Patents

Literature

380results about How to "Fast filling speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

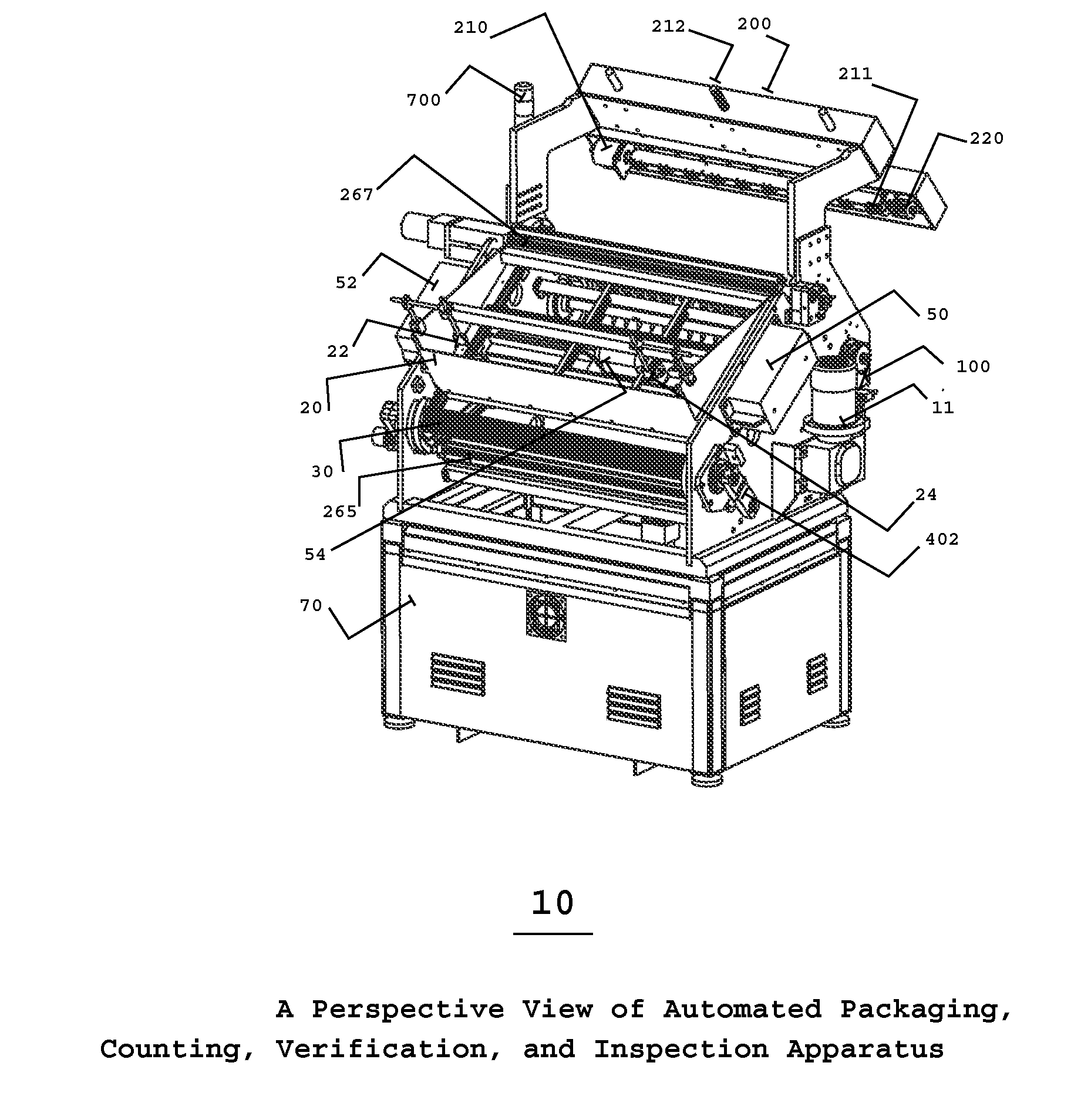

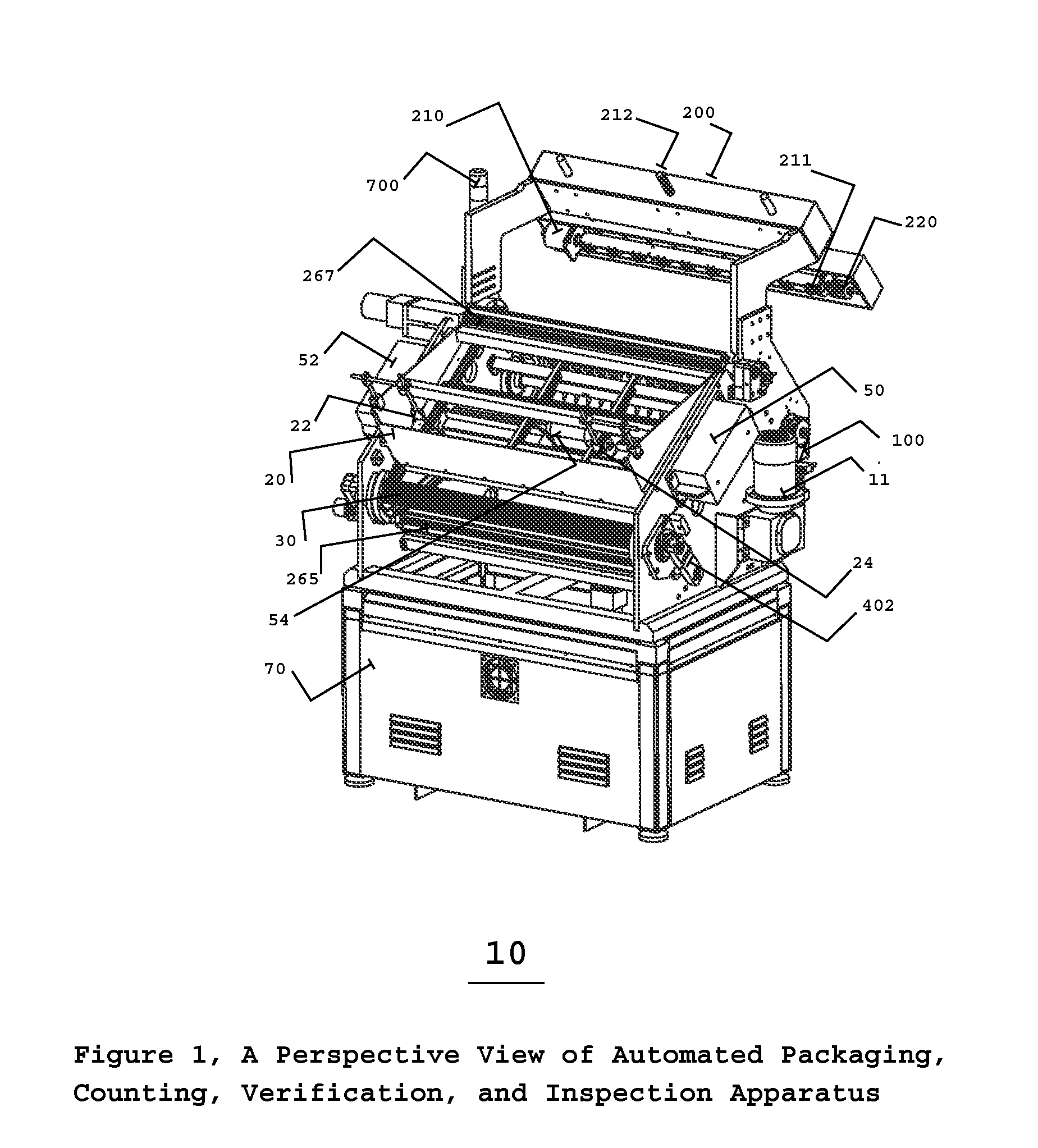

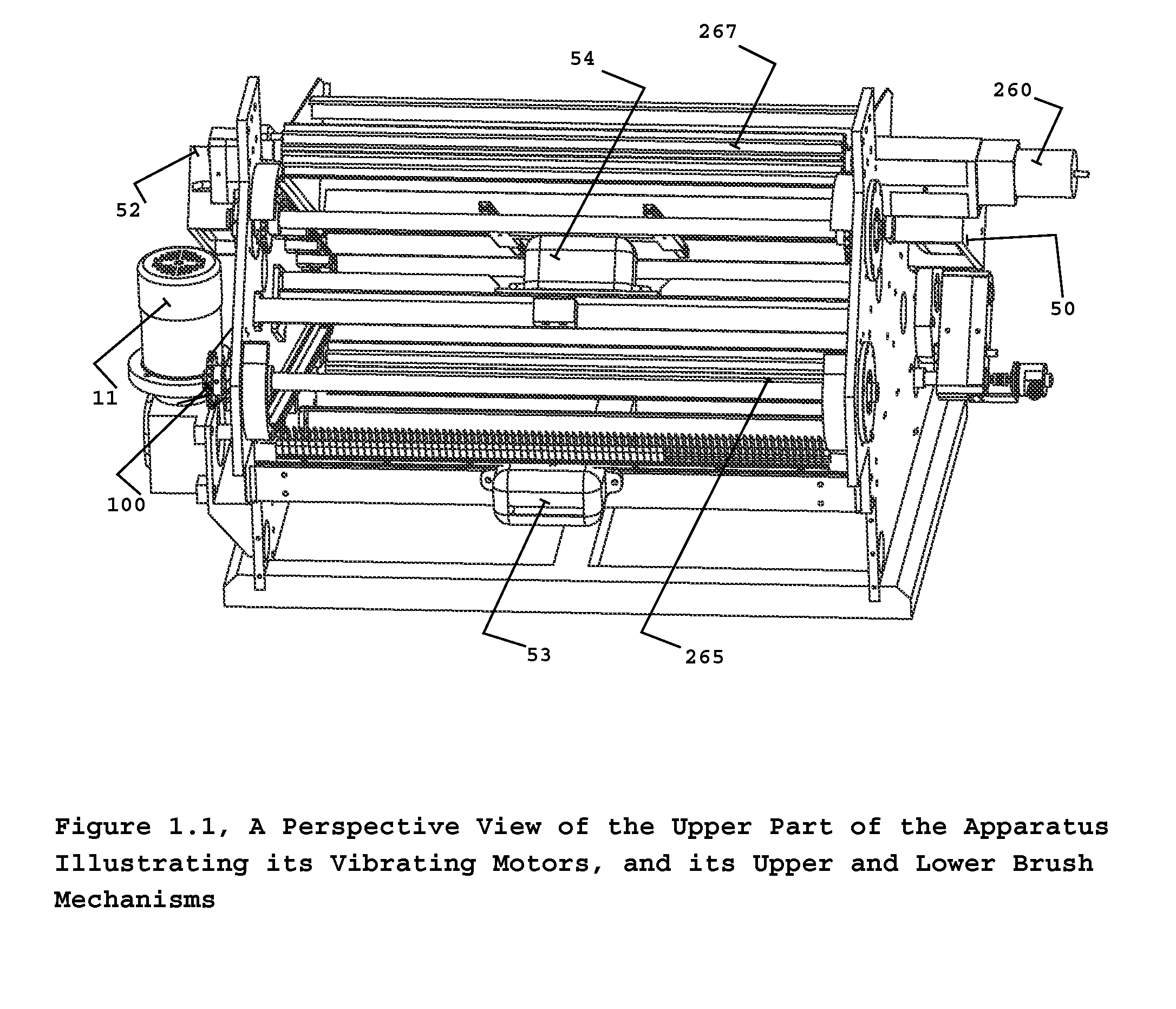

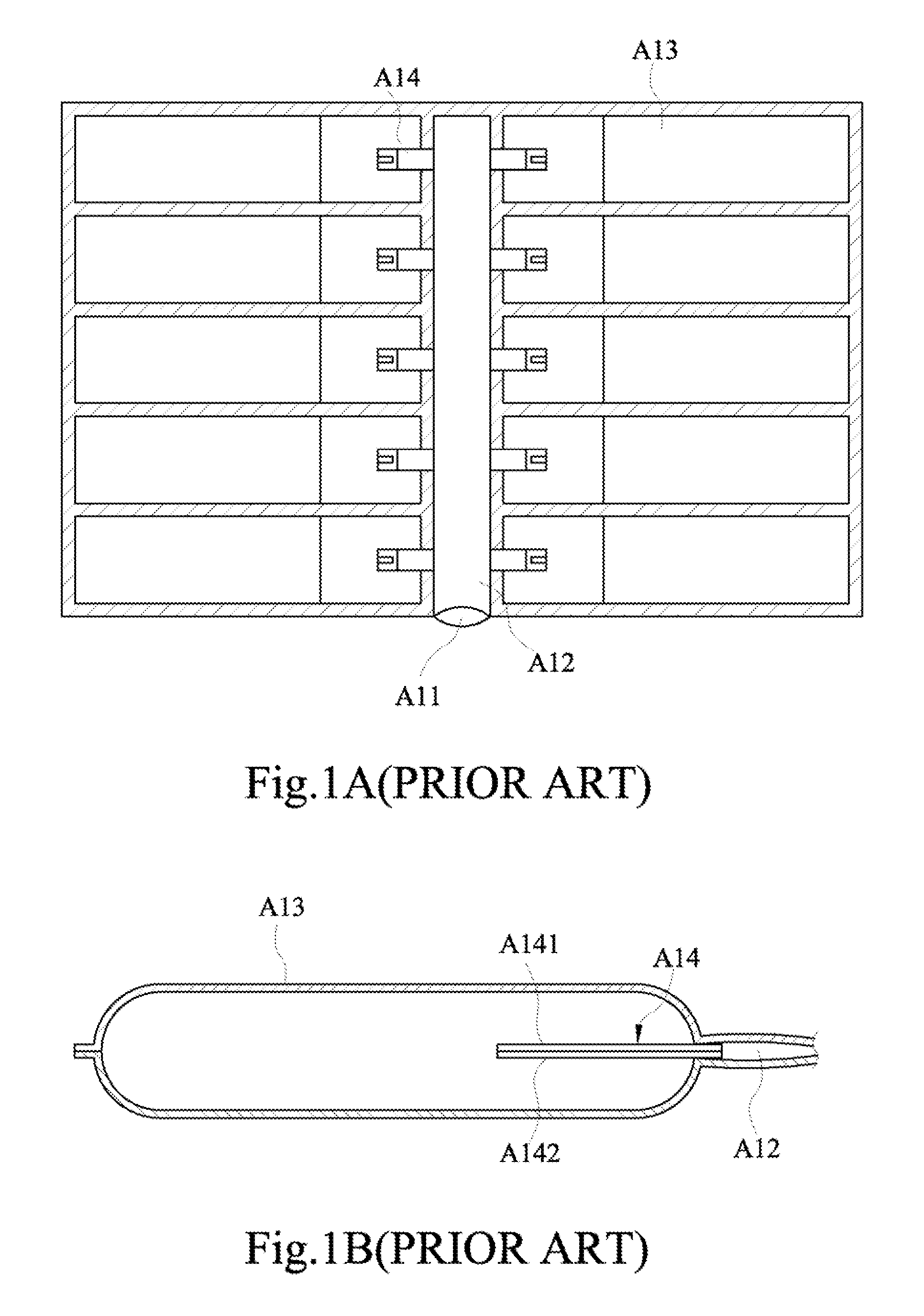

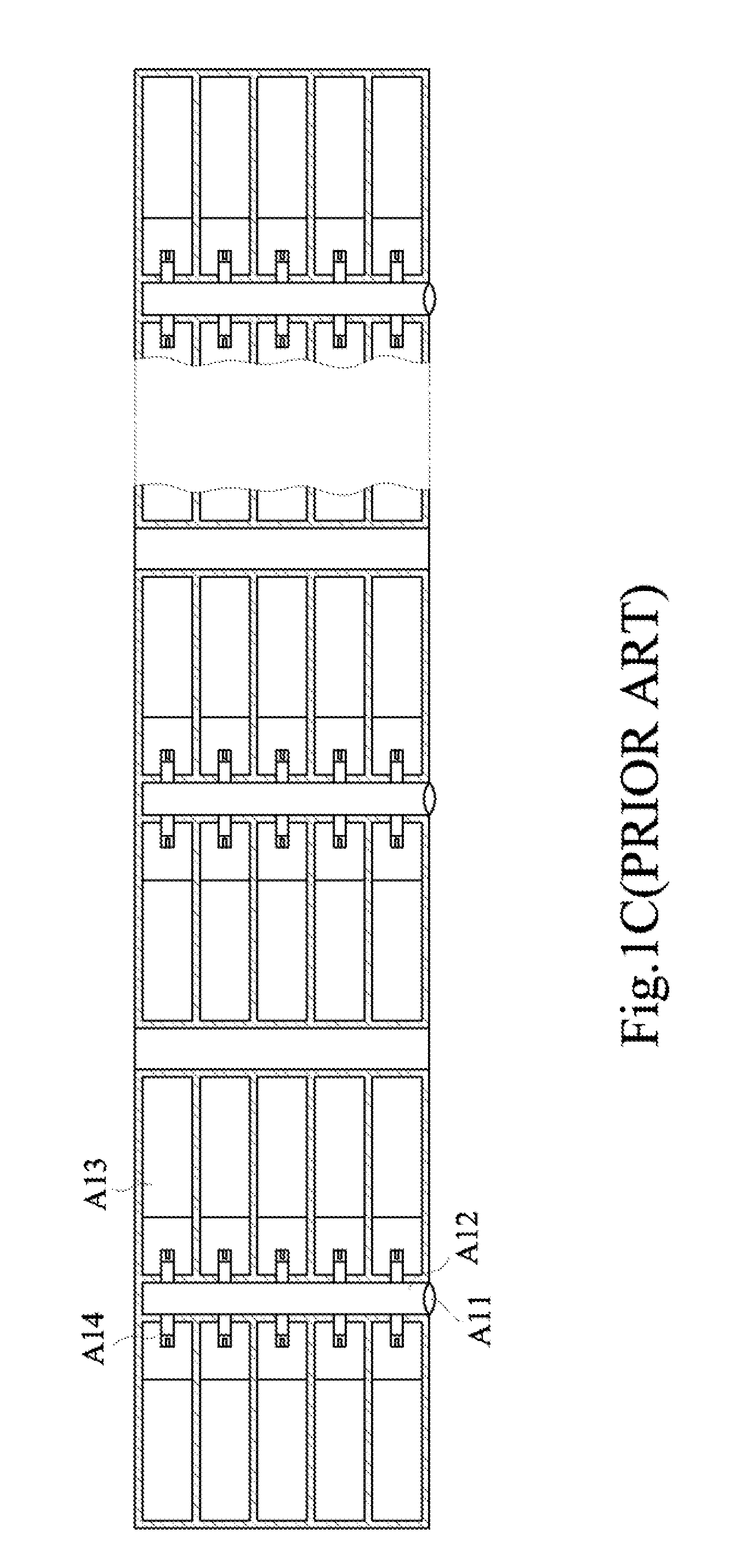

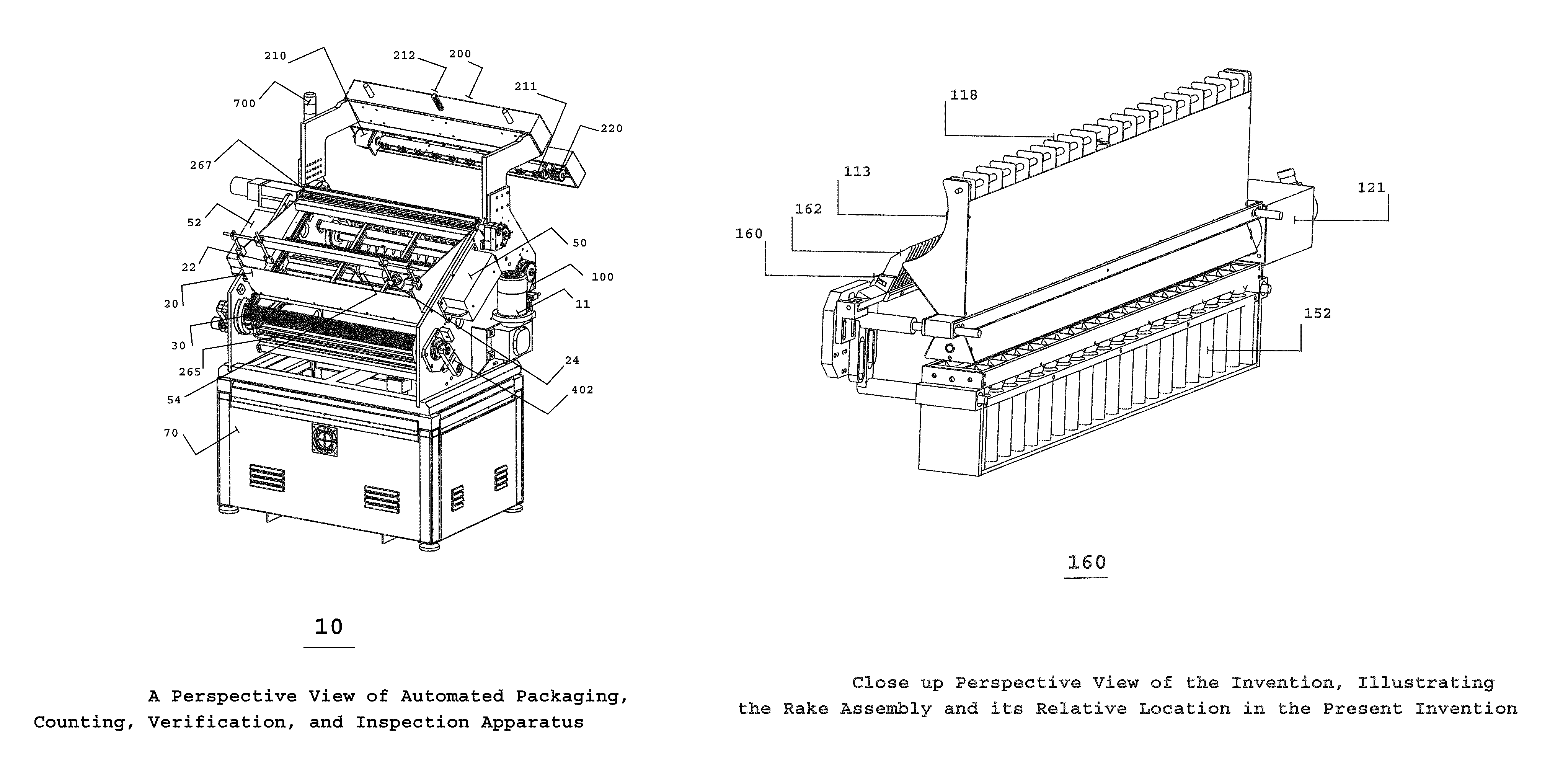

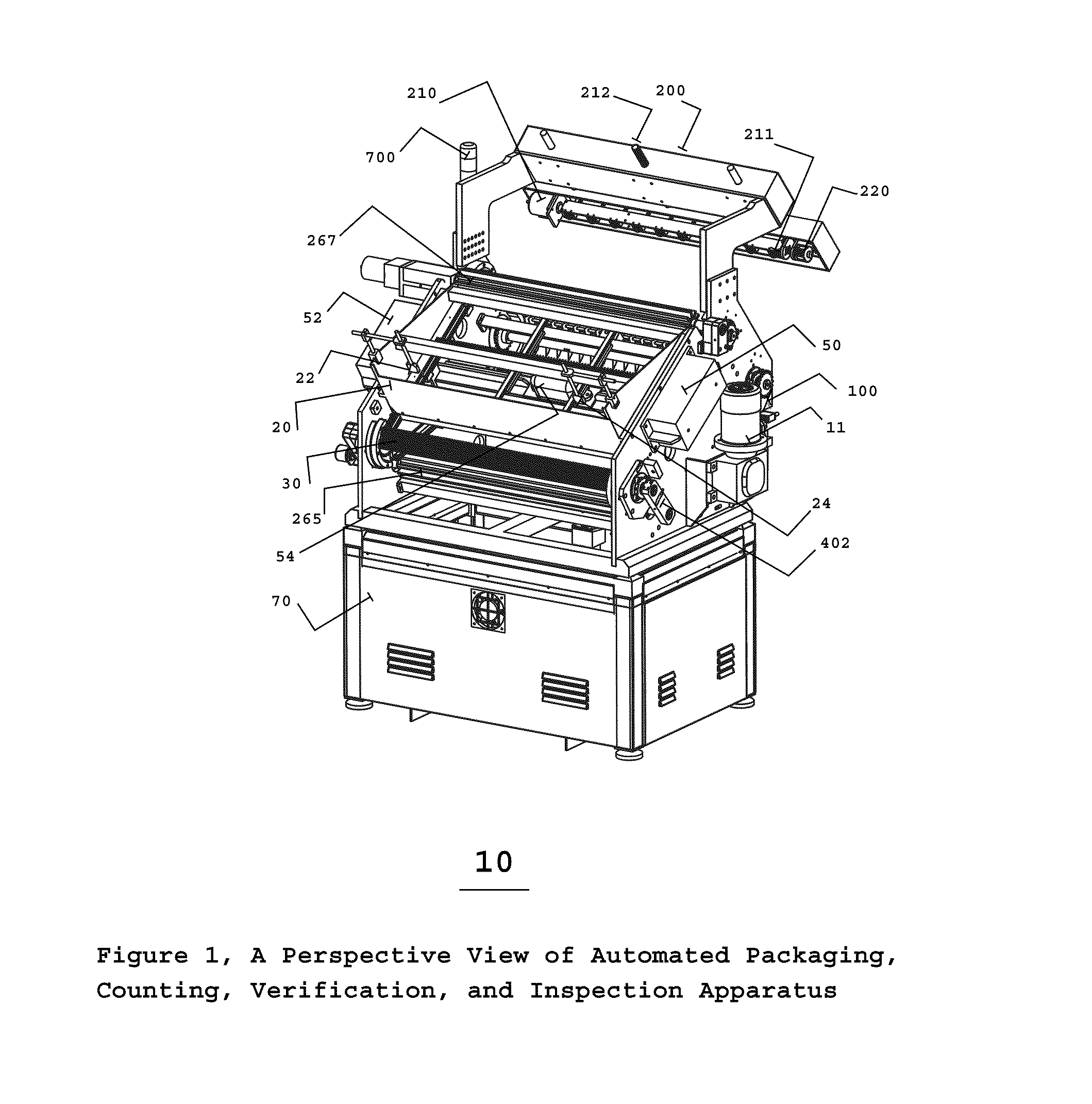

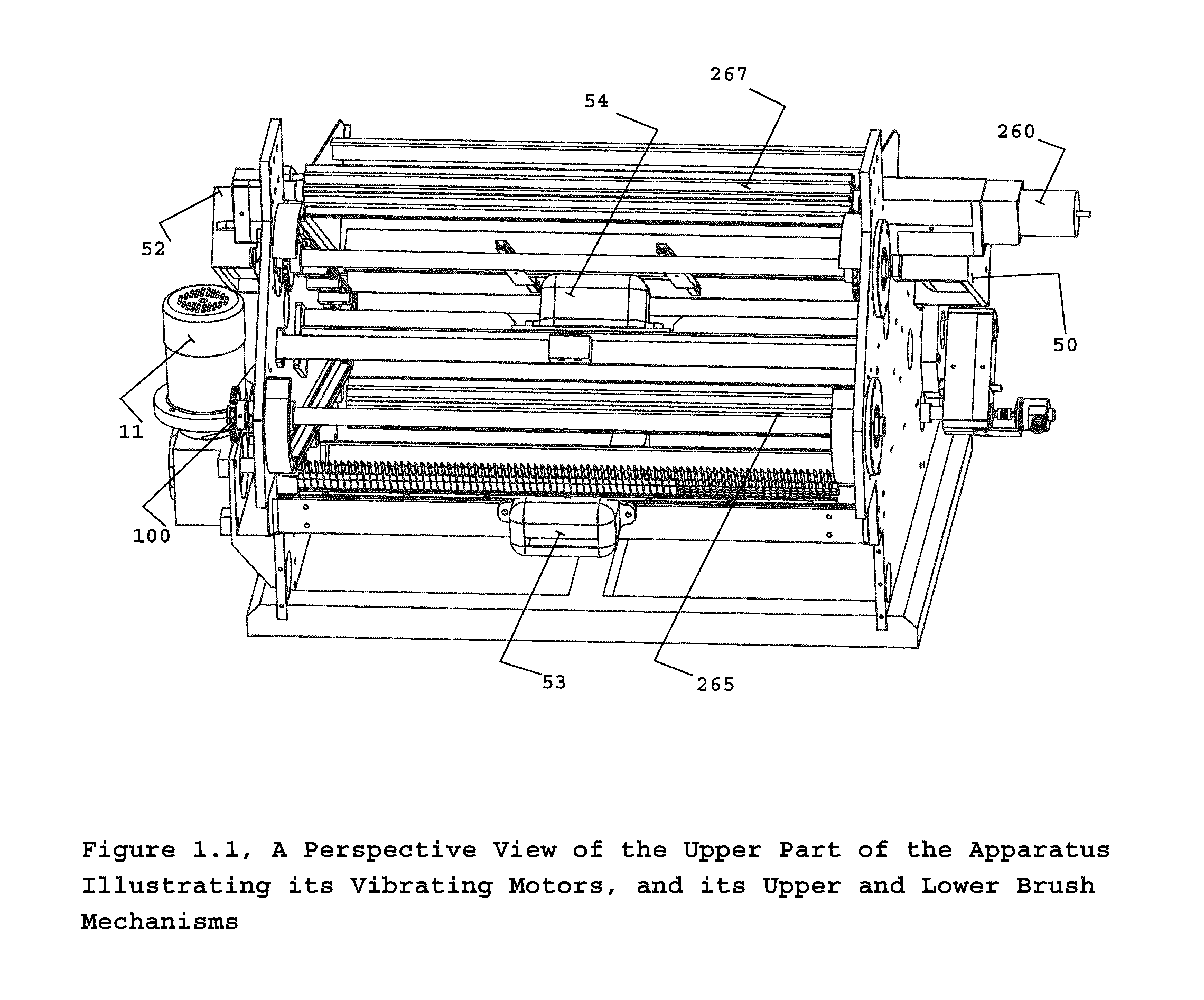

Automated pharmaceutical product packaging, inspection, verification, and counting apparatus

InactiveUS20100175352A1High container filling speedFast filling speedCapsCapping machinery safety/controlProcess engineeringEngineering

The present invention is an automated packaging apparatus utilizing a rotating assembly of elongated slats containing cavities to receive discrete pharmaceutical, vitamin, or food products. Quantities of discrete products such as tablets, capsules, or gels are deposited into the hopper of the apparatus. The apparatus then dispenses the discrete products into containers moving on a conveyor system such that each container receives a predetermined quality and quantity of pharmaceutical, vitamin, or food products. While operating at high speed, the apparatus inspects, counts, identifies and analyzes each product deposited into the containers and maintains electronic records describing the status of each product. In the event any errors occur the apparatus produces various alerts to inform the operator. The presence of foreign products or objects may cause the apparatus to instantly stop the entire system including peripheral equipment. A series of Good Manufacturing Practice protocols can then be enforced as per FDA requirements.

Owner:SOLOMAN SABRIE

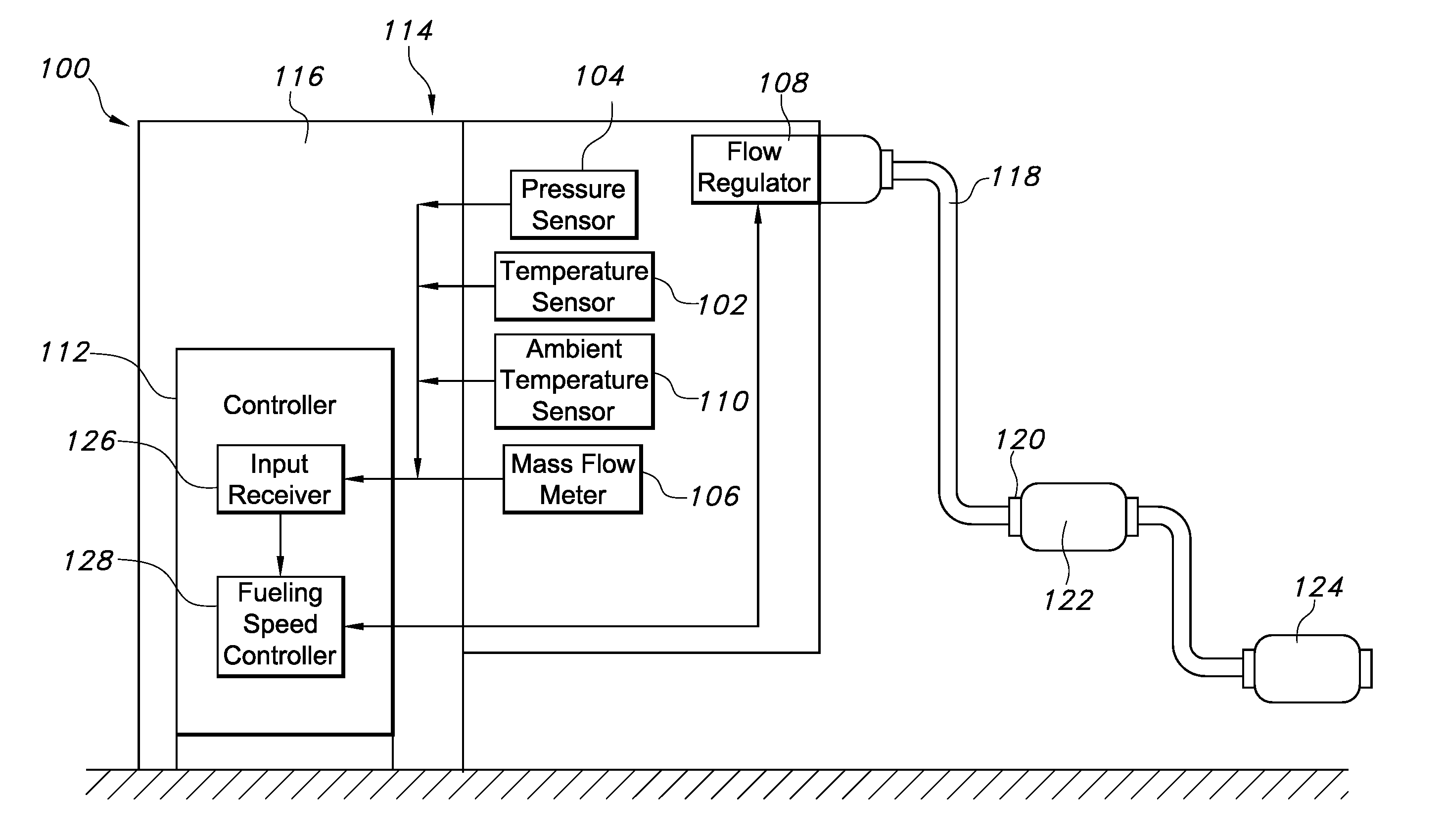

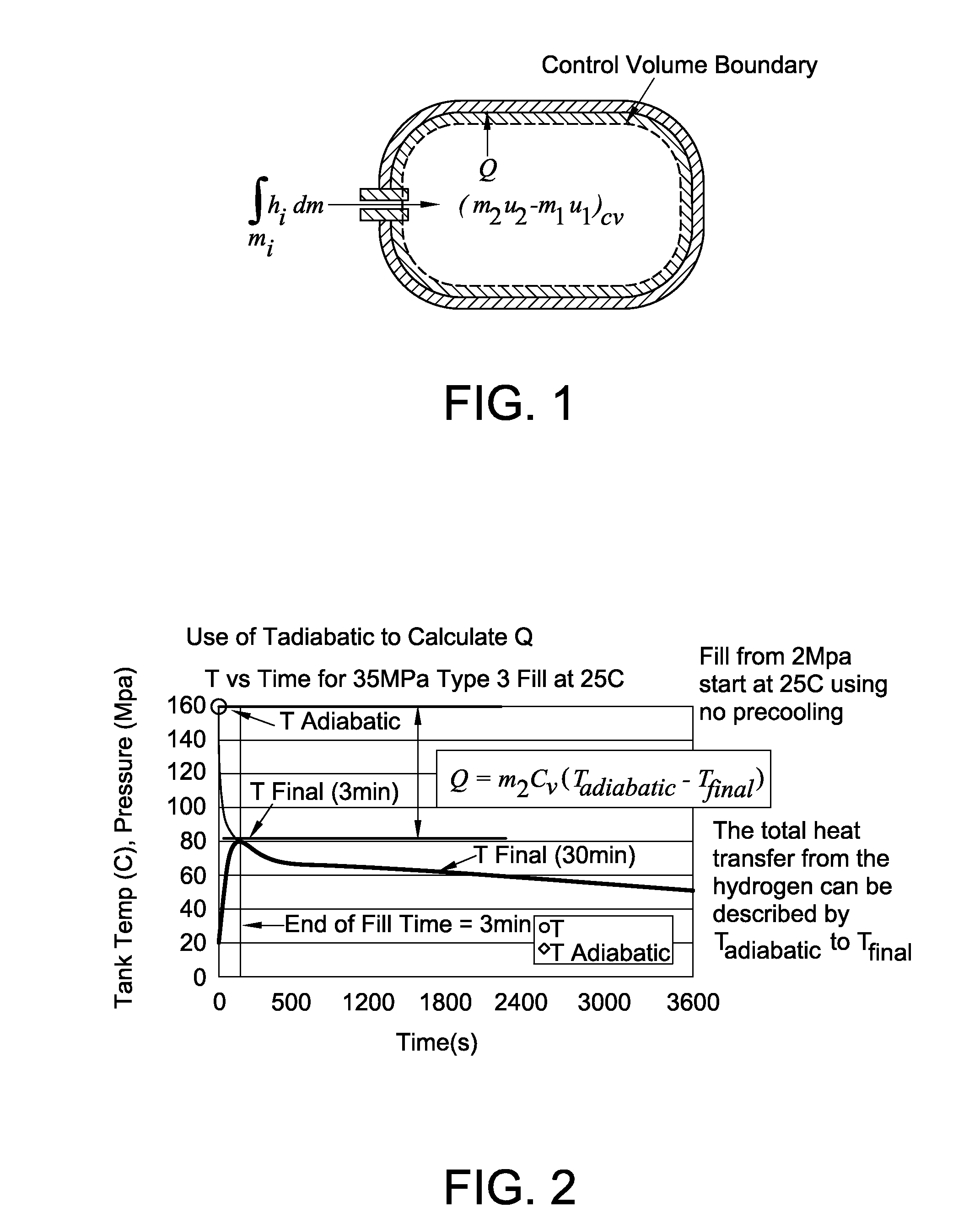

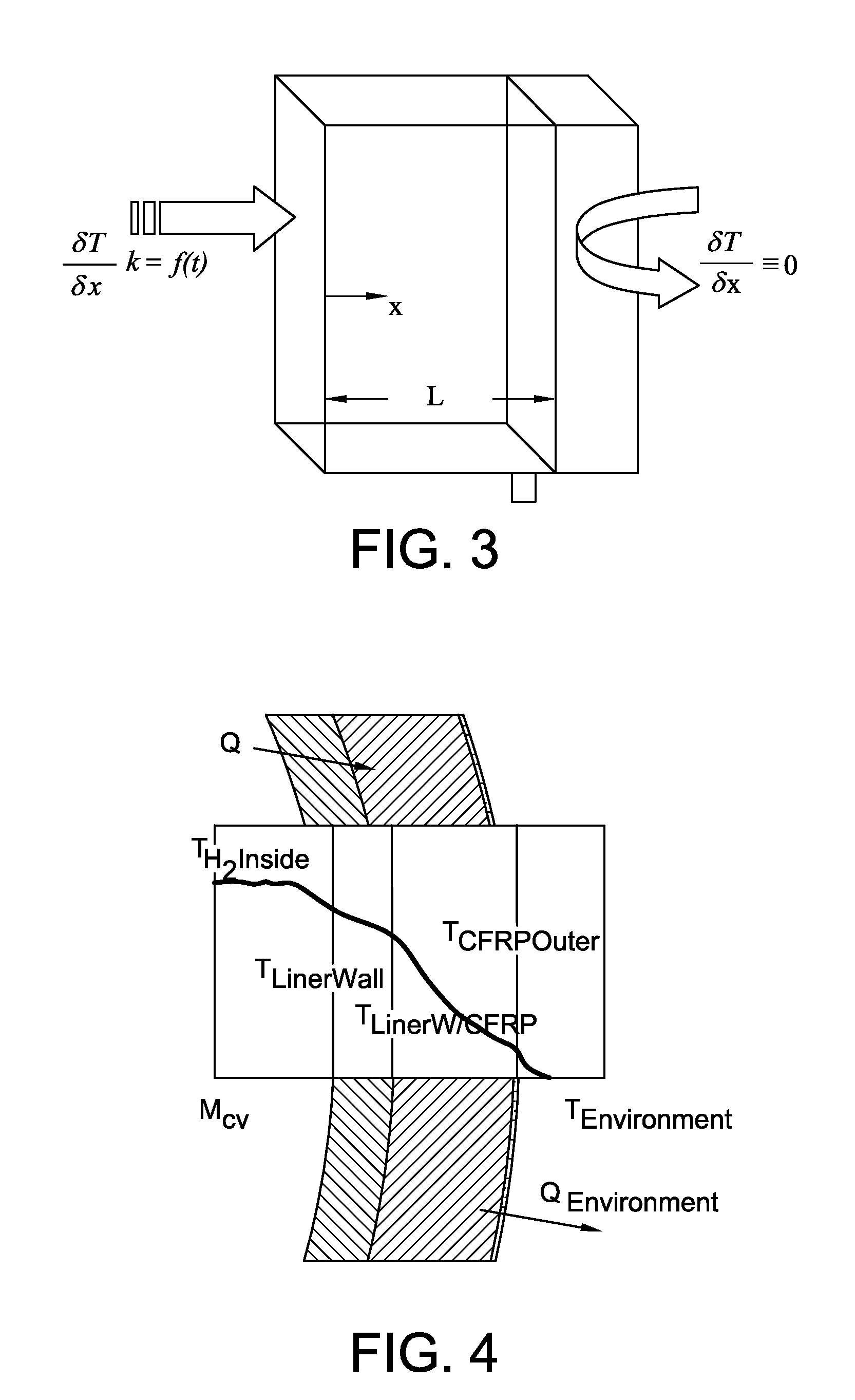

Method and system for tank refilling using active fueling speed control

ActiveUS20140290790A1Improve performanceImprove fuel performanceLiquid fillingGas handling applicationsAnalytical equationsFuel tank

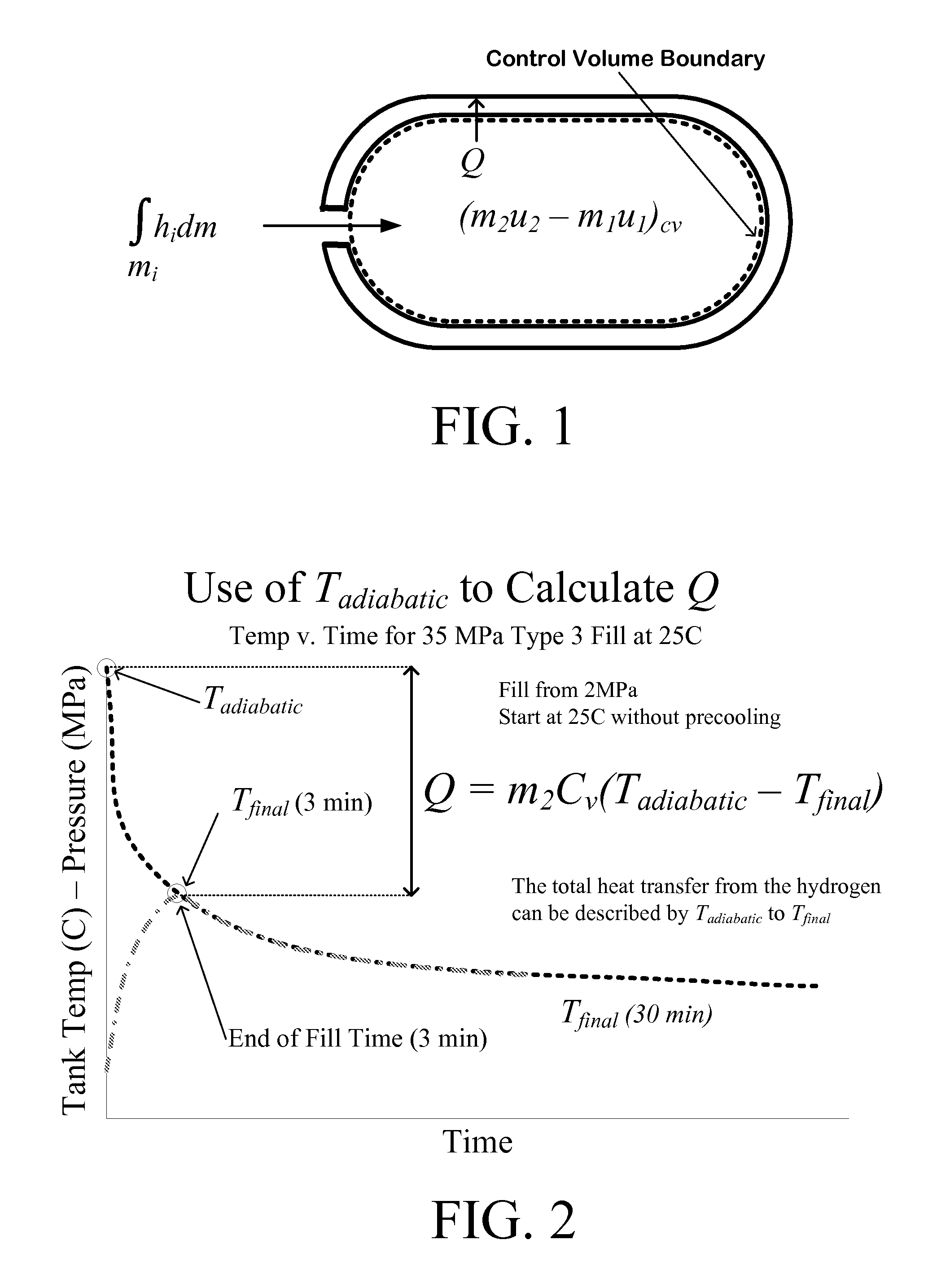

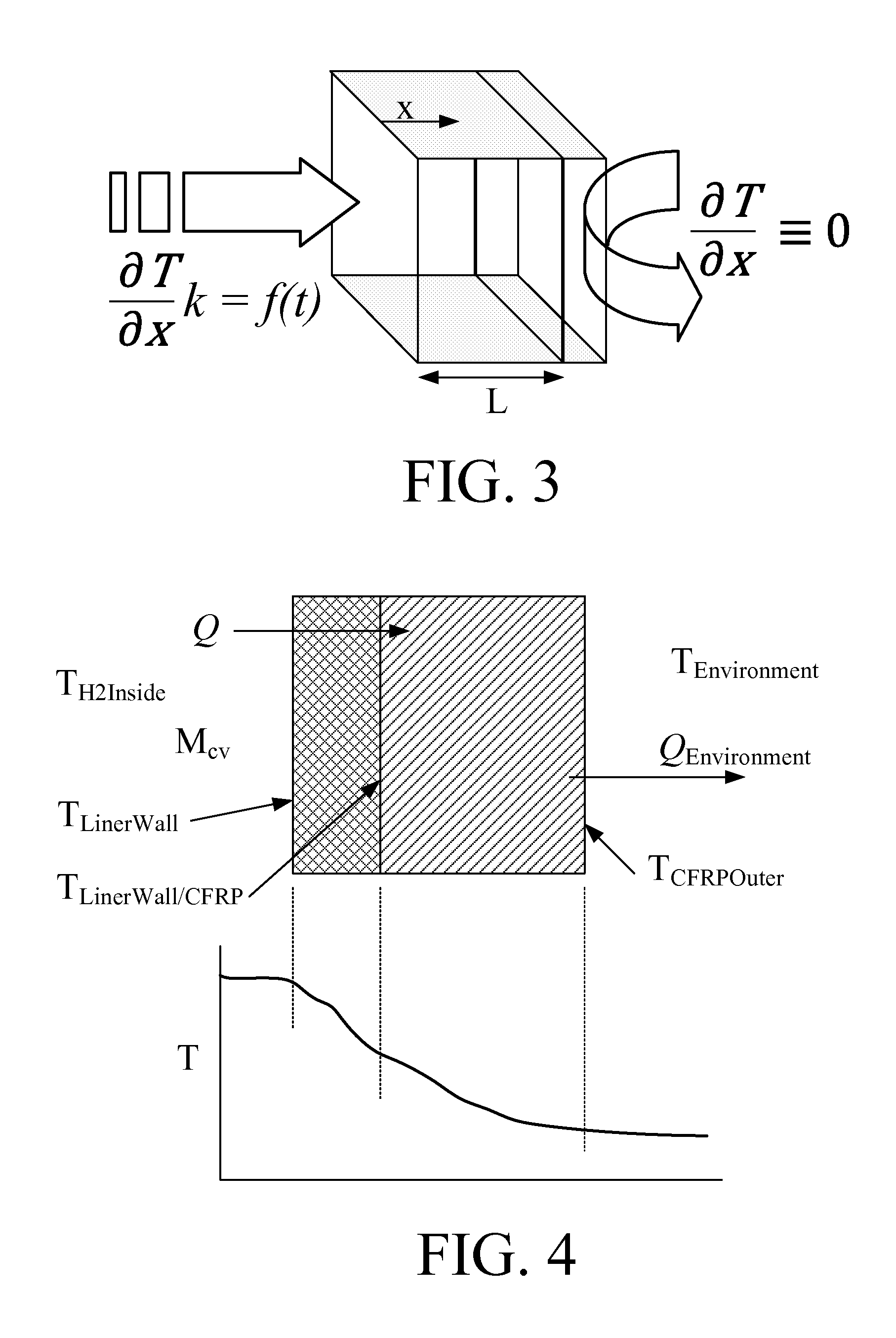

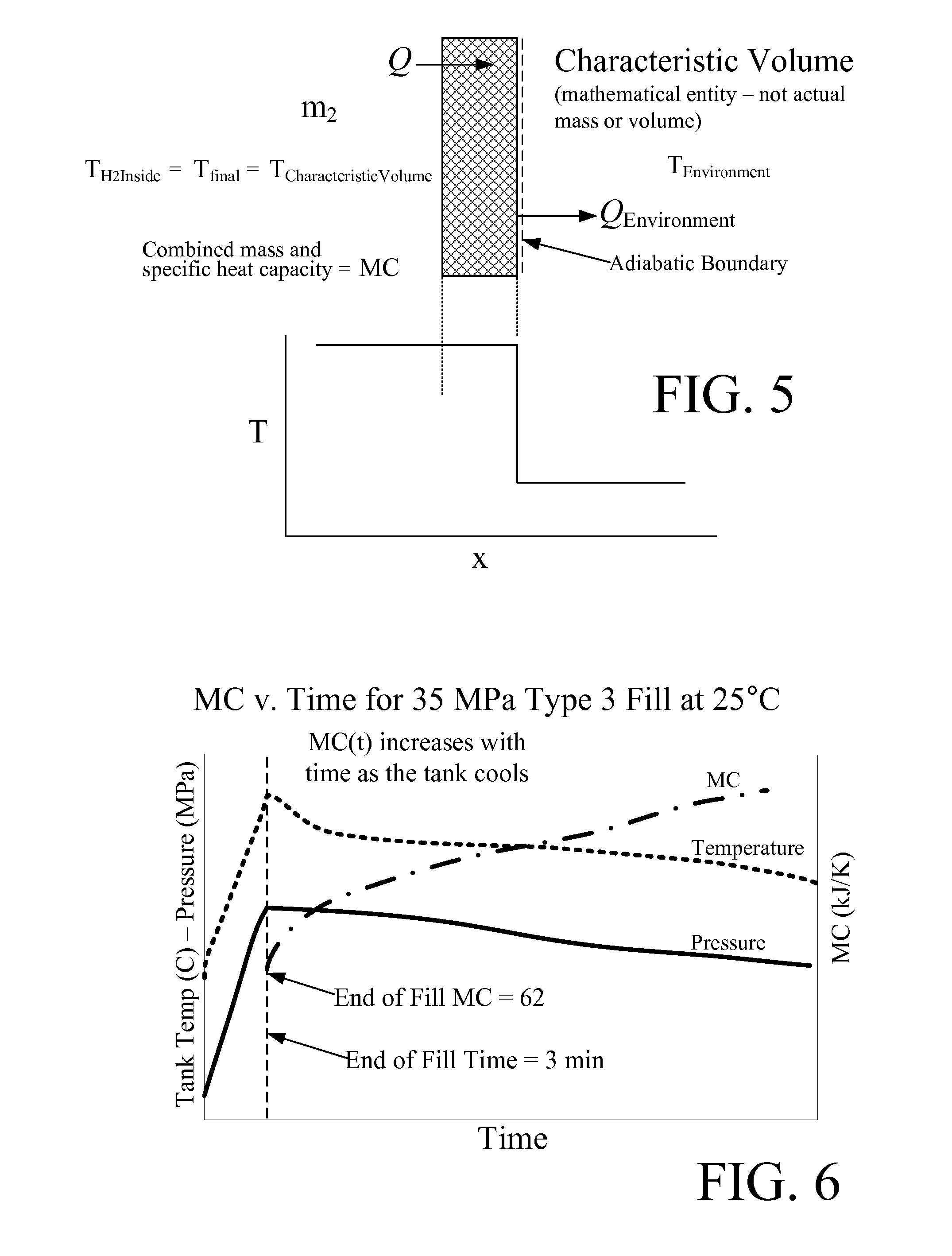

Disclosed is an improved analytical method that can be utilized by hydrogen filling stations for directly and accurately calculating the end-of-fill temperature in a hydrogen tank that, in turn, allows for improvements in the fill quantity while tending to reduce refueling time. The calculations involve calculation of a composite heat capacity value, MC, from a set of thermodynamic parameters drawn from both the tank system receiving the gas and the station supplying the gas. These thermodynamic parameters are utilized in a series of simple analytical equations to define a multi-step process by which target fill times, final temperatures and final pressures can be determined. The parameters can be communicated to the station directly from the vehicle or retrieved from a database accessible by the station. Because the method is based on direct measurements of actual thermodynamic conditions and quantified thermodynamic behavior, significantly improved tank filling results can be achieved.

Owner:HONDA MOTOR CO LTD

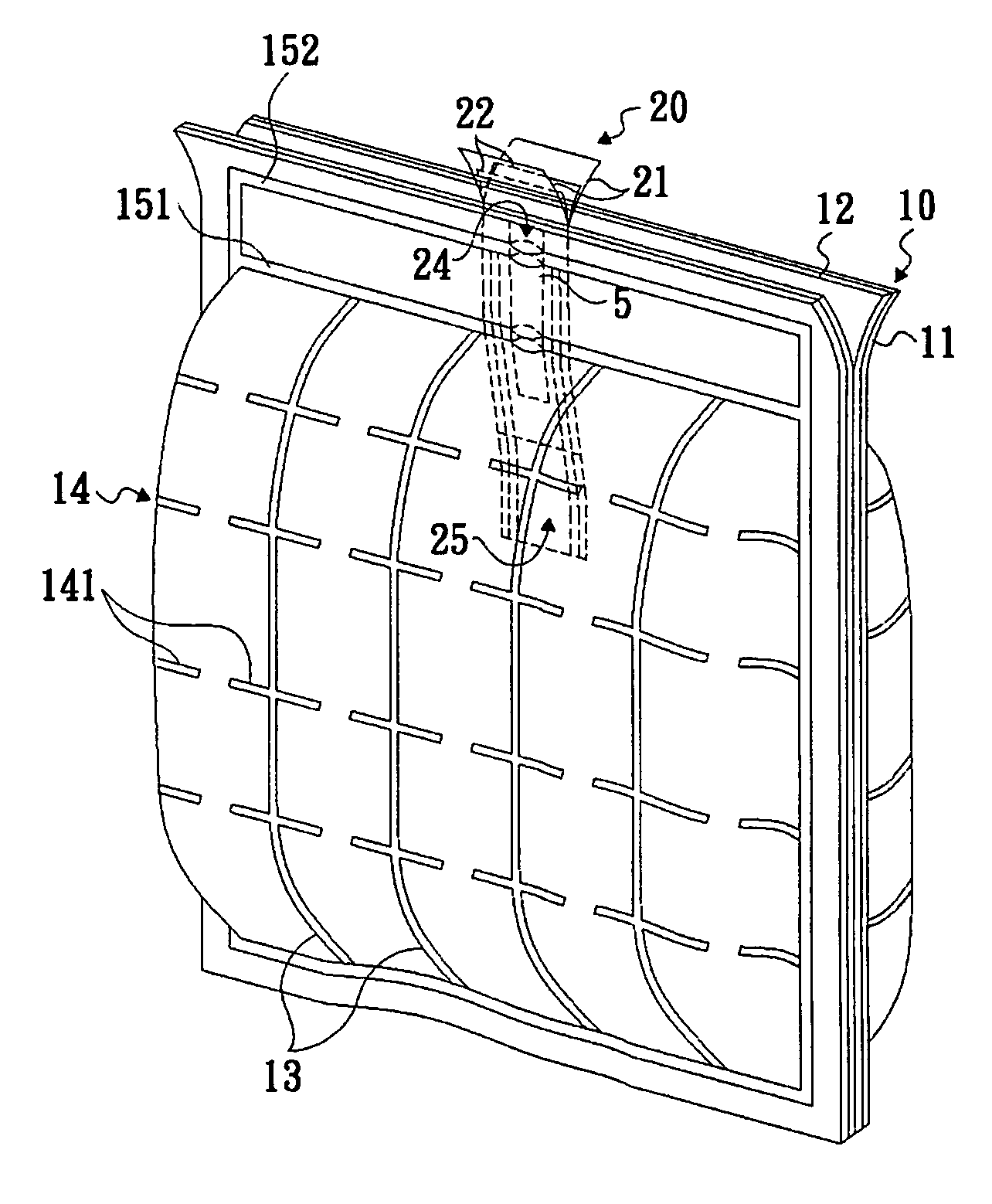

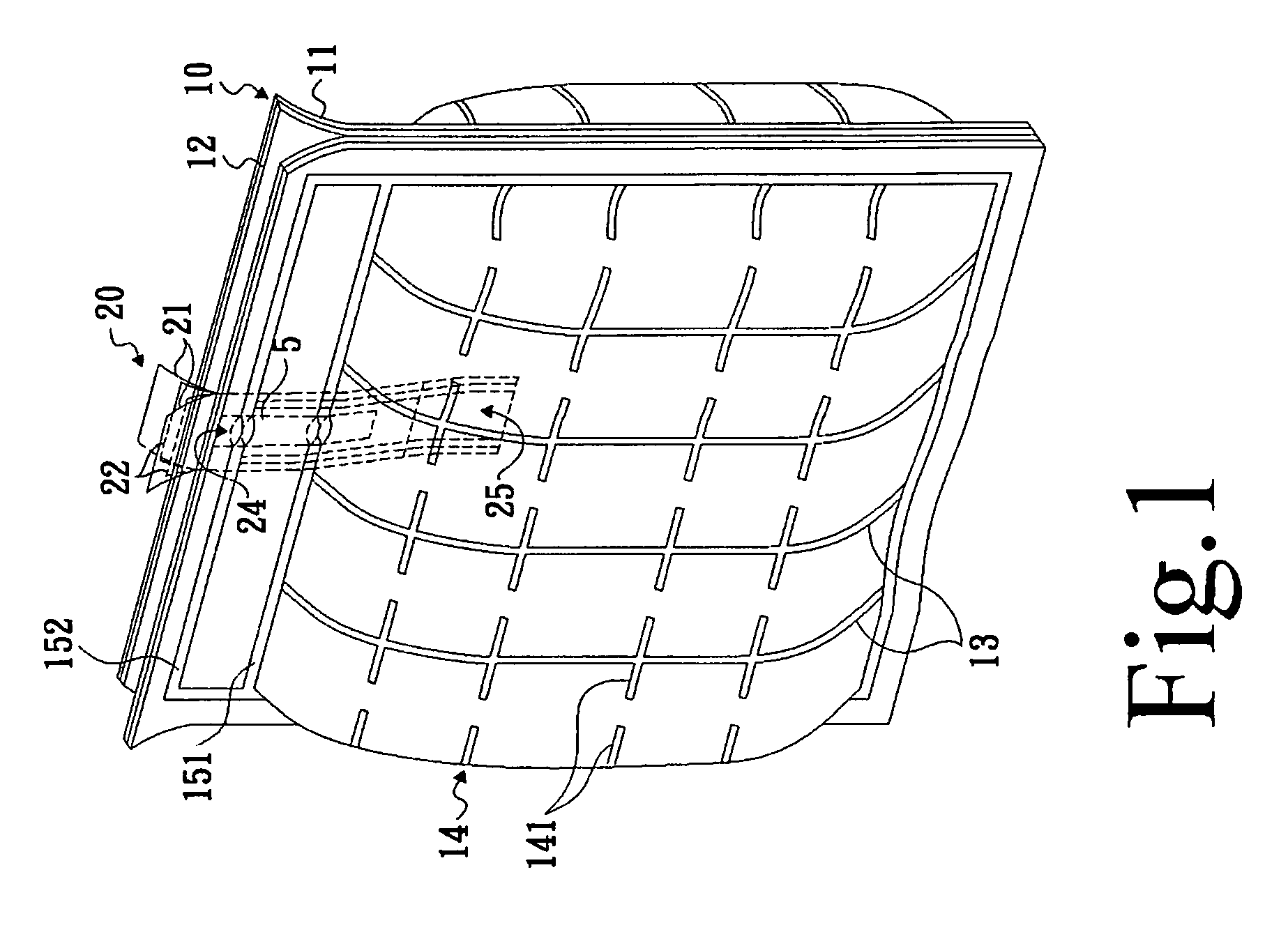

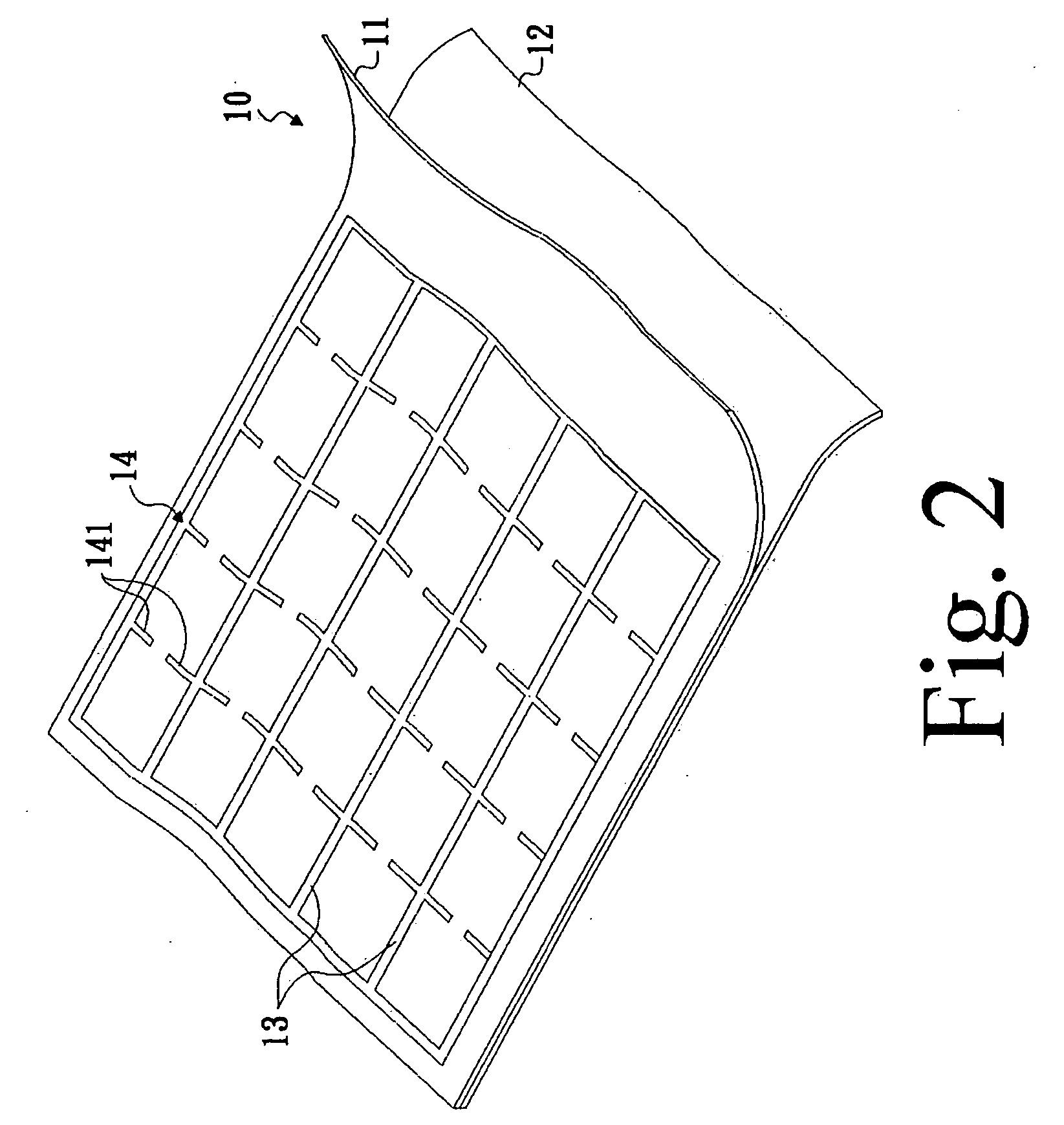

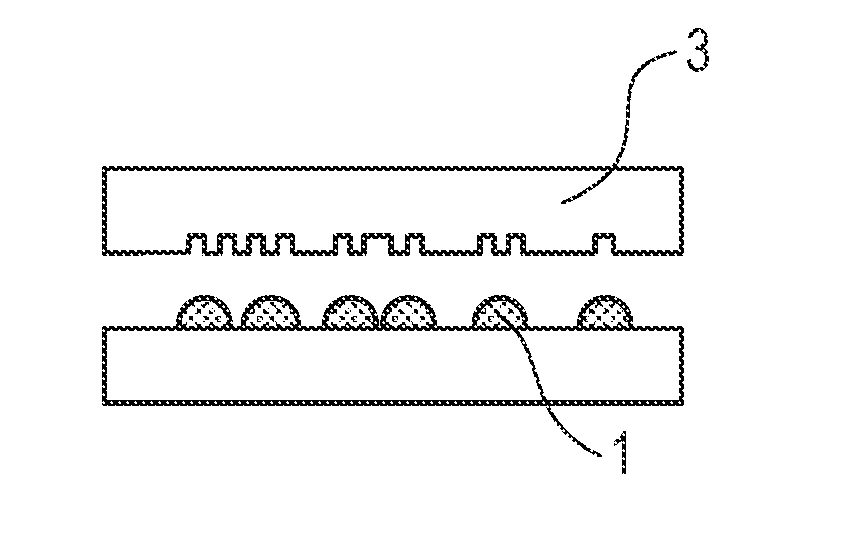

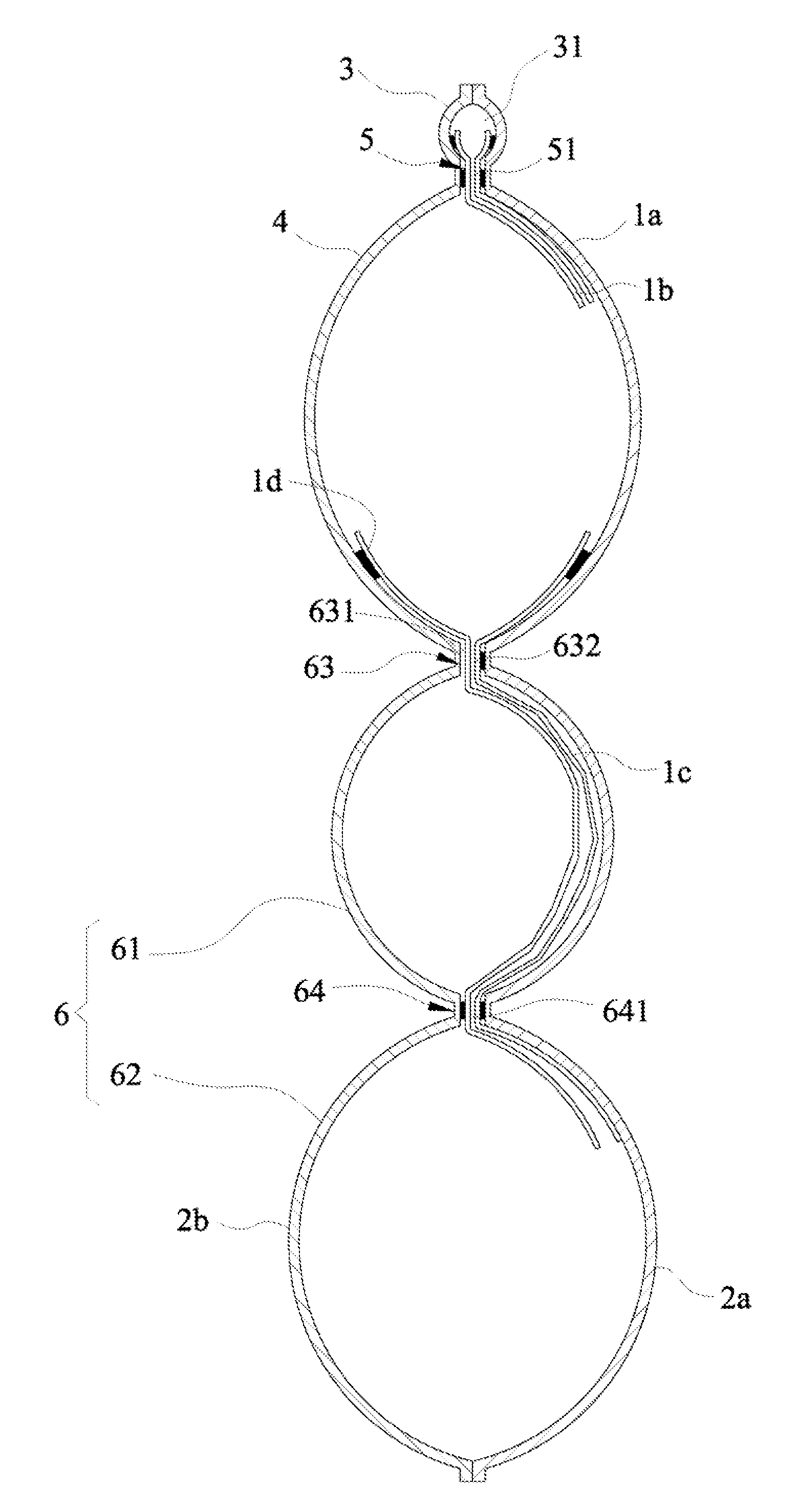

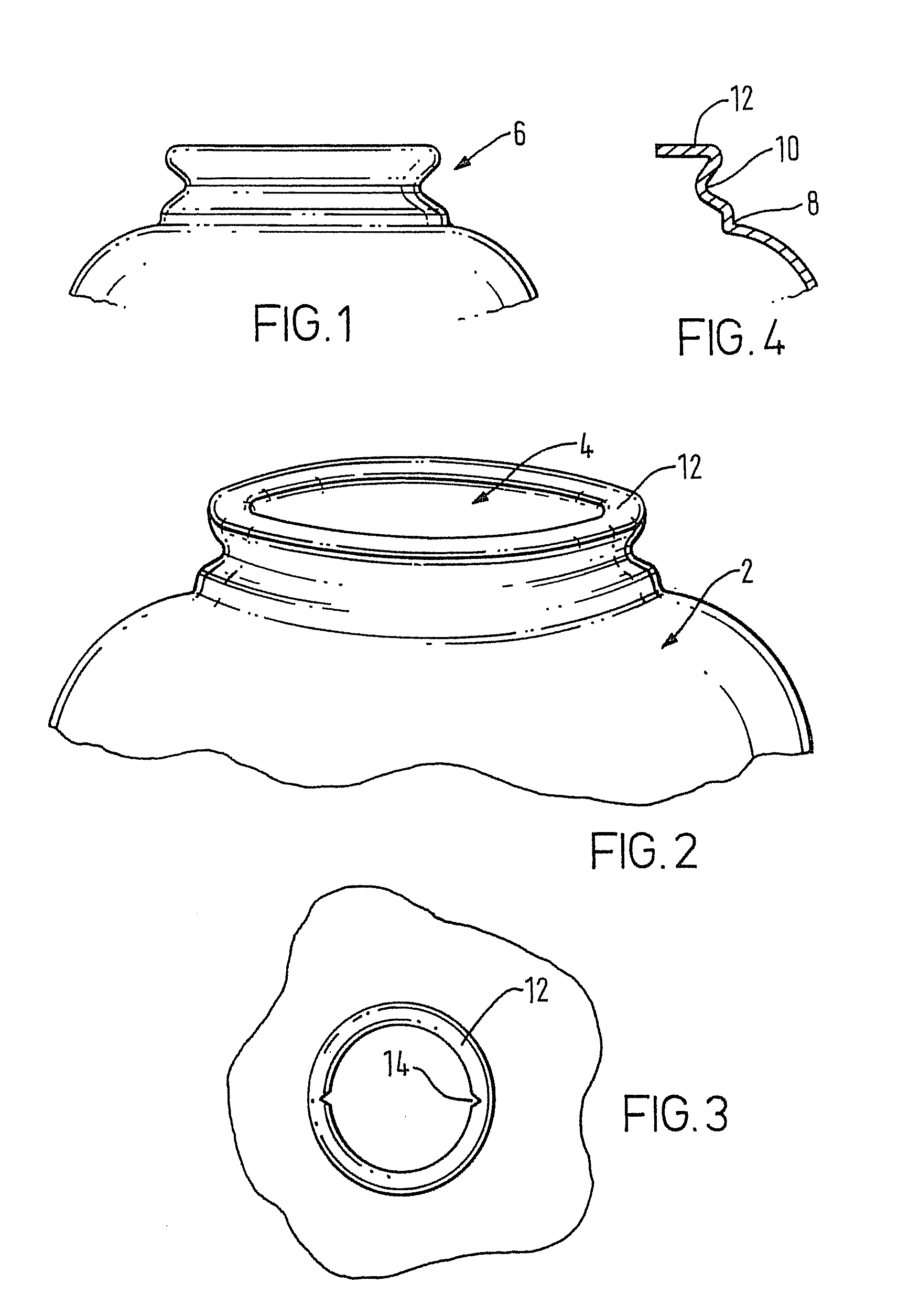

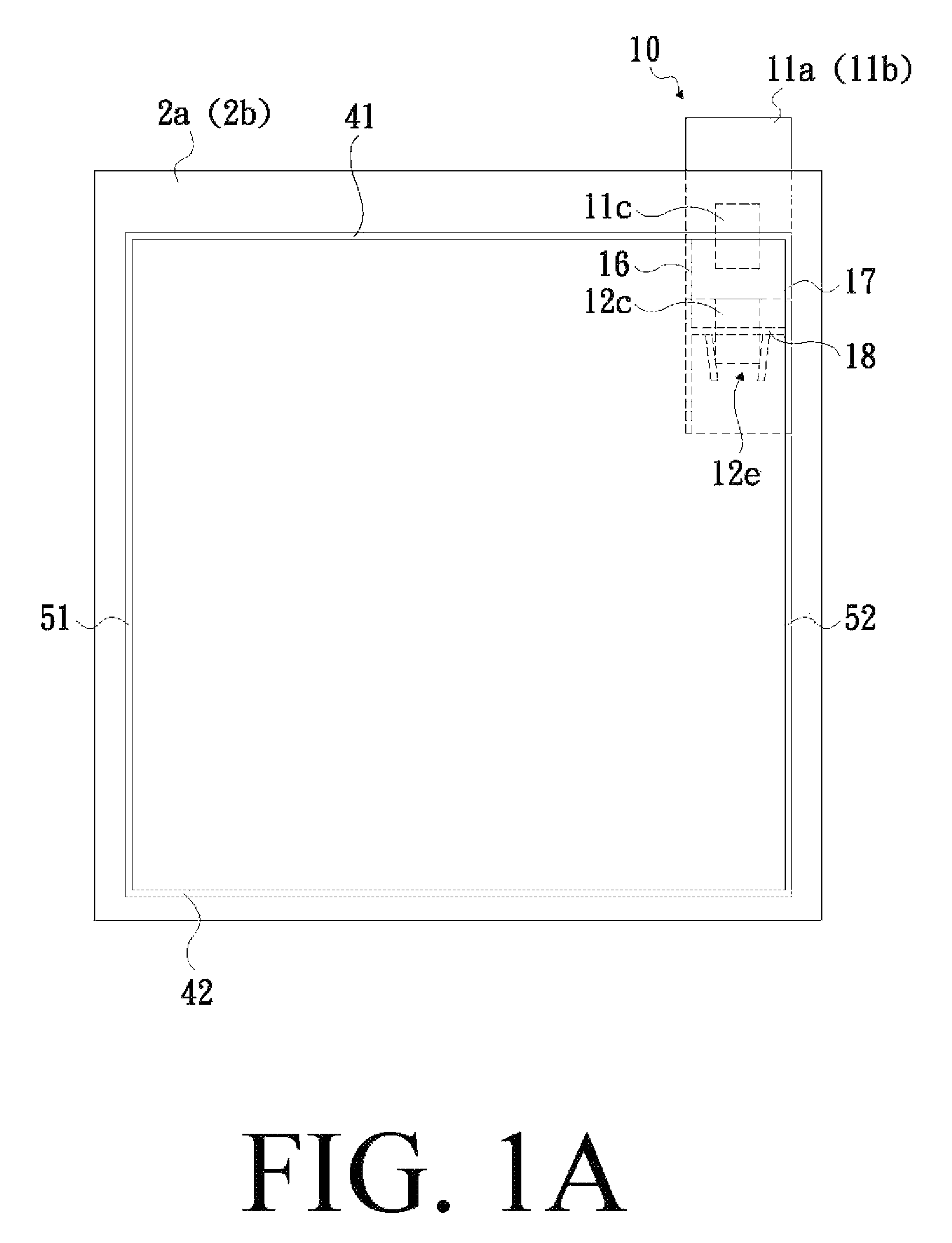

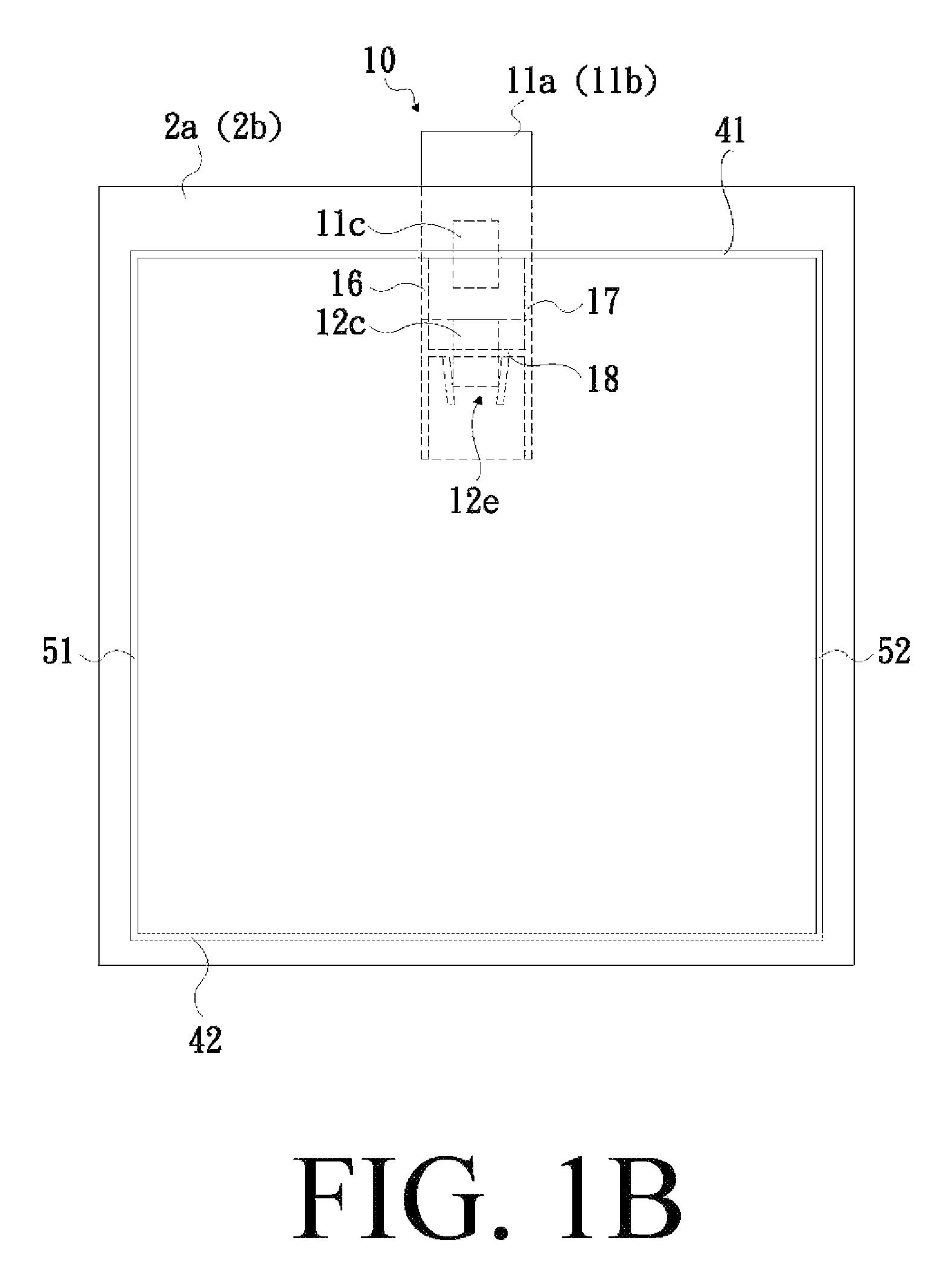

Air filling bag with outer film strengthening structure

Owner:LIAO CHIEH HUA

Air filling bag with outer film strengthening structure

An air filling bag with an outer film strengthening structure includes two outer films and a main check valve, where the two outer films are adhered to each other to form an air chamber by means of hot sealing, in which each outer film includes the first film sheet and the second film sheet stacked together, and a plurality of first hot sealing lines is formed by adhering the first film sheet to the second film sheet by means of hot sealing in a first direction together with a plurality of second hot sealing lines formed by adhering the first film sheet to the second film sheet by means of hot sealing in a second direction. The main check valve is positioned between the two outer films and one end thereof projects from the air chamber. Air in the air chamber can compress the main check valve to shield a first air passageway of the main check valve so as to prevent air from leaking out of the air chamber after outside air flows in the air chamber via the first air passageway.

Owner:LIAO CHIEH HUA

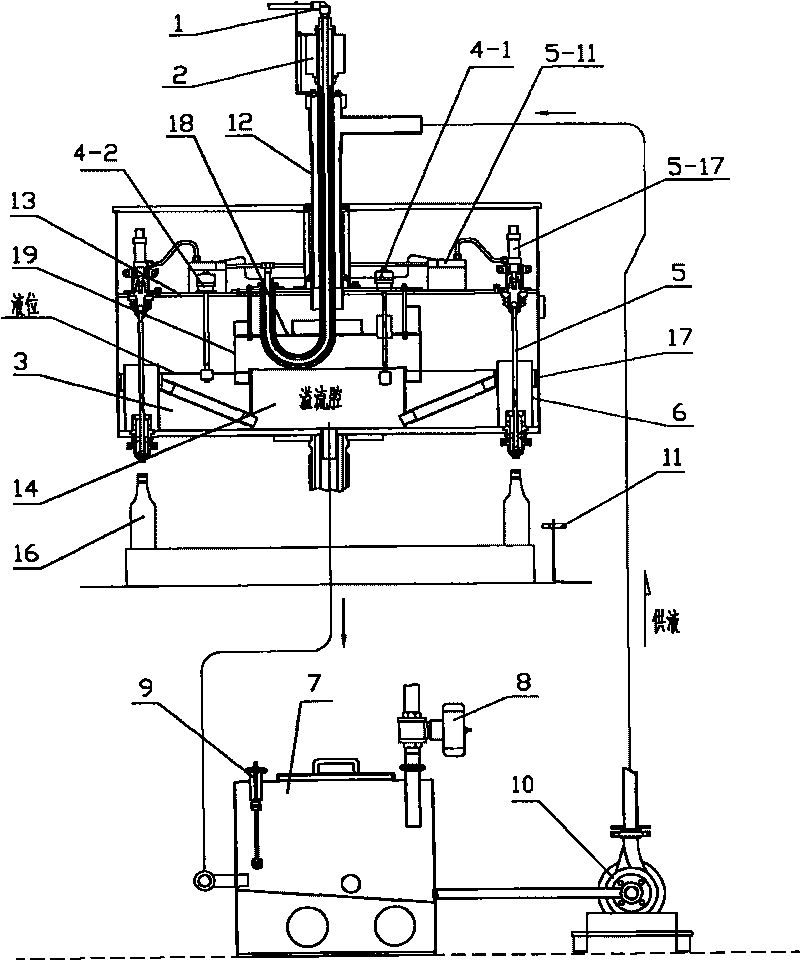

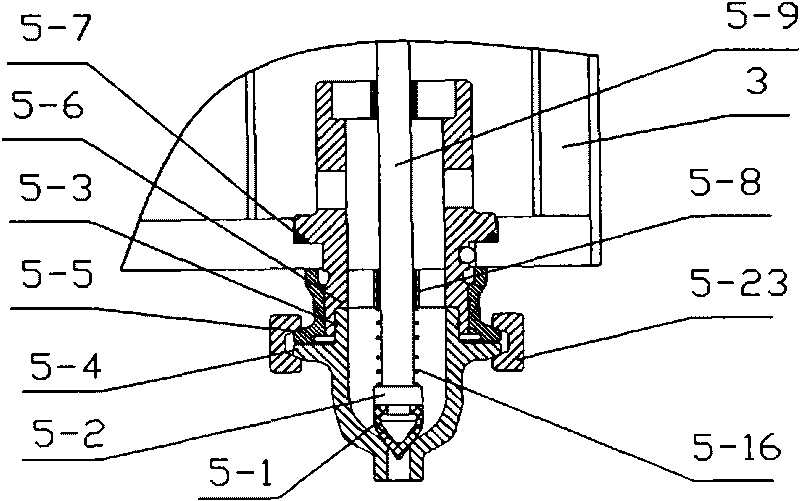

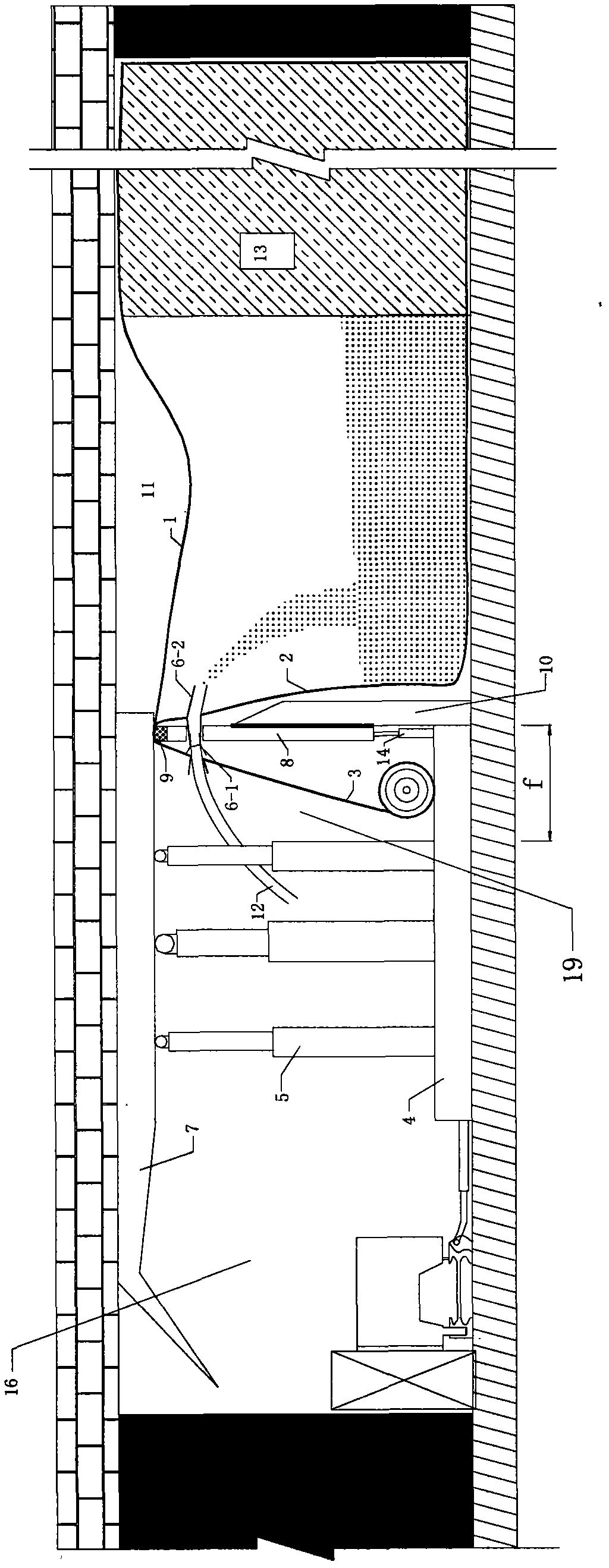

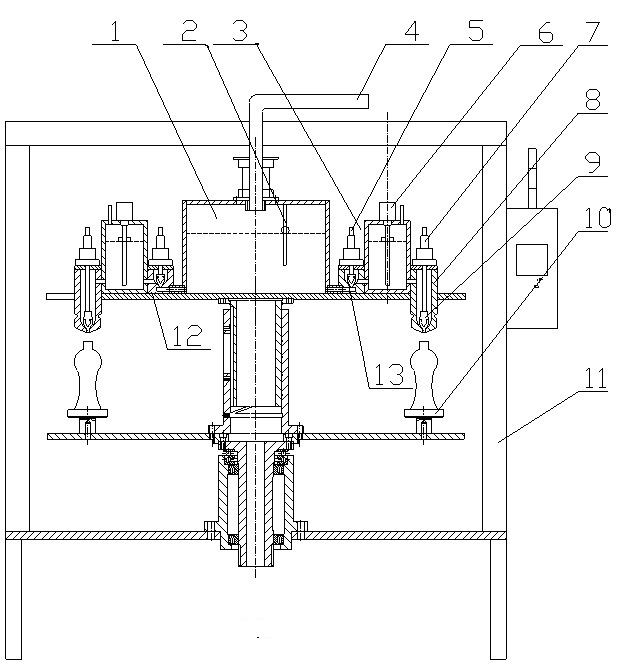

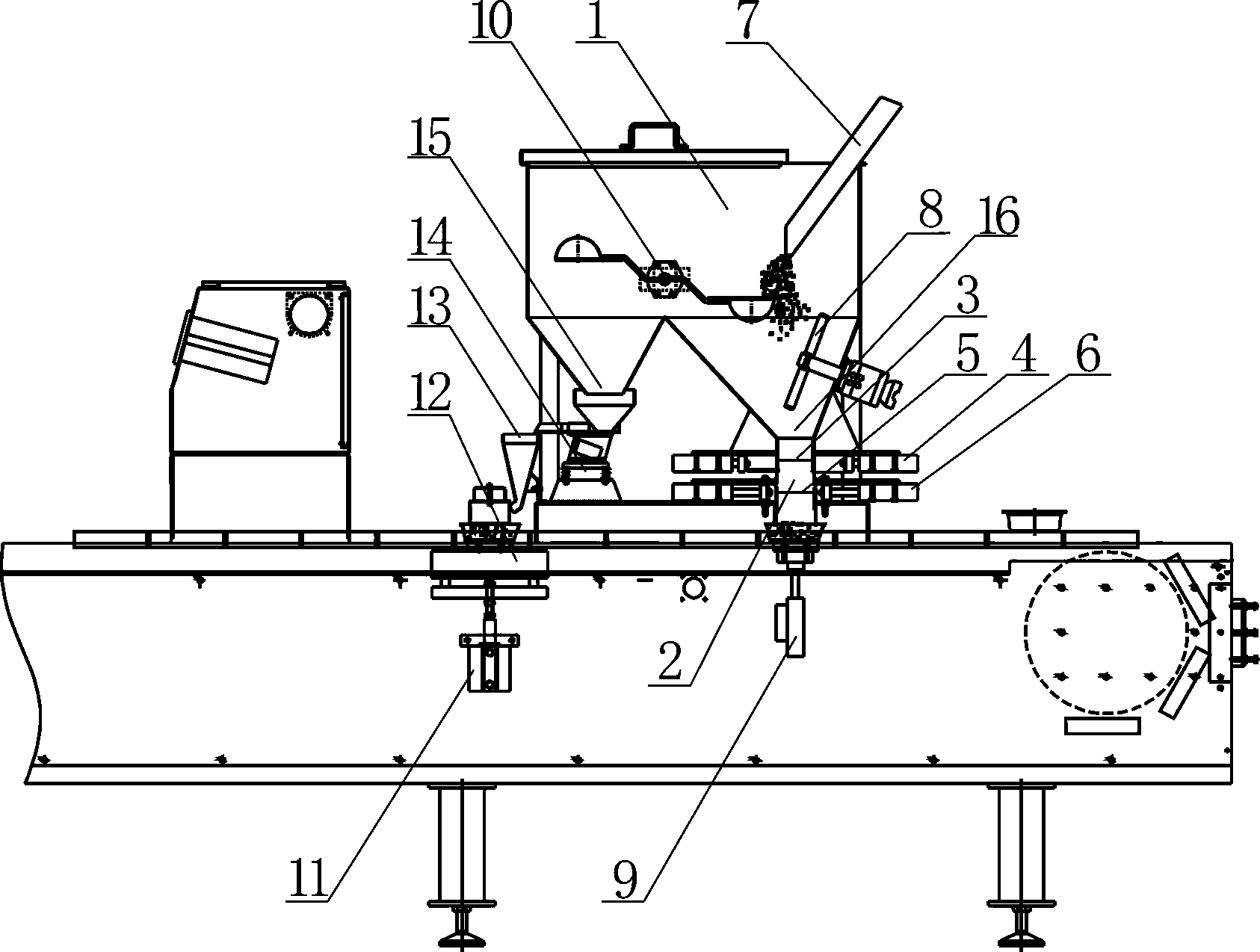

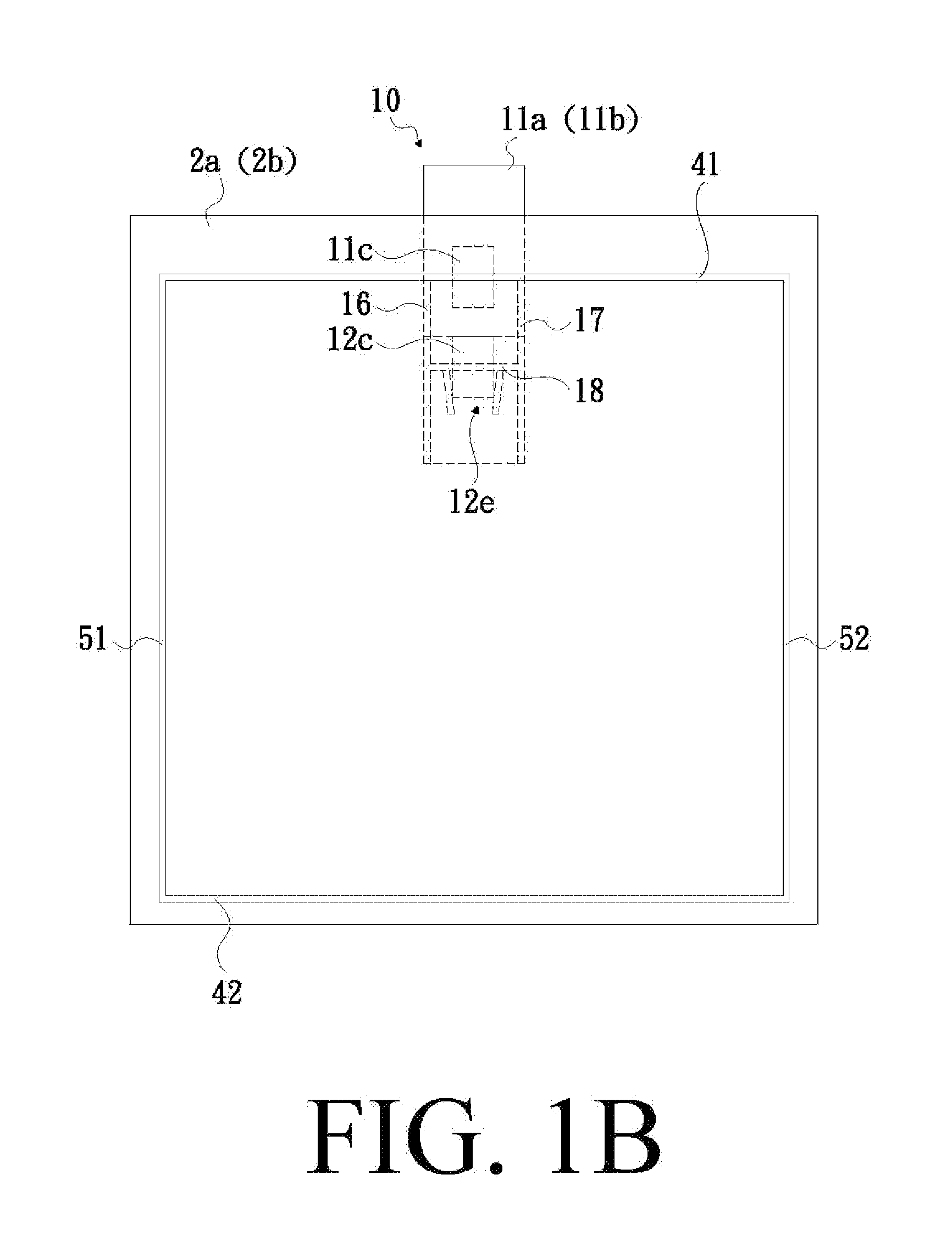

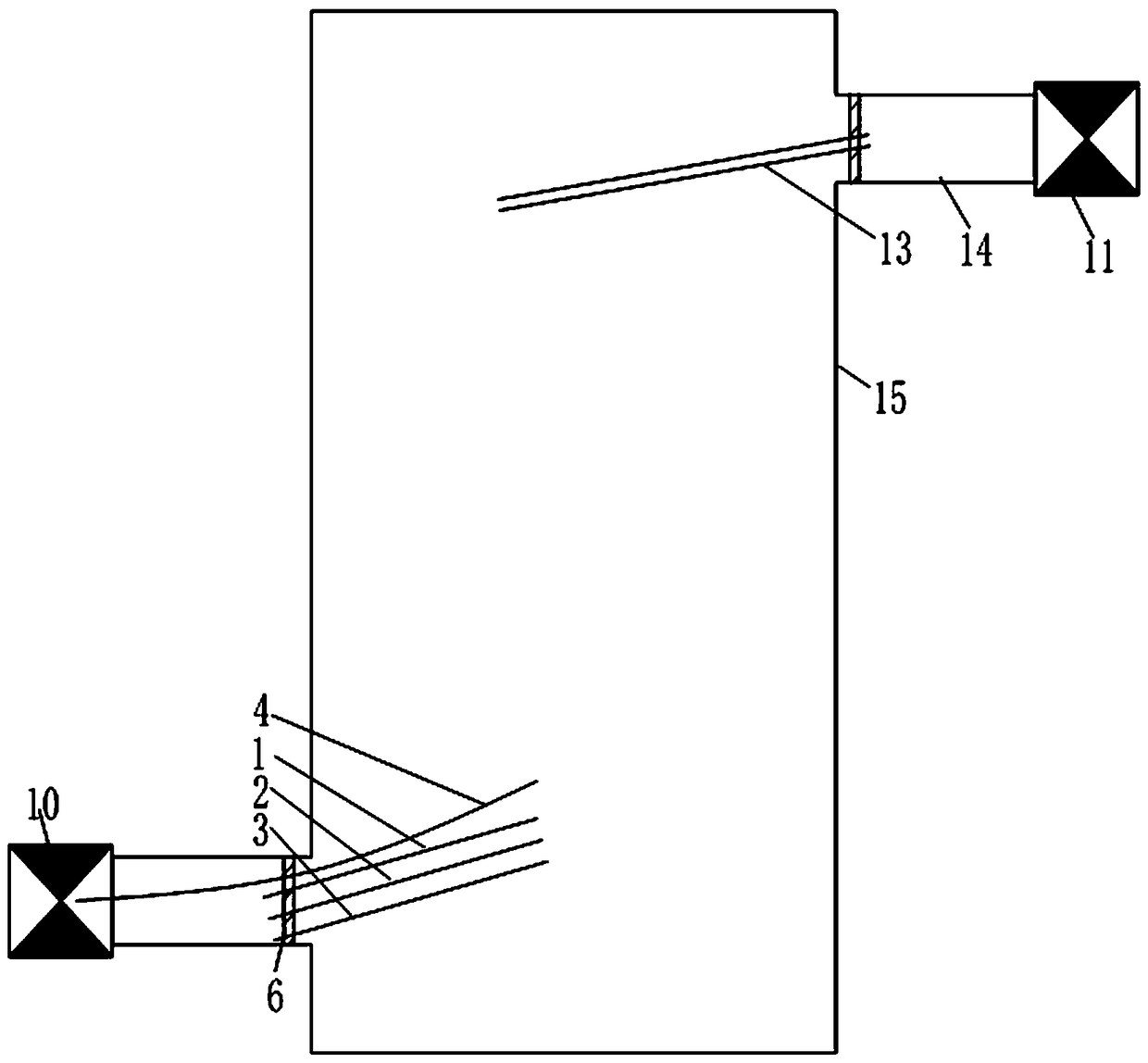

Quantitative filling device for filing machine

The invention discloses a quantitative filling device for a filing machine, which comprises a rotary liquid tank which is arranged on the filing machine, wherein a PLC controller is arranged on the filing machine; a horizontal clapboard is arranged on the middle part of the rotary liquid tank; a filing valve passing through the middle part and the bottom part of the rotary liquid tank is arranged around the rotary liquid tank; a liquid outlet nozzle is arranged on the lower part of the filing valve; a scanning sensor is arranged on the part of the filing machine, which corresponds to the liquid outlet nozzle; an air cylinder used for driving the filing valve to open and close is arranged on the horizontal clapboard; a solenoid valve used for controlling the opening and closing of the air cylinder is arranged on an air supply pipeline of the air cylinder; a buffer tank used for supplying liquid to the rotary liquid tank is independently arranged on one side of the filing machine; and the scanning sensor and the solenoid valve are controlled by the PLC controller. In the invention, the filing capacity is controlled by controlling a filing time, the capacity can be adjusted steplessly and conveniently in a large range, and the volume fixing accuracy is high; and the internal structure of the filing value is simple, the liquid flow resistance is small, the filing speed is high, and the filing valve adopting terminal opening and closing has no leakage and residual drip.

Owner:刘耀宇

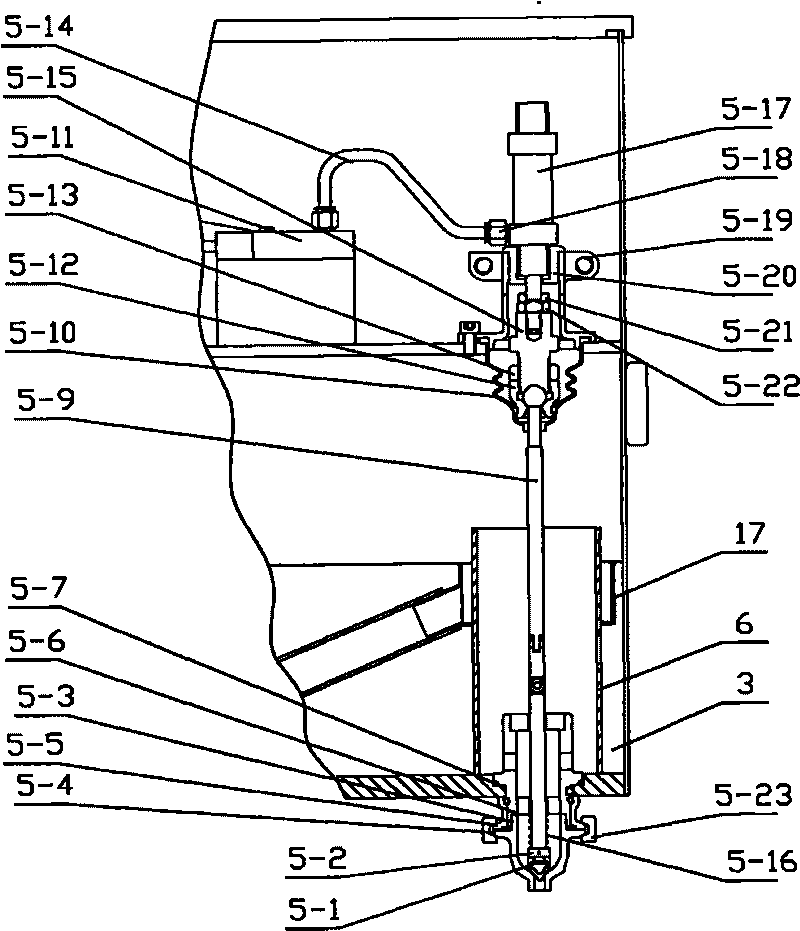

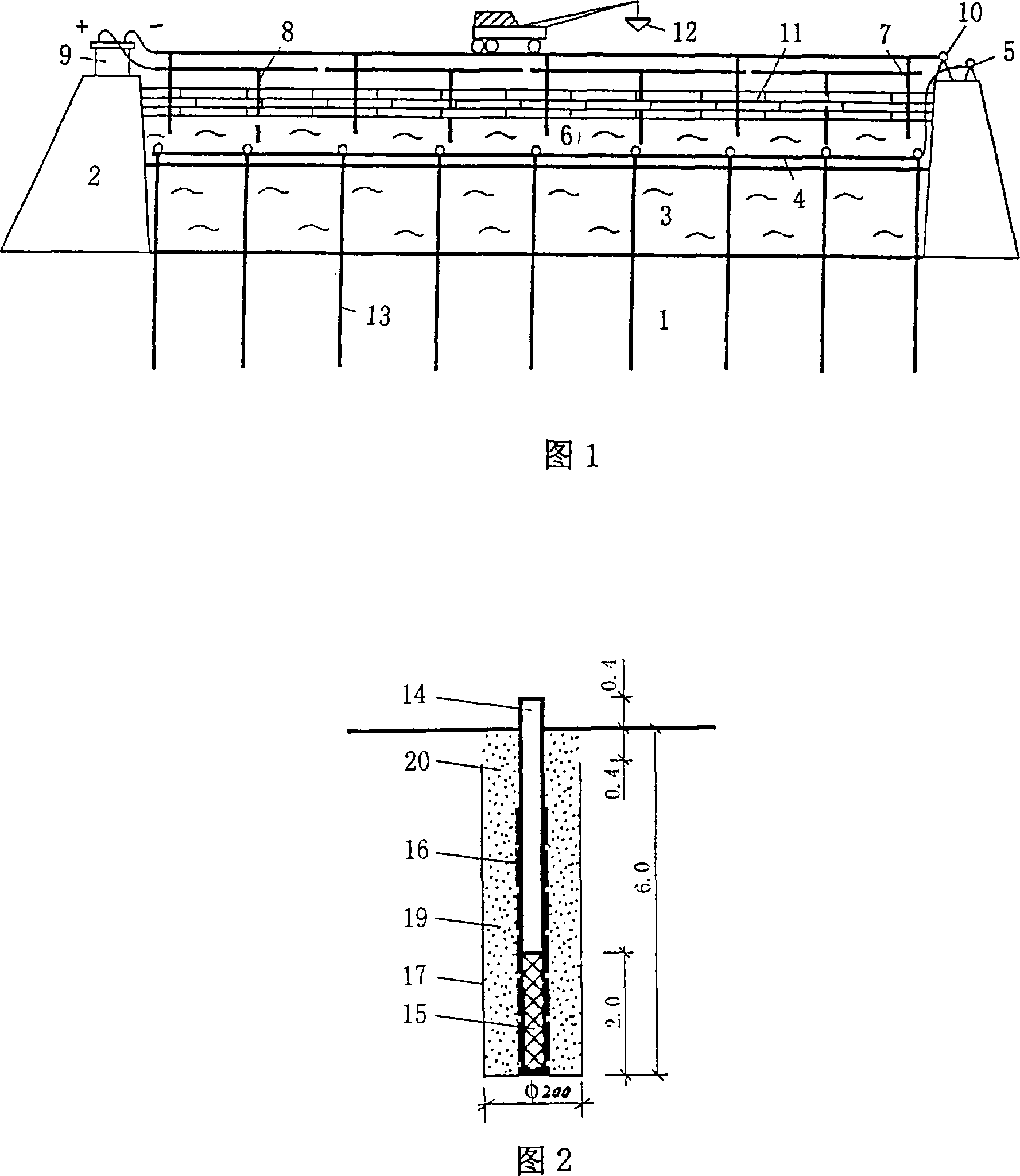

Method for double-vacuum self-loading prepressing and earthwork composite filling low-energy strong-ramming reinforcing soft soil

InactiveCN101100852ALow costEliminate recharge phenomenonSoil preservationMaterials sciencePrecipitation

A ground reinforce procedure includes the steps of: A. low position vacuum self-loading pre-press; B. vacuum well point precipitation; C. vacuum electroosmosis precipitation and complex stuffing paving simultaneously; D. low power strong tamp; E. vibrate rolling; F. smoothing.

Owner:张志铁 +1

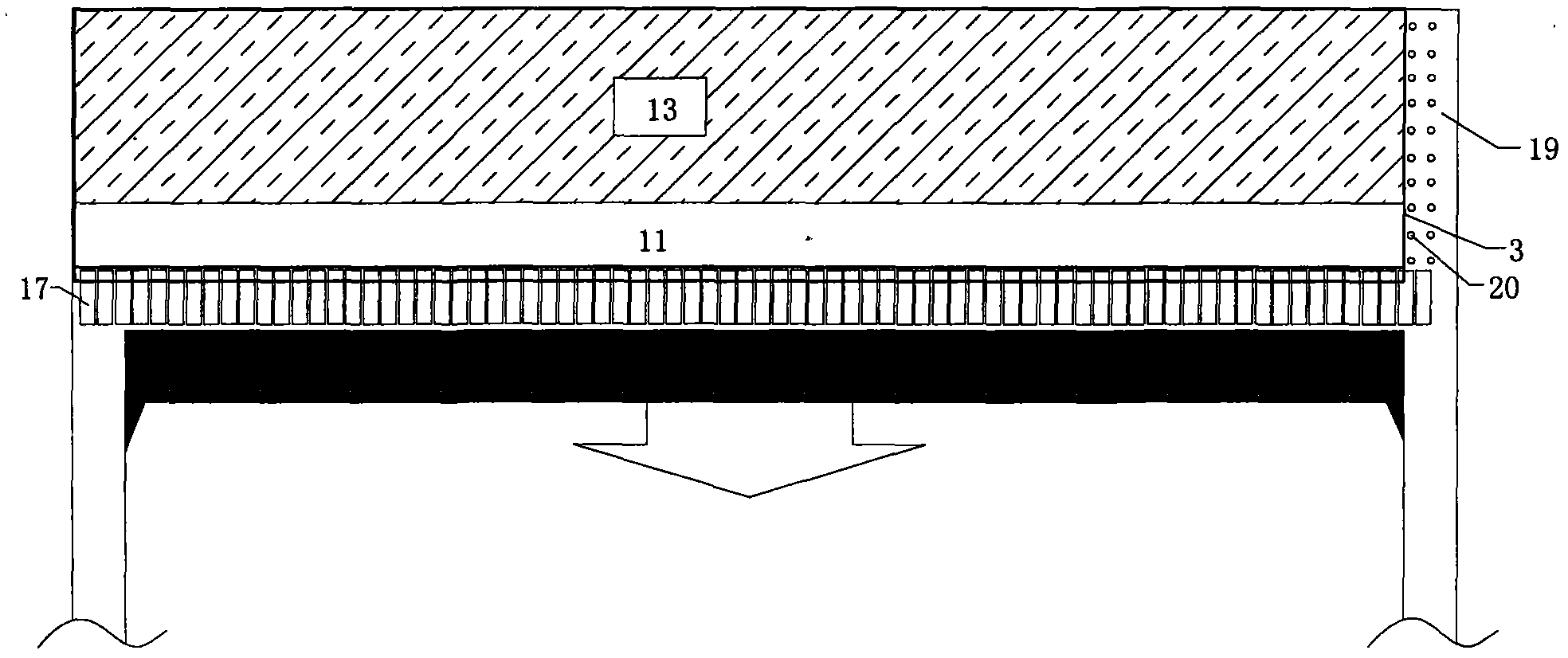

Mine gob filling and entry retaining device system and filling method

InactiveCN102606207AImprove isolationSimple structureMaterial fill-upMine roof supportsFiberFilling materials

The invention discloses a mine gob filling and entry retaining device system and a filling method. A workshop is arranged at the rear end of a hydraulic support, a lifting side protecting plate and a fixing side protecting plate are disposed on a side of the workshop and are close to a gob, a rubber pad is inlaid at the top end of the lifting side protecting plate, a flexible isolation mold barrel is wound around the top end of the rubber pad to enter the gob on the rear of the hydraulic support, two layers of high-strength fiber cloth are sewn to form the flexible isolation mold barrel, a filling barrel is arranged in the second layer of high-strength fiber cloth, a filling conveying pipe is inserted into the filling barrel and is connected with the filling barrel in a bound manner, components of the isolation mold barrel are continuously connected by sewing threads by the aid of a portable sewing machine, a plurality of rows of single bodies are disposed in a retained roadway to support and limit the flexible isolation mold barrel, filling materials are filled into the flexible isolation mold barrel of the gob from the filling barrel via the conveying pipe, a roadway is retained in the gob during filling of the materials, and coal mining without pillars is realized. The mine gob filling and entry retaining device is simple in structure, low in cost, fine in isolation and fast in speed, and is widely used in industries including coal mines, metallurgical mines and the like, and personnel do not operate in the gob.

Owner:SHAANXI PIONEERING ARCHITECTURAL TECH

Liquid filling machine

InactiveCN102180430AHigh metering and filling accuracyEasy to processLiquid bottlingLiquid tankFloat switch

The invention discloses a liquid filling machine and belongs to the field of filling equipment. The liquid filling machine comprises a liquid inlet pipe and a filling machine liquid storage pot, wherein the liquid inlet pipe passes through the upper end of a stander and is directly connected with the upper end of the filling machine liquid storage pot; and a filling machine liquid storage pot floating switch and a plurality of groups of air cylinders are arranged in the filling machine liquid storage pot. In the liquid filling machine, one air cylinder controls one filling head; an equal height counting mode of the inner liquid level of the liquid storage pot is not required; a constant liquid level cup type stable liquid level is adopted, so one filling head needs only one air cylinder, and the counting and filling precision is high; the filling machine is easy to process and the number of output points of an industrial control computer is small, so the cost can be reduced by over 1 / 2; the liquid filling machine is durable, the liquid level is easy to control, and the reliability is enhanced; backflow control is not needed, so the power is saved; the liquid filling machine is easy in maintenance, good in sealing property and safe; liquid is hard to volatilize during filling; the filling precision is enhanced and the filling speed is high; and the liquid filling machine can be widely applied to rotary gas-free liquid filling machines, discharging gas-free liquid filling machines and the like.

Owner:LUZHOU JIANGXU MACHINERY MFG

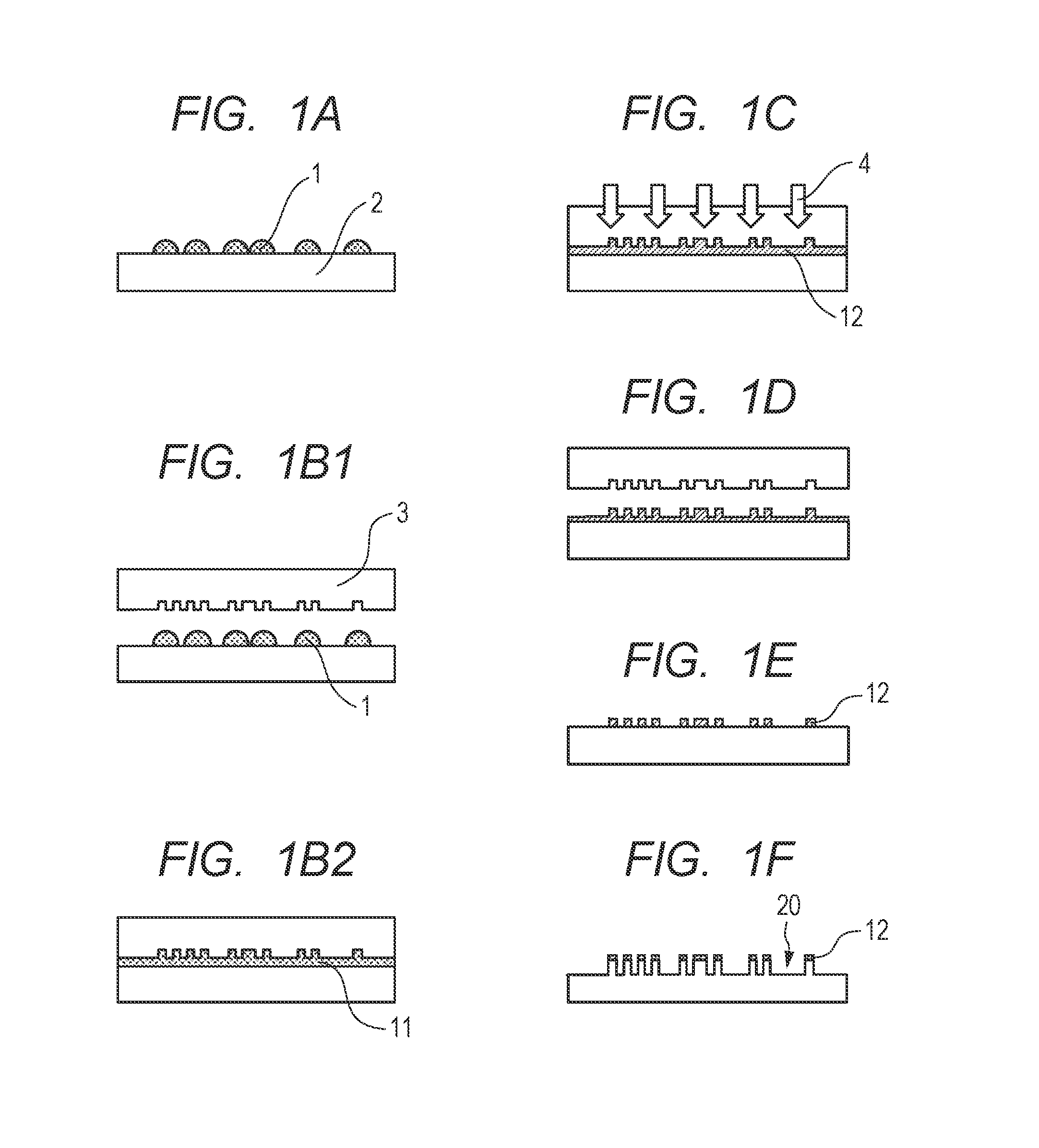

Curable composition, film, and method of producing film

ActiveUS20160160003A1Fast filling speedGood release effectImpression capsDecorative surface effectsOrganic chemistryPolymerization

Provided is a curable composition, including a polymerization initiator; a polymerizable compound; and an internal addition type release agent having a hydrophilic functional group, in which the internal addition type release agent is prevented from being unevenly distributed in a gas-liquid interface of the curable composition.

Owner:CANON KK

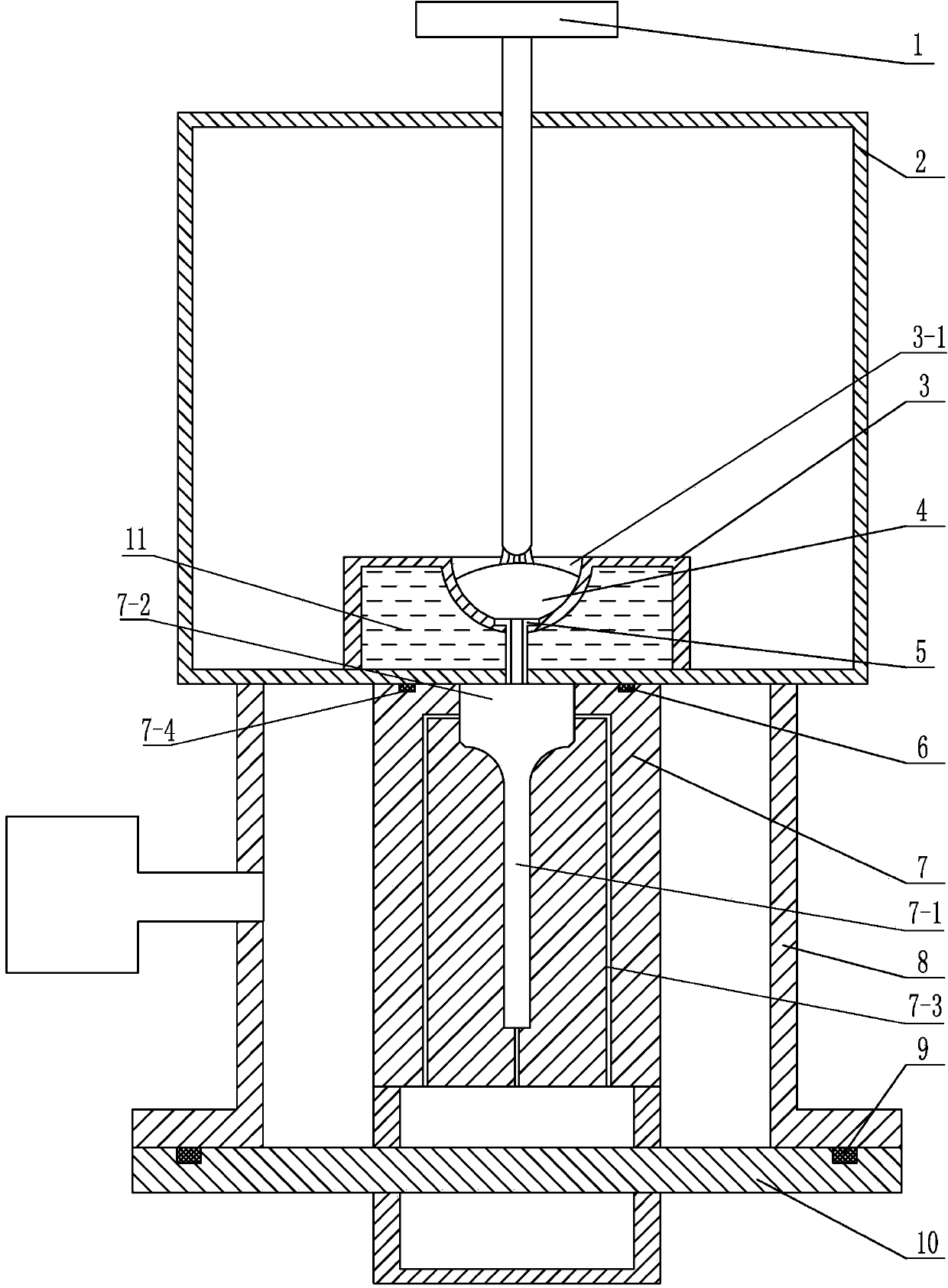

Method for casting and forming TiAl-based alloy vent valve

The invention provides a method for casting and forming a TiAl-based alloy vent valve, and relates to casting methods for the TiAl-based alloy vent valve. The technical problems that gravity casting of an existing TiAl-based alloy vent valve can not enable mold filling to be conducted smoothly, inner quality can not be guaranteed, a centrifugal casting method is complex in process, the material utilization rate is low, the casting process is too complex, and the surface quality is poor are solved. The method mainly comprises the steps that first, the prior art is used for manufacturing a metal mold of the vent valve; second, the metal valve of the vent valve in the first step is placed in a suction casting chamber of a smelting furnace, and the metal mold of the vent valve is mounted on a mold seat; third, a graphite suction port is mounted on a water cooling crucible; fourth, a TiAl-based alloy pig which is smelted in advance is placed in a suction casting crucible of a vacuum arc melting furnace, and overheating melt is obtained by smelting; fifth, a vacuum system of a suction casting chamber of the vacuum arc melting furnace is opened, a suction casting button is opened, suction casting, mold filling and cooling are conducted, and a casting is obtained. The method is used for preparing TiAl-based alloy vent valve castings.

Owner:HARBIN INST OF TECH

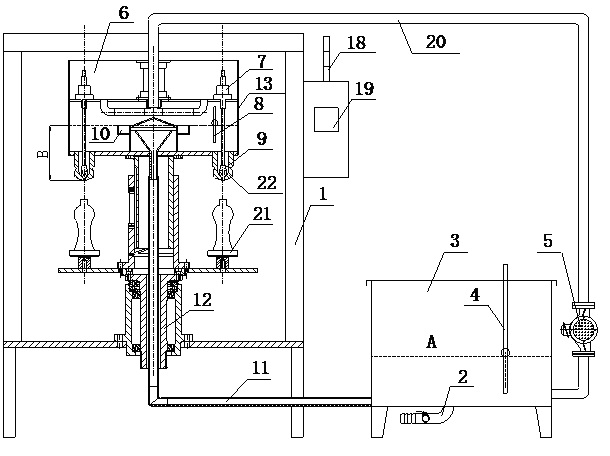

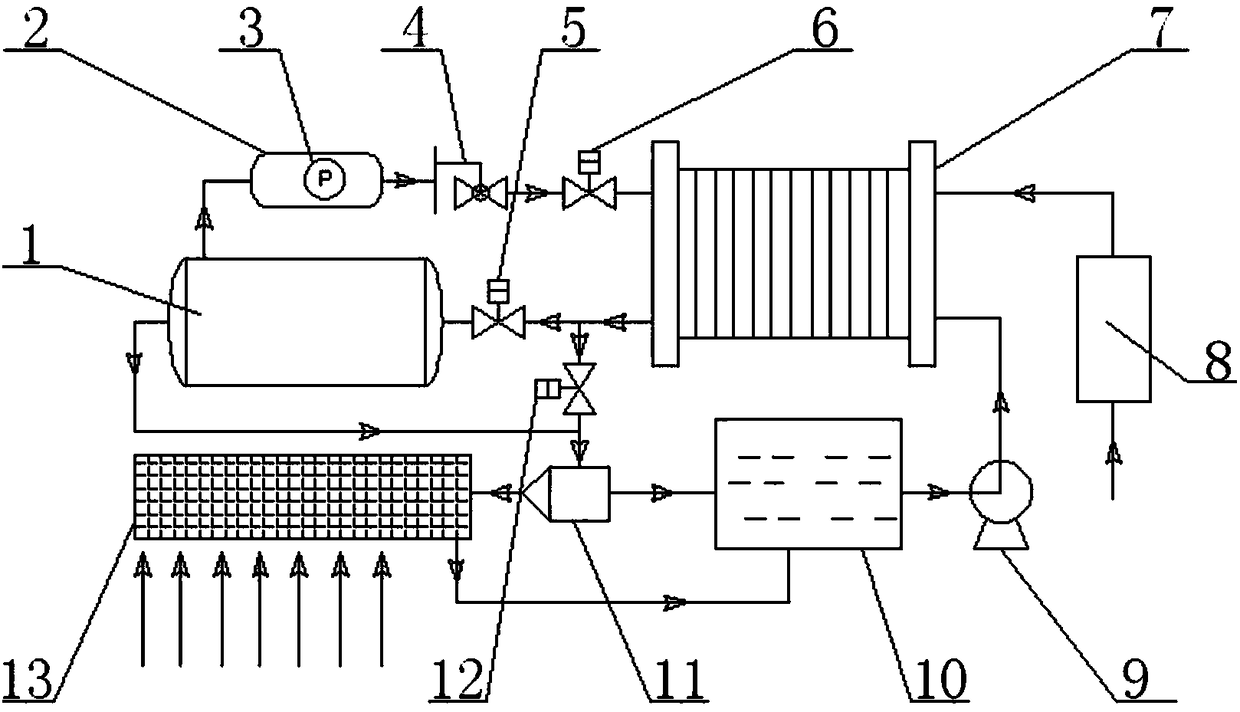

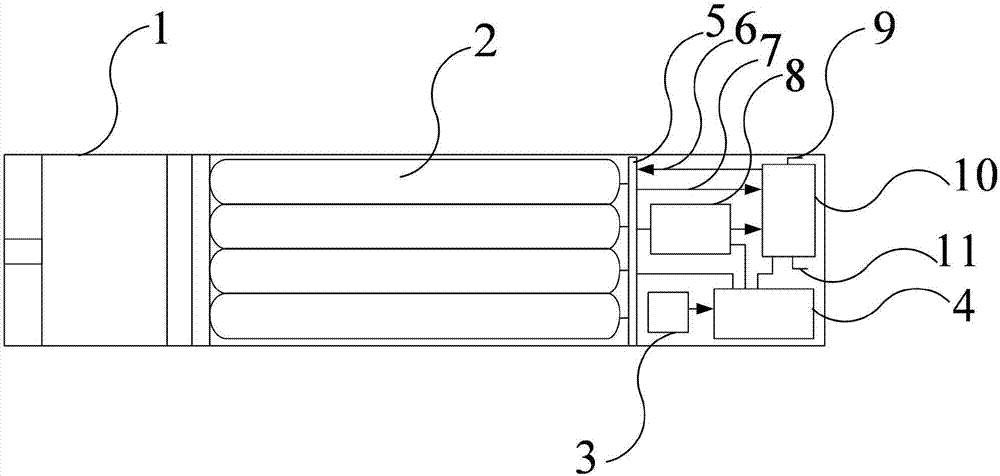

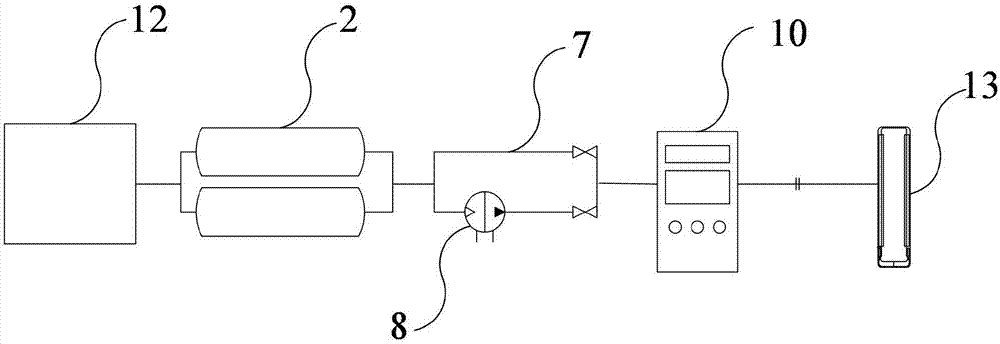

High-specific-energy aeronautical fuel cell power generation apparatus and control method thereof

ActiveCN108123163AIncrease energy densityExtended power generation timeFuel cell heat exchangeReactant parameters controlHydrogen pressureGas cylinder

The invention relates to a high-specific-energy aeronautical fuel cell power generation system, especially an aeronautical proton exchange membrane fuel cell power generation system with liquid hydrogen as a fuel. The power generation system comprises a liquid hydrogen storage tank, a buffer tank, a pressure sensor, a hydrogen pressure reducer, a solenoid valve for water, a solenoid valve for hydrogen, a proton exchange membrane fuel cell, an air pump, a circulating water pump, a water tank, a temperature regulator, a heat exchanger, etc. According to the invention, the own heat of the fuel cell is used for providing a heat source to the liquid hydrogen storage tank so as to realize gasification of hydrogen; oxygen in the air is used as an oxidant; and high-speed incoming air out of an aircraft is used as a cold medium to dissipate excess heat of the fuel cell. Compared with conventional aeronautical fuel cell power generation systems storing hydrogen with high-pressure gas cylinders,the high-specific-energy aeronautical fuel cell power generation system of the invention has the advantages of great hydrogen storage capacity, light weight, small size, low working pressure, safety,reliability, fast fuel filling rate, simple fuel filling mode and the like and especially applicable to aeronautical fuel cell power generation systems with high requirements for long endurance, weight and size.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

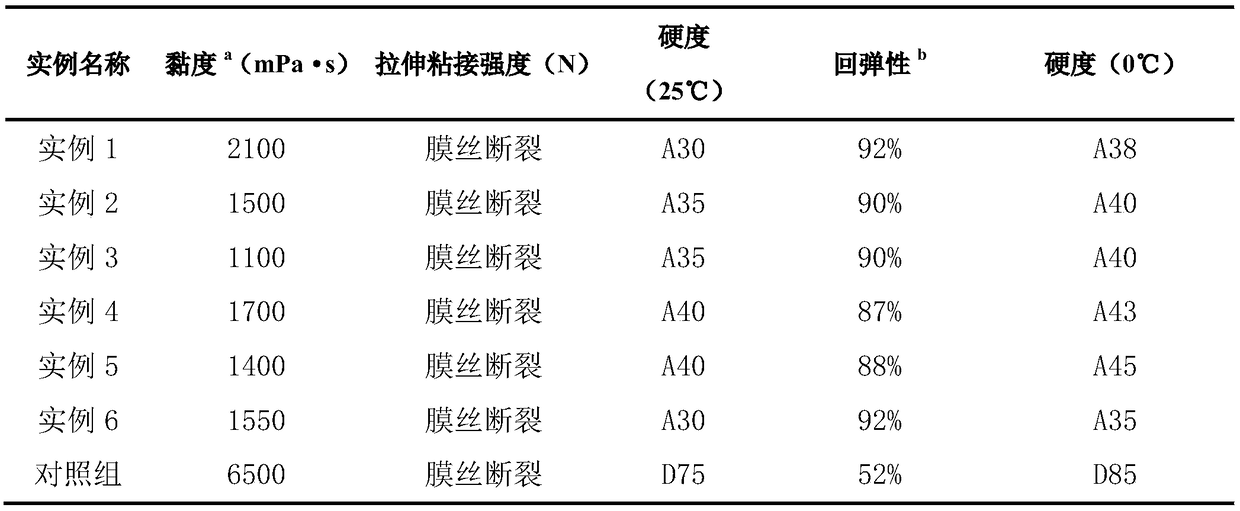

Low-hardness and high-elasticity water treatment membrane component epoxy pouring sealant preparation method and application

The invention discloses a low-hardness and high-elasticity water treatment membrane component epoxy pouring sealant preparation method and application. An epoxy pouring sealant comprises a component Aand a component B, the component A comprises, by weight, 30-70 parts of epoxy resin, 5-20 parts of activated thinners, 10-20 parts of toughening agents, 5-30 parts of fillers and 0.1-3 parts of coupling agents, the component B comprises, by weight, 20-50 parts of polyether amine, 40-70 parts of alicyclic amine and 2-15 parts of curing accelerators, and the weight ration of the component A to thecomponent B is (100:10)-(100:50). By the aid of a 'trinity' toughening modified mode of the flexible toughening agents, the activated toughening thinners and flexible curing agents, the epoxy pouringsealant is characterized of low hardness, high elasticity and stable hardness within wide temperature range, the epoxy pouring sealant has excellent adhesive performance and is low in initial viscosity, high in mold filling speed, simple and convenient to operate and applicable to the fields such as package of water treatment membrane components and flexible package of electronic devices, and theblocking efficiency of the membrane components can be greatly improved.

Owner:浙江航通舟新材料科技股份有限公司

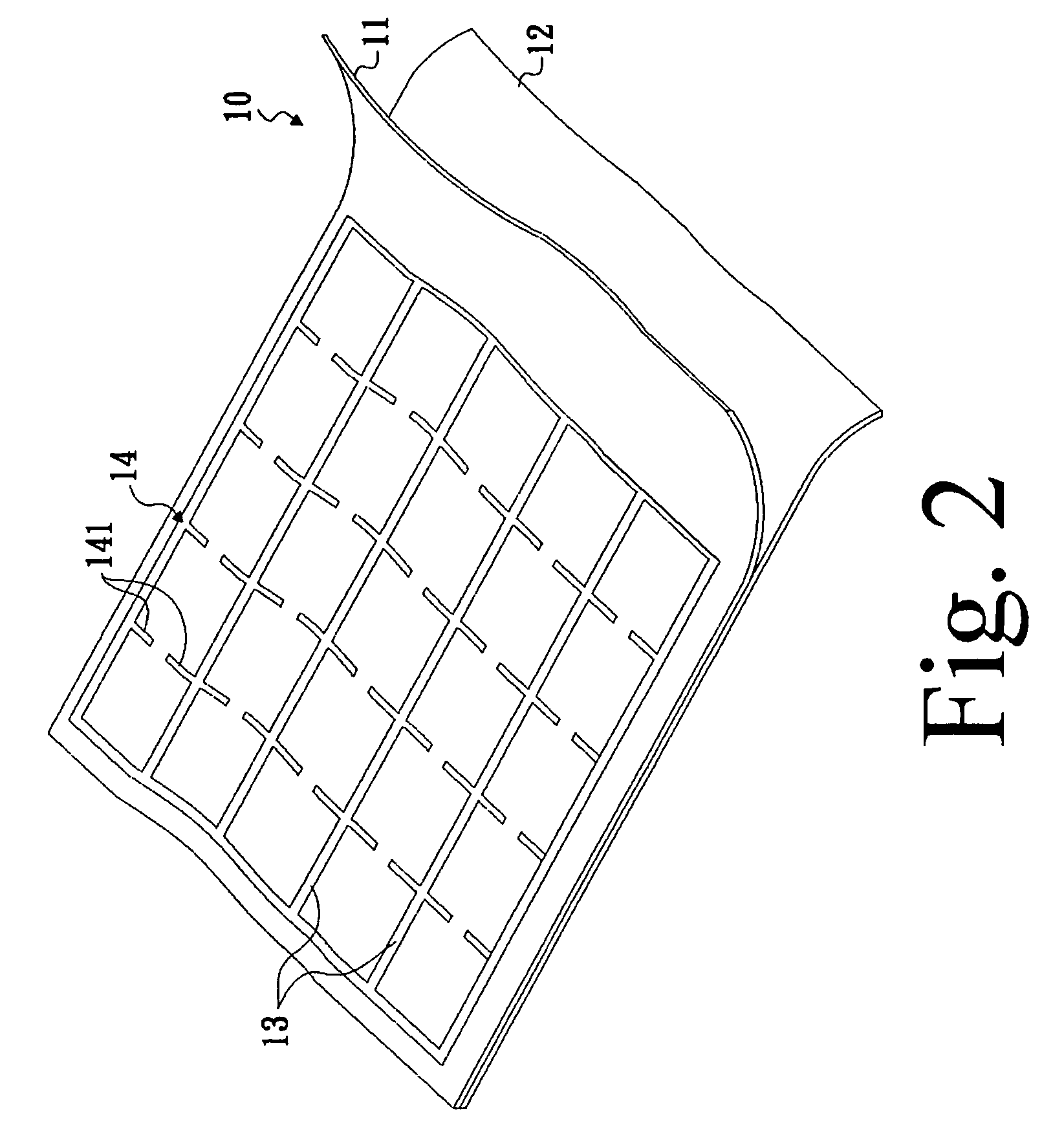

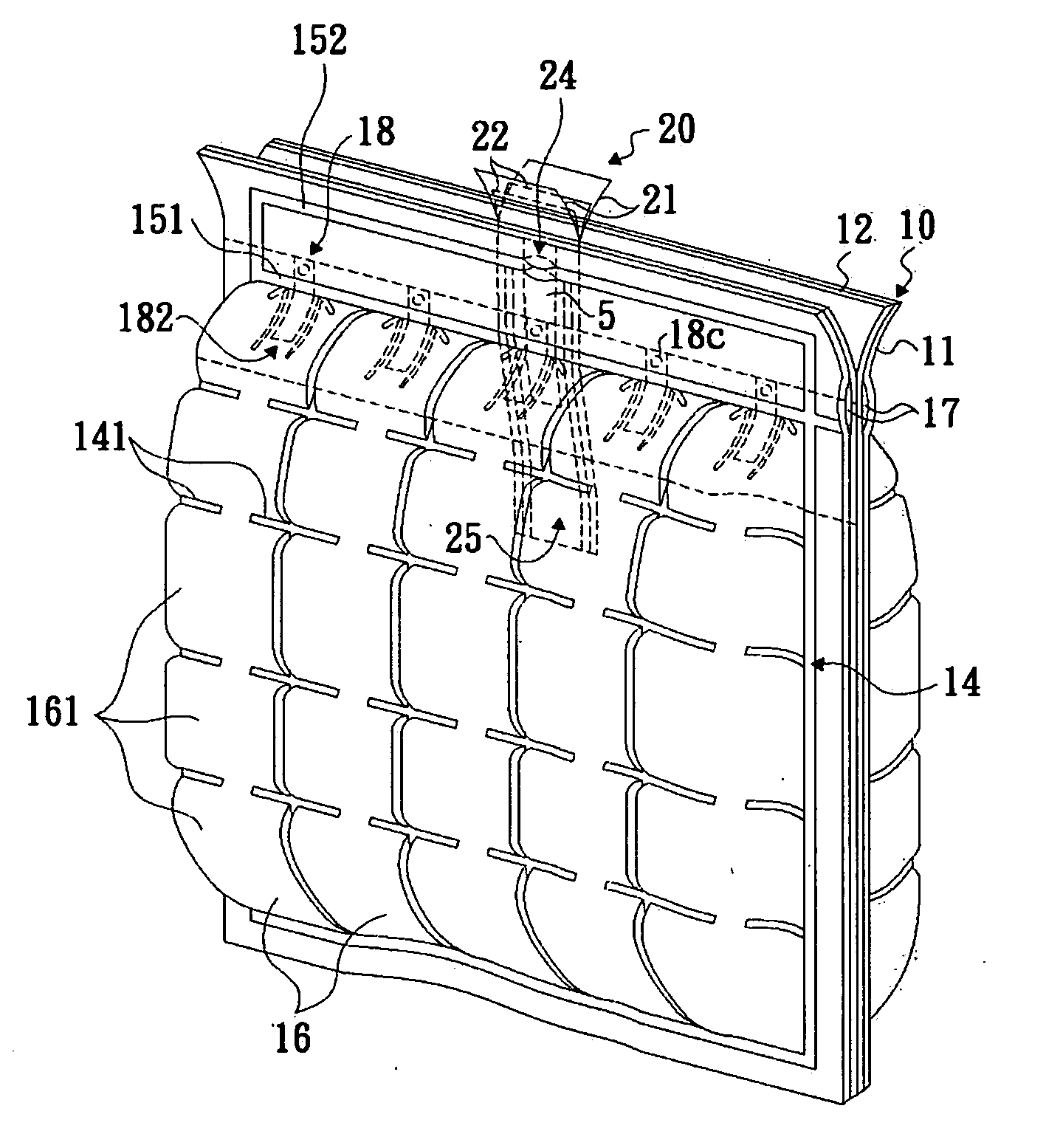

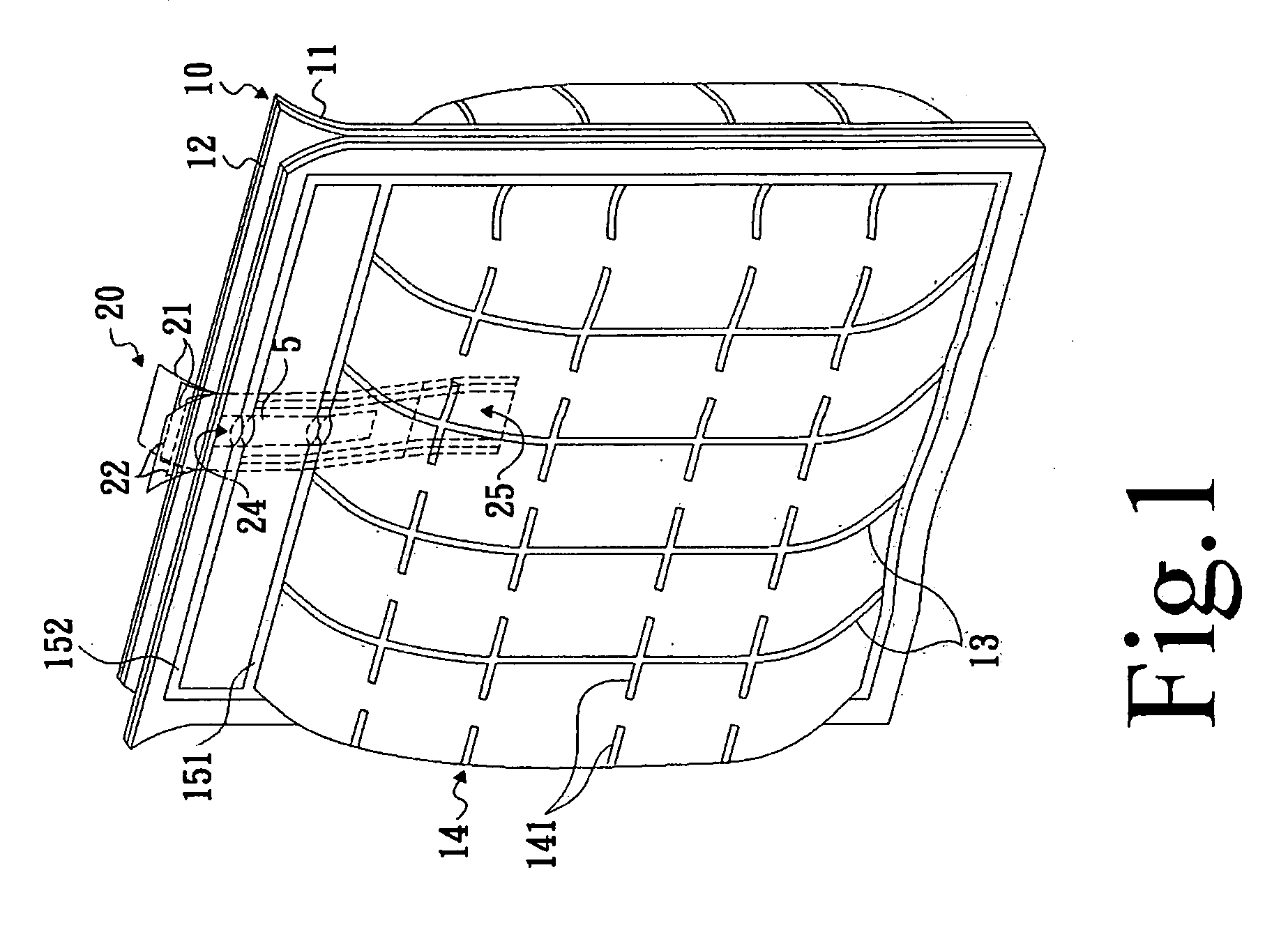

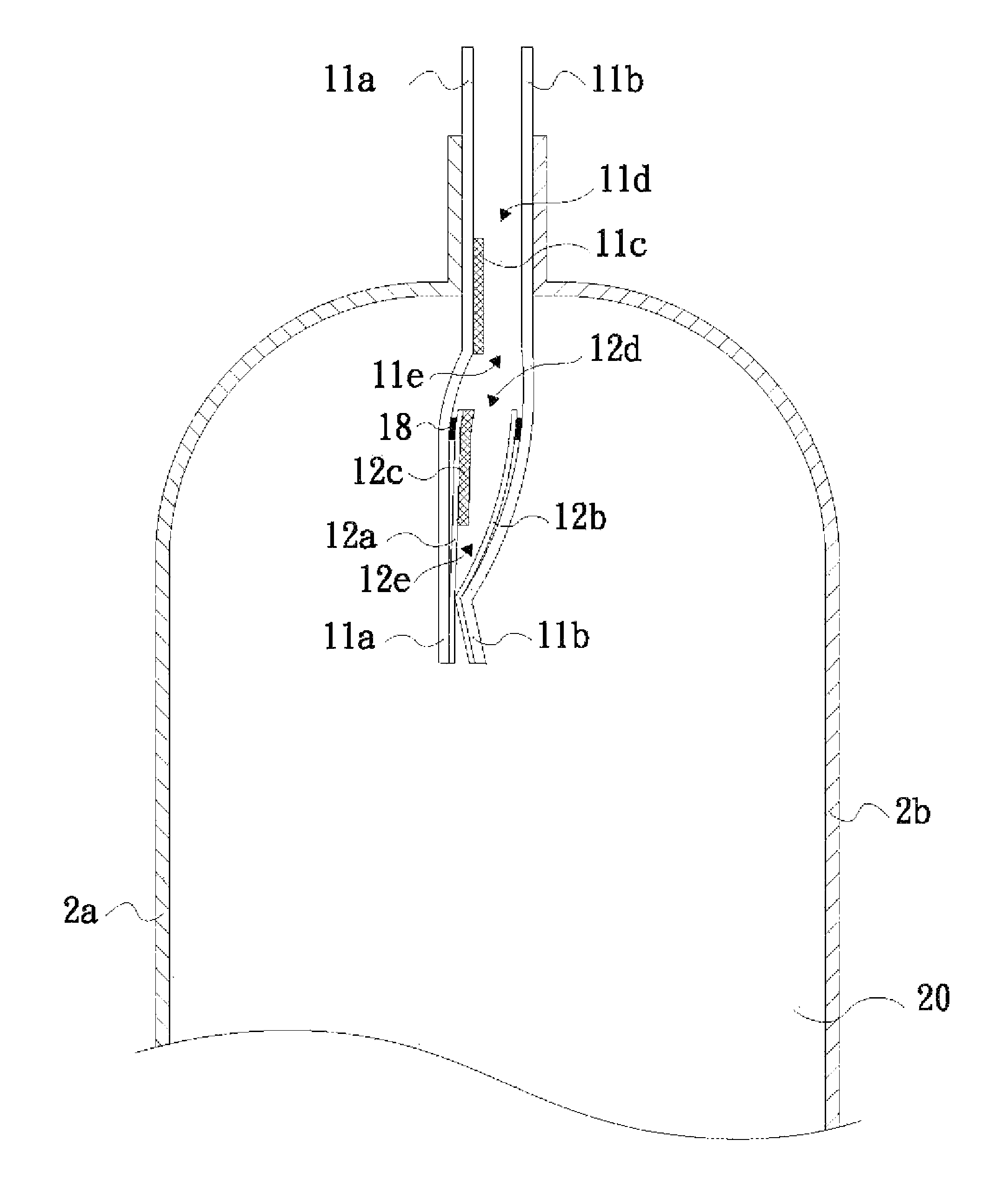

Multi-sectional airtight seal for continuous air-filling and air valve device thereof

InactiveUS7934522B2Fast fillFast filling speedLiquid fillingPaper/cardboard articlesHermetic sealEngineering

Owner:LIAO CHIEH HUA

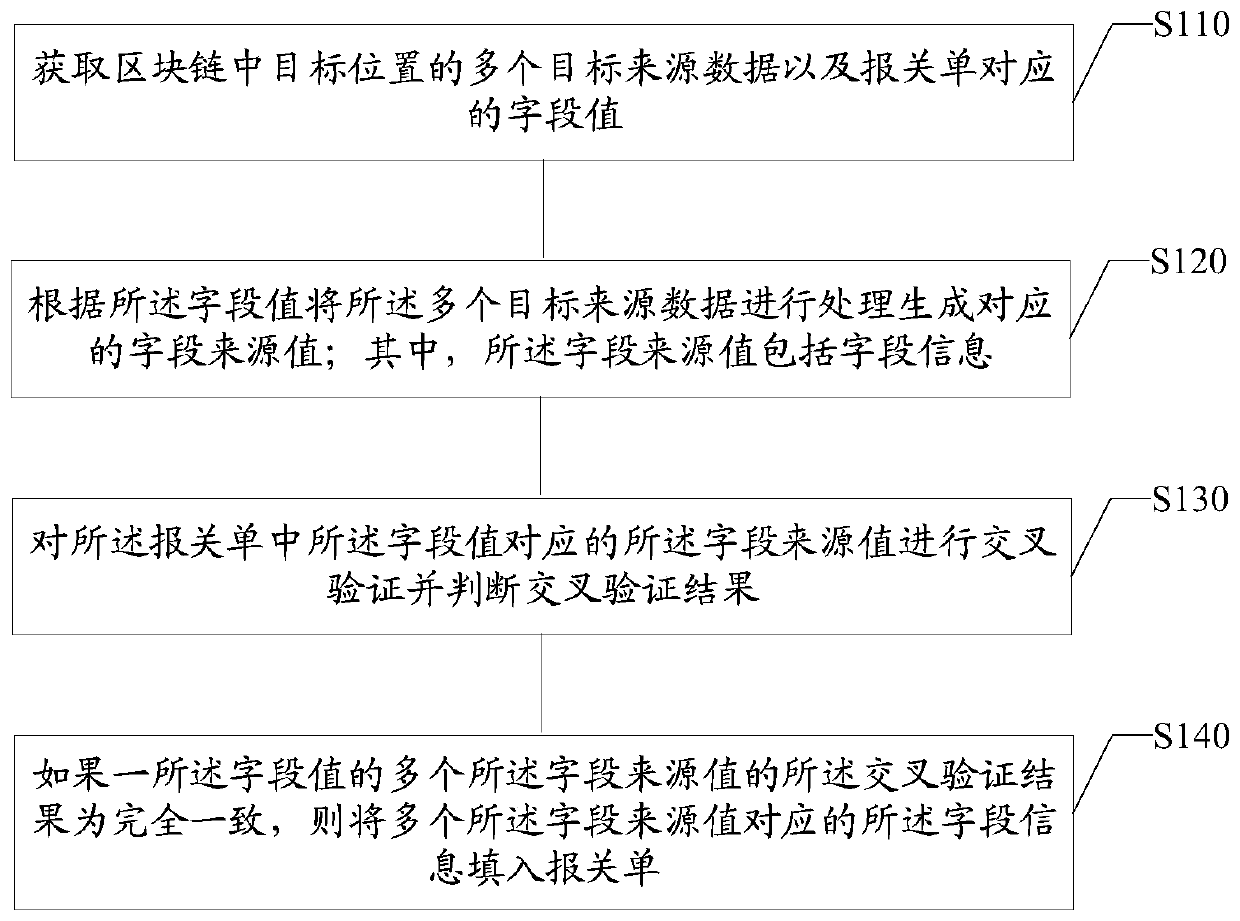

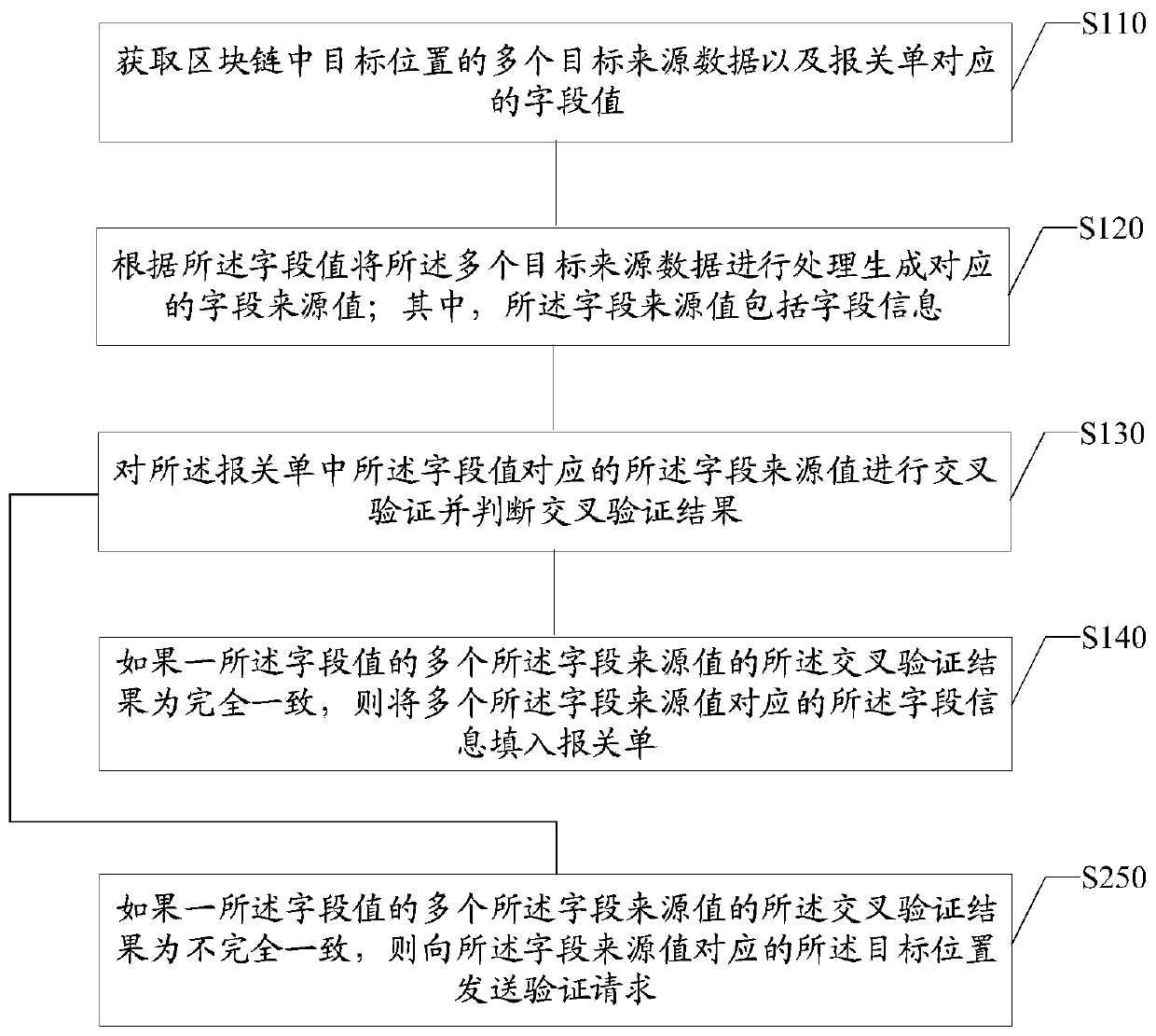

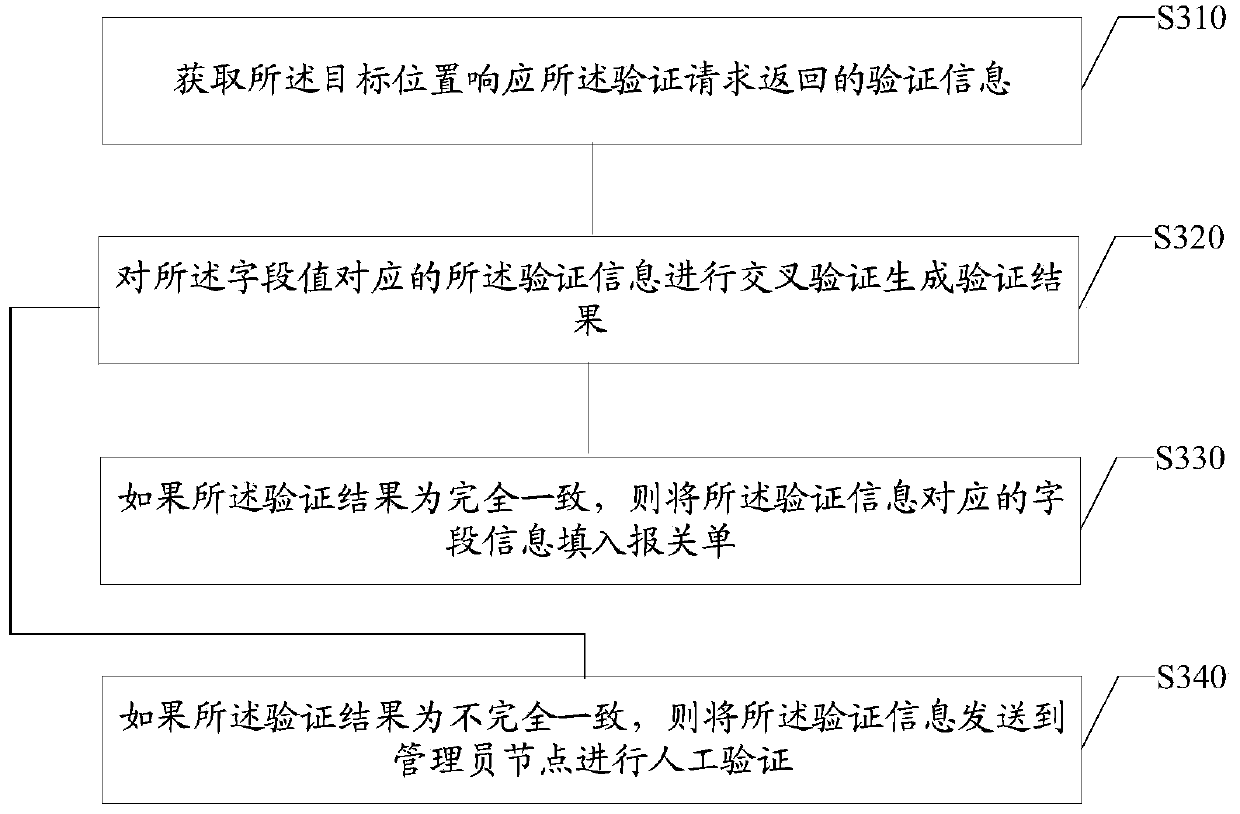

Custom declaration list generation method and device based on block chain, equipment and storage medium

PendingCN110335130AImprove customs clearance efficiencyFast filling speedFinanceElectric equipmentComputer science

The invention provides a custom declaration list generation method and device based on a block chain, an electronic device and a storage medium, and relates to the technical field of data processing.The custom declaration generation method comprises the steps of obtaining a plurality of target source data of a target position in a block chain and field values corresponding to customs declaration;processing the plurality of target source data according to the field values to generate corresponding field source values; wherein the field source value comprises field information; performing cross validation on the field source value corresponding to the field value in the customs declaration list and judging a cross validation result; and if the cross validation result of the plurality of field source values of the field value is completely consistent, filling the customs declaration list with the field information corresponding to the plurality of field source values. According to the technical scheme provided by the embodiment of the invention, the custom declaration information can be automatically generated, the consistency and accuracy of different source information of the custom declaration information can be ensured, and the customs clearance efficiency of the custom declaration is improved.

Owner:ONE CONNECT SMART TECH CO LTD SHENZHEN

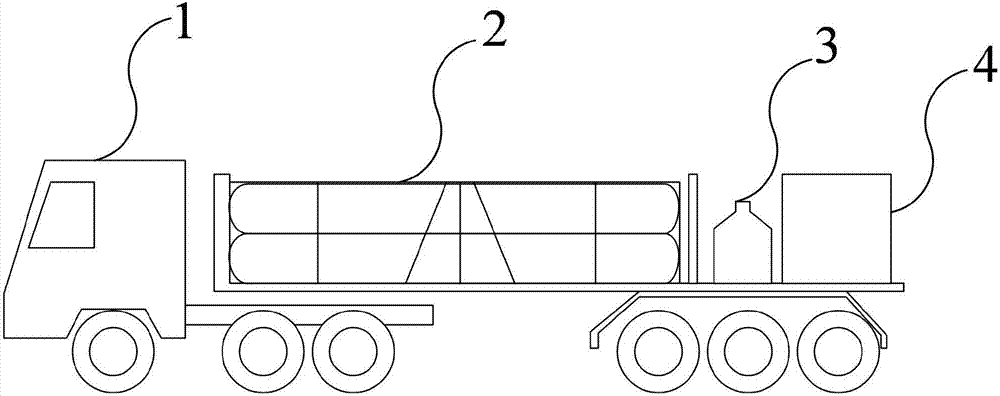

Supercharged mobile hydrogenation car and running method

PendingCN107388031AOptimizing the filling strategyFilling speed is fastGas handling/storage effectsFluid handledProcess engineeringControl system

The invention discloses a supercharged mobile hydrogenation car and a running method. The hydrogenation car comprises a traction car, the traction car is provided with a hydrogen storage system, hydrogen storage tanks in the hydrogen storage system are connected with a hydrogen main pipe at the same time, the hydrogen main pipe is connected with a control system, the temperature, pressure and capacity parameters of hydrogen in the hydrogen storage tanks of the hydrogen storage system are obtained through detection of an instrument gas supply system, the signal output of the instrument gas supply system is connected with the signal input of the control system, the first output of the control system is connected with the control input of a supercharged system, the second output of the control system is connected with the control input of a hydrogen dispenser, the hydrogen main pipe is connected with a hydrogen storage system inflation pipeline, a balance filling pipeline and a supercharged system, the hydrogen storage system inflation pipeline is connected with the hydrogen dispenser, the balance filling pipeline is connected with the hydrogen dispenser, the supercharged system is connected with the hydrogen dispenser, during hydrogen filling, intelligent judgment is carried out through the control system, and balanced hydrogen filling or supercharged hydrogen filling can be achieved. The hydrogen storage amount of the hydrogenation car can be improved, the hydrogen storage pressure is reduced, and safety performance is improved.

Owner:HUANENG CLEAN ENERGY RES INST

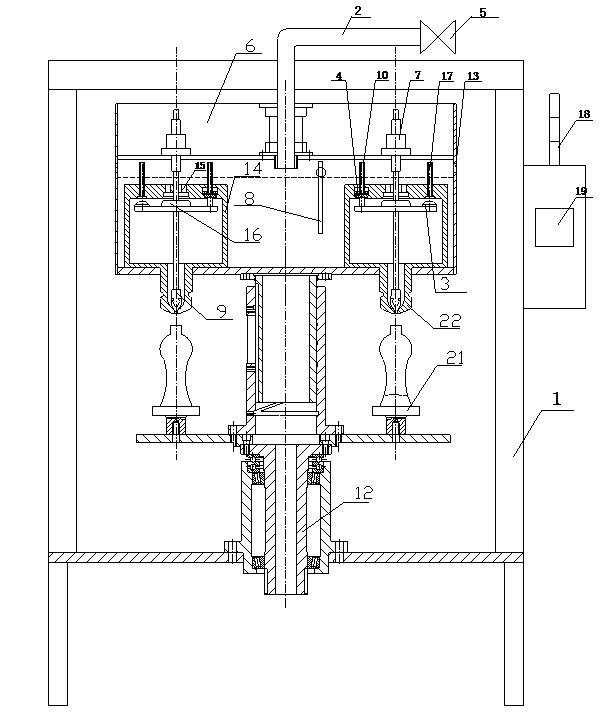

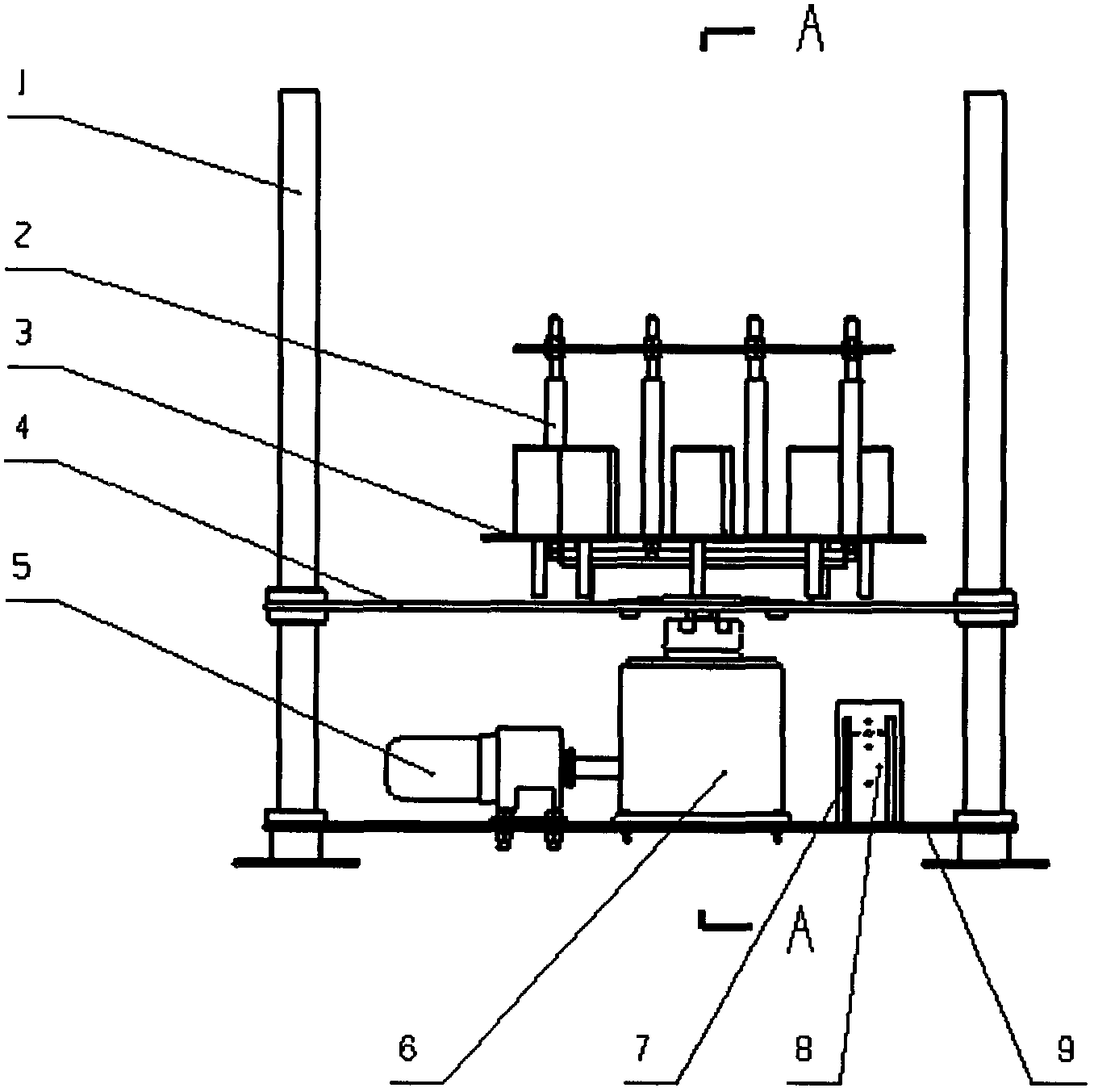

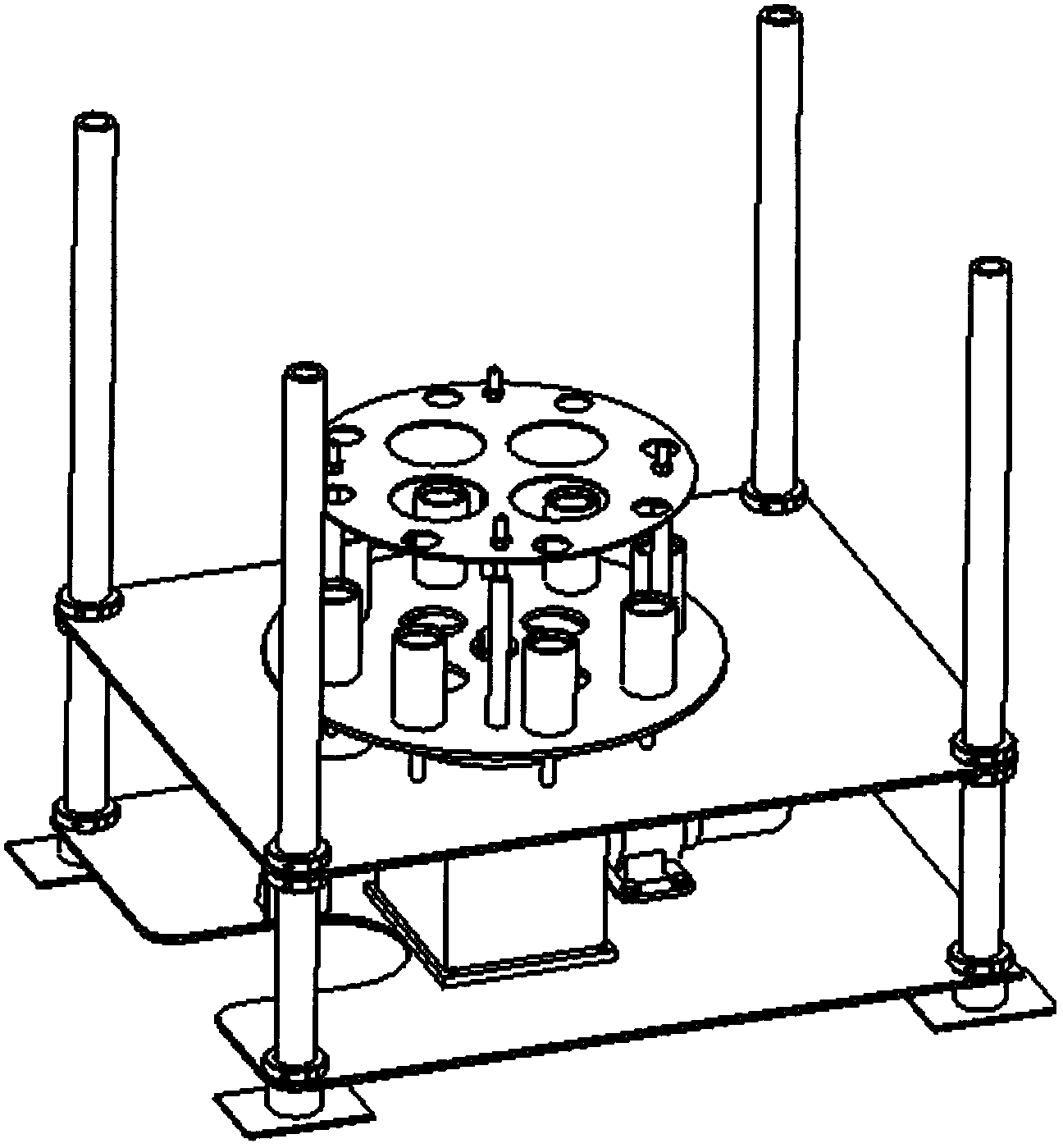

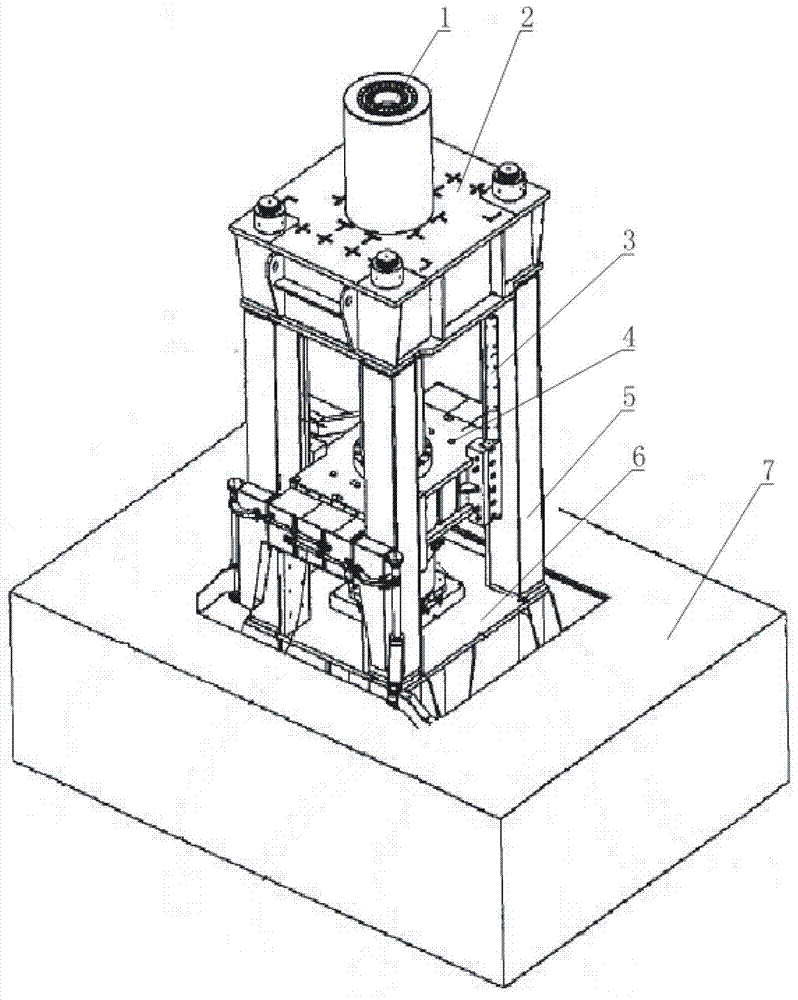

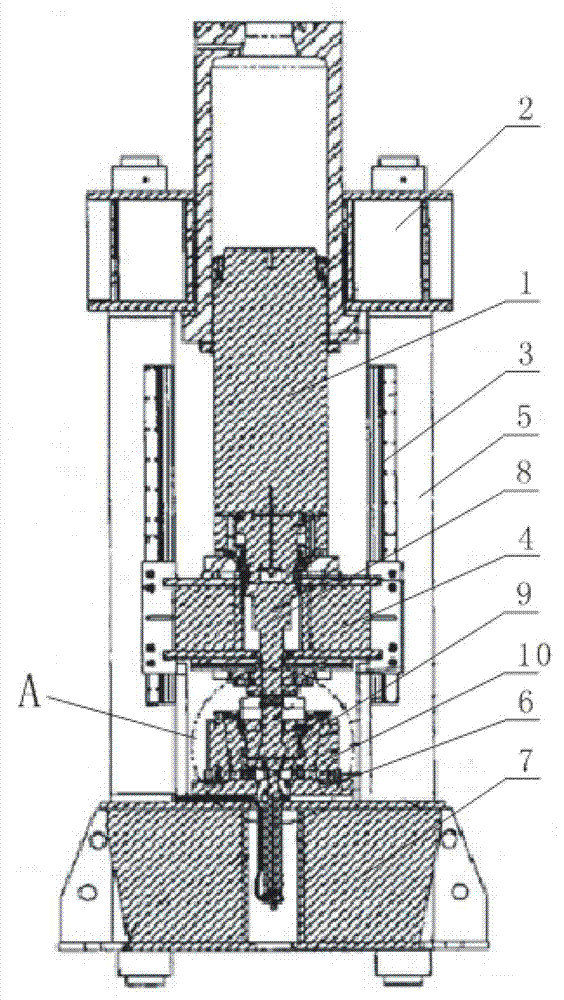

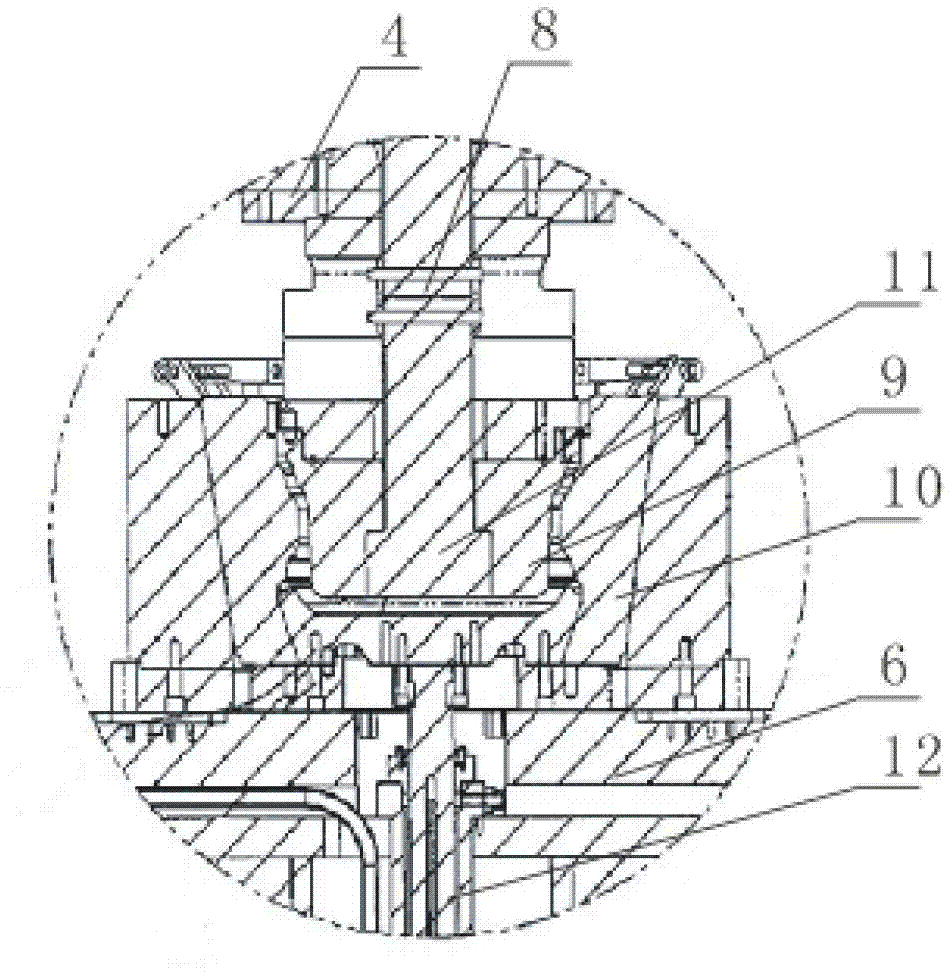

Rotation indexing table for encapsulation and package of cylindrical cylinder

ActiveCN103466138AFast filling speedReduce packaging workersPackagingEngineeringMechanical engineering

The invention discloses a rotation indexing table for encapsulation and package of a cylindrical cylinder. The rotation indexing table is formed by a motor, a rack and a rotation table, wherein the motor is used for supplying power to the rotation indexing table, the power can be transmitted to a flange rotating shaft of an output shaft through an indexer, and a cylindrical cylinder supporting plate and all components arranged on the cylindrical cylinder supporting plate are driven to rotate in an indexing way according to certain requirements under the rotation of the flange rotating shaft; the rack is formed by four upright posts and two rack supporting plates, the distance between the two rack supporting plates is adjustable, and thus the encapsulation and the package of cylindrical cylinders in different heights can be adapted; the rotation table is formed by a rotating disk bearing supporting frame, a rotating disk bearing, the cylindrical cylinder supporting plate, a cylindrical cylinder guide sleeve and a cylindrical cylinder guide plate.

Owner:JIANGNAN UNIV

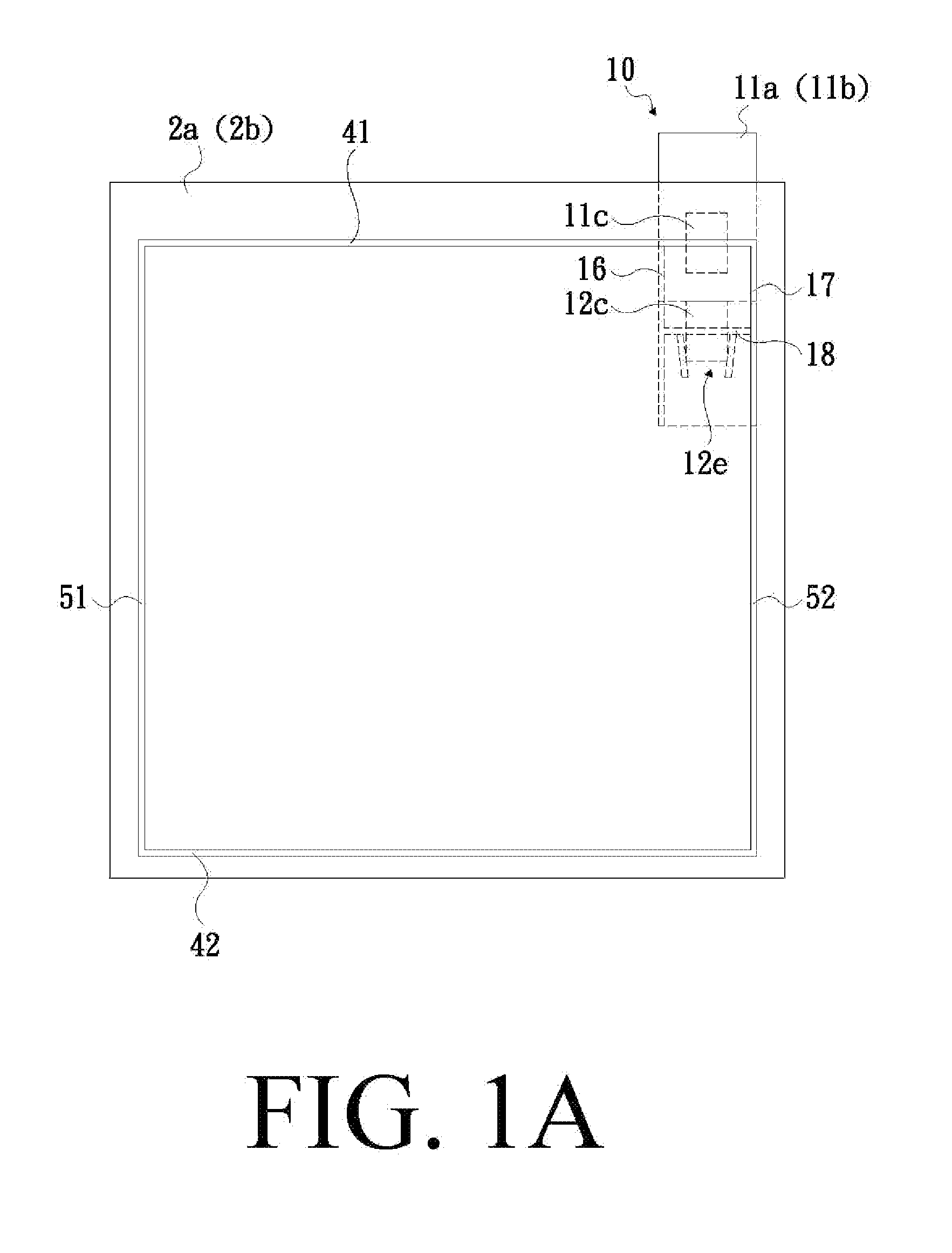

Automated packaging, inspection, verification, and counting apparatus

InactiveUS8146331B2Fast filling speedCapsCapping machinery safety/controlEngineeringProcess engineering

The present invention is an automated packaging apparatus utilizing a rotating assembly of elongated slats containing cavities to receive discrete pharmaceutical, vitamin, or food products. Quantities of discrete products such as tablets, capsules, or gels are deposited into the hopper of the apparatus. The apparatus then dispenses the discrete products into containers moving on a conveyor system such that each container receives a predetermined quality and quantity of pharmaceutical, vitamin, or food products. While operating at high speed, the apparatus inspects, counts, identifies and analyzes each product deposited into the containers and maintains electronic records describing the status of each product. In the event any errors occur the apparatus produces various alerts to inform the operator. The presence of foreign products or objects may cause the apparatus to instantly stop the entire system including peripheral equipment. A series of Good Manufacturing Practice protocols can then be enforced as per FDA requirements.

Owner:SOLOMAN SABRIE

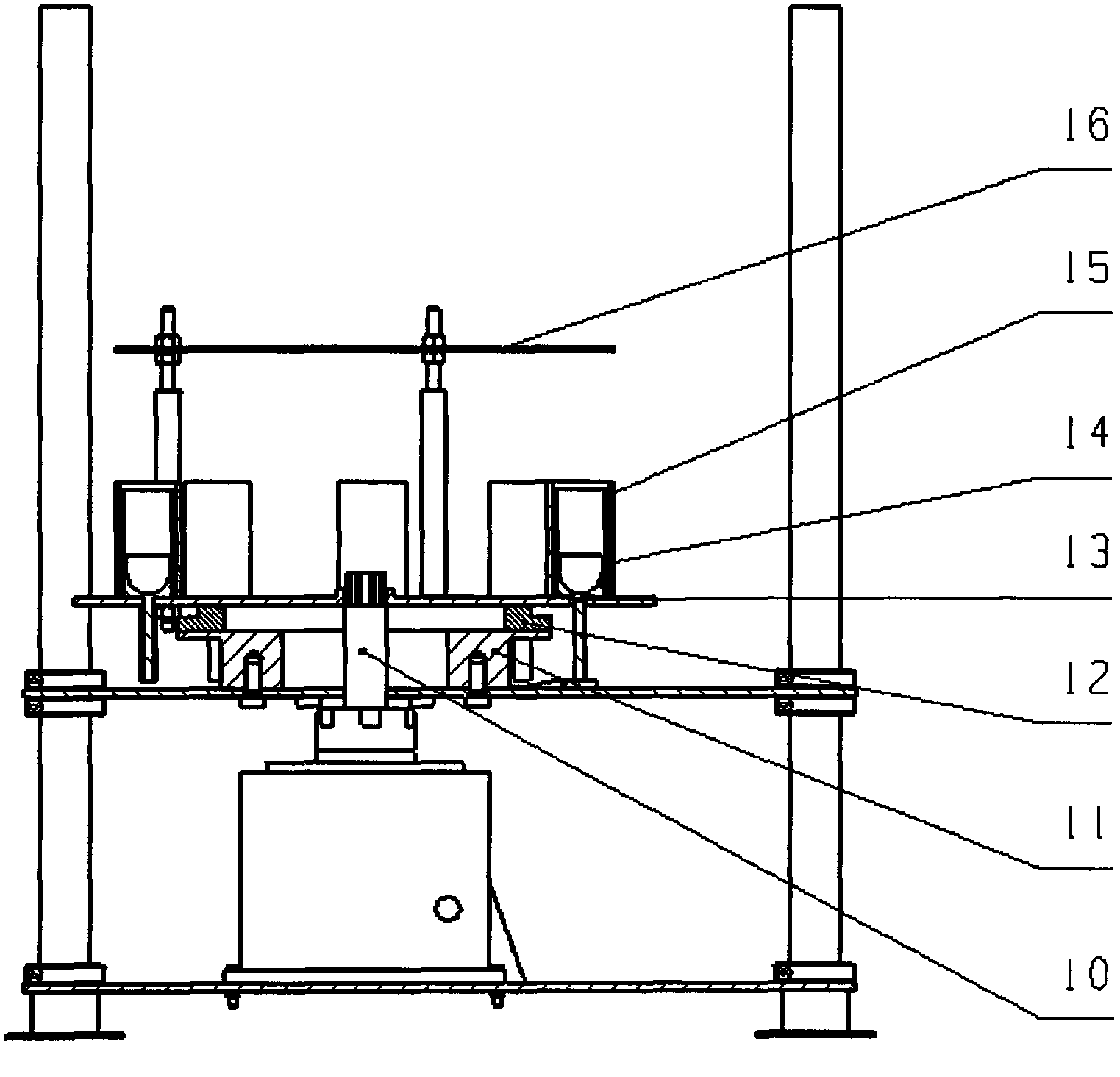

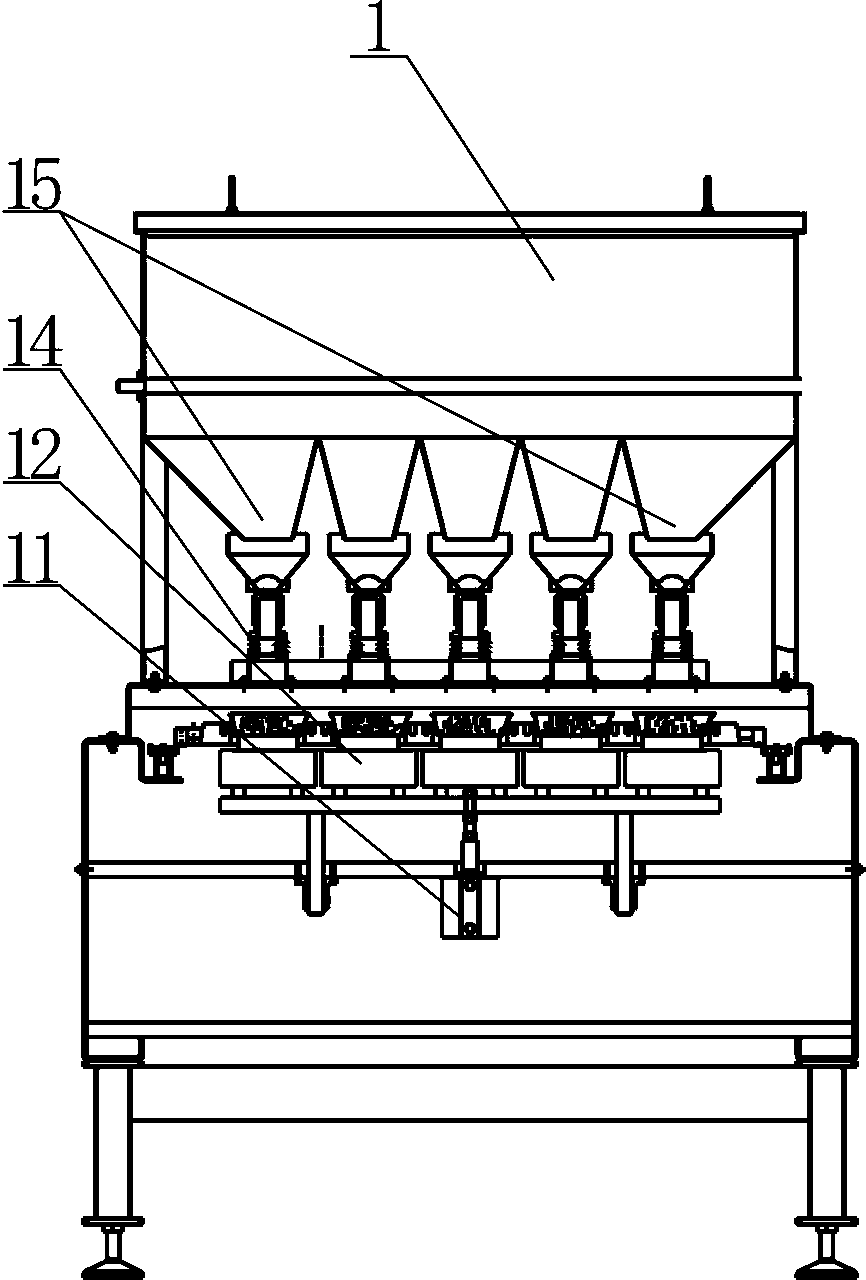

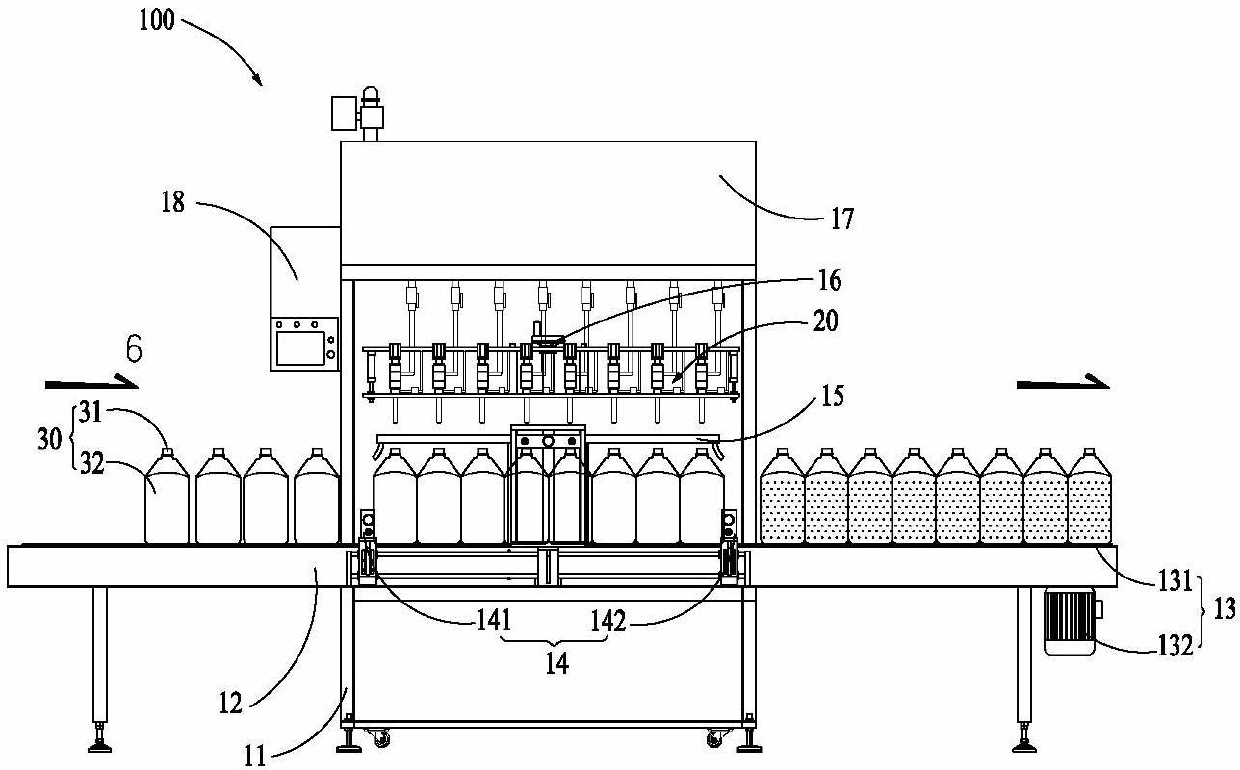

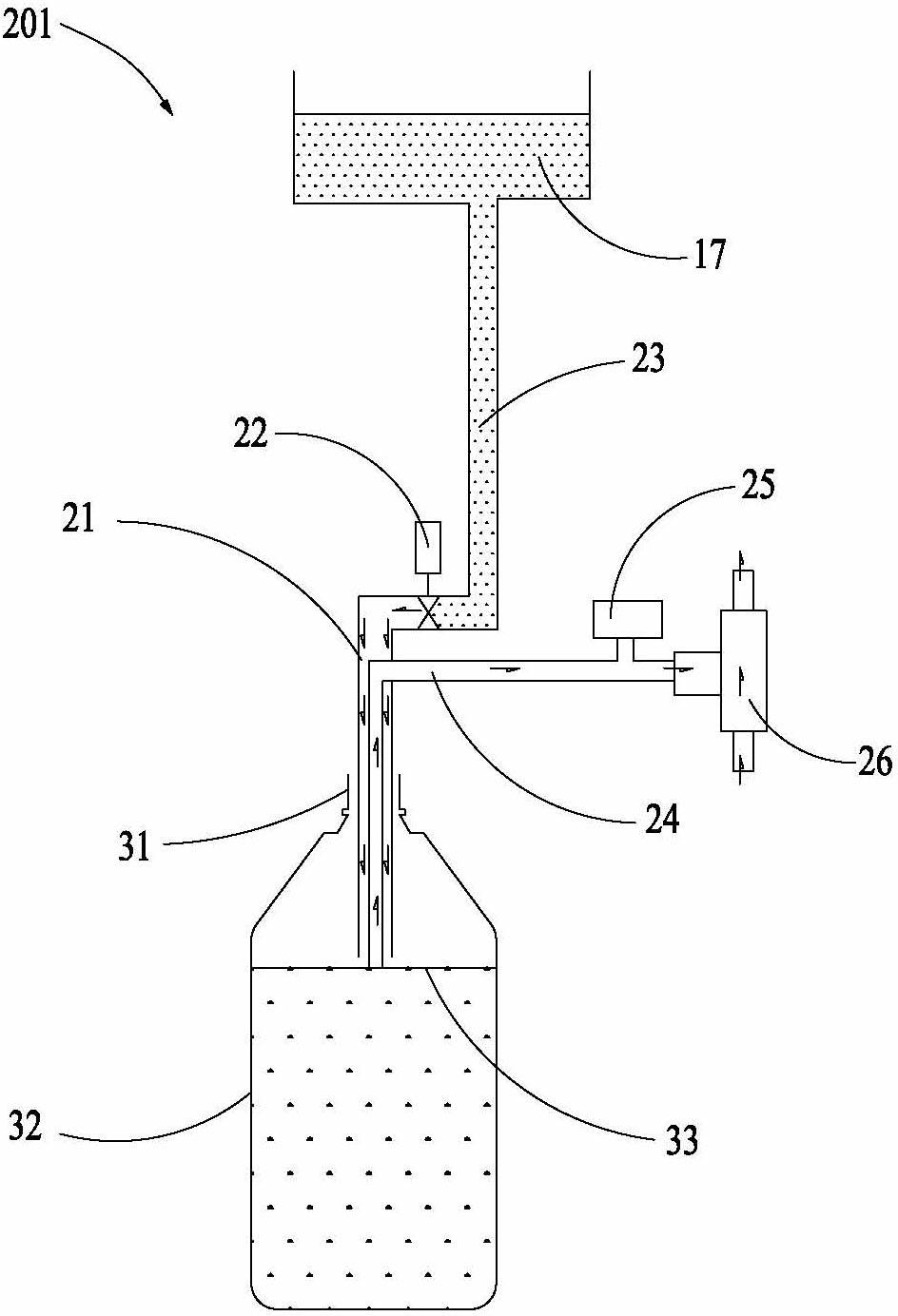

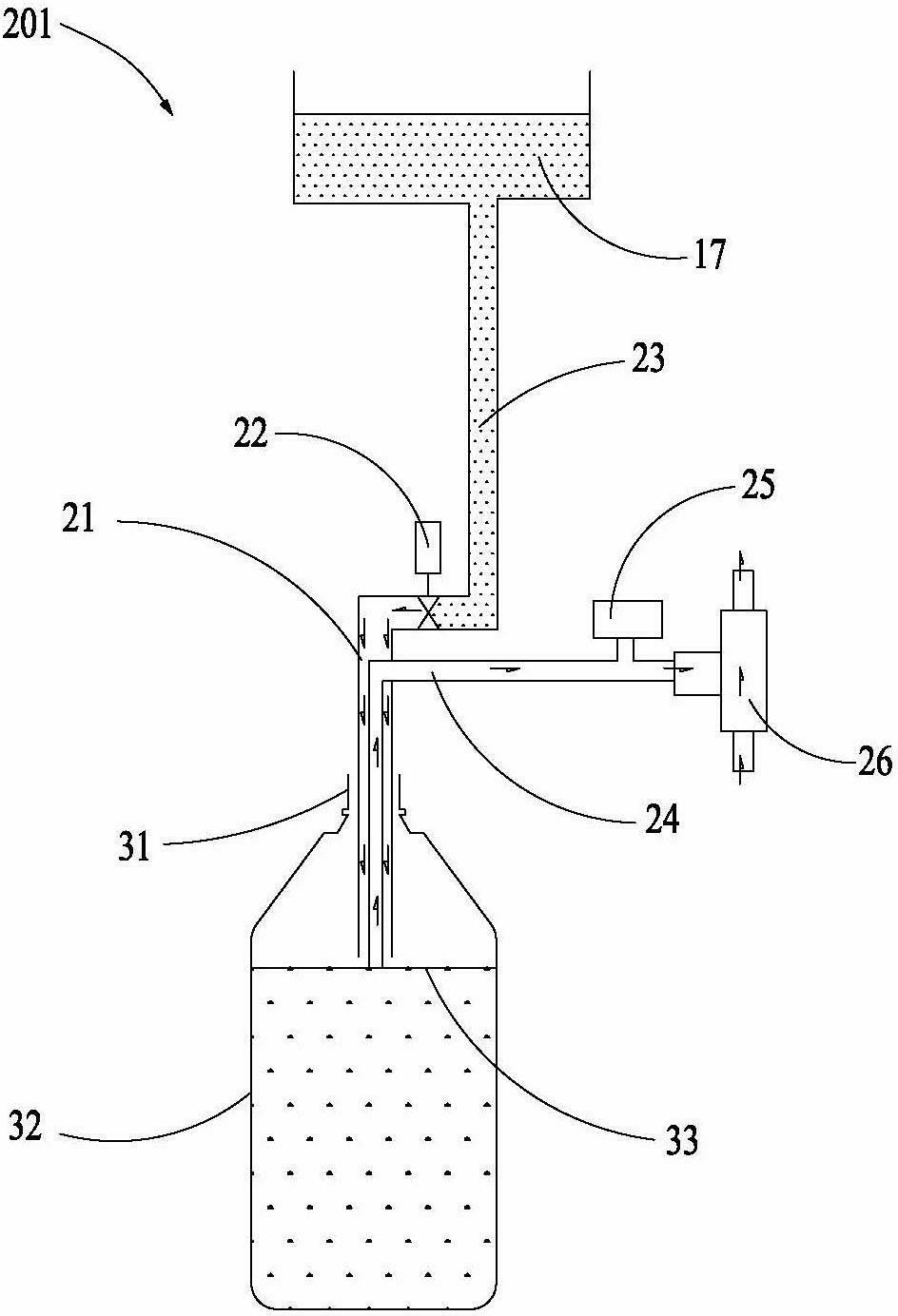

Multi-head automatic metering and filling system

ActiveCN103523249AAccurate measurementFast filling speedSolid materialEngineeringMechanical engineering

The invention discloses a multi-head automatic metering and filling system which is mainly composed of a hopper, a quantitative container, an upper insertion board, an upper air cylinder, a lower insertion board and a lower air cylinder. The quantitative container is of a tubular structure, and the upper end and the lower end of the quantitative container are open. The upper port of the quantitative container is formed in discharge ports in one side of the lower end of the hopper. The upper insertion board and the lower insertion board are inserted at the upper port and the lower port of the quantitative container respectively in a penetrating mode. The upper air cylinder and the lower air cylinder drive the upper insertion board and the lower insertion board respectively to move horizontally to open or close the quantitative container. The multi-head automatic metering and filling system further comprises a material supplementary device. By the adoption of the structural mode, the accuracy degree of the discharge ports is + / -3-6.5%. The multi-head automatic metering and filling system has the advantages of being high in filling speed, and the volume for filling each port can be adjusted independently according to production requirements. Particularly, the mode of first-level coarse quantitative filling and the mode of secondary-level high-accuracy rice supplementary quantitative filling are adopted, and the accuracy degree of the multiple discharge ports reaches + / -1-3g when the yield reaches 2000 boxes per hour. The multi-head automatic metering and filling system further has the advantages of being simple in structure, and more convenient to clean and maintain.

Owner:GUANGZHOU XIMING MACHINERY

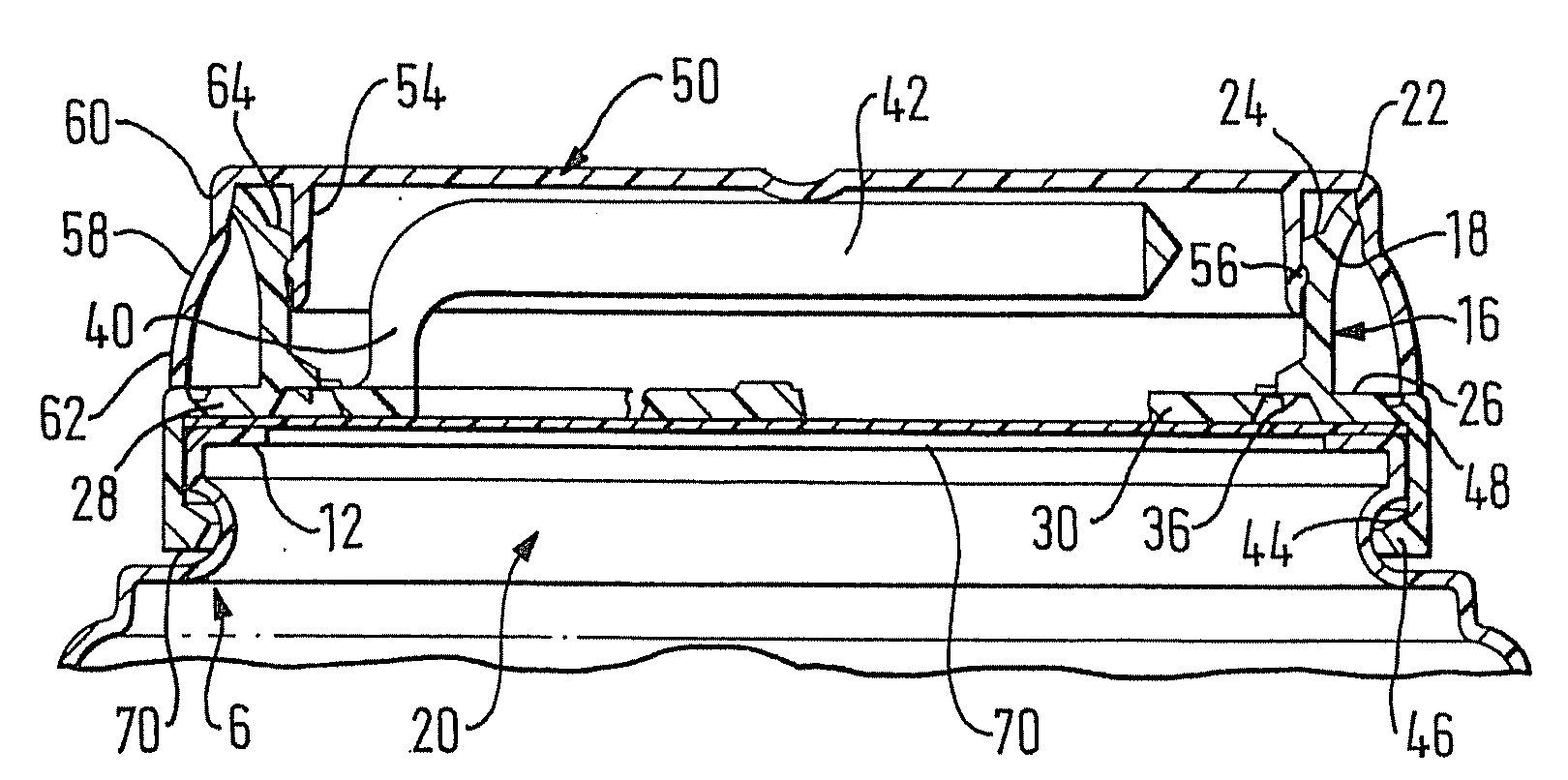

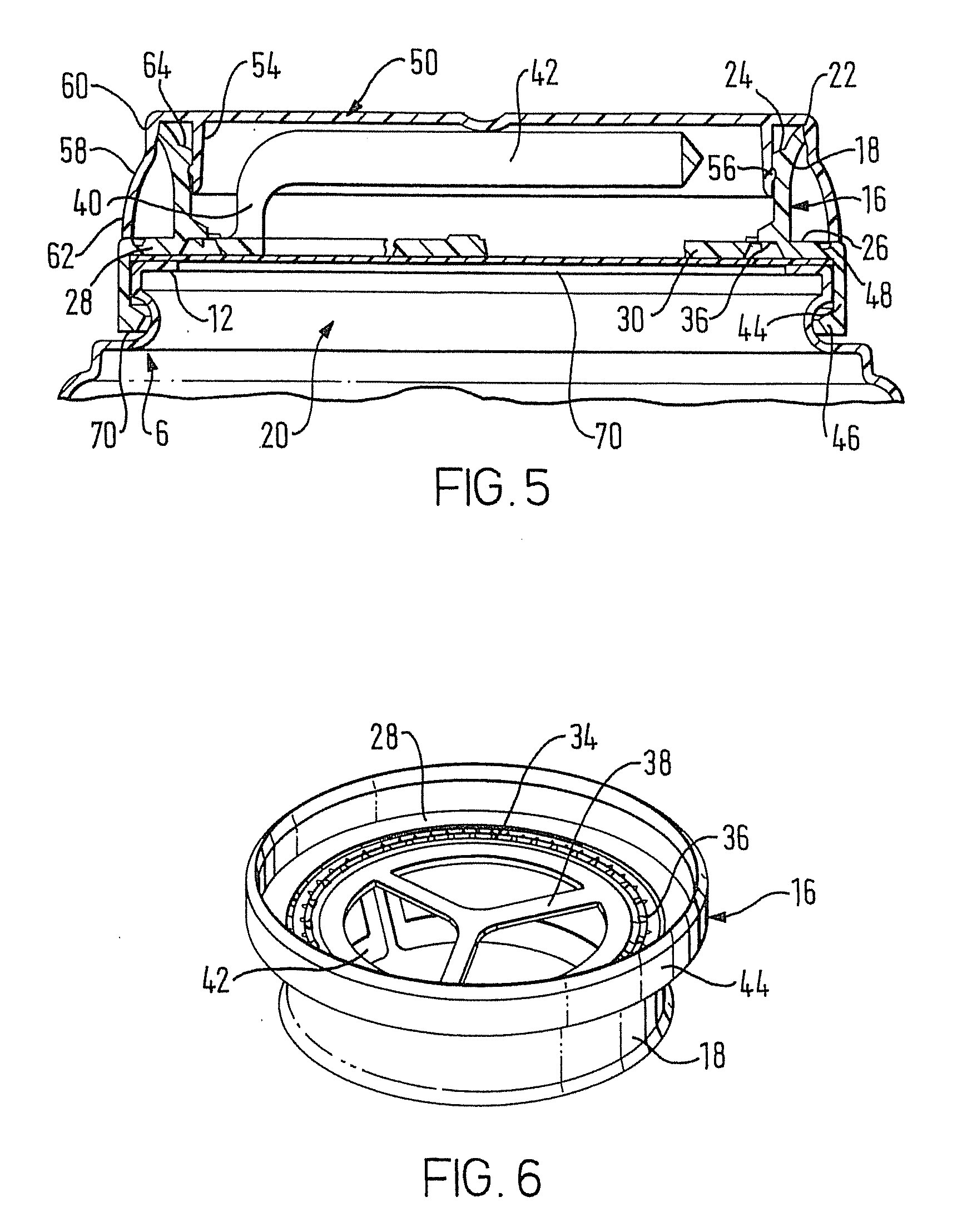

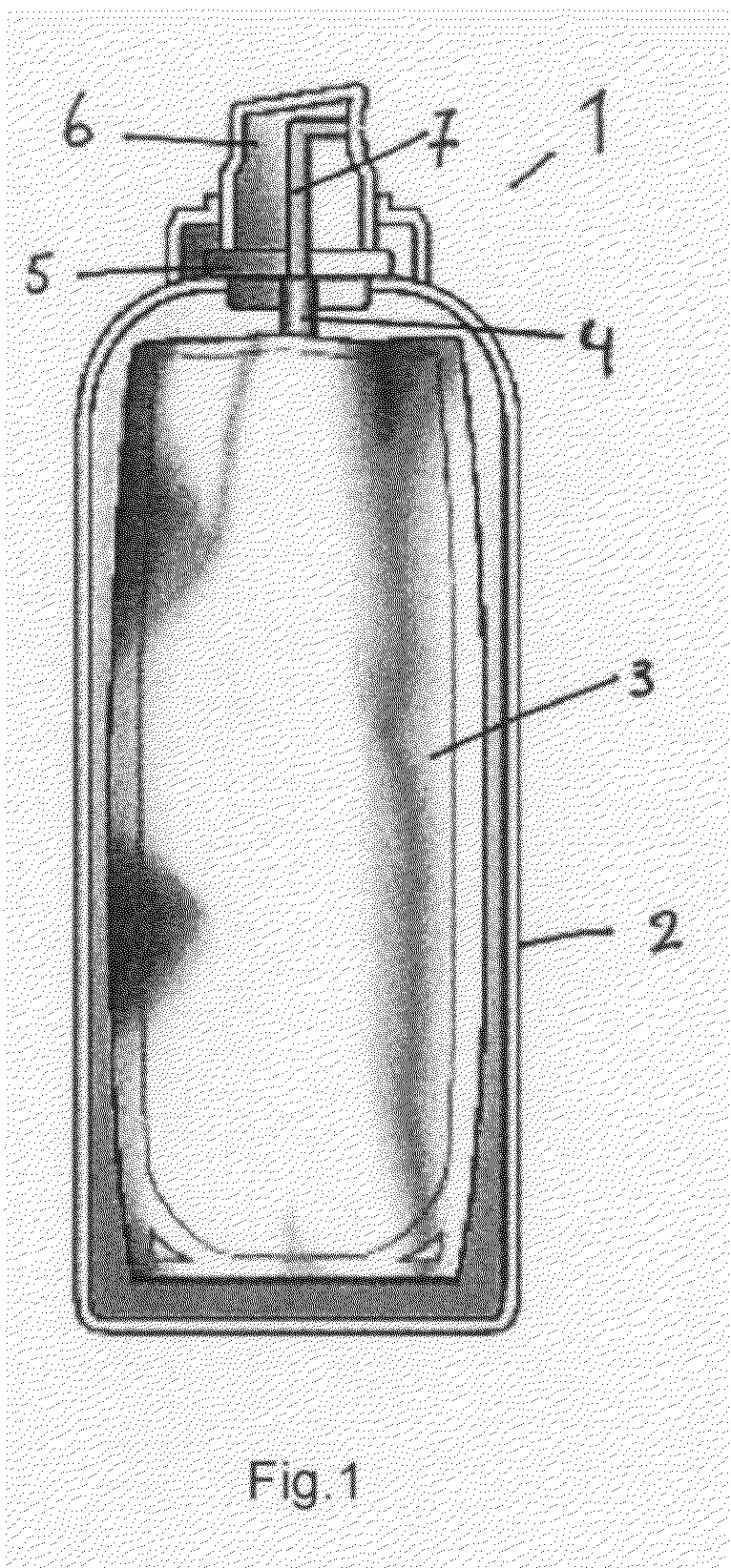

Cap Closure

InactiveUS20090277859A1Improve sealingFast filling speedCapsClosure using stoppersEngineeringInjection moulding

A sealing arrangement for a plastic bottle includes a blow-molded bottle having a body and a mouth that includes an opening, an injection molded neck that includes a continuous wall that defines a top wall-opening and a bottom wall-opening. The top wall-opening provides a pour spout for liquid contained within the body of the bottle. The bottom wall-opening is fused to the mouth of the bottle so as to surround the bottle's opening. A removable flange is located generally within the bottom wall-opening and a frangible region connects the flange to the wall. A foil is secured to a side of the flange that is generally adjacent to the bottom wall-opening, and the foil is adapted to close the bottom wall-opening. A plurality of foil-cutting teeth are carried by the wall generally adjacent to the bottom wall-opening, generally adjacent to the side of the flange and generally adjacent to the foil. A pull member is secured to the flange. Manual operation of the pull member separates the flange from the wall, as at least a portion of the foil is cut by the teeth. An injection-molded cap removably closes the top wall-opening. The wall includes a weakened portion that will break upon an attempt to physically remove the wall from the bottle. The cap includes a cover plate that covers the top wall-opening and a skirt that extends from the cover plate to cover the weakened portion of the wall.

Owner:BAPCO CLOSURES RES

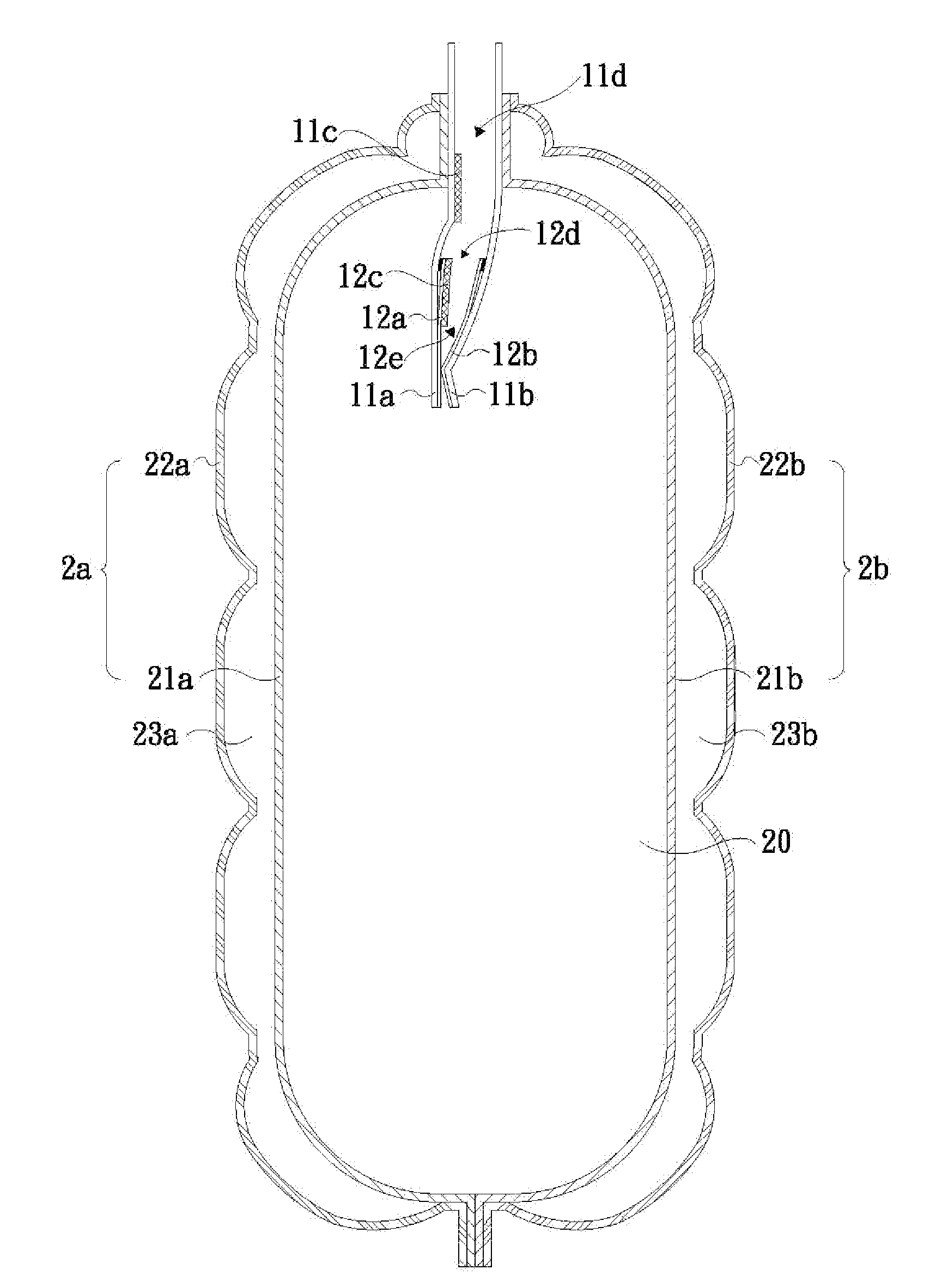

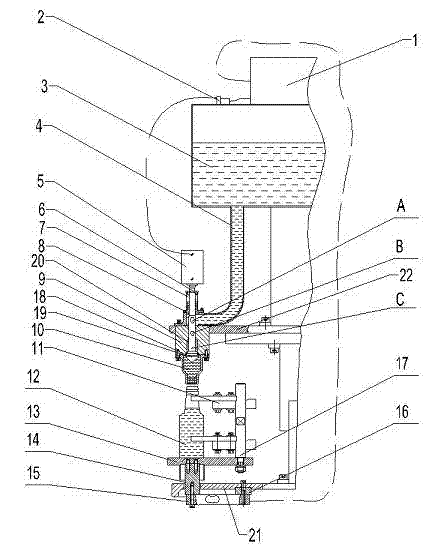

Air enclosure and check valve thereof capable of being filled with high pressure air

InactiveUS7959003B2Simple structureFast filling speedClosuresClosure using stoppersEngineeringHigh pressure

In an air enclosure and a check valve capable of being filled with high pressure air, two first inner films are installed between two outer films, and two second inner films are then stacked together between the two first inner film. The two outer films and the two first inner films are adhered together by means of hot sealing to allow the two first inner films to be positioned between the two outer films and an air cylinder to be formed between the two outer films; the two second inner films are adhered to each other by means of hot sealing to form a second air inlet between the two second inner films. Thereafter, an air filling tool may be used to force high pressure air into the second air inlet and into the air cylinder, causing the air cylinder to fill with air and expand.

Owner:LIAO CHIEH HUA

Air enlcosure and check value thereof capable of being filled with high pressure air

InactiveUS20090238496A1Simple structureFast filling speedClosuresClosure using stoppersEngineeringHigh pressure

In an air enclosure and a check valve capable of being filled with high pressure air, two first inner films are installed between two outer films, and two second inner films are then stacked together between the two first inner film. The two outer films and the two first inner films are adhered together by means of hot sealing to allow the two first inner films to be positioned between the two outer films and an air cylinder to be formed between the two outer films; the two second inner films are adhered to each other by means of hot sealing to form a second air inlet between the two second inner films. Thereafter, an air filling tool may be used to force high pressure air into the second air inlet and into the air cylinder, causing the air cylinder to fill with air and expand.

Owner:LIAO CHIEH HUA

Electronic-weighing flow-rate-variable filling device

ActiveCN102765500ASolving undetectableRealize dual flow rate fillingLiquid materialMagnetic valveWorking environment

Owner:安丘市鼎正机械设备有限公司

Aerosol container comprising a dermatological composition and a foaming agent

InactiveUS20130233310A1Fast filling speedNegatively affecting the foaming of the compositionCosmetic preparationsToilet preparationsFoaming agentMedicine

A bag-on-valve aerosol container includes a chamber, where a pressurized gas is contained, surrounding a flexible bag, and where a closable outlet is in fluid communication with the flexible bag. The flexible bag includes a leave-on dermatological composition having an oil-in-water emulsion, comprising one or more oils, the emulsion having an oil phase to water phase ratio of between 1:1 and 1:25; one or more oil-in-water emulsifiers; and one or more active dermatological ingredients. The leave-on dermatological composition has a viscosity at room temperature of between 1 and 20,000 mPa·s. The product compartment further includes one or more physical foaming agents having a standard boiling point of −50 to 70° C.

Owner:DREUMEX +2

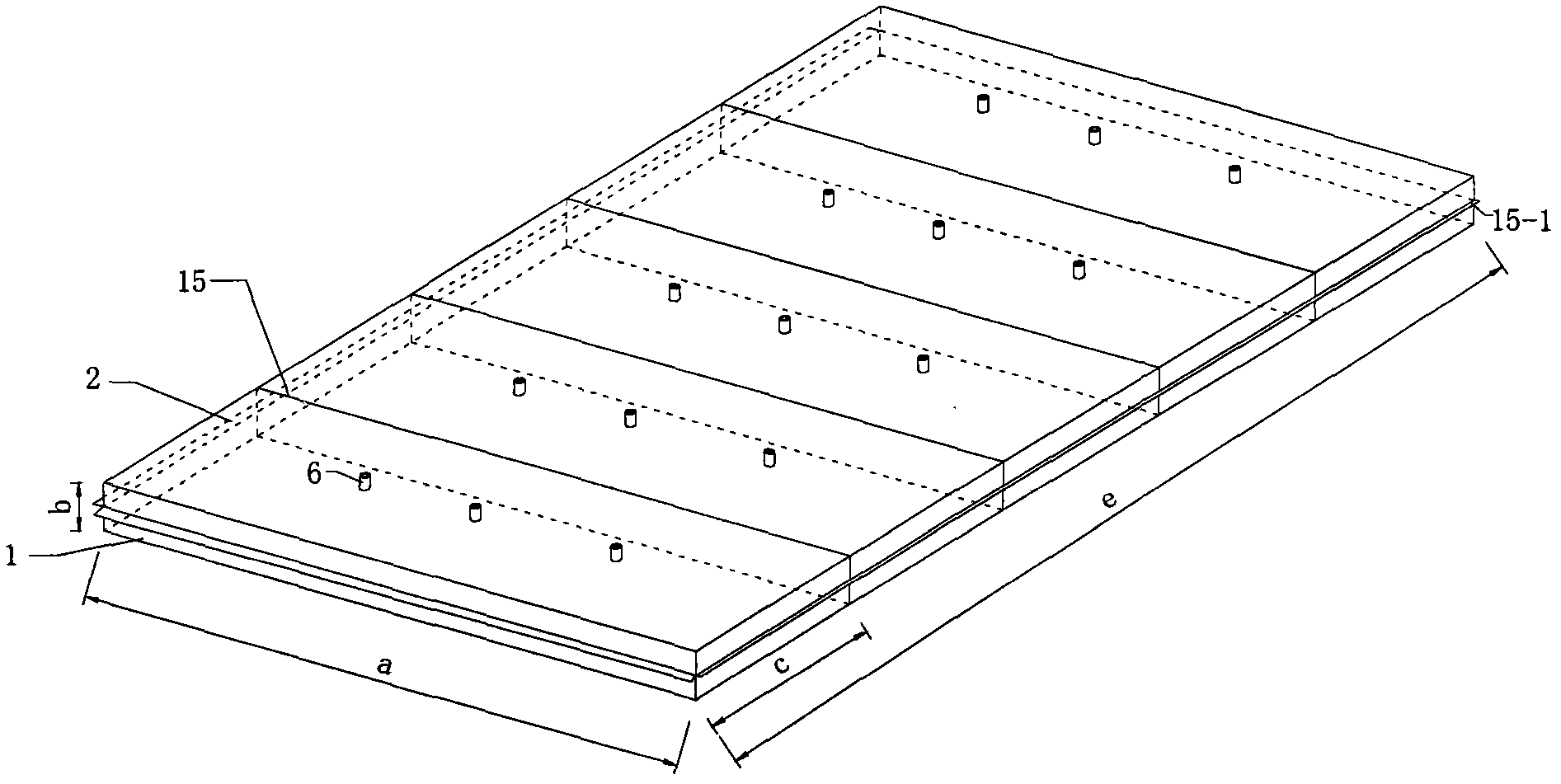

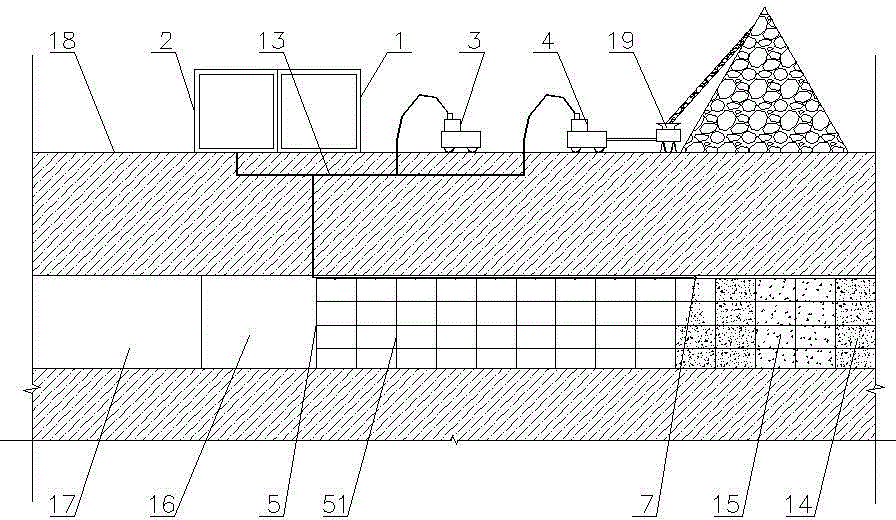

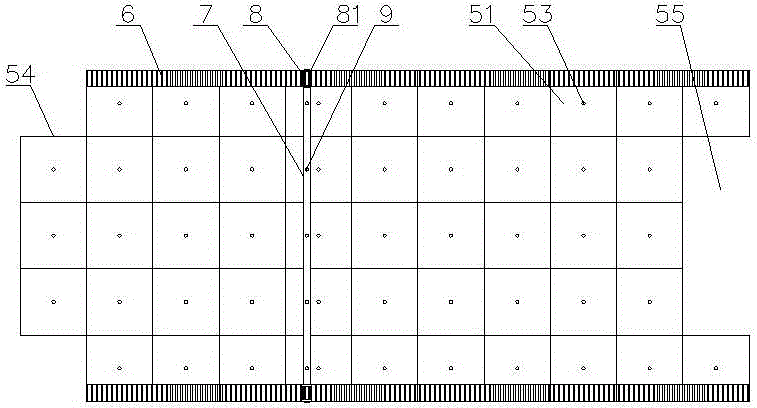

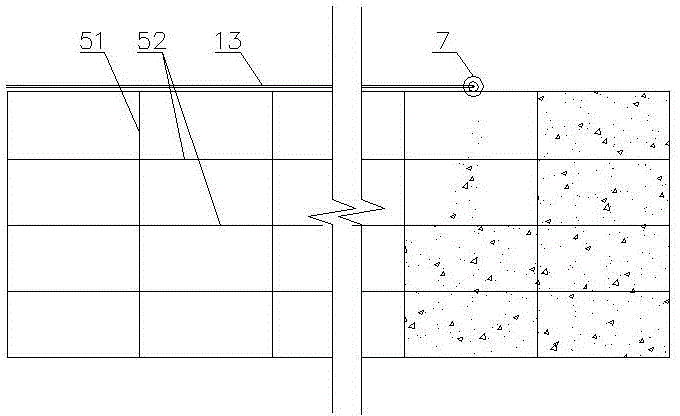

Coal mine gob filling system and method

The invention relates to a coal mine gob filling system and method. The coal mine gob filling system has the advantages that the structure is simple, the strength of airbag groups is high, the system adapts to large-volume gob filling, operators do not conduct operation in the gob, the safety and reliability are high, the isolation performance is good, the automation level is high, the construction speed is quick, the filling speed is quick and the mining speed is not influenced. The coal mine gob filling method has the advantages that the method adapts to large-volume gob filling and is widely applicable to coal mine gob control and treatment, the operators do not conduct operation in the gob, the operation is simple and convenient to conduct, the steps are simple, the production requirements of safety and high efficiency can be satisfied, the safety and reliability are high, the isolation performance is good, the automation level is high, the construction speed is quick, the filling speed is quick, the mining speed is not influenced, not only can the amount of used cement mortar be reduced, but also waste coal gangue can be digested, the waste is utilized and is prevented from polluting the environment, the economic performance and environmental friendliness are good and the filling cost is low.

Owner:HENAN POLYTECHNIC UNIV

Method and System for Tank Refilling

ActiveUS20130269828A1Improve performanceImprove fuel performanceVessel geometry/arrangement/sizeVessel wallsAnalytical equationsThermodynamic state

Disclosed is an improved analytical method that can be utilized by hydrogen filling stations for directly and accurately calculating the end-of-fill temperature in a hydrogen tank that, in turn, allows for improvements in the fill quantity while tending to reduce refueling time. The calculations involve calculation of a composite heat capacity value, MC, from a set of thermodynamic parameters drawn from both the tank system receiving the gas and the station supplying the gas. These thermodynamic parameters are utilized in a series of simple analytical equations to define a multi-step process by which target fill times, final temperatures and final pressures can be determined. The parameters can be communicated to the station directly from the vehicle or retrieved from a database accessible by the station. Because the method is based on direct measurements of actual thermodynamic conditions and quantified thermodynamic behavior, significantly improved tank filling results can be achieved.

Owner:HONDA MOTOR CO LTD

Forging method and forging device of twice forcing molten soup forging wheel

ActiveCN103084559AAvoid damageMeet mechanical performance requirementsRefined grainsMechanical property

The invention relates to a forging method and a forging device of a twice forcing molten forging wheel. The forging method of the twice forcing molten forging wheel is conducted circularly by the following steps: (1) materials smelting; (2) heat preservation deposit; (3) molten soup degassing; (4) the molten soup being injected into a lower die; (5) main piston forcing and pressure maintaining; (6) auxiliary piston forcing and pressure maintaining; (7) die sinking; (8) product transfer and deposit; (9) die cooling. Product quality is improved and molten soup dosage is reduced, and twice forcing is conducted to further improve inner structure refined grain of metals, and therefore the forging method and the forging device of the twice forcing molten forging wheel has the advantages of improving product mechanical property, tensile property and other overall properties, shortening product production time, increasing output, improving production efficiency and ex-factory percent of pass of products.

Owner:TIANJIN NANUO MACHINERY MFG

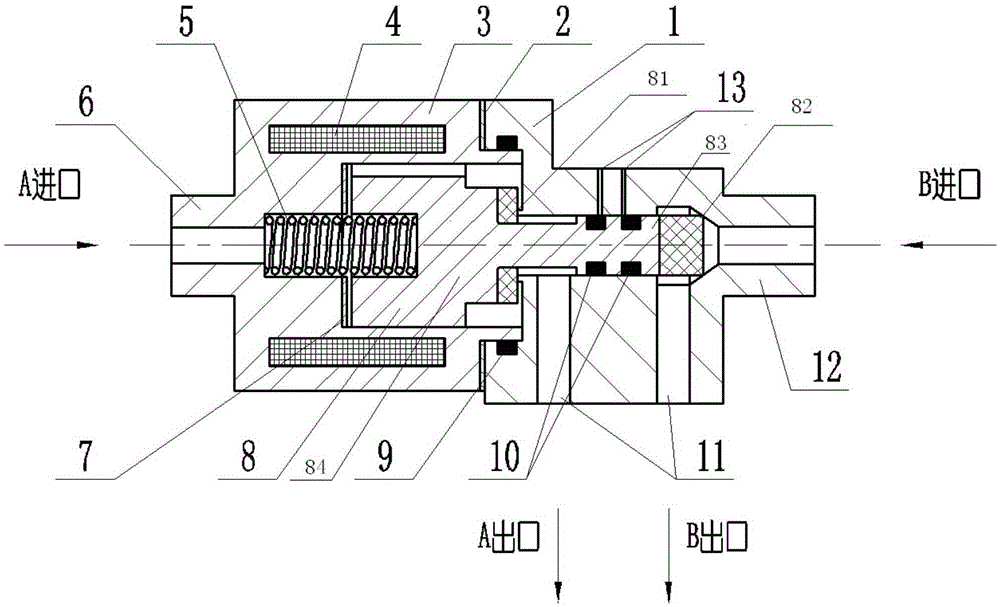

Mono-coil self-unloading type two-component electromagnetic valve

InactiveCN105387244ASimple structureReduce weightOperating means/releasing devices for valvesMultiple way valvesEngineeringHigh pressure

The invention discloses a mono-coil miniaturized self-unloading type two-component electromagnetic valve structure. The mono-coil miniaturized self-unloading type two-component electromagnetic valve structure is composed of a base body (an integrated valve body), a valve element, a spring, a coil, a gasket, a magnetic isolation pad, rubber O-shaped rings and the like. The electromagnetic valve is used for controlling startup and shutdown of an engine. Through the optimal matching design of the sealing positions of two-channel propulsive agents, self-unloading is achieved through a coaxial valve element by means of the mutual differences of the two-channel propulsive agents in the directions of medium force on the valve element, the carrying capacity caused by the medium force can be substantially reduced, and it is beneficial to reduce driving loads of an electromagnet and achieve the quick-response design of the valve. According to the electromagnetic valve structure, the two-channel valve element and the unloading structure are highly integrated and the mono-coil drives two-channel supply so that the miniaturization degree of the two-component control valve can be greatly improved. The pressure adaptive capacity of the valve is greatly improved through the self-unloading structure, the improvement of the high-pressure adaptive capacity of the valve based on the theory also becomes very easy, and a new pressure working condition can be adapted only by matching the spring force with the working pressure.

Owner:XIAN AEROSPACE PROPULSION INST

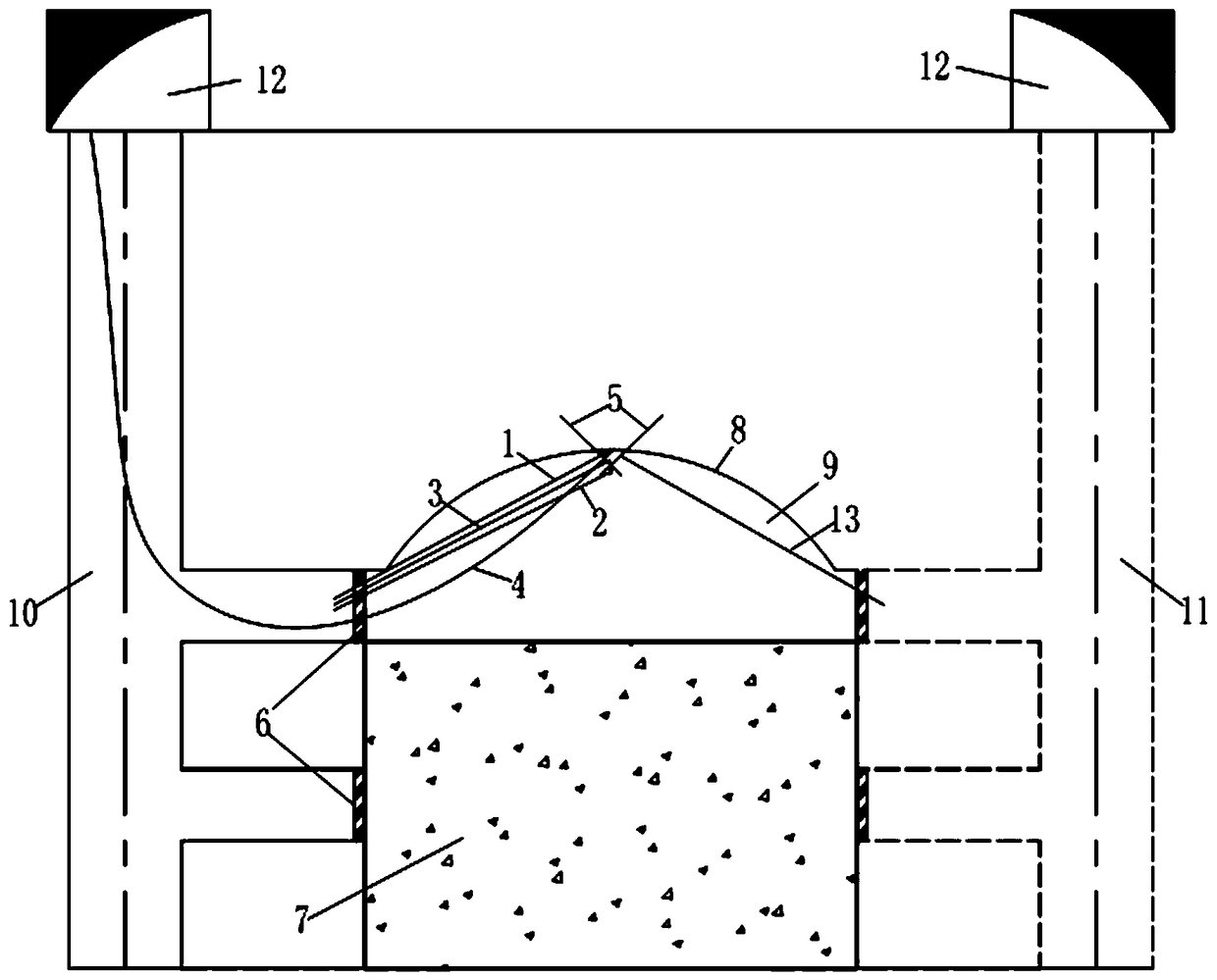

Roof contact method for stope filling

The invention relates to the technical field of combustion water heaters, and relates to a roof contact method for stope filling. The roof contact method for the stope filling comprises the followingstep that a stope empty area is filled with slag to a certain height to obtain a residual empty area, the height of the residual empty area is measured, the position of the highest point is determined, a hollow anchor rod is installed at the highest point, and a filling pipe is installed on the hollow anchor rod; a first dewatering pipe and a dewatering pipe are installed at the highest point, anda third dewatering pipe and a second dewatering pipe are installed from top to bottom according to the height difference; and the opening between the residual empty area and an inlet or a connectingchannel is blocked, and then filling slurry is conveyed into the filling pipe to realize roof-contacted filling of the residual empty area. The roof contact method for the stope filling has the characteristics of realizing effective roof-contacted filling of the stope empty area, and effectively ensuring the strength of the stope empty area.

Owner:GUANGXI ZHONGJIN LINGNAN MINING CO LTD

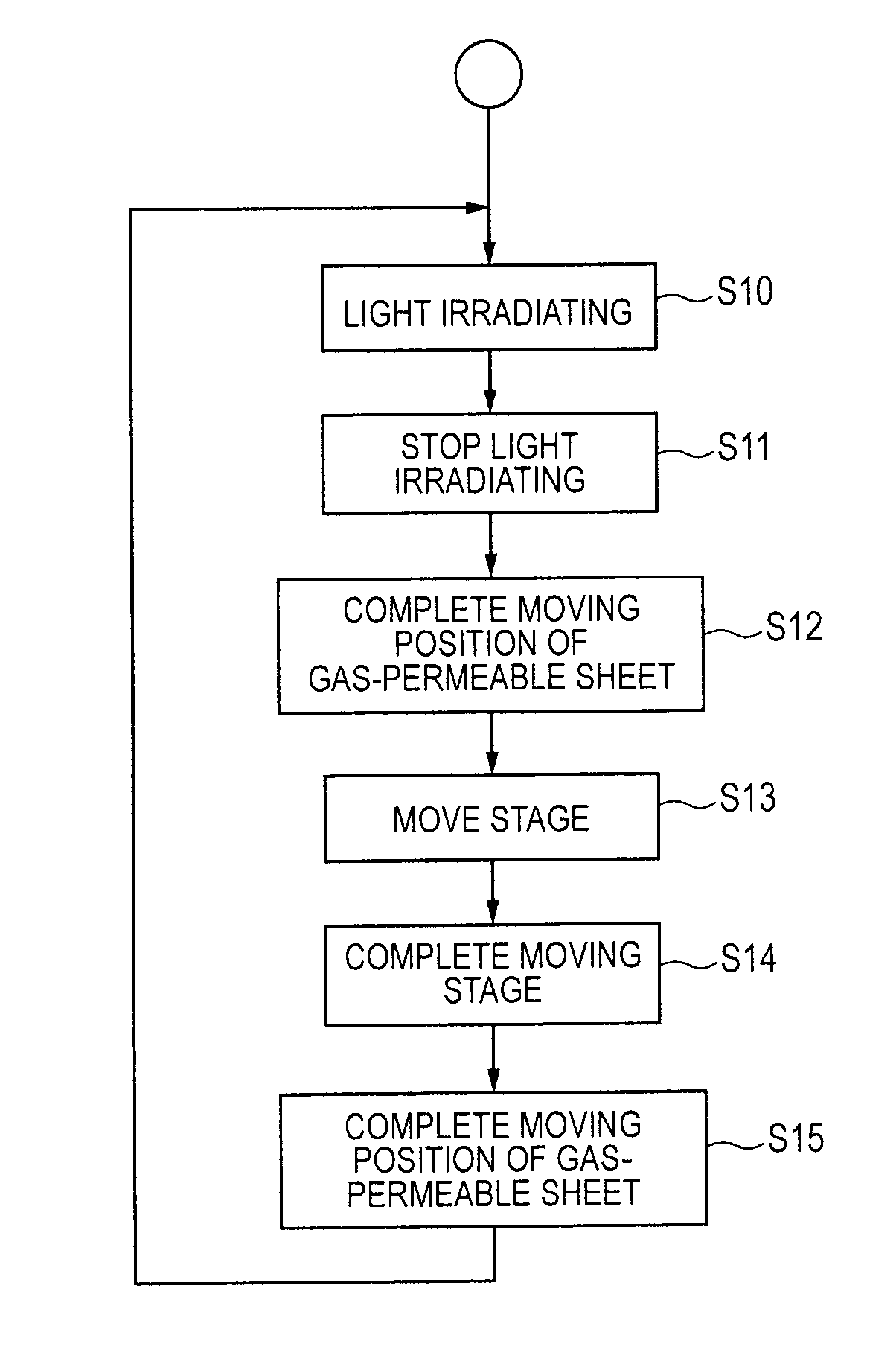

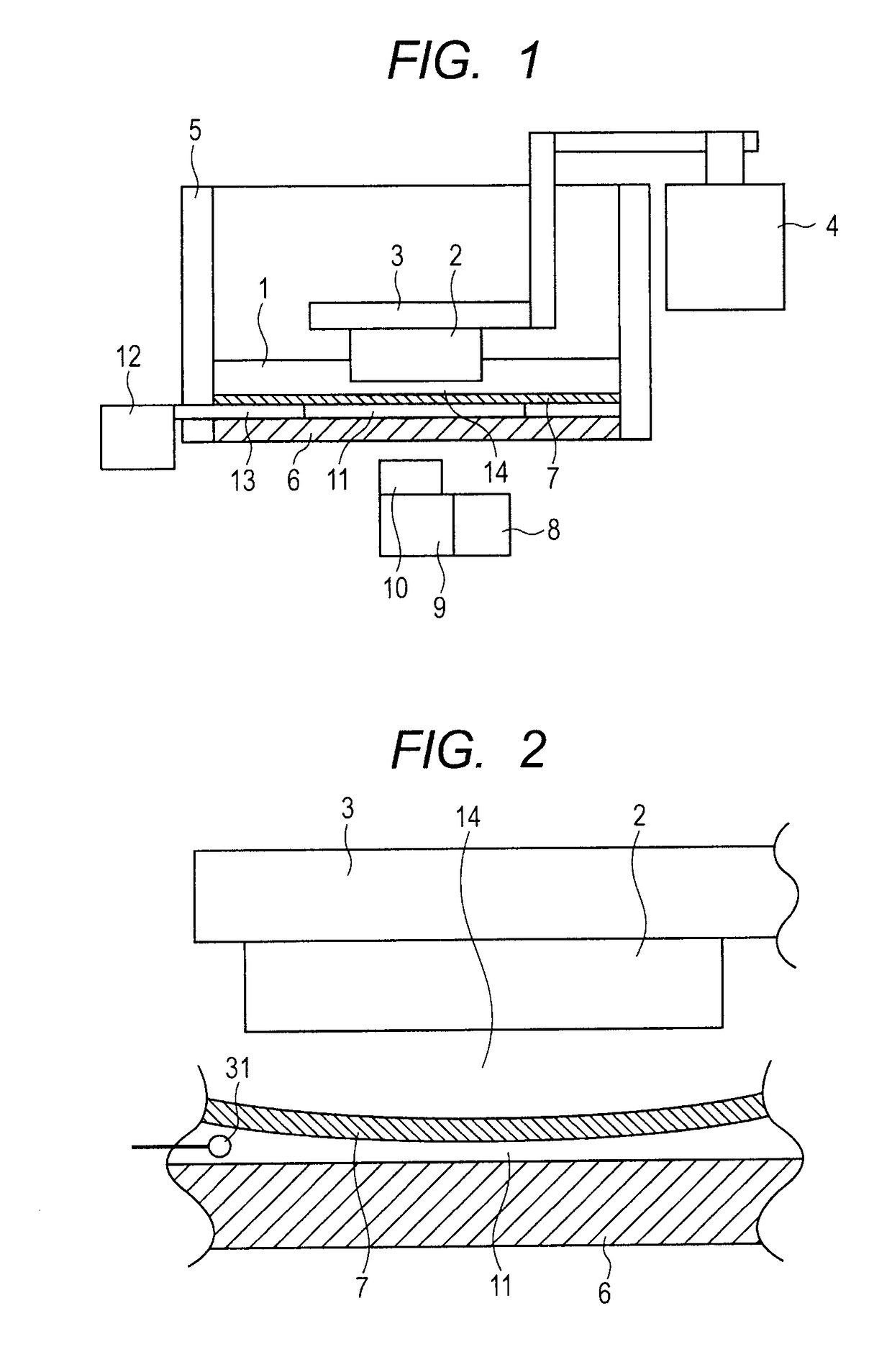

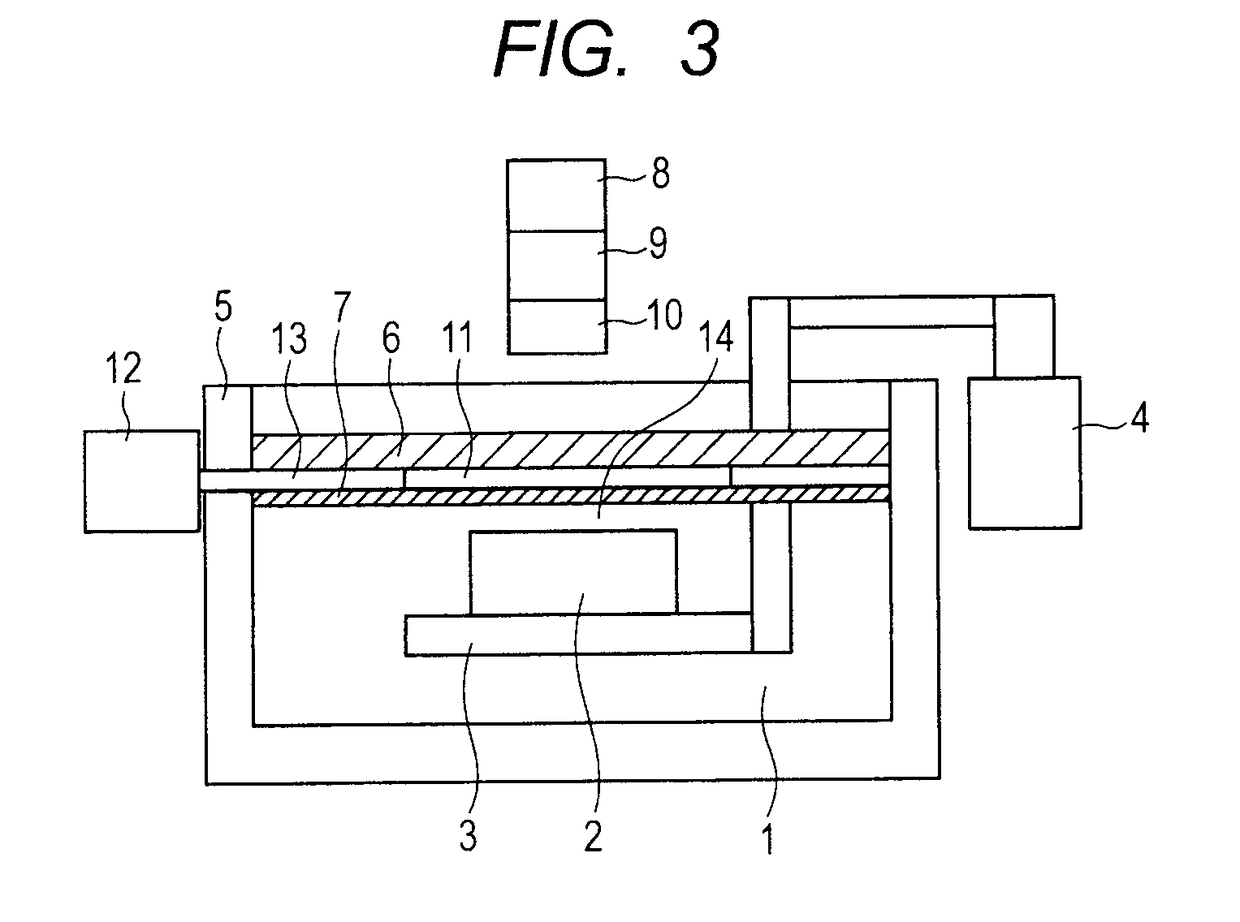

Three dimensional manufacturing apparatus and method for manufacturing three dimensional manufactured product

InactiveUS20180056587A1Increase speedSuppress in viscosityManufacturing enclosuresManufacturing environment conditioningLight irradiationEngineering

A three dimensional manufactured product is manufactured A speed of filing an uncured light curing resin in a space for a next layer is enhanced, to improve a manufacturing speed. One surface of a container housing a light curing resin is configured by a gas-permeable sheet that faces the light curing resin, and transmits irradiation light of a light irradiating apparatus, and a light transmitting plate disposed at an outer side of the container from the gas permeable member. A pressurizing chamber controllable in pressure by a pressure controlling apparatus is defined between the gas-permeable sheet and the light transmitting plate. At moving a manufacturing stage, an inside of the pressurizing chamber is de-pressurized to cause the gas-permeable sheet to perform concave surface deformation, and at a time of performing light irradiation, gas in the pressurizing chamber is caused to permeate into the light curing resin by pressurizing.

Owner:CANON KK

Automatic equal-liquid-level filling machine

InactiveCN102674223ASimple structureFast filling speedLiquid bottlingEngineeringMechanical engineering

The invention discloses an automatic equal-liquid-level filling machine, which comprise an engine seat, an operating platform, a transmission structure, a driving structure, a receiving trough, a lifting structure, a material cylinder, a control device, a photoelectric sensor and a filling system, wherein the filling system consists of at least one filling subsystem; the filling subsystem comprises a filling pipe, a filling valve, a feeding pipe, a vacuum pipe, a vacuum sensor and a vacuum generator; the filling pipe is connected with the feeding pipe through the filling valve; the feeding pipe is communicated with the material cylinder; one end of the vacuum pipe is arranged nearby the filling pipe, and the other end of the vacuum pipe is connected with the vacuum generator; the vacuum generator is used for vacuumizing the machine to generate negative pressure; and the vacuum sensor is arranged at one end of the vacuum pipe close to the vacuum generator and is used for monitoring the variation of the negative pressure. The automatic equal-liquid-level filling machine has a simple structure, is high in filling speed and low in liquid loss and is suitable for high-viscosity materials and plastic bottles with thin walls.

Owner:广州市冠浩机械设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com