Semipermeable reflective plate and reflective plate and semipermeable polazied plate and reflective polazied plate and liquid crystal display

A liquid crystal display, reflective polarizer technology, applied in optics, instruments, optical components, etc., can solve the problems of surfactant removal, fire, electrical failure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

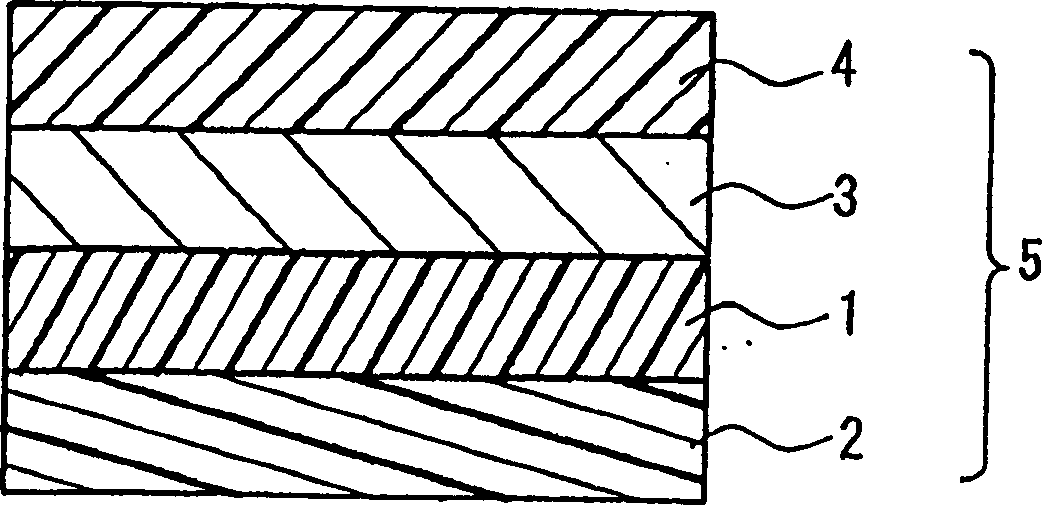

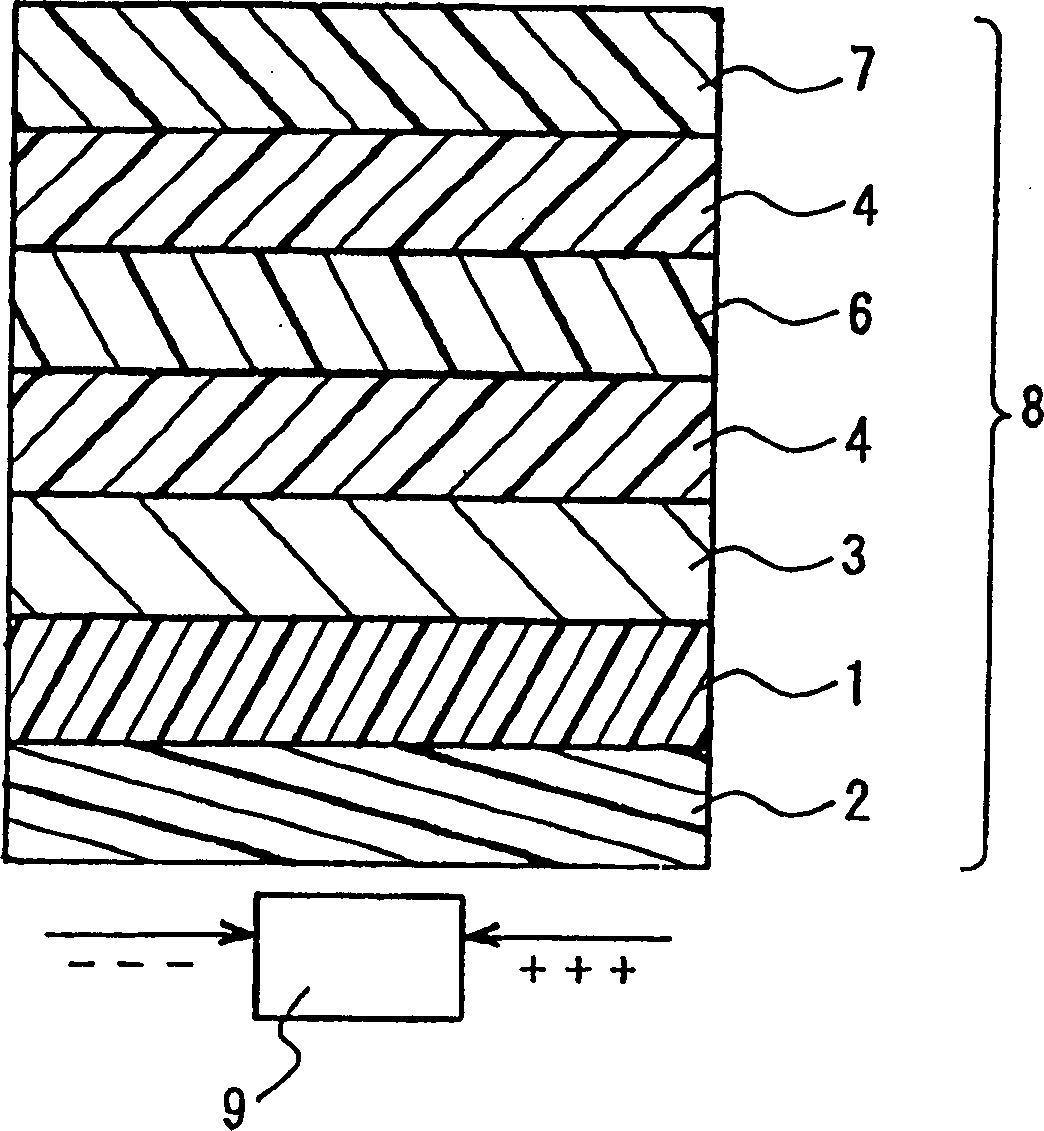

[0046] On a reflection plate (trade name: Alpet50; manufactured by Toyo Aluminum; the thickness of the aluminum foil: 15 microns; the thickness of the PET substrate: 50 microns) is coated with a conductive polymer type antistatic agent to form a 0.2 micron thickness antistatic Static layer. The surface resistance of the antistatic layer is 6*10 5 ohm. A polarizing plate (trade name: F1205; manufactured by Nitto Denko Corporation) was laminated and bonded thereon through an adhesive layer having a thickness of 25 µm to form a reflective polarizing plate. image 3 It is a schematic view showing the cross-sectional structure of the reflective polarizer, wherein the aluminum foil 3 in an insulating state is sandwiched between the adhesive layer 4 and the PET substrate 1 . Reference numeral 6 shows the polarizing plate, and reference numeral 6 shows the release layer 7 .

[0047] With this reflective polarizing plate, the 180-degree peeling test carried out by using a practical ...

example 2

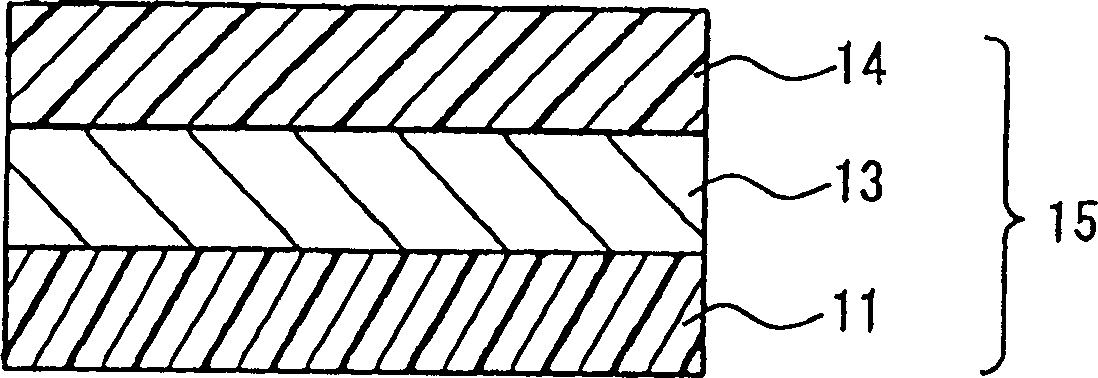

[0050] A silver-deposited transflector (transmittance: 10%; reflectance: 70%; thickness of PET substrate: 50 μm) is coated with a conductive filler (Sno) (trade name) dispersed therein. : P3001; manufactured by Shokubai Kasei K.K.) conductive paint to form an antistatic layer with a thickness of 1 µm and 80% light transmittance. The surface resistance of the antistatic layer is 10*10 6 ohm. A polarizing plate (trade name: F1205; manufactured by Nitto Denko Corporation) was laminated and bonded thereon through an adhesive layer having a thickness of 25 µm so as to obtain a half-transmission polarizing plate. Also in this structure, the silver deposition film in an insulating state is sandwiched between the adhesive layer and the PET substrate.

[0051] In the same manner as in Example 1, the adhesion force (peel strength) between the antistatic layer and the PET substrate was measured to be 2N / 25mm through a 180-degree peel test at a peel rate of 0.3m / min.

[0052] Then, whe...

example 3

[0055] Coating a conductive filler (trade name: D600; D600; A conductive paint manufactured by Shinto Toryo K.K.) to form an antistatic layer with a thickness of 20 µm and a light transmittance of 70%. The surface resistance of the antistatic layer is 10*10 10 ohm. A polarizing plate (trade name: F1205; manufactured by Nitto Denko Corporation) was laminated and bonded thereon through an adhesive layer having a thickness of 25 µm so as to obtain a half-transmission polarizing plate. Also in this structure, the silver deposition film in an insulating state is sandwiched between the adhesive layer and the PET substrate.

[0056] In the same manner as in Example 1, the adhesion force (peel strength) between the antistatic layer and the PET substrate was measured to be 2N / 25mm through a 180-degree peel test at a peel rate of 0.3m / min.

[0057] Then, when this roll of product was unrolled through metal rollers, the charge did not exceed 500V.

[0058] When a protective plate on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com