Workmanship of indoor microscopic oil displacement model

A production process and oil displacement technology, which is applied in the fields of production fluid, wellbore/well components, earthwork drilling and production, etc. It can solve problems such as difficult to accurately simulate pore diameter, glass sintering, and microscopic models difficult to be smaller than 20 μm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

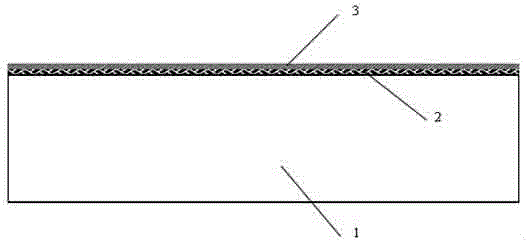

[0021] Embodiment 1: First select a glass substrate that has been polished on both sides, place it in a mixed solution of 70 g of concentrated sulfuric acid and 30 g of hydrogen peroxide, and boil it for 2 hours, then clean it with ultrasonic water for 5 minutes, and then dry the surface of the glass substrate with nitrogen. Place it on a baking sheet and set the temperature at 180°C for 10 minutes. Then spin-coat a layer of tackifier (German AllRESIST AR 300-80) on the glass substrate, place it on a baking sheet, control the temperature at 180°C, bake for 2 minutes, and continue to spin-coat the photoresist on the glass substrate ( Germany AllRESIST AR-P3200), placed on a baking sheet, set the temperature at 98°C, and baked for 10 minutes, such as figure 1 shown.

Embodiment 2

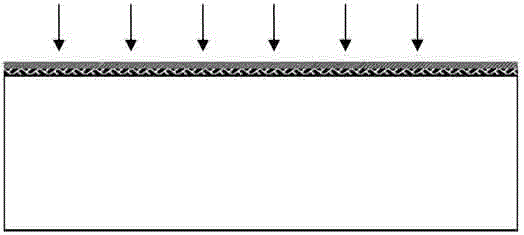

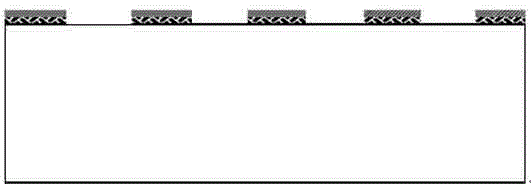

[0022] Example 2: Import the image of the oil reservoir with a pore size of 5 μm into the maskless exposure software, and expose the glass substrate sheet under ultraviolet light for 55 seconds. figure 2 As shown, the glass substrate was then placed in a developer solution (Germany AllRESIST AR 300-26) for 2.5 minutes to develop as image 3 shown. The developed glass substrate was placed on a baking sheet at a temperature of 110° C. and baked for 15 minutes.

Embodiment 3

[0023] Embodiment three: use paraffin to seal other regions except exposed on the glass substrate sheet, be placed in the etching solution that 25g HF, 1.79gNH F and 75g deionized water form, etching time is 180s, as Figure 4 As shown, scrape off the paraffin on the surface of the glass substrate, remove the residual paraffin with kerosene, and clean the photoresist on the surface of the glass substrate with a glue remover (Germany AllRESIST AR 300-72). The mixed solution is boiled for 2h, such as Figure 5 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com