Mechanical equipment for drying chemical raw material

A technology of mechanical equipment and chemical raw materials, applied in the field of chemical product production and processing machinery, can solve the problems of unfavorable enterprise development, reduced efficiency of chemical product production quality, low drying efficiency of drying treatment device, etc., and achieves high quality and good uniformity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

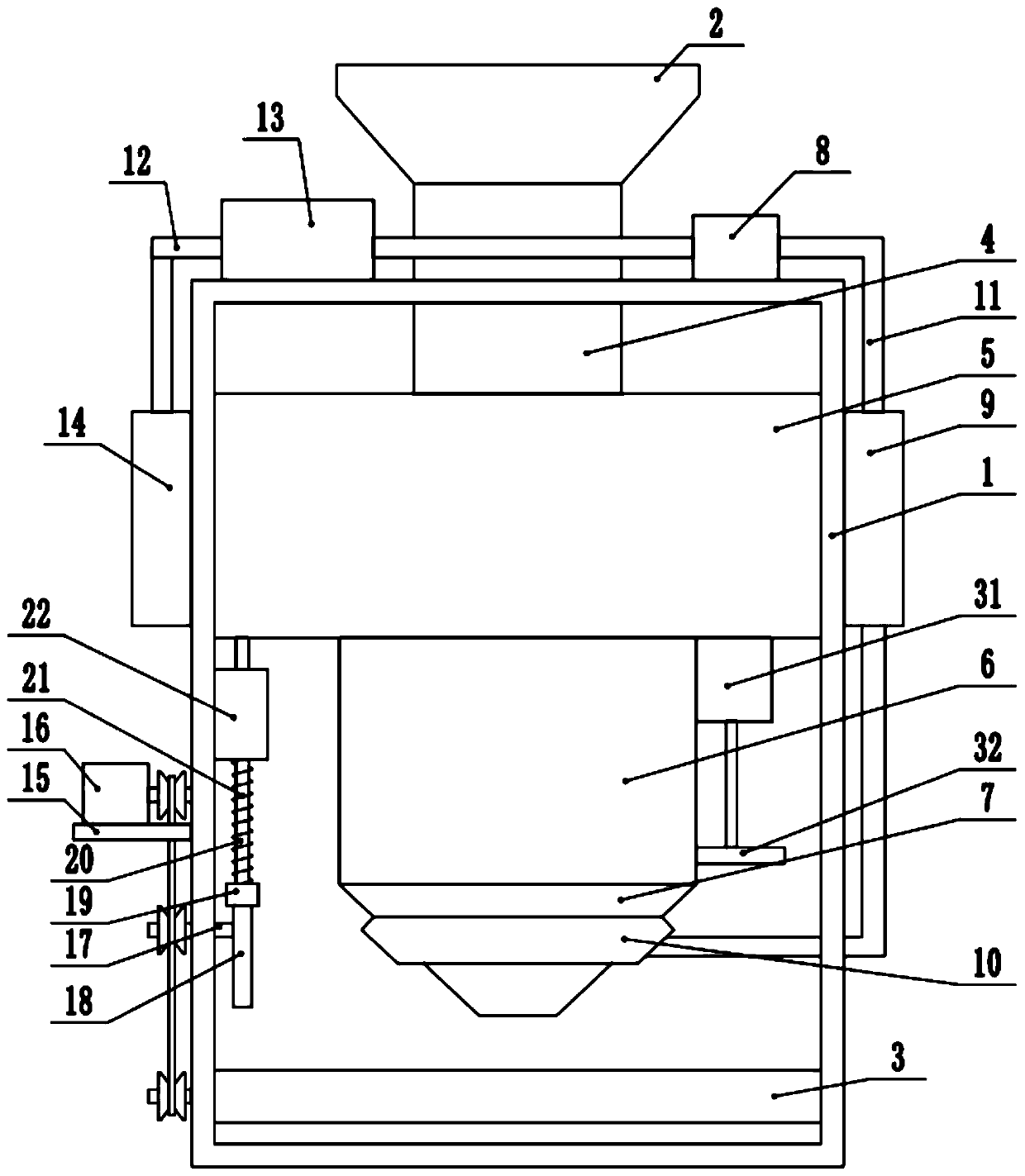

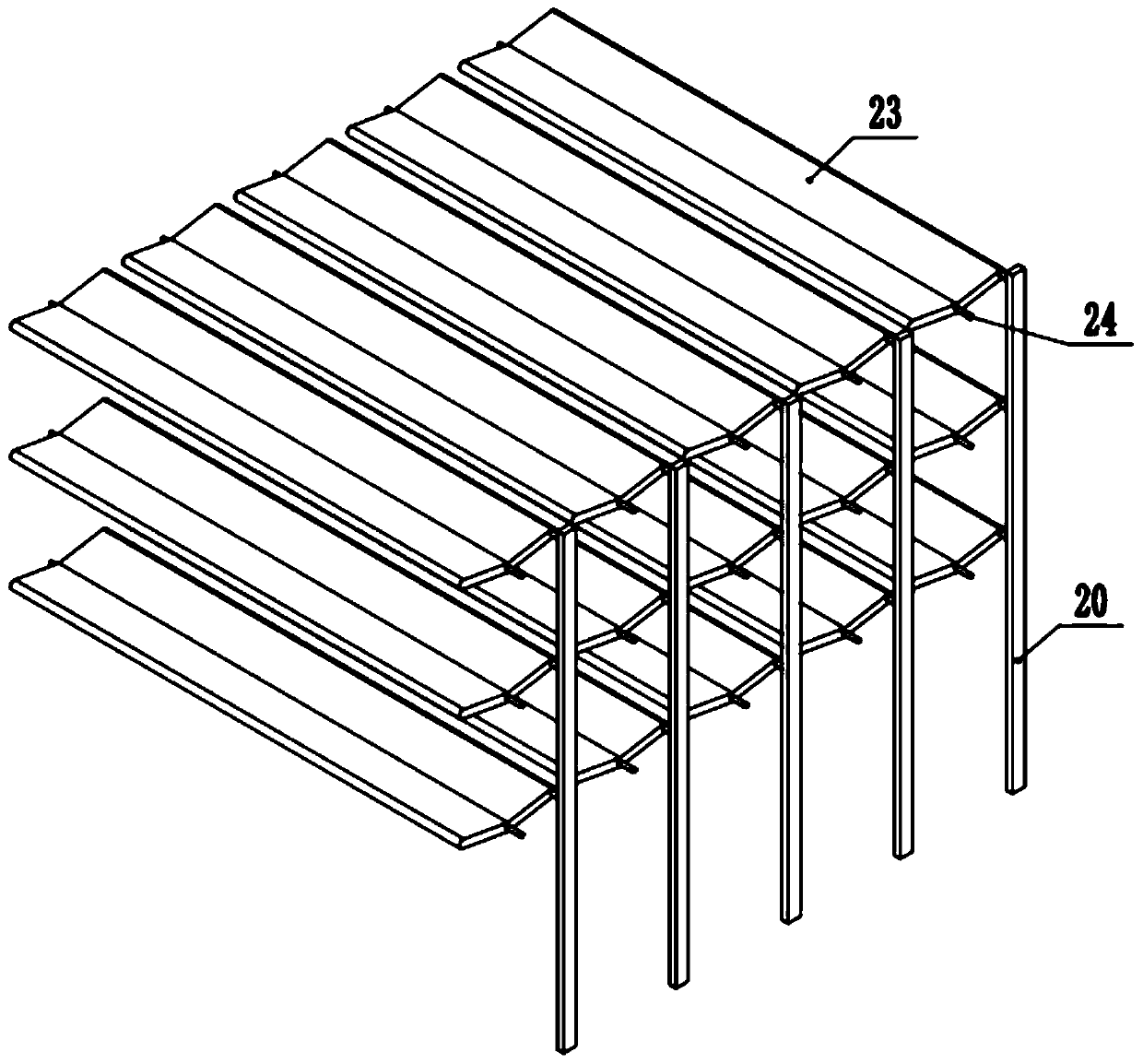

[0023] see Figure 1-3 , a mechanical device for drying chemical raw materials, comprising a drying box 1, the top of the drying box 1 is fixedly connected to a feed hopper 2, and the bottom end of the feed hopper 2 is fixedly connected to a feed cover 4, and the feed cover 4 is located in the dry box 1 and its bottom end is fixedly connected with the first-level drying cover 5, and the bottom end of the first-level drying cover 5 is fixedly connected with the second-level drying cover 6, and the first-level drying cover 5 and the second-level drying cover 6 are respectively equipped with a first-level drying mechanism and a second The first-level drying mechanism, the bottom end of the second-level drying cover 6 is fixedly connected to the discharge bottom cover 7, and the discharge conveyor belt 3 is arranged below the discharge bottom cover 7, and the outside of the drying box 1 is provided with a hot air circulation mechanism. The air circulation mechanism is fixedly conn...

Embodiment 2

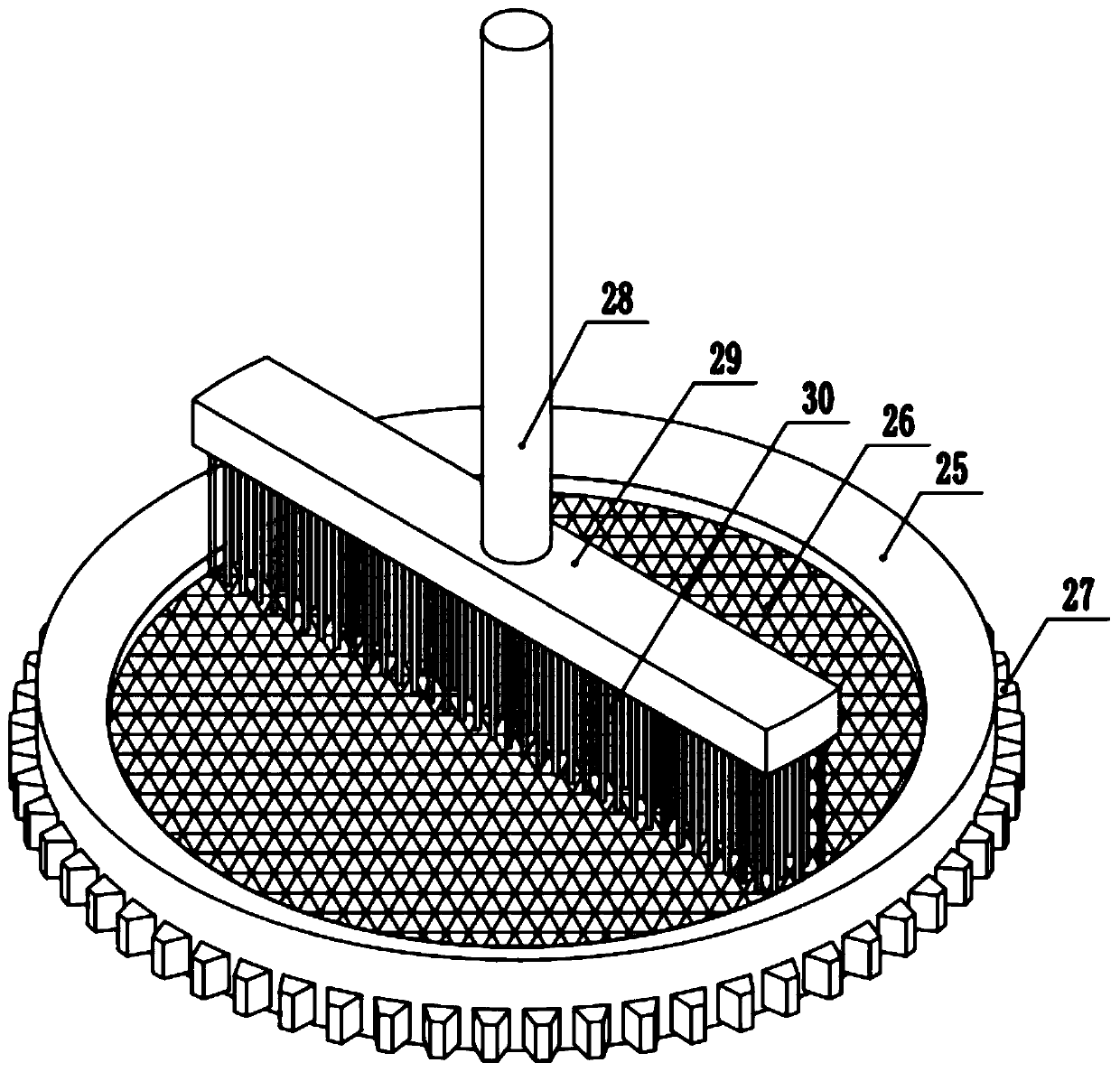

[0032] see Figure 1-3 , the other content of this embodiment is the same as that of Embodiment 1, the difference is that: the bottom end of the primary drying cover 5 is fixedly connected to the second rotating rod 28, and the bottom end of the second rotating rod 28 is fixedly connected to the brush plate 29, The bottom end of the brush plate 29 is fixedly connected with the bristles 30 .

[0033] In the implementation process of the present invention, the chemical raw materials are put into the primary drying cover 5 from the feed hopper 2, the chemical raw materials fall onto the raw material placement plate 23, the hot air blower 8, the driving motor 16 and the internal motor 31 are started, and the driving motor 31 drives the cam 18 to rotate, and under the action of the return spring 21, the pressure rod 20 reciprocates up and down, thereby driving the raw material placement plate 23 to swing continuously to shake off the chemical raw materials on it, and the chemical r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com