Rotation indexing table for encapsulation and package of cylindrical cylinder

An indexing table and cylindrical technology, applied in packaging and other directions, can solve problems such as low degree of automation, low accuracy, and slow filling speed, and achieve the effects of reducing labor costs, improving production efficiency, and increasing filling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] specific implementation plan

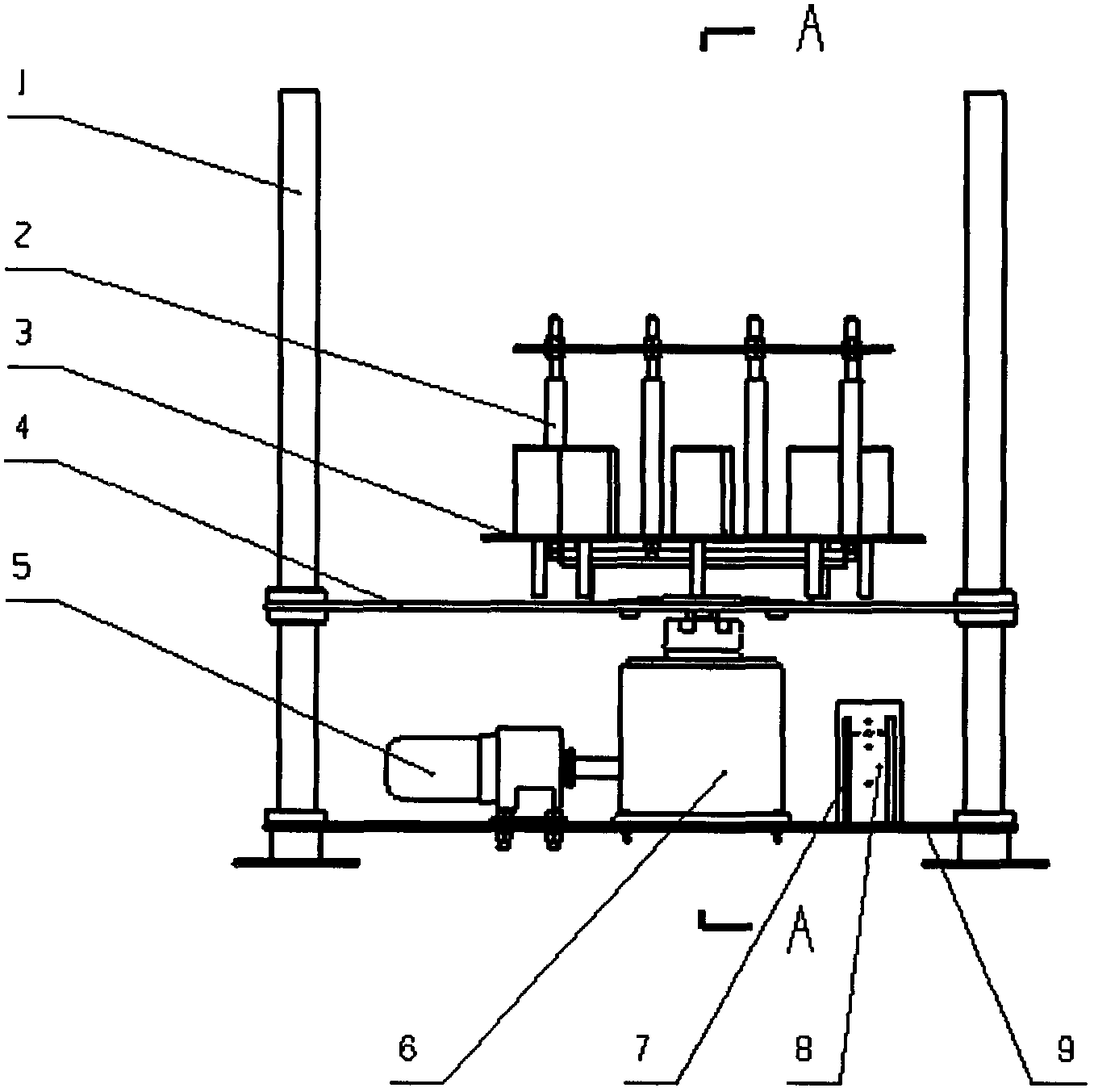

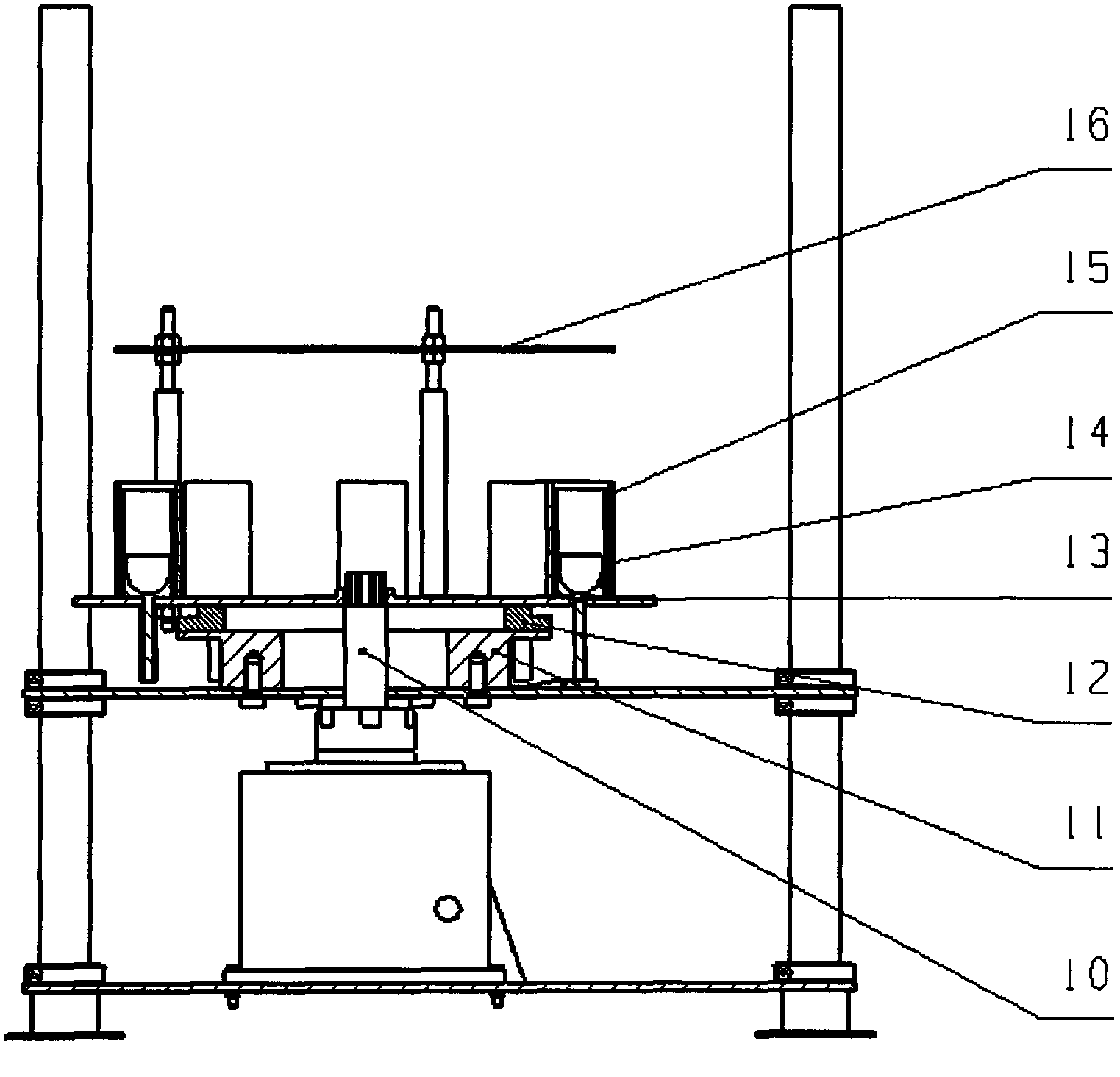

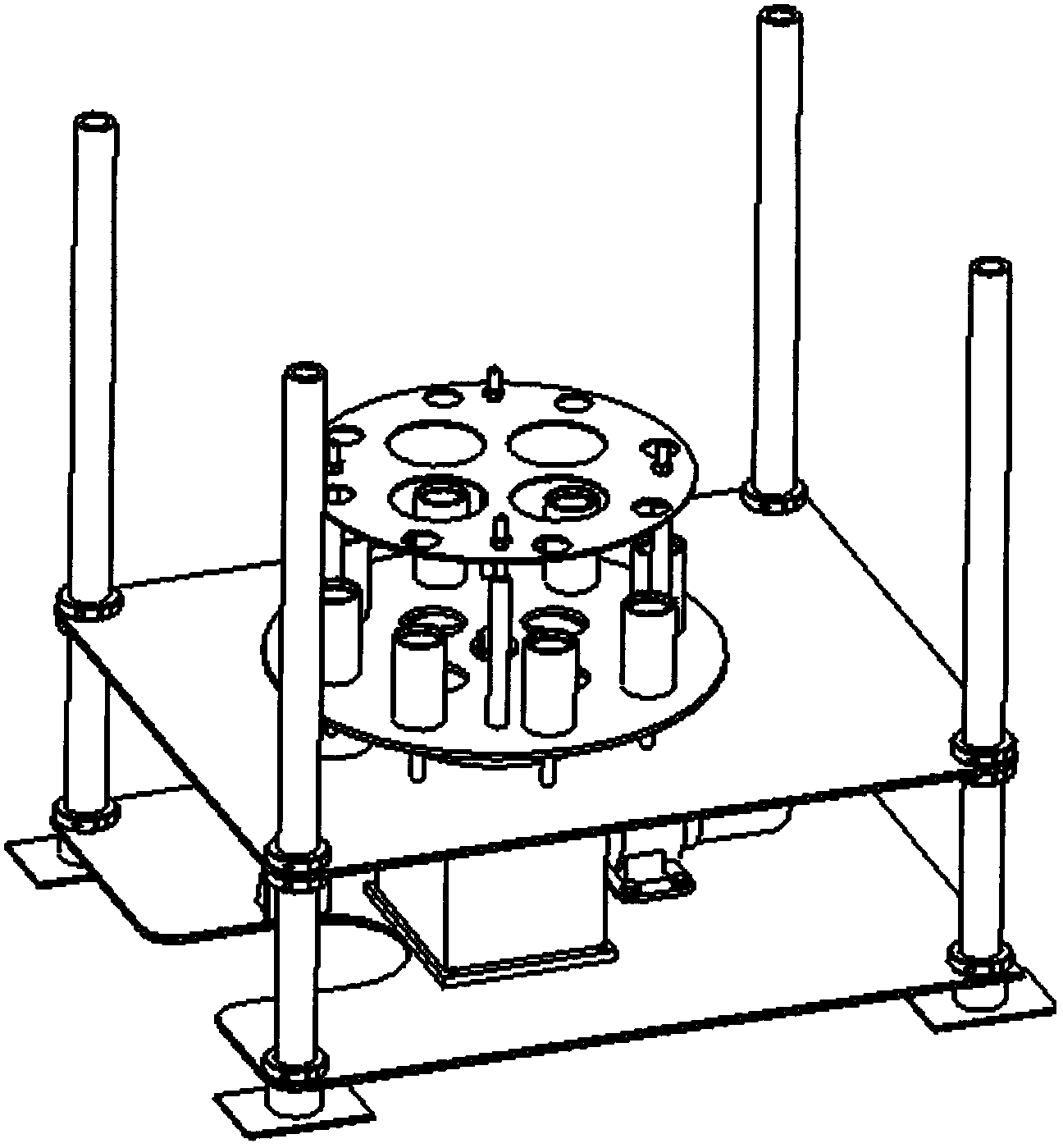

[0016] Such as figure 1 , figure 2 As shown, the rotary indexing table of the present invention is composed of important parts such as a column 1, a cylindrical cylinder support plate 3, a frame support plate 4, a motor 5, an indexer 6, a cylindrical cylinder guide sleeve 15, and a cylindrical cylinder guide plate 16. :.

[0017] The rotary indexing table is supported by 4 columns, and the cylindrical tube supporting plate 3 and the frame bottom plate 9 are used as supporting plates, wherein the positions of the cylindrical tube supporting plate 3 and the frame bottom plate 9 on the columns can be adjusted to suit Requirements for packing and capping devices for cylindrical barrels of different heights. The height of the column can be designed according to actual needs. Wherein, the distance between the cylindrical cylinder support plate 3 and the cylindrical cylinder guide plate 16 is also adjustable, so as to meet the guiding requir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com