Three dimensional manufacturing apparatus and method for manufacturing three dimensional manufactured product

a manufacturing apparatus and three-dimensional technology, applied in the direction of manufacturing tools, manufacturing enclosures, additive manufacturing processes, etc., can solve the problems of reducing the manufacturing speed, requiring a large driving force for the moving apparatus of the manufacturing stage, and reducing the viscosity of the light curing resin, so as to suppress the solidification, reduce the viscosity of the light, and increase the speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

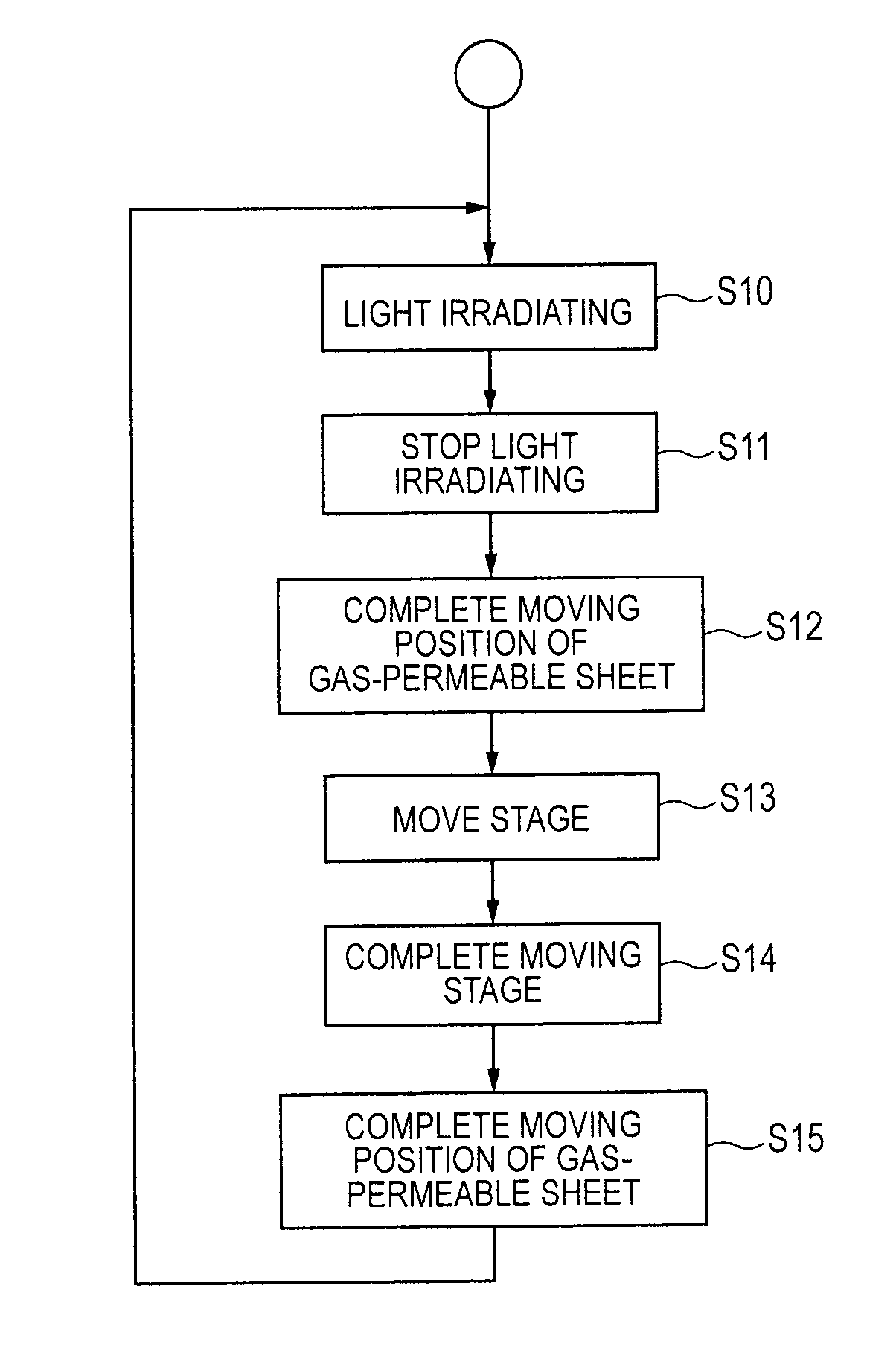

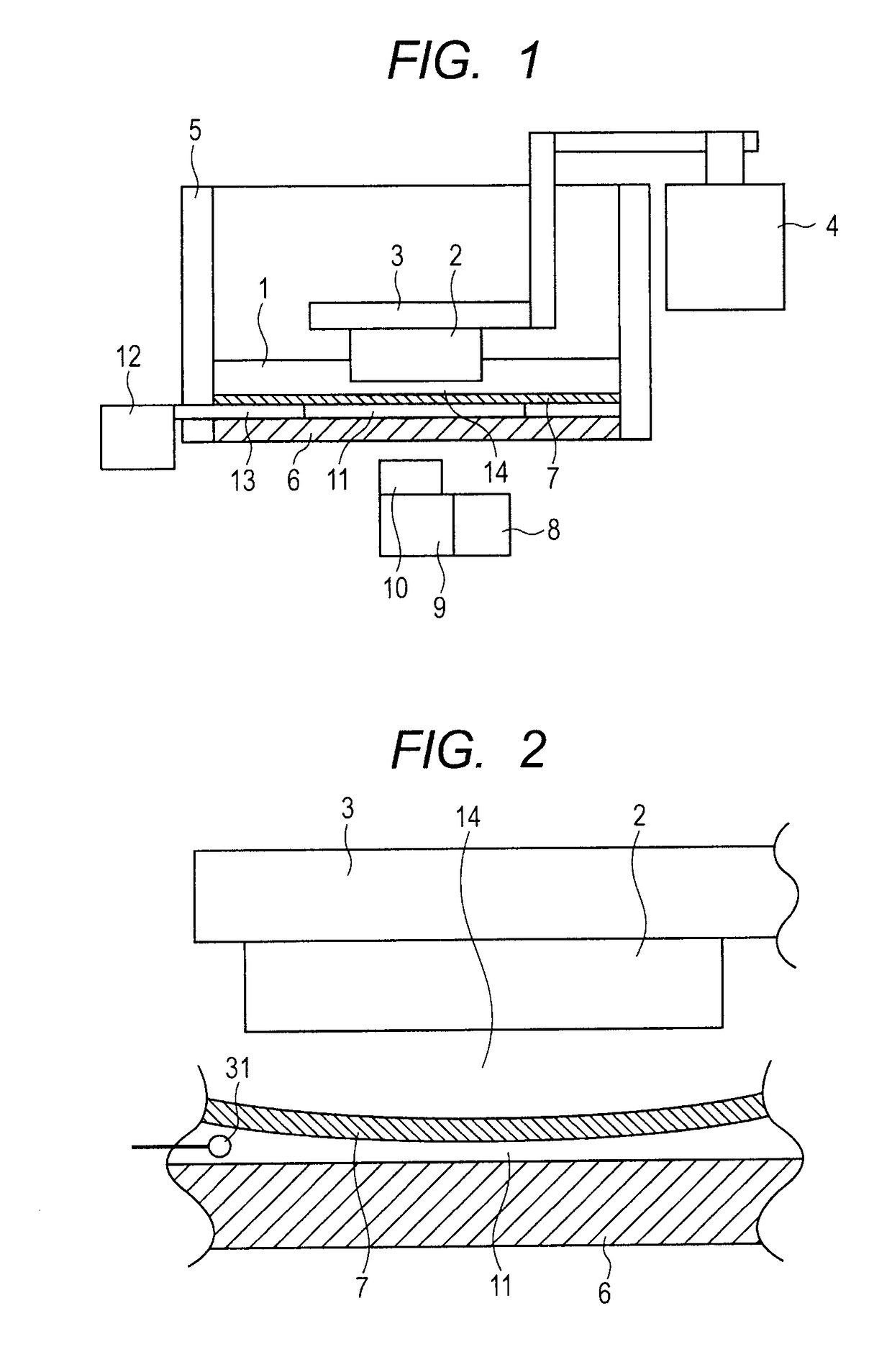

[0030]FIG. 1 illustrates a configuration of a three dimensional manufacturing apparatus for manufacturing a three dimensional manufactured product as a sectional structure, in embodiment 1. In FIG. 1, a light curing resin 1 in a molten (uncured) state is housed in a container 5. In the present description, a liquid light curing resin in a molten (uncured) state is described as a light curing resin.

[0031]As the light curing resin 1, a well-known light curing resin can be used. The light curing resin can include a monomer or an oligomer, a photopolymerization initiator, and various additives (a stabilizer, a filler, a pigment and the like). Further, both a monomer and an oligomer may be included. Monomers are organic materials that are polymerized into large molecules to form plastics. Oligomers are obtained by reacting some of monomers in advance and are materials that are polymerized into large molecules to form plastics similarly to monomers. A light polymerization initiator absorb...

embodiment 2

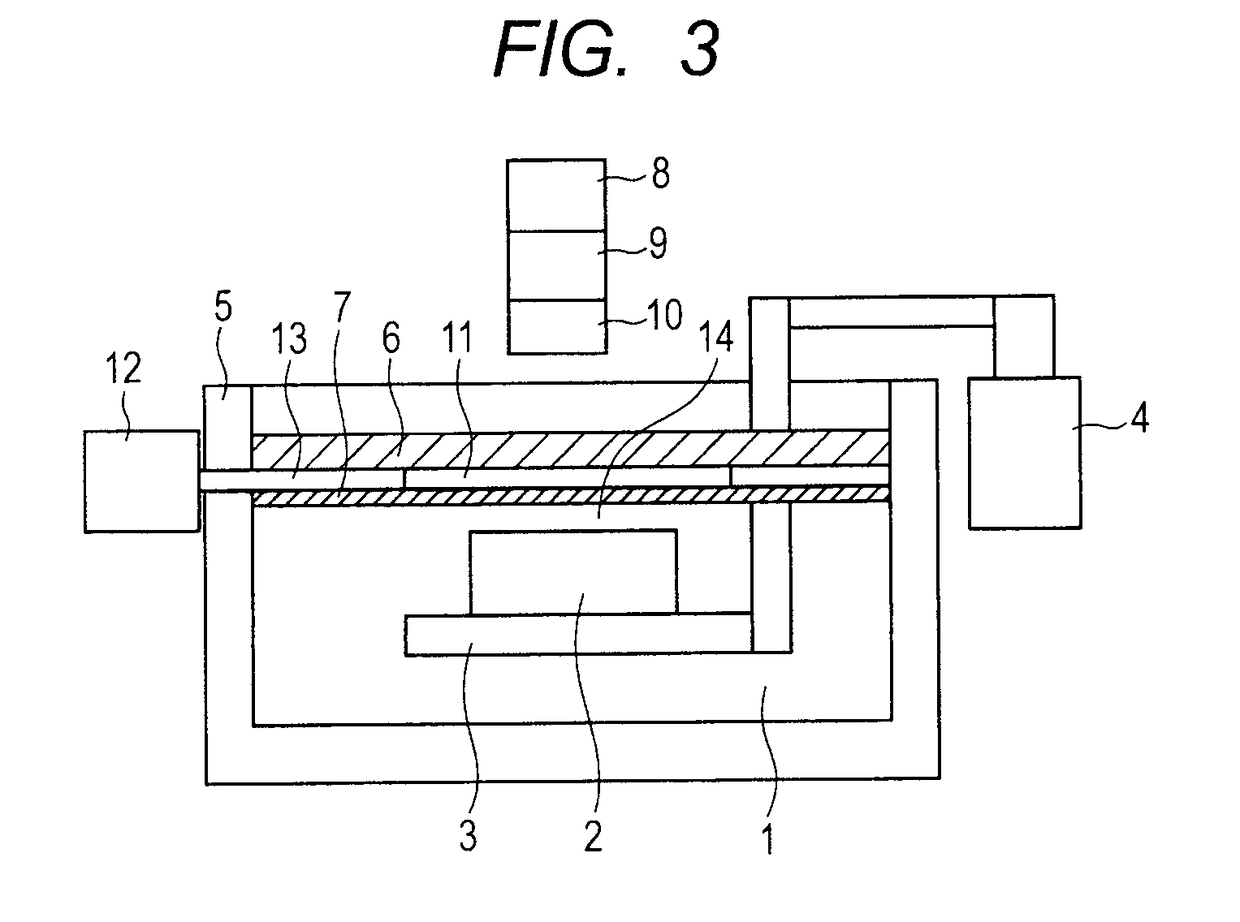

[0071]In embodiment 1, the configuration is illustrated, in which light irradiation for curing the light curing resin is performed from below the container 5, and the manufacturing stage 3 is moved upward by the lifting / lowering apparatus 4 for each layer formation as illustrated in FIG. 1, FIG. 2 and the like. However, the direction of light irradiation for curing the light curing resin 1, and the moving direction of the manufacturing stage 3 are not necessarily limited to the directions as described above.

[0072]For example, as illustrated in FIG. 3, in a configuration in which light irradiation for curing the light curing resin 1 is performed from above the container 5, and the manufacturing stage 3 is moved downward by the lifting / lowering apparatus 4 for each layer formation, a configuration is conceivable, in which an equivalent operation and effect to the operation and effect of embodiment 1 are exhibited.

[0073]A manufacturing apparatus illustrated in FIG. 3 includes respectiv...

embodiment 3

[0078]FIG. 6 is a view schematically illustrating a section of the apparatus to describe a structure of a three-dimensional manufacturing apparatus according to embodiment 3 of the present invention.

[0079](Configuration of Apparatus)

[0080]In FIG. 6, reference sign 201 designates a container, reference sign 202 designates a light curing resin, reference sign 203 designates a resin supplying unit, reference sign 204 designates a light transmitting portion, reference sign 205 designates a light shielding portion, reference sign 206 designates a hydrophilic surface portion, reference sign 207 designates a light source, reference sign 208 designates a mirror unit, reference sign 209 designates a lens unit, reference sign 210 designates a light source unit, reference sign 211 designates a base, reference sign 212 designates a lifting / lowering arm, reference sign 213 designates a lifting / lowering unit, and reference sign 214 designates a three dimensional manufactured product.

[0081]The con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| droplet diameter | aaaaa | aaaaa |

| droplet height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com