Quantitative filling device for filing machine

A filling device and filling machine technology, applied in packaging, bottle filling, liquid bottling, etc., can solve problems such as high failure rate, changeable flow path bending, and slow filling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

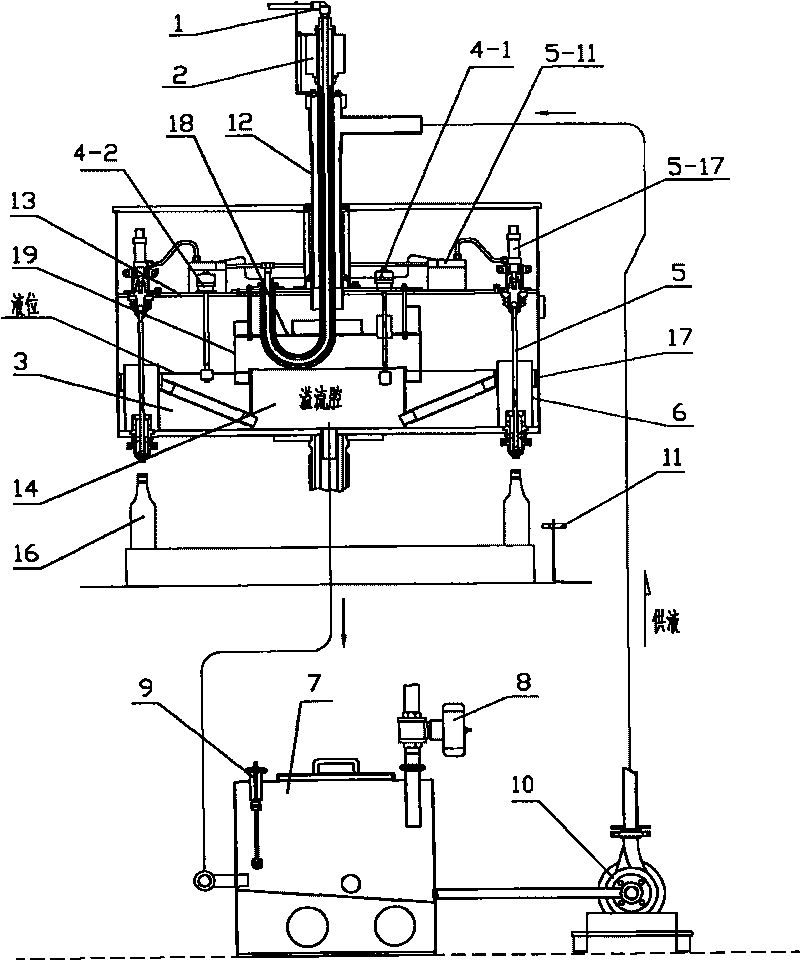

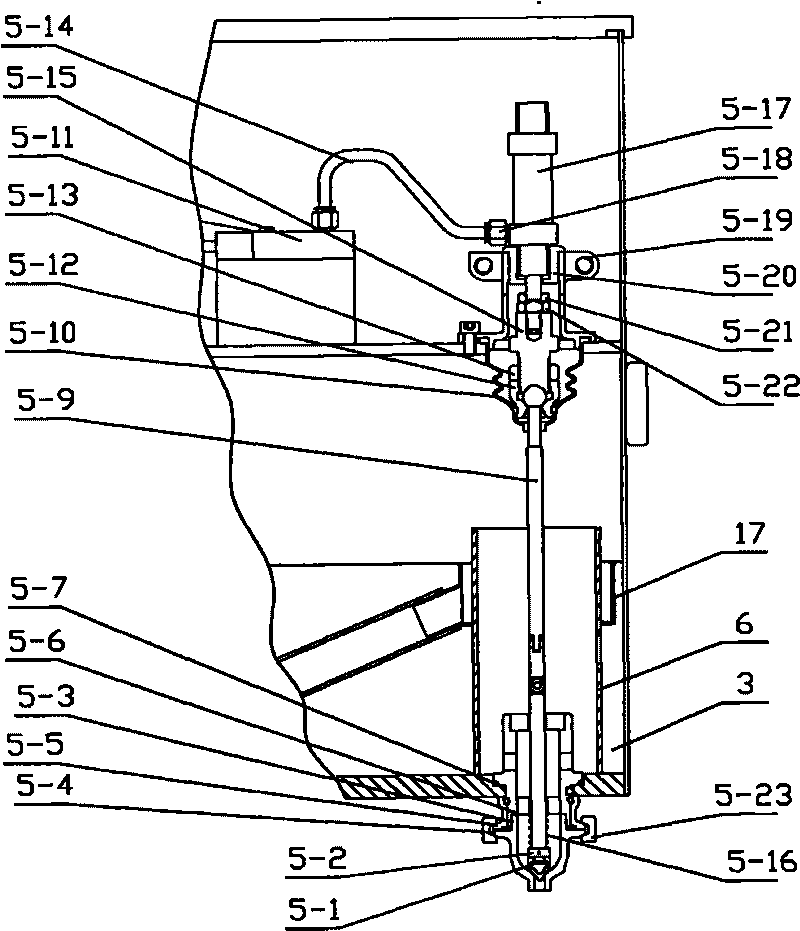

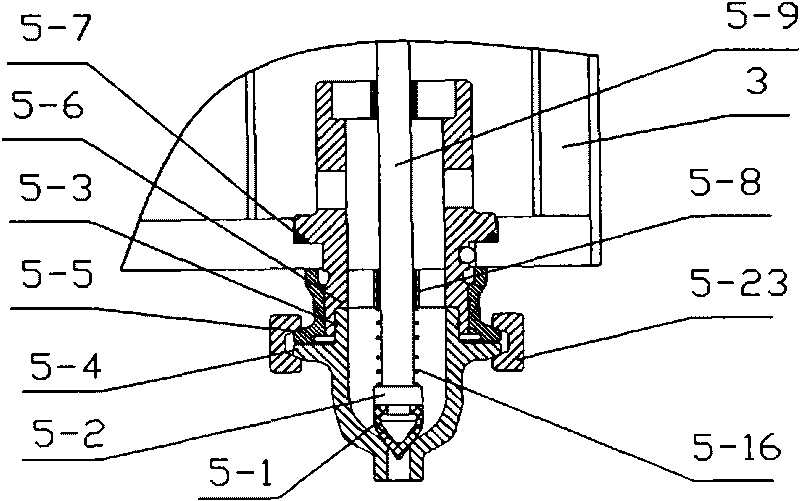

[0019] Referring to the accompanying drawings, the quantitative filling device used in the filling machine is to install a rotary liquid cylinder 3 on the top of the filling machine. The filling machine is equipped with a PLC controller (filling machine control system), and in the rotary liquid cylinder 3 A filling valve 5 is installed, and a liquid nozzle is installed at the lower part of the filling valve 5. A scanning sensor 11 is installed on the filling machine corresponding to the liquid nozzle, and the scanning sensor 11 is fixed behind the bottle-feeding wheel. Under the action of the bottle-feeding wheel, the bottle-feeding chain enters the turntable of the main machine, and when it rotates around the center of the main machine with the turntable, it passes through the front end of the scanning sensor, and the scanning sensor sends a signal to the PLC controller, and then the PLC sends an instruction to open the filling valve, filling starts. On one side of the fillin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com