Alkyd resin preparation method and prepared resin thereof, and acrylic acid modified alkyd resin preparation method and prepared resin thereof

An alkyd resin, functional technology, applied in the direction of coating, etc., can solve the problems of slow drying speed, slow surface drying speed of paint film, easy gelation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

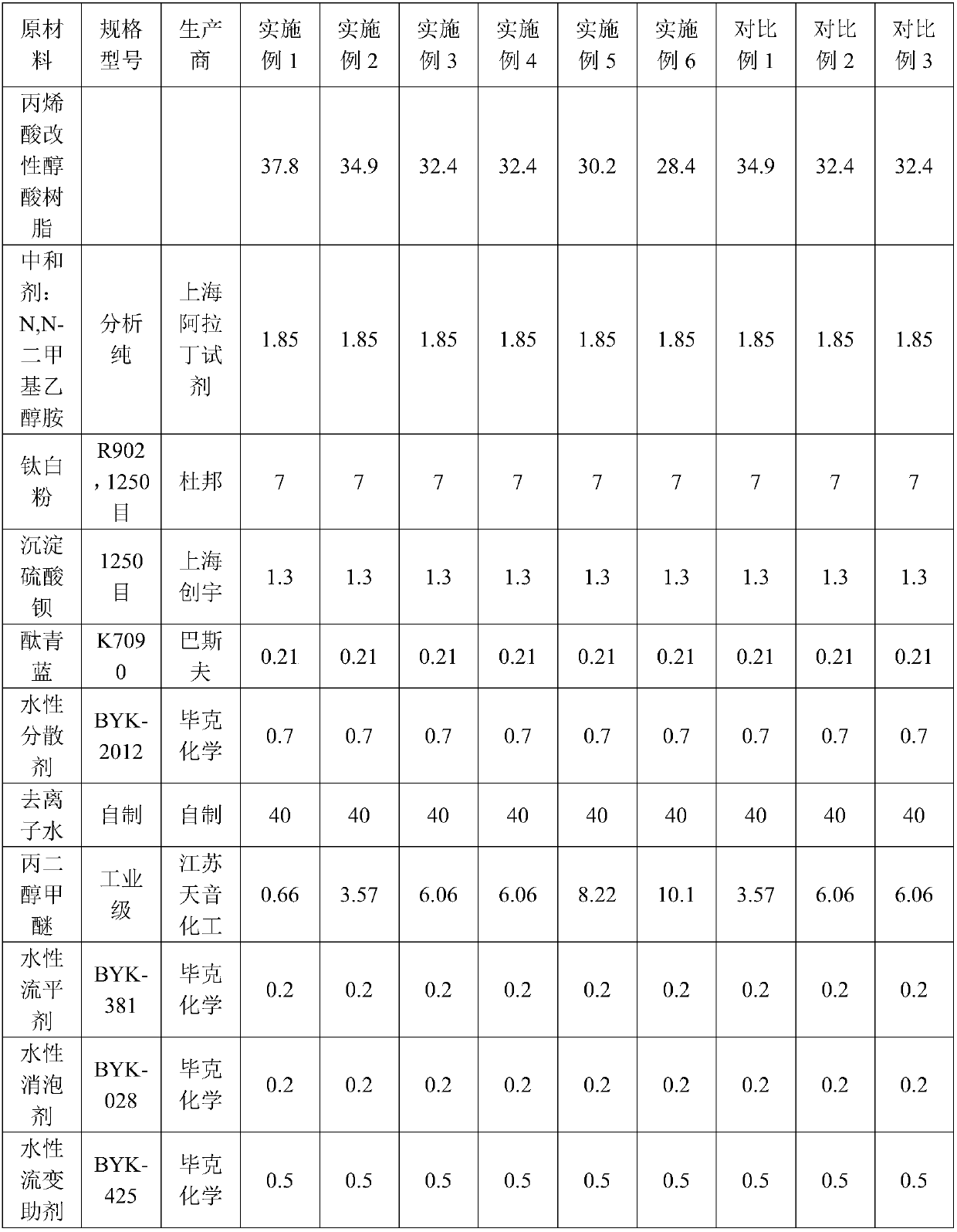

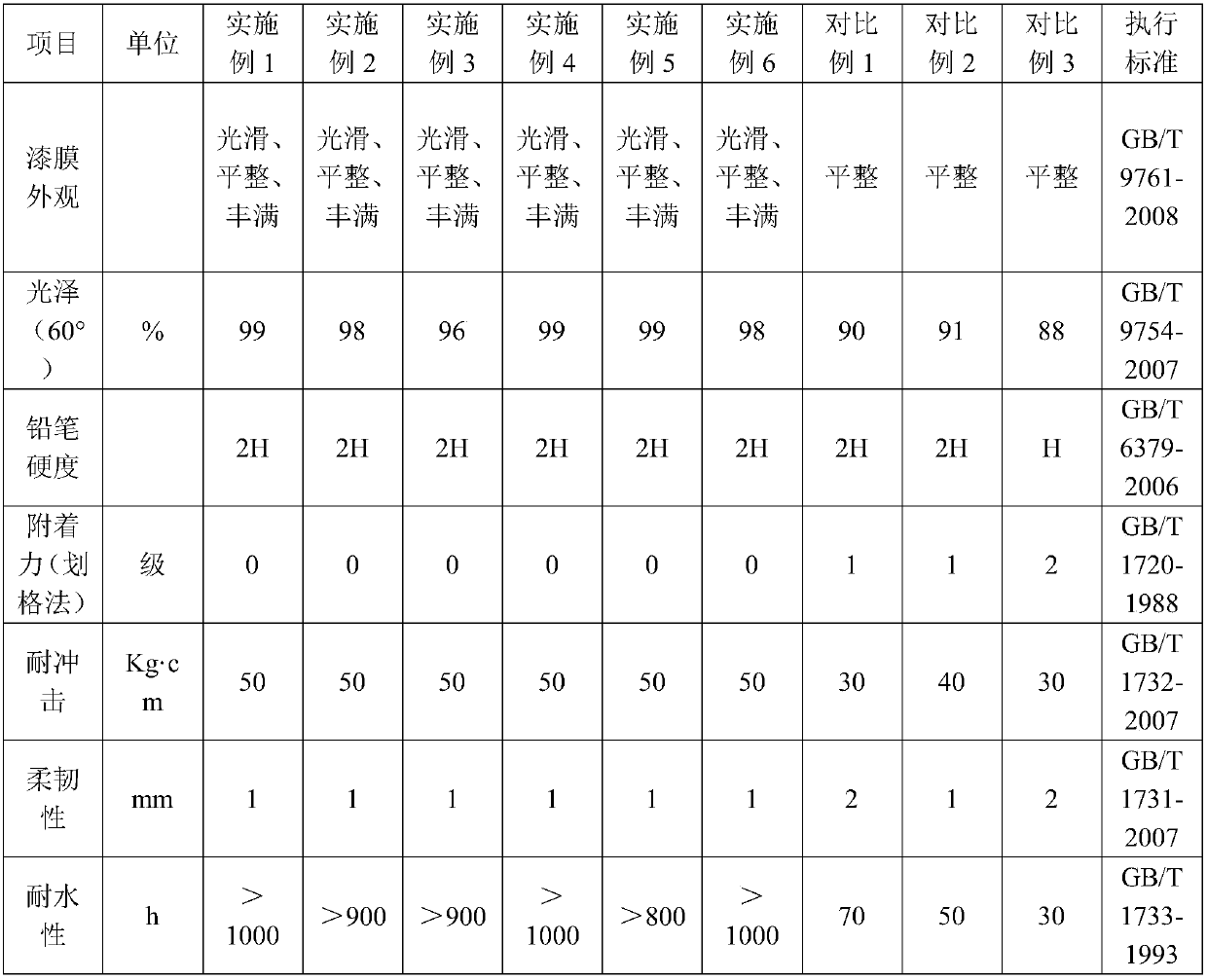

Examples

Embodiment 1

[0092] The preparation method of alkyd resin is as follows:

[0093] 1. Under a nitrogen atmosphere, put 225.9g of soy oil, 353g of trimethylolpropane, 35.1g of pentaerythritol, 361.8g of isophthalic acid, and 1g of tetrabutyl titanate into the reactor, start stirring, and raise the temperature to 175°C. The reaction time is 2 hours, then continue to heat up rapidly to 245±5°C for reaction, when the reaction system in the reactor is clear and transparent, continue to keep warm for 30 minutes;

[0094] 2. Cool down the reaction system to 175°C, put in 9.2g of maleic anhydride and 60g of butyl acetate, raise the temperature to 220°C, and the reaction time is 2 hours. The reaction process is condensed and refluxed for dehydration;

[0095] 3. Lower the temperature of the reaction system to 175°C, add 15g of maleic anhydride, control the temperature of the reaction system at 165°C to react, and the reaction time is 1 hour;

[0096] 4. Start the vacuum pump to remove the reflux so...

Embodiment 2

[0103] The preparation method of alkyd resin is as follows:

[0104] 1. Under a nitrogen atmosphere, put 180g of soy acid, 141g of linoleic acid, 70g of neopentyl glycol, 266g of pentaerythritol, 177g of isophthalic acid, 124g of phthalic anhydride, 17.4g of trimellitic anhydride, and 1g of tetrabutyl titanate. In the reaction kettle, start stirring, raise the temperature to 180°C, and the reaction time is 1.5 hours, then continue to rapidly raise the temperature to 245°C for reaction, and start the vacuum pump to force dehydration at the end of the water outlet, when the reaction system in the reaction kettle is clear and transparent, continue to keep warm for 30 minutes ;

[0105]2. Cool down the reaction system to 175°C, put in 9.6g of maleic anhydride, raise the temperature to 220°C, and the reaction time is 1.5 hours. During the reaction process, use a vacuum pump to force dehydration;

[0106] 3. Lower the temperature of the reaction system to 170°C, add 15g of maleic a...

Embodiment 3

[0115] The preparation method of alkyd resin is as follows:

[0116] 1. Under a nitrogen atmosphere, put 100g of ricinoleic acid, 305.8g of soy oil, 293.6g of trimethylolpropane, 29.2g of pentaerythritol, 200g of isophthalic acid, 46.8g of terephthalic acid, and 1g of tetrabutyl titanate. In the reactor, start stirring, raise the temperature to 175°C, the reaction time is 2 hours, then continue to rapidly raise the temperature to 250°C for the reaction, when the reaction system in the reactor is clear and transparent, continue to keep warm for 40 minutes;

[0117] 2. Cool down the reaction system to 170°C, put in 9.6g of maleic anhydride and 38g of butyl acetate, raise the temperature to 225°C, and the reaction time is 1 hour, and the reaction process is condensed and refluxed for dehydration;

[0118] 3. Lower the temperature of the reaction system to 170°C, add 15g of maleic anhydride, and control the temperature of the reaction system to react at 160°C, and the reaction tim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com