Up-conversion luminescence transparent ferroelectric ceramic material, preparation method and application thereof

A ferroelectric ceramic, transparent technology, applied in the field of ceramic materials, can solve problems such as physical health and environmental impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The present invention also provides a preparation method for the up-conversion luminescent transparent ferroelectric ceramic material described in the above technical solution, comprising the following steps:

[0026] (1) According to the stoichiometric ratio of the up-conversion luminescent transparent ferroelectric ceramics, the raw materials potassium carbonate, sodium carbonate, niobium pentoxide, strontium carbonate, ytterbium oxide and M 2 o 3 After mixing, first-level ball milling treatment and first-level pre-sintering treatment are carried out successively, and then cooled to obtain a first-level ceramic powder; the M 2 o 3 for Er 2 o 3 or Ho 2 o 3 ;

[0027] (2) The primary ceramic powder obtained in the step (1) is sequentially subjected to secondary ball milling and secondary pre-sintering, and then cooled to obtain a secondary ceramic powder;

[0028] (3) The secondary ceramic powder obtained in the step (2) is sequentially granulated, pressed and si...

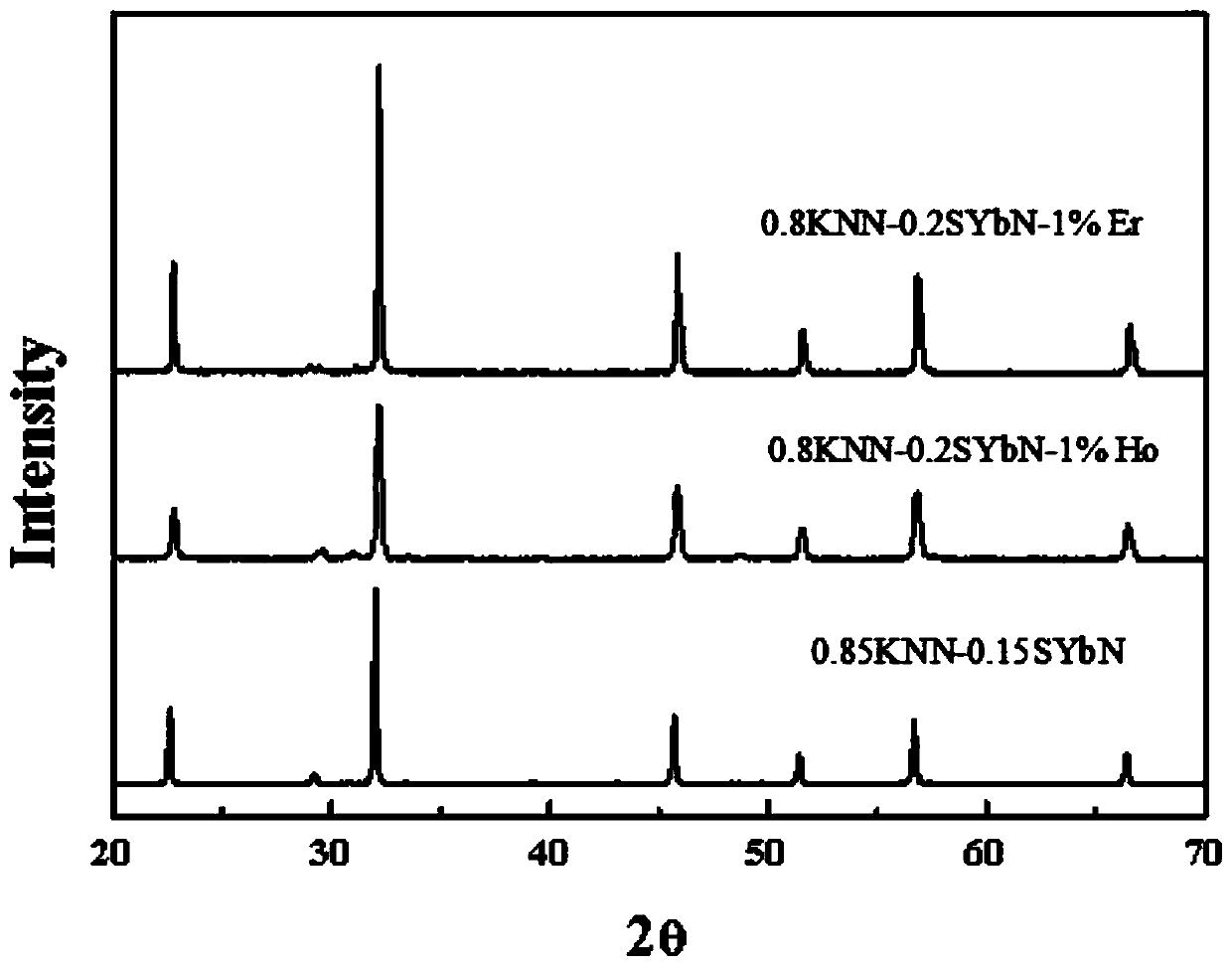

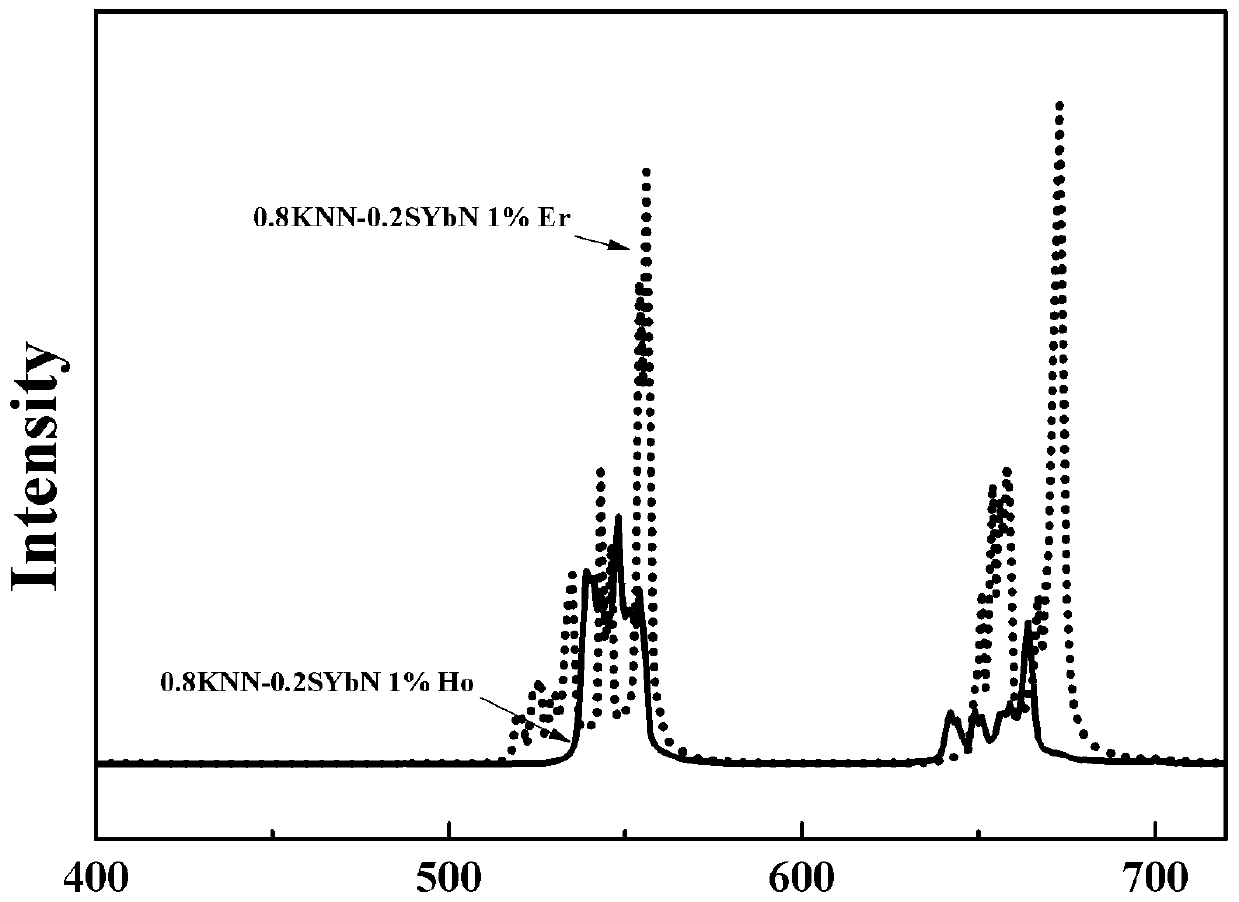

Embodiment 1

[0052] Potassium sodium niobate-ytterbium strontium niobate doped with rare earth holmium up-conversion luminescent transparent ferroelectric ceramics: 0.8K 0.5 Na 0.5 NbO 3 -0.2Sr(Yb 0.5 Nb 0.5 )O 3 -0.01Ho

[0053] (1) Ingredients: weigh 2.7739g K 2 CO 3 (99.5%), 2.1243g Na 2 CO 3 (99.8%), 11.9625gNb 2 o 5 (99.99%), 2.9550g SrCO 3 (99.9%), 1.9703gYb 2 o 3 (99.95%) and 0.1892g Ho 2 o 3 (99.99%) raw material.

[0054] (2) Ball milling: put the weighed raw materials into ball mill jars with zirconium balls of different sizes (5 and 8 mm in diameter), and then add 40 mL of ethanol as a solvent. Then ball milled on a drum mill for 24 hours.

[0055] (3) Drying and sieving: put the ball-milled raw material powder into an oven at 70°C and dry for 12-15 hours until the alcohol in the tank evaporates to dryness, and then dry at 90°C for 5 hours. Finally, pass through a 100-mesh sieve.

[0056] (4) Pre-burning: Put the dried and sieved raw material powder in a cruci...

Embodiment 2

[0066] Potassium sodium niobate-ytterbium strontium niobate doped with rare earth erbium up-conversion luminescent transparent ferroelectric ceramics: 0.8K 0.5 Na0.5 NbO 3 -0.2Sr(Yb 0.5 Nb 0.5 )O 3 -0.01Er

[0067] (1) Ingredients: weigh 2.7739g K 2 CO 3 (99.5%), 2.1243g Na 2 CO 3 (99.8%), 11.9625gNb 2 o 5 (99.99%), 2.9550g SrCO 3 (99.9%), 1.9703gYb 2 o 3 (99.95%) and 0.1913g Er 2 o 3 (99.99%) raw material.

[0068] (2) Ball milling: put the weighed raw materials into ball milling jars with zirconium balls of different sizes, and then add 40 mL of ethanol as a solvent. Then ball milled on a drum mill for 24 hours.

[0069] (3) Drying and sieving: put the ball-milled raw material powder into an oven at 70°C and dry for 12-15 hours until the alcohol in the tank evaporates to dryness, and then dry at 90°C for 5 hours. Finally, pass through a 100-mesh sieve.

[0070] (4) Pre-burning: Put the dried and sieved raw material powder in a crucible, raise the temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com