Mono-coil self-unloading type two-component electromagnetic valve

A self-unloading, dual-component technology, applied in valve details, multi-port valves, valve devices, etc., can solve the problems of large weight and size, complex structure of dual-component fast response control valves, etc., and achieve lightweight products. The degree of improvement, the realization of quick response, the effect of improving the manufacturability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

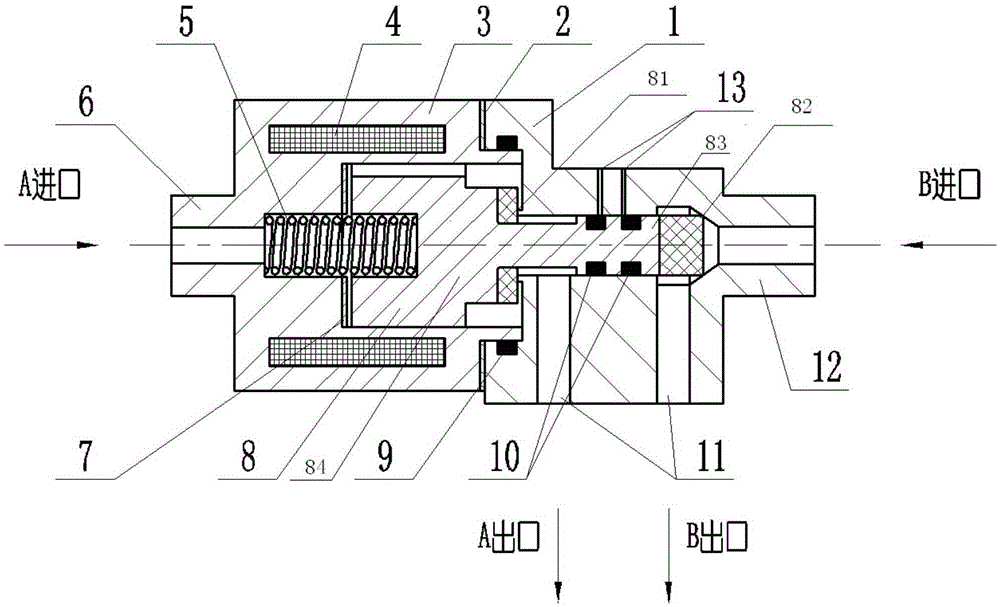

[0034] The following is attached figure 1 A preferred embodiment of the present invention will be described in detail.

[0035] Such as figure 1 As shown, the single-coil miniaturized self-unloading double-component solenoid valve structure of the present invention consists of valve body A3, adjusting gasket 2, valve body B1, coil 4, spring 5, disc spring 7, valve core 8 , Rubber seal 9, rubber O-ring 10, A medium inlet channel 6, B medium inlet channel 12 and so on. The A medium inlet passage is arranged on the valve body A3, and the B medium inlet passage is arranged on the valve body B1. A medium inlet channel and B medium inlet channel are respectively located at both ends of the valve core and are coaxial with the valve core; In body A3, the spool includes a sealing surface A81 and a sealing surface B82. The sealing surface B82 is set on the end surface of the front section of the spool. The sealing surface B82 and the valve body B1 are sealed by a conical surface. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com