Patents

Literature

34results about How to "Fast Mechanical Properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

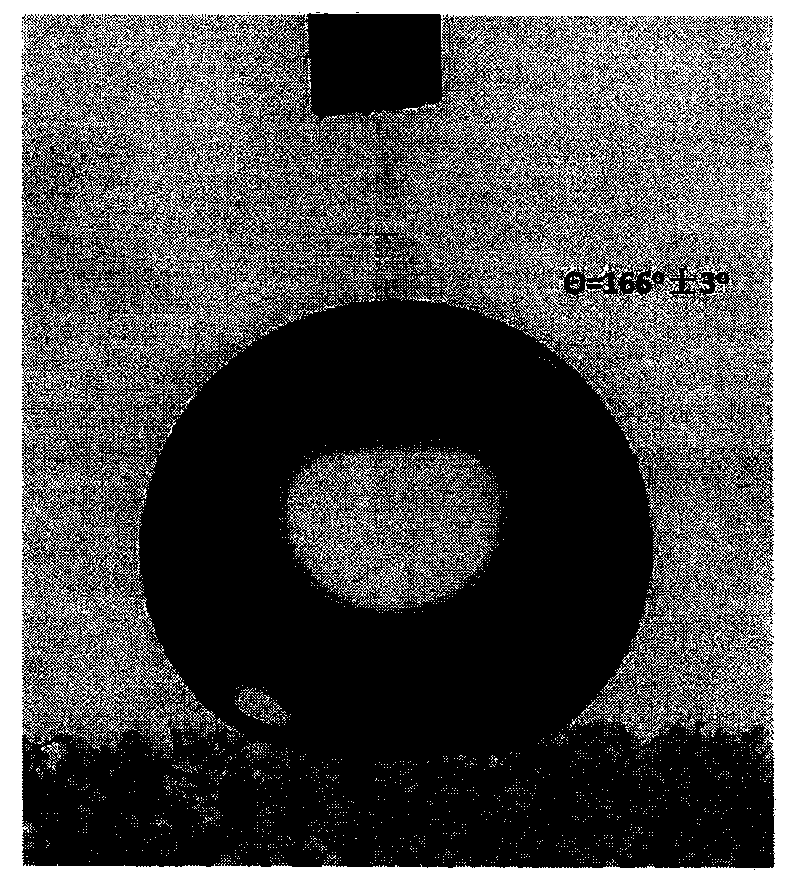

Preparation method of super-hydrophobic, super-oleophylic and ultralight sponge

ActiveCN104324524ASmall surface areaHigh oil absorption rateLiquid separationSurface energyOrganic chemicals

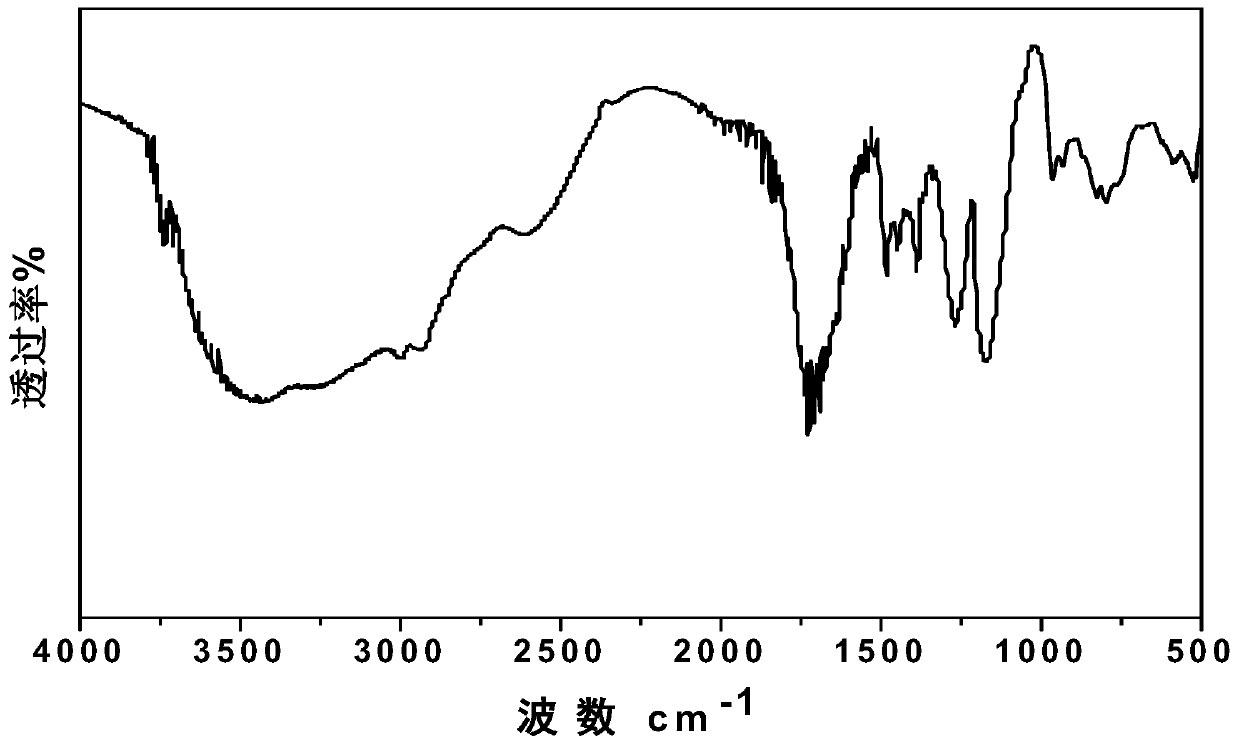

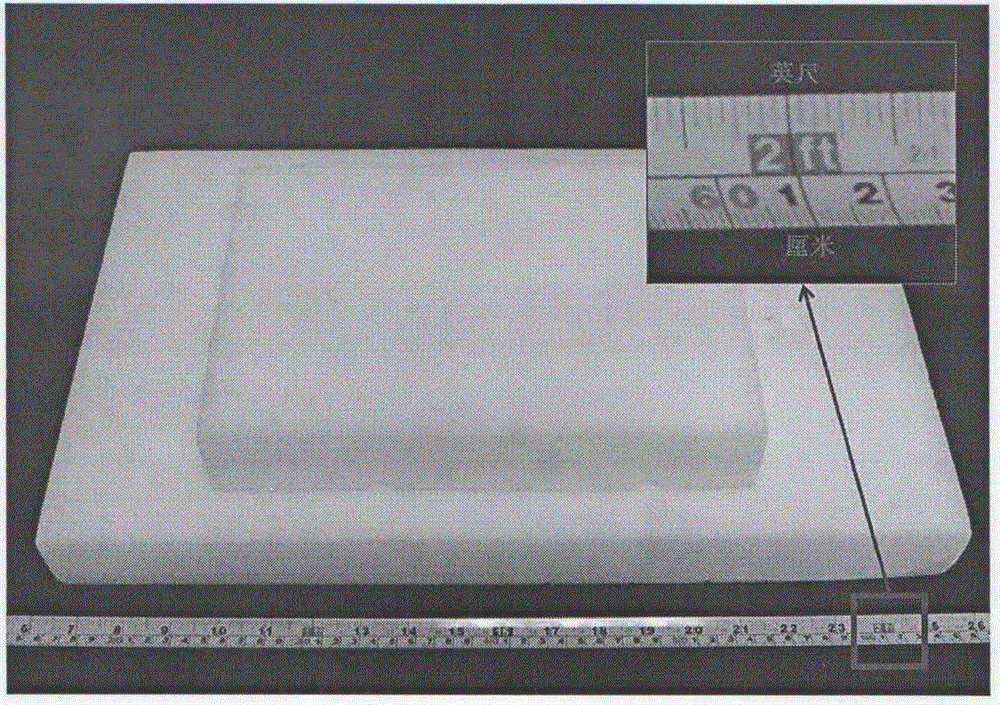

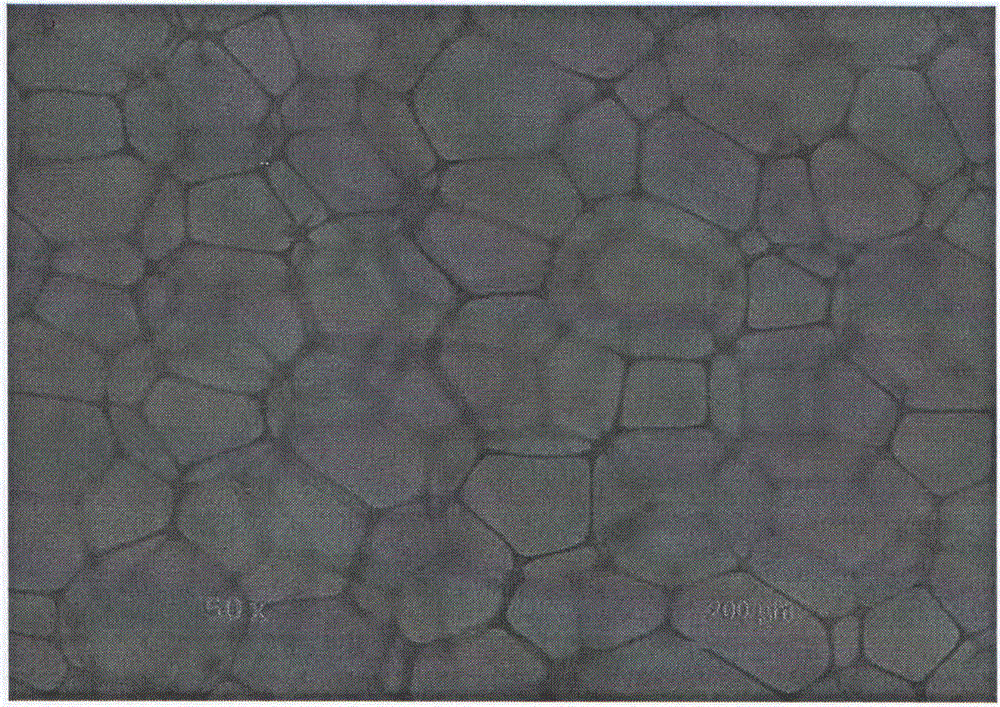

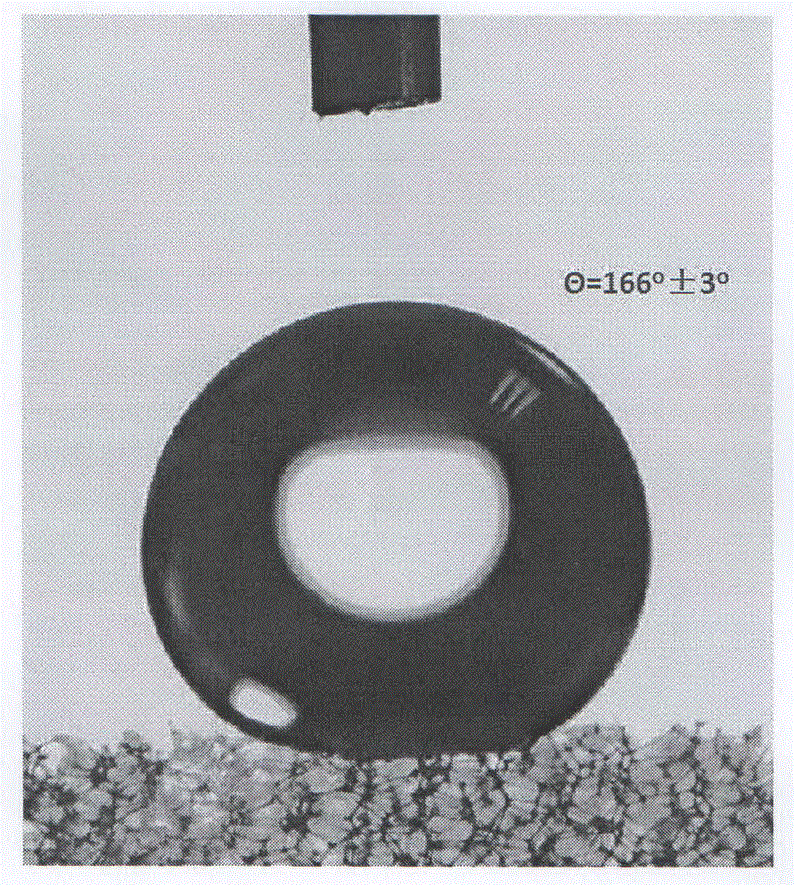

The invention relates to a preparation method of super-hydrophobic, super-oleophylic and ultralight sponge. The preparation method comprises two steps of performing functionalized processing on melamine sponge by using an impregnation method and performing a curing reaction after processing. The melamine sponge used by the invention has a large quantity of active functional groups such as hydroxyl groups and amino groups on the surface, the content of the hydrophobic active functional groups on the surface of the sponge is remarkably reduced after the active groups are chemically functionalized, which causes a result that the surface energy of the material is reduced, thus the sponge is endowed with super-hydrophobic and super-oleophylic effects, and a contact angle between the sponge and water exceeds 150 degrees; and the modified melamine sponge belongs to an ultralight material due to density. The method disclosed by the invention has the advantages that raw materials are low in price and easy to available, the process is simple and easy to operate, the large-scale preparation is easily realized, and the like. The sponge prepared according to the preparation method has the advantages of low density, excellent compression resistance, high oil absorbing speed, high oil absorbing rate, high oil and water separation selectivity and the like, is a novel and efficient ultralight-density oil and water separating material, and has a wide application prospect in the fields such as organic chemical reagent treatment, oil-containing wastewater treatment, and leaking crude oil recovery.

Owner:中科瑞丽分离科技无锡有限公司

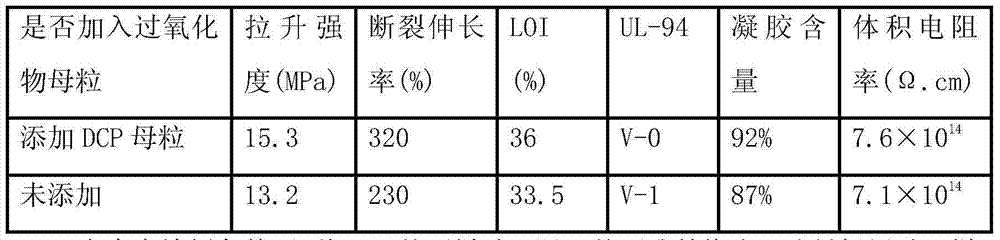

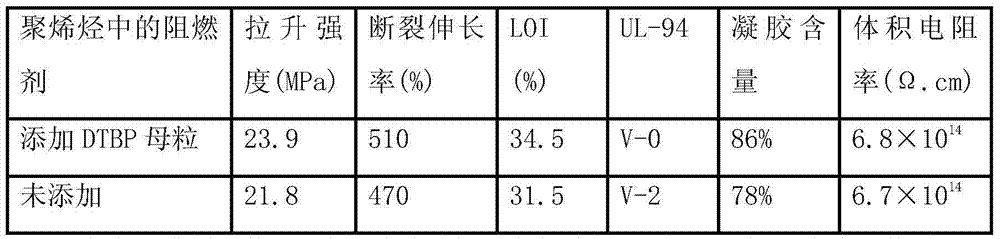

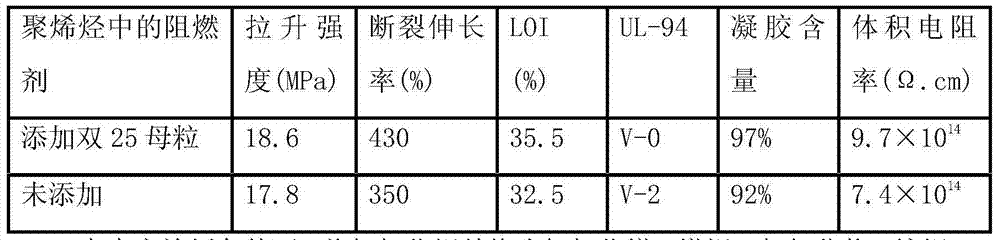

Peroxide pre-crosslinked low smoke zero halogen flame retarding irradiation crosslinking polyolefin composite and preparation method thereof

The invention discloses a peroxide pre-crosslinked low smoke zero halogen flame retarding irradiation crosslinking polyolefin composite and a preparation method thereof. The preparation method comprises steps of adding 0.5-5 parts of antiflaming synergist into 50-70 parts of polyolefin, mixing uniformly, then adding 30-50 parts of fire retardant, 0.5-5 parts of polyfunctional group cross-linking agent and 0.1-1 part of antioxygen, mixing uniformly, then extruding and pelletizing so as to obtain an irradiation crosslinking material, then uniformly mixing 100 parts of irradiation crosslinking material and 1-5 parts of peroxide master batch, extruding and wrapping on the electric lead core of an electric wire, finally, irradiating 60-180KGy dosage with high-power electron beam or cobalt source for crosslinking, wherein the components above are weighed in parts by weight. The low smoke zero halogen flame retarding irradiation crosslinking polyolefin composite prepared through peroxide pre-crosslinking has fast crosslinking speed, high productivity, low energy consumption, and good flame resistance, and also has excellent smoke suppression performance and better mechanical property.

Owner:合肥聚泰安全材料合伙企业(有限合伙)

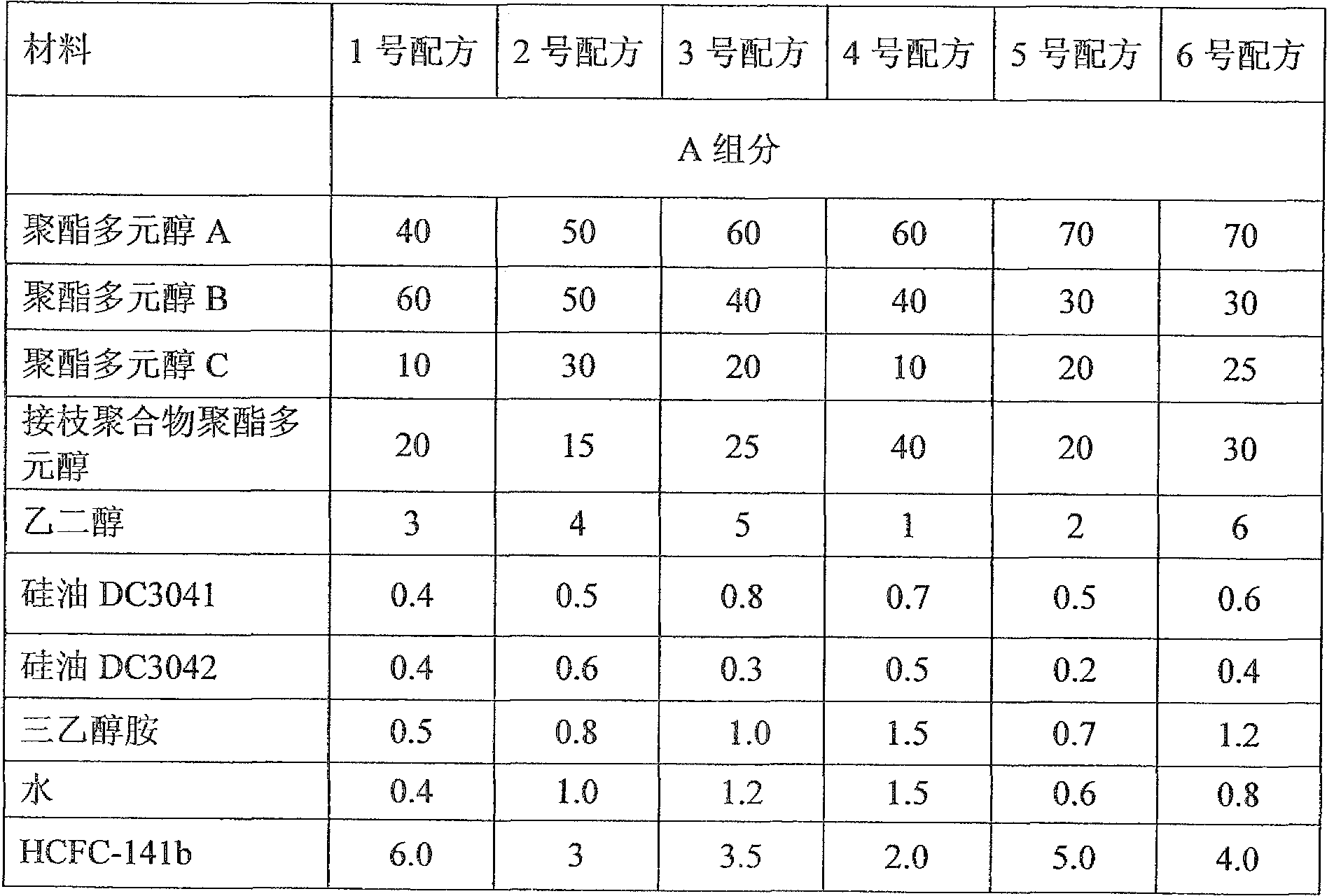

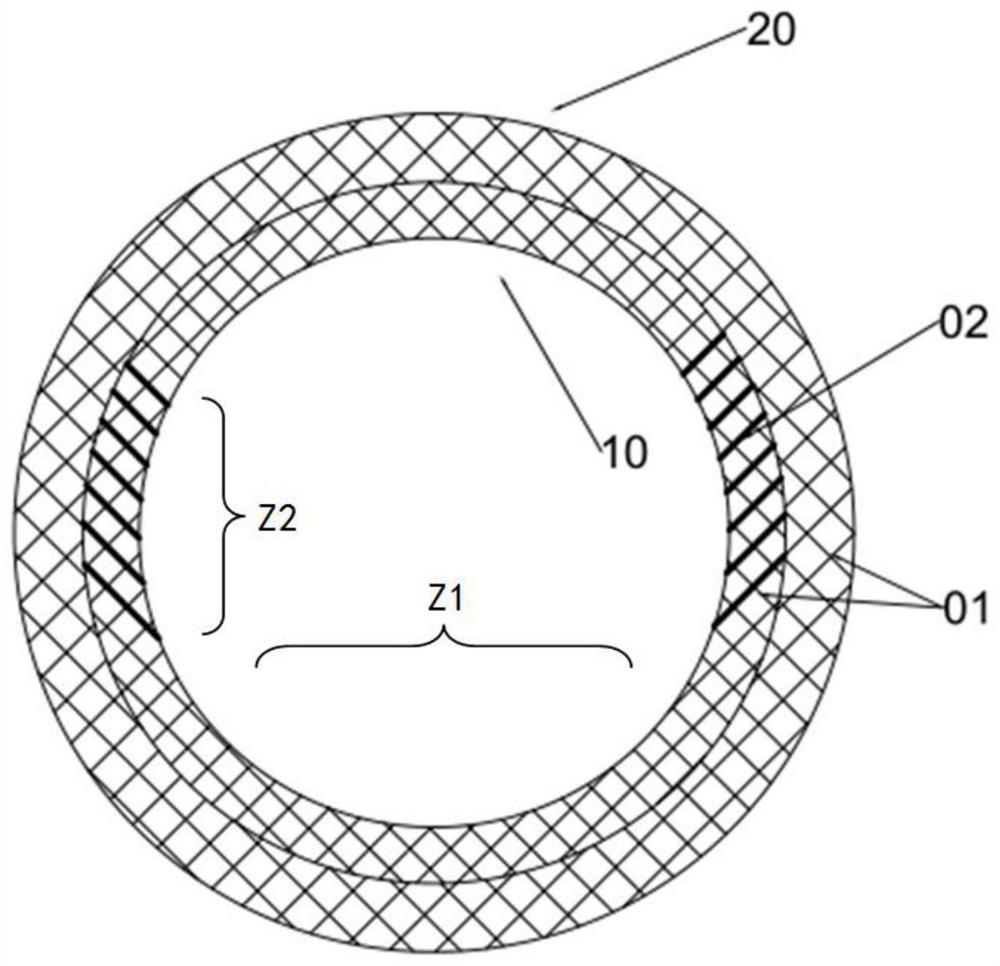

Polyester type ultra-low density polyurethane resin for shoes

The present invention is the recipe of three component polyurethane resin for insole. The polyurethane resin includes one component A of active hydrogen-containing mixture comprising long chain polyol polymer, chain expanding agent, cross-linking agent, surfactant, foaming agent and other assistants; one component B comprising polyester or polyether modified MDI pre-polymer; and one component C or catalyst component of glycol solution of triethylidene diamine. The polyurethane resin has density as low as 0.25-0.30 g / cu cm, capacity of making the product firm and good in appearance, and other advantages.

Owner:无锡双象新材料有限公司

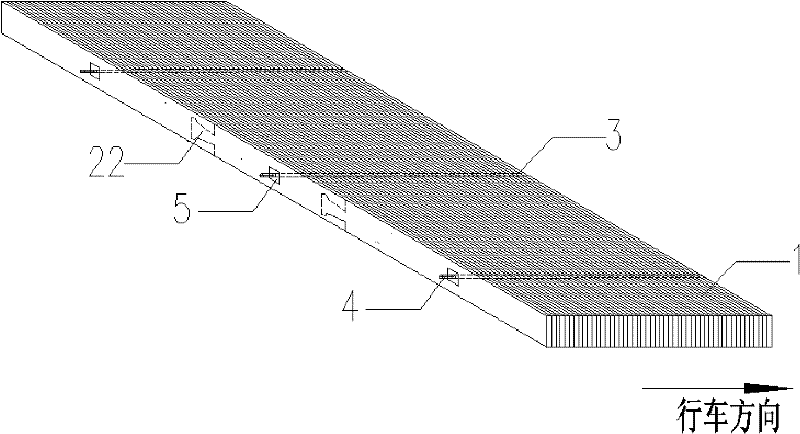

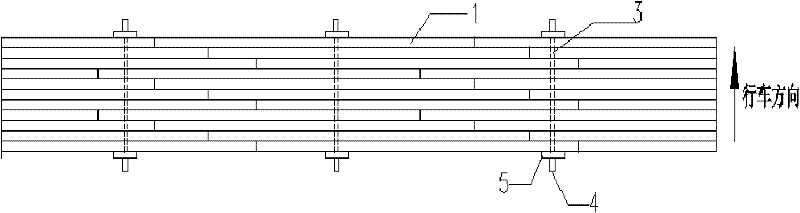

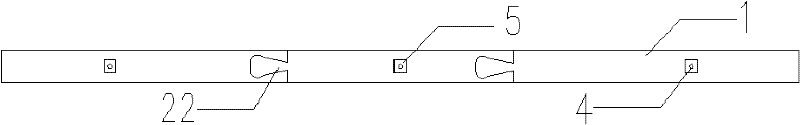

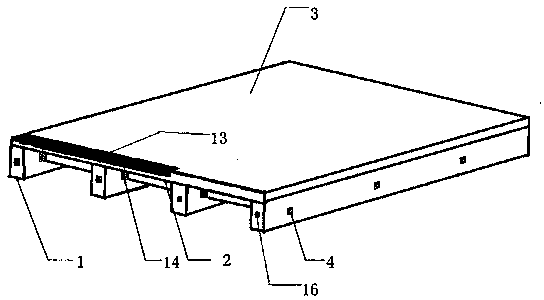

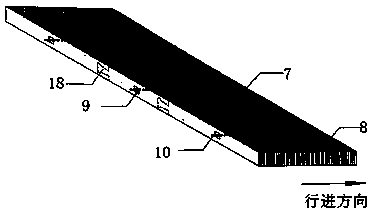

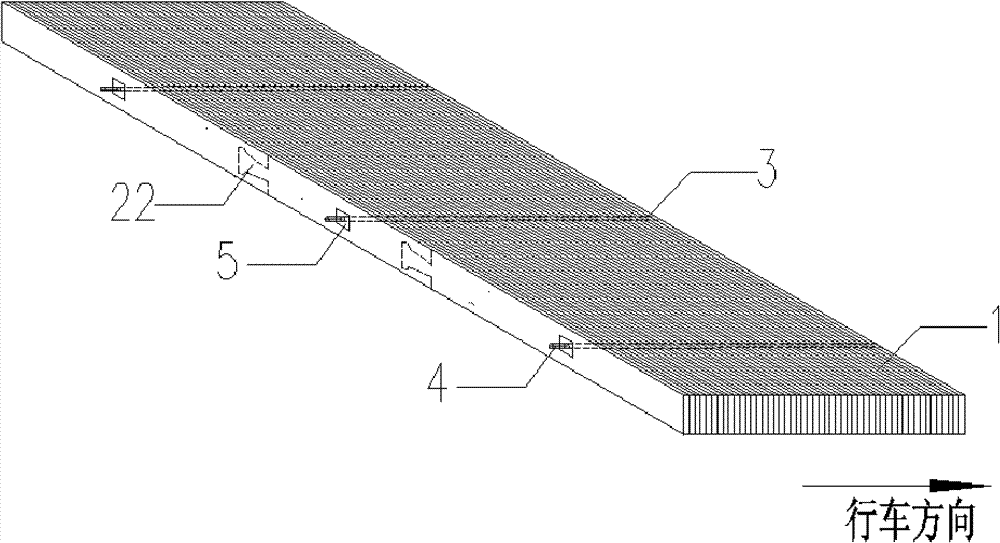

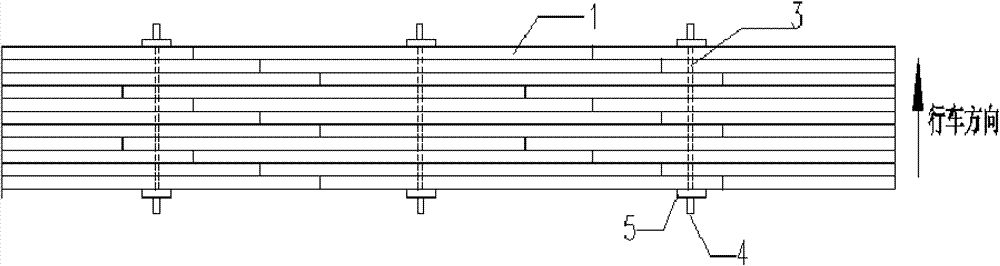

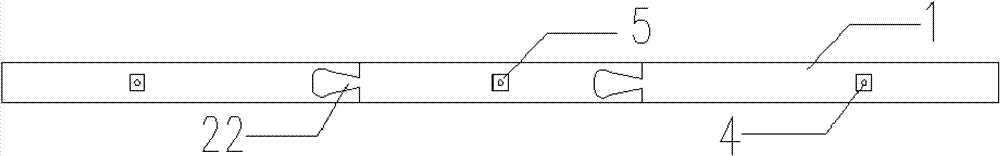

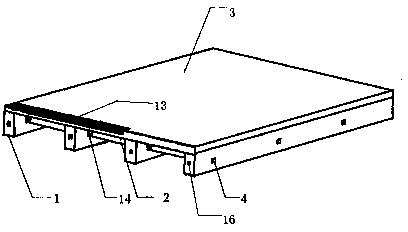

Bamboo bridge deck

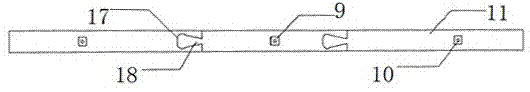

InactiveCN102561180AReduce the degree of prestress lossImprove connection strengthBridge structural detailsPre stressSingle plate

The invention discloses a bamboo bridge deck, which comprises prestressed ribs and a plurality of superposed bridge deck sheets, wherein the prestressed ribs penetrate through the bridge deck sheets; two ends of the prestressed ribs penetrate through shim plates and are fixed and tightened by using anchorage devices to constrain the bridge deck sheets; and each bridge deck sheet is formed by sequentially joggling a plurality of single bridge decks made of bamboo veneers end to end, and the joggled parts of the two adjacent bridge deck sheets are staggered. The required width of the bridge deck is achieved in the transverse direction by the method for sequentially joggling the single bridge decks end to end in the cross section width of a bridge. The basic single decks of the bamboo bridge deck can be conveniently prefabricated in a factory and assembled on site to form the bamboo bridge deck; the construction process is simple and fast, and the construction materials are environment-friendly and are easily reclaimed; and the bamboo bridge deck is suitable for a combined structural bridge, and is a bridge deck capable of meeting the using functions and the durability.

Owner:SOUTHEAST UNIV

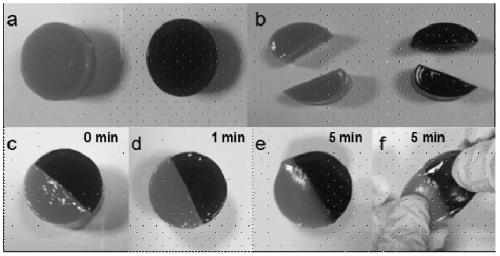

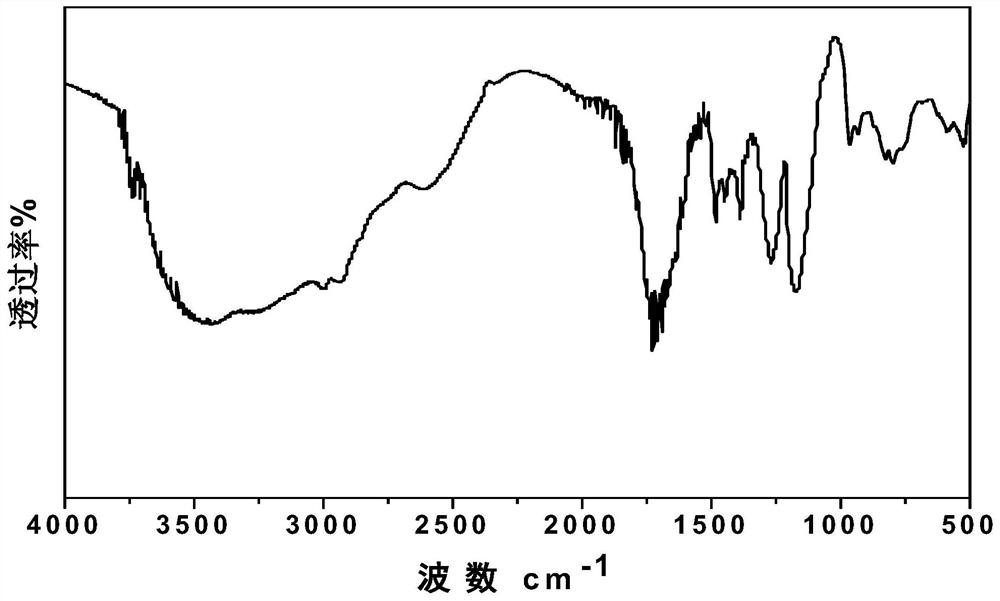

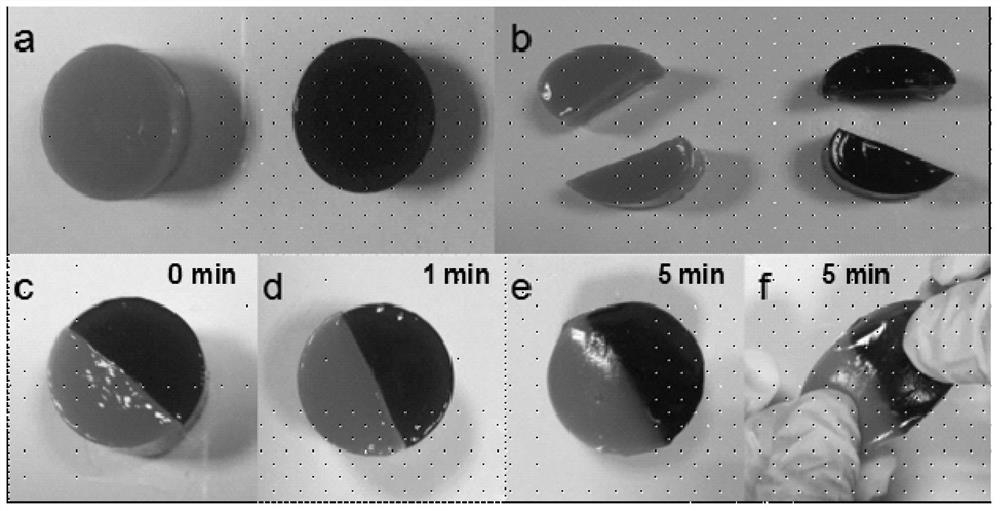

Preparation and application of high strength anti-tear magnetic hydrogel

InactiveCN105175970AGood mechanical propertiesFast mechanical propertiesCatheterOrganic/organic-metallic materials magnetismMechanical propertyPolyacrylamide Hydrogel

The invention relates to preparation and application of high strength anti-tear magnetic hydrogel. The preparation is as below: dissolving acrylamide monomer and a sodium alginate powder in a sodium alginate@Fe3O4 magnetic fluid, adding a crosslinking agent and an initiator to obtain a polyacrylamide hydrogel penetrated by a sodium alginate@Fe3O4 polymer chain and a free sodium alginate polymer chain; immersing the obtained hydrogel in an aqueous solution containing Mn<+> multivalent cations to diffuse Mn<+> into the hydrogel, crosslinking the sodium alginate@Fe3O4 and free sodium alginate polymer chain by electrostatic interaction to obtain the Fe3O4@(M-sodium alginate / polyacrylamide)magnetic hydrogel, which has high mechanical properties (tensile strength up to 1.0MPa, the maximum elongation at break of up to 11 times, compressive strength of up to 5.0MPa, and the maximum energy to break up to 2800J / m<2>), and is insensitive to the crack (the maximum elongation at break of the sample containing cracks up to 9 times). The high strength anti-tear magnetic hydrogel can be applied to magnetic medical catheters.

Owner:XI AN JIAOTONG UNIV

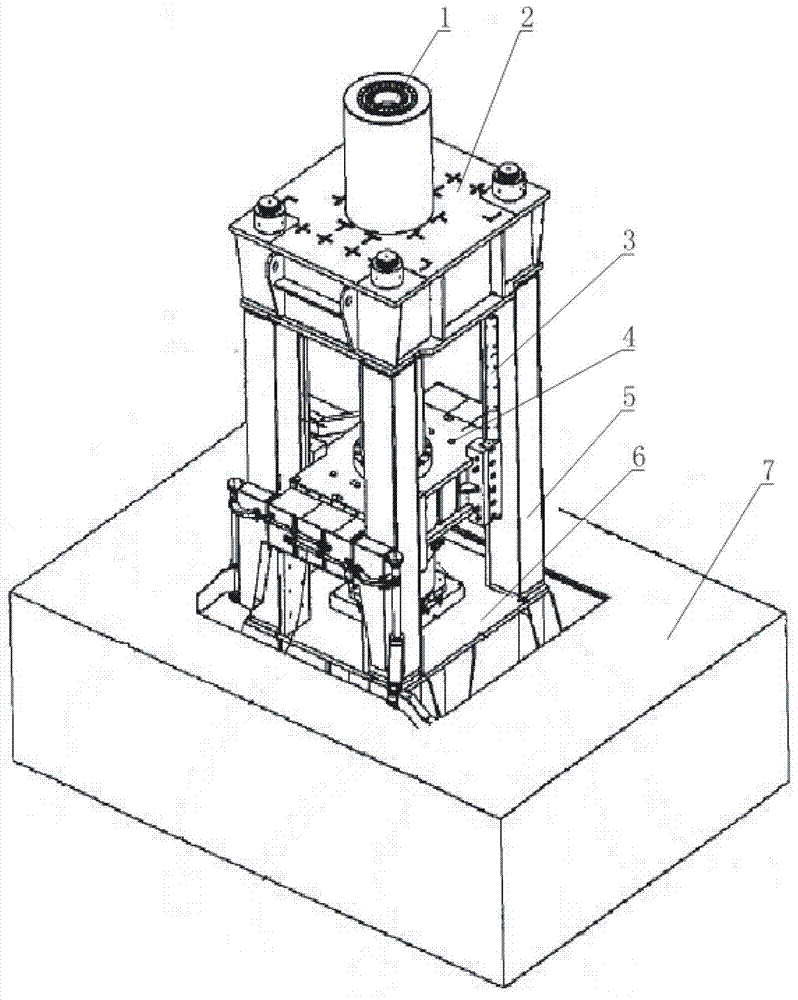

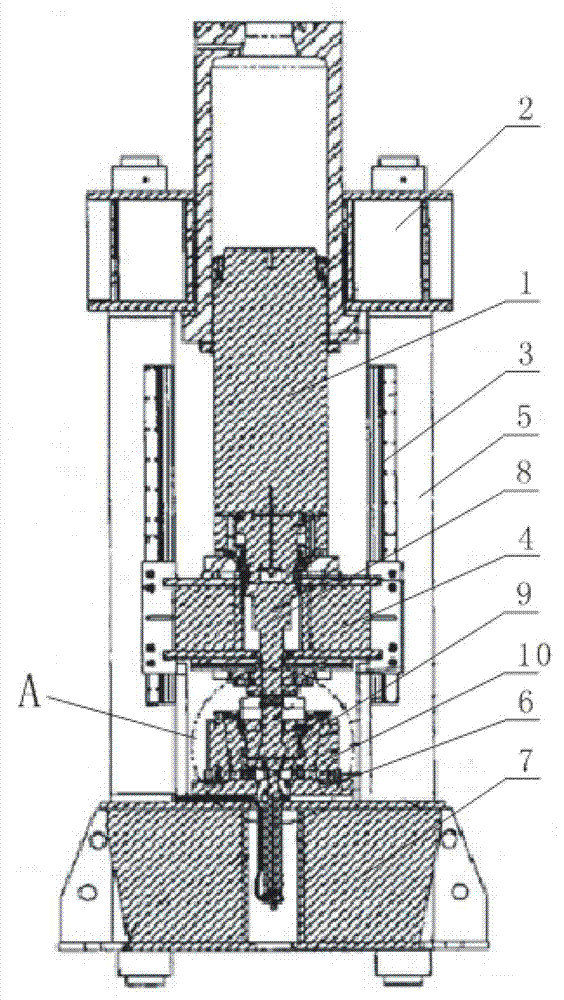

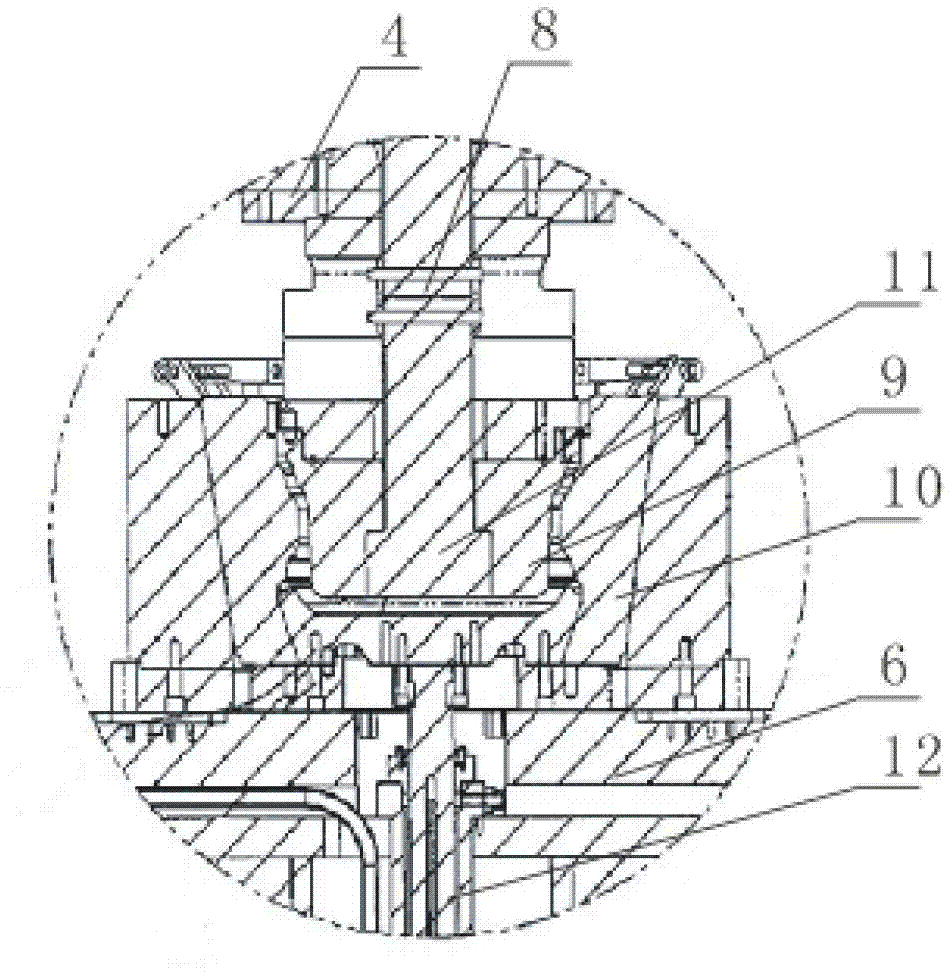

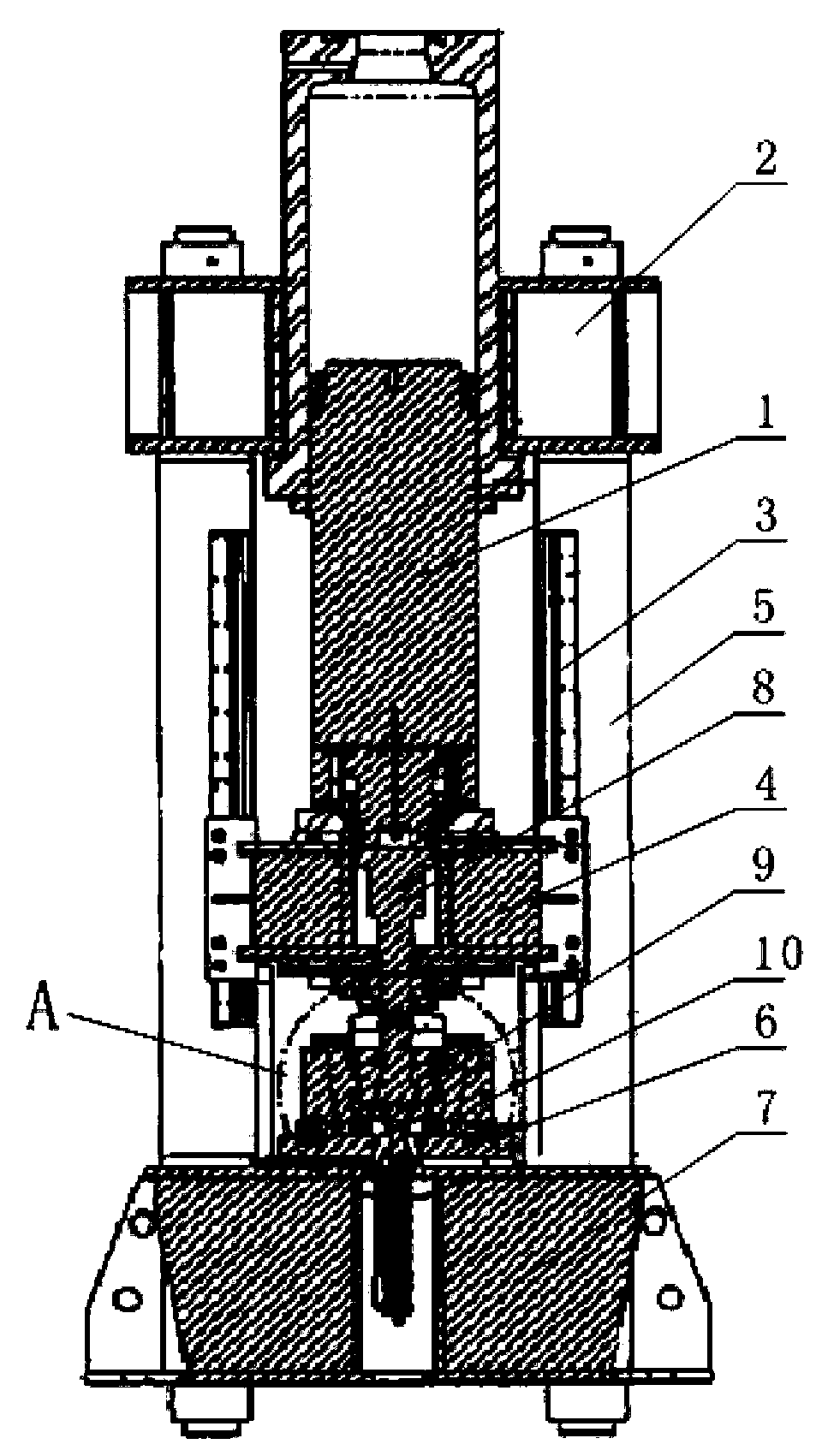

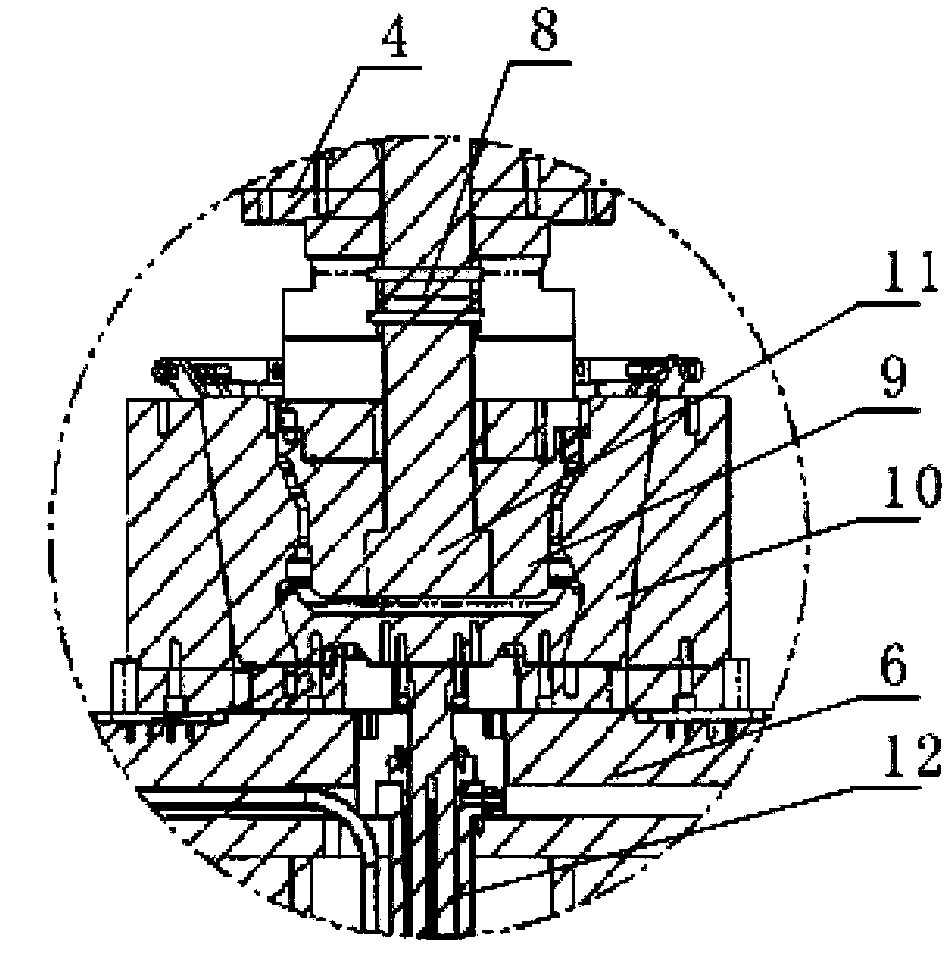

Forging method and forging device of twice forcing molten soup forging wheel

ActiveCN103084559AAvoid damageMeet mechanical performance requirementsRefined grainsMechanical property

The invention relates to a forging method and a forging device of a twice forcing molten forging wheel. The forging method of the twice forcing molten forging wheel is conducted circularly by the following steps: (1) materials smelting; (2) heat preservation deposit; (3) molten soup degassing; (4) the molten soup being injected into a lower die; (5) main piston forcing and pressure maintaining; (6) auxiliary piston forcing and pressure maintaining; (7) die sinking; (8) product transfer and deposit; (9) die cooling. Product quality is improved and molten soup dosage is reduced, and twice forcing is conducted to further improve inner structure refined grain of metals, and therefore the forging method and the forging device of the twice forcing molten forging wheel has the advantages of improving product mechanical property, tensile property and other overall properties, shortening product production time, increasing output, improving production efficiency and ex-factory percent of pass of products.

Owner:TIANJIN NANUO MACHINERY MFG

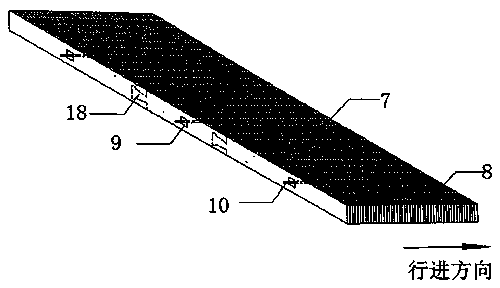

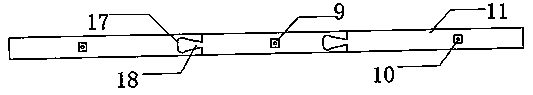

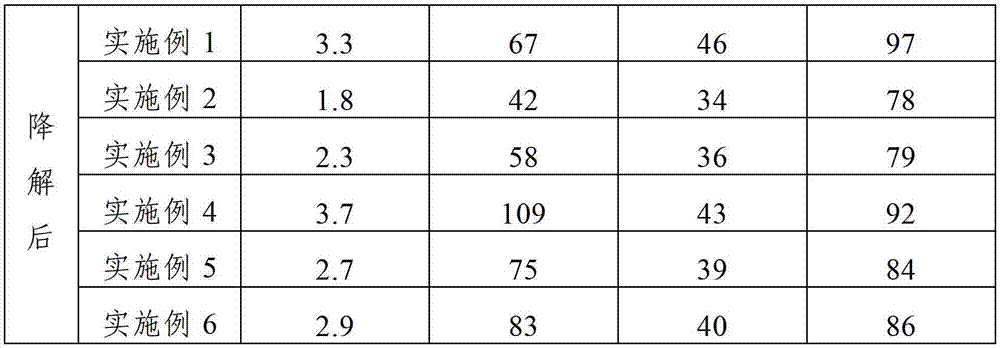

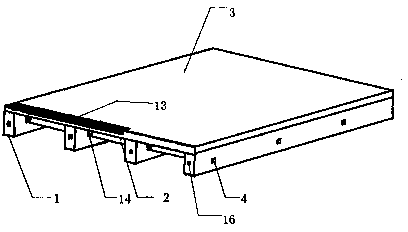

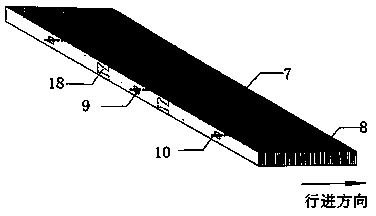

Assembly type bamboo bridge with variable expansion coefficients

ActiveCN103452035AHigh tensile strengthNo possibility of crackingSynthetic resin layered productsBridge structural detailsPolymer sciencePolymer chemistry

The invention provides an assembly type bamboo bridge. The assembly type bamboo bridge comprises bamboo longitudinal beams (1), bamboo transverse beams (2), bamboo panels (3), transverse pre-stressing tendons (4) and longitudinal pre-stressing tendons (16), the outer surface of a bamboo is sequentially and uniformly coated with a layer of waterborne polyurethane resin, a layer of polyurethane resin, a layer of waterborne polyurethane resin and a layer of resorcinol formaldehyde resin, and the expansion coefficients of the four coating layers are sequentially lessened from the outer surface of the bamboo to outside. The assembly type bamboo bridge provided by the invention has the advantages that the structural strength is large, the ductility is good, a selected material is environment-friendly, standardization degree and assembling degree of structural members are high, the structural integrity is good, the advantages of the material can be fully expressed, and the requirements on normal use and durability of a bridge structure can be met.

Owner:HAIMEN THE YELLOW SEA ENTREPRENEURSHIP PARK SERVICE CO LTD

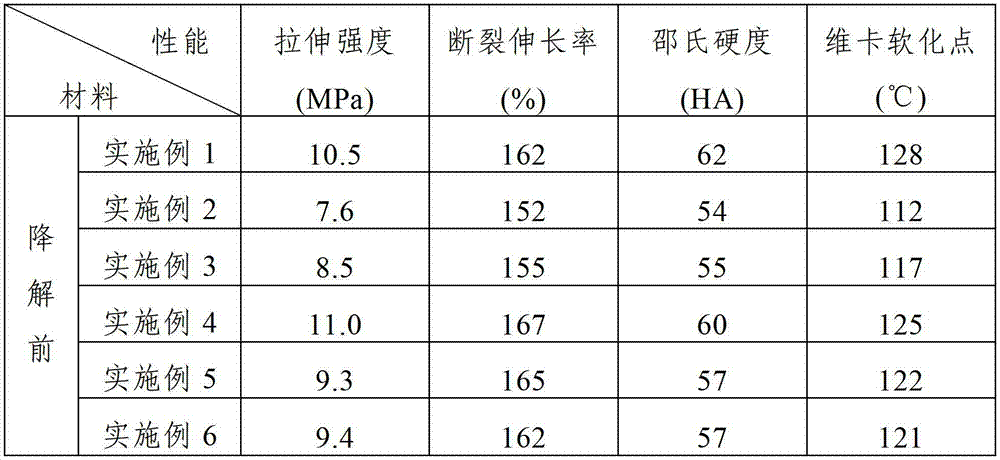

Preparation method of bamboo powder/white carbon black composite reinforced starch-based degradable plastic

The invention provides a preparation method of bamboo powder / white carbon black composite reinforced starch-based degradable plastic. The preparation method comprises the following steps of: 1, weighing starch, bamboo powder, white carbon black, polyvinyl alcohol, a plasticizer, compound additive and water in parts by weight; 2, adding various weighed materials into a mixer and uniformly mixing to obtain a mixture; and 3, adding the mixture into a double-screw extruder to extrude to obtain the bamboo powder / white carbon black composite reinforced starch-based degradable plastic. According to the preparation method, raw materials are well-sourced, the preparation process is simple, and the preparation method is suitable for large-scale industrial production. The bamboo powder / white carbon black composite reinforced starch-based degradable plastic prepared by adopting the preparation method has favorable mechanical property, heat resistance and biodegradability and has important meanings in terms of environment protection, resource development and the like.

Owner:SHAANXI UNIV OF TECH

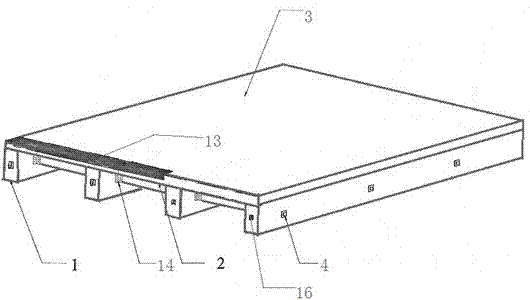

Novel energy-saving bamboo bridge

InactiveCN103498412AHigh tensile strengthNo possibility of crackingLighting elementsReed/straw treatmentLight equipmentEngineering

The invention provides a novel energy-saving bamboo bridge. The novel energy-saving bamboo bridge comprises longitudinal bamboo beams (1), transverse bamboo beams (2), bamboo panels (3), transverse pre-stressed trusses (4) and longitudinal pre-stressed trusses (16). A layer of waterborne polyurethane resin, a layer of polyurethane resin, a layer of waterborne polyurethane resin and a layer of resorcinol formaldehyde coat the outer surfaces of all the bamboo materials of the bamboo bridge in sequence. The bamboo bridge further comprises lighting devices and a brightness sensor, and the lighting devices are controlled to be started through the numerical value measured by the brightness sensor. The novel bamboo bridge can start the lighting device according to the brightness and save energy sources.

Owner:ZHONGBEI UNIV

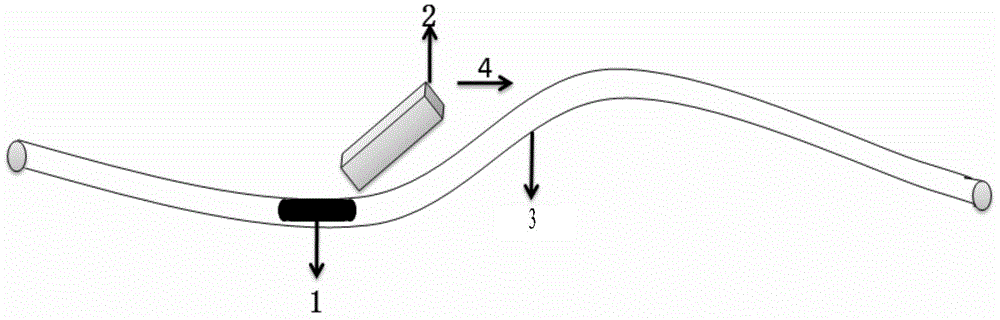

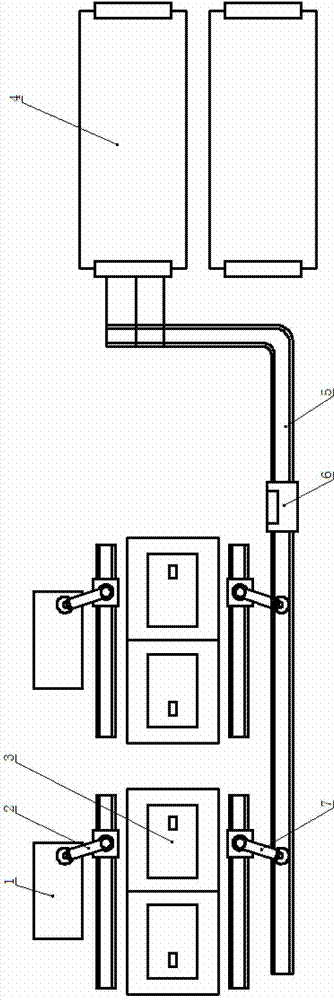

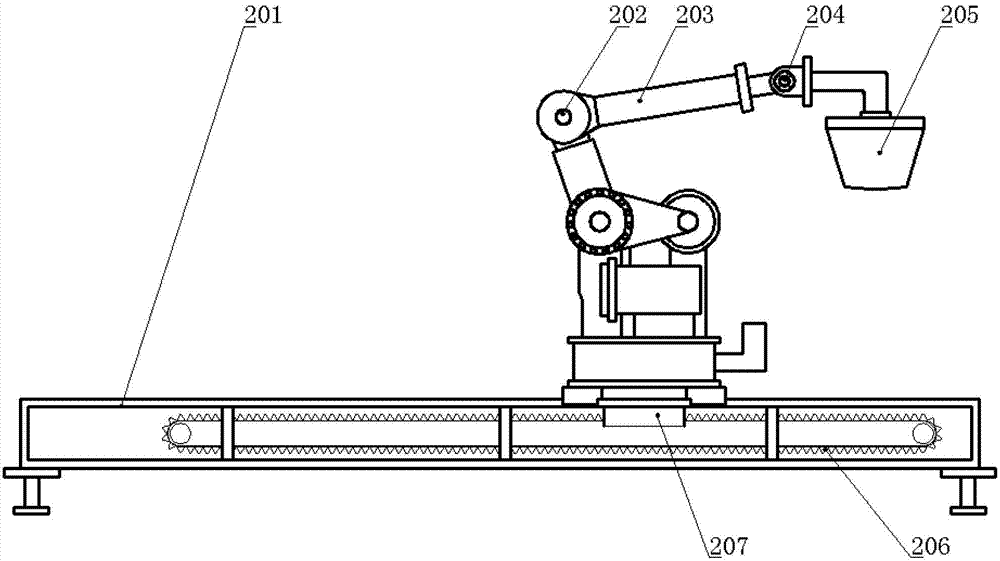

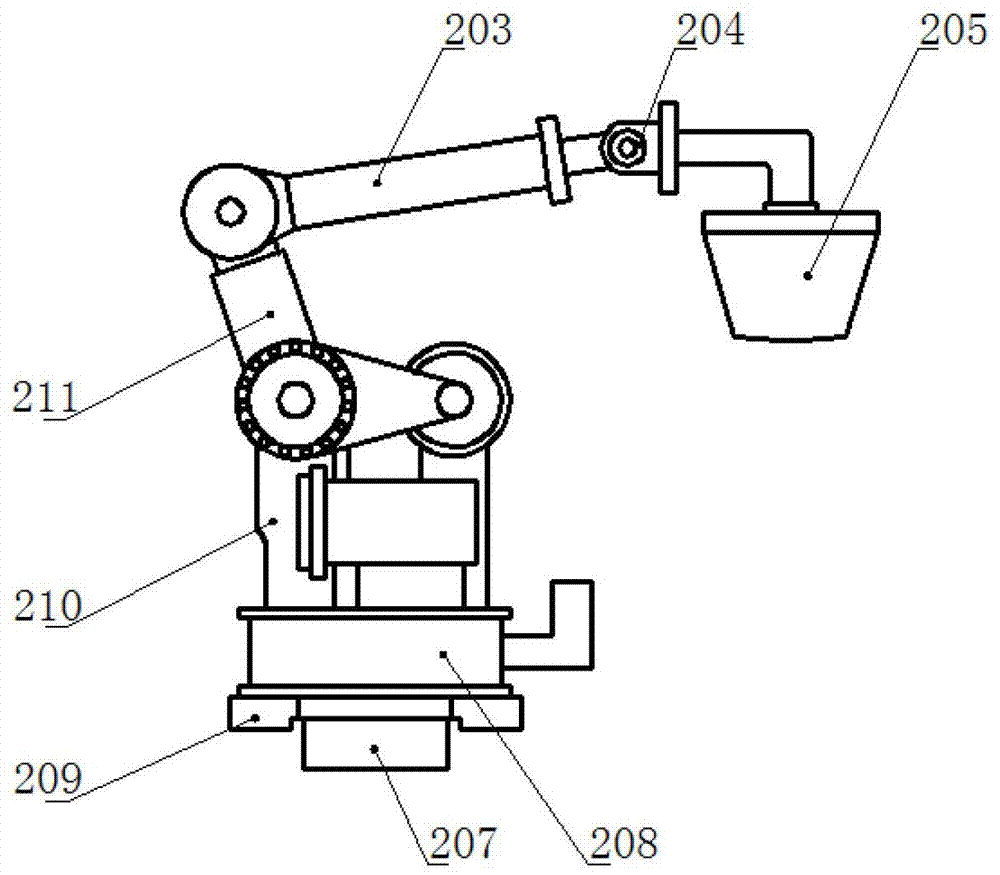

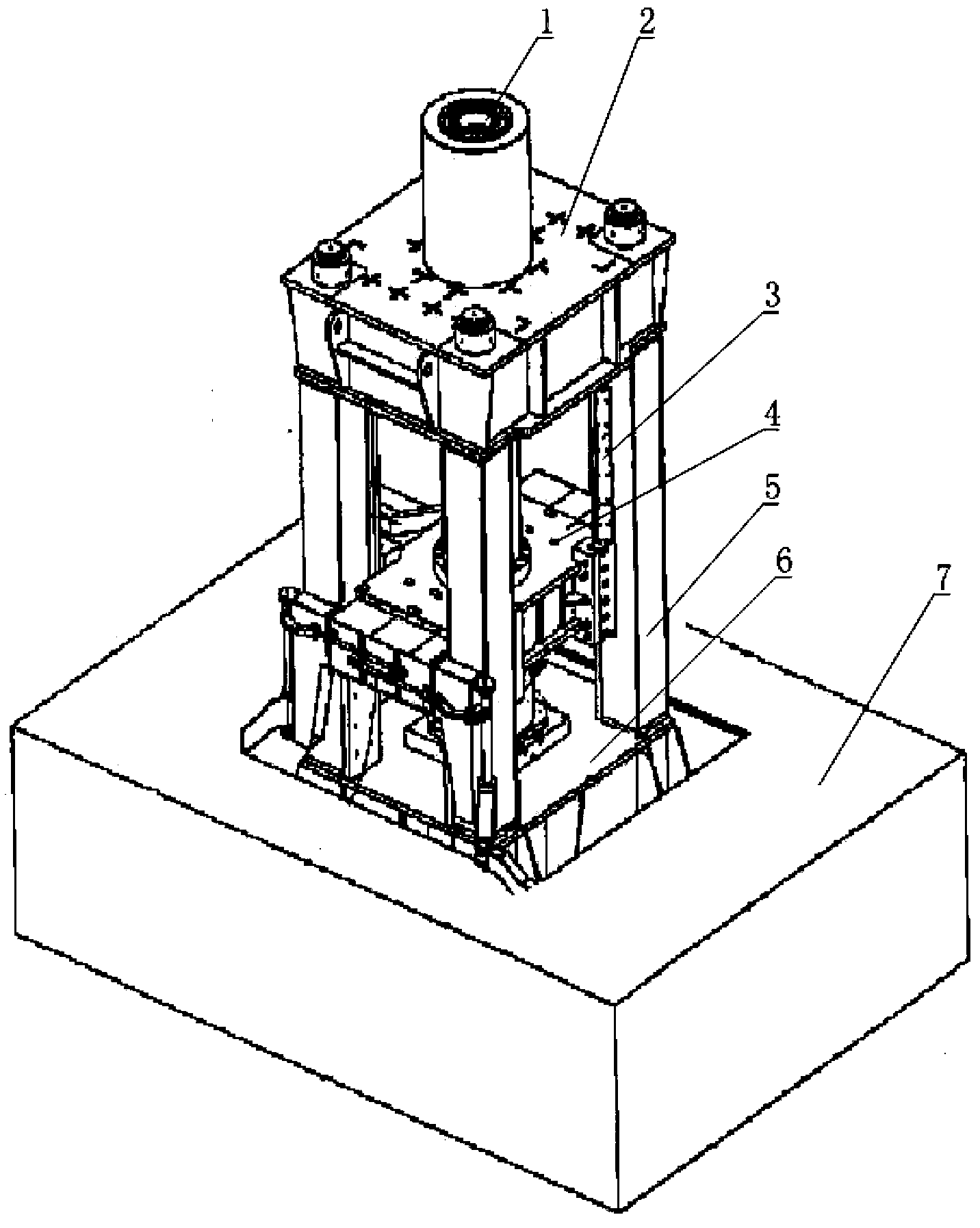

Double-station hydraulic die forging machining system and machining process

ActiveCN103111571AAvoid damageMeet the mechanical performance requirementsForging/hammering/pressing machinesForging press detailsRobot handMachine

The invention relates to a dual-station hydraulic die forging machining system and a machining process. The machining system comprises a heat preservation furnace, a forging machine, a melt feed manipulator, a product grabbing manipulator, a transferring rail and a storage frame. The heat preservation furnace is arranged at one side of the forging machine, and the melt feed manipulator installed between the forging machine and the heat preservation furnace scoops melt from the heat preservation furnace and conveys to the forging machine for machining. The other side of the forging machine is provided with the transferring rail, and the product grabbing manipulator is installed between the forging machine and the transferring rail. The machining system can achieve multi-station full-automatic production, and is simple in layout, easy and convenient to operate, capable of qualifying work of two forging machines when only one operator is needed, capable of making use of resources in the greatest degree and saving labor cost, meanwhile capable of obviously improving production efficiency, stable in operation, and reliable in quality.

Owner:TIANJIN NANUO MACHINERY MFG

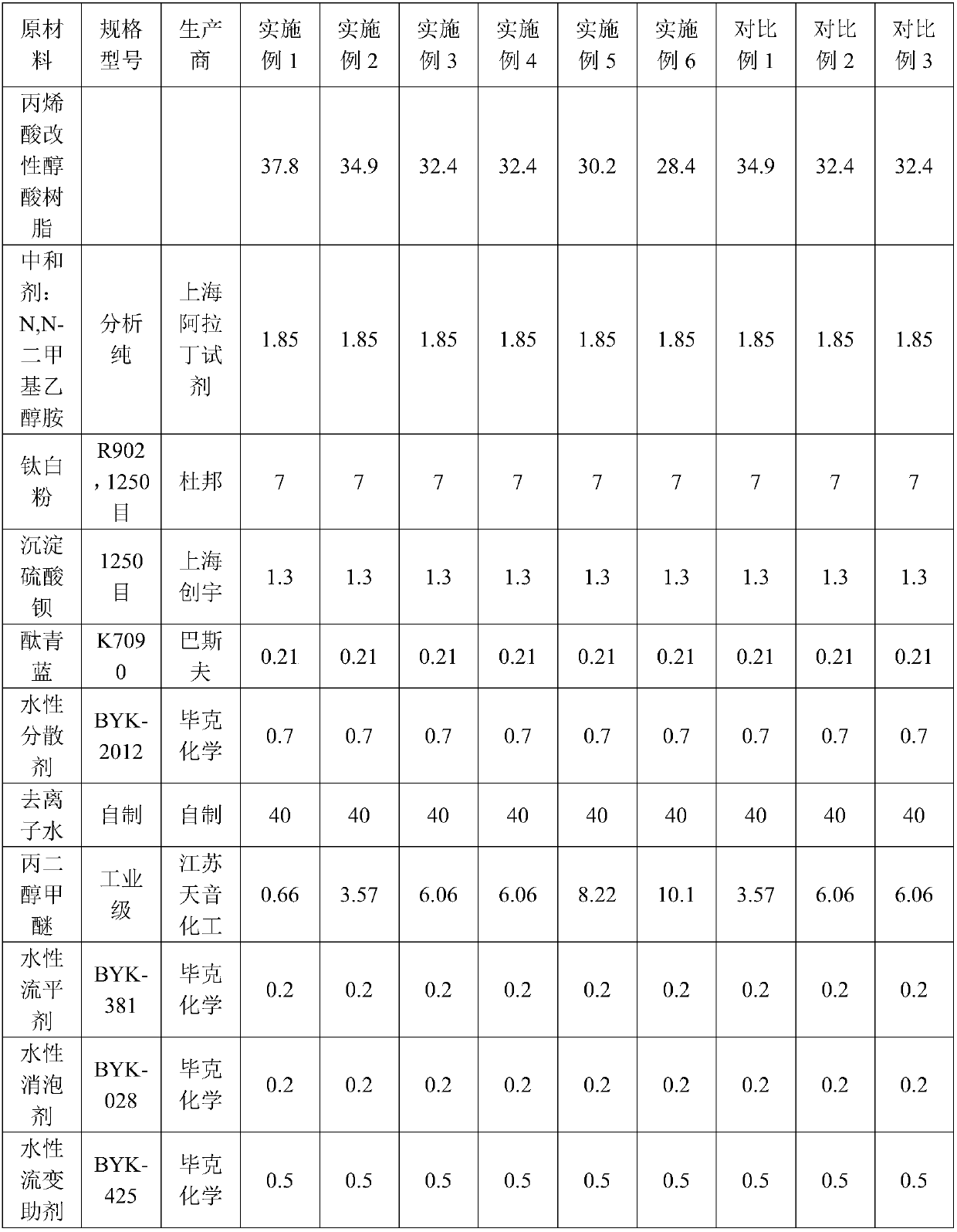

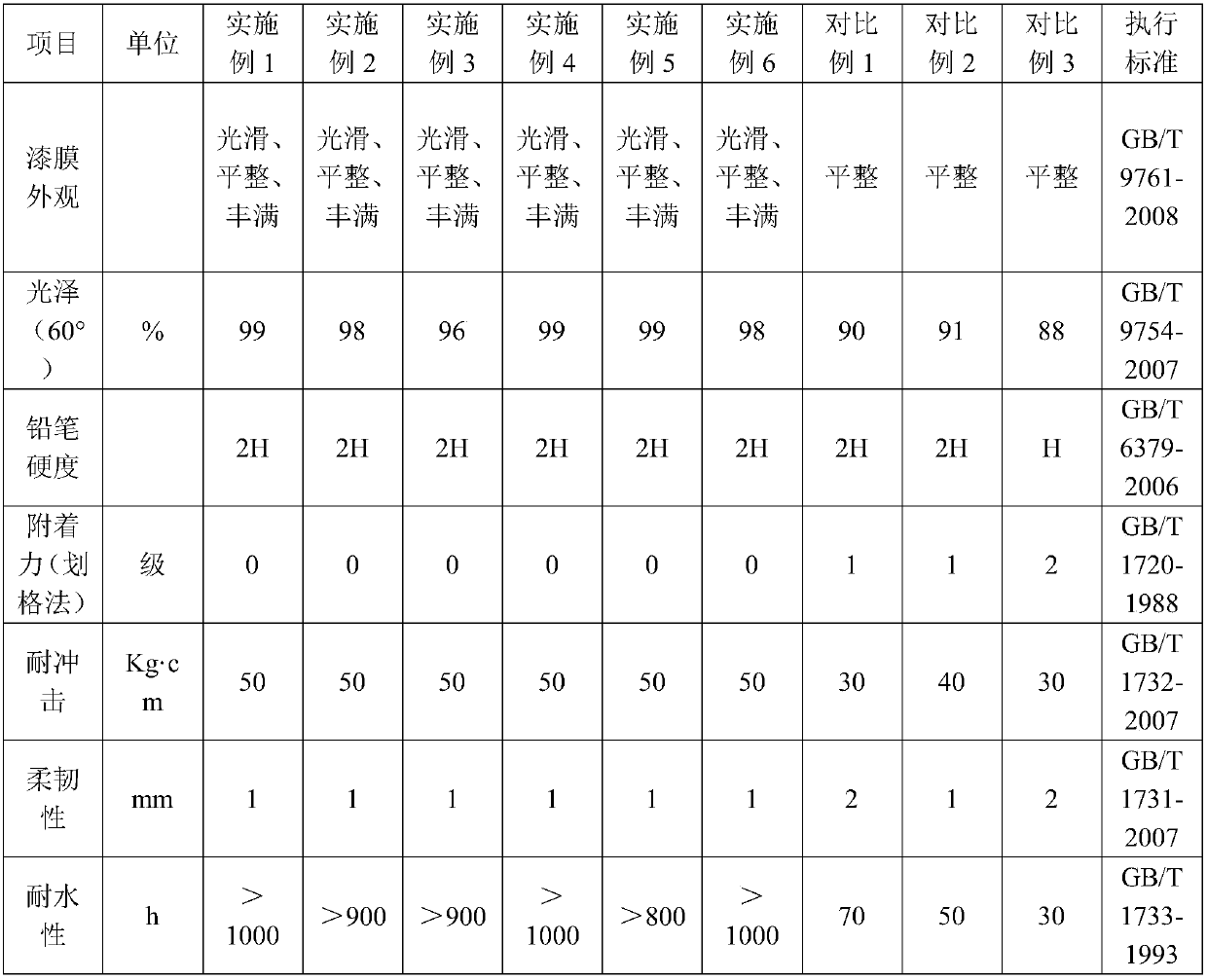

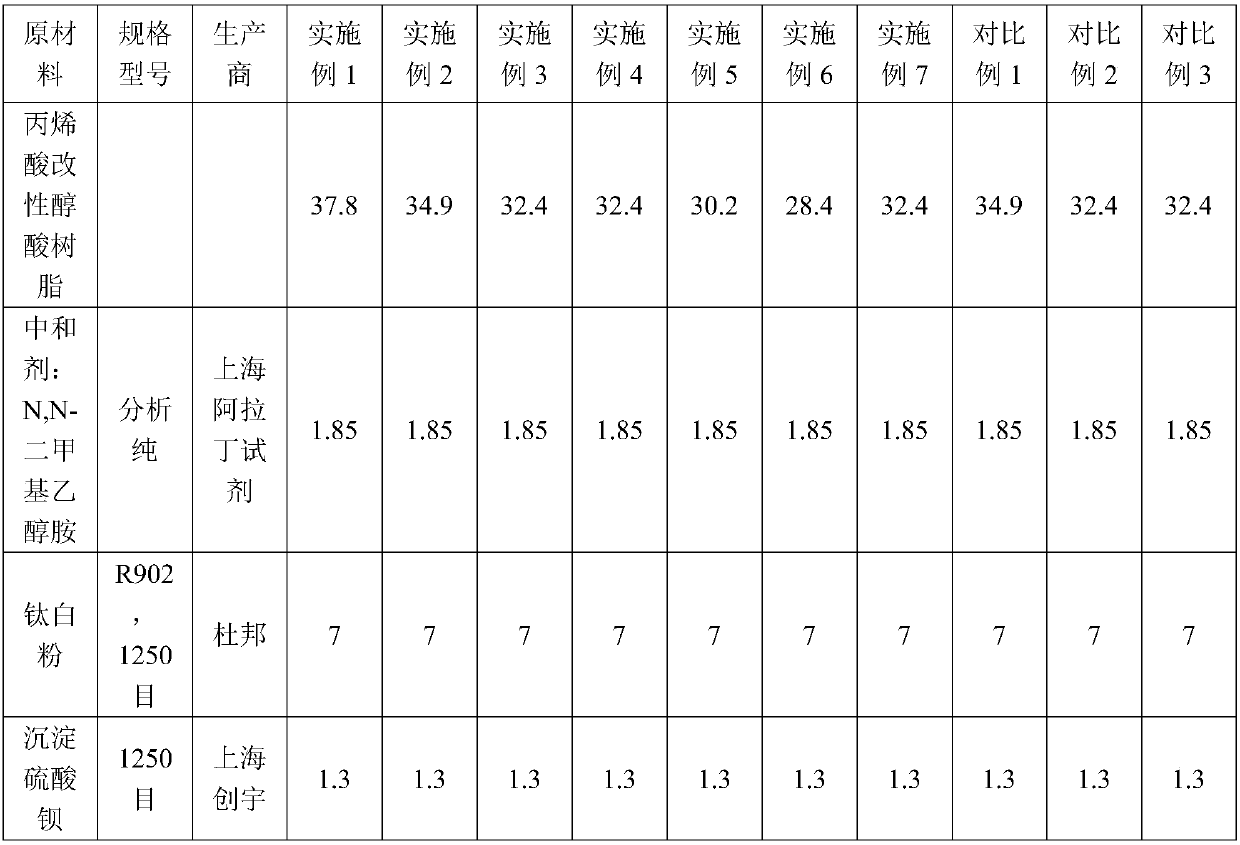

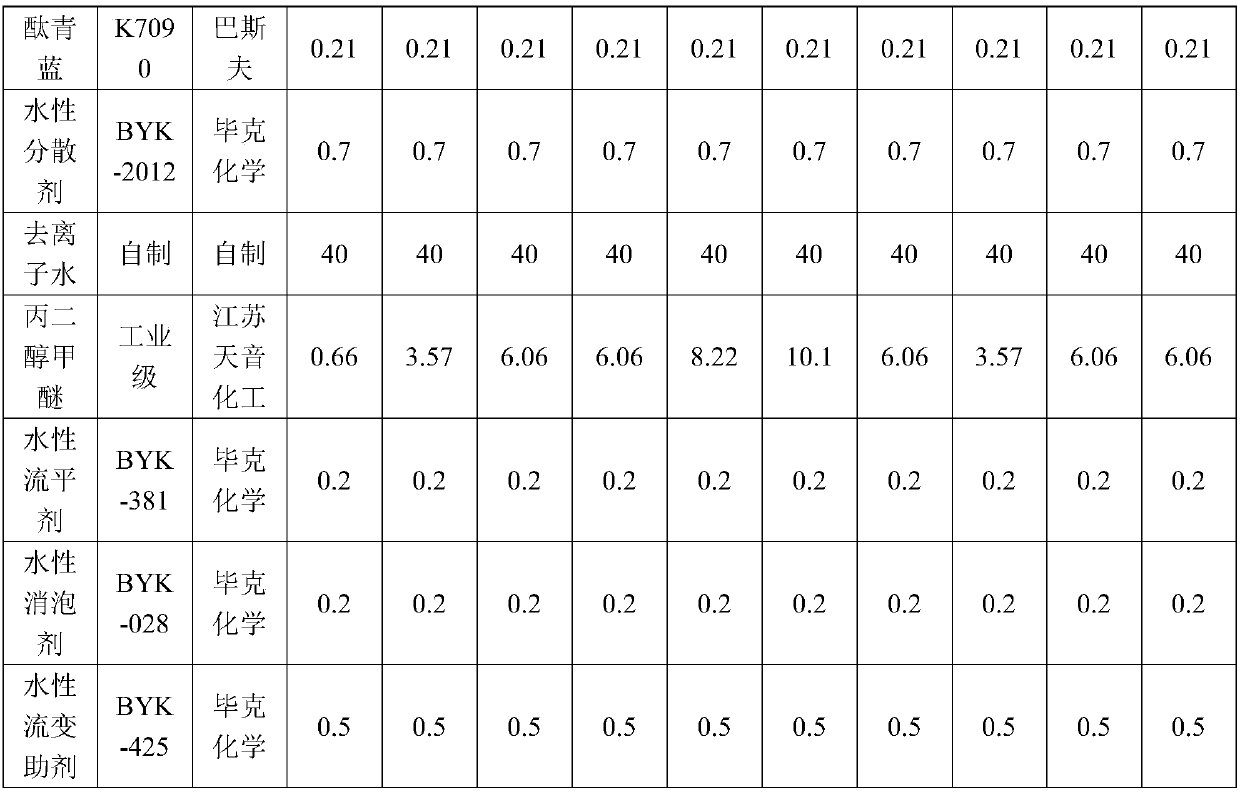

Alkyd resin preparation method and prepared resin thereof, and acrylic acid modified alkyd resin preparation method and prepared resin thereof

The invention provides an alkyd resin preparation method and the prepared resin thereof, and an acrylic acid modified alkyd resin preparation method and the prepared resin thereof. According to the alkyd resin preparation method, unsaturated carboxylic acid and / or unsaturated anhydride are / is added step by step to improve the structure of the alkyd resin. According to the acrylic acid modified alkyd resin preparation method, a unsaturated monomer is fed step by step, and the feeding time is controlled, so that the unsaturated monomer is uniformly grafted on an alkyd resin, and the molecular weight distribution is narrow. The acrylic acid modified alkyd resin prepared by the preparation method is applied to water-based coating materials, so that a paint film has the advantages of high drying speed, high glossiness, good fullness, low VOC emission, excellent comprehensive performance and the like.

Owner:WANHUA CHEM BEIJING +1

Assembly type bamboo bridge

ActiveCN103437271AHigh tensile strengthNo possibility of crackingSynthetic resin layered productsBridge structural detailsPolymer sciencePolymer chemistry

The invention provides an assembly type bamboo bridge. The assembly type bamboo bridge consists of bamboo longitudinal beams (1), bamboo transverse beams (2), bamboo panels (3), a transverse pre-stressing tendon (4) and a longitudinal pre-stressing tendon (16). All bamboos used by the assembly type bamboo bridge are soaked in a gum dipping tank which contains polyurethane resin and phenolic resin before being assembled, and boiled for 10-15 minutes at 100 DEG C-110 DEG C, wherein the volume ratio of the polyurethane resin to the phenolic resin is (2-2.5):1; and then, the bamboos are got out and dried, and a layer of waterborne polyurethane resin, a layer of polyurethane resin, a layer of waterborne polyurethane resin and a layer of resurcinolformaldehyde resin are uniformly coated on the outer surfaces of all bamboos in sequence. The assembly type bamboo bridge is large in structural strength, good in drawability, green and environment-friendly in used materials, standard in structural components, high in assembly degree, good in structural integrity, and capable of sufficiently bringing the advantages of the materials into play, and satisfying the normal use and durability needs of the bridge beam structure.

Owner:HAIMEN THE YELLOW SEA ENTREPRENEURSHIP PARK SERVICE CO LTD

Preparation of rice hull powder/talcum powder composite reinforced starch-based degradable plastic

The invention provides a preparation method of rice hull powder / talcum powder composite reinforced starch-based degradable plastic. The preparation method comprises the following steps of I, weighing and taking starch, rice hull powder, talcum powder, polyvinyl alcohol, a plasticizer, a compound additive and water according to certain parts by weight: II, adding various weighed and taken raw materials into a mixer, and uniformly mixing, so as to obtain a mixed material; III, adding the mixed material into a double screw extruder, and extruding, so as to obtain the rice hull powder / talcum powder composite reinforced starch-based degradable plastic. The sources of the raw materials in the preparation method are wide; the preparation process is simple; the method is suitable for large-scale industrialized production. The rice hull powder / talcum powder composite reinforced starch-based degradable plastic prepared by adopting the preparation method provided by the invention has favorable mechanical performance, heat resistance and biodegradability, and has important significance in all aspects of environmental protection, resource development and the like.

Owner:四川鑫达企业集团有限公司

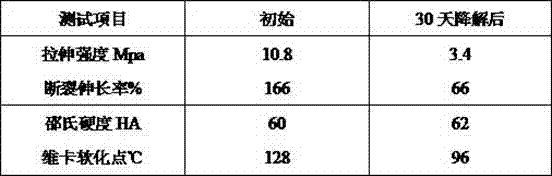

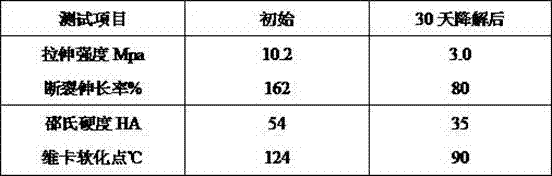

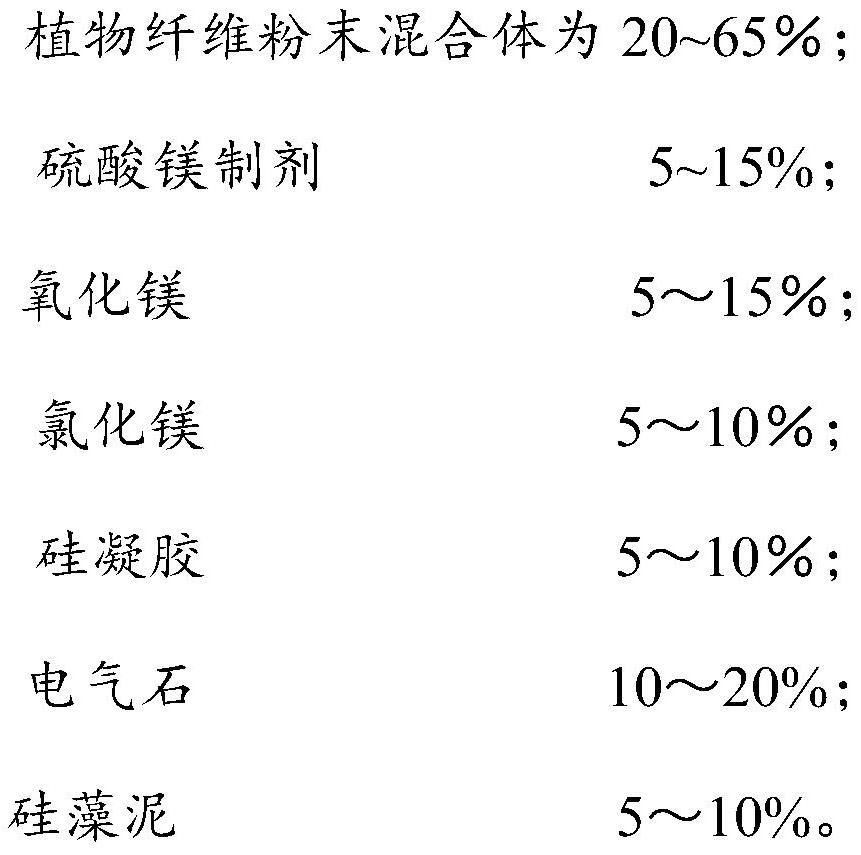

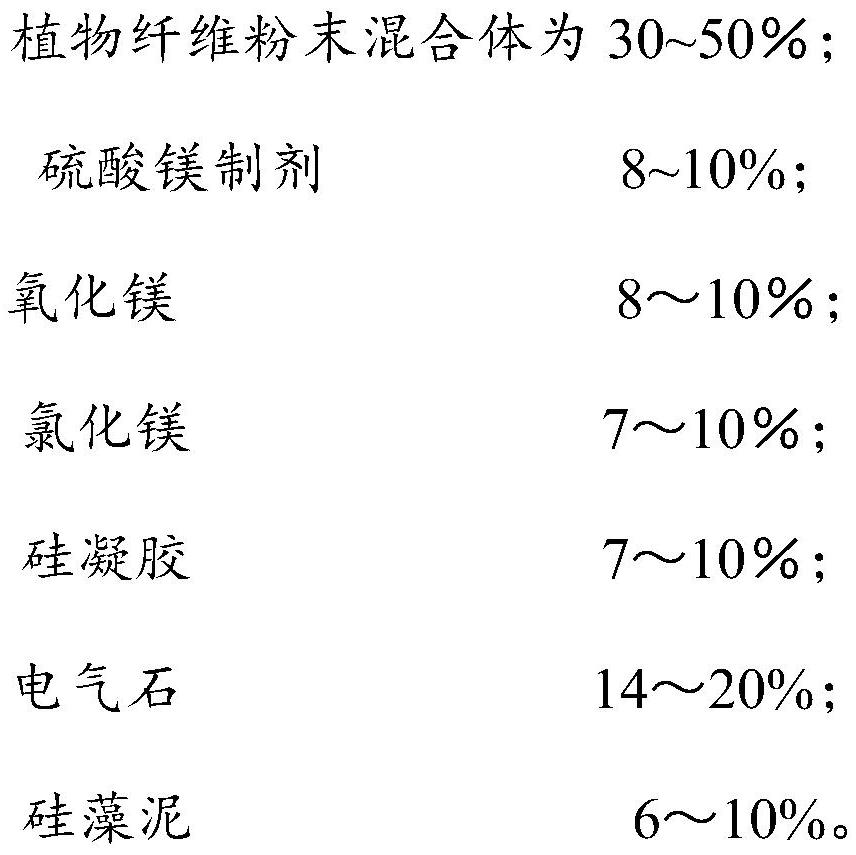

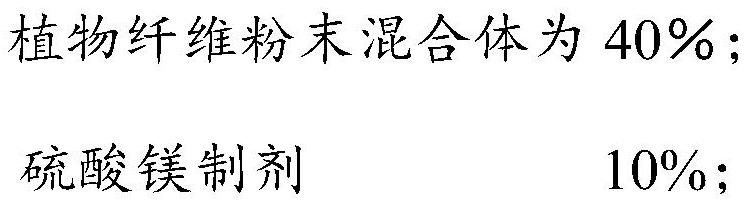

Negative ion plant fiber formaldehyde-free waterproof fireproof plate and preparation method thereof

PendingCN111777400AFast purificationImprove purification efficiencyMagnesium chlorateMagnesium sulphate heptahydrate

The invention provides a negative ion plant fiber formaldehyde-free waterproof fireproof plate and a preparation method thereof. The formaldehyde-free waterproof fireproof plate comprises the following components in parts by weight: 20-65% of a plant fiber powder mixture, 5-15% of a magnesium sulfate preparation, 5-15% of magnesium oxide, 5-10% of magnesium chloride, 5-10% of silica gel, 10-20% oftourmaline and 5-10% of diatom ooze. Magnesium oxysulfate and tourmaline are mixed for use, on one hand, a large amount of harmful gas in air is absorbed through diatom ooze, on the other hand, air negative ions are generated through tourmaline, the harmful gas is decomposed through the negative ions in the air, the purpose of rapidly purifying air is achieved, the purification speed is high, andthe purification efficiency is high.

Owner:上海苏云木业有限公司

Waterborne quick-drying anticorrosive and rustproof paint for high-speed rail chassis

InactiveCN107022305AFast dryingImprove mechanical propertiesAnti-corrosive paintsEpoxy resin coatingsWater basedEpoxy

The invention discloses a waterborne quick-drying anticorrosive and rustproof paint for a high-speed rail chassis. The paint is prepared from the following raw materials: 5-15 parts of water-based methacrylic acid epoxy resin, 16-25 parts of water-based fluorosilicone resin, 3-5 parts of chitosan, 6-20 parts of a rustproof pigment, 15-25 parts of talcum powder, 0.1-0.5 part of a cationic FM emulsifier, 0.1-0.5 part of a polycarboxylic sodium salt dispersant, 1-2 parts of sodium nitrite, 0.1-0.5 part of a water-based acrylic drier, 0.1-0.5 part of a pH regulator, and 20-40 parts of deionized water. The primer provided by the invention has the advantages of low VOC emission, fast drying, good anticorrosion and rustproof performance, high mechanical properties, resistance to acid, alkali and salt fog, and good impact resistance, etc., and can be applied to long-term protection of various products needing high quality coating properties.

Owner:CHUZHOU JINQIAO TEXAS NEW MATERIALS CO LTD

Forging method and forging device of twice forcing molten soup forging wheel

ActiveCN103084559BAvoid damageMeet the mechanical performance requirementsEngineeringMechanical engineering

The invention relates to a forging method and a forging device of a twice forcing molten forging wheel. The forging method of the twice forcing molten forging wheel is conducted circularly by the following steps: (1) materials smelting; (2) heat preservation deposit; (3) molten soup degassing; (4) the molten soup being injected into a lower die; (5) main piston forcing and pressure maintaining; (6) auxiliary piston forcing and pressure maintaining; (7) die sinking; (8) product transfer and deposit; (9) die cooling. Product quality is improved and molten soup dosage is reduced, and twice forcing is conducted to further improve inner structure refined grain of metals, and therefore the forging method and the forging device of the twice forcing molten forging wheel has the advantages of improving product mechanical property, tensile property and other overall properties, shortening product production time, increasing output, improving production efficiency and ex-factory percent of pass of products.

Owner:TIANJIN NANUO MACHINERY MFG

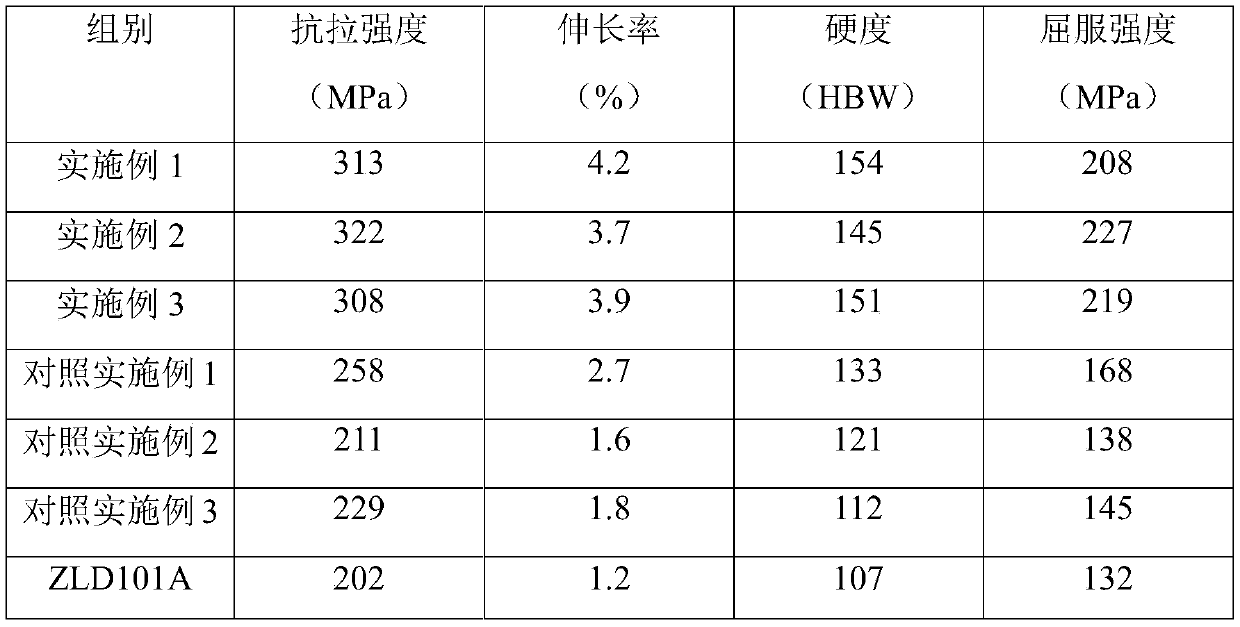

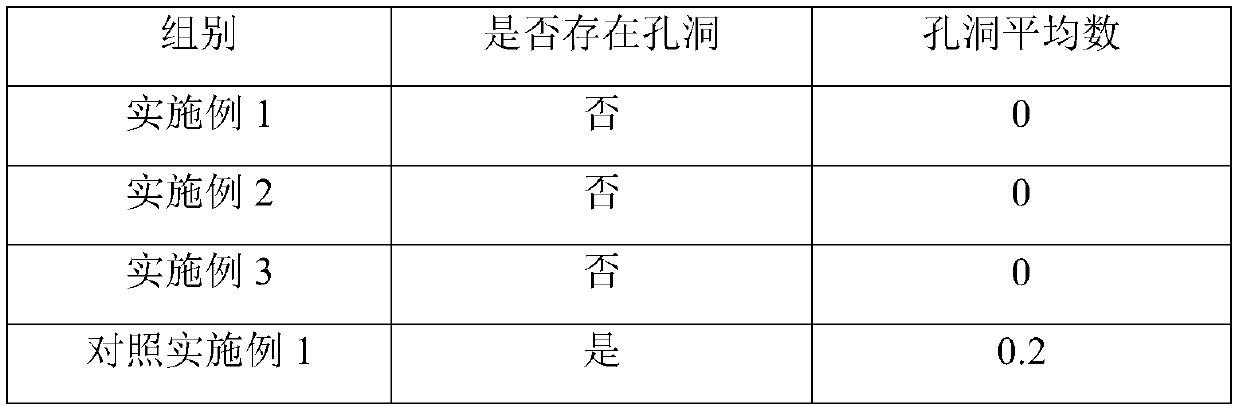

Aluminum alloy refining material and preparation method and application thereof

The invention discloses an aluminum alloy refining material and a preparation method and an application thereof and relates to the field of aluminum alloy modifiers. The aluminum alloy refining material comprises the following raw materials in percentage by weight: 5-8% of potassium fluoroaluminate, 7-11% of sodium fluoroaluminate, 3-5% of disodium hydrogen phosphate hydrate, 5-7% of potassium chloride, 4-8% of sodium chloride, 0.4-0.8% of barium acetate, 3-6% of barium nitrate, 0.2-0.9% of samarium fluoride, 0.2-0.9% of aluminum acetate, 6-8% of aluminum chloride, 15-20% of lepidolite compound powder and the balance of pure aluminum. The aluminum alloy refining material has the beneficial effects that the four modifiers of barium, sodium, lithium and samarium are combined according to thecharacteristics and a sintered body with a loose structure is prepared by adopting spray deposition and extrusion calcination in one step, so that the metamorphic activity is effectively retained andthe material has the characteristics of short metamorphic incubation period, long effective metamorphic time and stable metamorphic effect; and the lepidolite powder can serve as a modifier carrier for degassing and slag removal and the alloy hardness can be significantly increased by utilizing high hardness matters contained in the lepidolite powder.

Owner:ANHUI POLYTECHNIC UNIV MECHANICAL & ELECTRICAL COLLEGE

Bamboo bridge deck

InactiveCN102561180BIncrease the lengthReduce the degree of prestress lossBridge structural detailsPre stressArchitectural engineering

The invention discloses a bamboo bridge deck, which comprises prestressed ribs and a plurality of superposed bridge deck sheets, wherein the prestressed ribs penetrate through the bridge deck sheets; two ends of the prestressed ribs penetrate through shim plates and are fixed and tightened by using anchorage devices to constrain the bridge deck sheets; and each bridge deck sheet is formed by sequentially joggling a plurality of single bridge decks made of bamboo veneers end to end, and the joggled parts of the two adjacent bridge deck sheets are staggered. The required width of the bridge deck is achieved in the transverse direction by the method for sequentially joggling the single bridge decks end to end in the cross section width of a bridge. The basic single decks of the bamboo bridge deck can be conveniently prefabricated in a factory and assembled on site to form the bamboo bridge deck; the construction process is simple and fast, and the construction materials are environment-friendly and are easily reclaimed; and the bamboo bridge deck is suitable for a combined structural bridge, and is a bridge deck capable of meeting the using functions and the durability.

Owner:SOUTHEAST UNIV

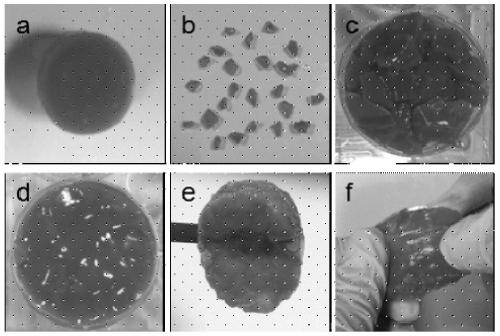

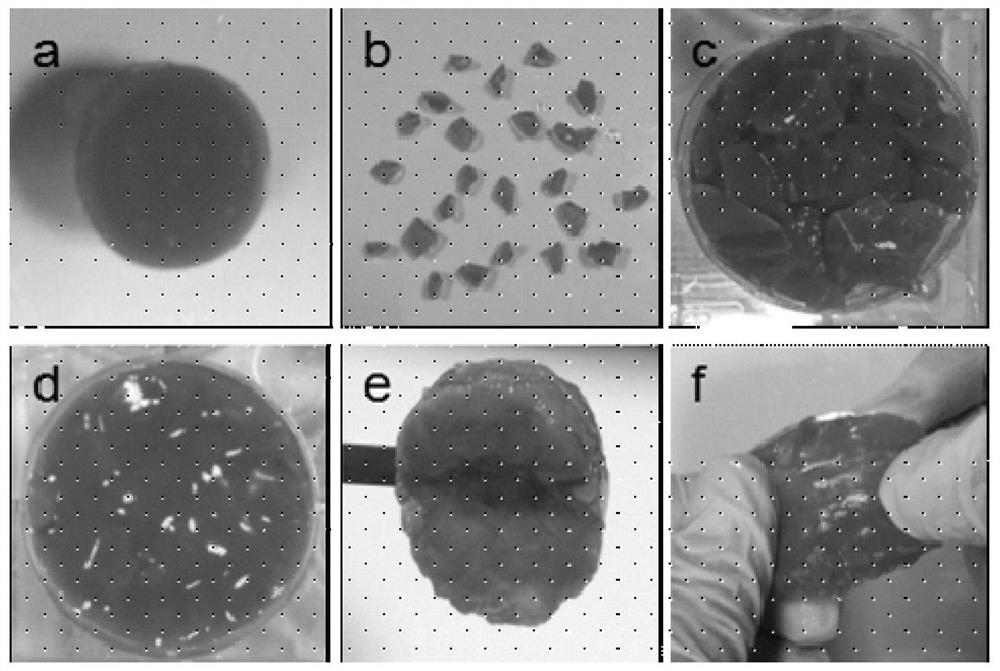

Soluble self-healing natural polymer hydrogel and preparation method thereof

The invention discloses a soluble self-healing natural polymer hydrogel and a preparation method thereof. Natural polymer sodium alginate can be used as raw material, functional monomer methacrylic acid can be introduced, initiator and deionized water can be used as auxiliary raw material, and thus the natural polymer hydrogel (SAM) with excellent self-healing and solubility can be prepared by one-pot method. The hydrogel prepared by the invention has the advantages of fast self-healing rate, healing with no limitation of incision section and good solubility. The hydrogel is put into a certainamount of water, and the hydrogel can be completely dissolved without residue. The hydrogel is used as a drug carrier, and the drug release rate is stable, and the 100% of drug can be completely released without residue. And the prepared hydrogel has good biocompatibility and degradability, and the soluble self-healing natural polymer hydrogel prepared by the invention has wide application prospects in the fields of biomedical materials such as wound dressing, tissue organ culture and biological scaffold materials.

Owner:EAST CHINA NORMAL UNIV

Process for preparing electronic ink by using light complex functional ball of optical subwavelength

InactiveCN101333352BFast mechanical propertiesImprove mechanical propertiesInksNon-linear opticsEngineeringMechanical property

The invention relates to a method for preparing electronic ink from light composite function ball at sub-optical wavelength. Mixing dispersant and organic solvent, oscillating with ultrasonic wave, adding light composite function ball at sub-optical wavelength and blending, thus obtaining light composite function ball suspension at sub-optical wavelength with bistability; then adding background dye and mixing, thus obtaining electrophoretic display liquid, namely the electronic ink; or dispersing the light composite function ball at sub-optical wavelength in organic solvent, oscillating with ultrasonic wave, heating to 105-120 DEG C, adding Tissuemat E gradually and blending, thus obtaining light composite function ball suspension at sub-optical wavelength with bistability; then adding background dye and dispersant and mixing, thus obtaining electrophoretic display liquid, namely the electronic ink. Electronic paper display units made from the electronic ink are of good mechanical property, wear resistance, pressure resistance, impact resistance and quick response, and the images produced have clear boundaries, high contrast grade and high resolution.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

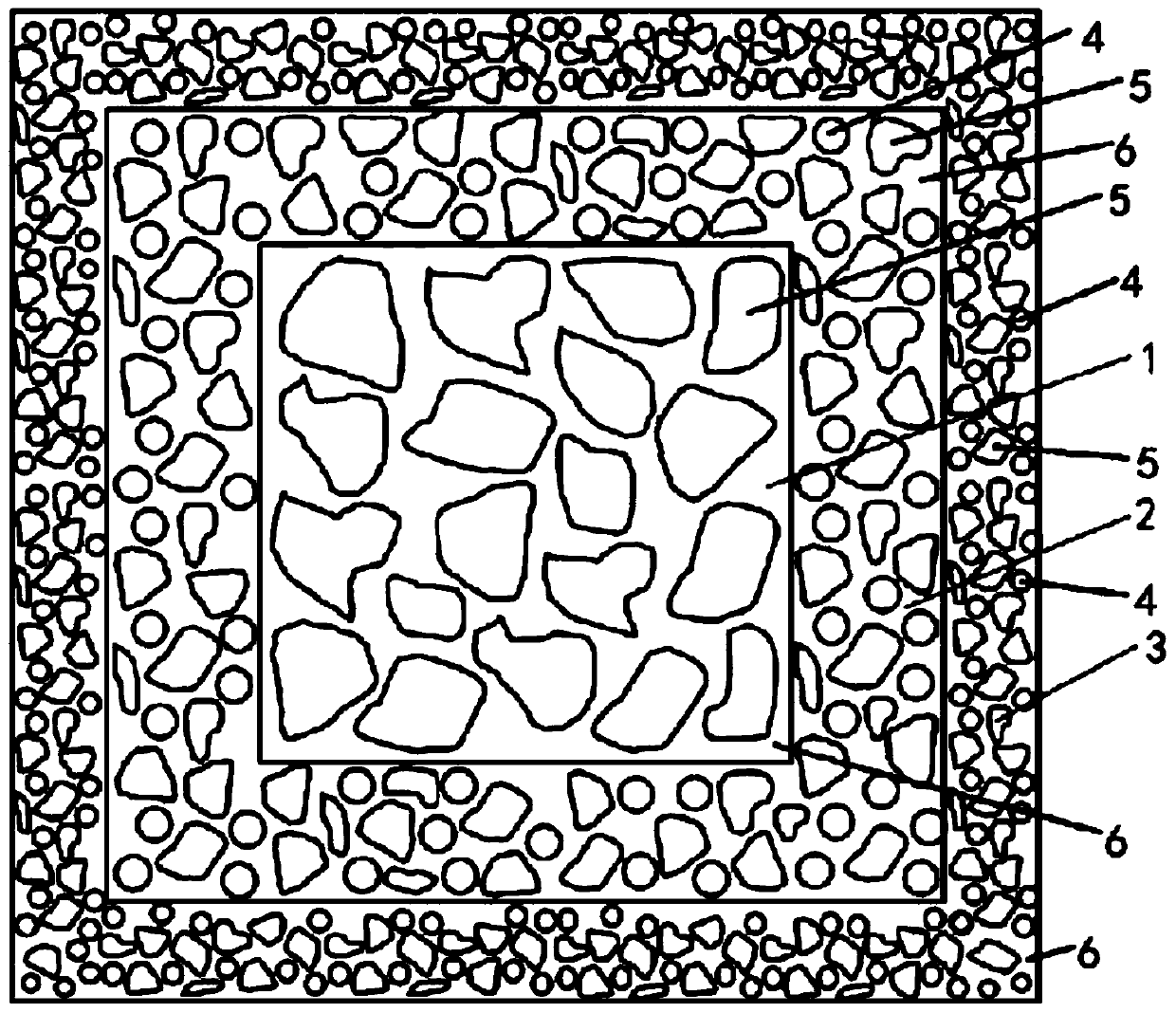

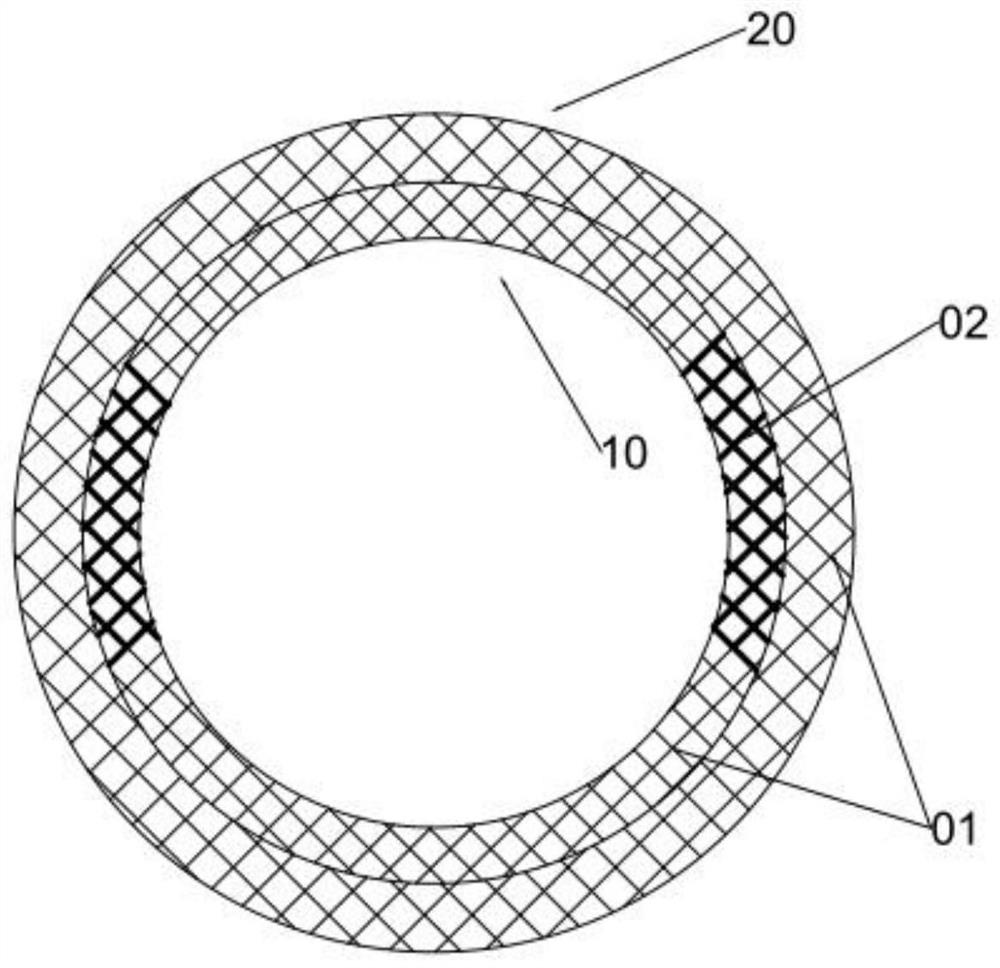

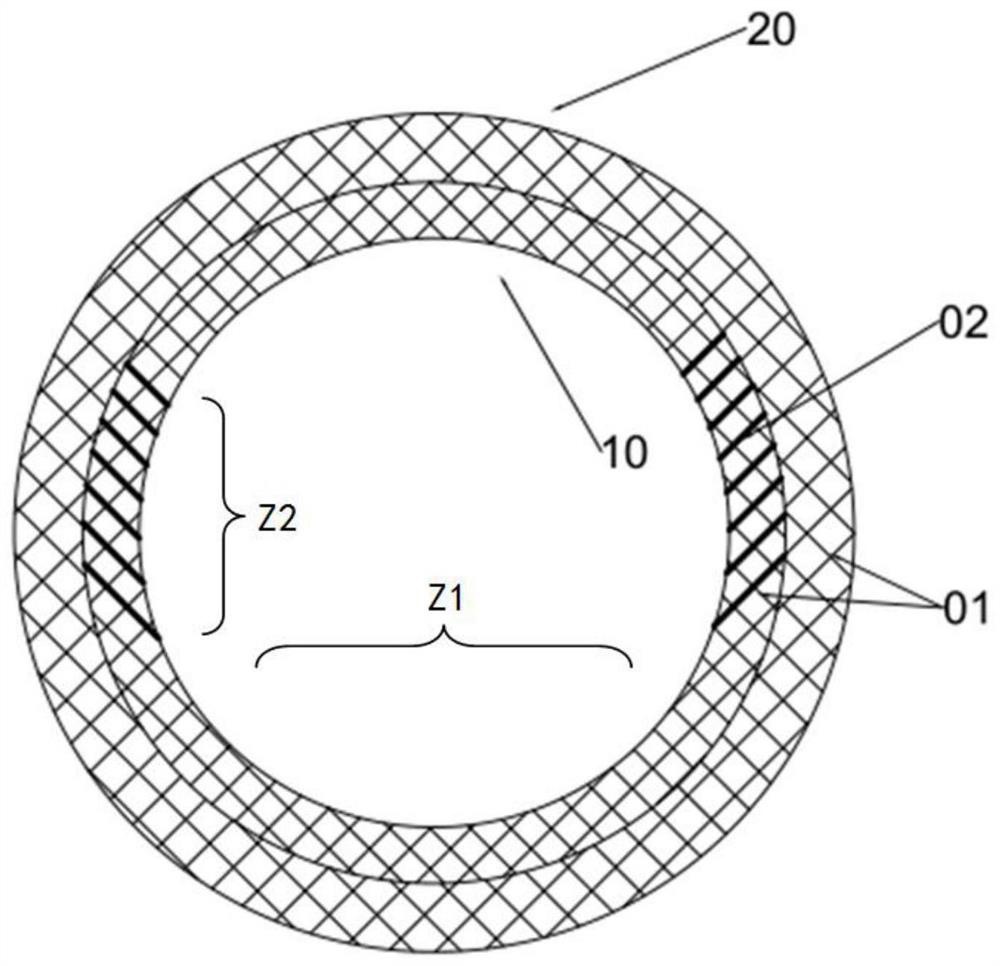

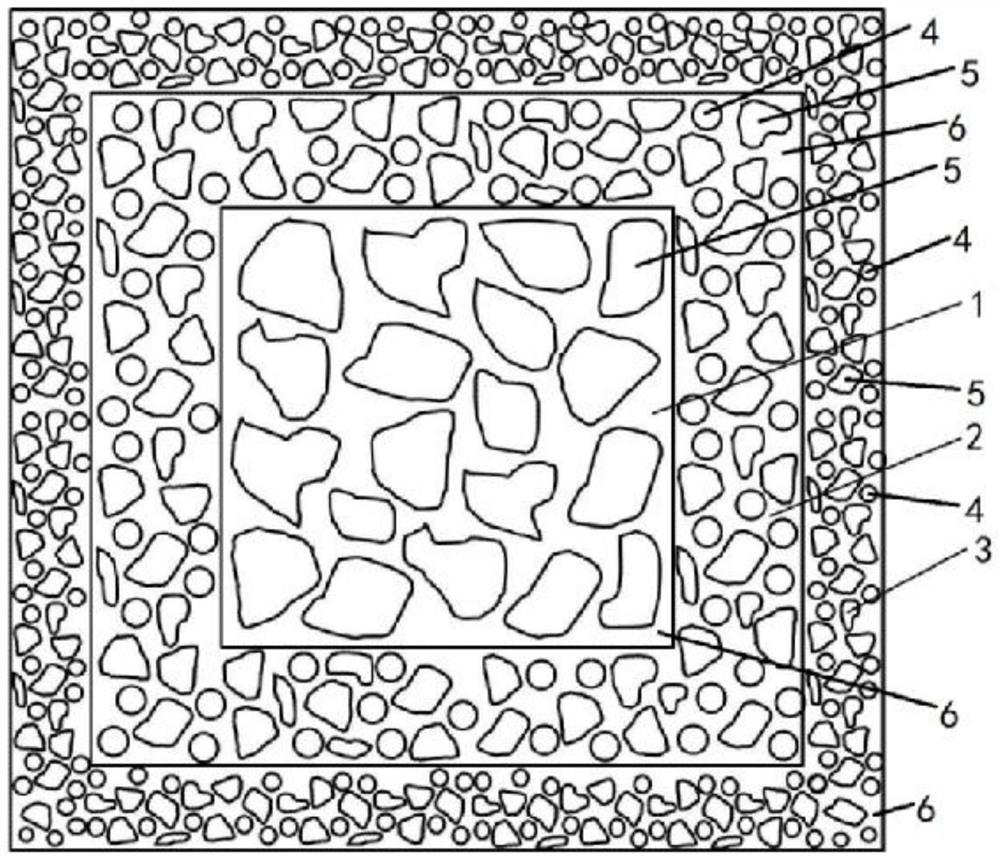

Bone tissue engineering gradient porous magnesium-based metal component body and preparation method thereof

ActiveCN110639064AAchieve degradationImprove mechanical propertiesTissue regenerationProsthesisHuman bodyBone tissue engineering

The invention relates to a bone tissue engineering gradient porous magnesium-based metal component body. The bone tissue engineering gradient porous magnesium-based metal component body is characterized in that an inner core prefabricated body, an outer layer prefabricated body and a middle layer prefabricated body are at least included, wherein the outer layer prefabricated body is located on theperiphery of the inner core prefabricated body and is in an annular shape, the middle layer prefabricated body is located between the inner core prefabricated body and the outer layer prefabricated body and is in an annular shape, the inner core prefabricated body, the middle layer prefabricated body and the outer layer prefabricated body are each provided with a pore, the pores of the inner coreprefabricated body, the middle layer prefabricated body and the outer layer prefabricated body communicate with one another, and the porosity rate of the inner core prefabricated body, the middle layer prefabricated body and the outer layer prefabricated body is sequentially decreased. The invention further relates to a preparation method. After the bone tissue engineering gradient porous magnesium-based metal component body is implanted into the human body, the different demands of dynamic matching between the degradation rate and mechanical properties at different times can be met.

Owner:CHINA WEAPON SCI ACADEMY NINGBO BRANCH

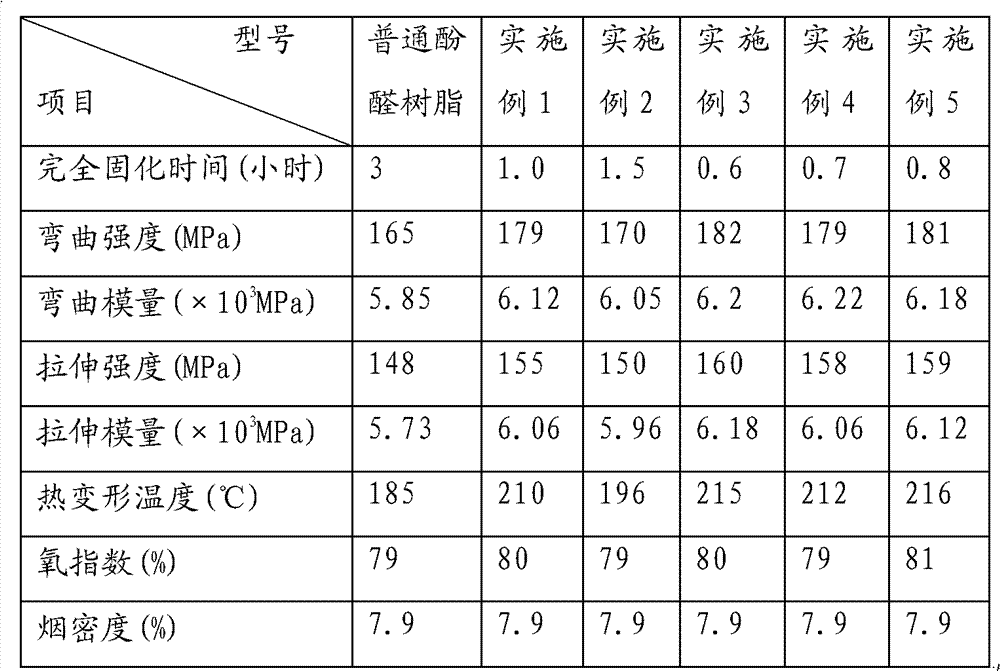

Preparation method of phenolic resin used for hand lay-up fiberglass-reinforced plastic

The invention discloses a preparation method of phenolic resin used for hand lay-up fiberglass-reinforced plastic. The method comprises the following steps of: (1) adding phenol, polyhydroxy phenol, formaldehyde and a basic catalyst to a reaction kettle at a mol ratio of 1.0:(0.1-1.5):(0.8-2.0):(0.02-1.0), heating to 40-75 DEG C, carrying out reaction at a constant temperature for 2-10 hours, heating to 85-95 DEG C and continuing reacting for 1-5 hours to obtain a mixture; and (2) vacuum-distilling the mixture obtained in step (1) for dewatering to liquid viscosity 5000-10000 MPa.s / 25 DEG C. According to the invention, polyhydroxy phenol with more active hydroxyl groups compared with that of phenol is added during the synthesis process of phenolic resin, thus improving the solidifying speed of phenolic resin, shortening the solidifying time and improving production efficiency under the condition of identical solidifying agent addition amount; and high hydroxyl group content increases crosslinking points and improves mechanical properties of phenolic resin.

Owner:SHANDONG SHENGQUAN NEW MATERIALS CO LTD

A kind of preparation method of superhydrophobic superlipophilic ultralight sponge

ActiveCN104324524BSmall surface areaHigh oil absorption rateLiquid separationUltralight materialRaw material

The invention relates to a preparation method of super-hydrophobic, super-oleophylic and ultralight sponge. The preparation method comprises two steps of performing functionalized processing on melamine sponge by using an impregnation method and performing a curing reaction after processing. The melamine sponge used by the invention has a large quantity of active functional groups such as hydroxyl groups and amino groups on the surface, the content of the hydrophobic active functional groups on the surface of the sponge is remarkably reduced after the active groups are chemically functionalized, which causes a result that the surface energy of the material is reduced, thus the sponge is endowed with super-hydrophobic and super-oleophylic effects, and a contact angle between the sponge and water exceeds 150 degrees; and the modified melamine sponge belongs to an ultralight material due to density. The method disclosed by the invention has the advantages that raw materials are low in price and easy to available, the process is simple and easy to operate, the large-scale preparation is easily realized, and the like. The sponge prepared according to the preparation method has the advantages of low density, excellent compression resistance, high oil absorbing speed, high oil absorbing rate, high oil and water separation selectivity and the like, is a novel and efficient ultralight-density oil and water separating material, and has a wide application prospect in the fields such as organic chemical reagent treatment, oil-containing wastewater treatment, and leaking crude oil recovery.

Owner:中科瑞丽分离科技无锡有限公司

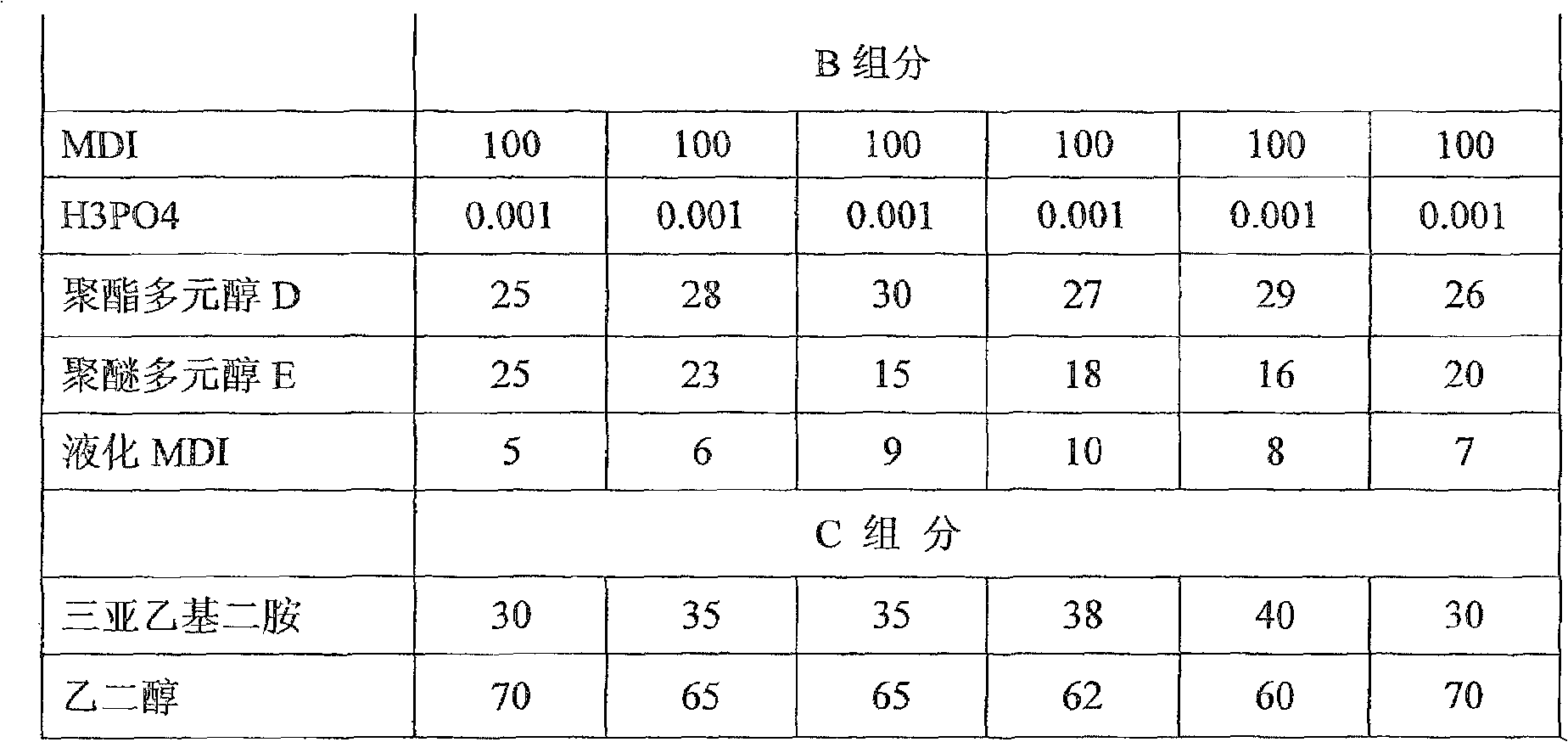

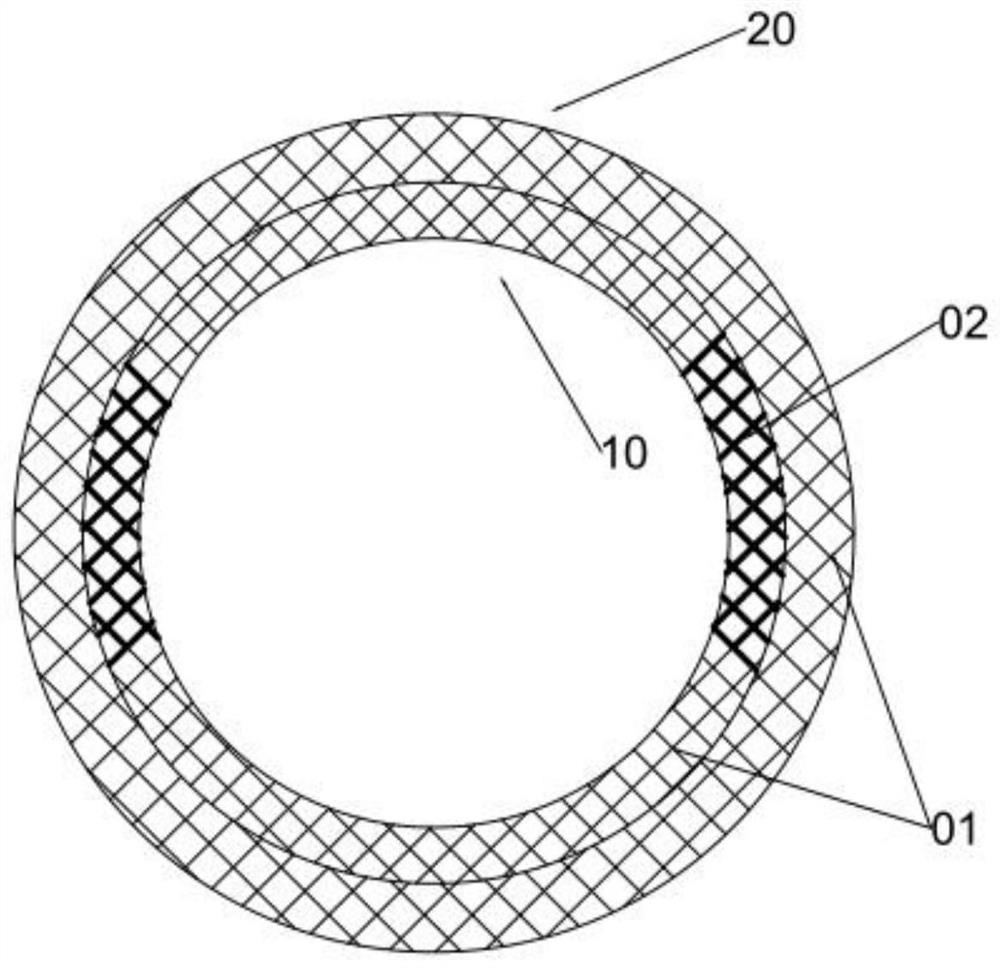

Medical stent for digestive system and manufacturing method thereof

The invention provides a medical stent for a digestive system. The medical stent is obtained by 3D printing of a degradable polymer material, and at least comprises two continuous layers of three-dimensional grid structures in the radial direction, wherein the outer layer of three-dimensional grid structure is formed by printing a degradable polymer main material, the inner layer of three-dimensional grid structure is formed by composite printing of the degradable polymer main material and at least one degradable polymer auxiliary material, and the degradation of all the degradable polymer auxiliary materials is earlier than that of the degradable polymer main material; and in the inner layer of three-dimensional grid structure, the extension area of the continuous and continuous part of at least part of the degradable polymer main material in the axial direction of the whole medical stent on the radial cross section of the inner layer of three-dimensional grid structure is not less than 20% of the total area of the radial cross section of the inner layer of three-dimensional grid structure. The degradable medical stent is manufactured by means of a 3D printing process, fine adjustment of mechanical properties and control of drug release and degradation period are realized through planning of the main and auxiliary materials, and the overall performance of the more universal medical stent for the digestive system is optimized.

Owner:SHANDONG PROVINCIAL HOSPITAL AFFILIATED TO SHANDONG FIRST MEDICAL UNIVERSITY

Assembly type bamboo bridge

ActiveCN103437271BHigh tensile strengthNo possibility of crackingSynthetic resin layered productsBridge structural detailsPre stressPre stressing

The invention provides an assembly type bamboo bridge. The assembly type bamboo bridge consists of bamboo longitudinal beams (1), bamboo transverse beams (2), bamboo panels (3), a transverse pre-stressing tendon (4) and a longitudinal pre-stressing tendon (16). All bamboos used by the assembly type bamboo bridge are soaked in a gum dipping tank which contains polyurethane resin and phenolic resin before being assembled, and boiled for 10-15 minutes at 100 DEG C-110 DEG C, wherein the volume ratio of the polyurethane resin to the phenolic resin is (2-2.5):1; and then, the bamboos are got out and dried, and a layer of waterborne polyurethane resin, a layer of polyurethane resin, a layer of waterborne polyurethane resin and a layer of resurcinolformaldehyde resin are uniformly coated on the outer surfaces of all bamboos in sequence. The assembly type bamboo bridge is large in structural strength, good in drawability, green and environment-friendly in used materials, standard in structural components, high in assembly degree, good in structural integrity, and capable of sufficiently bringing the advantages of the materials into play, and satisfying the normal use and durability needs of the bridge beam structure.

Owner:HAIMEN THE YELLOW SEA ENTREPRENEURSHIP PARK SERVICE CO LTD

Alkyd resin preparation method and resin prepared by the same, and acrylic acid modified alkyd resin preparation method and resin prepared by the same

The invention provides an alkyd resin preparation method and a resin prepared by the same, and an acrylic acid modified alkyd resin preparation method and a resin prepared by the same. According to the alkyd resin preparation method, vegetable oil is used as a raw material, and unsaturated carboxylic acid and / or unsaturated anhydride are / is added step by step, so that the structure of the alkyd resin is improved. According to the preparation method of the acrylic acid modified alkyd resin, a unsaturated monomer is fed step by step, and the feeding time is controlled, so that the unsaturated monomer is uniformly grafted on an alkyd resin, and the molecular weight distribution is narrow. The acrylic acid modified alkyd resin prepared by the preparation method is applied to water-based coating materials, so that a paint film has the advantages of high drying speed, high glossiness, good fullness, low VOC emission, excellent comprehensive performance and the like.

Owner:WANHUA CHEM BEIJING +1

Polyester type ultra-low density polyurethane resin for shoes

The invention is a shoe resin formulation for insoles, which belongs to polyester type three-component polyurethane resin. Component A is OH-based raw material, which is a mixture containing active hydrogen, mainly composed of long-chain polymer polyols, chain extenders, crosslinking agents, surfactants, foaming agents and other additives. Component B is NCO raw material, mainly MDI prepolymer modified with polyester or polyether. Component C is a catalyst, which is composed of triethylenediamine in ethylene glycol solution. The present invention adopts four kinds of polyester polyols in component A, changes the skeletons of the past two polyols, and adds two polyols of polyester polyols b and d, which is a major breakthrough in the skeleton and changes The structure of the material is changed, which also makes a fundamental change in the appearance and physical properties of the material. In addition, two kinds of foaming agents and two kinds of silicone oils are used, which greatly increase the foaming power and fluidity of the material, make the density of the product lower and more stable, and save the amount of material used. The density is also much lower than similar polyester products, the general density is 0.25~0.30g / cm3. Not only that, the present invention also improves the B component, which greatly reduces the shrinkage phenomenon of the product, the cortex is thicker, the appearance surface effect is better, and the product grade is improved. The product produced by the invention has fast setting, fast curing and short mold release time, which can be released from the mold in 2.5 to 3.5 minutes from the original 7 to 9 minutes, which greatly improves the production efficiency.

Owner:无锡双象新材料有限公司

Medical stent for digestive system and manufacturing method thereof

Owner:SHANDONG PROVINCIAL HOSPITAL AFFILIATED TO SHANDONG FIRST MEDICAL UNIVERSITY

A kind of dissolvable self-healing natural polymer hydrogel and preparation method thereof

ActiveCN109721742BLow toxicityRich materialSurgical adhesivesBandagesBiologic scaffoldFunctional monomer

The invention discloses a dissolvable self-healing natural polymer hydrogel and a preparation method thereof. The natural polymer sodium alginate is used as a raw material, the functional monomer methacrylic acid is introduced, and an initiator and deionized water are used as auxiliary raw materials. , a natural polymer hydrogel (SAM) with excellent self-healing properties and solubility was prepared by a one-pot method. The hydrogel prepared by the invention has a fast self-healing rate, the healing is not limited by the section of the incision, and has good solubility. When the hydrogel is put into a certain amount of water, the hydrogel can be completely dissolved without residue , using it as a drug carrier, its release rate is stable, and the drug can achieve 100% complete release without residue. And the prepared hydrogel has good biocompatibility and degradability, and the dissolvable self-healing natural polymer hydrogel prepared by the present invention is used in the field of biomedical materials such as wound dressings, tissue and organ culture and biological scaffold materials. It has broad application prospects.

Owner:EAST CHINA NORMAL UNIV

Gradient porous magnesium-based metal component body for bone tissue engineering and preparation method thereof

ActiveCN110639064BAchieve degradationImprove mechanical propertiesTissue regenerationProsthesisHuman bodyBone tissue engineering

The invention relates to a gradient porous magnesium-based metal component body for bone tissue engineering, which is characterized in that it at least includes an inner core prefabricated body, a ring-shaped outer layer prefabricated body located on the periphery of the inner core prefabricated body, and an inner inner prefabricated body and an outer layer prefabricated body. Between the ring-shaped middle layer prefabricated body, the core prefabricated body, the middle layer prefabricated body and the outer layer prefabricated body all have pores, and the pores of the three are connected, and the inner core prefabricated body, the middle layer prefabricated body The porosity of the body and the outer prefabricated body decreases sequentially. The invention also relates to a preparation method. After being implanted in the human body, it can meet the different requirements for dynamic matching between degradation rate and mechanical properties in different periods.

Owner:CHINA WEAPON SCI ACADEMY NINGBO BRANCH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com