Thin film transistor and image display apparatus

一种薄膜晶体管、半导体的技术,应用在晶体管、半导体器件、电固体器件等方向,能够解决成本提高、成品率降低等问题,达到降低生产过程成本、高对比度、显示性能优越的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

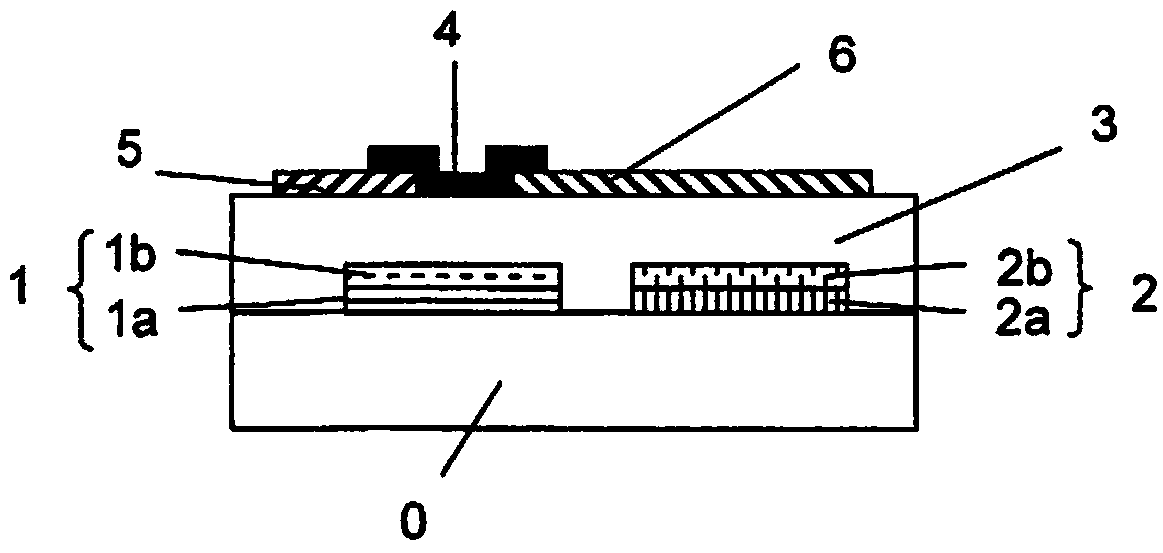

[0064] Next, Example 1 of the thin film transistor of this embodiment will be described based on the drawings.

[0065] figure 1 is a schematic diagram of the thin film transistor fabricated in Example 1.

[0066] In Example 1, produced as figure 1 The thin film transistor shown. Specifically, alkali-free glass 1737 produced by Corning Corporation was used as the insulating substrate 0, and the first layers 1a, 2a constituting the gate electrode 1 and the capacitor electrode 2 were formed on the insulating substrate 0 using a DC magnetron sputtering device. Room temperature deposition of ITO (thickness 100nm) and IGZO (thickness 10nm) constituting the second layers 1b, 2b. Next, gate electrode 1 and capacitor electrode 2 are formed from ITO and IGZO deposited at room temperature by simultaneous etching using photolithography. The input power for ITO film formation is 200W, the gas flow rate is Ar=100SCCM, O2=1SCCM, the film formation pressure is 1.0Pa, the input power for ...

Embodiment 2

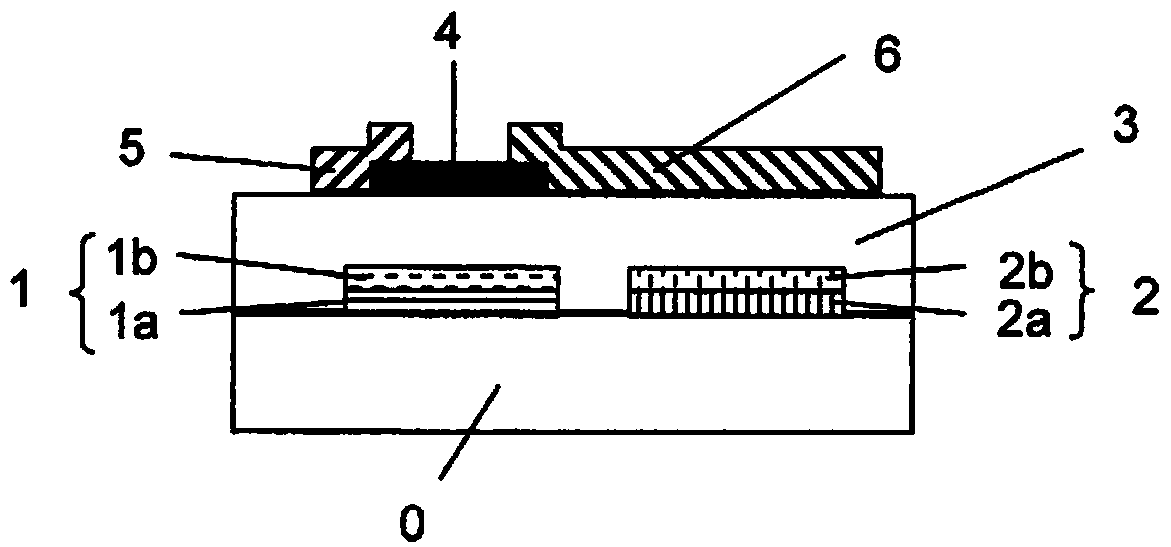

[0069] Next, Example 2 of the thin film transistor of this embodiment will be described based on the drawings.

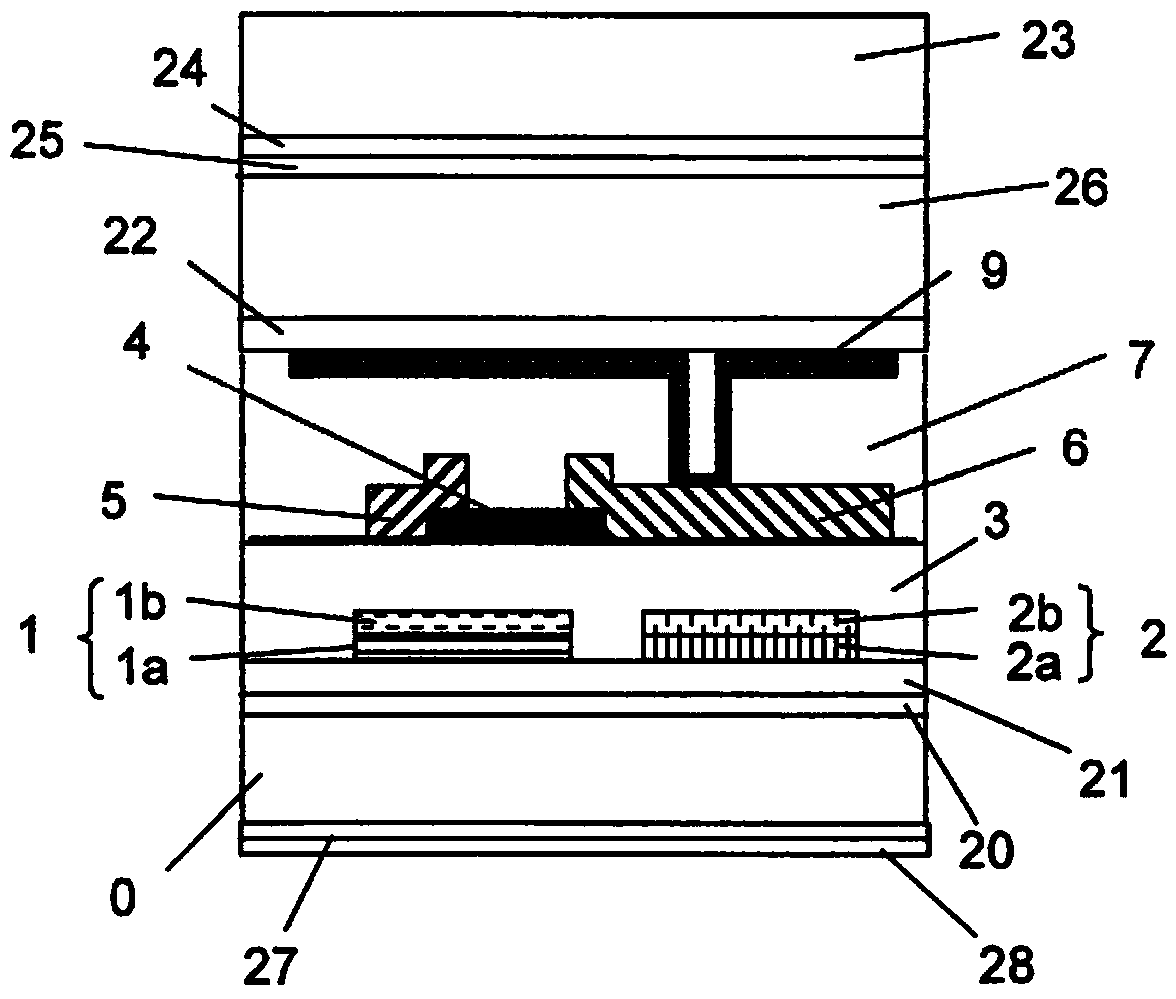

[0070] figure 2 It is a schematic cross-sectional view showing the structure of the thin film transistor of Example 2. image 3 It is a schematic cross-sectional view showing the structure of the image display device of the second embodiment.

[0071] In Example 2, produced as figure 2 TFTs as shown and as image 3 The image display device shown. Specifically, Corning's alkali-free glass 1737 was used as the insulating substrate 0 , and R (red) photosensitive resin was coated on the insulating substrate 0 by spin coating, and then patterned by photolithography. Similarly, the photosensitive resins G (green) and B (blue) were coated by spin coating, and then patterned by photolithography to form a color filter layer (color filter) 20 . Next, a light-transmitting resin is coated on the color filter layer 20 using a spin coating method to form the protective lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current | aaaaa | aaaaa |

| current | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com