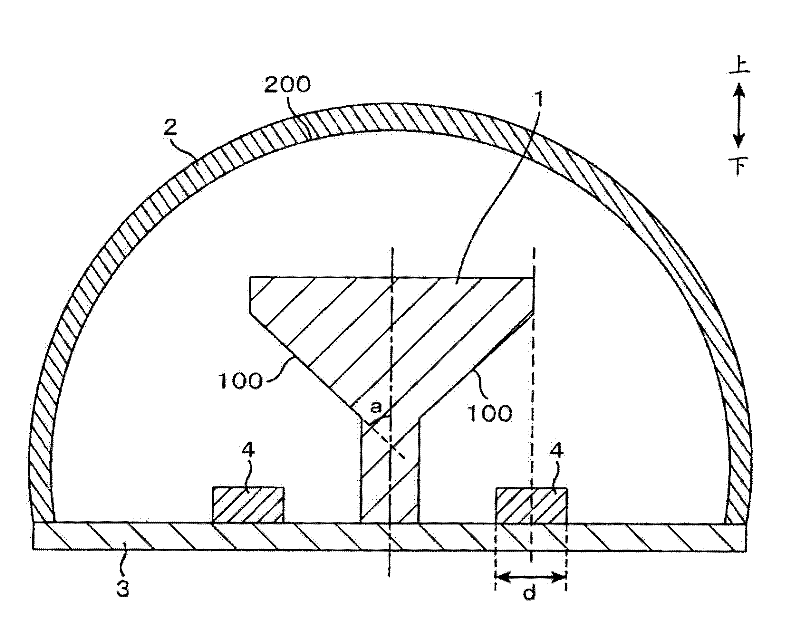

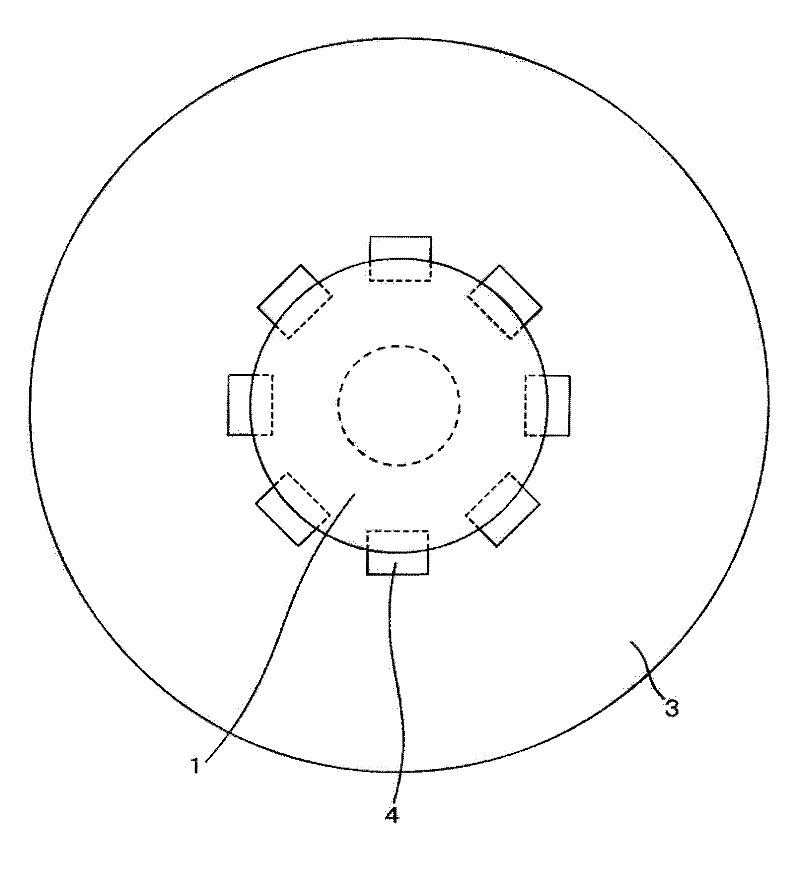

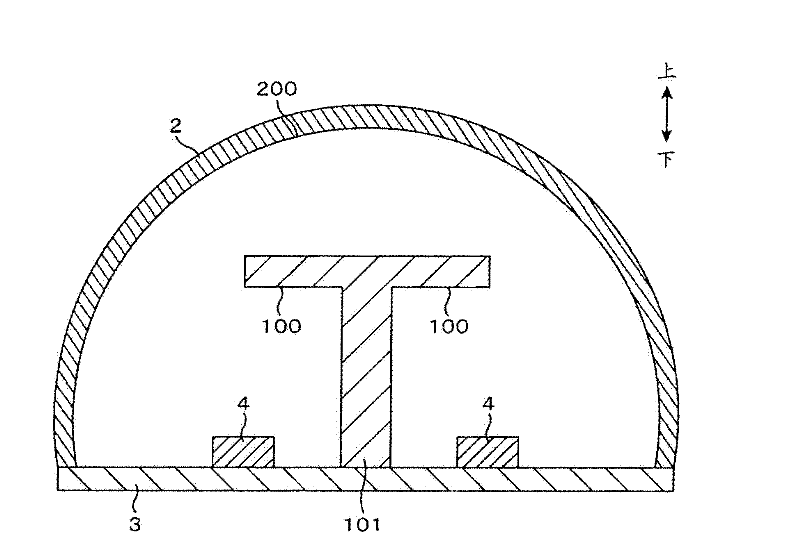

Light-emitting module and illumination device

InactiveCN101737672ASolution to short lifeCost advantagePlanar light sourcesLighting support devicesJunction temperatureEngineering

Owner:TOSHIBA LIGHTING & TECH CORP

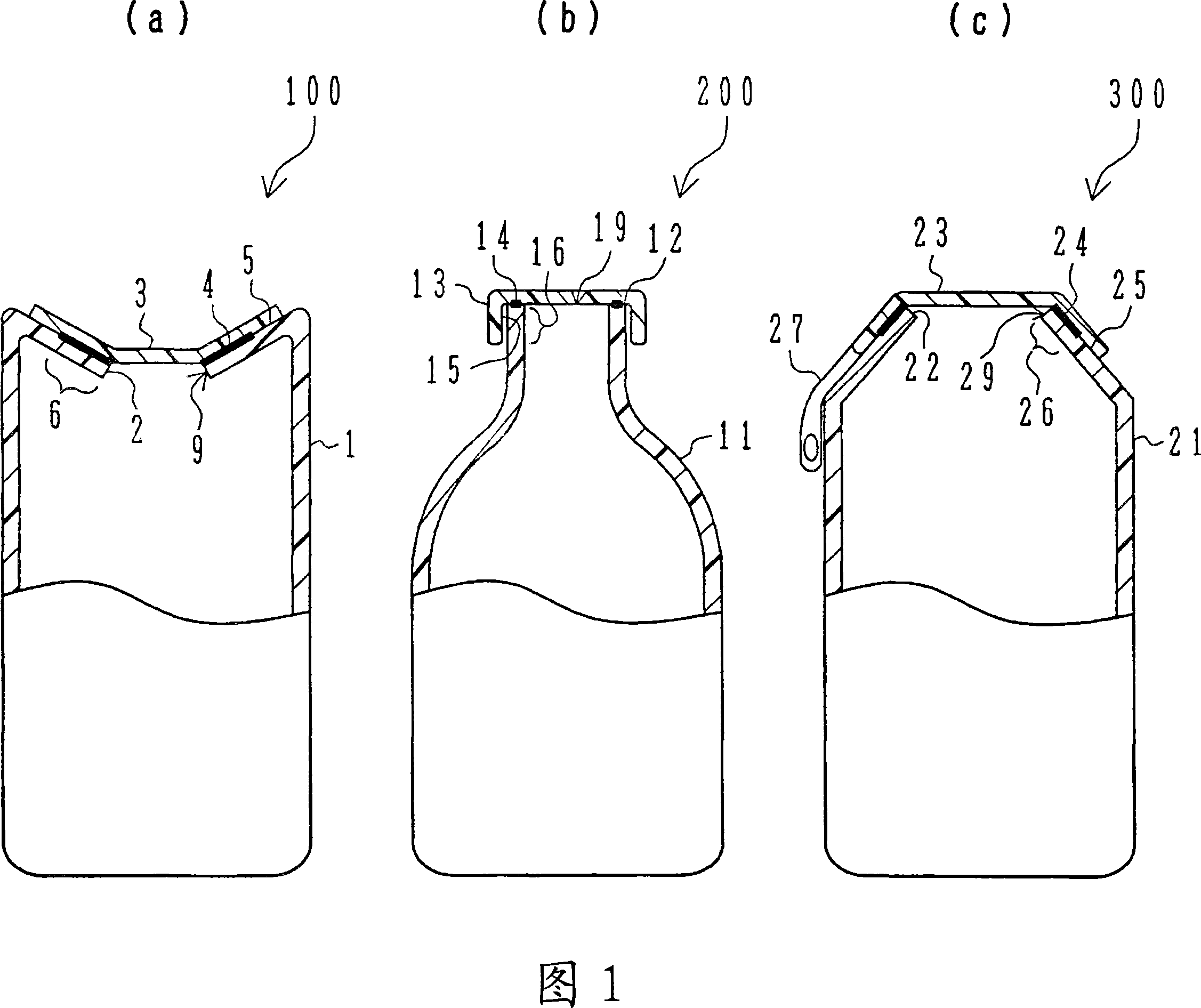

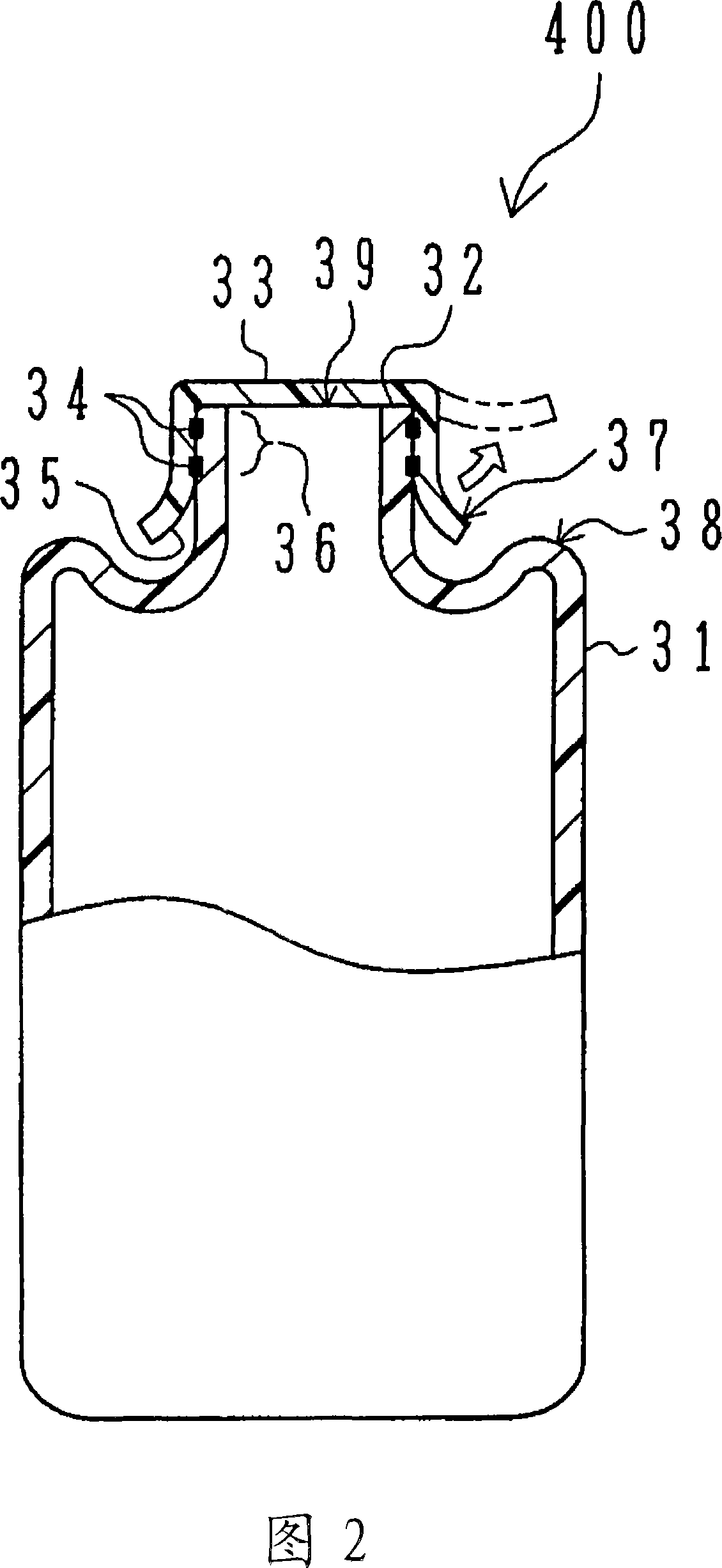

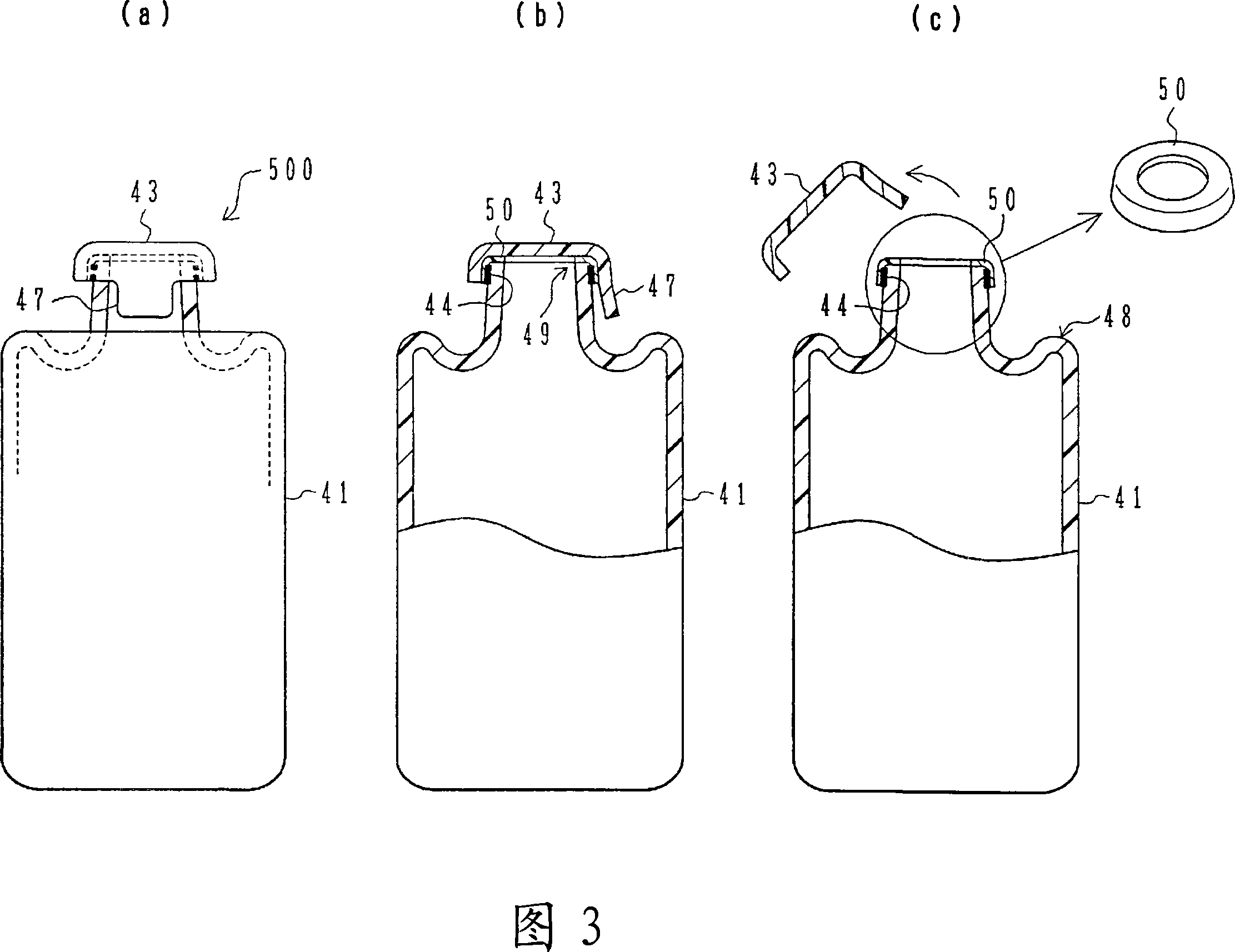

Sealed vessel and method of producing the same

InactiveCN1926025AImprove recycling effectGood touchPackage recyclingBottlesTouch sensationEngineering

It is an object of the present invention to provide a container in which it is difficult for liquid to drip at a mouth portion having a good touch sensation by forming a structure in which a welded portion that was laser welded in a sealed container does not form a flange, and to carry out the achievement of making polymer material unnecessary and making excessive material in the wind-fastening portion unnecessary. Further, it is also an object to construct the lid and barrel of the vessel by using the same material, thereby facilitating the recycling of material. The sealed container in which a container body 1 having an opening 9 is sealed by a lid portion 3 which closes and covers said opening, comprising a welded portion 4, 14 in which an outer wall surface of a peripheral portion 2 of said opening or an edge 12 surface of said opening and an inner wall surface of said lid portion are laser welded in order to make it possible for at least an inner wall surface of the peripheral portion of said opening from an inner wall surface 6 of said container body to make contact with container contents.

Owner:KIRIN BREWERY CO LTD

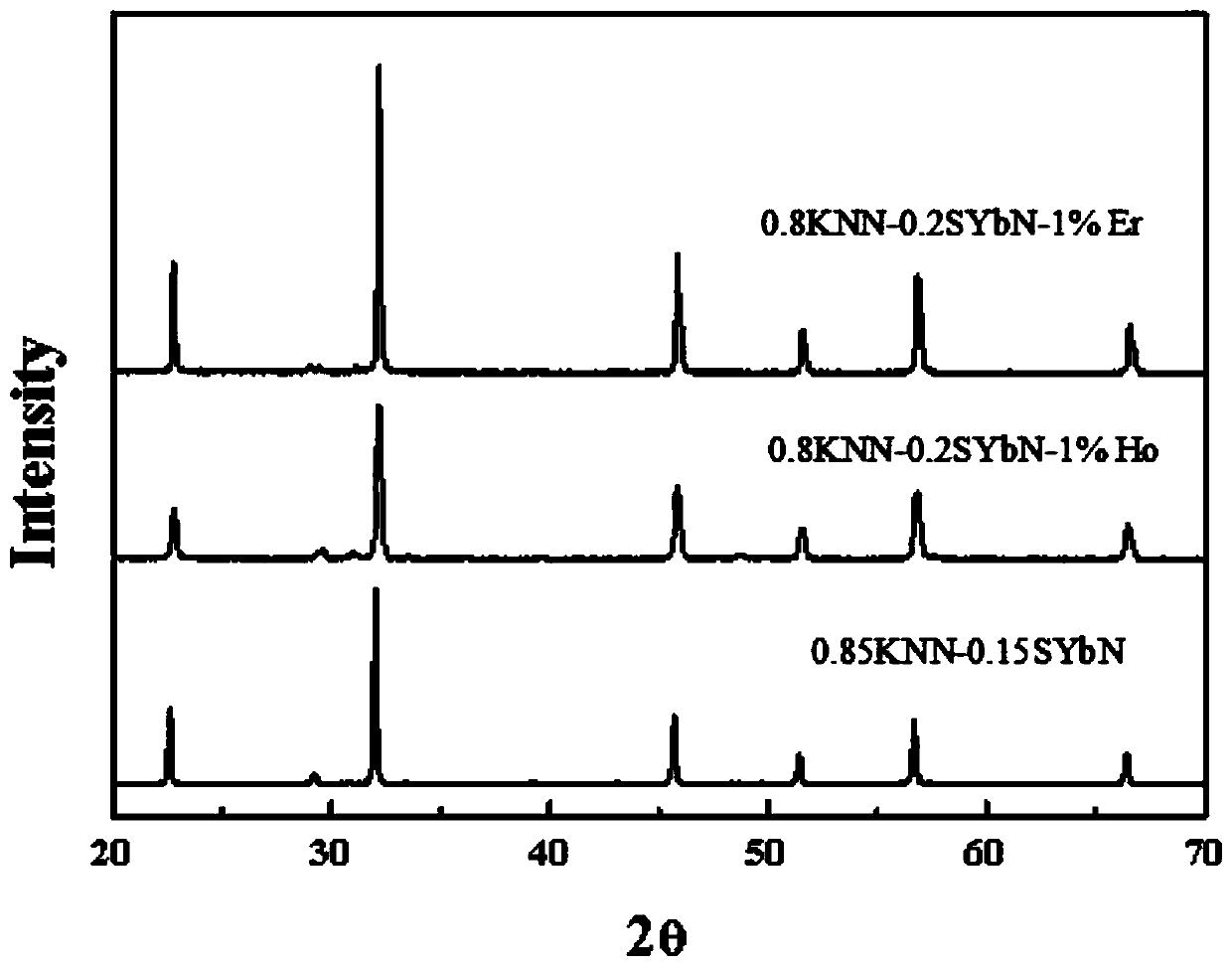

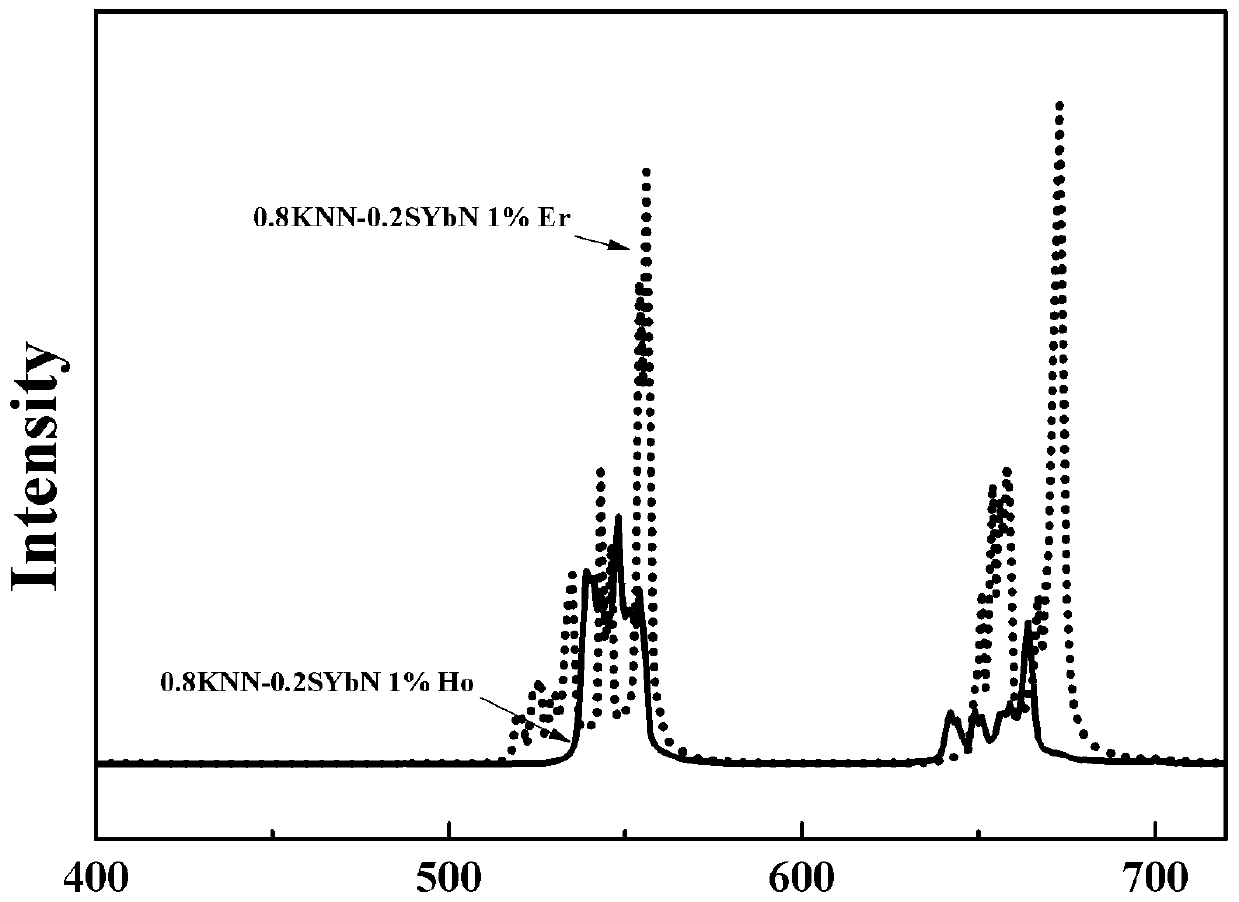

Up-conversion luminescence transparent ferroelectric ceramic material, preparation method and application thereof

ActiveCN110041074ATranslucentPossesses up-converting photoluminescent propertiesUpconversion luminescencePhotoluminescence

The invention provides an up-conversion luminescence transparent ferroelectric ceramic material and a preparation method and an application thereof, and belongs to the field of ceramic materials. Thestructural formula of the ceramic material provided by the invention is (1-x)K0.5Na0.5NbO3-xSr(Yb0.5Nb0.5)O3-yM, wherein M is Er or Ho, x = 0.05-0.35, y = 0.001-0.01. According to the ceramic materialprovided by the invention, the K0.5Na0.5NbO3 (KNN) ferroelectric ceramic is used as a matrix, and after the second component Sr(Yb0.5Nb0.5)O3 is subjected to solid solution, the ceramic material hastransparent performance. On the basis of the mentioned facts, the ceramic material has the up-conversion photoluminescence property by doping rare earths, Er or Ho. The ceramic material provided by the invention has relatively good up-conversion luminescence property and ferroelectric property at the same time, is relatively good in light transmittance, and is a multifunctional ceramic material.

Owner:GUILIN UNIV OF ELECTRONIC TECH

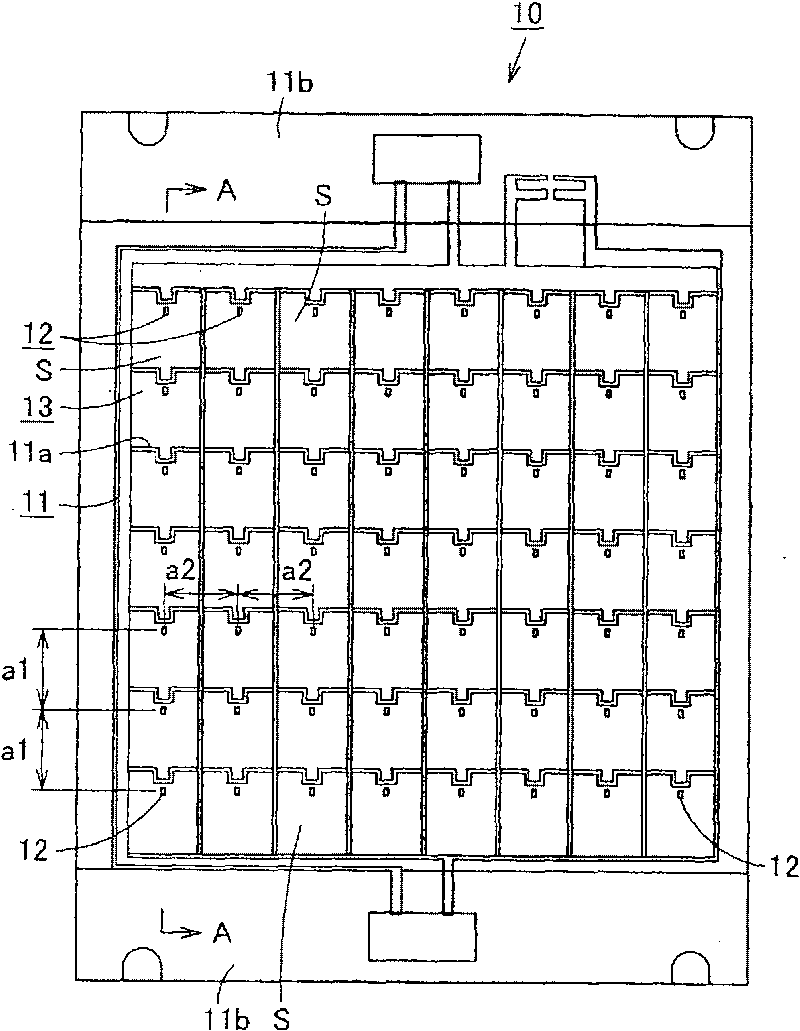

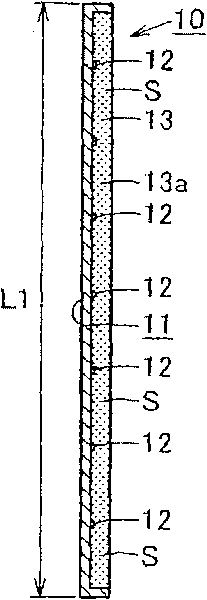

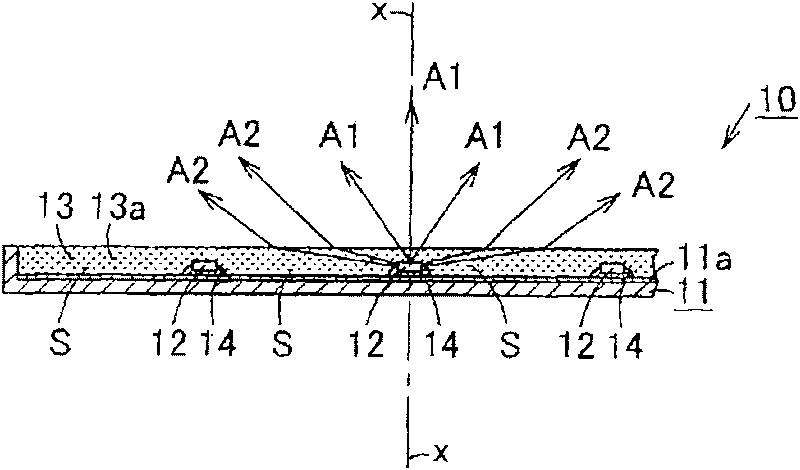

Semipermeable reflective plate and reflective plate and semipermeable polazied plate and reflective polazied plate and liquid crystal display

Owner:NITTO DENKO CORP

Degradable filtration and sterilization membrane and preparation method

PendingCN108722068ASolve the problem that the cleanliness of indoor air cannot be protected fundamentallyImprove adsorption efficiencyGas treatmentDispersed particle filtrationPolyesterHigh absorption

The invention discloses a degradable filtration and sterilization membrane and a preparation method. The filtration and sterilization membrane is prepared by electrostatic spinning of the following ingredients in parts by weight: 100 parts of degradable high polymer material and 1-60 parts of antibacterial nano auxiliary material, wherein the degradable high polymer material is one or a combination of degradable aliphatic polyester and a degradable natural polymer; and the antibacterial nano auxiliary material is one or a combination of graphene, graphite oxide, titanium dioxide, zinc oxide, Fe2O3, CdS and WO3. The degradable filtration and sterilization membrane is prepared by the electrostatic spinning of a degradable high polymer solution; at the same time, the antibacterial nano auxiliary material is added in a preparation process; and the membrane has the advantages of large air contact area, high absorption and antibacterial efficiency, easy recovery, no secondary pollution, recycling and the like.

Owner:BEIJING UNIV OF CHEM TECH

Lamp

InactiveCN102563412ATranslucentSuppress projectionPoint-like light sourceElectric lightingEngineeringLight-emitting diode

Owner:HITACHI APPLIANCES INC

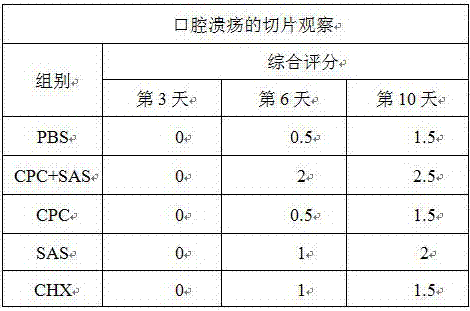

Production technology of compound sodium gualenate gargle

InactiveCN106974847AGood treatment effectFacilitated releaseAntibacterial agentsCosmetic preparationsMentha spicataLaboratory test

The invention discloses a production technology of compound sodium gualenate gargle. The production technology comprises the steps of preparing a solution I: heating purified water, then adding non-crystalline sorbitol, sodium benzoate and cetylpyridinium chloride into the heated purified water, and stirring for 20min; preparing a solution II: dissolving sodium gualenate by using ethanol to obtain the solution II; preparing a solution III: heating RH40 hydrogenated castor oil and propylene glycol until being molten, adding spearmint essence, and evenly stirring to obtain the solution III; adding the solution II and the solution III into the solution I, stirring for 10min to obtain a semi-finished product, taking samples for laboratory test to obtain a cetylpyridinium chloride semi-finished product, and canning the semi-finished product when the semi-finished product is qualified; when the cetylpyridinium chloride is insufficient, adding the cetylpyridinium chloride, taking samples for detection until the semi-finished product is qualified, and starting to fill; after the finished product is tested to be qualified, enabling the finished product to be put in storage, and discarding the unqualified products.

Owner:江苏恩为众心生物医药有限公司

Method for manufacturing soundboard of piano

The invention relates to a method for manufacturing a soundboard of a piano. The method comprises the following steps: firstly, dividing boards with different annual ring densities into five classes; secondly, transversely splicing a plurality of boards with the same density into a large board, and arranging the large boards according to the annual ring densities in the same way; and finally, splicing into a whole board, and then cutting into required soundboard shape. According to the method, the boards with different densities are distinguished and are reasonably arranged when being spliced, so that the densities of various parts of the whole soundboard are gradually increased or reduced, the density difference between the adjacent boards is reduced, the destructive effect generated by internal stress of the soundboard due to climatic change is overcome, and the vibration performance of the soundboard is improved, thereby increasing the tone quality of the piano.

Owner:NINGBO HAILUN MUSICAL INSTR

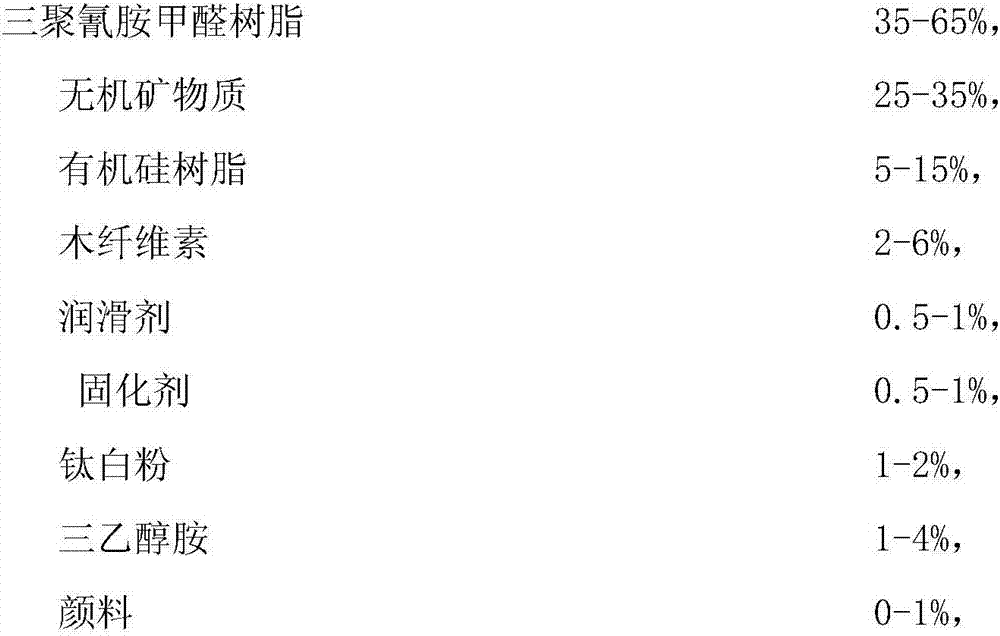

Moulding material used for high-grade melamine tableware and preparation method thereof

The invention relates to a moulding material used for high-grade melamine tableware and a preparation method thereof. The moulding material is prepared from the following raw materials in percentage by mass: 35-65% of melamino-formaldehyde resin, 25-35% of inorganic minerals, 5-15% of organic silicon resin, 2-6% of wood cellulose, 0.5-1% of a lubricating agent, 0.5-1% of a curing agent, 1-2% of titanium white, 1-4% of triethanolamine and 0-1% of pigment, wherein the sum of the weight percents of all the raw materials is 100%; and the inorganic minerals are formed by mixing silica powder, jade porcelain and calcium carbonate in a ratio of 3:(0.5-1.5):(0.5-1.5). The preparation method comprises the following steps: preparing the melamino-formaldehyde resin, kneading, drying, crushing and carrying out ball milling, and packaging. According to the invention, the inorganic mineral and organic silicon resin are added into melamine resin, and compression moulding is carried out, so that the tableware has the characteristics of higher density, strong compactness, higher break resistance, light transmission, glittering and translucent carving appearance and better quality compared with ceramic tableware.

Owner:DEQING LIANCHENG AMINO PLASTIC PROD CO LTD

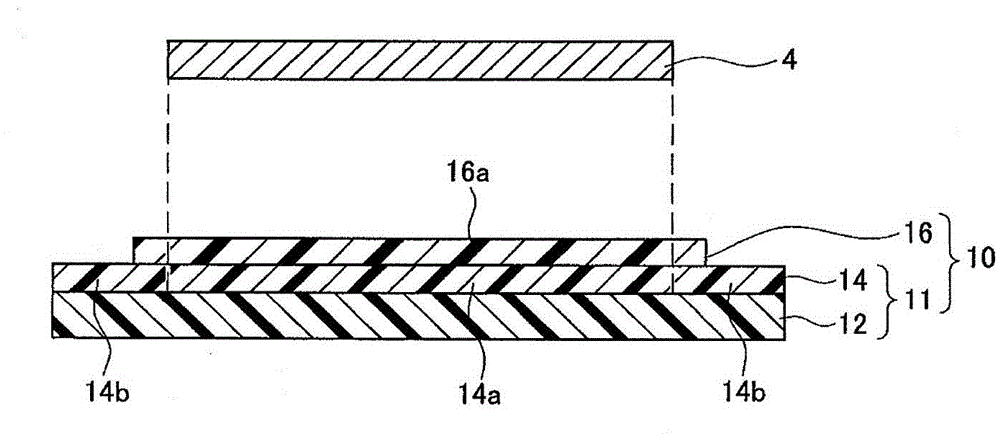

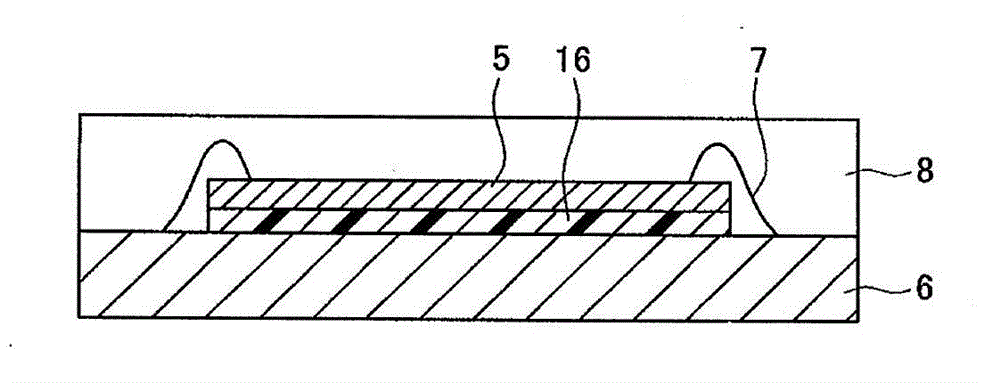

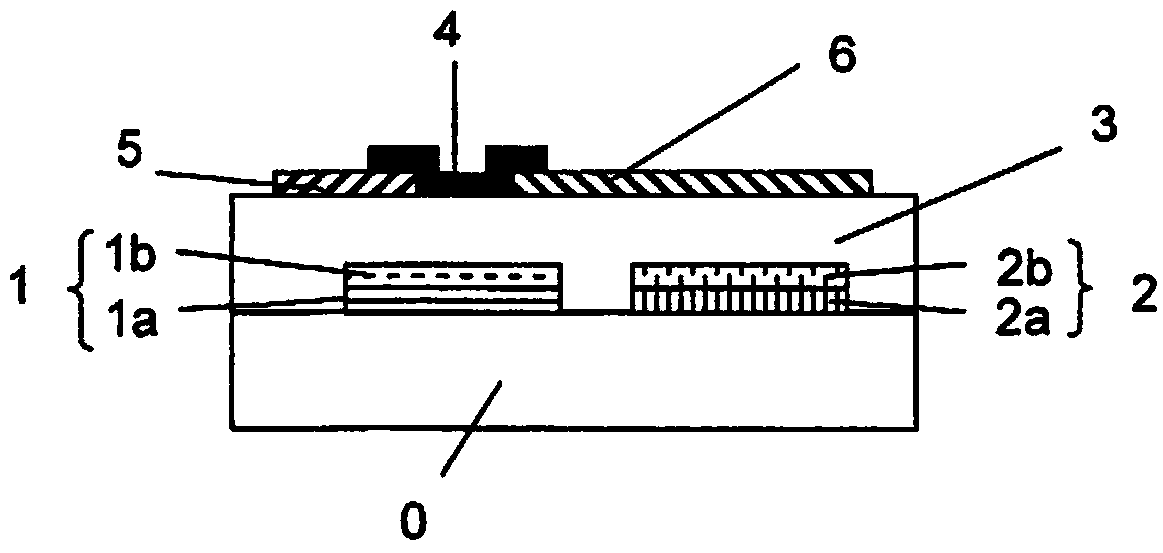

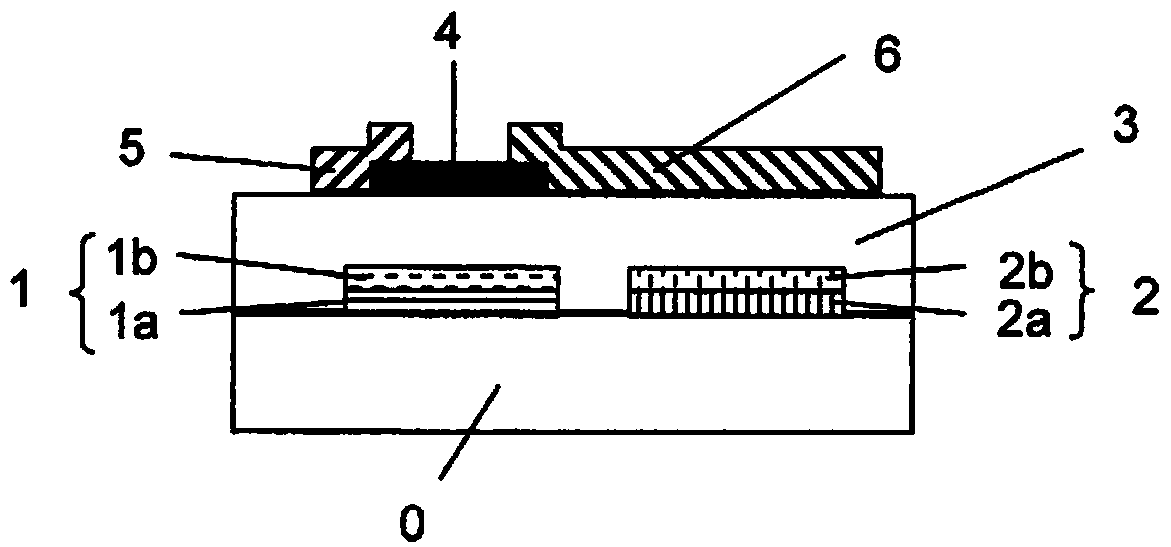

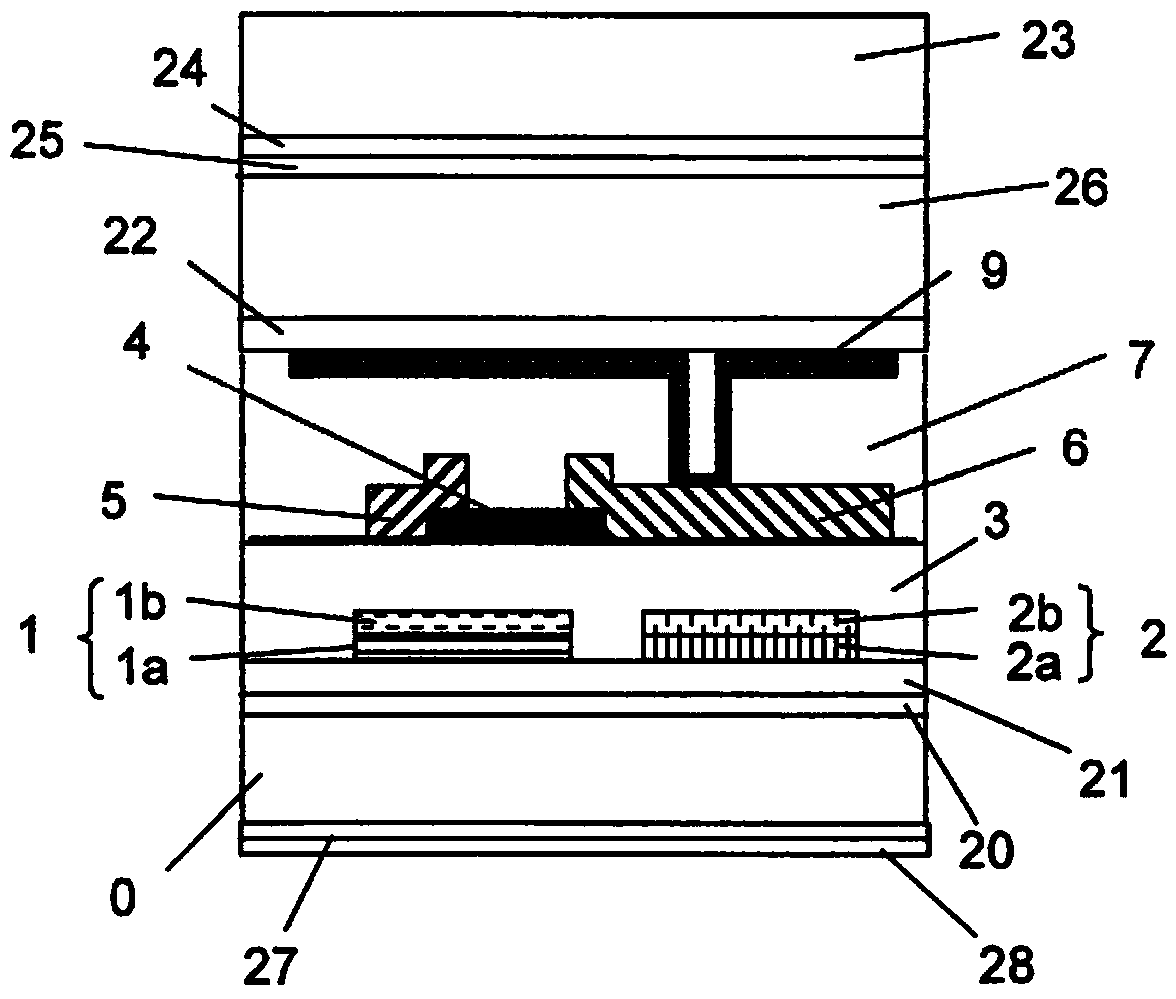

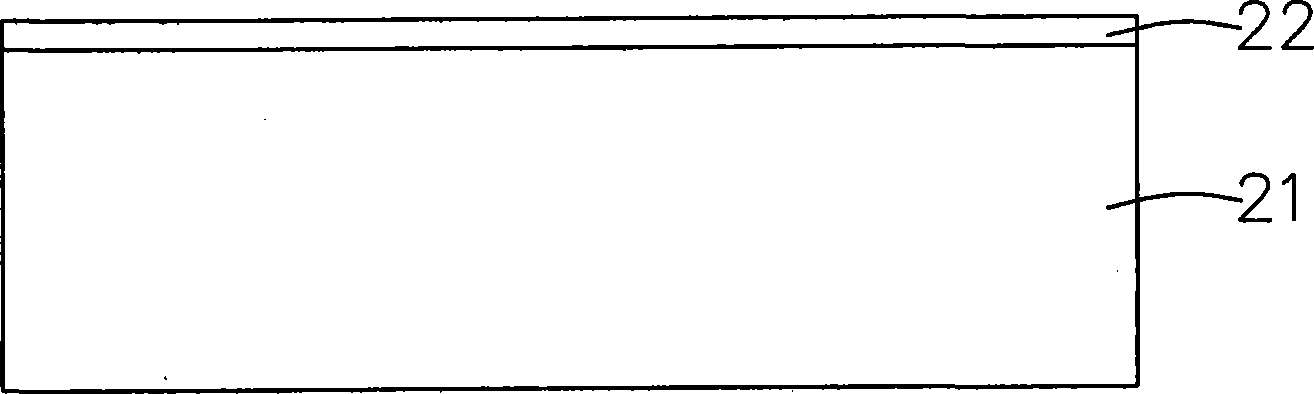

Chip bonding film, chip bonding film with cutting disk, semiconductor device, and manufacturing method for semiconductor device

ActiveCN104946146AEasy to findHigh light transmittanceFilm/foil adhesivesSolid-state devicesOptical transmittanceSemiconductor chip

Provided are a chip bonding film, a chip bonding film with a cutting disk, a semiconductor device, and a manufacturing method for the semiconductor device. The invention provides a chip bonding film which can easily determine fragments of a semiconductor chip. The chip bonding film is characterized in that when light transmittance in wavelength of 400 nm before thermofixation is set to be T1(%) and light transmittance in wavelength of 400 nm after the film is heated for one hour in 120 DEG C is set to be T2(%), T1 is more than 80%, and the difference (T1-T2) of T1 and T2 is lower than 20%.

Owner:NITTO DENKO CORP

Thin film transistor and image display apparatus

ActiveCN103975441AGood light transmissionImprove conductivityTransistorSolid-state devicesOptical transparencyHigh conductivity

Owner:TOPPAN INC

Degradable soil moisture preserving liquid film and its prepn

InactiveCN1357569ATranslucentWater-resistantOrganic fertilisersSoil conditioning compositionsChemistryFilm material

The degradable soil moisture preserving liquid film material is prepared by using the material including vinyl acetate, hydroxyl butyrate, hydroxyl valerate, modified starch, calcium carbonate and water. It may degraded completely in natural condition. When spread, it forms thin film adhered to soil and the has excellent heat and moisture preserving effect.

Owner:北京中宣绿环科技发展有限公司

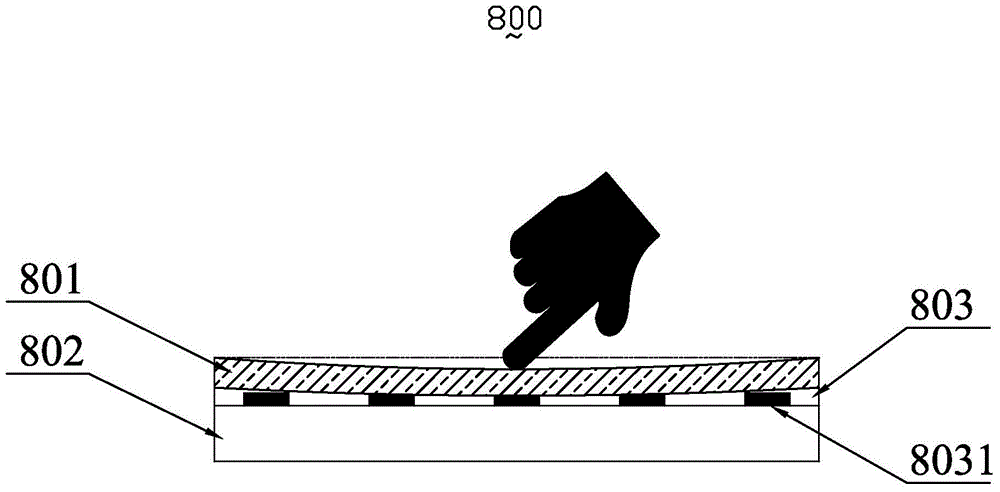

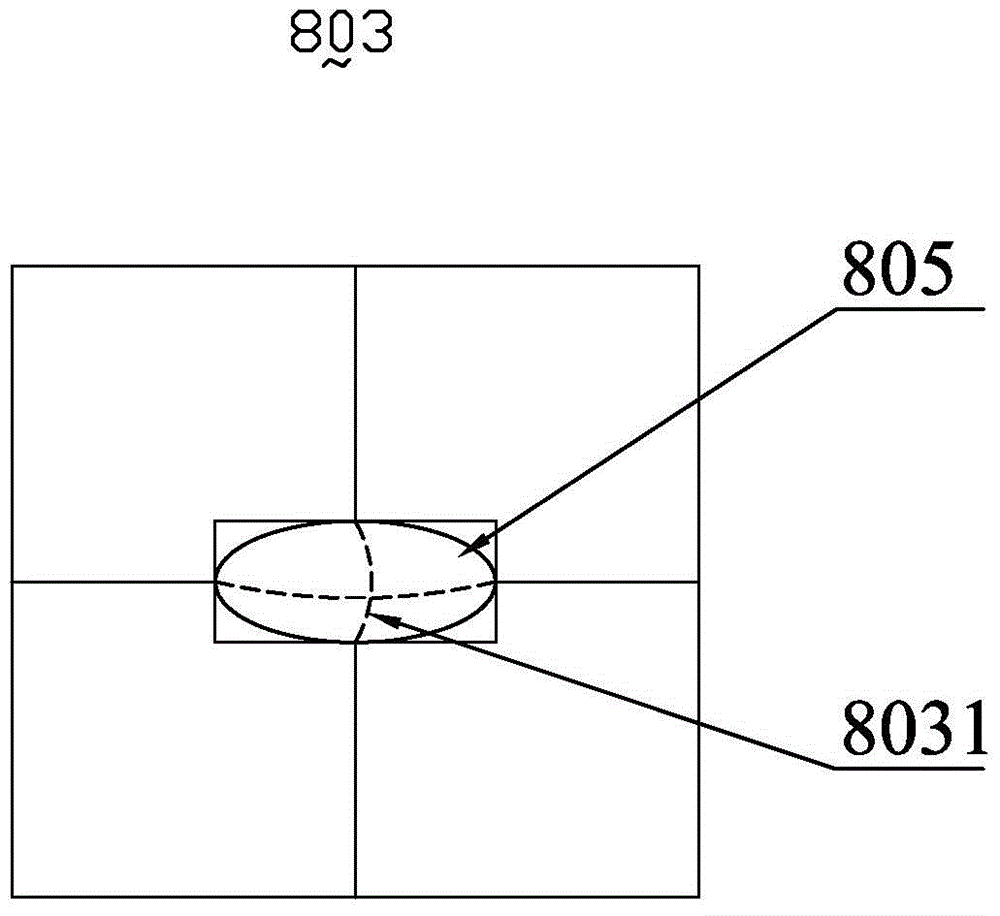

Pressure sensing device

PendingCN106325580AReduce thicknessFix visibility issuesInput/output processes for data processingPressure sensePressure sensing

The invention relates to the technical field of pressure sensing, and in particular to a pressure sensing device which can be used for detecting the pressure intensity. The pressure sensing device comprises a substrate, a conductive pattern layer and a pressure sensing signal wire, wherein the substrate comprises a first surface and a second surface; the first surface and the second surface are oppositely arranged; the conductive pattern layer is arranged on the first surface, comprises a plurality of pressure sensing electrodes and is used for sensing the touch pressure intensity; the pressure sensing signal wire is used for connecting the pressure sensing electrodes to a detection chip in a conducting manner and is of a hollow-out structure.

Owner:TPK TOUCH SOLUTIONS (XIAMEN) INC

LED (light emitting diode) lens

InactiveCN102691971AChange surfaceTranslucentPoint-like light sourceLighting heating/cooling arrangementsEngineeringLight-emitting diode

The invention provides an LED (light emitting diode) lens comprising an inner cover (3) covering an LED light source (4), and an outer cover (1) covering the outer side of the inner cover (3), wherein the inner cover (3) and the outer cover (1) are connected with each other in a sealing way to form a sealed cavity; and the outer cover (1) is provided with a curved surface which is matched with the inner cover (3) and used for changing a light path of the LED light source (4). The LED lens also comprises heat radiating liquid (2) which has light transmission performance and is arranged inside the sealed cavity. Comprising the heat radiating liquid (2) with a heat radiating function, the LED lens also has the heat radiating function; and when the LED lens is in use, heat generated by the LED light source can be radiated by the heat radiating liquid (2), and therefore the service life of the lens is prolonged.

Owner:THINKLUX (ZHEJIANG) LIGHTING TECH CO LTD

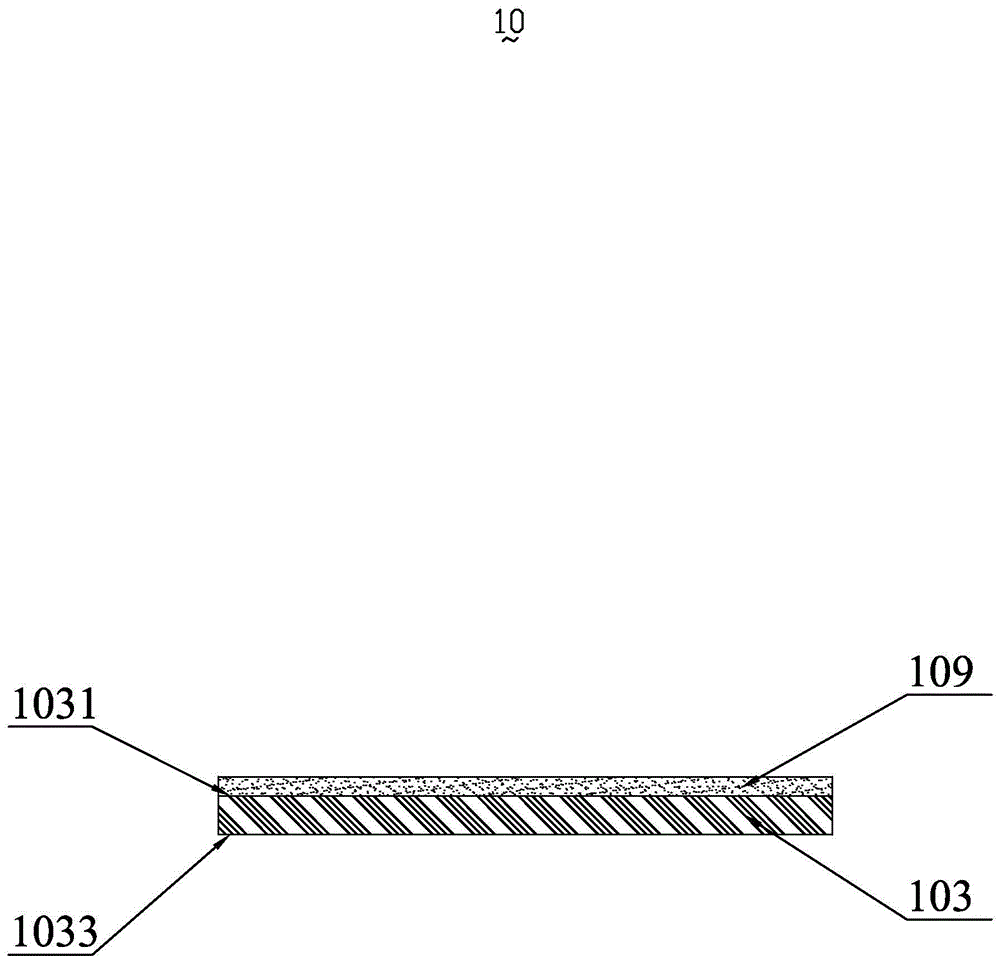

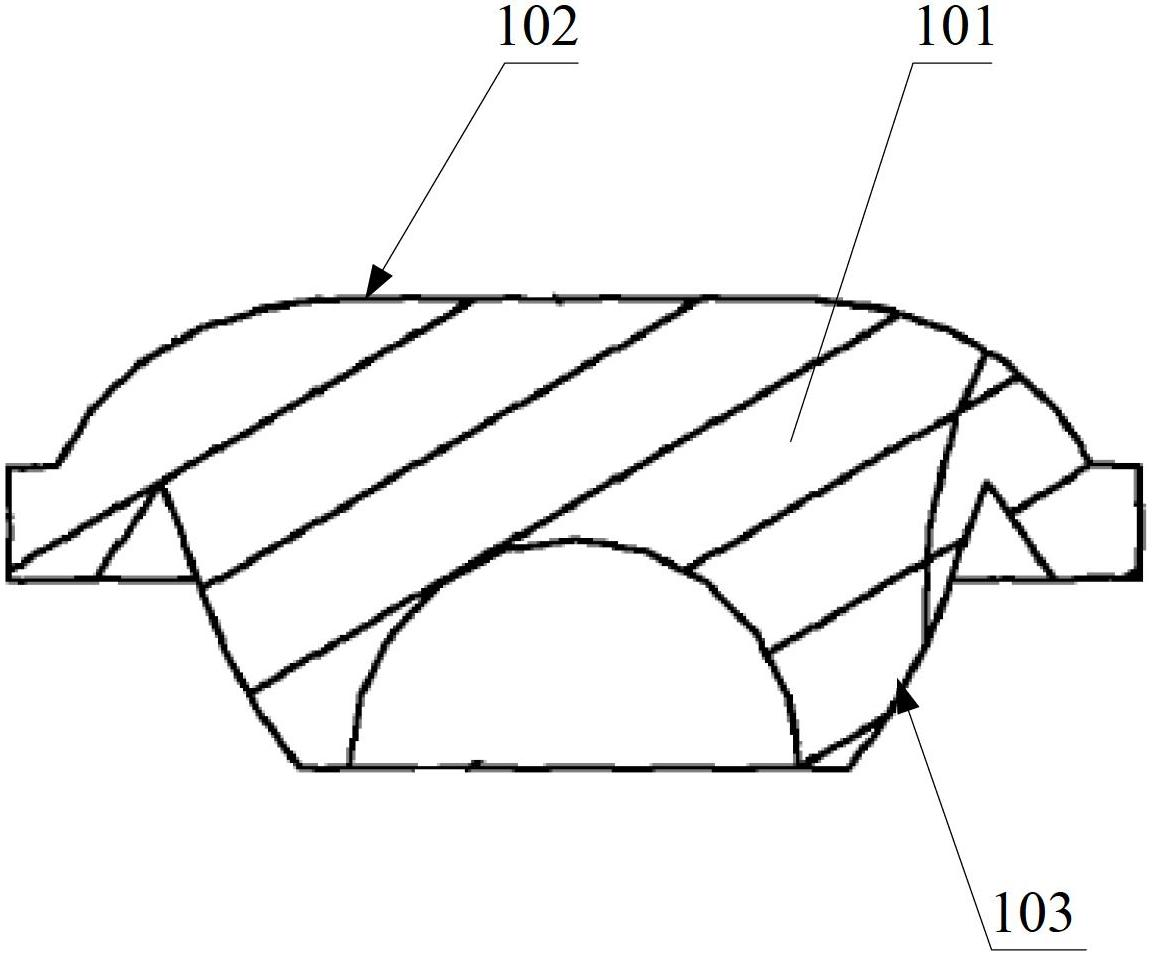

Semiconductor light emitting element and method for fabricating the same

ActiveCN101369618ATranslucentAdjust the far-field luminescence patternSemiconductor devicesSemiconductorEpiwafer

The invention relates to a semiconductor luminous element and a manufacturing method thereof. The semiconductor luminous element comprises a substrate, a p-type semiconductor layer formed on the substrate, a luminous layer formed on the p-type semiconductor layer, and an n-type semiconductor layer formed on the luminous layer; micron and nanometer columns which are numerously vertical to the substrate direction and have a depth of not less than 0.2 micron are formed on the surface of the n-type semiconductor layer. The nanometer columns are deepened to change the luminous field pattern of the semiconductor luminous element and improve the positive light emitting strength and the light emitting efficiency. The manufacturing method of the semiconductor luminous element comprises: forming the n-type semiconductor layer, the luminous layer and the p-type semiconductor layer on the first substrate through epitaxial wafers; providing a conductive substrate, reversing the epitaxial structure on the first substrate to lie on the conductive substrate, and exposing the surface of the n-type semiconductor layer; scattering numerous spherical particles on the surface of the n-type semiconductor layer, etching and shielding; etching the n-type semiconductor layer in the direction vertical to the conductive substrate, and forming numerous micron and nanometer columns with a depth of not less than 0.2 micron. Through the manufacturing method, relatively deep nanometer columns can be formed, and the positive light emitting strength can be improved.

Owner:LITE ON TECH CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com