Roof contact method for stope filling

A technology for stopes and backfills, which is applied in fields such as backfills, mining equipment, and earth-moving drilling, etc., and can solve the threats to mine workers and goaf residents, the failure of support forces to meet the support requirements, damage and negative effects It can reduce the surface subsidence, not affect the recovery speed, and reduce the filling cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Below is that the present invention is described in further detail in conjunction with the embodiment of the present invention:

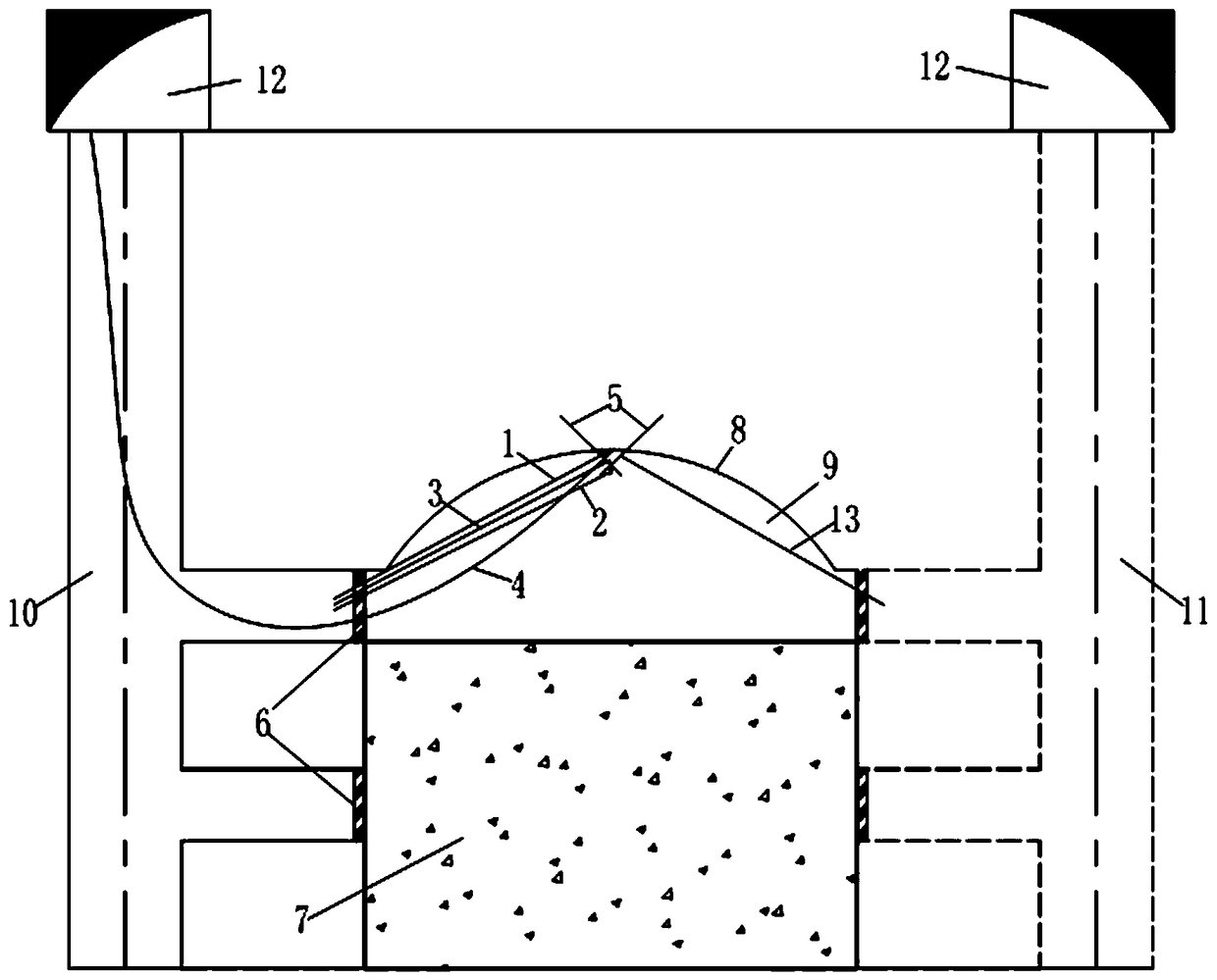

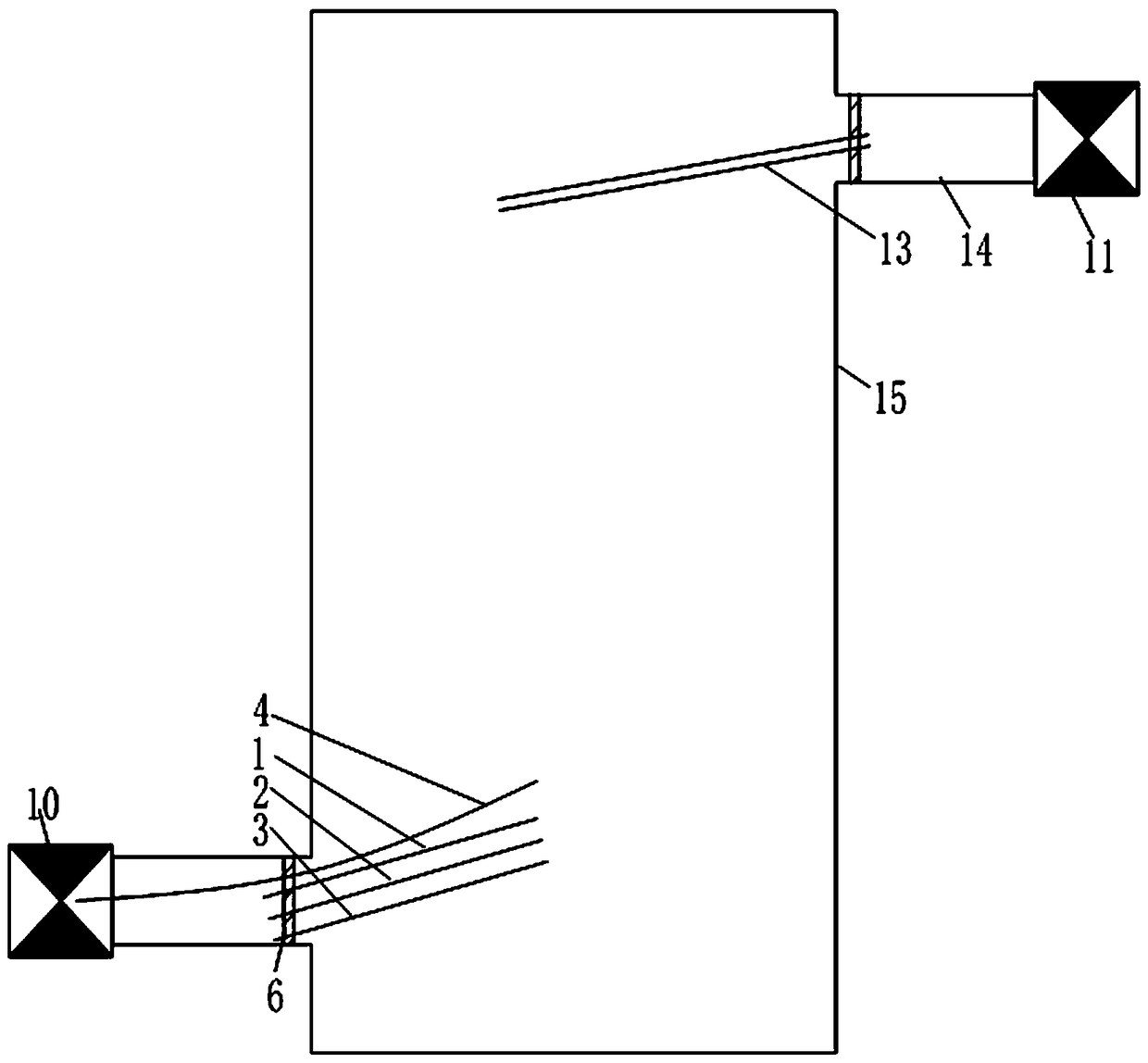

[0043] see Figures 1 to 2 Shown, a kind of top connection method of stope filling, described top connection method comprises the following steps:

[0044] (1) Effectively measure the roof and sides of the stope goaf;

[0045] (2) Use slag to fill normally to the predetermined position above the stope approach or contact road to obtain the filling body, and the remaining empty space is formed between the top surface of the filling body and the top of the stope empty area;

[0046] (3) Measure the height of the above remaining empty area to determine the highest point of the remaining empty area;

[0047] (4) Set the anchor rod at the highest point of the remaining empty space above, and install the outlet end of the filling pipe on the anchor rod;

[0048] (5) Separately install the first dehydration pipe to the highest point of the remain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com