Forging method and forging device of twice forcing molten soup forging wheel

A secondary pressurization and molten soup forging technology, applied in the field of wheel forging, can solve the problems of poor continuity, long production time, labor-intensive, etc., and achieve fast forming speed, fast production cycle, and time-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

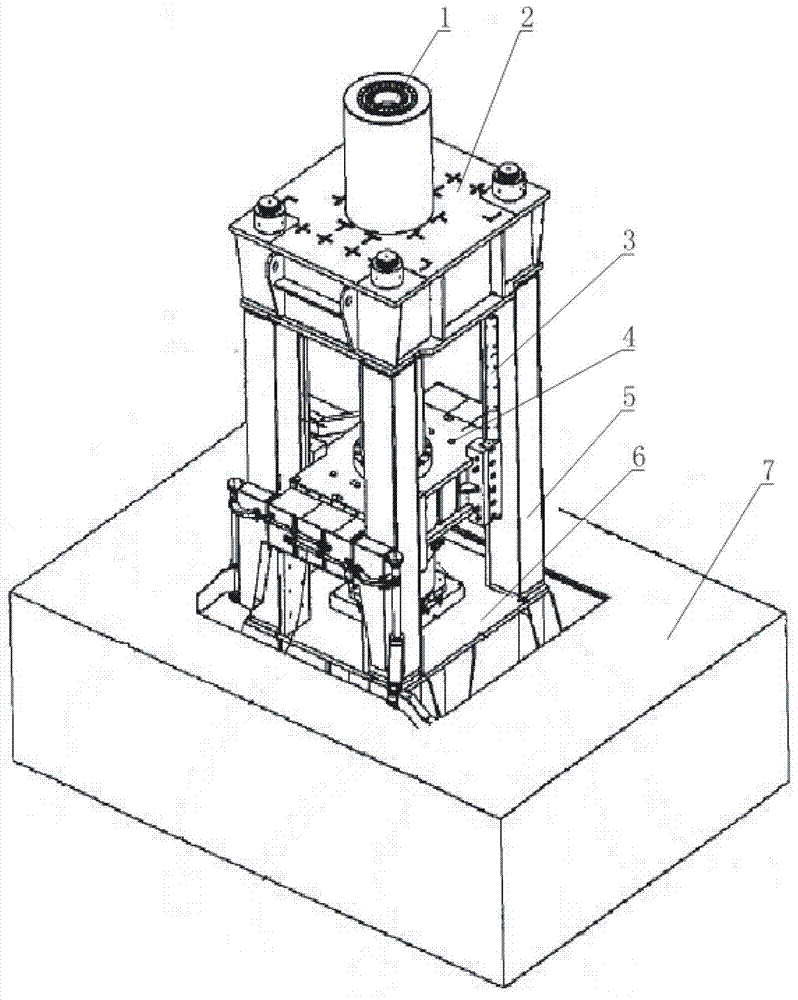

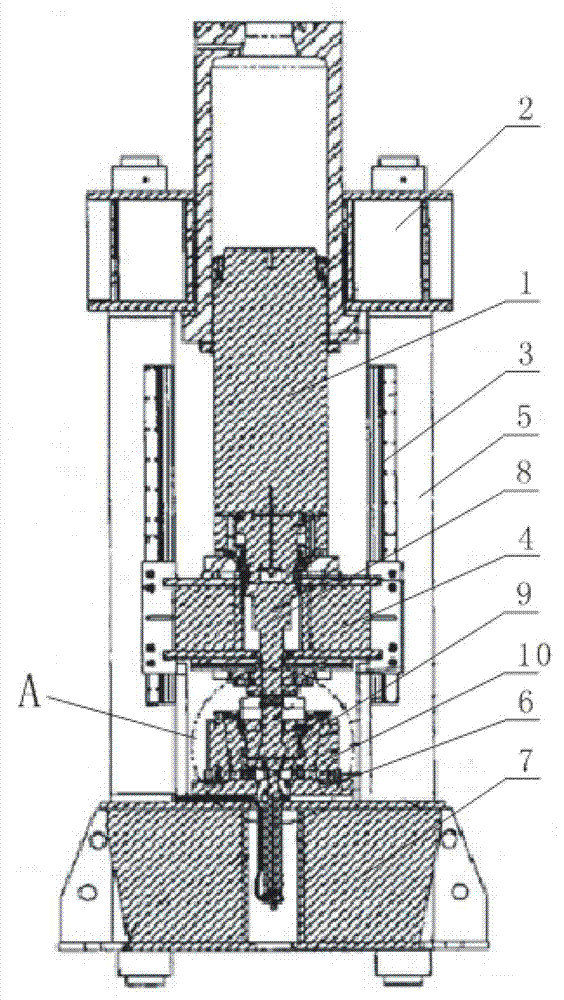

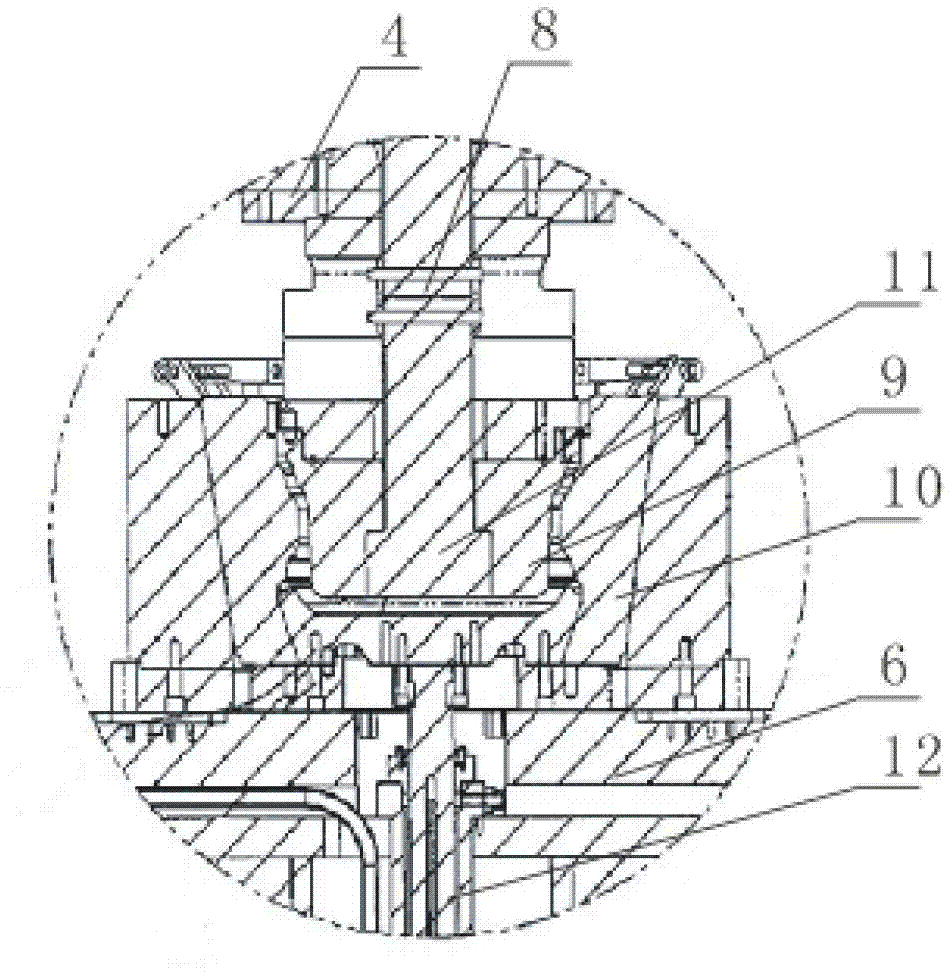

[0040] The present invention will be described in further detail below with reference to the drawings and specific embodiments. The following embodiments are only descriptive and not restrictive, and the protection scope of the present invention cannot be limited by this.

[0041] A forging method for forging wheels with a secondary pressurized molten soup, according to the following steps:

[0042] ⑴ Raw material smelting: the raw materials are smelted in a smelting furnace, and the raw materials are smelted to obtain the molten stock required for forging;

[0043] ⑵Heat preservation: the molten soup is stored in an open holding furnace, and the temperature is kept at 760℃;

[0044] ⑶ Molten soup degassing: Infinite internal circulation degassing equipment is installed in the lower part of the holding furnace to circulate the molten soup in the holding furnace;

[0045] The position of the smelting furnace and the holding furnace is set from high to low, and the melting, degassing and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com