Aerogel honeycomb sandwich board

An aerogel honeycomb and sandwich panel technology is applied in the field of building wall materials, which can solve the problems of large volume and thick walls, and achieve the effects of good sound insulation performance, less material and good impact resistance performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

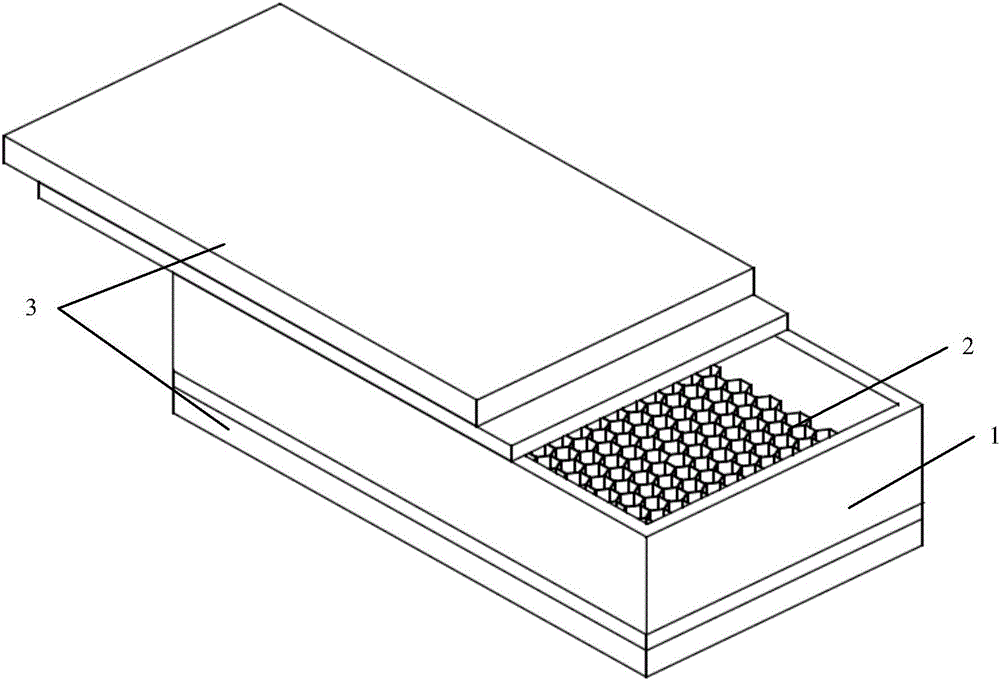

[0051] Such as figure 1 As shown, the present embodiment provides a kind of airgel honeycomb sandwich panel, and described sandwich panel is made up of upper and lower two-layer panel 3 and middle airgel honeycomb core body; Wherein, the structure of airgel honeycomb core body is: The gel sheet 1 completely covers the honeycomb core 2 . Airgel sheet 1 is SiO 2 airgel. The thickness of the airgel sheet 1 is 0.5-30mm. The material of the honeycomb core body 2 is aluminum or aramid fiber. The material of the panel 3 is metal, non-metal, wood or other composite materials. The airgel sheet 1, the honeycomb core 2, the panel 3, and the faces of the airgel sheet 1 are bonded or otherwise physically connected; wherein the adhesive is an acrylate water-based adhesive or Polyurethane adhesive.

Embodiment 2

[0053] Such as figure 1 As shown, the present embodiment provides a kind of airgel honeycomb sandwich panel, and described sandwich panel is made up of upper and lower two-layer panel 3 and middle airgel honeycomb core body; Wherein, the structure of airgel honeycomb core body is: The gel sheet 1 completely covers the honeycomb core 2 . Airgel sheet 1 is SiO 2 airgel. The thickness of the airgel sheet 1 is 0.5-30mm. The material of the honeycomb core body 2 is paper (the specific gravity of the paper honeycomb core body is lighter, and it is sound-proof, heat-insulating, moisture-proof and non-toxic). The material of the panel 3 is metal, non-metal, wood or other composite materials. The airgel sheet 1, the honeycomb core 2, the panel 3, and the faces of the airgel sheet 1 are bonded or otherwise physically connected; wherein the adhesive is an acrylate water-based adhesive or Polyurethane adhesive.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com