WMT solar cell module and preparation method thereof

A technology of solar cells and components, applied in electrical components, circuits, photovoltaic power generation, etc., can solve the problems of MWT components that cannot be popularized and applied, clean energy pollution, high prices, etc., to solve scratches and environmental pollution, and save costs , the effect of improving life expectancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

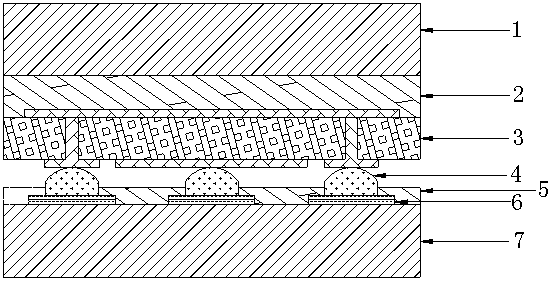

[0021] Embodiment 1: The MWT solar cell assembly of the present invention consists of an upper layer of glass 1, a first hot-melt adhesive film layer 2, a MWT solar cell string 3, a conductive adhesive layer 4, a second hot-melt adhesive film layer 5, and a conductive foil stacked in sequence. The layer 6 and the lower glass 7 are packaged, and the pattern of the conductive foil layer 6 matches the electrode pattern on the back of the MWT solar cell string 3; the second hot-melt adhesive film layer 5 corresponds to the conductive foil layer 6 A hole is opened at the position, so that the conductive foil layer 6 can be in contact with the electrodes on the back of the MWT solar cell string 3; the conductive adhesive layer 4 is arranged on the conductive foil layer 6 and the electrodes on the back of the MWT solar cell string 3 between. The MWT solar battery string 3 is composed of a plurality of MWT solar battery sheets with emitter electrodes and base electrodes printed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com