Automatic equal-liquid-level filling machine

A filling machine, liquid level technology, applied in liquid bottling, packaging, bottle filling and other directions, can solve the problems of slow filling speed, large liquid material loss, long maintenance time, etc., to achieve fast filling speed, liquid material The effect of low loss and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

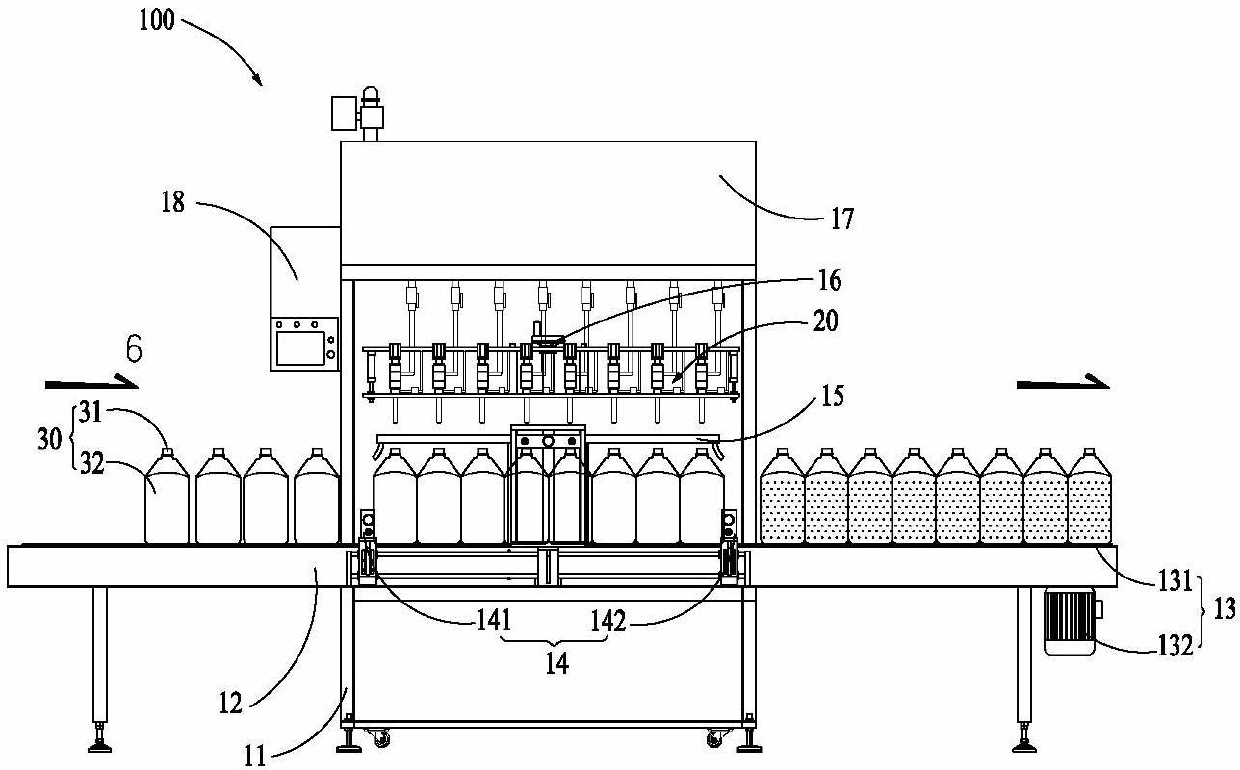

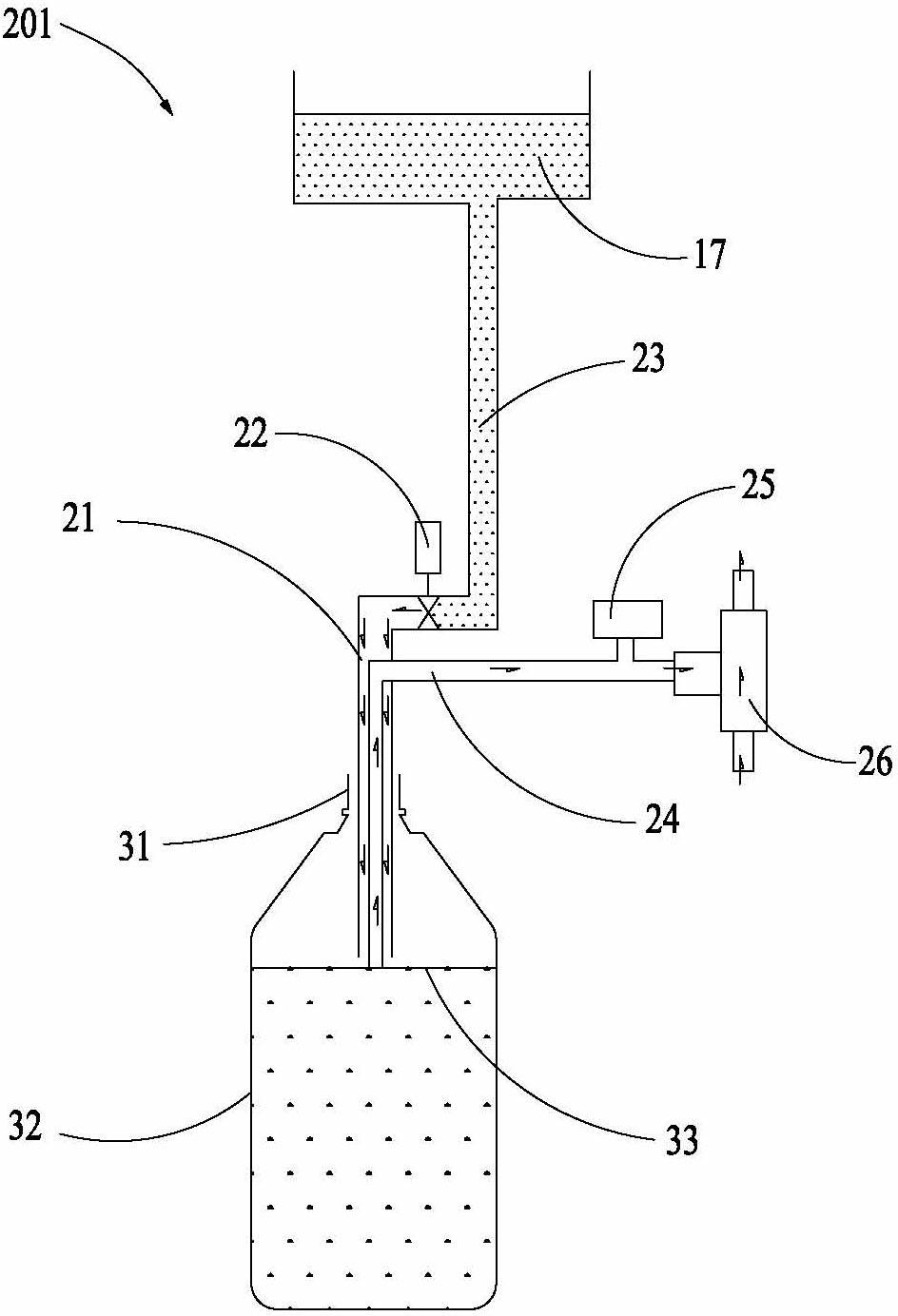

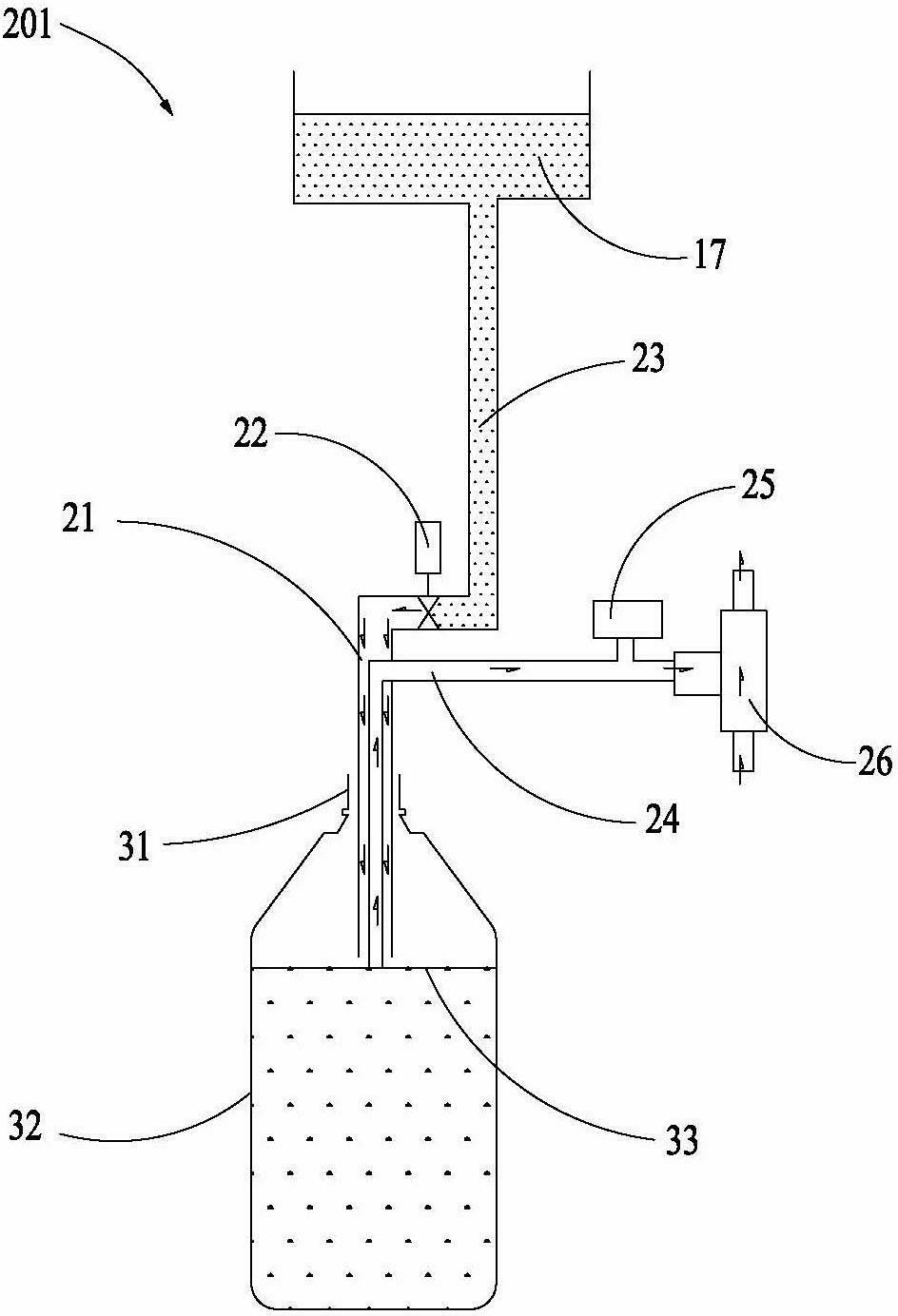

[0014] see figure 1 , the present invention discloses an automatic equal liquid level filling machine 100, which is used to realize equal liquid level filling, reduce liquid material loss, and has low energy consumption, including a machine base 11, a worktable 12, a transmission structure 13, and a drive structure 14 , receiving tank 15, lifting structure 16, material cylinder 17, control device 18, photoelectric sensor (not shown) and filling system 20.

[0015] The machine base 11 is used for fixed support, one end of which is in contact with the ground, and the other end is fixedly connected with the workbench 12 . The workbench 12 is arranged on the base 11 and kept parallel to the ground. It can be understood that the base 11 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com