Sealed vessel and method of producing the same

A technology for sealing containers and manufacturing methods, applied in the direction of containers, sealing, rigid containers, etc., which can solve the problems of promoting liquid dripping, unfavorable drinking, unresolved flanges, etc., to achieve improved conveying efficiency, increased filling speed, and good contact feeling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

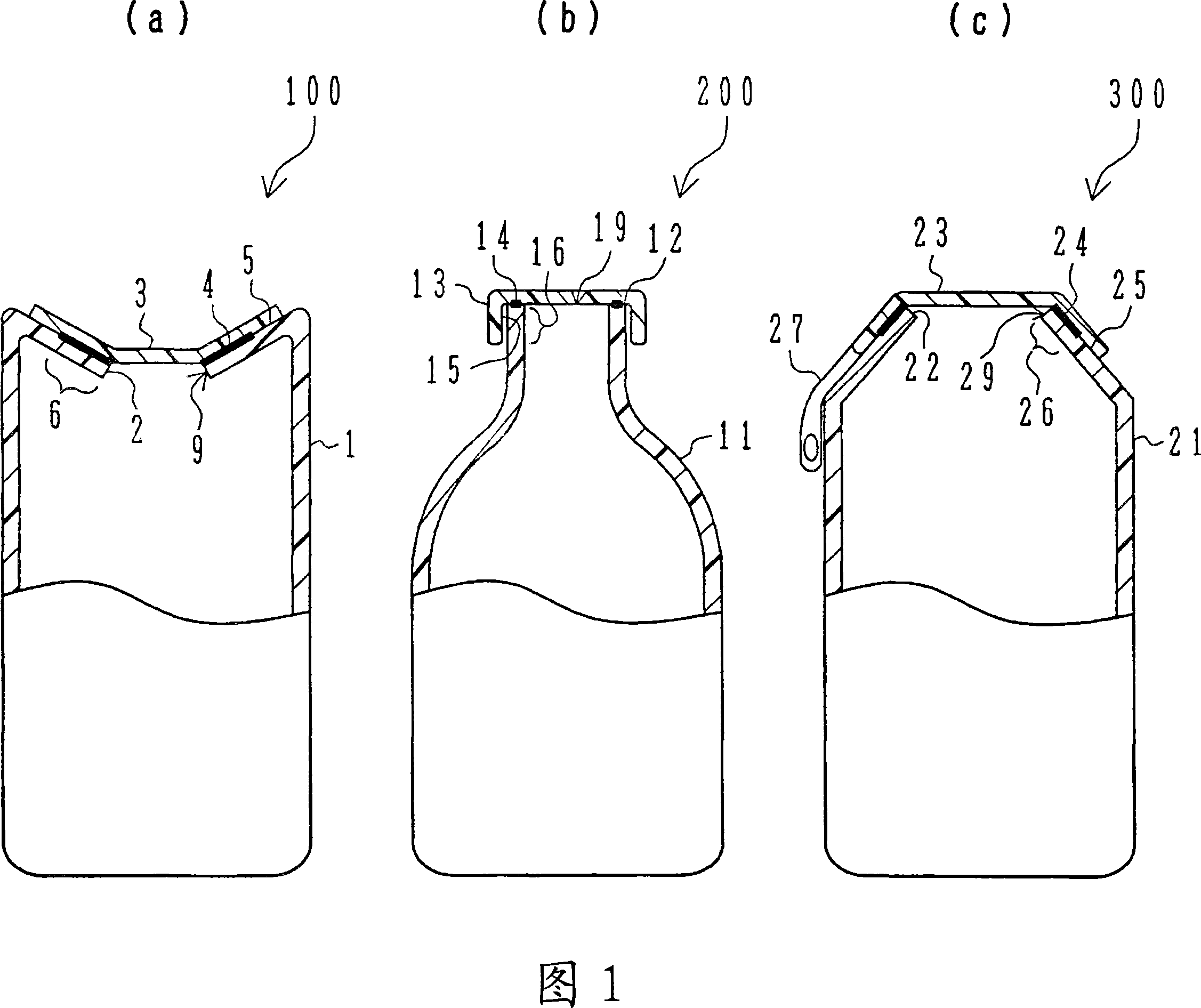

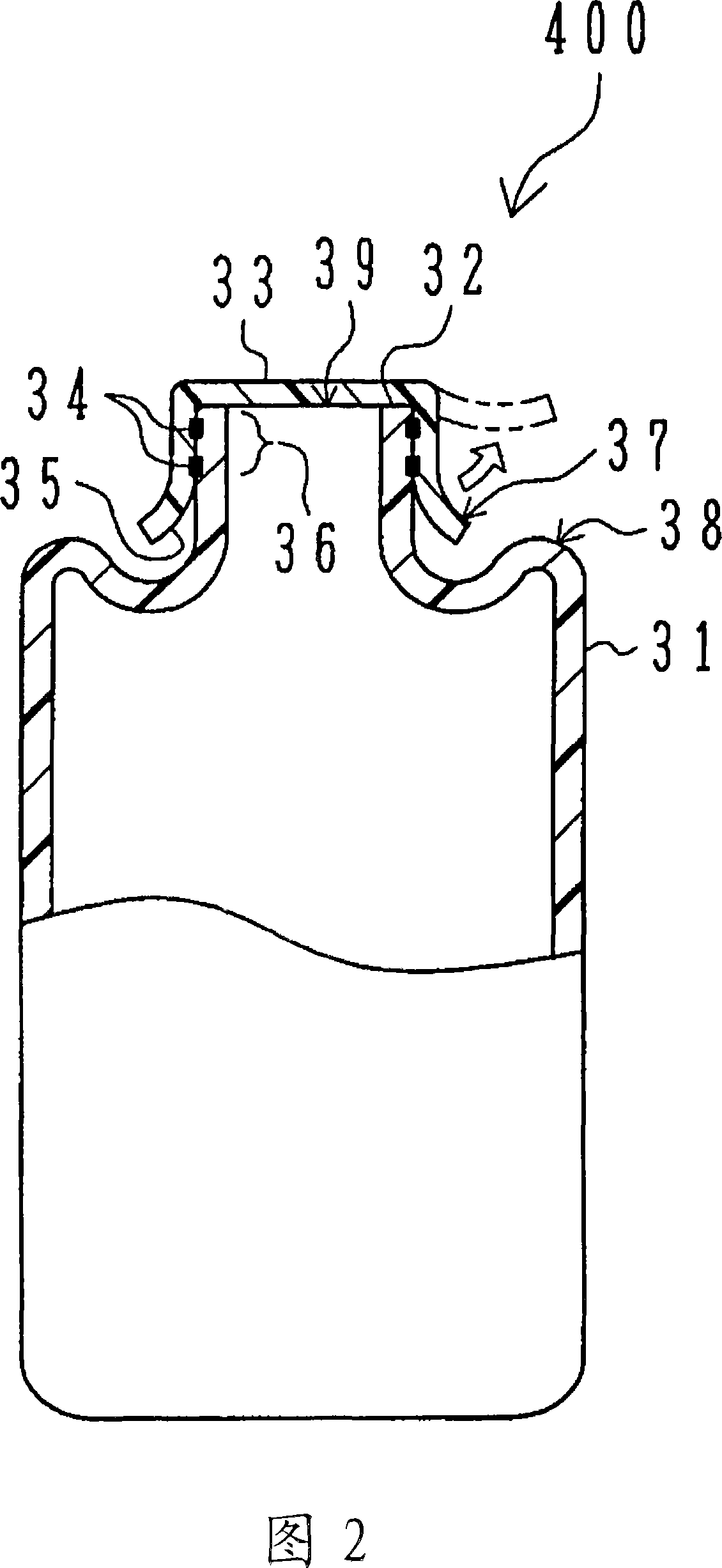

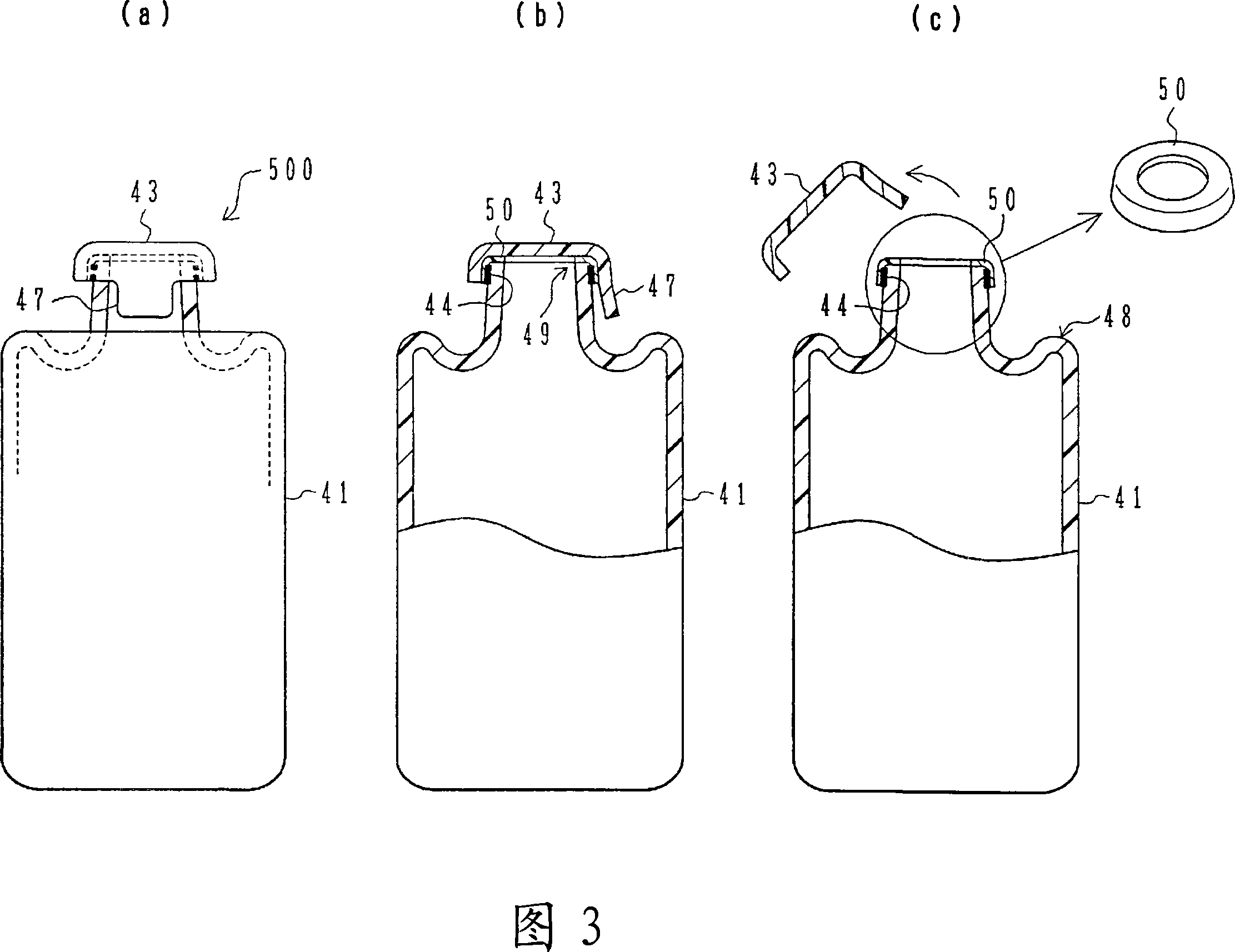

[0053] Embodiments of the present invention are shown below and described in detail, but the present invention should not be construed as being limited to these descriptions. First, the airtight container of this embodiment is demonstrated with reference to FIGS. 1-3. In addition, the same reference numerals are assigned to the same components / same parts.

[0054] FIG. 1( a ) shows a schematic partial vertical cross-sectional view of a sealed container according to a first aspect of the present embodiment. The airtight container 100 of the first aspect, the container main body 1 having the opening 9 is sealed by the lid 3 closing the opening 9, and is characterized in that: the inner wall surface of the container main body 1 includes at least the peripheral portion of the opening 9 The outer wall surface of the peripheral portion 2 of the opening portion 9 and the welding portion 4 of the inner wall surface of the lid portion 3 are laser-welded so that the inner wall surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com