Patents

Literature

53results about How to "Dry comprehensive" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

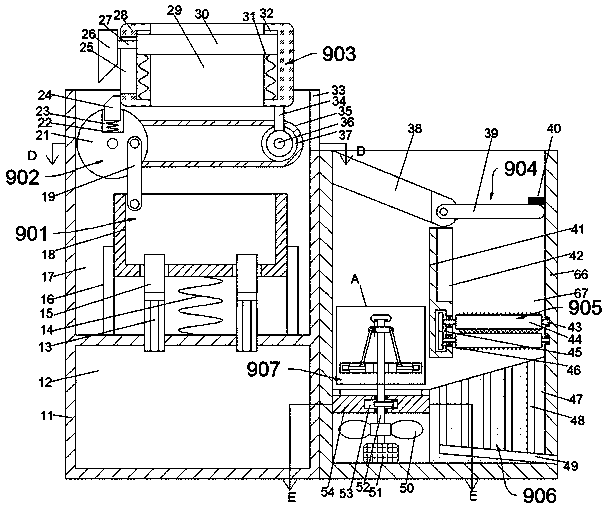

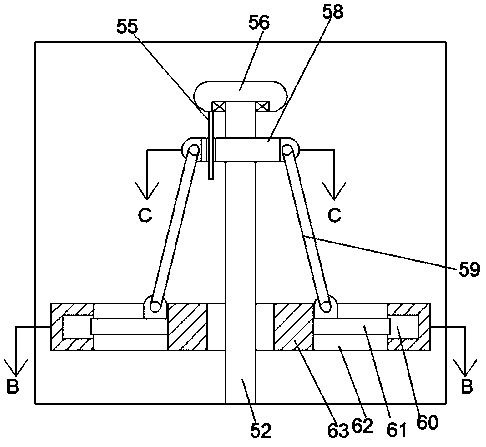

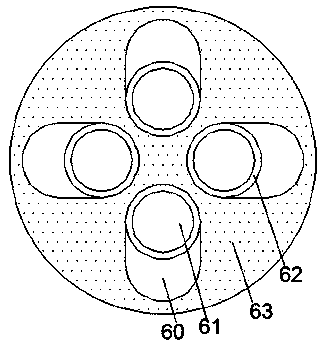

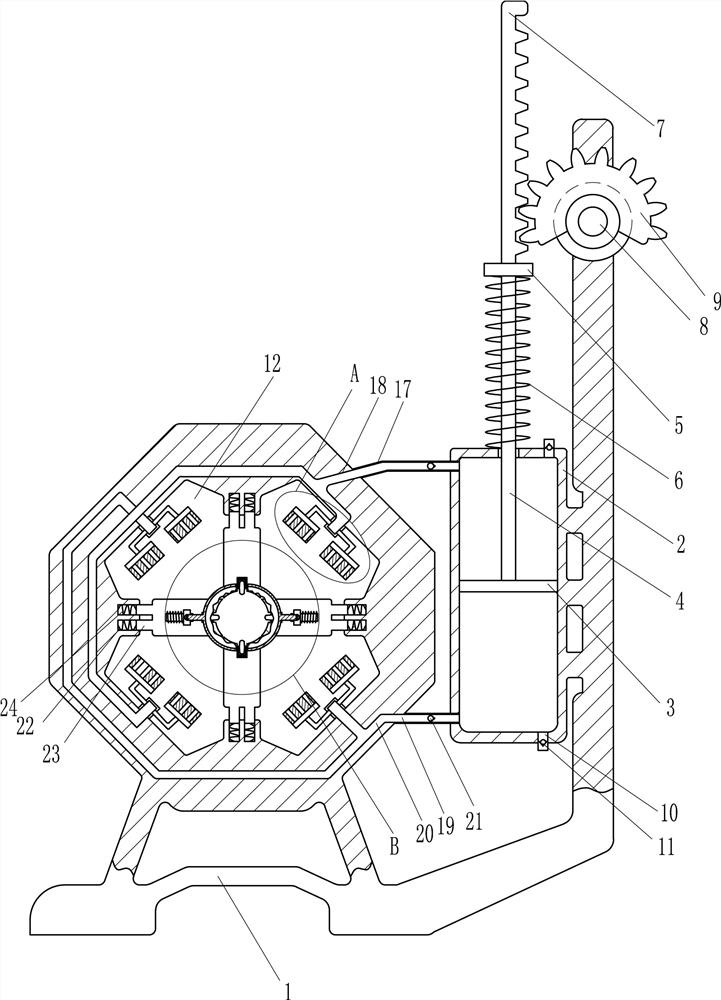

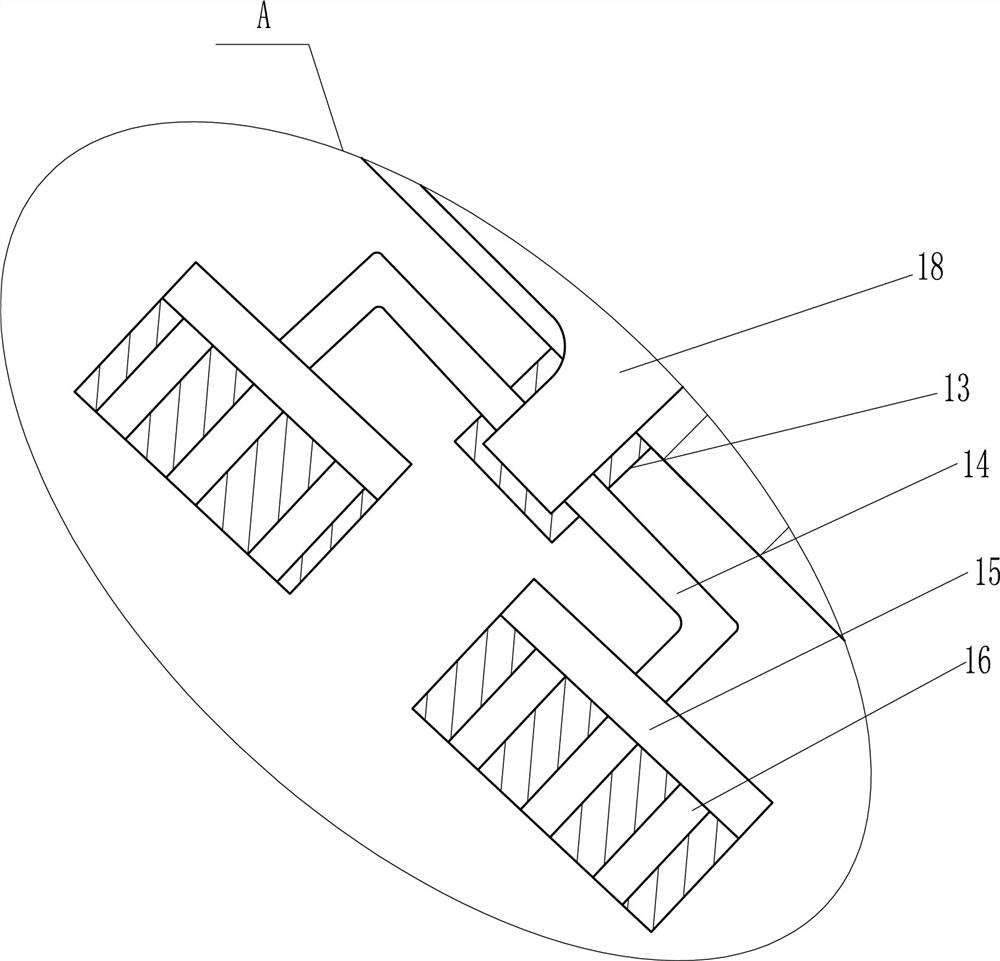

Medical appliance cleaning circulation sterilization drying device

InactiveCN106668891AScrub comprehensivelyImprove efficiencyDrying gas arrangementsCleaning using toolsDrive shaftDrive motor

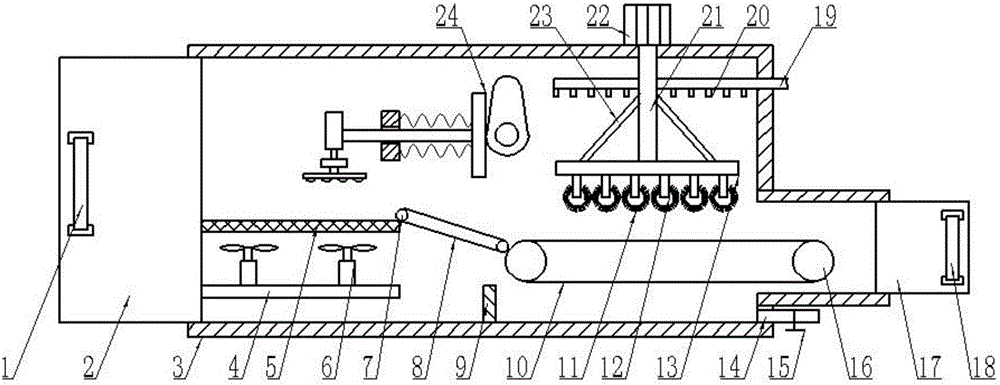

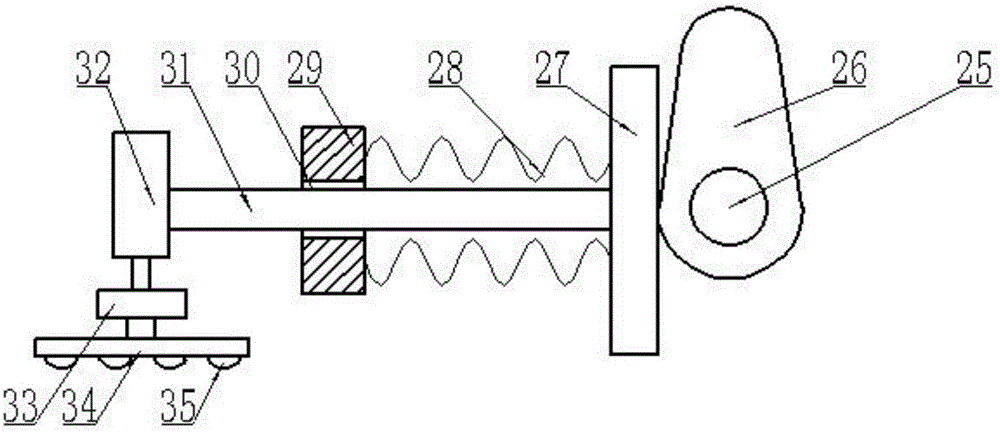

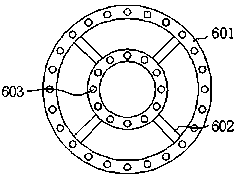

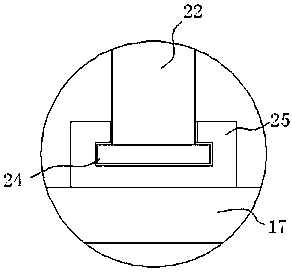

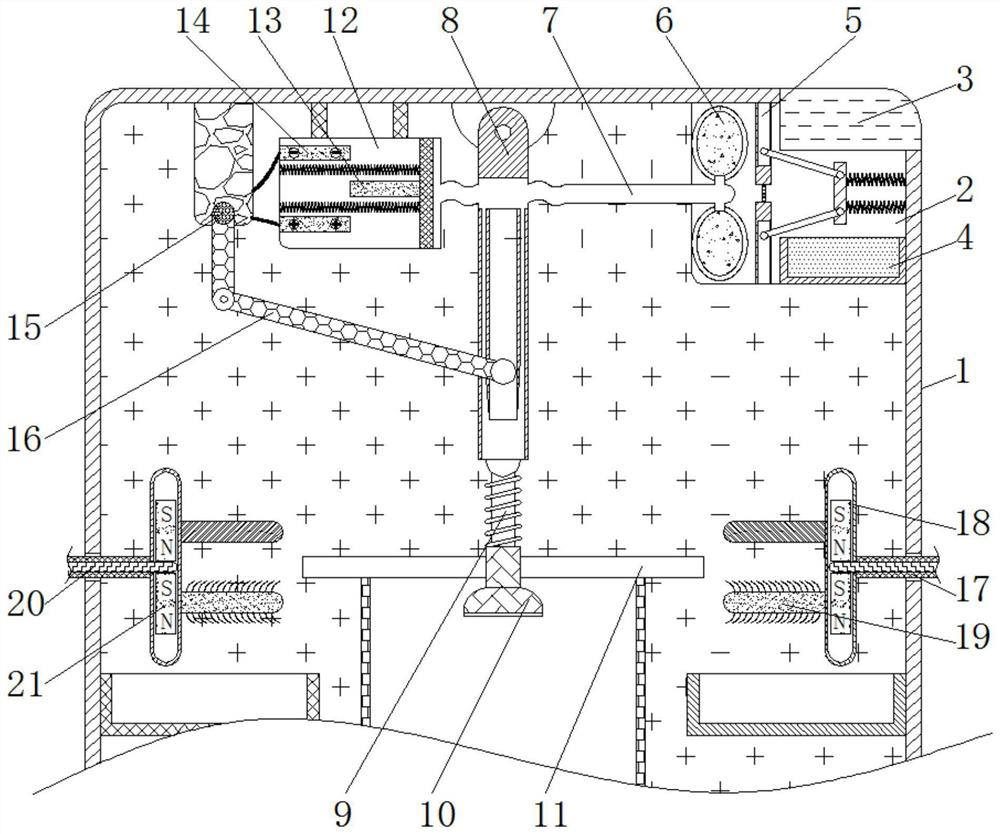

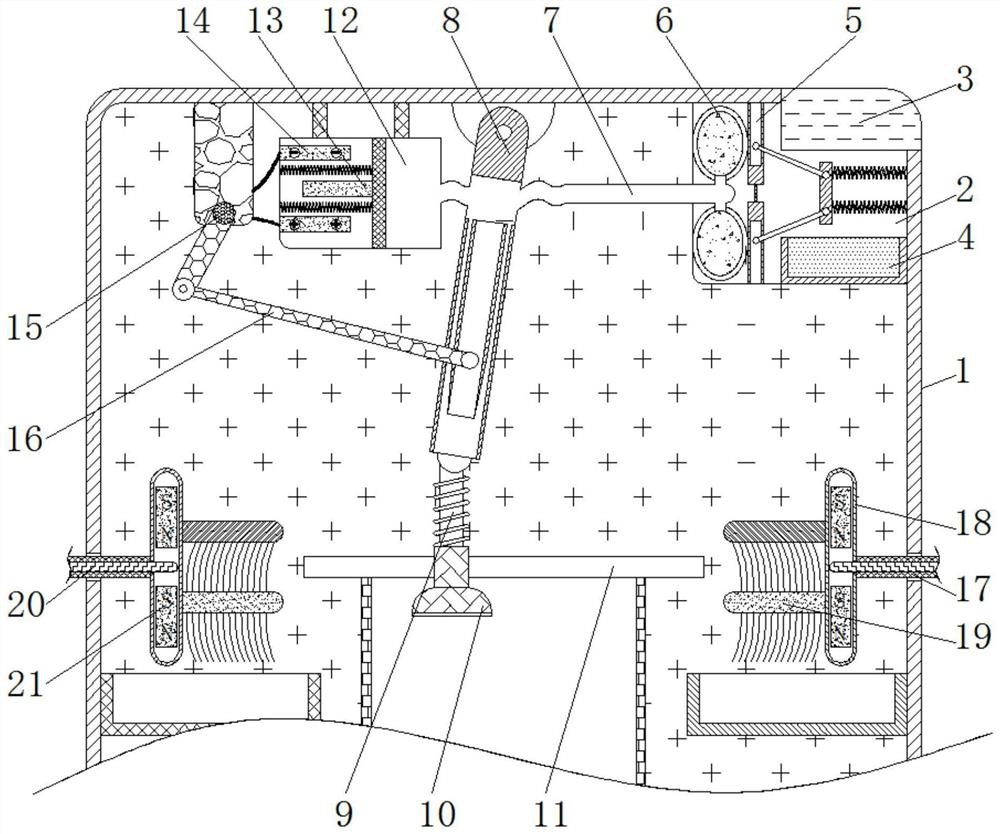

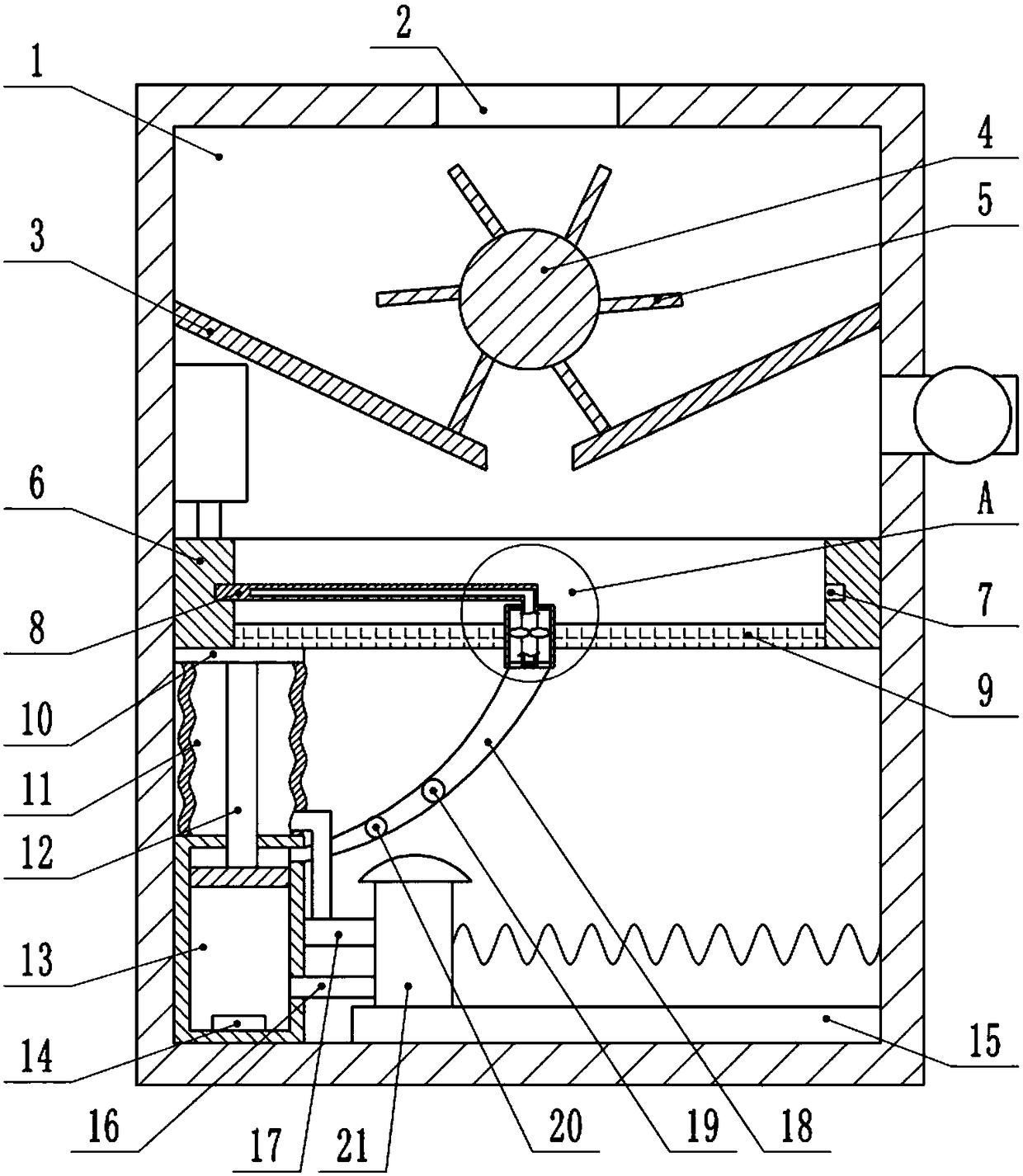

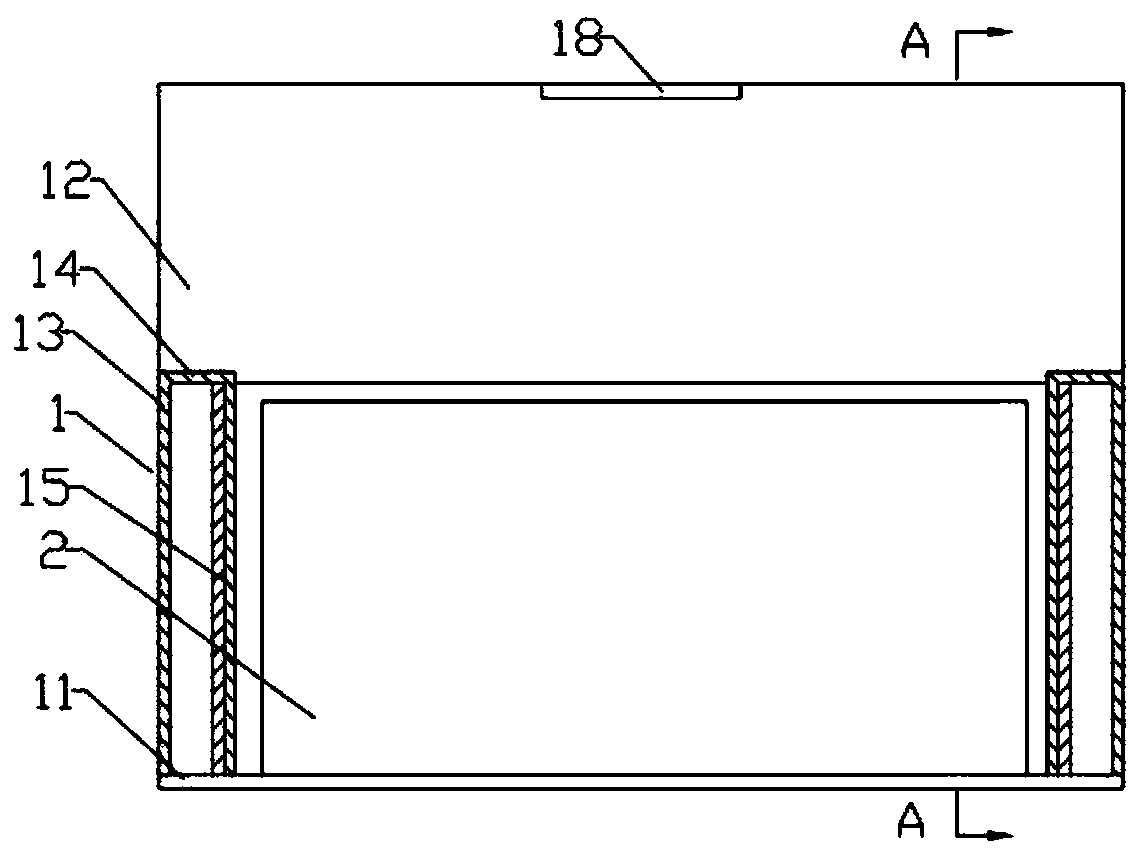

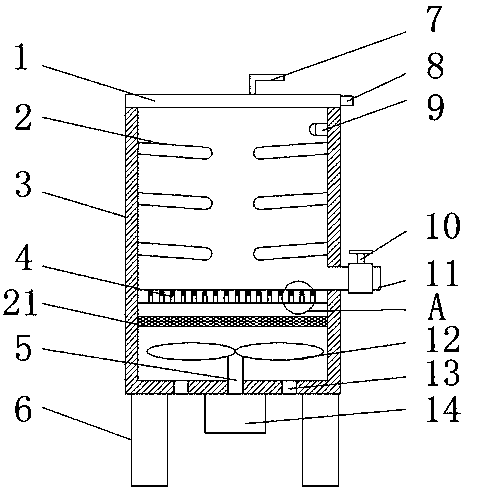

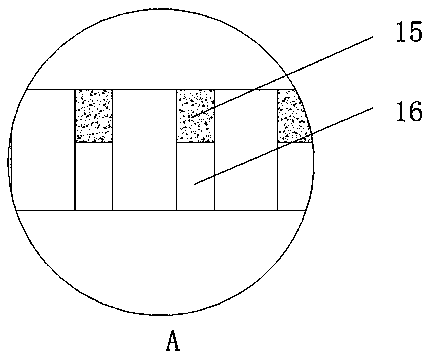

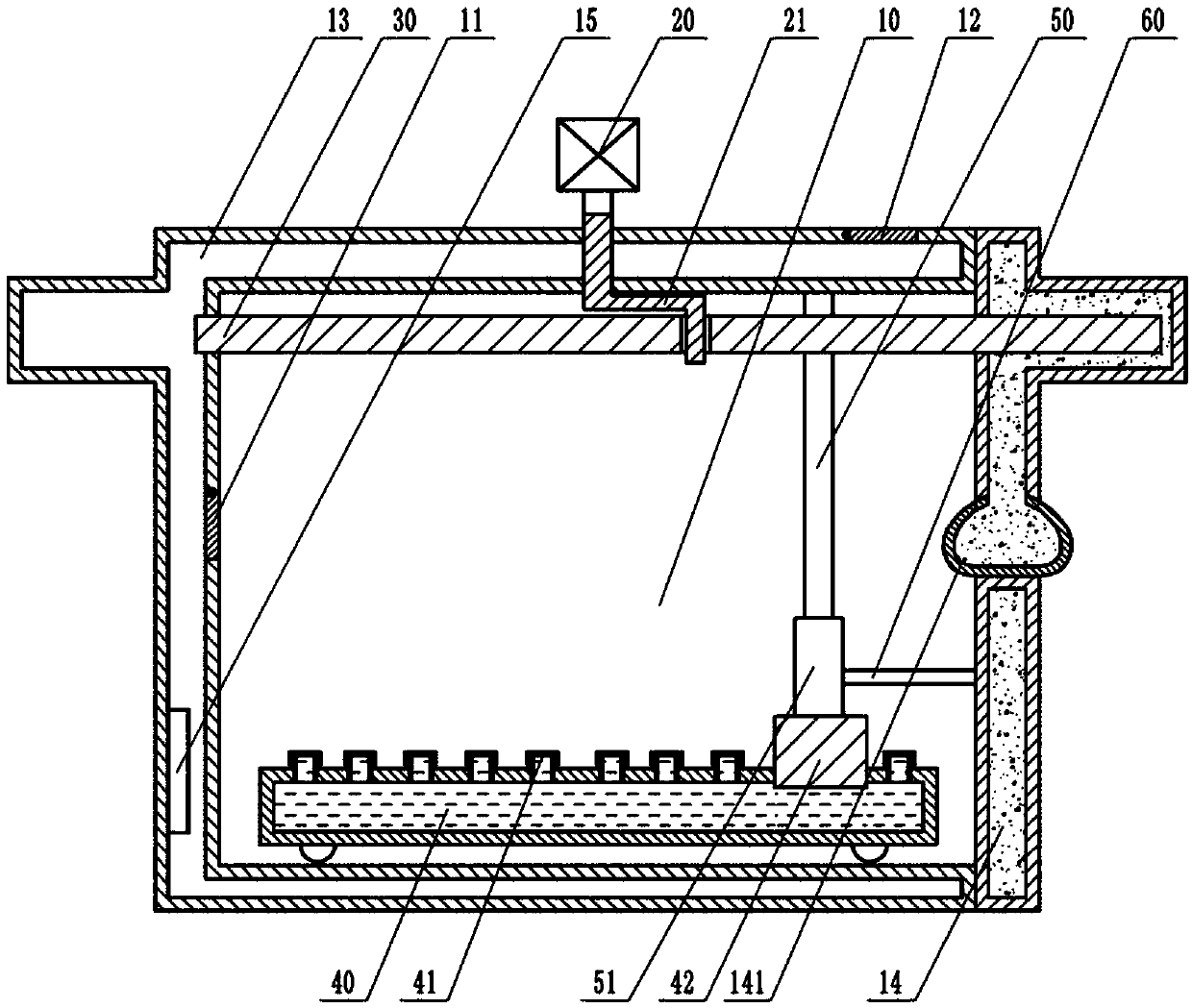

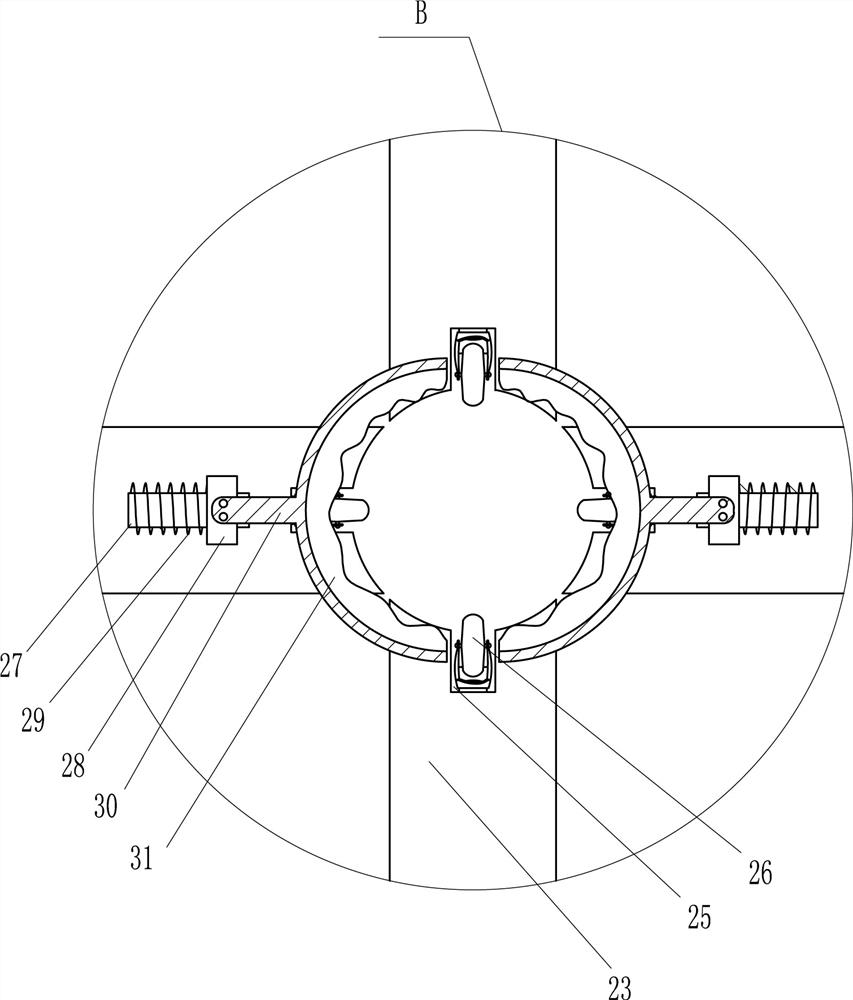

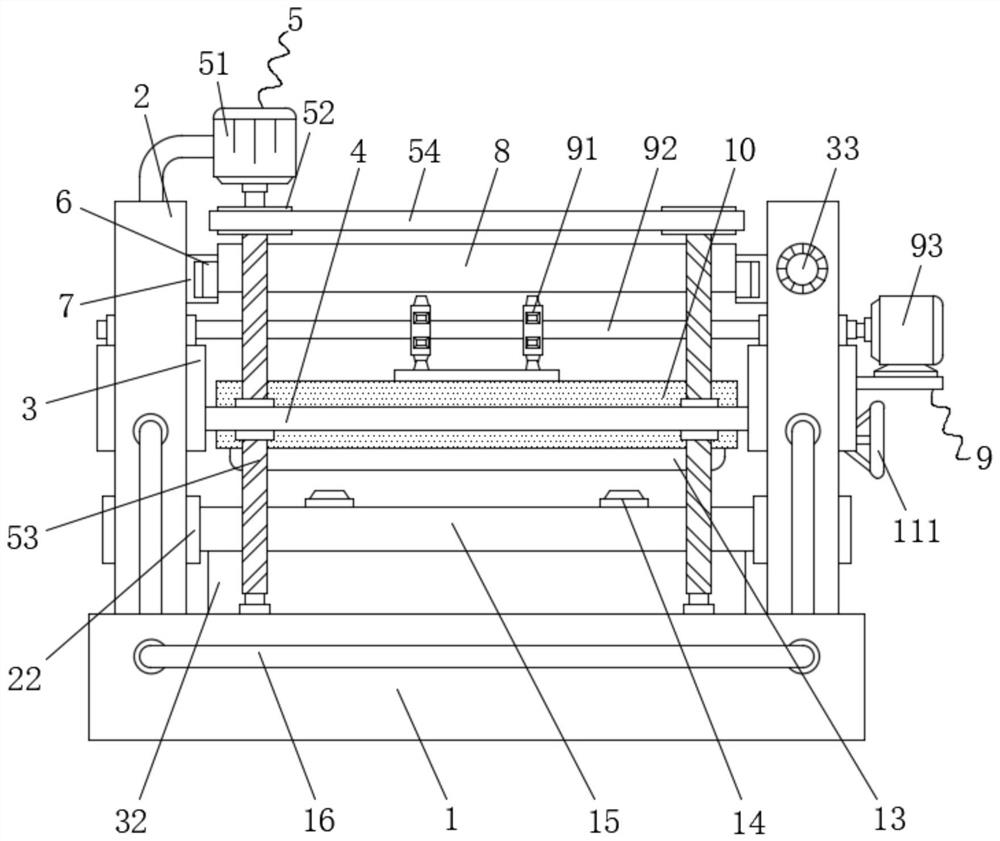

The invention provides a medical appliance cleaning circulation sterilization drying device, which comprises a left box door, a box body and a right box door, wherein a cleaning device, a conveying device, a sterilization device and a drying device are arranged on the box body; the cleaning device comprises a water outlet pipe, a water inlet pipe and a driving motor; the driving motor is fixed at the upper end of the box body; the lower end of the driving motor is provided with a telescopic shaft; the conveying device comprises a first conveying roller, a first conveying belt, a second conveying roller and a second conveying belt; the sterilization device comprises a driving shaft, a cam, a baffle plate, a guide plate, a connecting and an electric push rod; the drying device comprises an article placing plate and a drying plate; a separation plate is arranged between the drying device and the cleaning device; the article placing plate is fixed on the box body in a welding mode; an electric fan is arranged on the article placing plate; the drying plate is fixed on the box body in a welding mode, and is in a reticular shape. The medical appliance cleaning circulation sterilization drying device has the advantages that the cleaning is fast and clean; the sterilization is comprehensive; the drying and sterilization can be performed at the same time.

Owner:河南常青藤信息科技有限公司

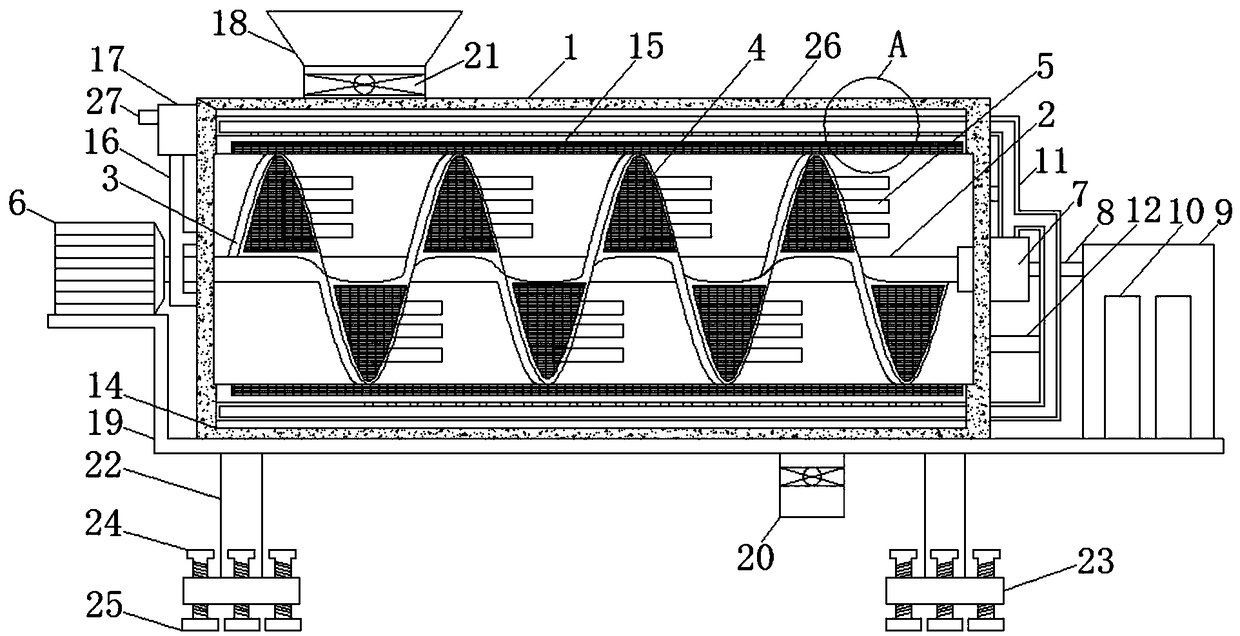

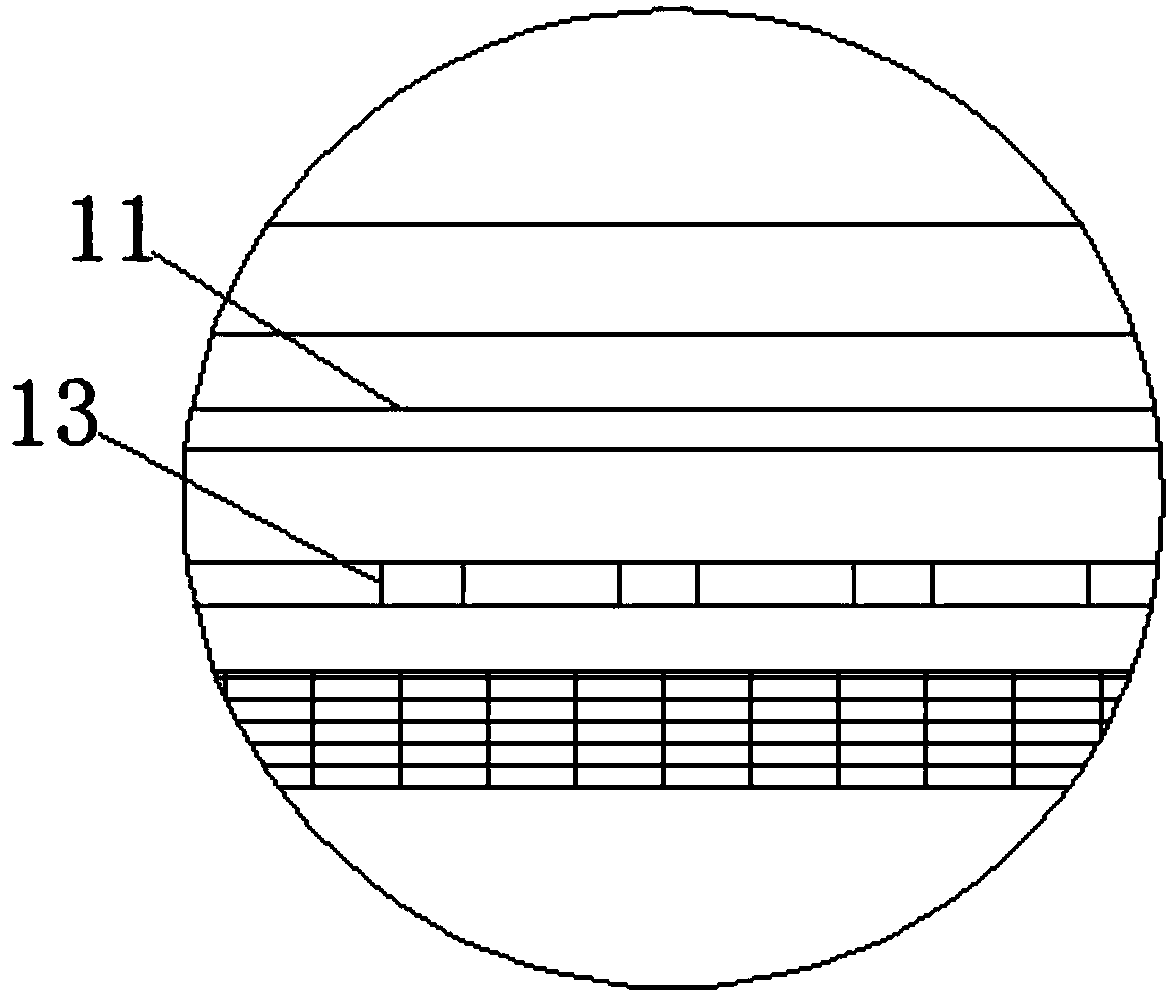

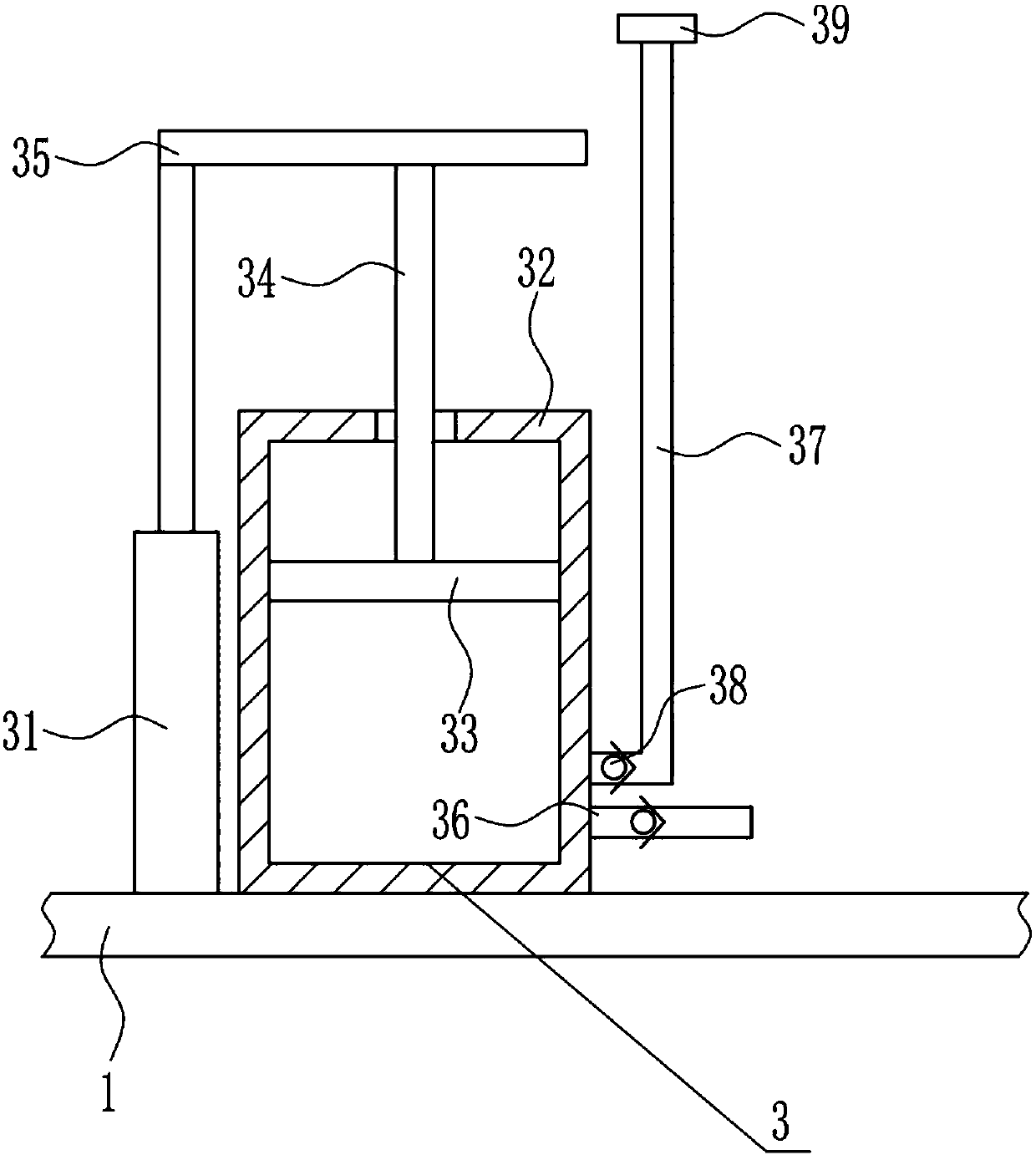

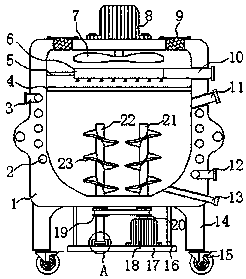

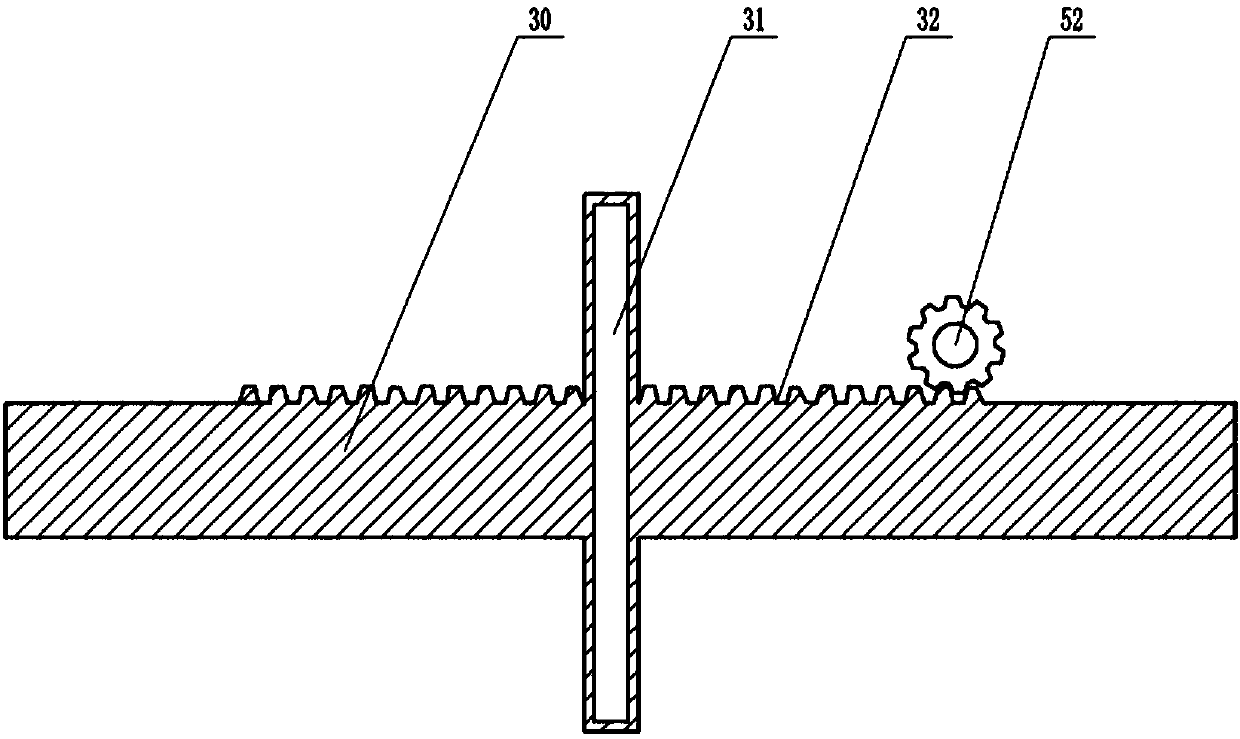

Push type medicinal materials drier

InactiveCN102393131ADry comprehensiveLarge drying capacityDrying solid materials with heatDrying gas arrangementsAgricultural engineeringLower upper

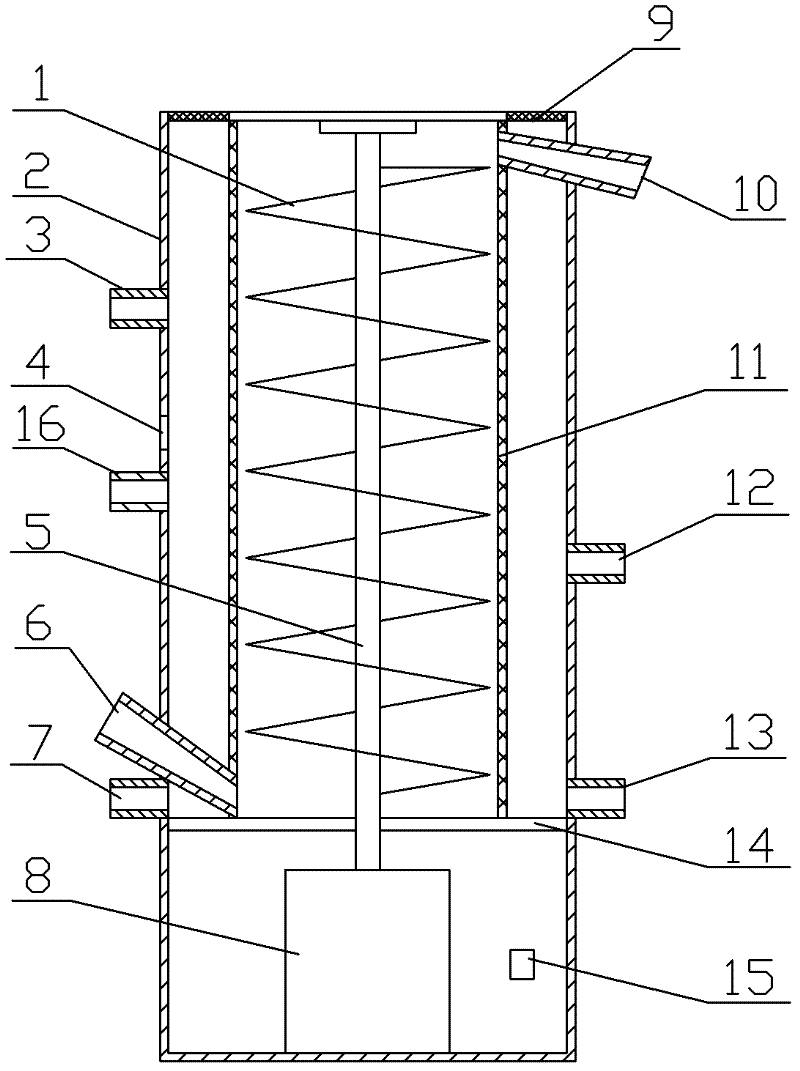

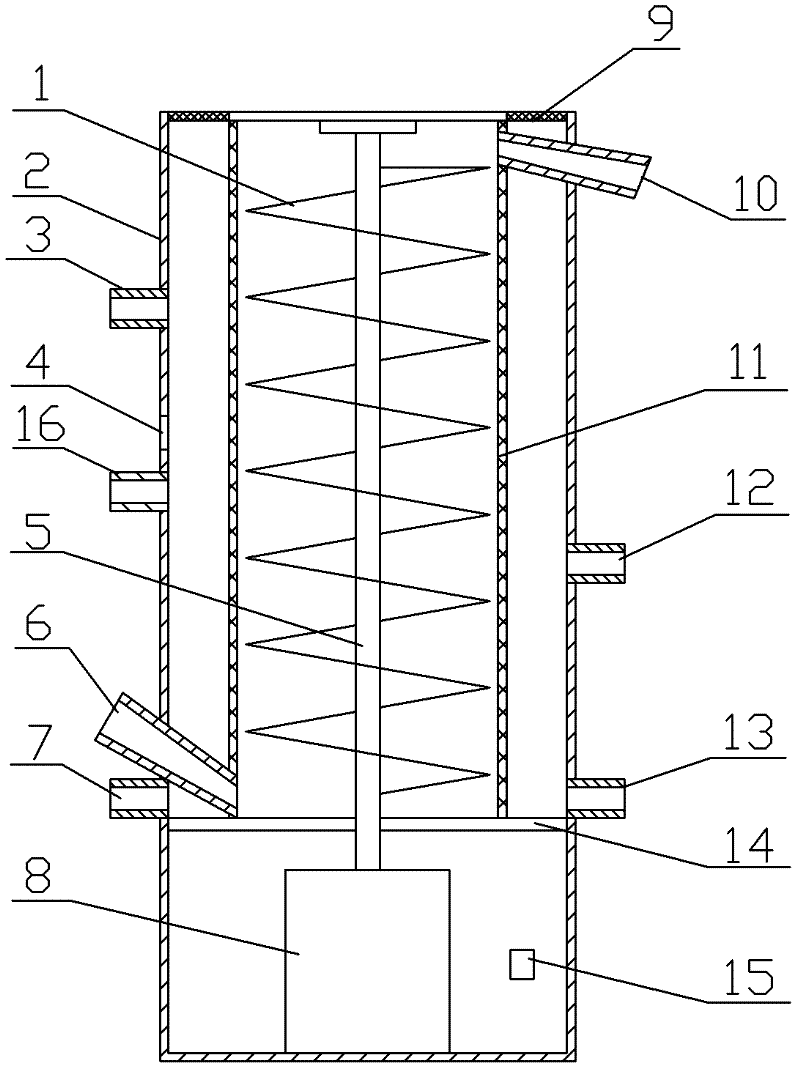

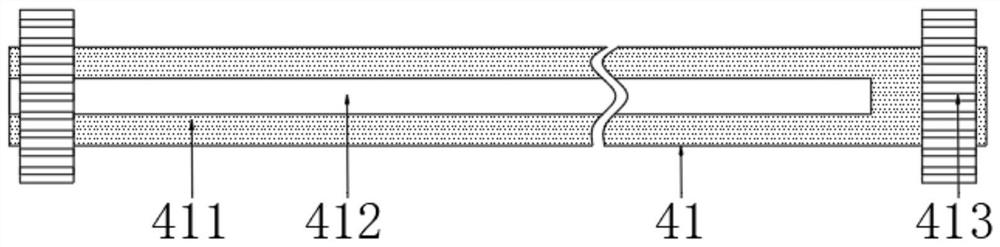

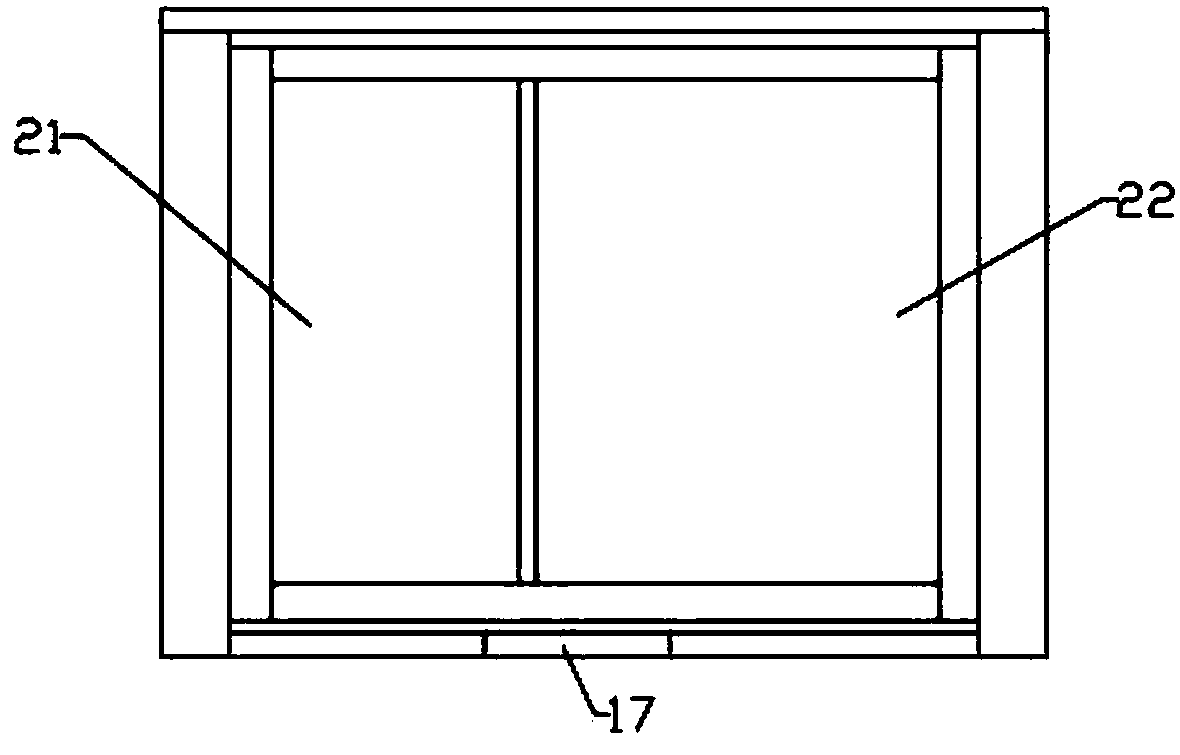

The invention discloses a push type medicinal materials drier which belongs to a drier. The structure comprises a shell, a mesh-typed sleeve, a speed-regulating motor, a spiral boosting piece and a hot wind inlet. Wherein a partition plate is arranged in the shell, the mesh-typed sleeve is arranged on the upper part of the partition plate, the speed-regulating motor is arranged at the lower part of the partition plate, a rotating shaft connected with the speed-regulating motor penetrates through the partition plate and is arranged in the mesh-typed sleeve, the spiral boosting piece is arranged on the rotating shaft, a speed-regulating switch connected with the speed-regulating motor is arranged on the shell, a material feeding opening and a material discharging opening are respectively arranged at the lower part and the upper part of the mesh-typed sleeve, a hot wind inlet and a viewing port are respectively arranged on the shell at the upper part of the partition plate, a primary dehumidification port is arranged on the side wall of the shell, and a moisture removing port is arranged on top of the shell. The push type medicinal materials drier has the characteristics that: weather effect can be avoided when the drier is dried, machining can be carried out at any time, drying quantity is large, whole area of the medicinal materials can be comprehensively contacted by hot wind, medicinal materials heating is comprehensive, drying speed is increased, and the like.

Owner:INST OF AGRO FOOD SCI & TECH SHANDONG ACAD OF AGRI SCI

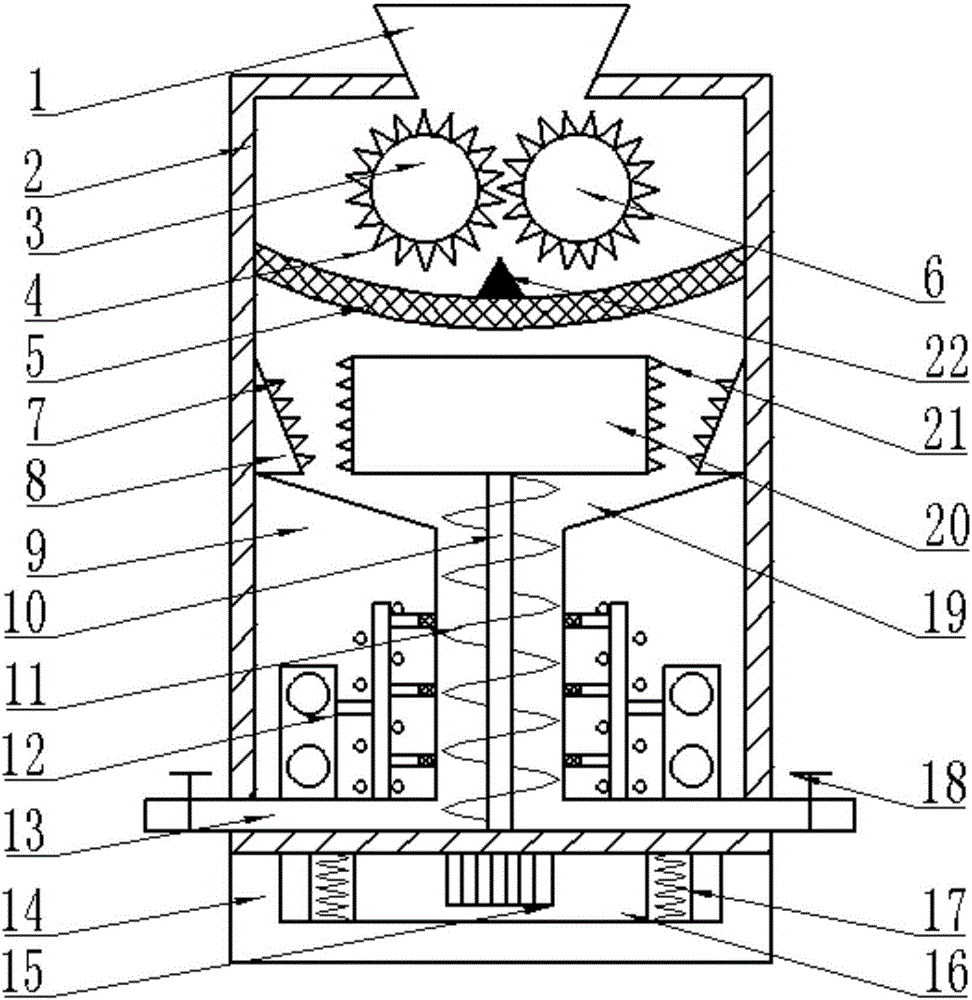

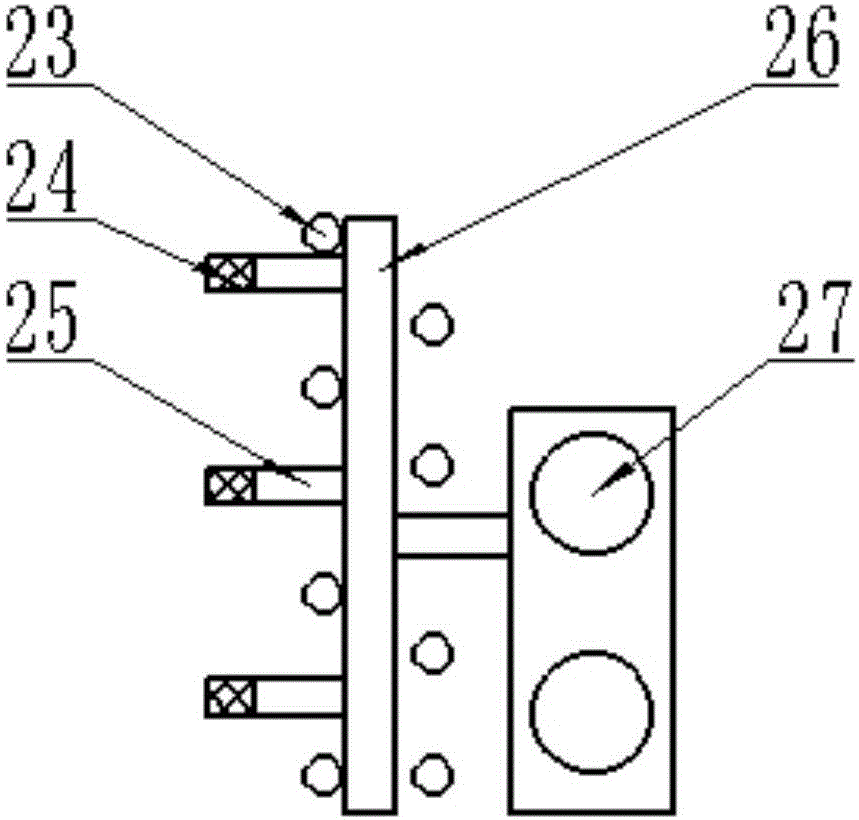

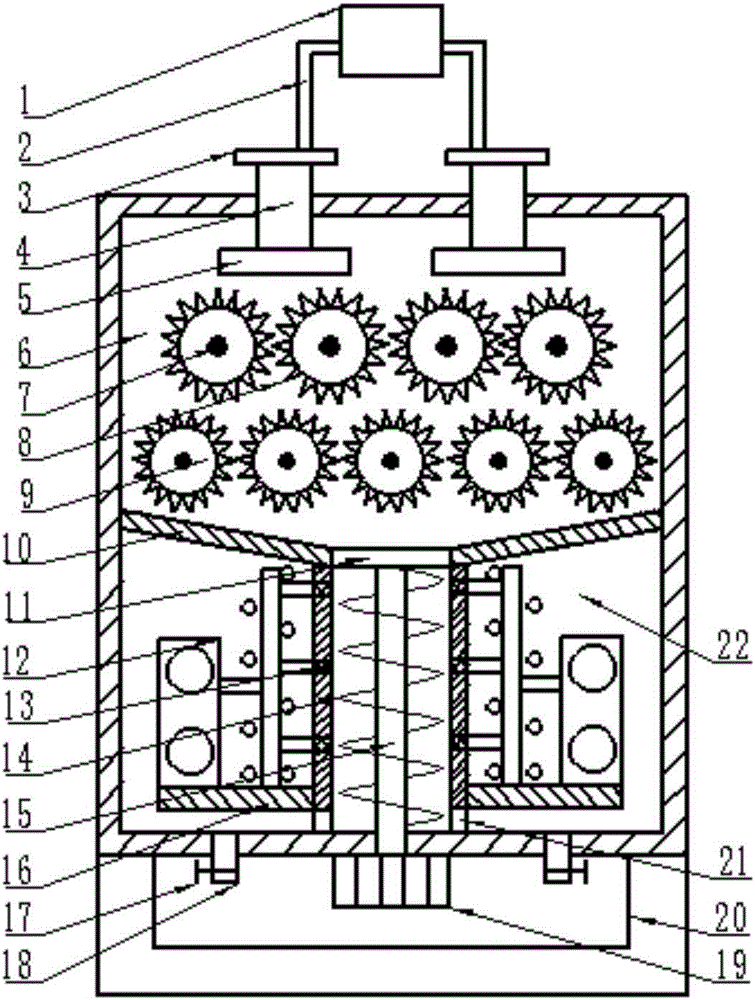

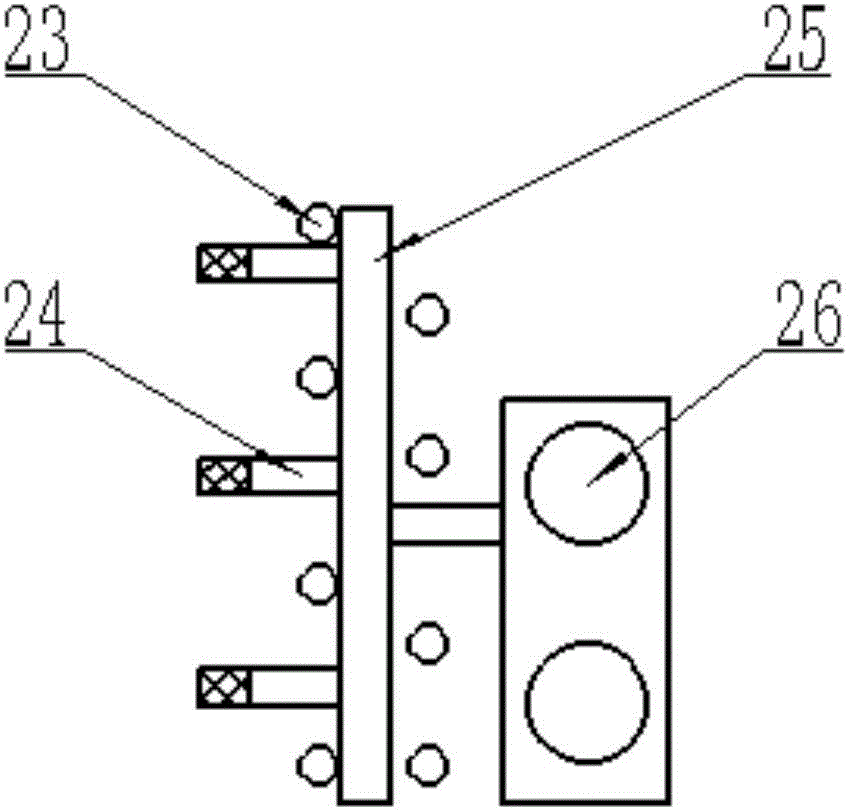

Smashing and drying device for rubber production

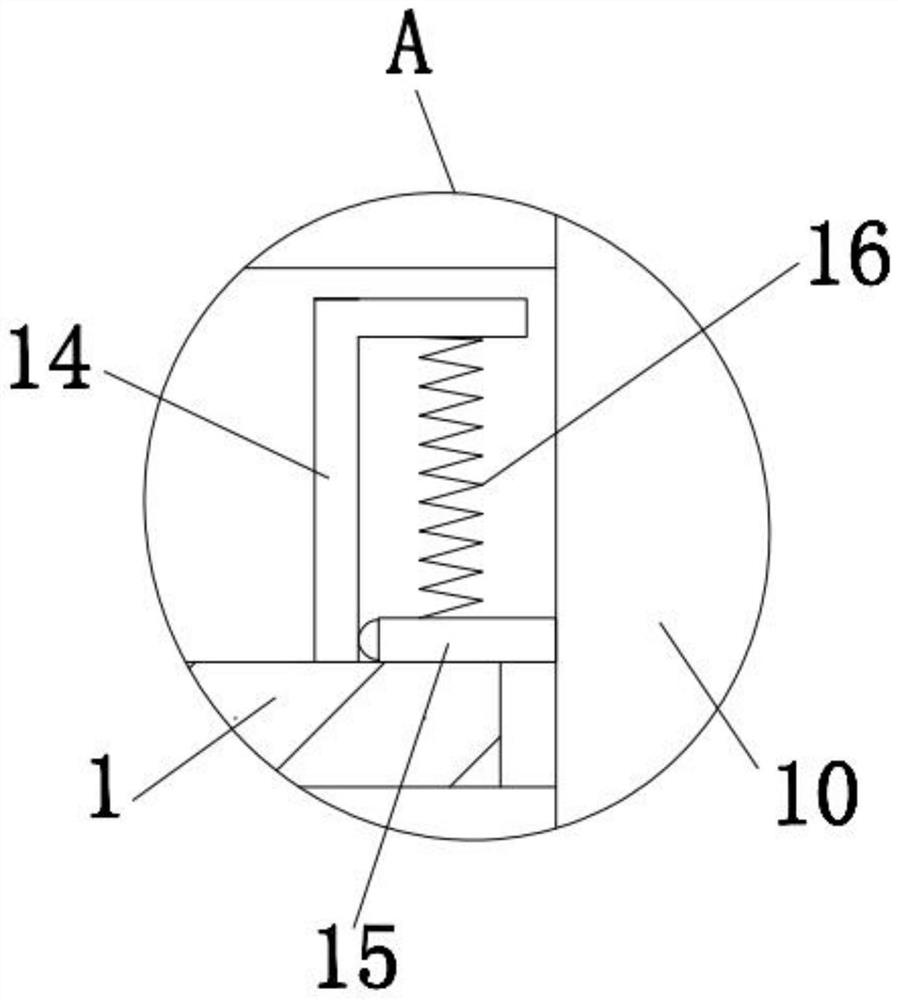

InactiveCN106738484ADry comprehensiveReduce vibrationPlastic recyclingDrying gas arrangementsDrive motorShock absorber

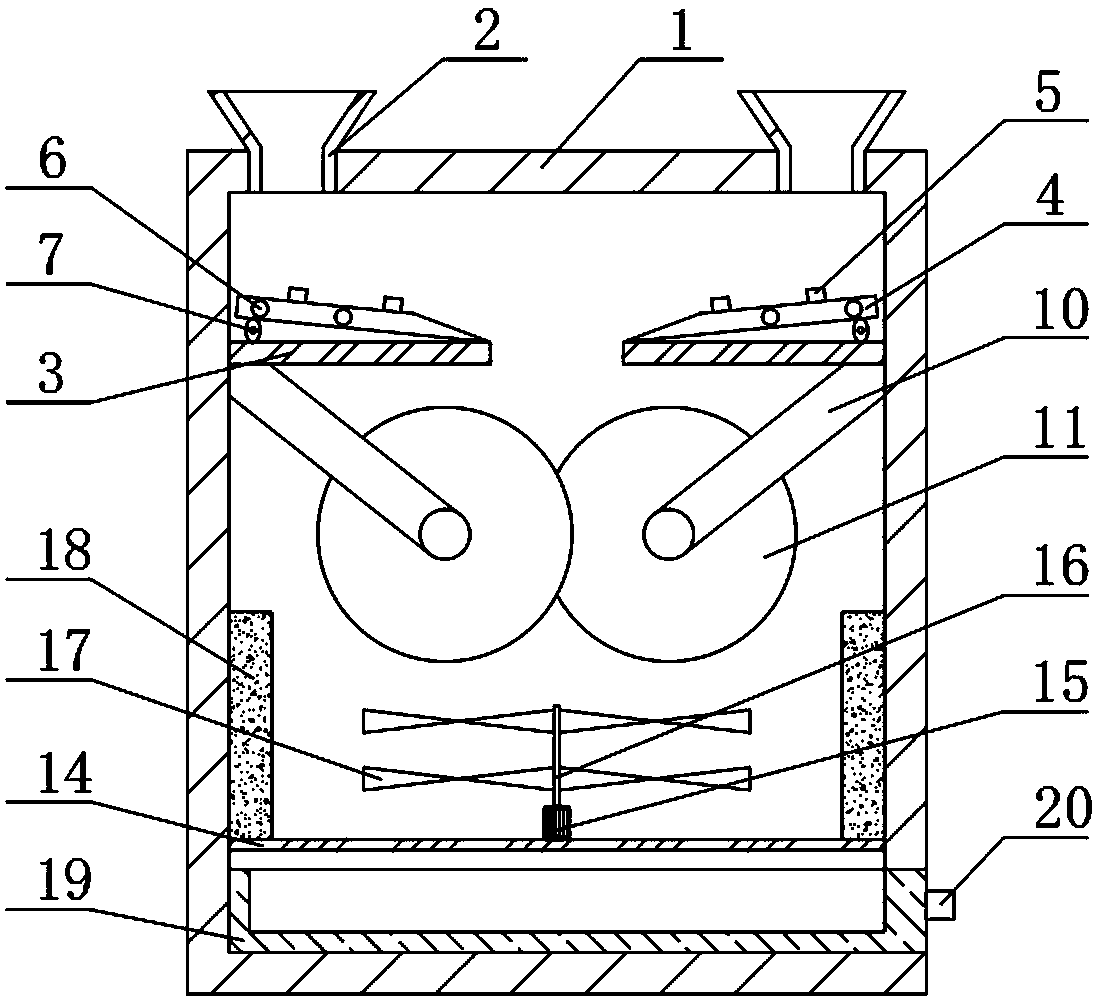

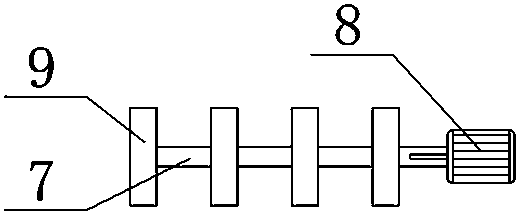

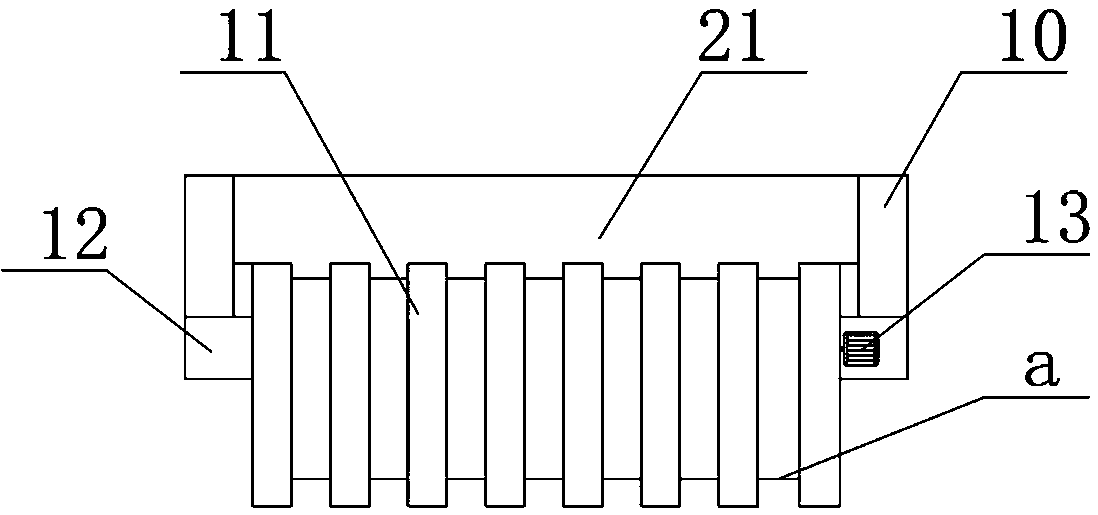

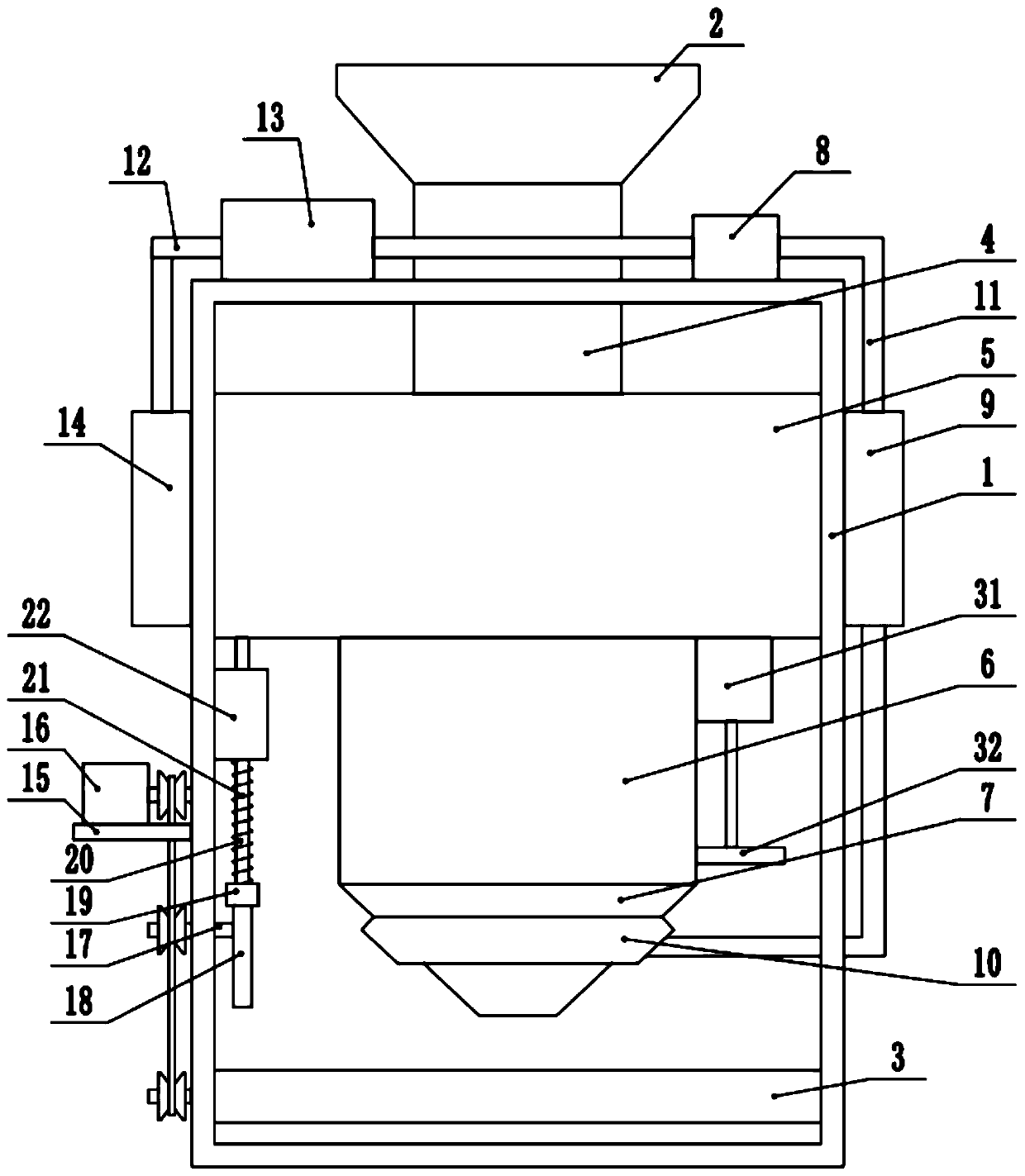

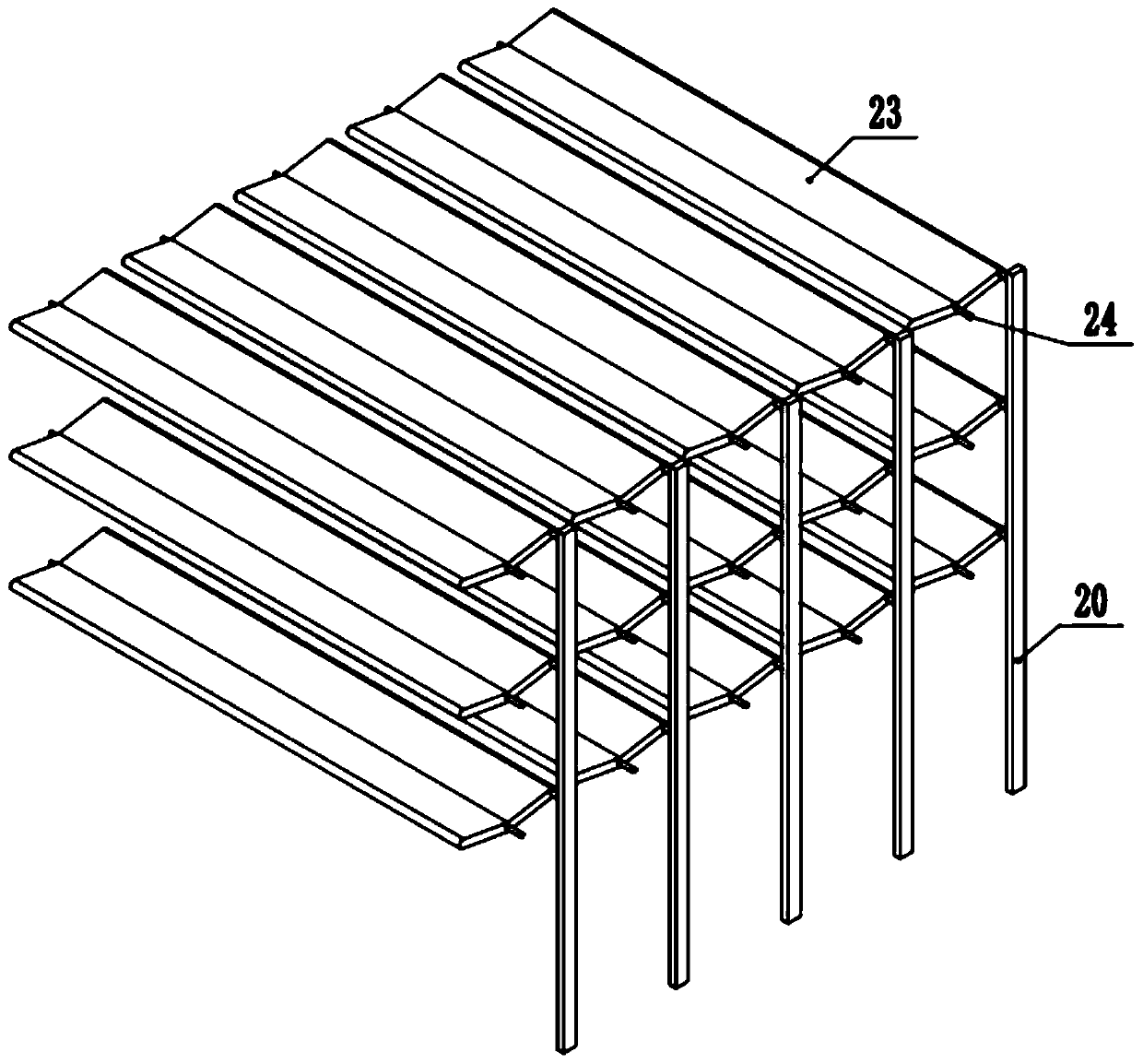

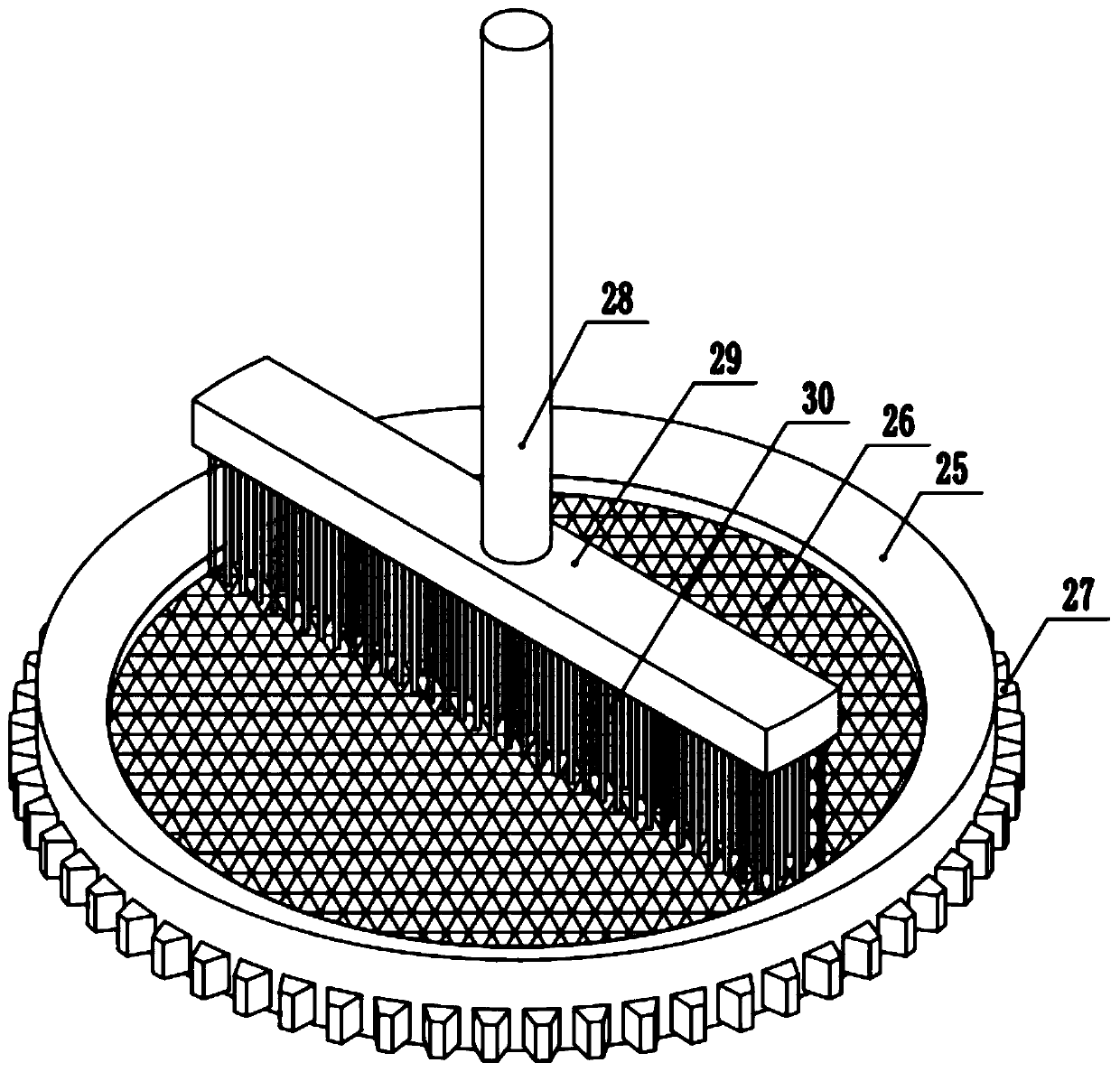

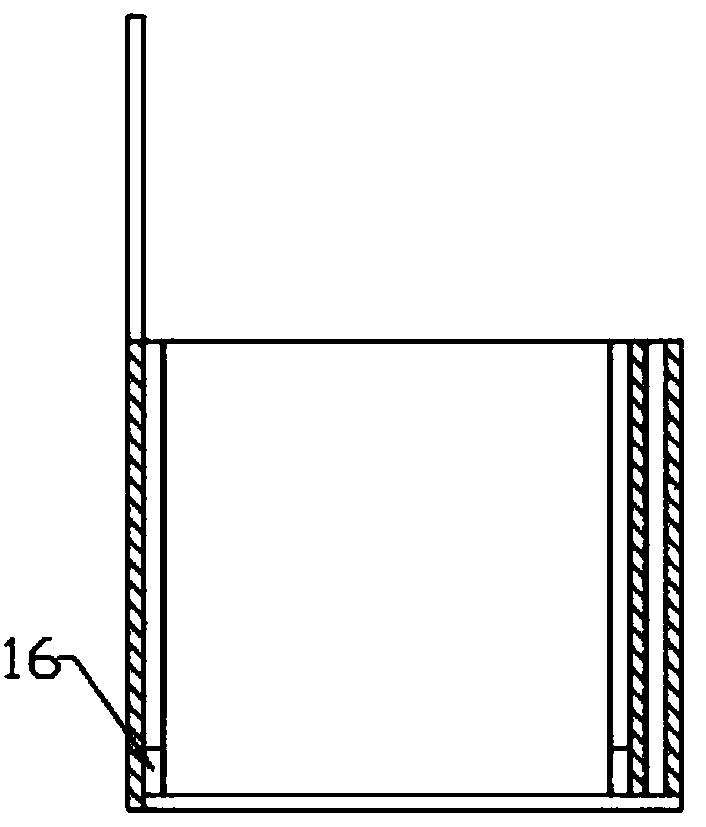

The invention provides a smashing and drying device for rubber production. The smashing and drying device comprises a box body, a smashing device, two drying chambers and a motor chamber, wherein a feed hopper and discharge pipes are arranged on the box body; the smashing device comprises a left smashing roller, a right smashing roller, side plates and an intermediate plate; the left smashing roller and the right smashing roller are arranged on the upper end of the interior of the box body; smashing teeth are arranged on the left smashing roller and the right smashing roller; a rotating shaft is arranged between the two drying chambers; a drying device is arranged in each drying chamber; a discharge channel is formed among the drying chambers and the intermediate plate; each drying device comprises heating pipes, a main pipe and blowers; the motor chamber is arranged at the lower end of the box body; a base is arranged at the lower end of the motor chamber; a drive motor and two shock absorbers are arranged in the motor chamber; the base is fixed to the bottom end of the box body in a welding manner; and a spring is arranged in each of the shock absorbers. The smashing and drying device disclosed by the invention is capable of performing thorough smashing to obtain uniform smashed particles, drying and absorbing shock.

Owner:郑州吉音动漫科技有限公司

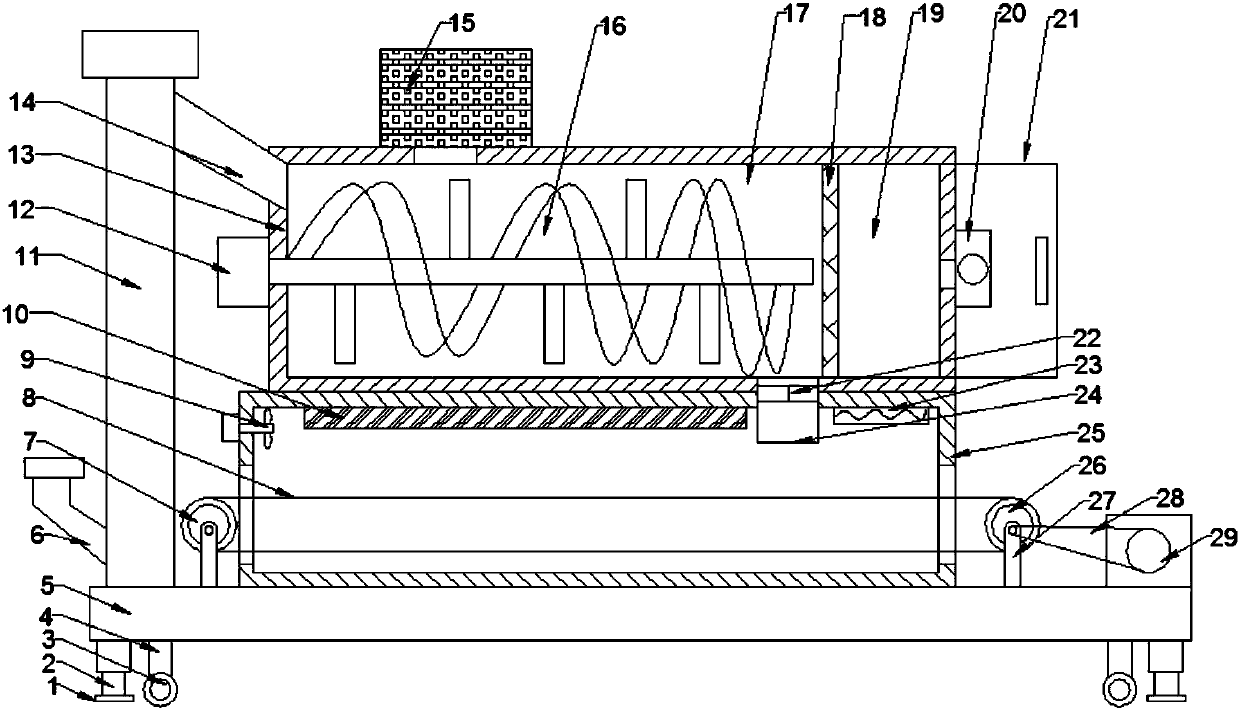

Drying method for wood

InactiveCN106393342AFast dryingStable Quantitative ProductionRadiation/waves wood treatmentWood treatment detailsMicrowaveWood plank

The invention discloses a drying method for wood. The drying method comprises the following steps that A, the wood is pre-planed, and the wood is cut into boards with the same size; B, the pre-planed wood is soaked with brine; C, the wood soaked with the brine is wrapped with tin foil paper and baked; D, the baked wood is coated with a wood anti-cracking agent, and then the wood is subjected to microwave and ultrasonic drying; and E, the wood obtained after microwave and ultrasonic drying is performed is subjected to thermal convection drying. By the adoption of the drying method for the wood, the moisture in the wood can be dried effectively, and the moisture content of the wood is less than 8.5% and meets the dry standard; the phenomena of cracking, deformation, bending and warping of the wood and the like can be avoided; the drying speed of the wood can be increased effectively, the time is shortened, the cost is lowered, and the stable mass production of the wood is achieved; and the quality of the obtained wood is stable, and the error between the moisture content and the target moisture content of dried products is small.

Owner:玉溪万德能源技术有限公司

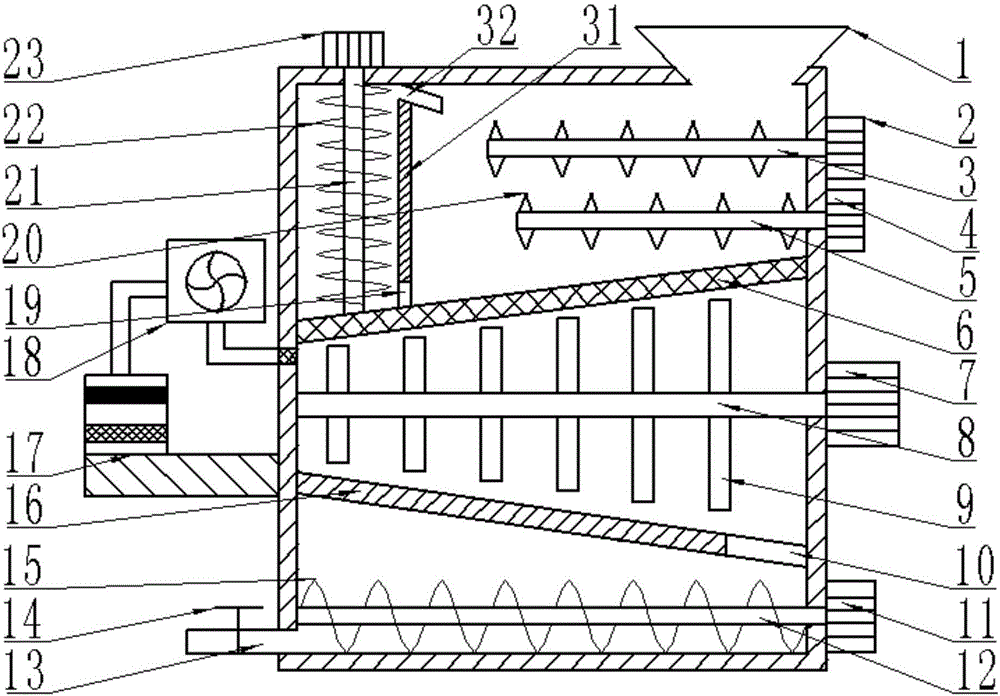

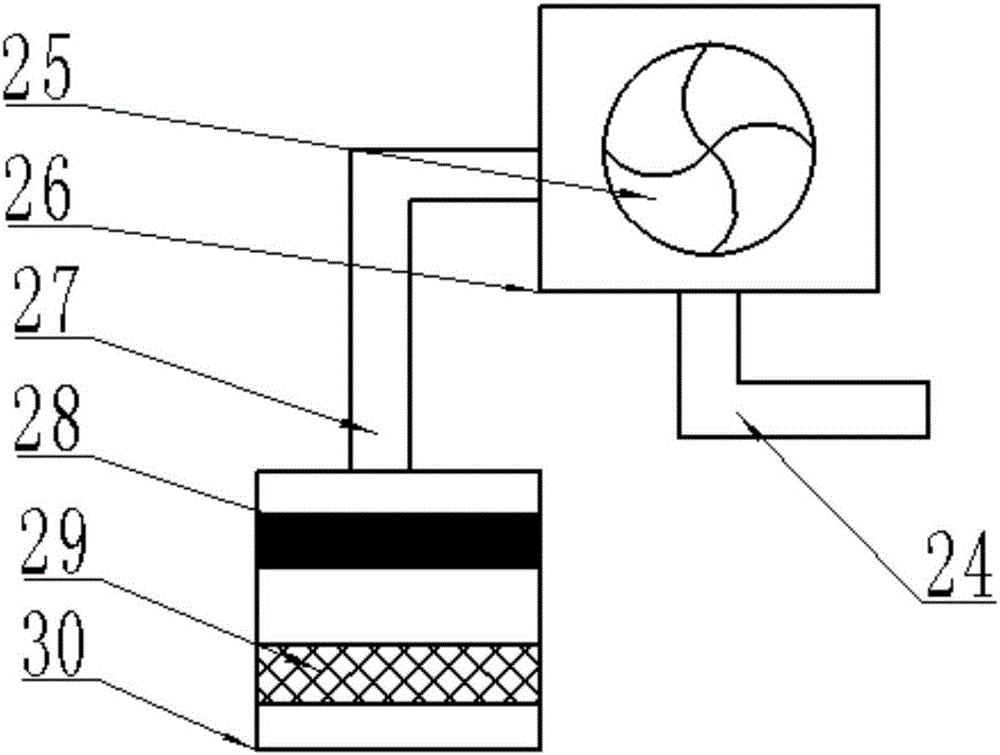

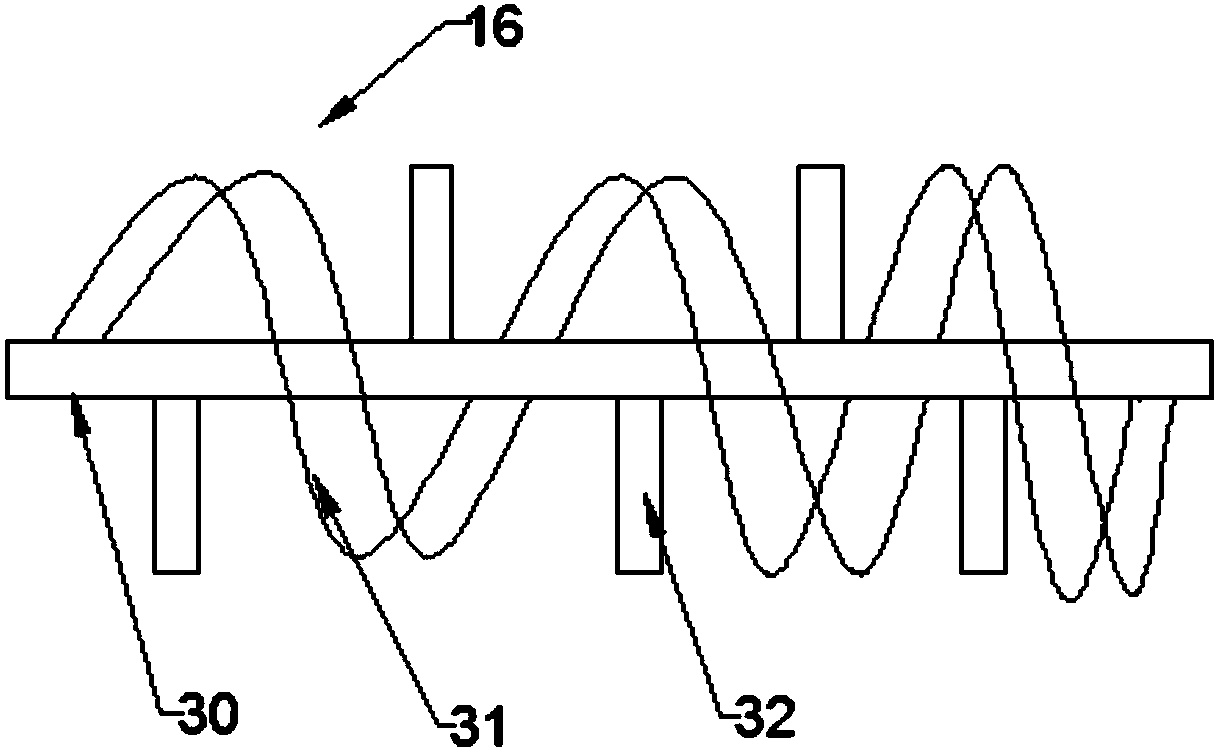

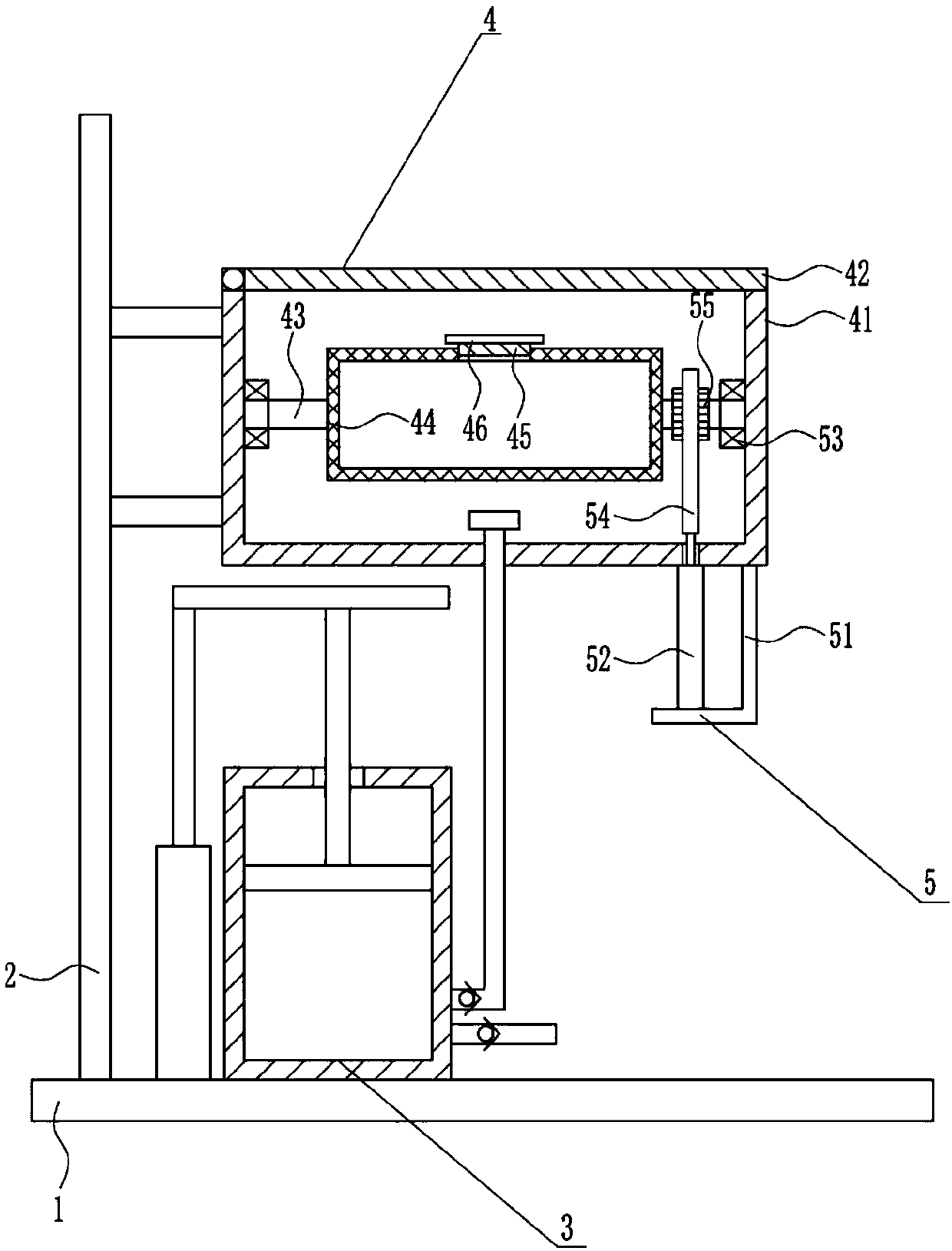

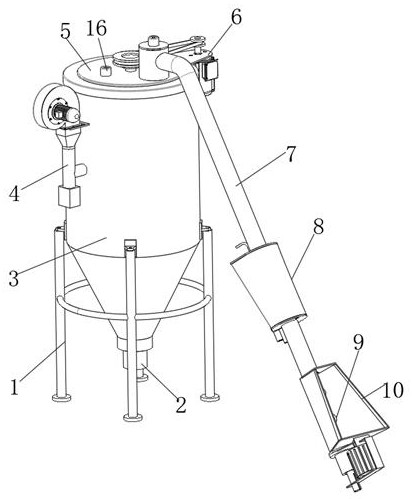

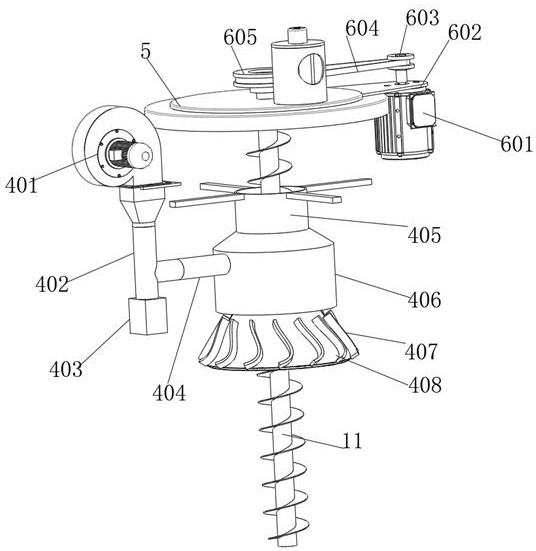

Smashing, drying and reutilization device of straw

InactiveCN106513135AUniform sizeDry comprehensiveRotary stirring mixersTransportation and packagingHelical bladeDrive motor

The invention provides a smashing, drying and reutilization device of straw. The smashing, drying and reutilization device comprises a feed hopper, a smashing device, a stirring device, a conveying device, a discharge pipe and a drying device, wherein the smashing device comprises a first driving motor, a second driving motor and a fifth driving motor; a feed inlet is formed in the lower end of a partition; a discharge hole is formed in the upper end of the partition; the stirring device comprises a third driving motor, a third rotating shaft and stirring rods; a sieve plate is arranged at the upper end of the stirring device; the sieve plate is obliquely arranged; the left end of the sieve plate is low and the right end of the sieve plate is high; the conveying device comprises a fourth driving motor, a fourth rotating shaft and a helical blade; an oblique plate is arranged at the upper end of the fourth driving motor; the oblique plate is obliquely arranged; the left end of the oblique plate is high and the right end of the oblique plate is low; the right end of the oblique plate and the right wall of a box form an unloading hole; a placing plate is arranged at the lower end of the drying device; and the drying device comprises an air inlet pipe, an air blower, an air blowing channel and a filter box. According to the smashing, drying and reutilization device, the smashing is thorough, the drying is convenient and comprehensive, smashing, drying and stirring are integrated, and the efficiency is high.

Owner:郑州吉音动漫科技有限公司

Pig feed smashing and drying device

The invention provides a pig feed smashing and drying device. The pig feed smashing and drying device comprises feeding inlets, a smashing cavity, a drying cavity and a base. The number of the feeding inlets is two, and the two feeding inlets are formed in the upper end of a box body. The upper end of each feeding inlet is provided with an air inlet pipe, and the lower end of each feeding inlet is provided with a blanking pipe. The smashing cavity is formed in the upper end of the inside of the box body. Rotating shafts and smashing rollers are arranged in the smashing cavity. The drying cavity is formed in the lower end of the smashing cavity. Partition plates, a bearing plate, drying devices, placing plates and discharging outlets are arranged in the drying cavity. The drying devices comprise heating pipes, header pipes and air blowers. The header pipes are provided with air outlet pipes. The base is fixed to the lower end of the box body. Discharging pipes and a driving motor are arranged inside the base. The number of the discharging pipes is two, and the two discharging pipes are symmetrically distributed at the two ends of the driving motor. The discharging pipes are provided with corresponding valves. The driving motor is fixed to the lower end of the box body. A rotating shaft is arranged at the upper end of the driving motor. The pig feed smashing and drying device is thorough in smashing effect, and particles are uniform; blanking can be controlled so that blocking can be prevented; and feed can be dried.

Owner:郑州吉音动漫科技有限公司

Integrated livestock feed dust removing, sterilizing and drying device

InactiveCN107897986AKeep dryDry comprehensiveFeeding-stuffRotary stirring mixersOzone generatorDrive wheel

The invention provides an integrated livestock feed dust removing, sterilizing and drying device, and belongs to the technical field of processing of livestock feeds. The integrated livestock feed dust removing, sterilizing and drying device comprises supporting devices and a dust removing, sterilizing and drying device, wherein a hoisting machine is arranged at a left end of the upper surface ofa bottom plate; a stirring device is fixedly arranged at the right end of a stirring motor through welding; a filter screen is arranged on the right side of an inner cavity of a stirring tank; an electric expansion plate is arranged in a discharging hopper; an electrical heating plate is fixedly arranged at the upper end of an inner cavity of a drying box; an ultraviolet ray lamp is fixedly arranged at the right end of the upper surface of the inner cavity of the drying box; and a motor is connected with a driving wheel through a belt. According to the integrated livestock feed dust removing,sterilizing and drying device disclosed by the invention, an ozone generator is fixedly arranged on the left side of the upper surface of the stirring tank, so that the integrated livestock feed dustremoving, sterilizing and drying device has the function of sterilizing feeds by adopting an ozone manner; a sucking pump is fixedly arranged on the right side of the stirring tank, so that the integrated livestock feed dust removing, sterilizing and drying device has the functions of performing dust suction and moisture exhaust on the stirring tank; and the integrated livestock feed dust removing, sterilizing and drying device has the characteristics of being simple in structure, high in practicality and various in functions.

Owner:ZHENGZHOU LIFUAI BIOLOGICAL TECH CO LTD

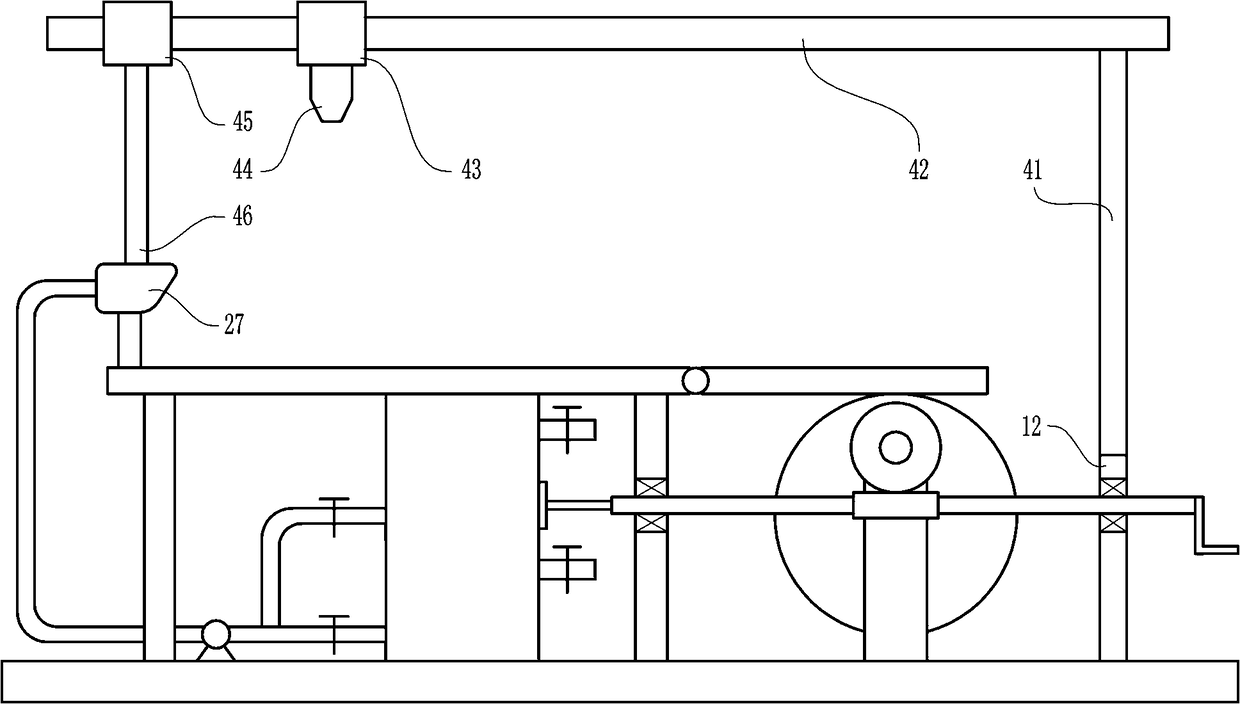

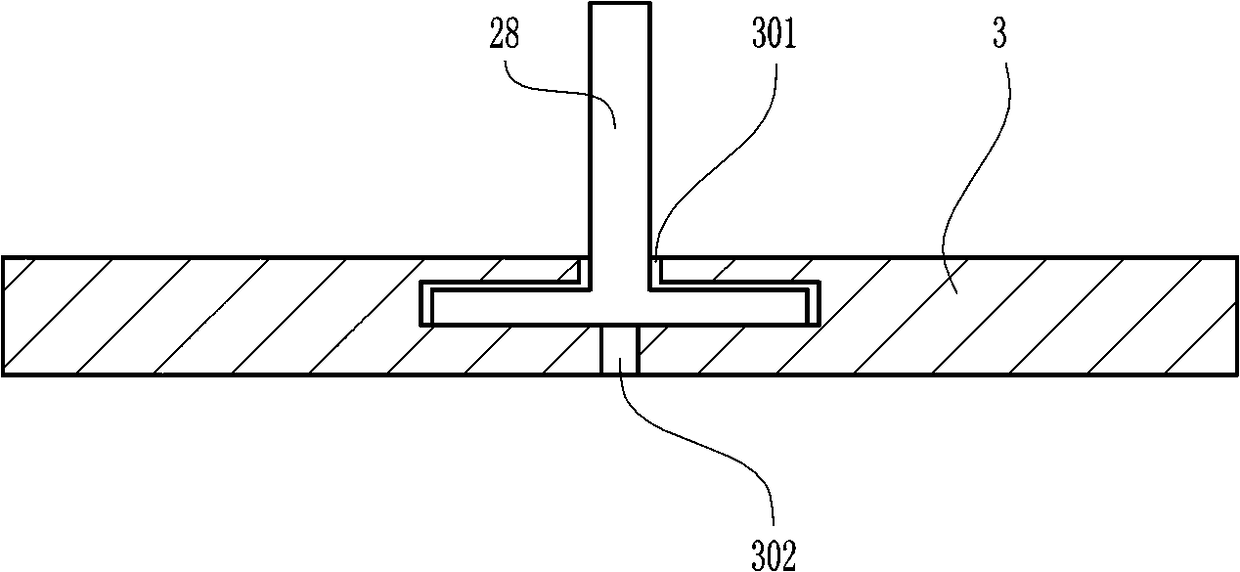

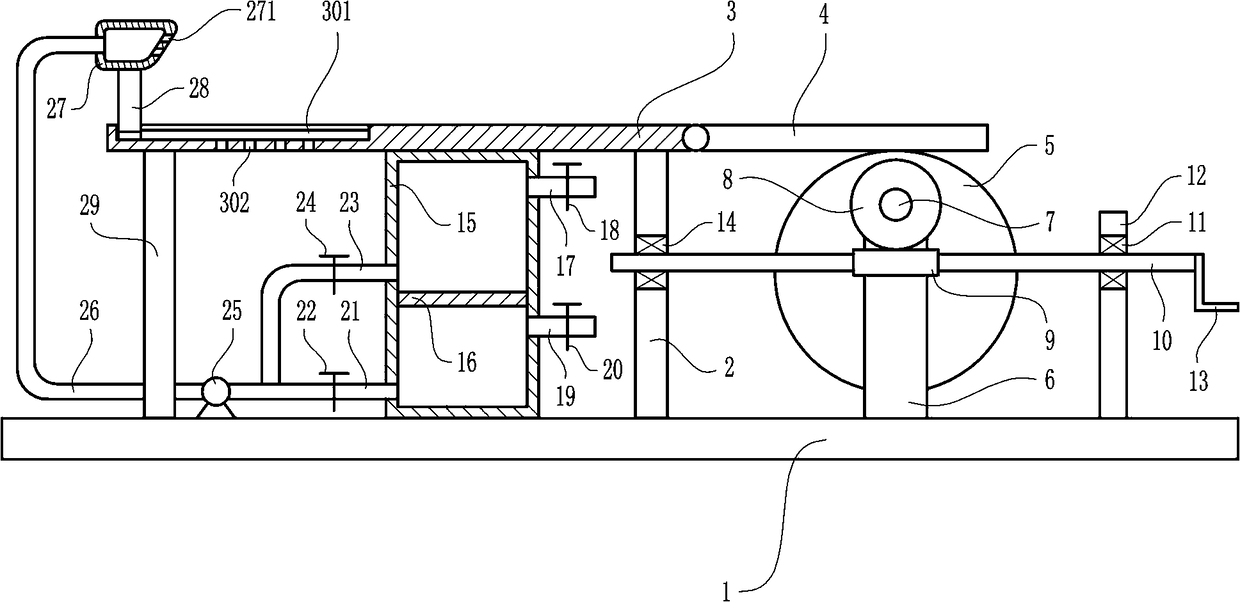

Rapid drying and recycling device for liquid dung

InactiveCN110104919ADryness qualifiedDry comprehensiveSludge treatment by de-watering/drying/thickeningWastewaterWeight gaining

The invention discloses a rapid drying and recycling device for liquid dung. The device comprises a filter tank, wherein the filter tank is internally provided with a waste water chamber, the upper end of the waste water chamber is provided with an overturning cavity with an upward opening, and the inner wall of the bottom end of the overturning cavity is slidably connected with a water level switch. The rapid drying and recycling device for the liquid dung has the advantages that a method for separately treating dung and liquid is adopted, so that a drying process is accelerated; the weight gain caused by accumulation after liquid filtering is taken as a power source for turning over and putting; the limitation of overturning power can be unlocked after the weight of the dung on a filternet reaches a certain value, thereby achieving the automatic process of quantity putting; the impact when the dung falls off drives a cutting structure to rotate, so that the dung is cut into small pieces, thereby ensuring the comprehensiveness of drying; a double structure of wind blowing and grinding is used for ensuring the qualified dryness of the treated dung while improving the recycling efficiency.

Owner:SHENZHEN MINGJIAN COMMODITY CO LTD

Air-blowing drier for production of attapulgite zearalenone adsorbing agent

InactiveCN108955170APull away quicklyEasy to pass throughDrying gas arrangementsDrying machines with non-progressive movementsSorbentSpiral blade

The invention discloses an air-blowing drier for production of an attapulgite zearalenone adsorbing agent. A spiral blade is fixedly connected to the outer side of a rotary roller, a first screen plate is connected with the middle of the spiral blade in a penetrating mode, a stirring plate is fixedly connected with the right side of the first screen plate, an air pump is fixedly connected with themiddle of the right side of a machine body, a first air inlet pipe communicates with the top of the air pump, the upper portion and the lower portion of the face, close to the right side of the machine body, of the first air inlet pipe communicate with second air inlet pipes, the opposite sides of two groove inner cavities are connected with a second screen plate in a penetrating mode, one end ofan air outlet pipe communicates with an exhaust fan, a feeding groove communicates with the left side of the top of the machine body, and a discharge groove is connected with the right side of the bottom of a supporting plate in a penetrating mode. By arranging the air pump, the first air inlet pipe, air inlet holes, the first screen plate, the exhaust fan, the spiral fan, the feeding groove, thedischarge groove, a valve, a bottom plate, a bolt and a gasket, the air-blowing drier for production of the attapulgite zearalenone adsorbing agent is high in practicability.

Owner:江苏伊居科技有限公司

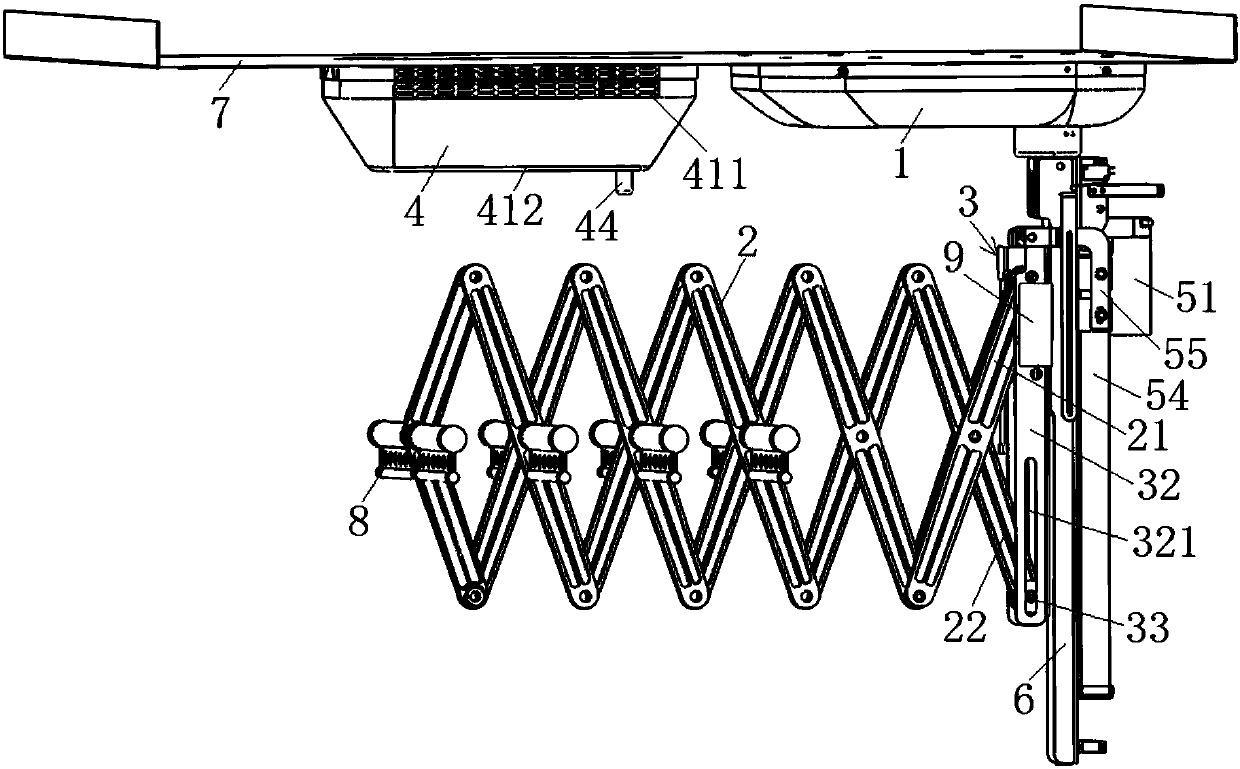

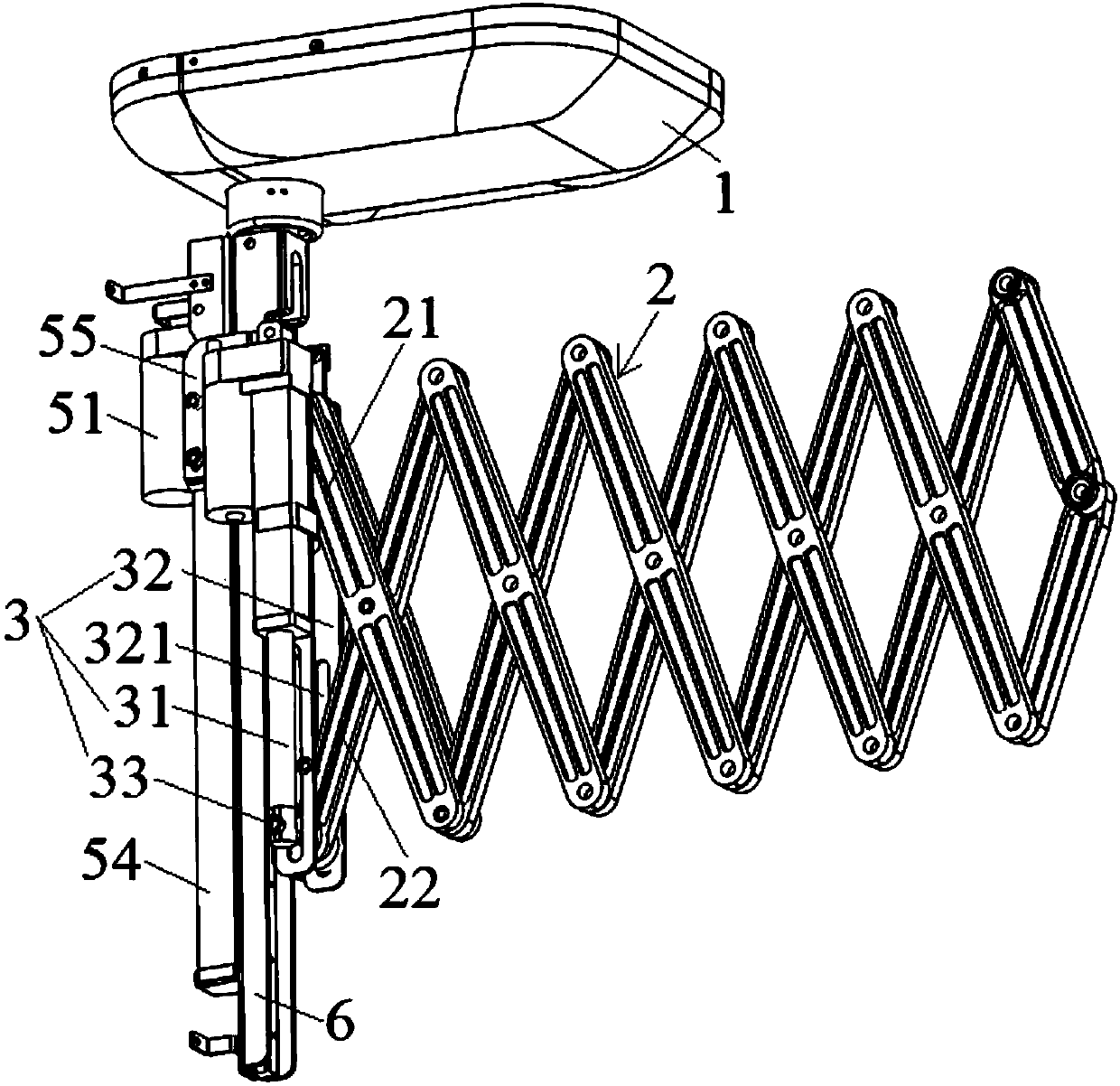

Laundry rack with dynamic drying function

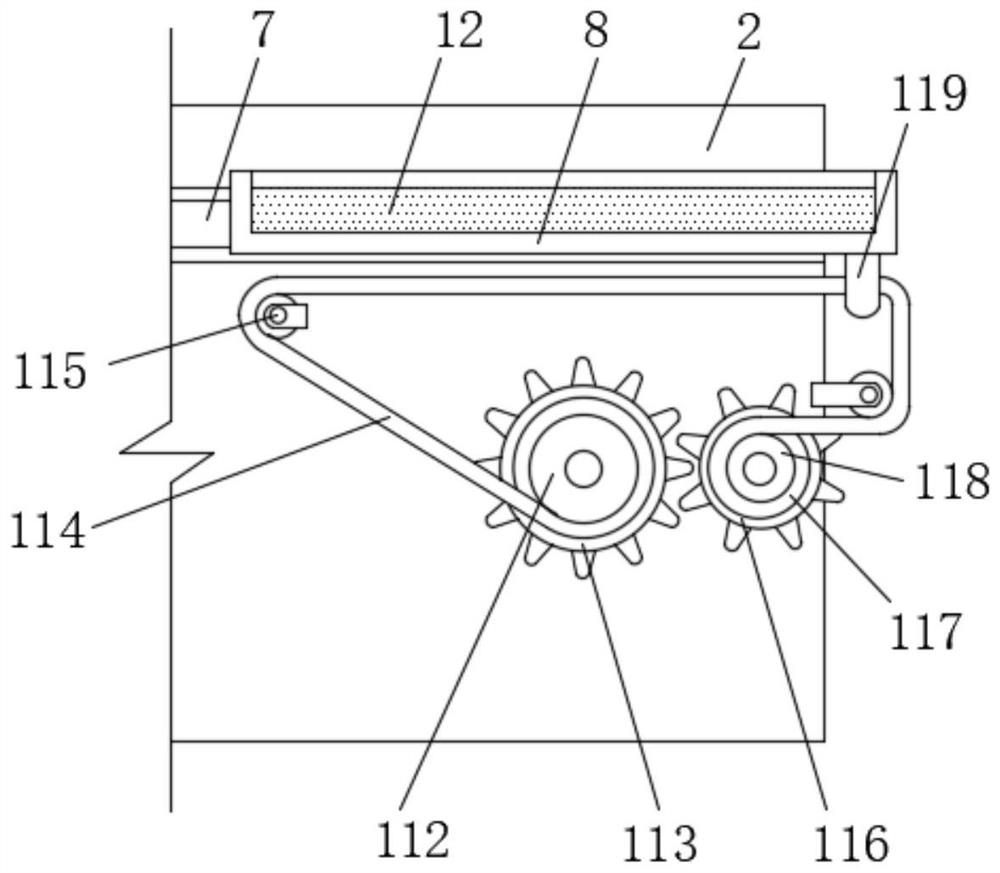

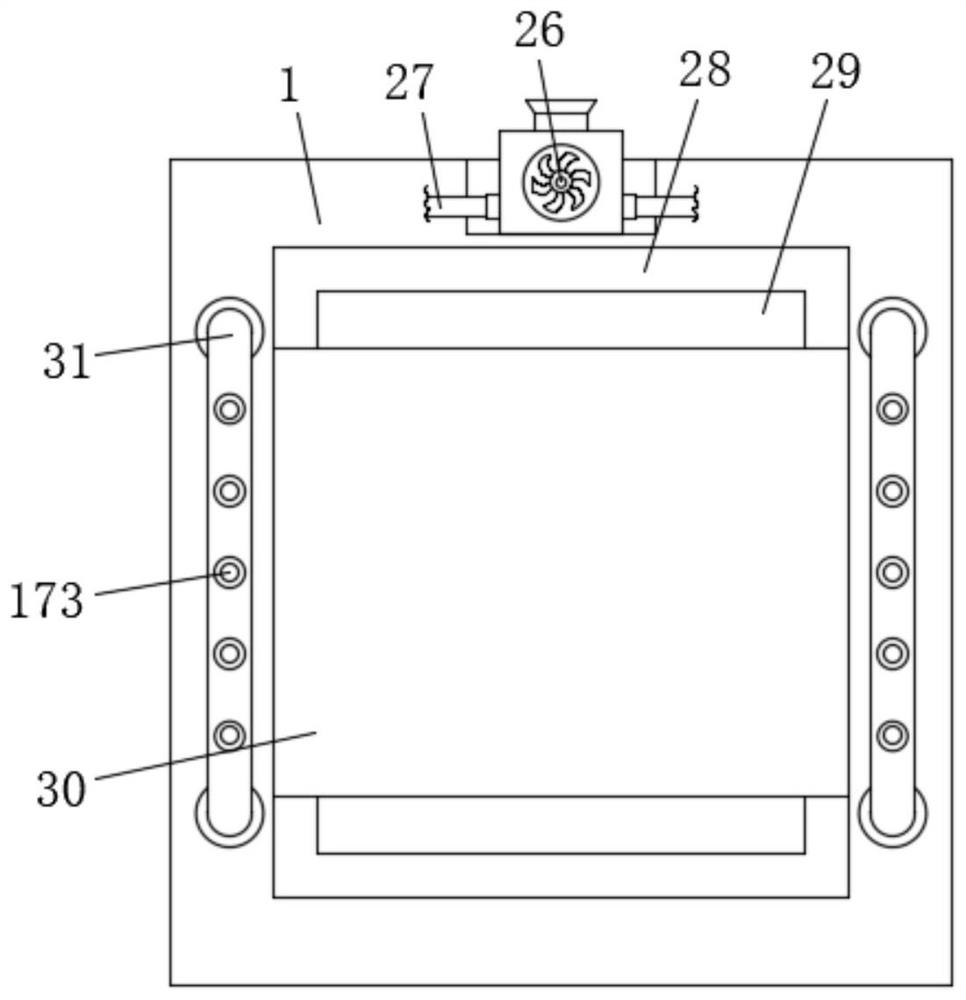

PendingCN107724019AAchieve horizontal movement dryingAvoid the defect that the heating temperature is too highTextiles and paperLaundry driersEngineeringLaundry

The invention discloses a laundry rack with a dynamic drying function. The laundry rack comprises a top mounting seat fixedly connected to a ceiling, a plurality of cross rods for hanging the clotheshangers, a cross rod flexible driving mechanism and a hot air drier; the cross rod flexible driving mechanism comprises an electric push rod and a cross rod fixing seat; a supporting rod forming eachcross rod is fixedly connected to the cross rod fixing seat while the other supporting rod forming each cross rod is fixedly connected to the tail end of the electric push rod; the hot air drier is fixedly mounted on the ceiling above the cross rods, and the hot air outlet of the hot air drier faces the cross rods. According to the laundry rack, clothes are dried in horizontal and lifting movements, and the laundry rack has a dynamic drying function, so that clothes on the laundry rack are fully and quickly dried, and therefore, the drying efficiency is high, the problem that the clothes wrinkle and are uneven is solved, and the laundry rack is low in energy consumption and convenient to use.

Owner:上海光臣智能科技有限公司

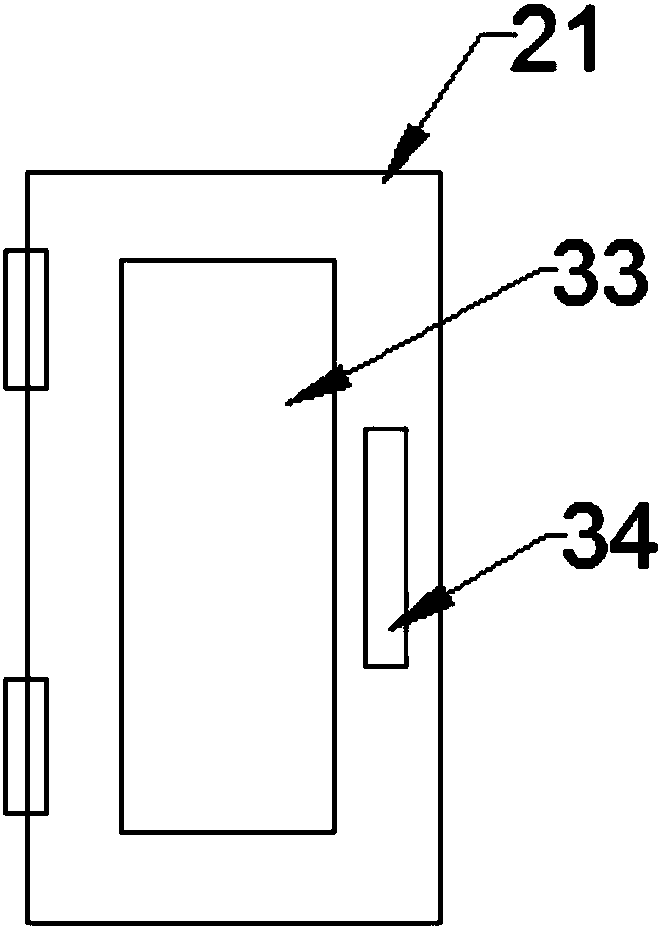

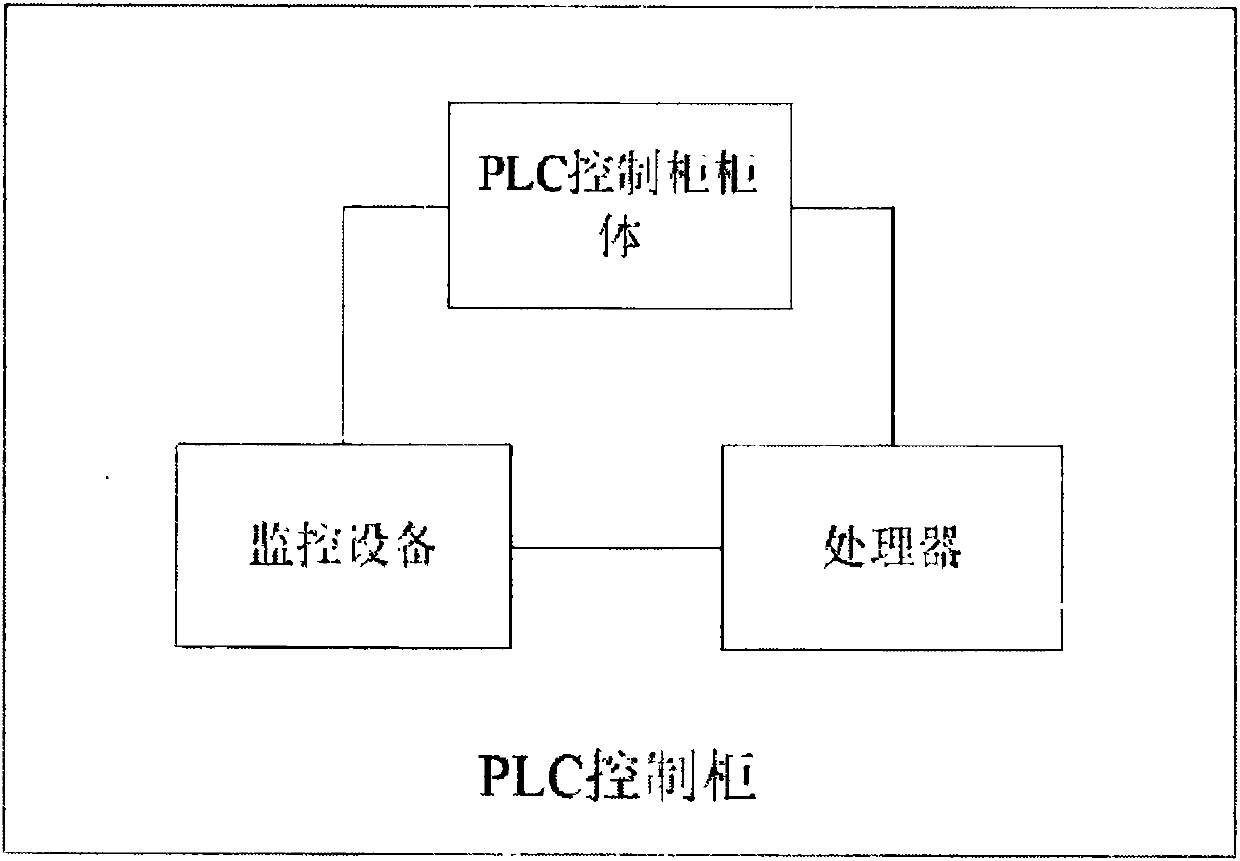

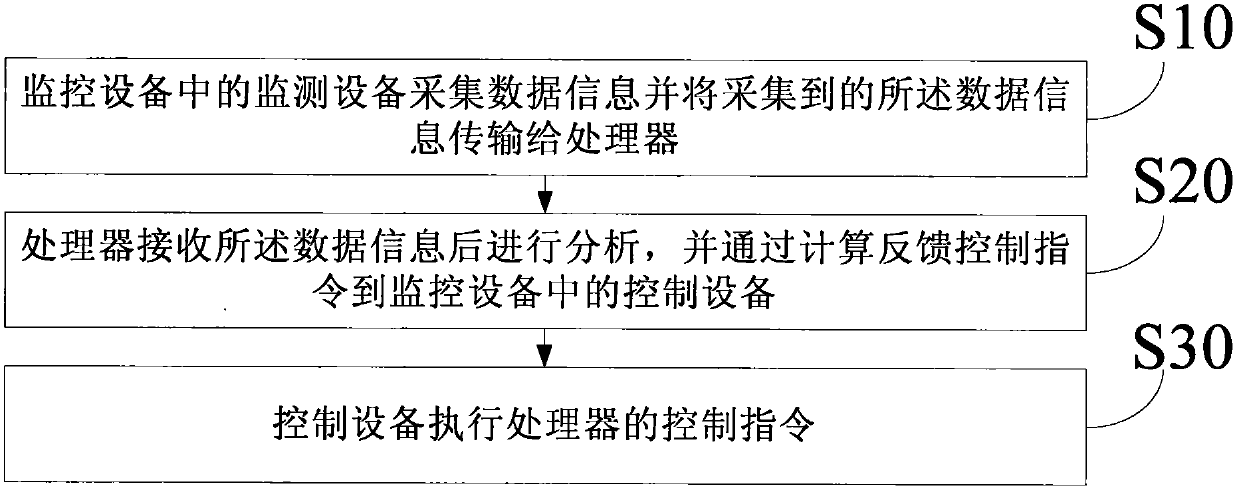

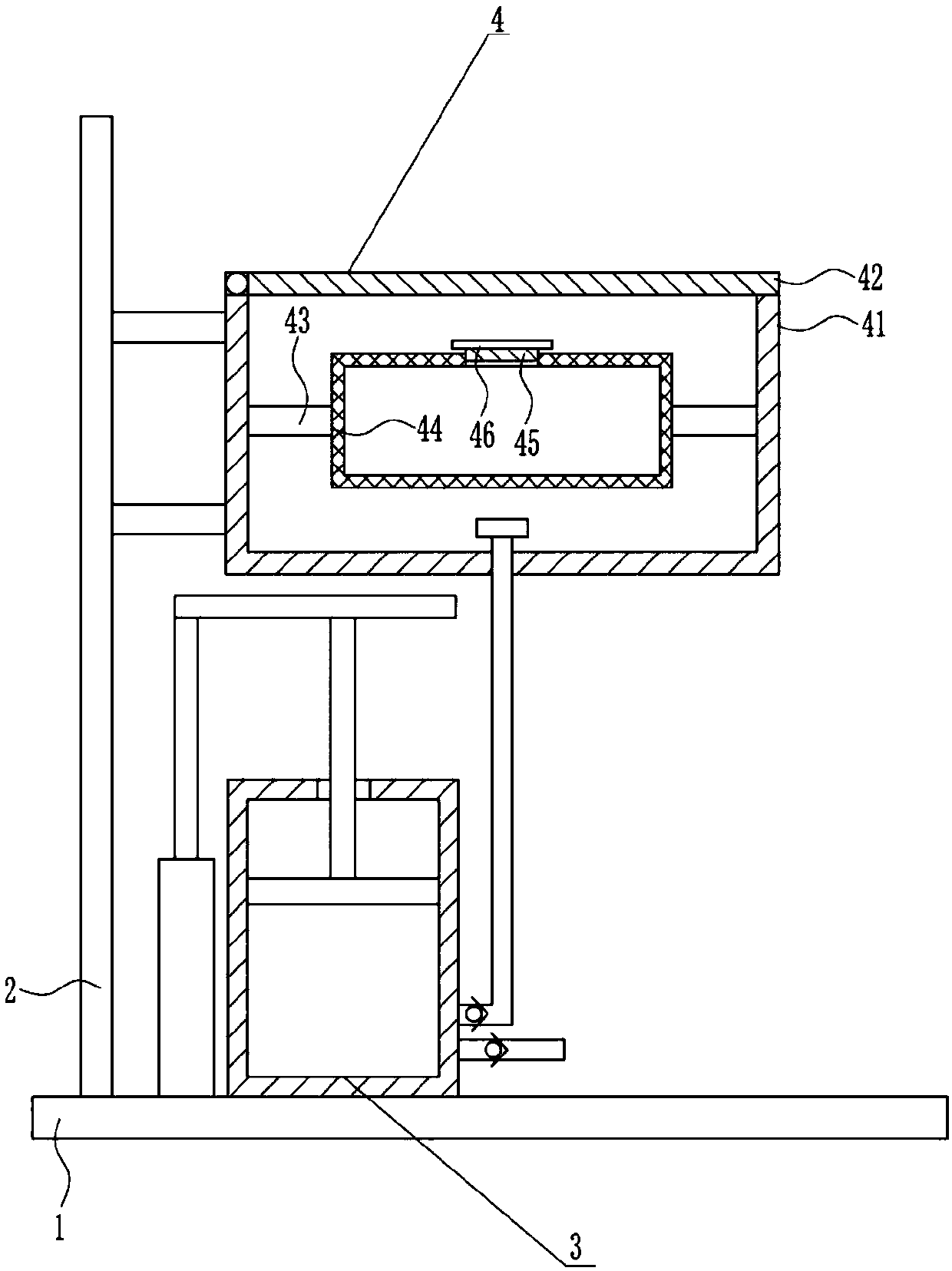

PLC automatic control cabinet

InactiveCN107589711ARealize acquisitionAchieve energy controlProgramme control in sequence/logic controllersElectrical apparatus casings/cabinets/drawersAutomatic controlData information

The invention provides a PLC automatic control cabinet, and relates to the technical field of automation. The control cabinet comprises monitoring equipment, a processor, and a PLC control cabinet body. The monitoring equipment is disposed in the PLC control cabinet body, and comprises a monitoring device and a control device, which are respectively in communication connection with the processor.The monitoring device is used for collecting data information and transmitting the collected data information to the processor, and the control device is used for executing a control instruction of the processor. The processor is disposed in the PLC control cabinet body or outside the PLC control cabinet body, receives the data information, processes the received data information, and feeds back acontrol instruction to the control device through calculation. According to the invention, the monitoring equipment and the processor are added on the basis of a conventional control cabinet, therebyachieving the collection of the temperature state and power state of the PLC control cabinet and the information of a person who opens and closes a door.

Owner:FUSHUN KAITELI ELECTROMECHANICAL & CHEM

Preserved fruit making and drying device for food processing

The invention discloses a preserved fruit making and drying device for food processing, belongs to the technical field of food processing and aims at providing a preserved fruit making and drying device used for food processing, low in manufacturing cost, simple in operation, capable of performing uniform and comprehensive drying and high in working efficiency. For solving the technical problem, the preserved fruit making and drying device comprises a base plate, a support, an air spraying device and a loading device for to-be-processed fruits to be placed. The support is vertically arranged at one end of the base plate, the loading device is arranged at the upper portion of the support, the air spraying device is arranged on the base plate and is arranged below the loading device, and anair spraying part of the air spraying device can extend into the loading device. By adopting the mode of spraying hot air in a box body to dry processed fruits, the effects of low manufacturing cost,simple operation, uniform and comprehensive drying and high working efficiency are achieved.

Owner:广东同享食品有限公司

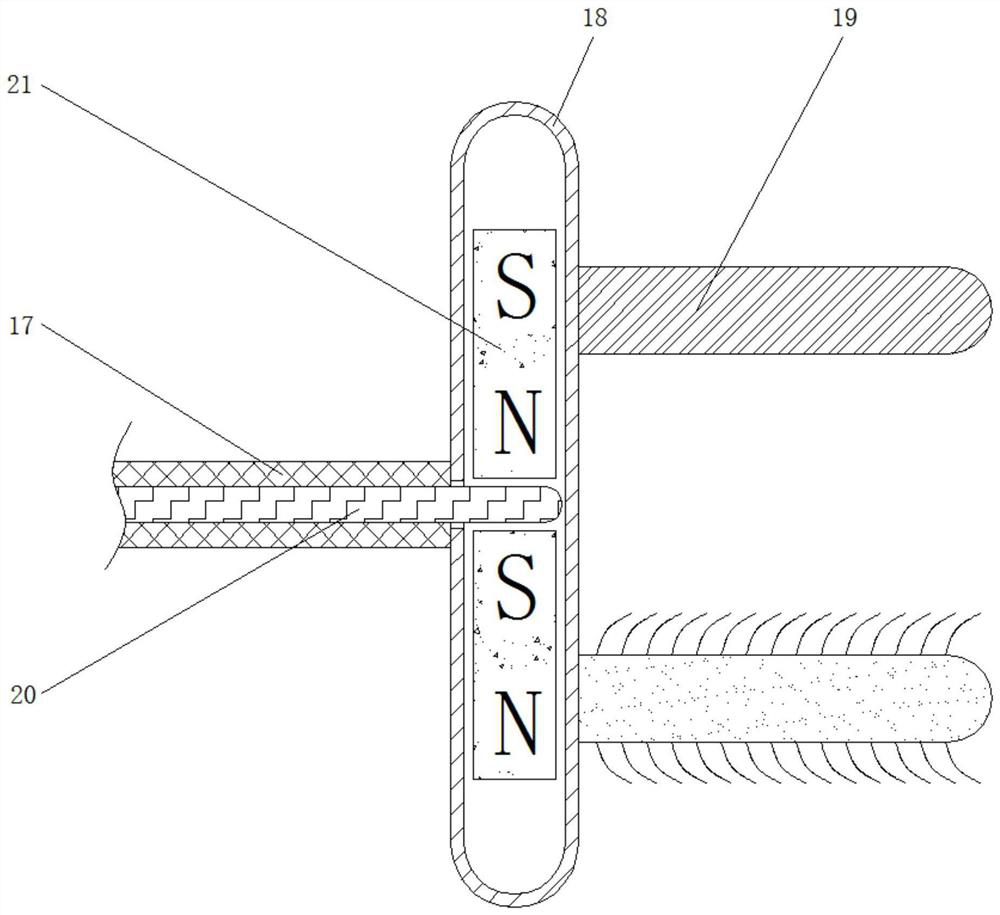

Storage device capable of avoiding moths and having protection effect for traditional Chinese medicine, and method

ActiveCN111806892AGuarantee the quality of savingsGuaranteed service lifeContainers for heating foodContainers preventing decayBiotechnologyOfficinal

The invention discloses a storage device capable of avoiding moths and having a protection effect for a traditional Chinese medicine in the technical field of storage devices for the traditional Chinese medicine. The storage device comprises a storage box, wherein the top and the bottom of the inner cavity of the storage box are independently movably provided with two groups of placement plates; the front end and the rear end of two groups of placement plates are independently provided with a ventilated drying anti-moth mechanism with the same structure in a left and right penetration way; themiddle of the inner wall of the bottom of the storage box is provided with a vibrating and driving mechanisms cooperated with the two groups of placement plates; and the bottom of the right side of the storage box is provided with a heating mechanism. The storage device is provided with the drying anti-moth mechanisms, and in a storage process, external air can enter a cylindrical hollow column and then seeps from ventilation holes; in a similar way, air in the storage box can enter ventilation micro-holes from the ventilation holes, then enters the cylindrical hollow column, and is dispersedto the outside from two ends of the cylindrical hollow column to realize inside and outside ventilation, traditional Chinese medicine storage quality is guaranteed, and a situation that later-periodutilization of the traditional Chinese medicine is affected due to poor air permeability is avoided.

Owner:重庆蔷薇药业有限公司

Feed processing raw material crushing device

InactiveCN107736639ADry comprehensiveDry completelyFeeding-stuffGrain treatmentsEconomic benefitsEngineering

The invention relates to the technical field of feed processing, in particular to a raw material crushing device for feed processing, which includes a housing and a connecting rod. A feeding hopper is fixedly connected to the top of the housing, and a drying plate is arranged below the feeding hopper. The inner side of the drying plate is fixedly connected with a horizontally arranged heating wire, the top of the drying plate is fixedly connected with a gear lever, and the bottom of the drying plate is provided with a horizontally arranged support plate, and one end of the support plate is connected to the housing Fixedly connected, the outer top of the support plate is rotatably connected with an elliptical runner, the bottom end of the support plate is fixedly connected with a connecting rod, the bottom end of the connecting rod is fixedly connected with a second rotating shaft, and the second rotating shaft One end is fixedly connected with a second motor, and the inner side of the second motor is rotatably connected with a runner, which is conducive to improving the completion rate of products and increasing work efficiency, has huge economic benefits and broad market prospects, and is worthy of popularization and use.

Owner:邛崃驰阳农牧科技有限公司

Convenient disinfection delivery table for gynaecology and obstetrics

InactiveCN108309670AEasy to use forceImprove disinfection effectOperating tablesDrying gas arrangementsPhysical healthObstetric history

The invention relates to a delivery table for gynaecology and obstetrics, in particular to a convenient disinfection delivery table for gynaecology and obstetrics. The invention aims at providing theconvenient disinfection delivery table for the gynaecology and obstetrics, which is small in labor intensity, high in cleaning and disinfection efficiency, and thorough in cleaning and disinfection, saves time and labor and can protect physical health of a puerpera. The convenient disinfection delivery table for the gynaecology and obstetrics comprises a base, a support plate, a first table plate,a second table plate, a contact disk, a connecting plate, a rotating shaft, a worm gear, a worm, a long connecting shaft, a first bearing and a fixing plate, wherein the support plate is located above the base; and the bottom of the support plate is connected with the top of the base. The convenient disinfection delivery table for the gynaecology and obstetrics is small in labor intensity, high in cleaning and disinfection efficiency, thorough in cleaning and disinfection, simple in structure, convenient to operate, easy to maintain, low in maintenance cost and easy to produce and manufacture, saves the time and the labor and can protect the physical health of the puerpera.

Owner:林清

Organic fertilizer drying device for methane combustion energy conservation

PendingCN110285661ASpeed up the flowEasy to dryManure dryingDrying gas arrangementsDrive motorAgricultural engineering

The invention discloses an organic fertilizer drying device for methane combustion energy conservation. The organic fertilizer drying device comprises a drying oven, wherein a partition is welded to theposition, close to the top, in the drying oven; reversed-V-shaped vent holes are uniformly formed in the partition; and a first driving motor is fixed at the center of the top of the drying oven through bolts. Gas outlet spray heads spray hot air to organic fertilizer; the arranged first driving motor drives fan blades to rotate to accelerate flow of the hot air; cyclic hot water is supplied into a spiral groove, so that a wall of the drying oven performs secondary drying on the organic fertilizer,a multilayer drying effect is achieved,the drying efficiency of the organic fertilizer is improved, andthe manpower is saved; a second driving motor drives spiral blades to rotate to stir the organic fertilizer; the organic fertilizer can be dispersed and drop continuously in the drying oven under the action of the spiral blades rotating at a high speed; the hot air can dry the organic fertilizer uniformly; the drying effect is guaranteed; the rotating spiral blades can also crush the organic fertilizer; caking of the organic fertilizer is avoided; and the organic fertilizer is dried completely.

Owner:东营市延旭环保科技有限公司

Electric power reactive power compensation cabinet capable of avoiding moisture and removing dust

InactiveCN112564123AEasy to dryExtended service lifeGas treatmentSubstation/switching arrangement cooling/ventilationDust controlMoisture

The invention relates to the technical field of electric power reactive compensation, and discloses an electric power reactive compensation cabinet capable of avoiding moisture and removing dust, which comprises a cabinet body, a drying cavity is fixedly installed at the right side of the top end of the inner wall of the cabinet body, a water absorption block is fixedly installed at the top end ofthe drying cavity, and sodium particles are contained at the bottom end of the drying cavity. And a push block is slidably connected to the middle end of the interior of the drying cavity, a drying air bag is fixedly installed on the left side of the interior of the drying cavity, a soft air pipe is fixedly connected to the left side of the drying cavity, a rotating rod is rotatably connected tothe top end of the inner wall of the cabinet body, and a spring rod is rotatably connected to the bottom end of the rotating rod. According to the electric power reactive power compensation cabinet capable of avoiding moisture and removing dust, equipment is automatically dried when the equipment is damped to generate water drops, the service life of the equipment is prevented from being affectedby damp, meanwhile, dust in the equipment can be adsorbed and collected, and the equipment is prevented from breaking down due to dust accumulation.

Owner:罗光才

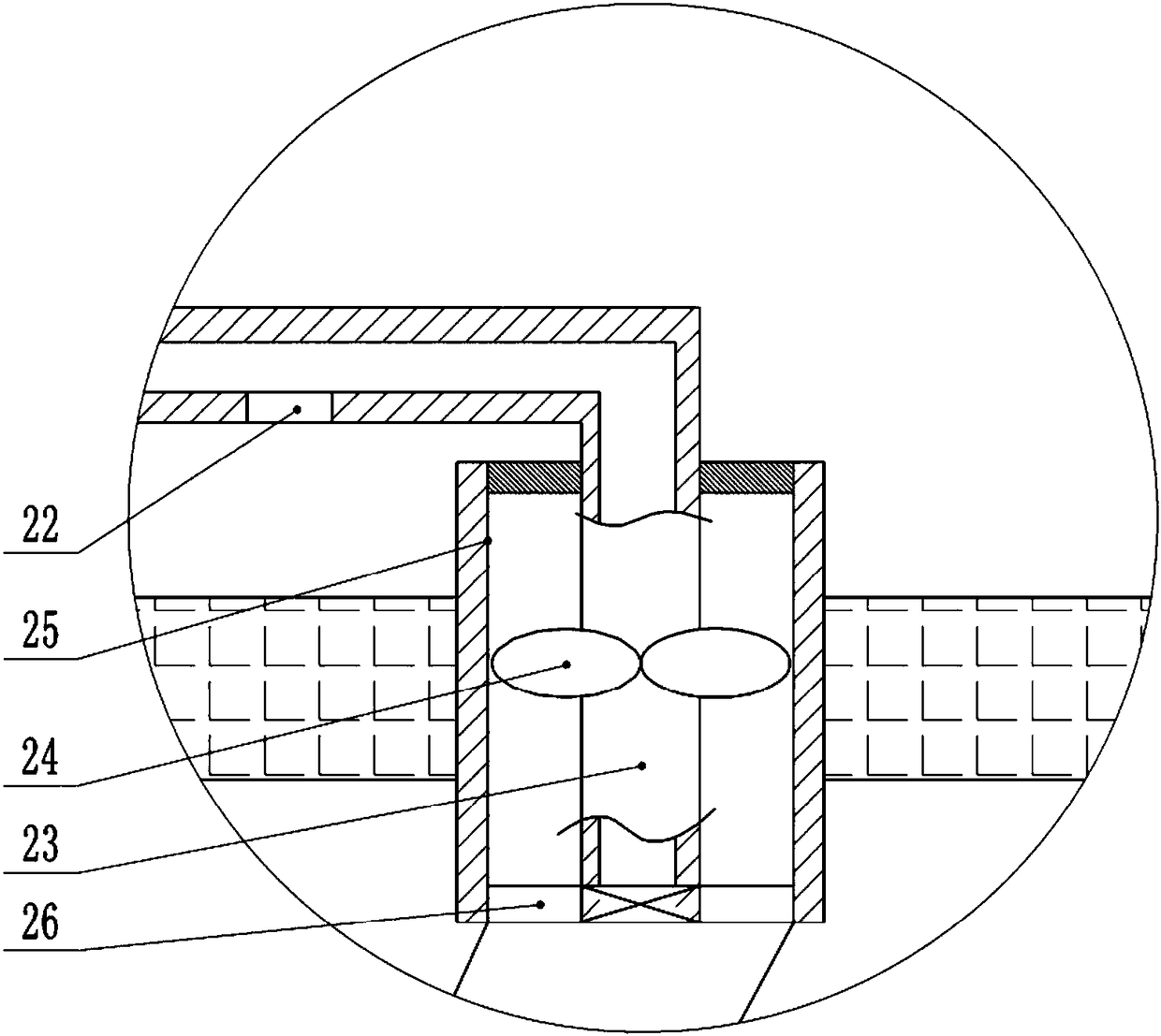

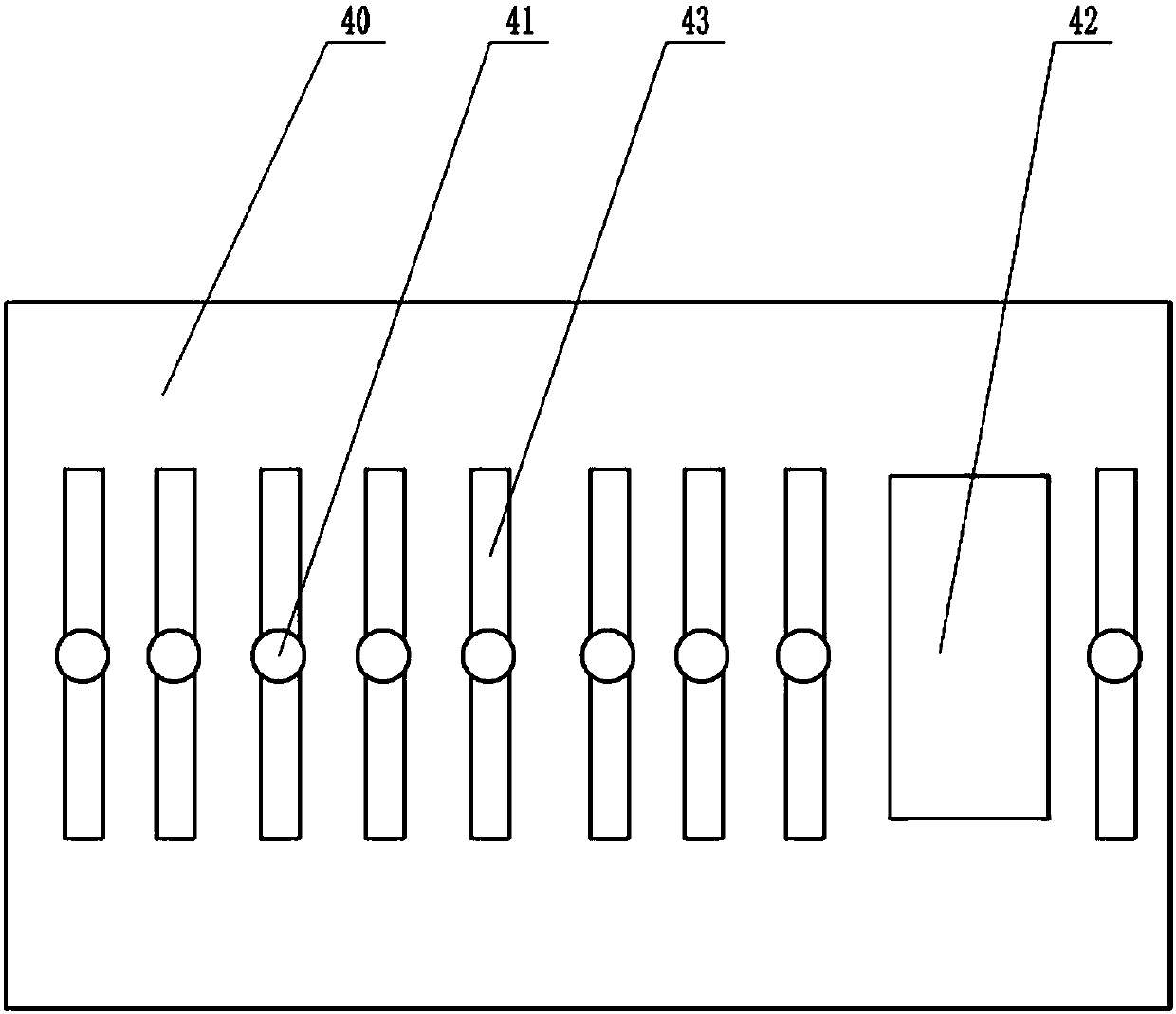

Medical instrument cleaning and cyclic disinfection and drying device for nursing department

PendingCN108906714AImprove cleaning and disinfectionSimple structureCleaning using liquidsHeatEngineeringCheck valve

The invention discloses a medical instrument cleaning and cyclic disinfection and drying device for the nursing department. The device comprises a cabinet, an air outlet pipe is arranged on the uppersurface of the cabinet, a check valve is arranged at the joint of the cabinet and the air outlet pipe, the upper end of the front surface of the cabinet is provided with a rectangular hole, and two symmetrical door sheets are hinged to the upper end of the front surface of the cabinet. A moving seat is arranged at the inner lower end of the cabinet, a storage rack is arranged on the upper surfaceof a mounting seat of the moving seat, two symmetrical partition plates are arranged in the middle of the inner lateral side of the cabinet body, the middle of the upper surface of each partition plate is provided with a round hole, and the two partition plates are connected through an ultraviolet disinfection light. The medical instrument cleaning and cyclic disinfection and drying device is simple in structure, medical instruments can be rotated for comprehensive cleaning, disinfection and drying treatment, and accordingly cleaning and disinfection effects can be improved; in addition, the medical instruments can be dried quickly, time saving is realized, and operating efficiency is improved.

Owner:GUANGDONG KNOWLEDGE CITY OPERATION SERVICES CO LTD

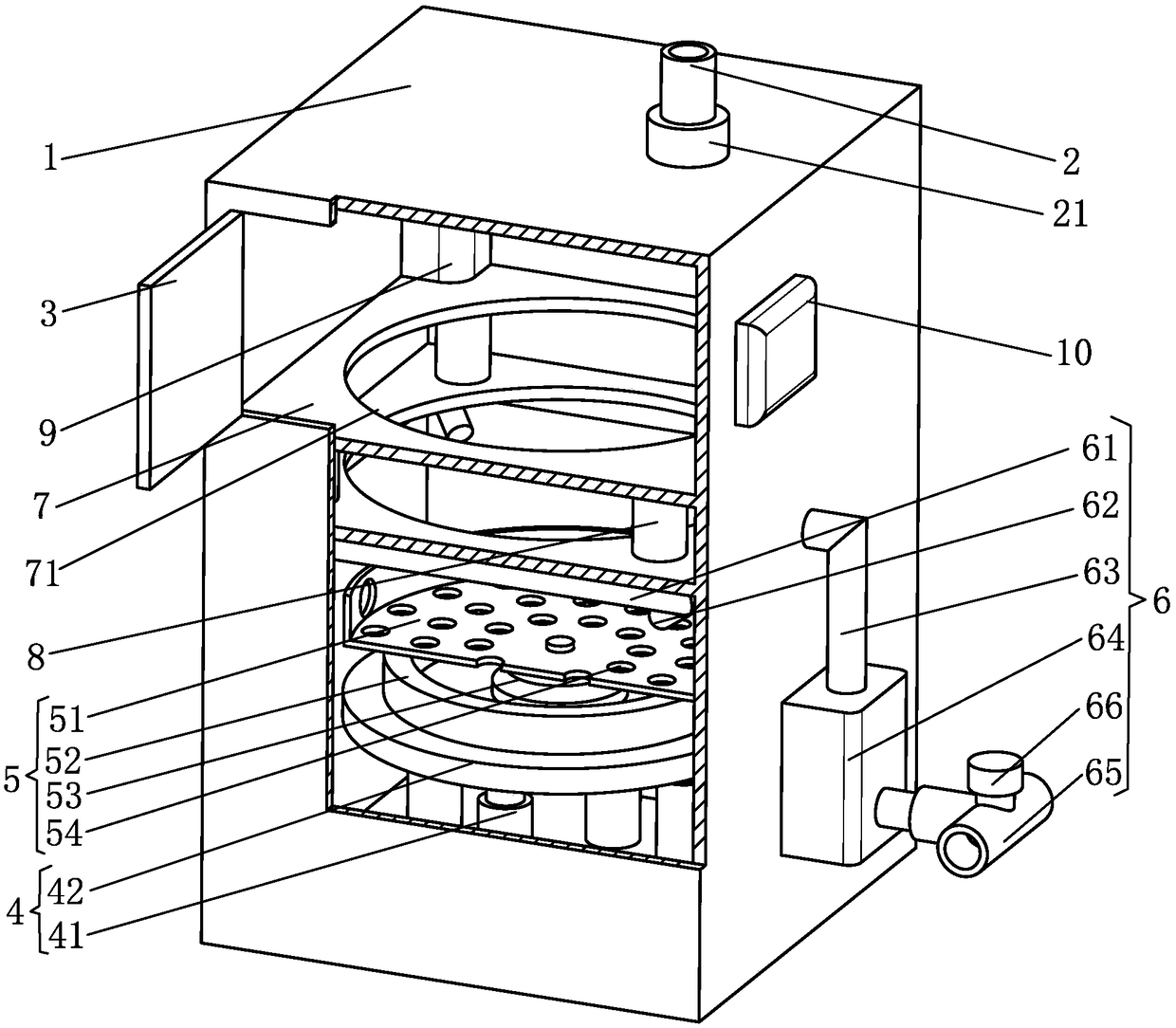

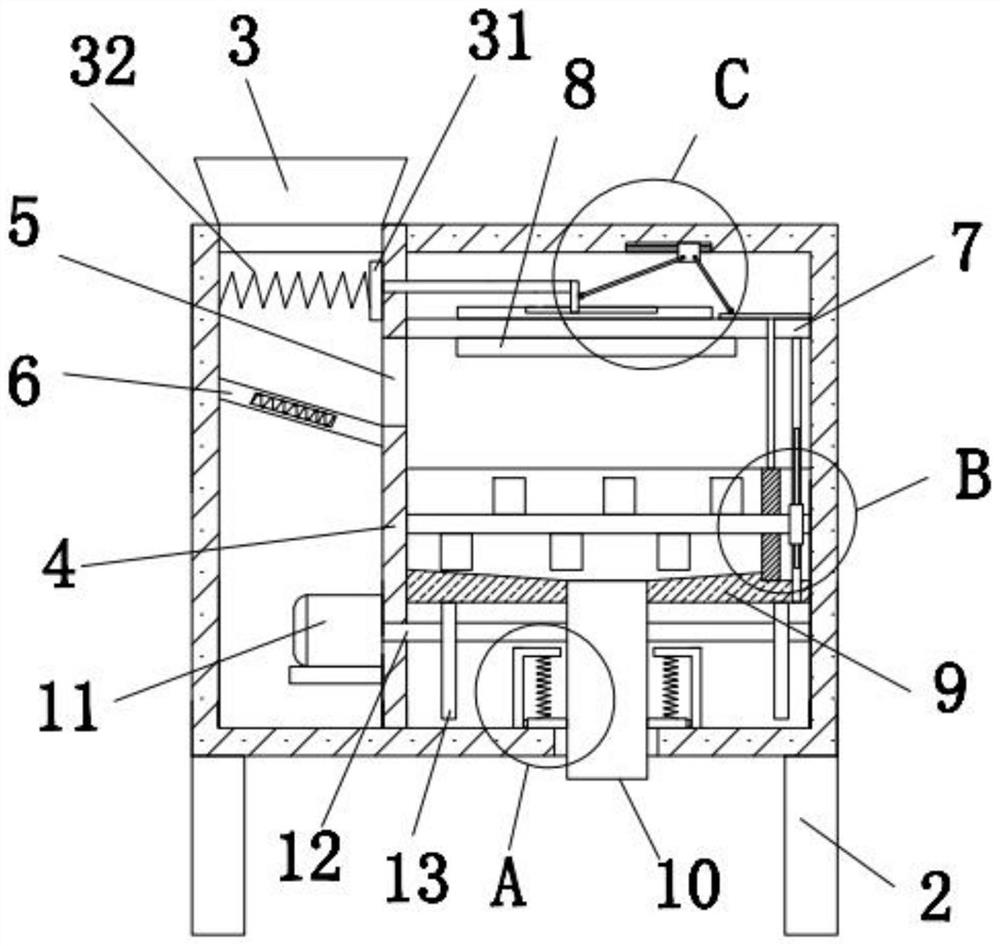

Convenient-to-use drying device for bio-fertilizer

PendingCN112815668ADry comprehensiveEasy flipDrying chambers/containersDrying solid materialsAgricultural engineeringStructural engineering

The invention belongs to the field of drying equipment, in particular to a convenient-to-use drying device for bio-fertilizer. The convenient-to-use drying device comprises a drying box, a plurality of supporting legs are fixedly mounted at the bottom of the drying box, a feeding hopper is fixedly mounted at the top of the drying box, a partition plate is fixedly mounted in the drying box, a feeding hole is formed in one side of the partition plate, a material guide plate is fixedly mounted on one side of the partition plate, a transverse plate is fixedly mounted on the other side of the partition plate, a drying lamp is fixedly mounted at the bottom end of the transverse plate, a drying chamber is slidably mounted in the drying box and slidably connected with the partition plate, and a discharging pipe is fixedly mounted at the bottom end of the drying chamber and extends to the position below the drying box. The device is reasonable in design, the bio-fertilizer can be preliminarily dried and scattered through reciprocating compression of a connecting spring, and the bio-fertilizer can be turned over through vertical movement of the drying chamber and reciprocating rotation of a stirring plate, so that the bio-fertilizer can be comprehensively dried.

Owner:莫永富

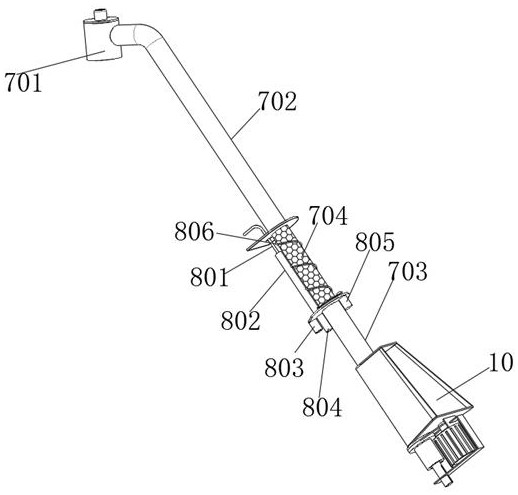

Multifunctional vacuum vertical spiral stirring, drying and pouring machine

PendingCN114688847ARealize self-cleaningReduce the situation of sticking to the wallDrying solid materials without heatDrying gas arrangementsStructural engineeringPipe

The invention discloses a multifunctional vacuum vertical spiral stirring, drying and pouring machine which comprises a pouring assembly, a material conveying assembly is arranged on one side of the pouring assembly, the upper portion of the material conveying assembly communicates with the upper portion of the pouring assembly, the material conveying assembly comprises a material conveying pipe assembly, and the material conveying pipe assembly comprises a feeding pipe. The feeding pipe communicates with the upper portion of the pouring assembly, the peripheral face of the feeding pipe is connected with a second conveying section, the end, away from the feeding pipe, of the second conveying section is connected with a metal net barrel, the end, away from the second conveying section, of the metal net barrel is fixedly provided with a first conveying section, and the lower end of the first conveying section is connected with a feeding hopper. One slope of the feeding hopper is of an opening structure, and the side, opposite to the opening, of the feeding hopper is of a cambered surface structure. According to the dust separation device, dust in materials can be separated while the materials are conveyed, self-cleaning of the dust separation mechanism can be achieved, the difficulty of cleaning and maintenance is lowered, manpower is saved, the working efficiency is improved, and the drying efficiency is improved.

Owner:CHANGZHOU YIMIN DRYING EQUIP

Mechanical equipment for drying chemical raw material

InactiveCN111520989AGood uniformityImprove qualitySievingScreeningProcess engineeringManufacturing engineering

The invention discloses mechanical equipment for drying a chemical raw material, and relates to the field of chemical product production and processing machinery. The mechanical equipment comprises adrying box; a feeding cover is positioned in the drying box and the bottom end of the feeding cover is fixedly connected with a first-stage drying cover; the bottom end of the first-stage drying coveris fixedly connected with a second-stage drying cover; a first-stage drying mechanism and a second-stage drying mechanism are respectively arranged in the first-stage drying cover and the second-stage drying cover; the bottom end of the second-stage drying cover is fixedly connected with a discharging bottom cover; a discharging conveying belt is arranged below the discharging bottom cover; a hotair circulating mechanism is arranged outside the drying box; and a pulling mechanism is arranged below the first-stage drying cover. According to the mechanical equipment for drying the chemical rawmaterial, the chemical raw material can be dried in a swing manner with hot air by arranging the first-stage drying mechanism and can be subjected to secondary drying in a dispersed drying manner byarranging the second-stage drying mechanism; the drying speed of the chemical raw material is high; the drying is comprehensive; and clumps can be removed in a drying process, so that the dried chemical raw material is good in uniformity and high in quality.

Owner:徐月美

Seed drying device

PendingCN108518947ASqueeze evenlyDry evenlyGranular material dryingDrying gas arrangementsEngineeringMechanical engineering

The invention belongs to the technical field of seed processing equipment and particularly discloses a seed drying device. The seed drying device comprises a box body and a material plate slidably arranged in the box body. A material sweeping rod is arranged on the material plate, and the end of the material sweeping rod is connected with a rotary rod rotationally arranged on the material plate. An air cavity is formed between the rotary rod and the material plate, and blades are arranged on the rotary rod. Cavities mutually communicating are formed in the rotary rod and the material sweepingrod, and an air outlet is formed in the side wall of the material sweeping rod. A gap is formed between the material sweeping rod and the material plate. A nozzle slides on the bottom wall of the boxbody, and a cylinder is arranged at the bottom of the box body. A piston is arranged in the cylinder, and a push rod connected with the material plate is arranged on the piston. A corrugated cover isconnected between the cylinder and the material plate in a sealed mode, and a pneumatic telescopic rod is arranged on the bottom wall of the box body. The interior of the corrugated cover communicateswith the interior of the pneumatic telescopic rod, and the pneumatic telescopic rod is connected with the nozzle. A heater is arranged on the lower portion of the cylinder, and the lower portion of the cylinder communicates with the nozzle. An elastic piece is arranged between the nozzle and the box body, and the upper portion of the cylinder and the air cavity communicate in a unidirectional mode. According to the seed drying device, mechanical drying of seeds is achieved, the drying efficiency is high, and the drying effect is good.

Owner:重庆众点农业有限公司

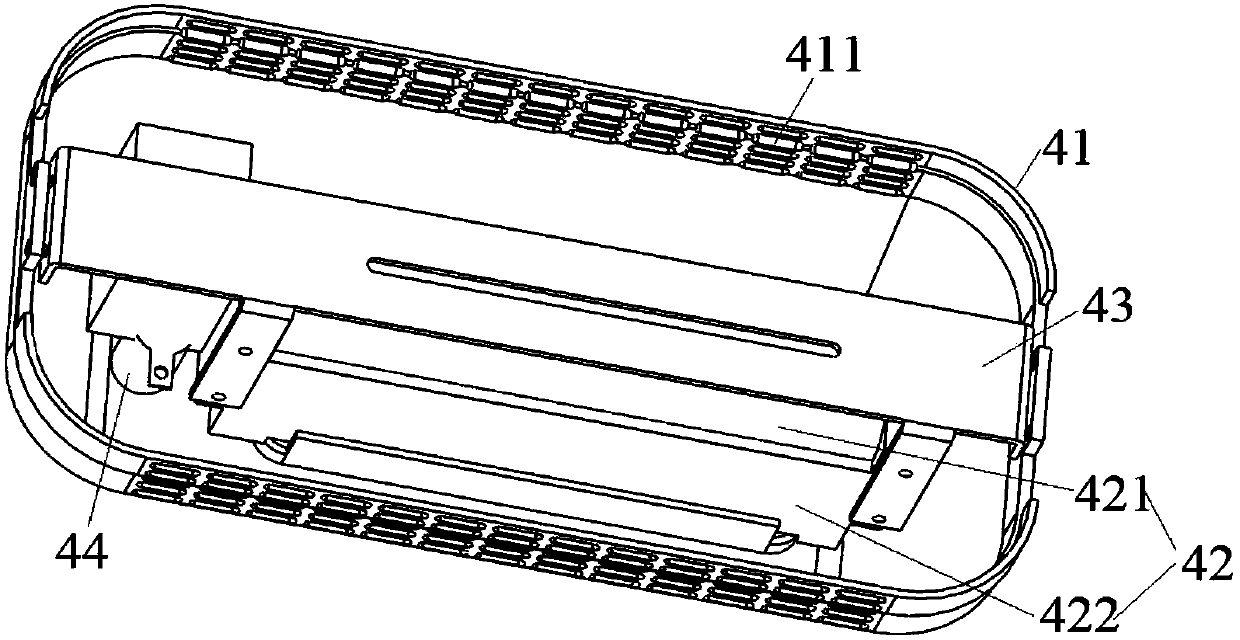

Drying equipment for spraying assembly line

The invention discloses drying equipment for a spraying assembly line, comprising an equipment body. The equipment body is provided with a drying channel and a first infrared light-emitting part located on the inner wall of the drying channel. A movable assembly is arranged inside the drying channel and can move along an extending direction of the drying channel. The movable assembly is provided with a rotatable support, and the rotatable support is provided with a second infrared light-emitting part. The rotatable support has a first position state and a second position state. When the rotatable support is in the first position state, a radiation direction of the second infrared light-emitting part is the same as the radiation direction of the first infrared light-emitting part. When therotatable support is in the second position state, the radiation direction of the second infrared light-emitting part faces the extending direction of the drying channel. The drying equipment for thespraying assembly line can fully dry the outer surface of a workpiece, and has high drying efficiency, low energy consumption, reduced production cost, strong flexibility and wide application.

Owner:苏州开泰利环保能源有限公司

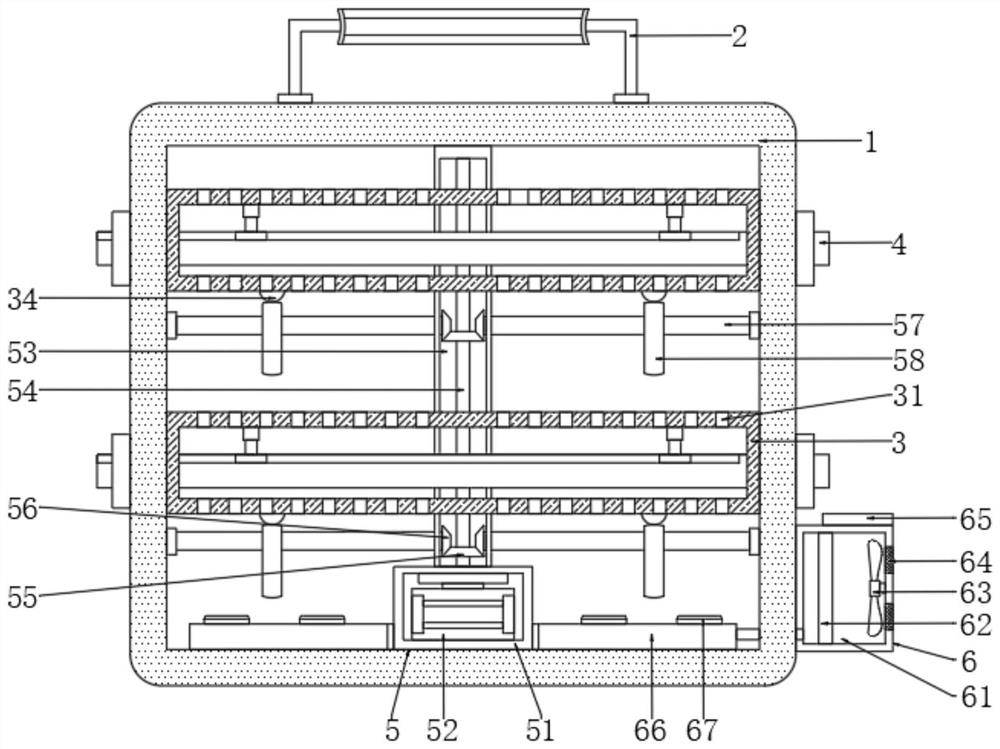

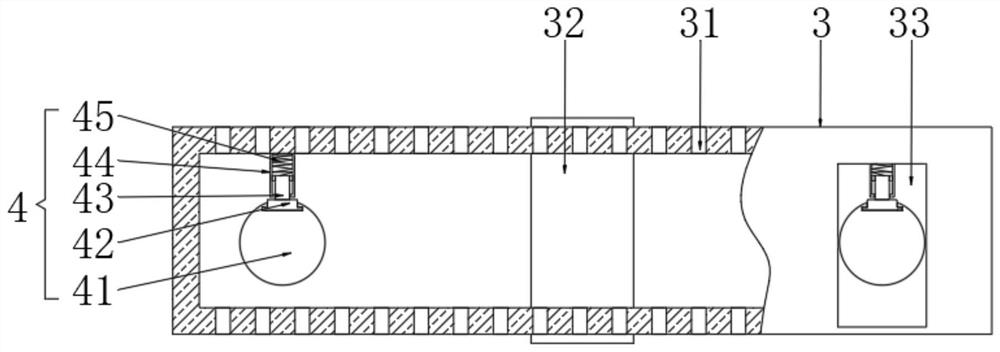

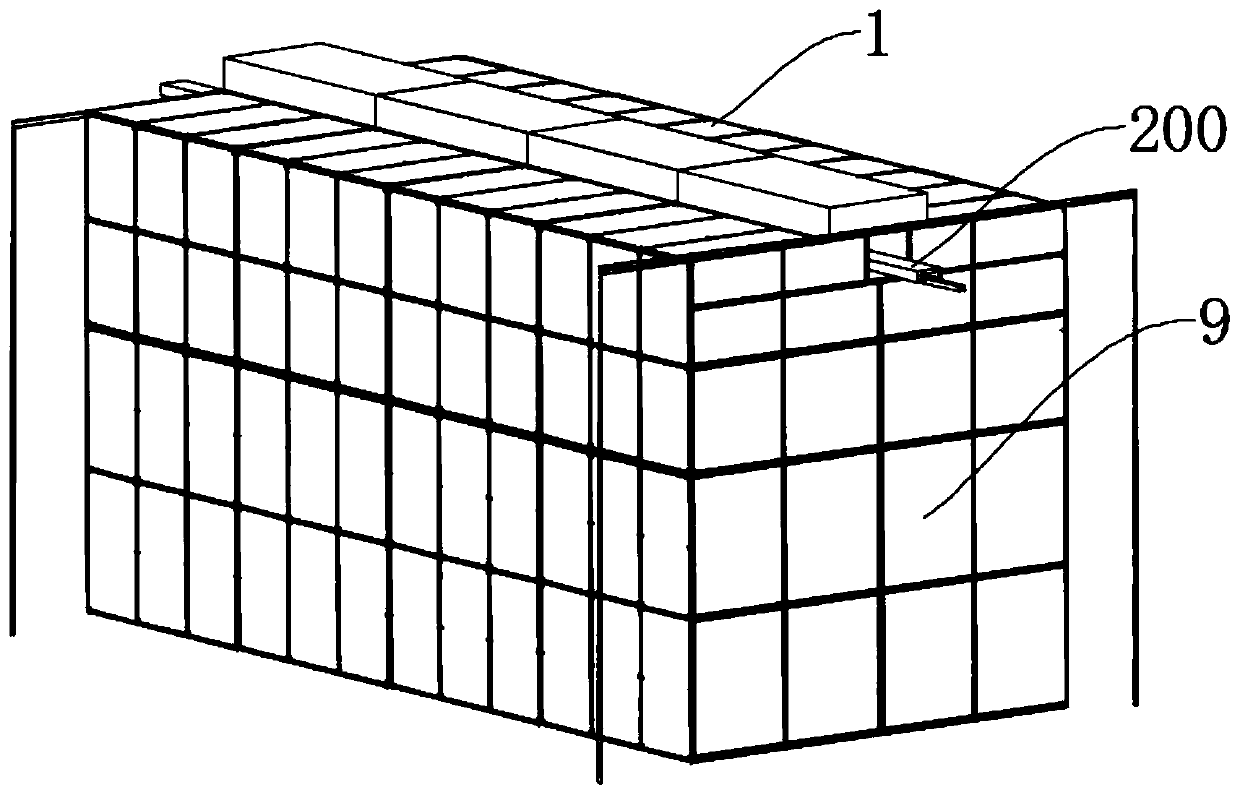

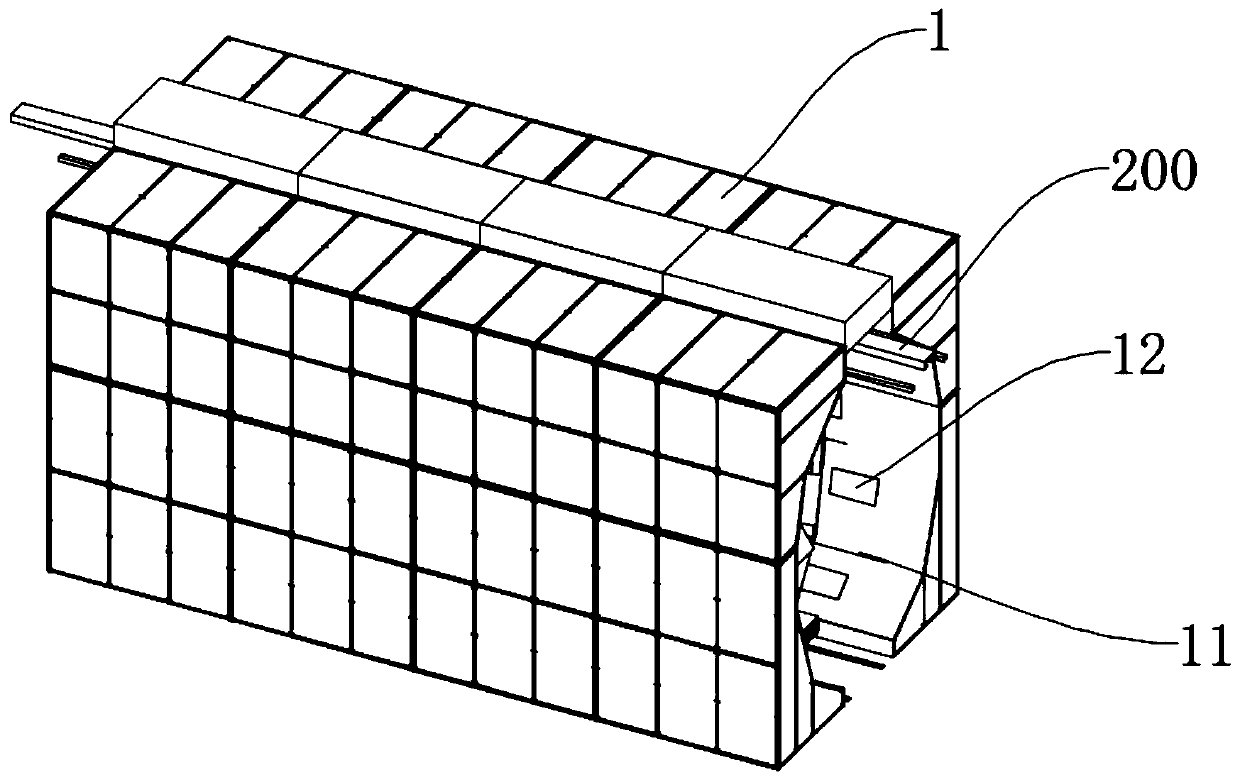

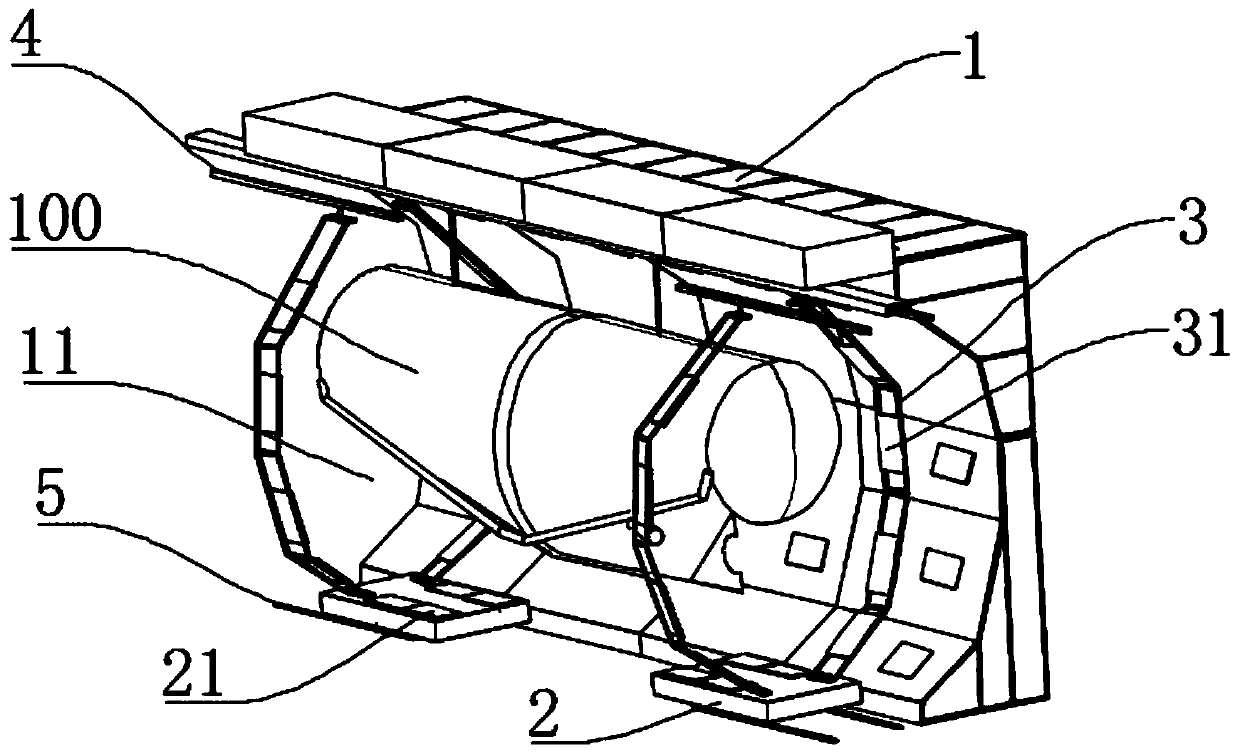

Grain comprehensive processing equipment

InactiveCN108157501AKeep dryDry comprehensiveDrying gas arrangementsSeed preservation by dryingOzone generatorDrive wheel

The invention provides grain comprehensive processing equipment, and belongs to the technical field of processing of agricultural grains. The grain comprehensive processing equipment comprises a supporting device and a dust removing, sterilizing and drying device; a feeding hopper is arranged at the lower part of the left side of a hoisting machine; a discharging hopper is arranged at the upper end of the right side of the hoisting machine; the lower end of the discharging hopper is connected with a stirring tank; a filter screen is arranged on the right side in an inner cavity of the stirringtank, and the stirring tank is divided into a stirring cavity and a dust collecting cavity; an electrical heating panel is fixedly arranged at the upper end of an inner cavity of a drying tank; a motor is connected with a driving wheel through a belt; and the driving wheel is arranged at the right end of the upper surface of a bottom plate through a bracket. According to the grain comprehensive processing equipment disclosed by the invention, an ozone generator is fixedly arranged on the left side of the upper surface of the stirring tank, so that the grain comprehensive processing equipmenthas a function of sterilizing grains in a manner of ozone; a sucking pump is fixedly arranged on the right side of the stirring tank, so that the grain comprehensive processing equipment has the functions of performing dust sucking and moisture exhausting on the stirring tank; and the grain comprehensive processing equipment has the characteristics of being simple in structure, high in practicality and various in functions.

Owner:HUNAN XIANGXUN ENTERPRISE MANAGEMENT CO LTD

Laboratory equipment storage box capable of completely drying

InactiveCN108692532AKeep dryEasy to storeDrying gas arrangementsDrying solid materialsMotor driveEngineering

The invention discloses a laboratory equipment storage box capable of completely drying. The laboratory equipment storage box capable of completely drying comprises a slide rail, a plurality of dryingrod, a storage box body, a partition plate, supporting legs, a handle, a sliding door, a humidity sensor, a valve, a discharging pipe, first grid mesh, a first ventilation hole, an outer layer, drying layers, second grid mesh, a plurality of second ventilation holes and filter mesh. The laboratory equipment storage box capable of completely drying has a better drying effect; due to the existenceof the drying rods, the drying layers in the drying rods can absorb moisture in placed objects to dry the placing objects; and due to the number of the drying rods and due to the fact that the secondventilation holes are formed in each drying rod, the placed objects can be dried more thoroughly, so that the drying effect of the placing objects is better; meanwhile, a motor drives a draught fan torotate, so that the placing objects stored in the storage box body is blown, and the placing objects can be dried quickly; and the double drying operation can enable the storage box to dry the placing objects more thoroughly and comprehensively, so that the placing objects are better stored, and the use is convenient for a user.

Owner:苏州奥科莱实验室仪器有限公司

Drying method for abamectin crystal

ActiveCN108489196ADry comprehensiveMeet drying requirementsDrying solid materials with heatDrying gas arrangementsAbamectinEngineering

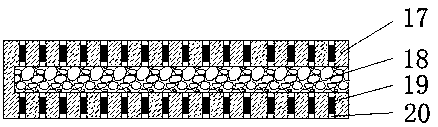

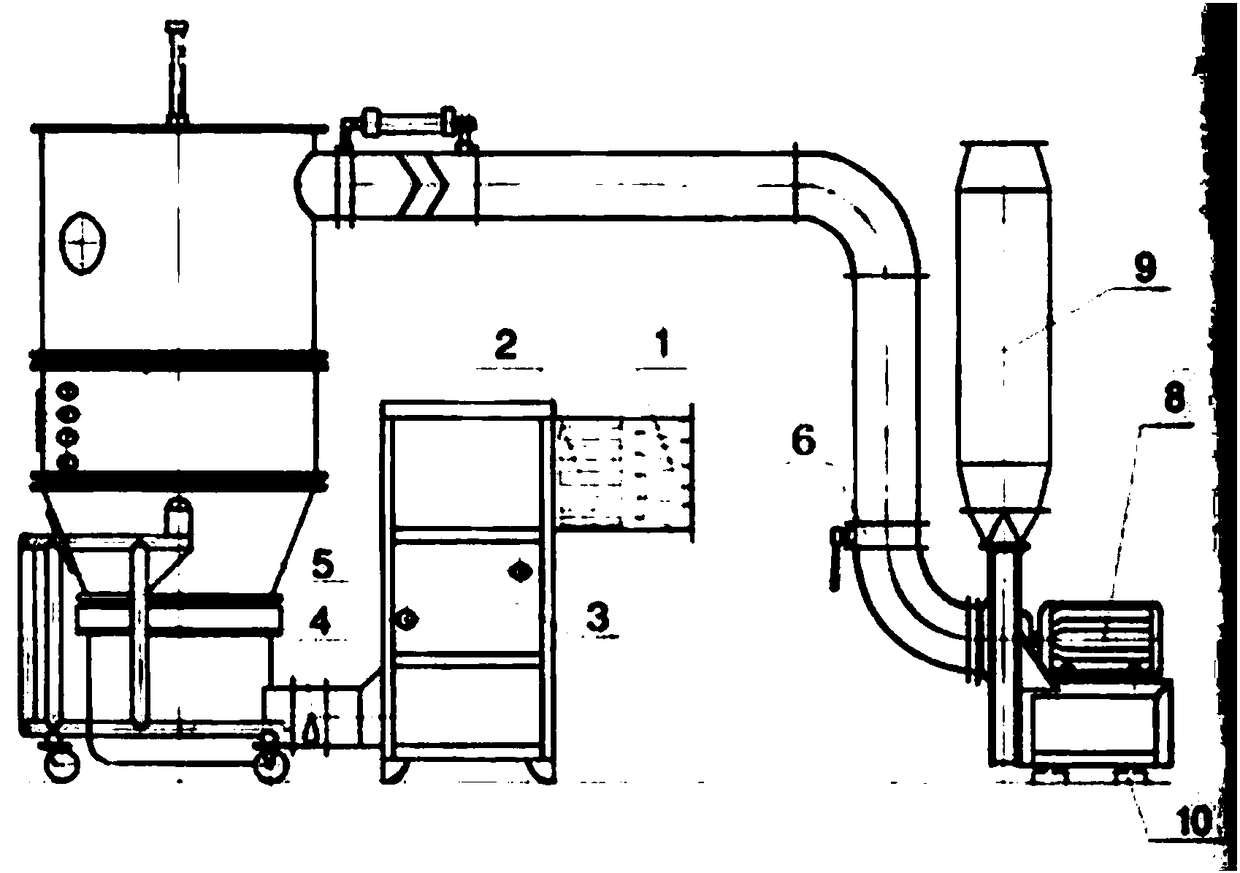

The invention provides a drying method for an abamectin crystal. The abamectin drying device provided by the invention needs to be used in a drying process. The device comprises a primary filter, an intermediate filter, a heater, a boiling dryer, an induced draft fan, a silencer, a shock absorber and other equipment. According to the abamectin drying method provided by the invention, compared withthe traditional oven drying method, the abamectin crystal is always in a fluidized state in the boiling dryer in the drying process, and is uniform in heating area and not liable to be decomposed, and the product is extremely low in degradation rate. Moreover, the whole drying process only needs 1.5h, and is short in drying time and low in energy consumption, and the temperature in the boiling dryer is decentralized, and high safety is achieved.

Owner:内蒙古拜克生物有限公司

Drying method for polypropylene composite materials

InactiveCN108582568AAvoid product qualityReduce manufacturing costDrying solid materials with heatDrying solid materials without heatPolypropylene compositesPolymer science

The invention discloses a drying method for polypropylene composite materials. The drying method comprises the drying method of raw materials and the drying method of modified additives in the preparation method of the polypropylene composite materials; the drying method of the raw materials comprises the following steps that solid or powdery raw materials are put into a drying plate, and air drying and vacuum drying are conducted in sequence; and the drying method of the modified additives comprises the following steps that mixed, stirred and diffused modified additives are cooled to the roomtemperature, the modified additives are evenly paved in the drying plate, and air drying and vacuum drying are conducted in sequence. Compared with a traditional drying method for the polypropylene composite materials, the drying method has the good drying effect, drying is more even and comprehensive, preparation of the polypropylene composite materials is facilitated, prepared polypropylene composite material products are good in quality, the drying process is simple, manufacturing is easy, and the production cost is low.

Owner:ANHUI HAINA SICHUAN PLASTICS TECH

Light-weight wallboard drying equipment

InactiveCN108050777AFast dryingShorten drying cycleDrying gas arrangementsDrying chambers/containersEngineeringWall plate

The invention belongs to the technical field of light-weight wallboard production equipment, and particularly discloses light-weight wallboard drying equipment. The light-weight wallboard drying equipment includes a drying room and a motor, an output shaft of the motor is provided with a Z-shaped rod in a connecting mode, and the lower end of the Z-shaped rod is located above the interior of the drying room; the right side wall of the drying room is isolated from other side walls, an oil cavity is formed in the right side wall of the drying room, cavities which can mutually communicate with each other are formed in other side walls of the drying room, and heating devices which are used for heating air are arranged in the cavities; the outer wall of the drying room is provided with a firstone-way door, and the inner wall of the drying room is provided with a second one-way door; a through groove is formed in the right side wall of the drying room, the upper portion of the through groove is provided with a rubber sleeve which communicates with the oil cavities in a connecting mode; and the upper of the interior of the drying room is provided with a cross-shaped slide bar, a strip-shaped through hole is formed in the center of the cross-shaped slide bar, and one side of the cross-shaped slide bar is slidably connected in the right side wall and the other side of the cross-shapedslide bar is slidably connected in the left side wall. According to the light-weight wallboard drying equipment, the light-weight wallboard can be effectively dried, and the drying period can be shortened.

Owner:重庆成维轻质墙板有限公司

A kind of cooling air-drying equipment for cable processing

ActiveCN111048260BFully air-driedReduce frictionCable/conductor manufactureProcess engineeringElectric cables

Owner:GUANGZHOU MINGXING CABLE

Ceramic tile printing device

ActiveCN112248628AWon't breakPrinting job impactRotary pressesCeramic materials productionTextile printerPlate pressure

The invention discloses a ceramic tile printing device, and belongs to the technical field of ceramic tile processing devices. The device comprises a base, side plates and a pressing plate; the left side and the right side of the upper surface of the base are fixedly connected with the side plates; first limiting holes are formed in the opposite surfaces of the two side plates; first limiting blocks are arranged in the first limiting holes; the two first limiting blocks are fixedly connected by the pressing plate; the pressing plate is in a square framework shape; a lifting mechanism is arranged on the pressing plate; and sliding rails are arranged on the left side face and the right side face of the inner wall of the pressing plate. According to the ceramic tile printing device, through the arrangement of a positioning plate, ceramic tiles can be pressed when the positioning plate moves downwards, the height of the positioning plate can be adjusted at will, and therefore the ceramic tiles with different thicknesses can be pressed; and through the arrangement of the pressing plate, a pressure sensor and an alarm, a printing roller can well print the ceramic tiles without causing excessively large stress to damage the ceramic tiles, and no influence is made on the printing work of the ceramic tiles.

Owner:YANGXI BODE PRECISION IND BUILDING MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com